High-radiation heat-radiating and heat-conducting plastics and preparation method thereof

A heat-conducting plastic and high-radiation technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of inability to meet the heat dissipation capacity of plastics, uneven dispersion, etc., and achieve strong structural strength, uniform material dispersion, and flame retardant performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

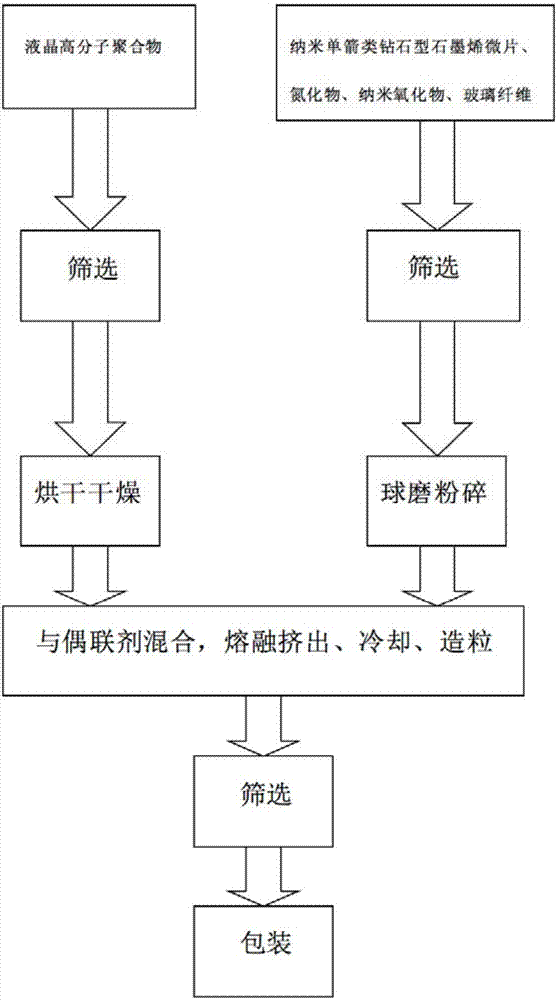

Method used

Image

Examples

Embodiment 1

[0033] A high-radiation heat-dissipating heat-conducting plastic provided by the present invention comprises the following components:

[0034] Liquid crystal polymer 45%;

