Powder interior repairing machine and repairing method thereof

A powder and powder pump technology is applied in the field of repairing devices in steel pipes to achieve the effects of large powder spraying surface, safe use and fast repairing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

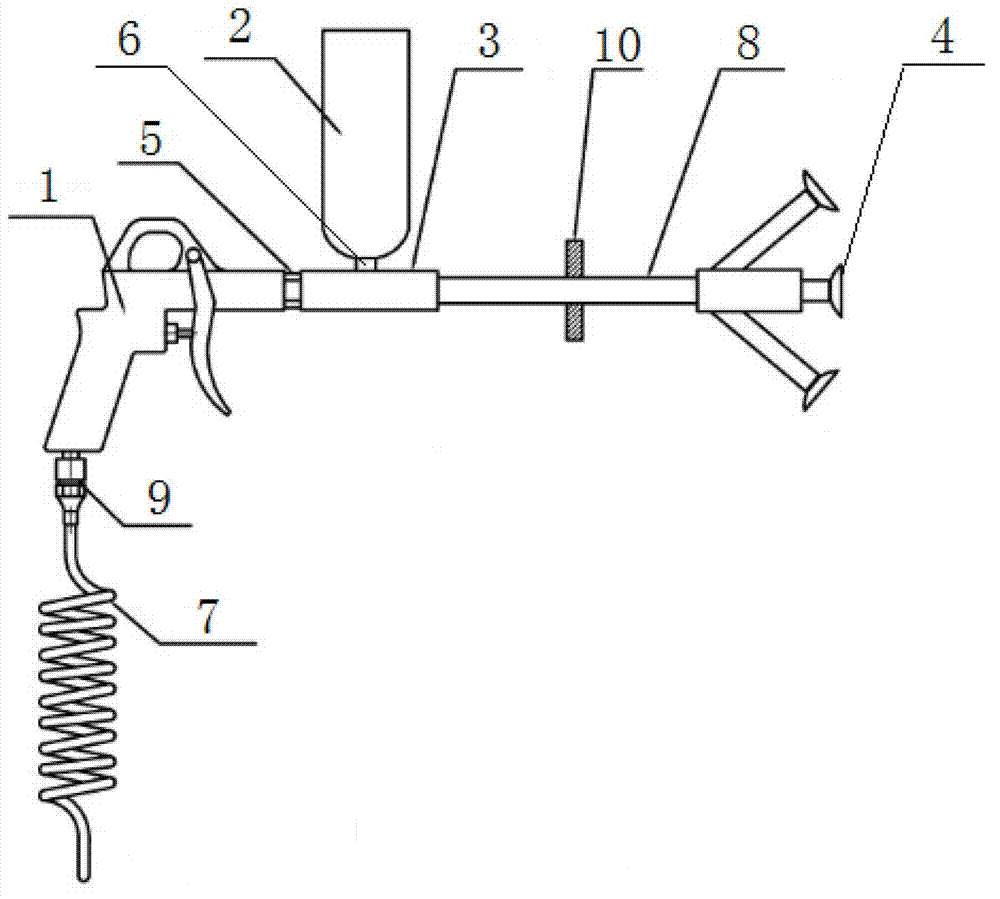

[0014] Such as figure 1 with figure 2 As shown, a powder internal repair machine includes a spray gun 1, a powder storage tank 2, a powder pump 3, and a spray head group 4. The muzzle of the spray gun 1 is connected to the air inlet of the powder pump 3 through a through joint 5. The powder storage tank 2 The powder outlet pipe 6 is connected with the powder inlet of the powder pump 3, the spray gun 1 is connected with an air source through a hose 7, and the powder outlet of the powder pump 3 is connected with the nozzle assembly 4 through a telescopic tube 8.

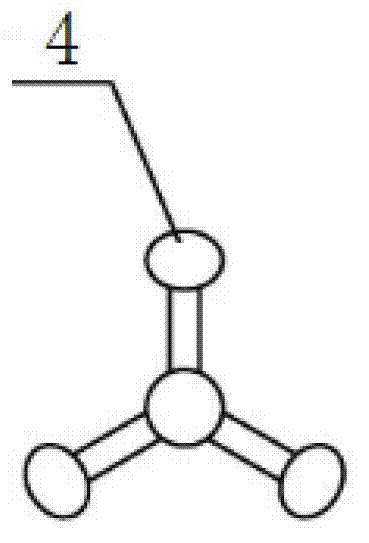

[0015] The spray gun 1 and the hose 7 are connected by a quick connector 9. The telescopic tube 8 is provided with a support seat 10, and the spray head group 4 is composed of three horn-shaped spray heads, and the gas source is 0.4-0.6 MPa.

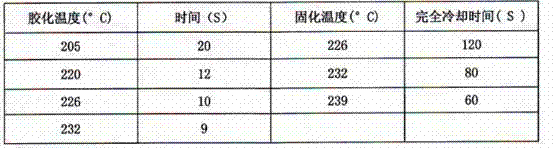

[0016] The invention is mainly suitable for the internal repair operation of the weld seam during the anti-corrosion construction of small-caliber steel pipes. The specific internal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com