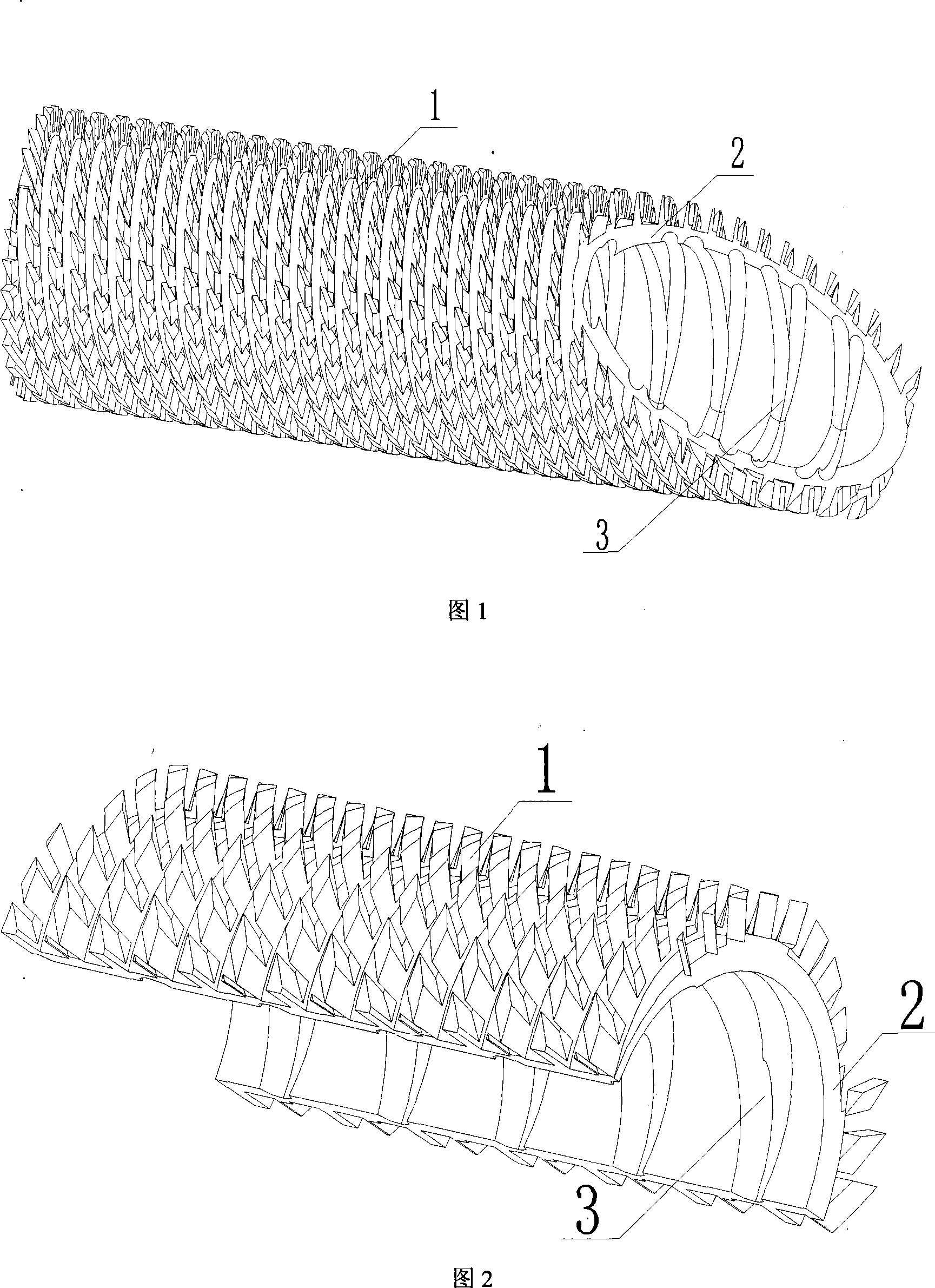

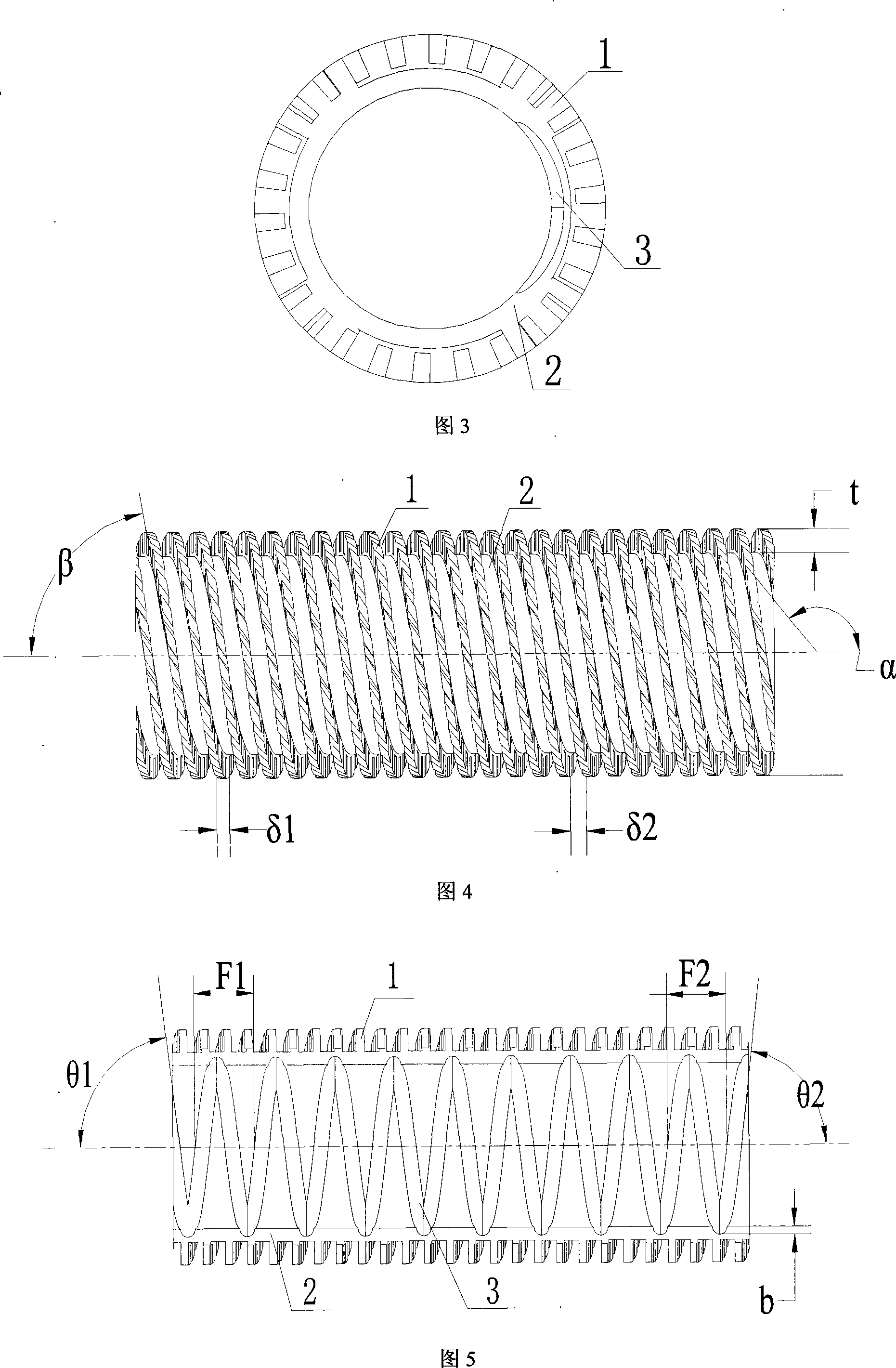

Inner chiasma spiral exterior three-dimensional diamond-type rib double-side intensify heat transfer pipe

A heat transfer tube and internal spiral technology is applied in the field of strengthening heat transfer tubes, which can solve the problems of inability to take into account the heat transfer effect inside and outside the tube, poor anti-scaling and anti-scaling functions, and large consumption of metal plates, so as to increase anti-scaling and anti-scaling. capacity, maintaining heat transfer performance, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] Now take the transformation of the oil cooler in thermal power plant as an example to illustrate the effect of the present invention:

[0046] The heat transfer efficiency of the copper smooth tube oil cooler in a power plant is low, which makes it impossible to cool the oil temperature to a given value, causing related equipment to malfunction and affecting the normal operation of the power plant. The present invention is now manufactured with steel pipes, and the structural parameters are as the above-mentioned specific examples of the present invention to replace the original copper pipes in the oil cooler for copper-free transformation.

[0047] After modification, under the same working condition, the total heat transfer coefficient of the oil cooler of the invention is 28%-54% higher than that of the copper smooth tube oil cooler. This shows that although the thermal conductivity of the steel pipe is less than half of that of the copper pipe, the total heat transf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com