Diamond-type honeycomb sandwich panel and preparation

A honeycomb paperboard and diamond-shaped technology, which is applied in the structure and forming field of multi-layer composite boards, can solve the problems of difficult processing, high cost of honeycomb paperboard, and restricted application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

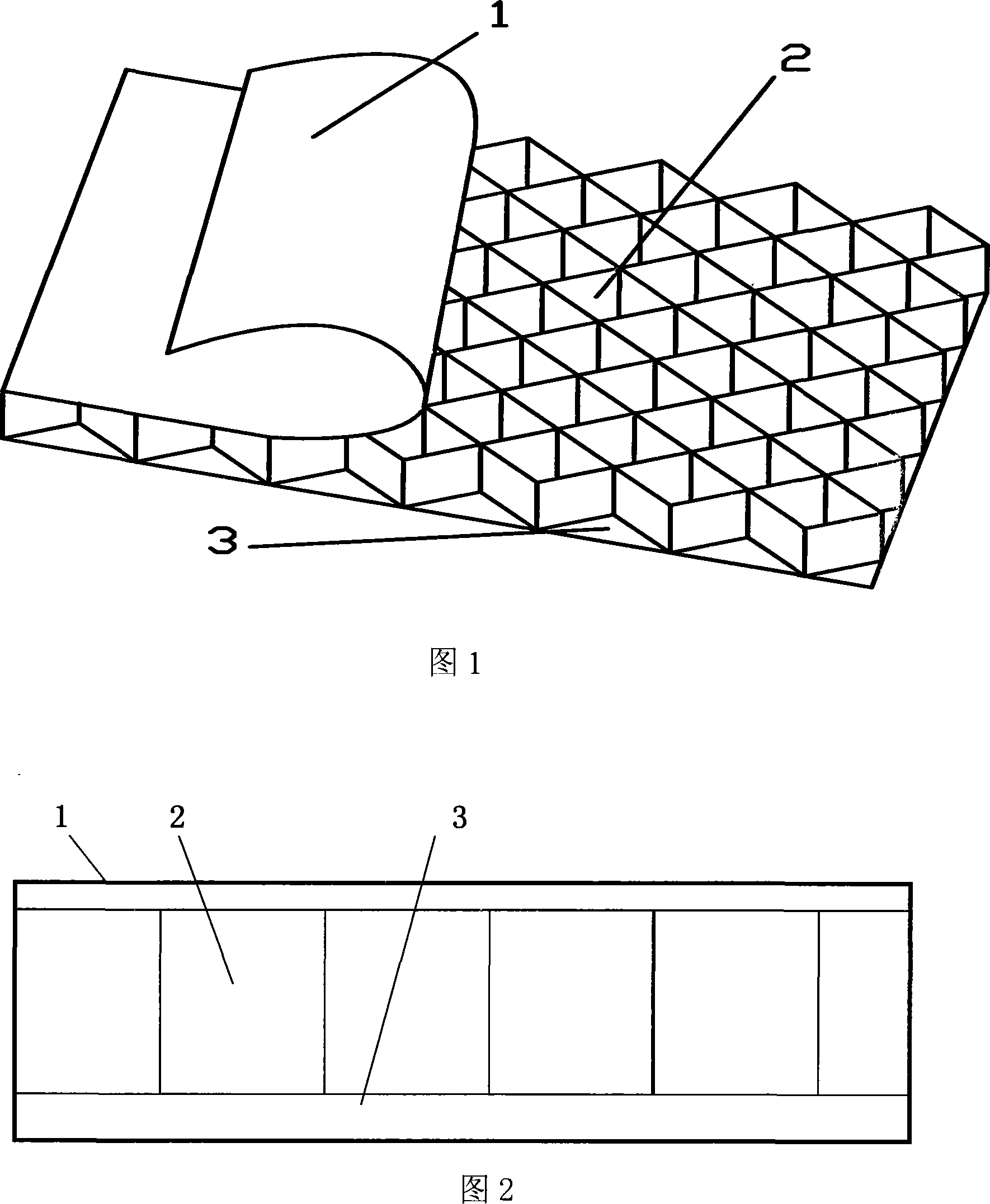

[0038] A diamond-shaped honeycomb paperboard and its manufacturing process. The diamond-shaped cardboard at least includes an upper surface layer, a lower surface layer and a sandwich layer, and is characterized in that the sandwich layer is a diamond-shaped honeycomb structure layer formed by splicing "V"-shaped paper strips. The processing technology of described rhombus cardboard is:

