Patents

Literature

98results about How to "Improve overall heat transfer coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology and device forsynthesizingmethanol

ActiveCN107382665AIncrease profitGood synchronization of service lifeOrganic compound preparationHydroxy compound preparationSyngasMixed gas

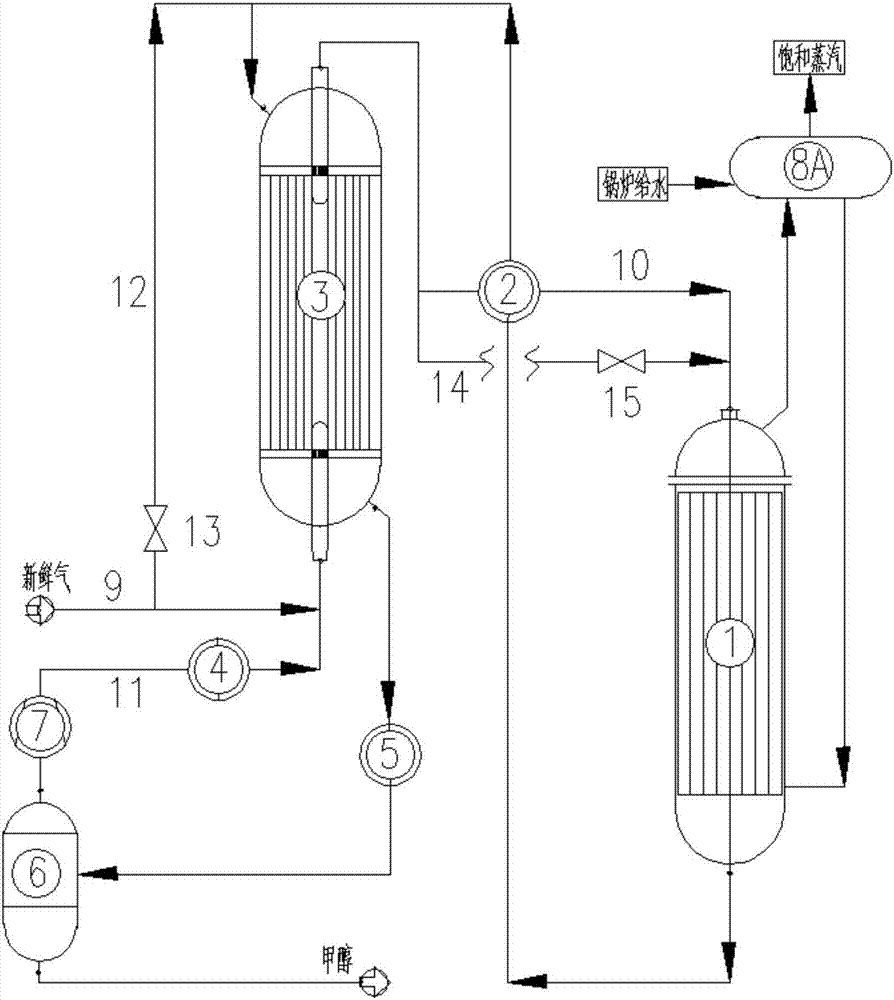

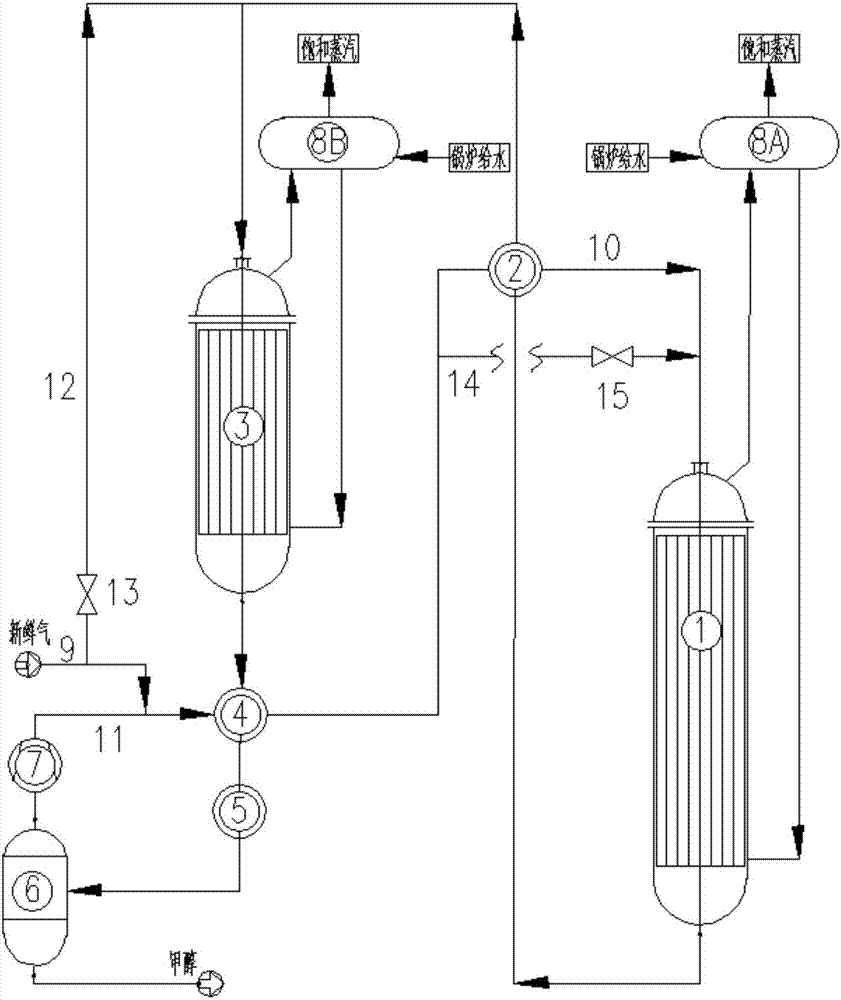

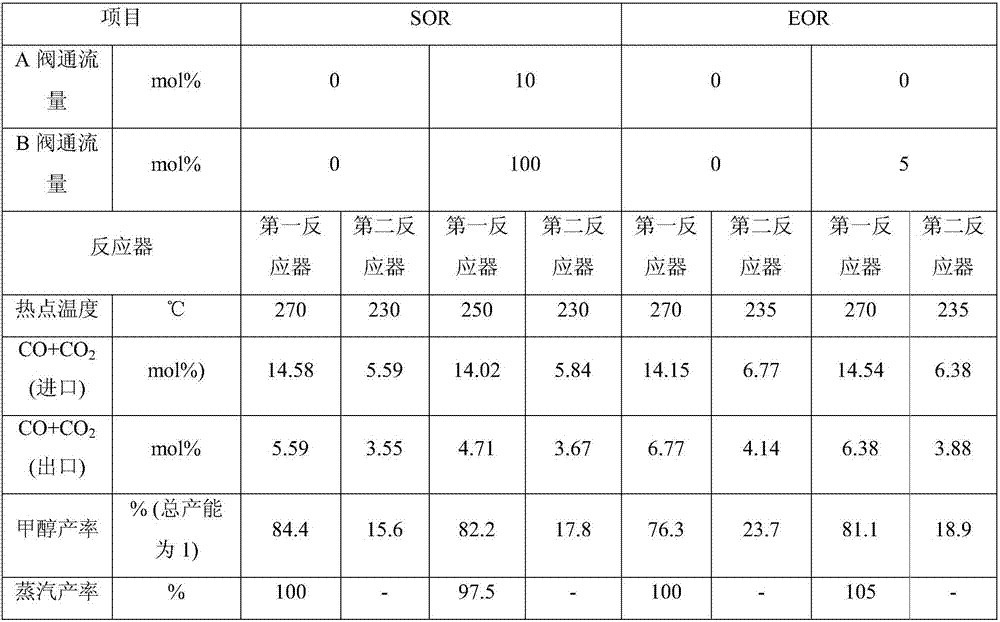

The invention discloses a technology for synthesizing methanol. The technology comprises the following steps: generating methanol by a methanol synthesis gas containing fresh gas through a first reactor; exchanging the heat of the mixed gas containing the synthesis gas and methanol steam with the heat of the synthesis gas containing fresh gas to be fed into the first reactor and then generating methanol through a second reactor; cooling the synthesis gas in higher methanol concentration after the reaction, and then guiding into a methanol separator and separating methanol; mixing the synthesis gas after separating methanol with fresh gas, thereby acquiring the synthesis gas containing fresh gas; guiding the synthesis gas containing fresh gas into the first reactor again; utilizing a valve A to directly guide a part of fresh gas into the second reactor and controlling the hot-spot temperature of a catalyst bed of the second reactor within 250 DEG C; keeping a part of synthesis gas containing fresh gas free from heat exchange and directly introducing into the first reactor by a valve B; controlling the gas inlet temperature of the second reactor at 200-240 DEG C. According to the invention, the use ratio of the catalyst is increased, the quality of the methanol product is improved and the running stability of the production device is improved.

