Alignment film repairing method capable of saving repairing cost

An alignment film and cost-effective technology, applied in the field of alignment film repair that can save repair costs, can solve the problems of wasting time and repair fluid costs, and achieve the effect of improving repair speed and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

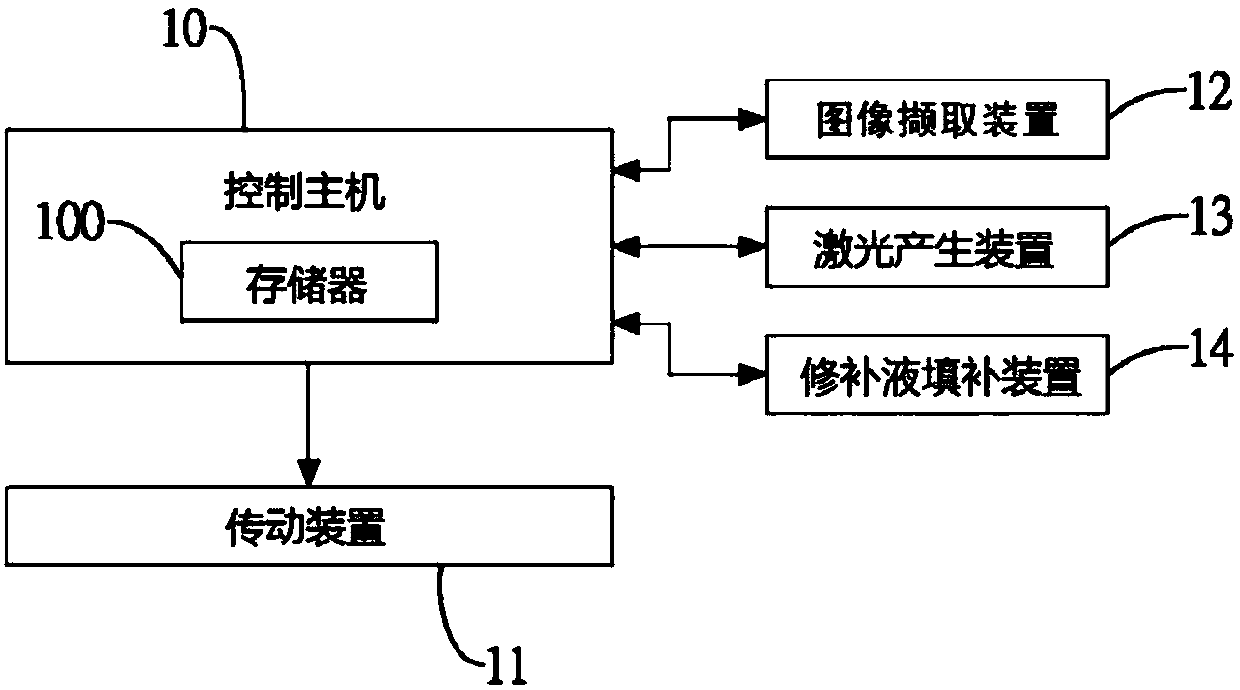

[0039] The alignment film repairing method of the present invention that can save the repair cost is applied to the alignment film repairing machine on the market or as described in the prior art. The alignment film repairing machine mainly includes a control host, a carrier, and a device arranged above the carrier. An image capturing device, a laser generating device and a repair fluid filling device, the image capturing device, the laser generating device and the repair fluid filling device can be arranged on a transmission device. Please refer to figure 1, the control host 10 is electrically connected to the transmission device 11, the image capture device 12, the laser generating device 13 and the repair fluid filling device 14, the control host 10 is a computer system that can be operated by the user, and it has a memory 100.

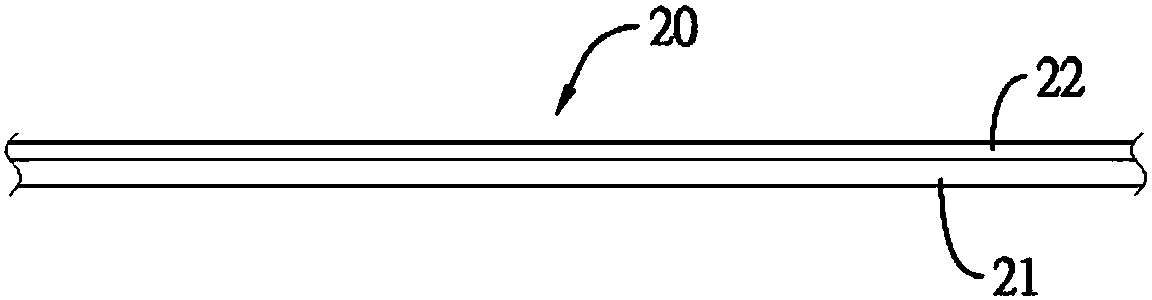

[0040] The stage is used to place a DUT, please refer to figure 2 , the object to be tested 20 includes a substrate 21 and an alignment film 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com