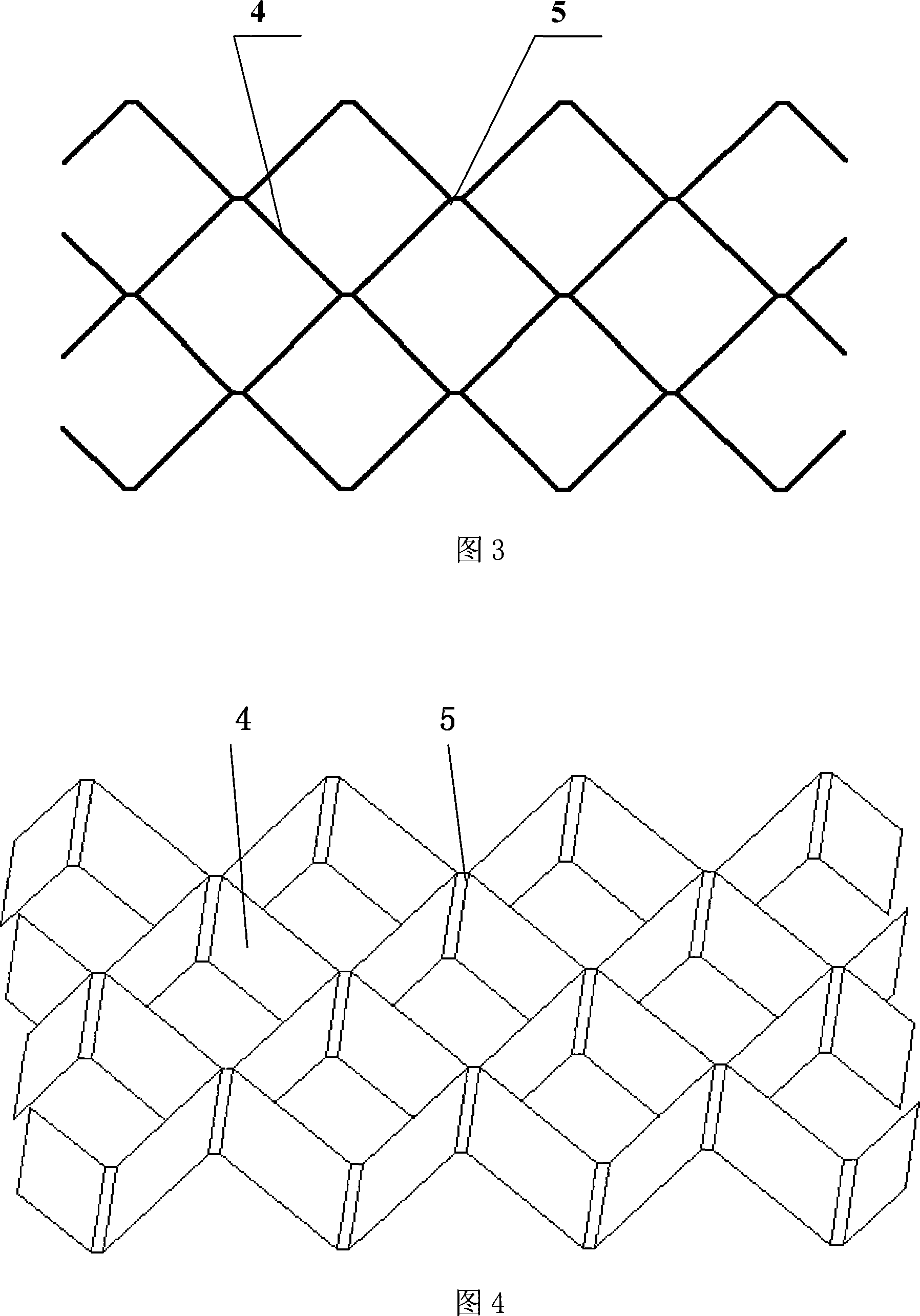

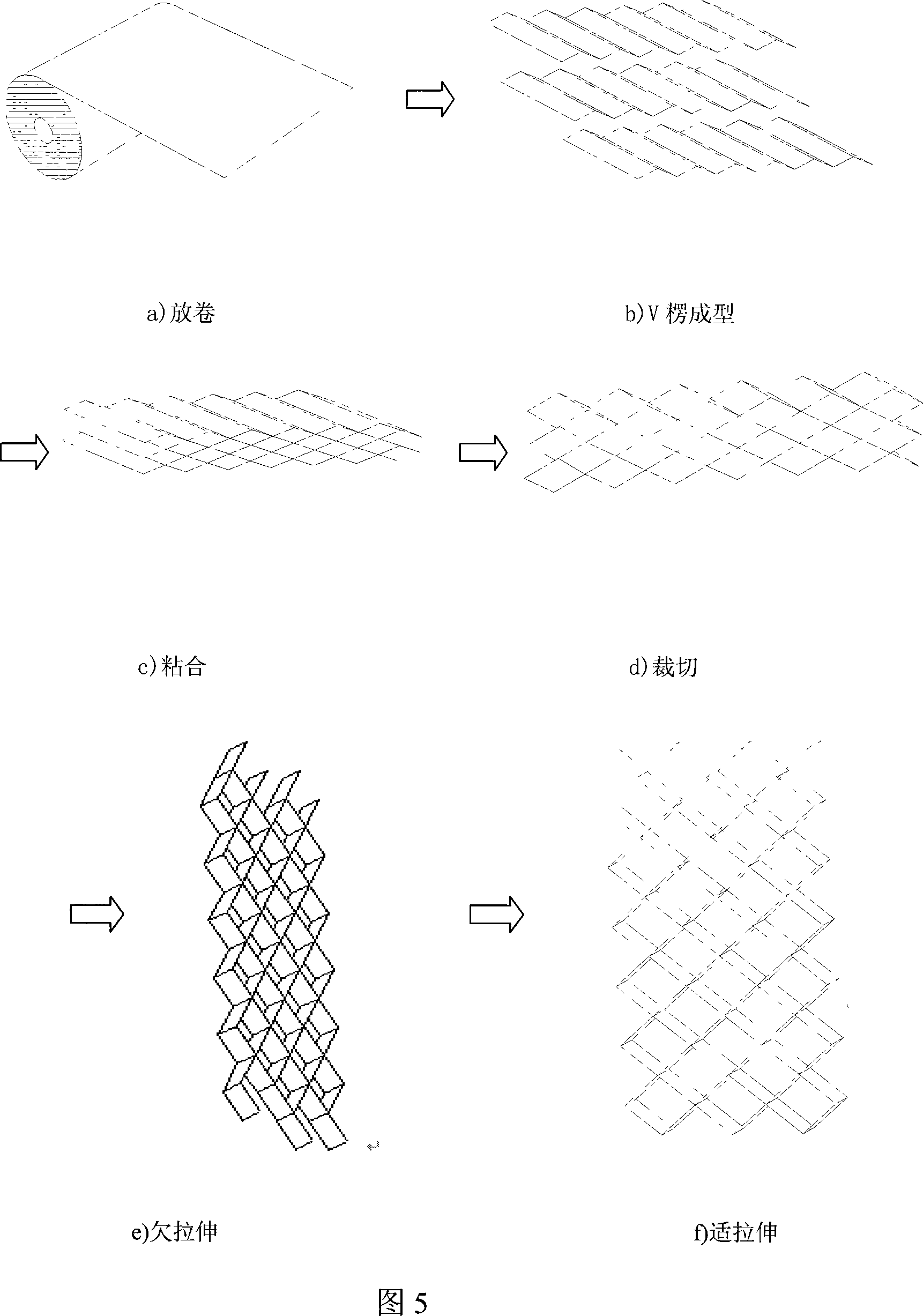

[0039] In the existing corrugated cardboard production line, V-shaped corrugated rollers are used to roll the corrugated base paper into a V shape in a similar manner to the production of corrugated medium paper, and then form a 1 to 8mm wide corrugated edge on the "V"-shaped corrugated edge. Then apply adhesive to the upper and lower peaks of the formed V-shaped core paper to obtain the first layer of V-shaped core paper with glue ribs; use the same method to obtain the second layer, the third layer, ..., the m-th layer of V-shaped core paper with glue ribs; then the m layers of core paper ...

Embodiment 2

[0041] Embodiment 2 has the same structure as Embodiment 1, except that the processing and manufacturing process of diamond-shaped cardboard is: first cut the above-mentioned paper base into core strips on the paper cutter according to the thickness of the cardboard, and then stretch the core strips to the required shape. horn. The forming angle is the two opposite angles of the rhombus quadrilateral in the stretching direction after forming; the value range of the forming angle of the rhombus grid is 30°-160°. The forming angle of the rhombus grid in this embodiment is 90°. At this time, the sandwich honeycomb is a regular quadrilateral; the characteristic of the regular quadrilateral honeycomb cardboard is that the bearing capacity of the cardboard on the four sides perpendicular to the edge is basically the same, that is, it is approximately orthotropic.

Embodiment 3

[0043] The structure of the third embodiment is the same as that of the first embodiment, except that the processing and manufacturing process of the diamond-shaped cardboard is: molding of the diamond-shaped honeycomb cushioning material. Apply adhesive on the upper and lower sides of the stretched mesh sandwich layer and paste the upper surface layer and the lower surface layer composed of facial paper to form a diamond-shaped honeycomb paperboard with a fixed size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com