Owner:NANJING GOODCHINA CHEM TECH

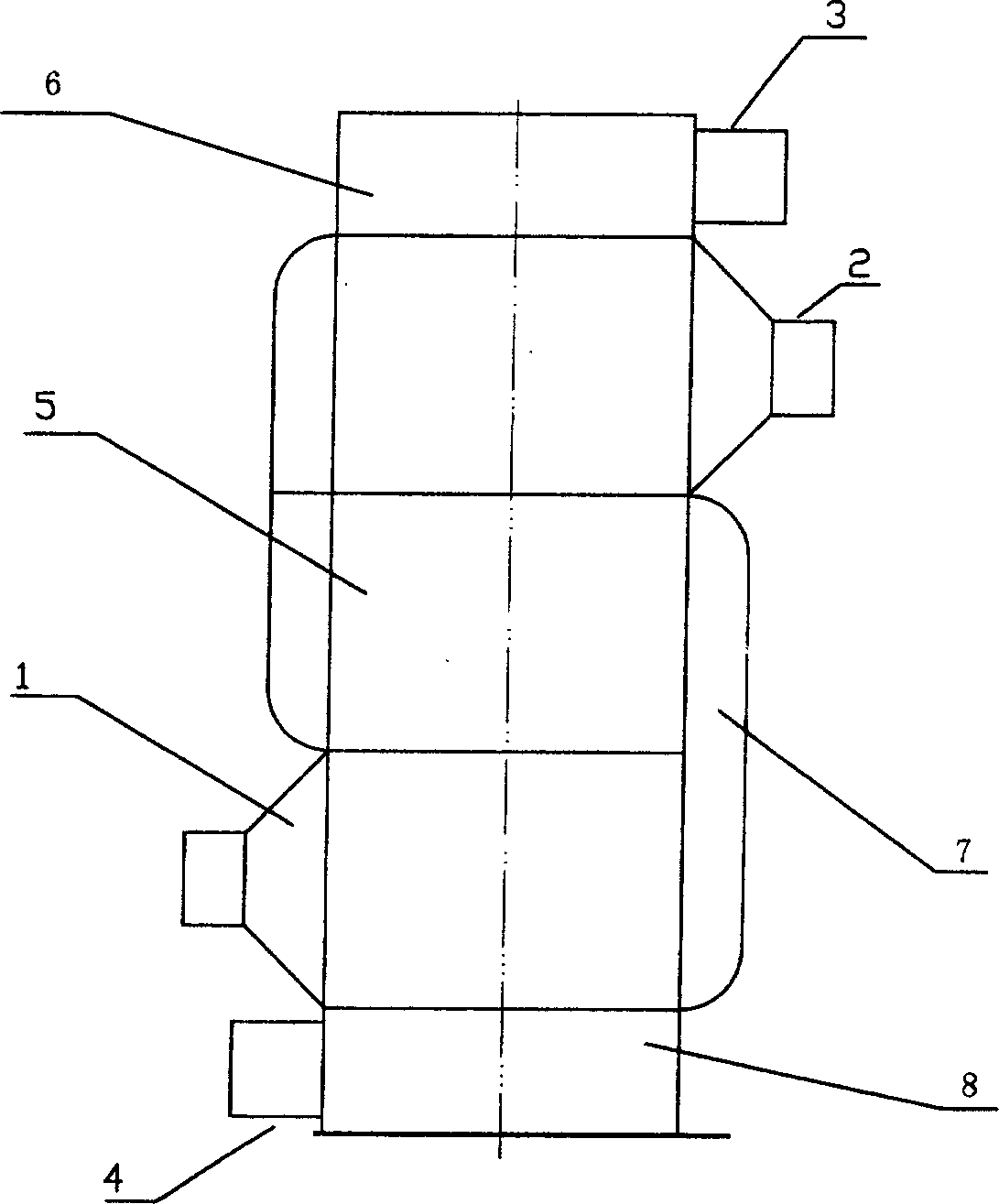

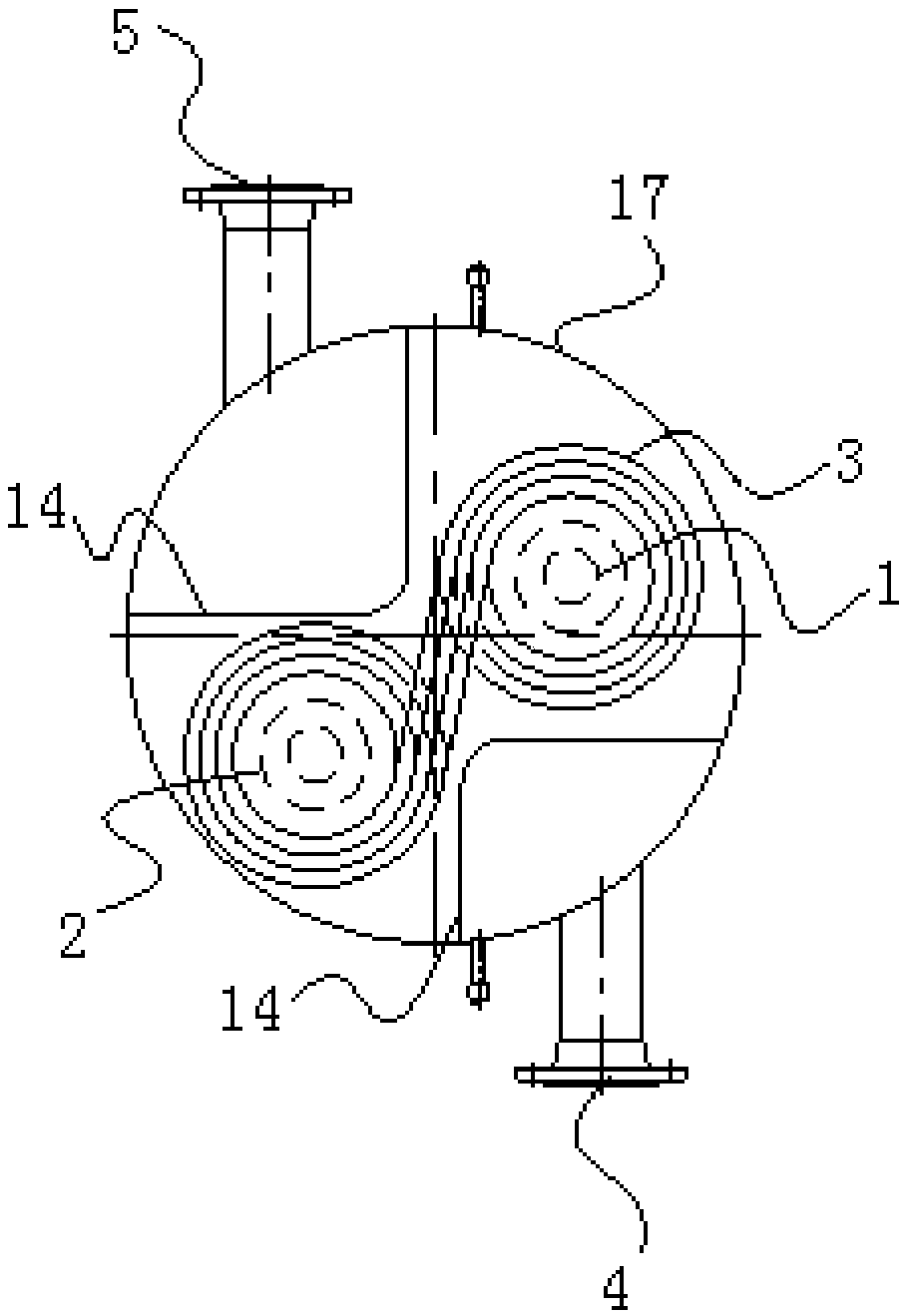

Boosted-ventilation direct air cooling tower

InactiveCN103712473AAdd adjustment functionImprove overall heat transfer coefficientSteam/vapor condensersAssisted ventilationCooling tower

The invention belongs to the field heat exchange, and relates to a boosted-ventilation direct air cooling tower, in particular to an air-cooling power generation air cooling island and an air driving mode. Due to winter-summer difference and day-night difference of air temperature, frequent natural wind and multiple changes of wind speed and wind direction, a pure natural ventilation and simple mechanical-assisted ventilation air cooling tower is difficult to meet current air cooling requirements. Condensation triangles composed of axial flow fans, finned tubes and the like are disposed around the lower portion of a natural ventilator. Cooling capacity of the air cooling tower in summer is greatly enhanced, damage of strong wind is weakened greatly, excess draft in the air cooling tower in winder can be utilized, energy is recovered through the axial flow fans, and hot air in the tower can be pumped out by reverse rotation of the fans to melt the accidentally-frozen fined tubes. The boosted-ventilation direct air cooling tower can be matched with direct air cooling and indirect air cooling units in various sizes.

