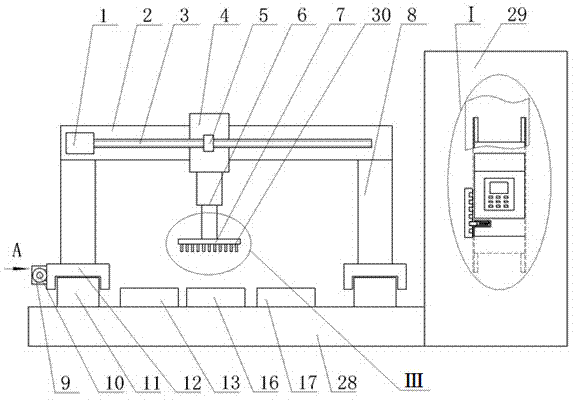

Ultra-small diamond type rectifier bridge adhesive assembly machine

A rectifier bridge, ultra-small technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of inaccessibility and complexity of the dispensing needle plate, achieve low manufacturing cost, improve accuracy, and simple and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

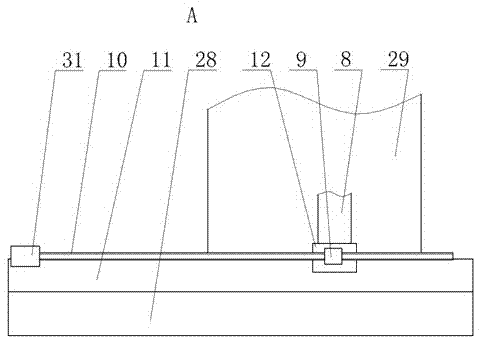

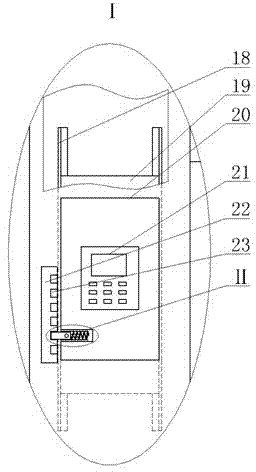

[0015] An ultra-small block rectifier bridge glue assembly machine, such as Figure 1 to Figure 5 As shown, including the base 28, the upper side of the base 28 is provided with two sliding rails 11 in parallel, the sliding block 12 is installed on the sliding rail 11, the second nut 9 is installed on one side of the sliding block 12, and the second step is installed on the end of the sliding block 11. Into the motor 31, the second screw mandrel 10 is installed on the output shaft of the second stepper motor 31, the second screw mandrel 10 cooperates with the second nut 9, the bracket 8 is installed on the slider 12, and the upper slide rail 2 is installed on the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com