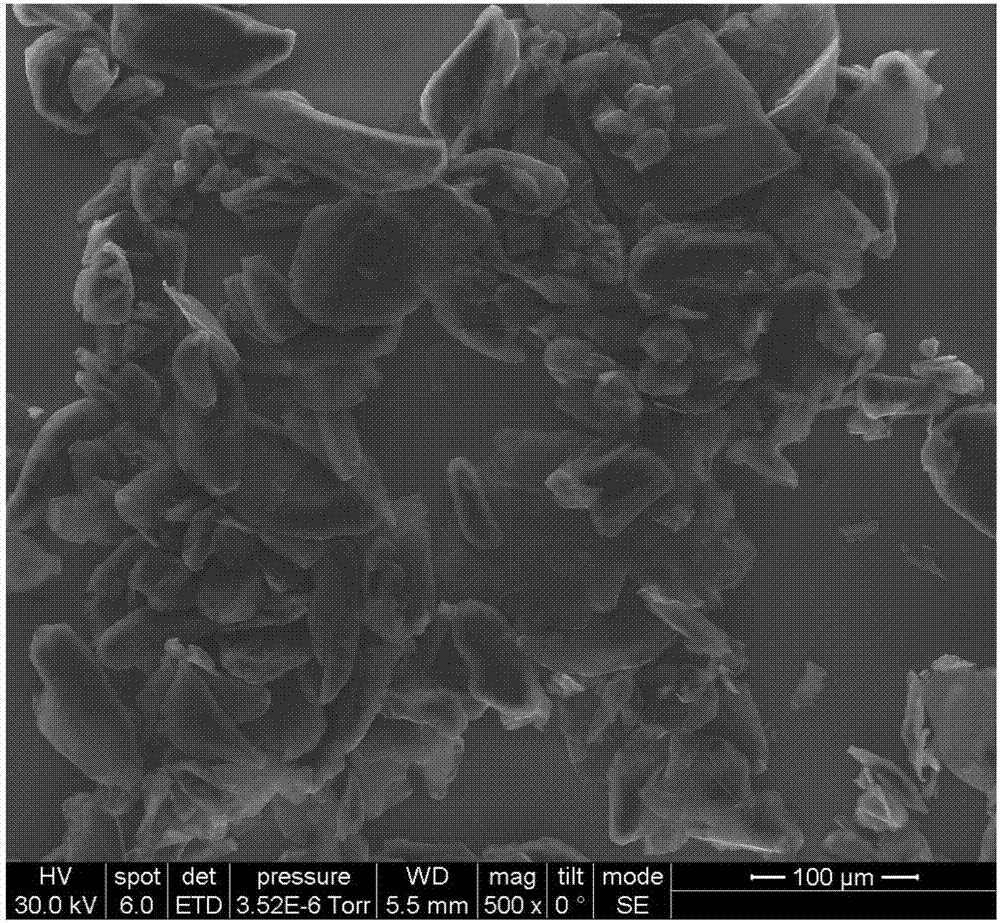

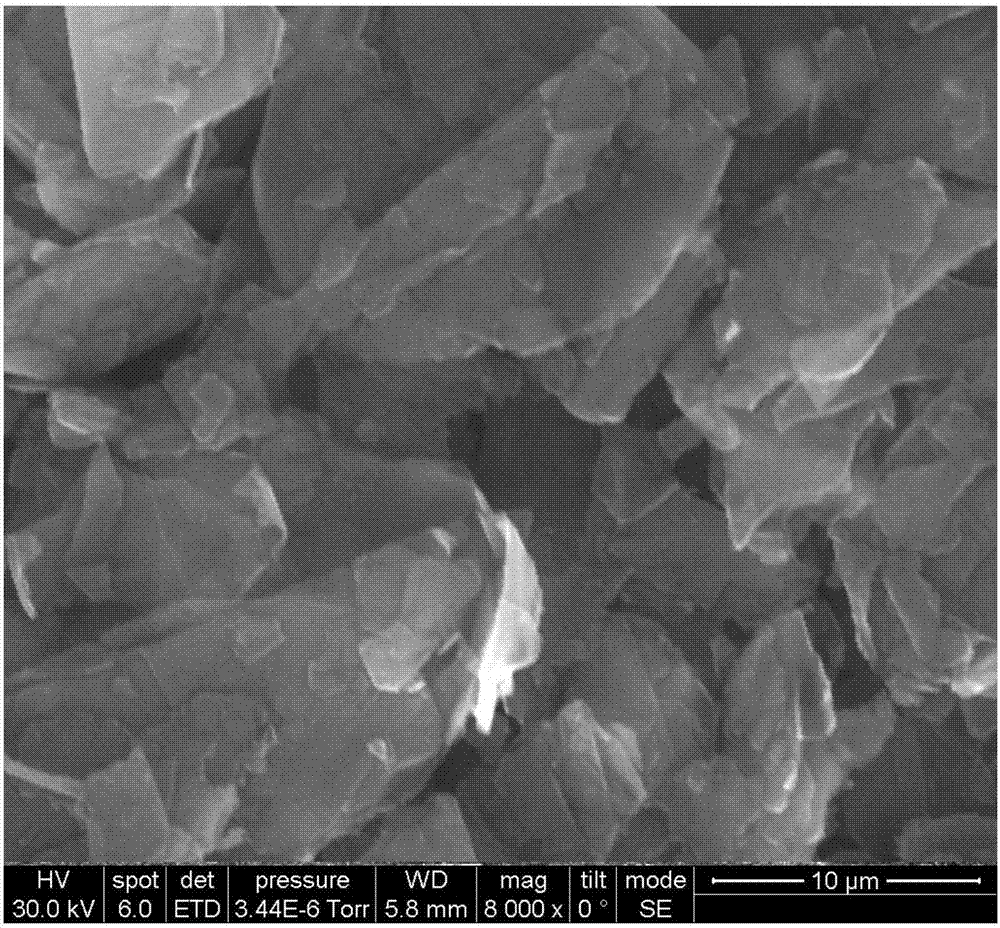

[0035] Nano-single arrow-like diamond-type graphene microsheets 2%;

[0036] Filler 50%;

[0037] Glass fiber 2%;

[0038] Coupling agent 1%;

[0039] The filler is mixed powder of nitride and nanometer oxide.

Embodiment 2

[0041] A high-radiation heat-dissipating heat-conducting plastic provided by the present invention comprises the following components:

[0042] Liquid crystal polymer 49.9%;

[0043] 1% of nano-single arrow-like diamond-type graphene microflakes;

[0044] Filler 48%;

[0045] Glass fiber 1%;

[0046] Coupling agent 0.1%;

[0047] The filler is mixed powder of nitride and nanometer oxide.

Embodiment 3

[0049] A high-radiation heat-dissipating heat-conducting plastic provided by the present invention comprises the following components:

[0050] Liquid crystal polymer 48%;

[0051] 1.8% of nano-single arrow-like diamond-type graphene microflakes;

[0052] Filler 47.9%;

[0053] Glass fiber 1.6%;

[0054] 0.7% coupling agent;

[0055] The filler is a mixed powder of nitrides, nano oxides, pigments and resins, and the resins are made of high-temperature-resistant polymers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com