Owner:李宁

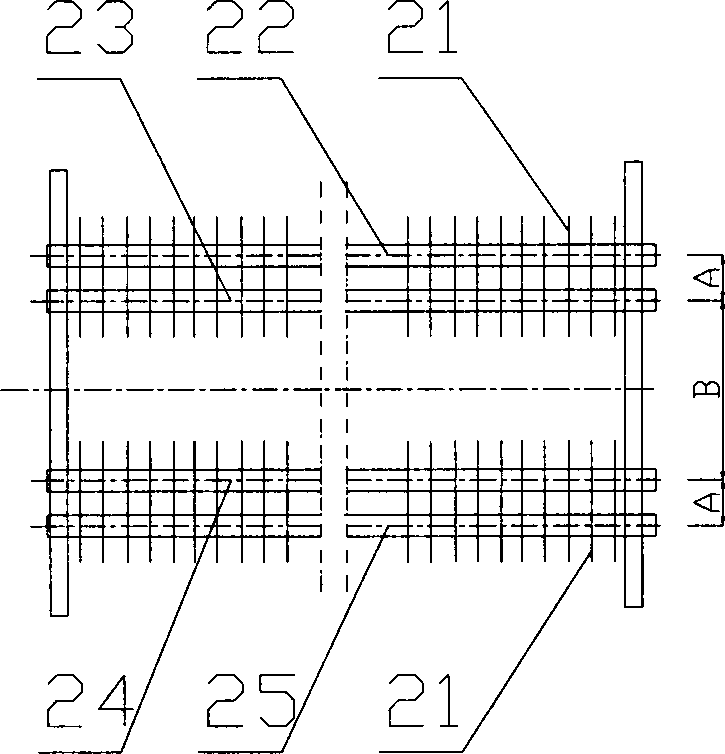

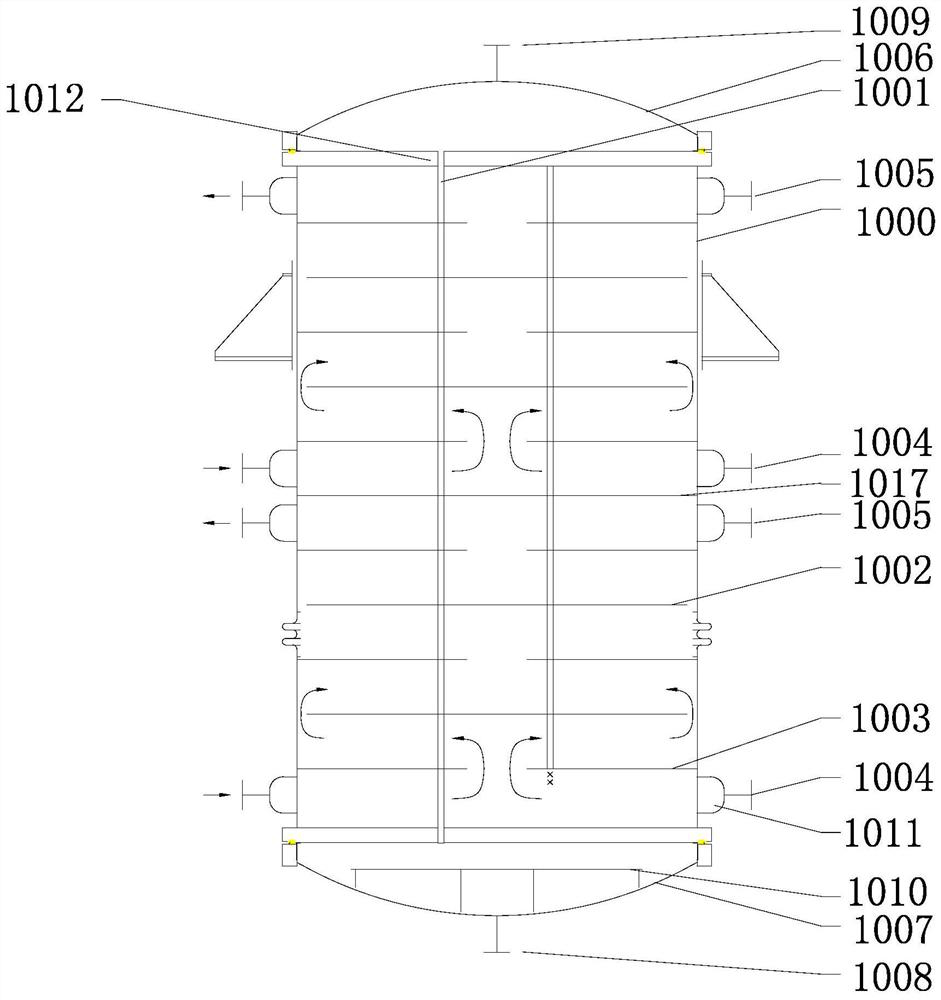

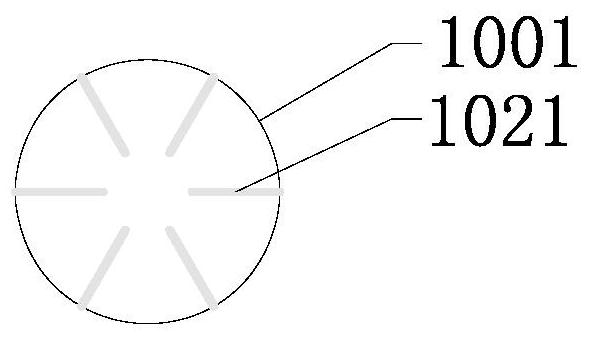

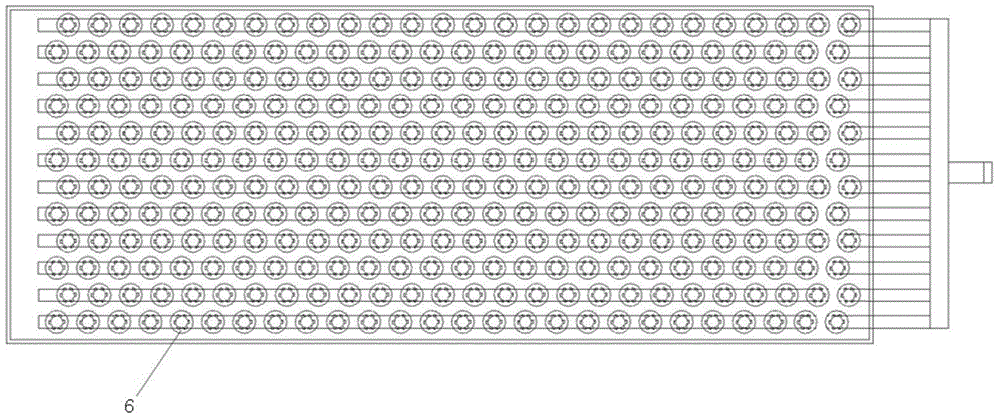

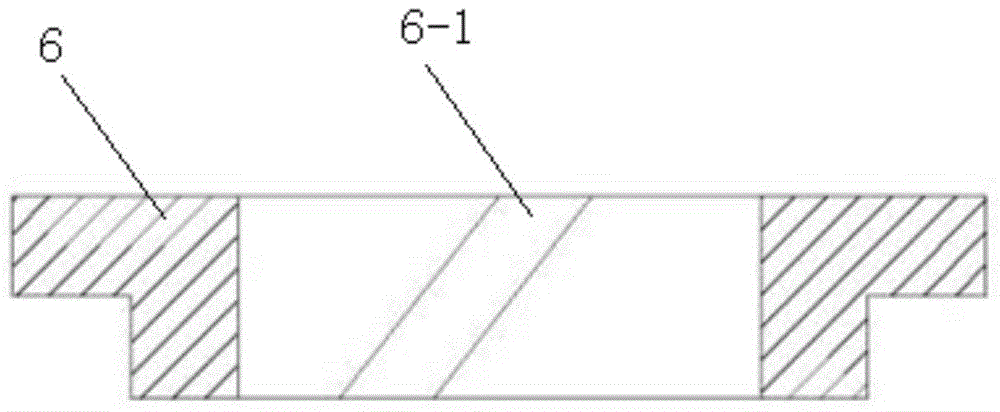

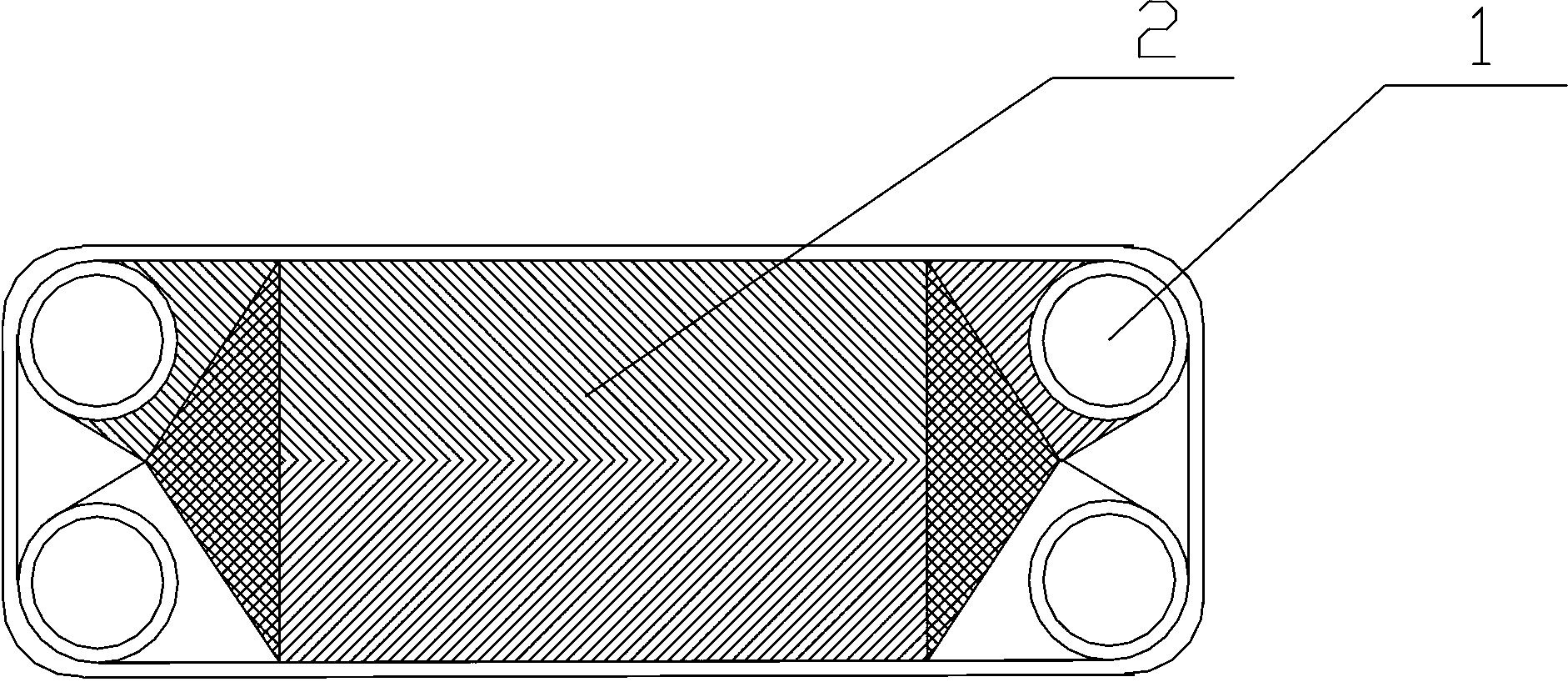

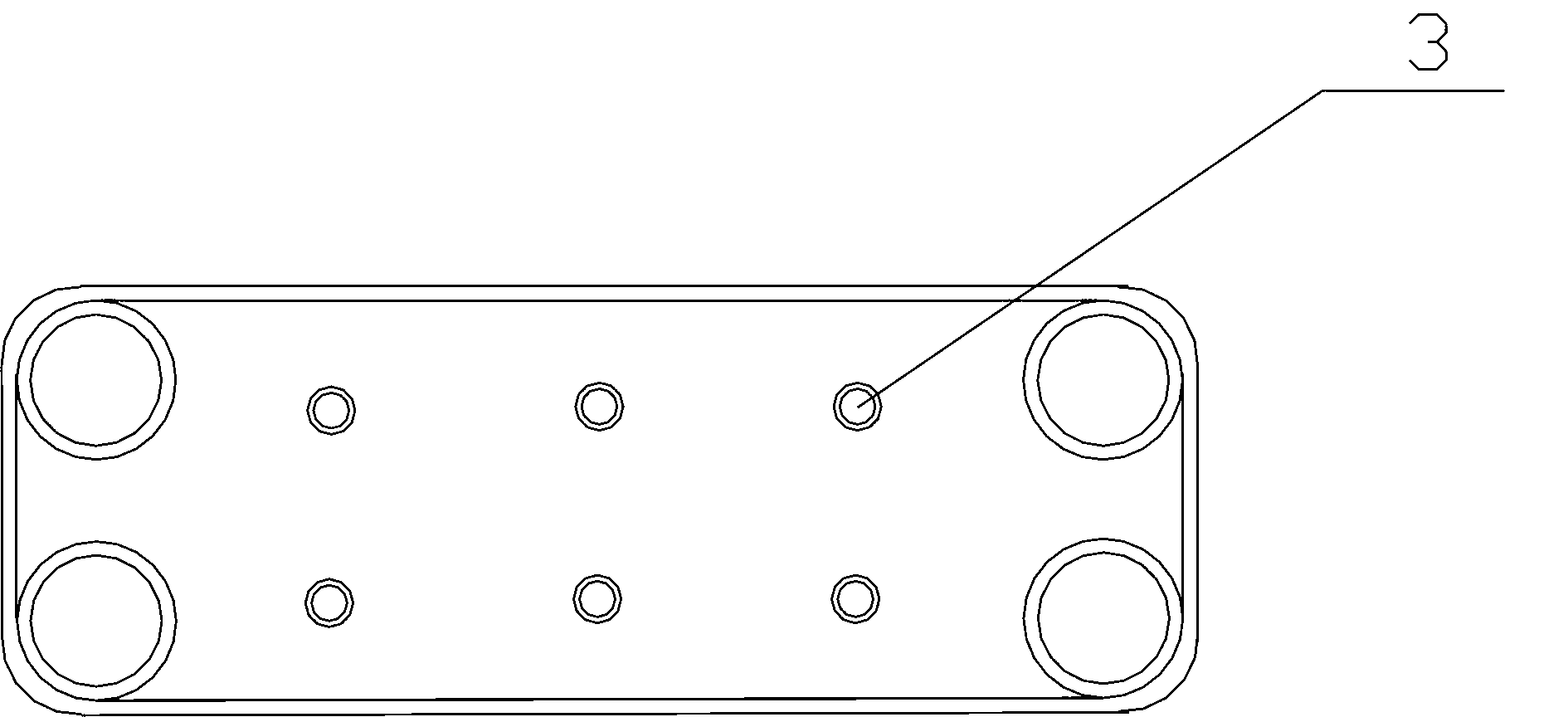

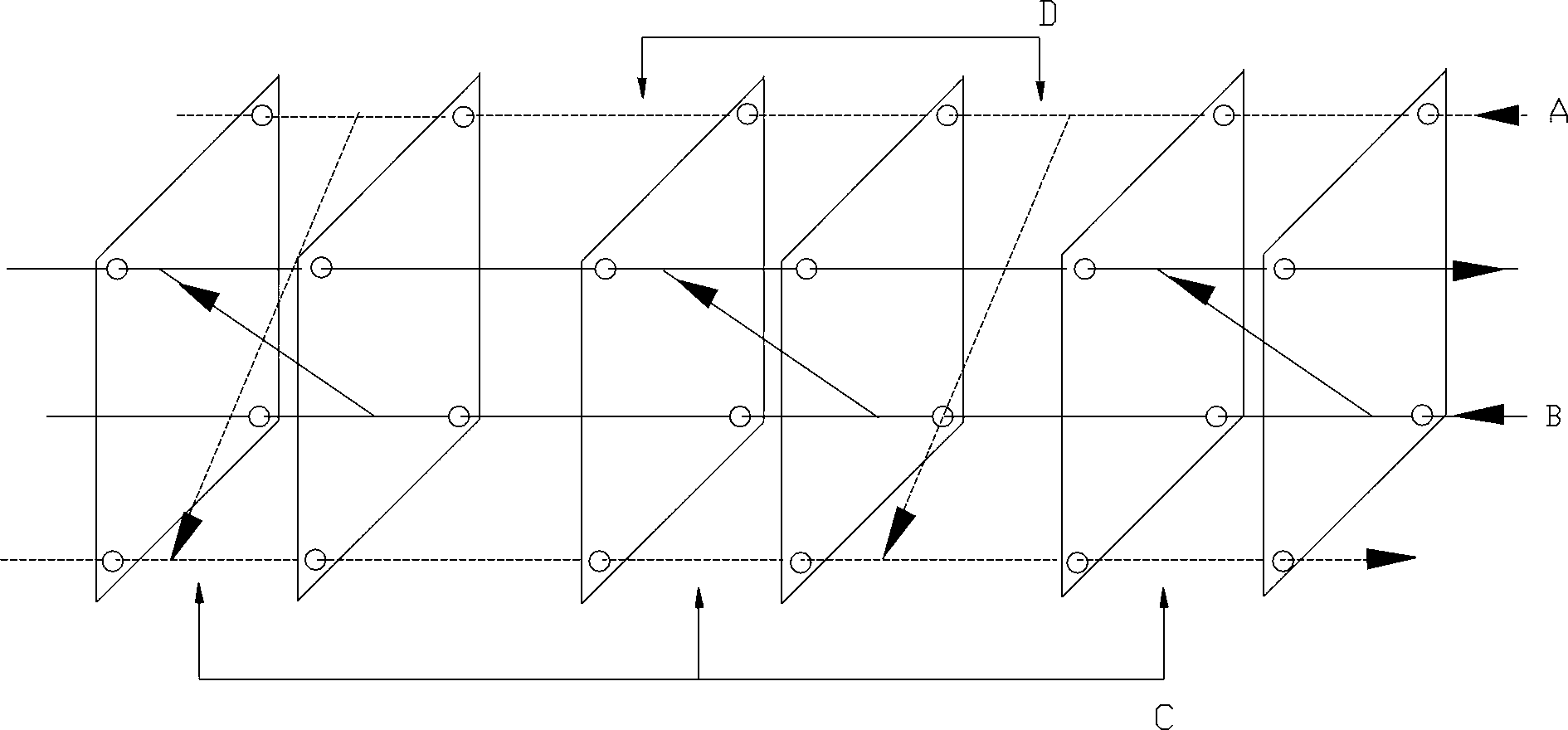

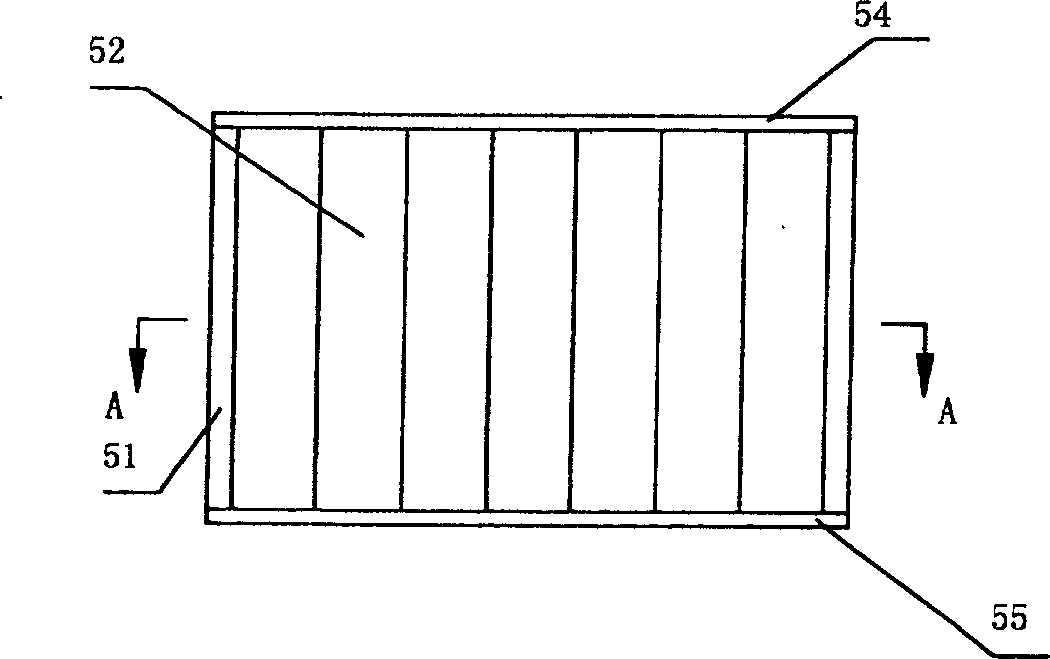

Preheating system of plate heat exchanger of hot blast furnace

ActiveCN101634529ACompact structureHigh temperature toleranceStationary plate conduit assembliesMetallic materialsEngineering

The invention relates to a preheating system of a plate heat exchanger of a hot blast furnace, which comprises a gas input pipeline, a gas output pipeline, an air input pipeline, an air output pipeline, a hot blast furnace waste gas flue, a chimney, a plurality of heat exchangers, an additional burning furnace, a connecting pipeline and a plurality of valves. The heat exchangers are plate heat exchangers which consist of a plurality of sets of plate bundle modules, the plate bundle modules are formed by laminating convex-concave corrugated partition boards, and pyrogenic fume and low-temperature gas or air reversely flow in a crossed and alternated plate cavity to form respective inlet and outlet. The preheating system ensures the pyrogenic fume and the low-temperature gas or the air directly exchange heat through the plate wall of the partition board without an intermediate heat transfer working substance, the preheating temperature is not limited by the critical temperature and / or critical pressure of the heat transfer working substance, and a metallic material or a ceramic material has high capability of high temperature resistance, so the preheating system of the plate heat exchanger of the hot blast furnace has the advantages of adapting to higher preheating temperature and more complicated preheating process flow, and the like. The preheating system can utilize the plurality of the heat exchangers to perform different combinations to form various preheating systems, meet different preheating requirements and ensure that the preheating system has practicability.

Owner:上海雷林工业设备有限公司

SWSR-8 pressurization sulfur recovery process

ActiveCN105947992AEmission reductionReduce sizeEnergy inputSulfur preparation/purificationSulfurFlue gas

The invention belongs to the field of sulfur recovery, and particularly relates to an SWSR-8 pressurization sulfur recovery process. The process comprises the steps that acid gas enters a sulfur making furnace, H2S is subjected to a high-temperature Claus reaction and converted into sulfur, and sulfur enters a two-stage converter to conduct two stage catalytic conversion for recovering sulfur; sulfur making tail gas enters a hydrogenation reactor, under the action of a hydrogenation catalyst, SO2 and COS are reduced to H2S through hydrogenation hydrolysis, reduced H2S gas is absorbed with an MDEA solution, and after purified tail gas recovers heat through incineration, flue gas is exhausted to the atmosphere through a chimney, wherein the pressure of acid gas entering the sulfur making furnace ranges from 90 kPa(g) to 120 kPa(g), and the pressure of the sulfur making furnace ranges from 90m kPa(g) to 120 kPa(g). The pressure of cooling and heat exchange equipment such as a sulfur making waste heat furnace, a first stage sulfur condenser, a second stage sulfur condenser, a third stage sulfur condenser, a steam generator and a tail gas waste heat boiler is higher than that in the prior art, the total heat transfer coefficient is increased, the occupied area is decreased, catalytic and absorption reactions can be conducted conveniently, the sulfur recovery rate is increased, and SO2 discharge is reduced.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD

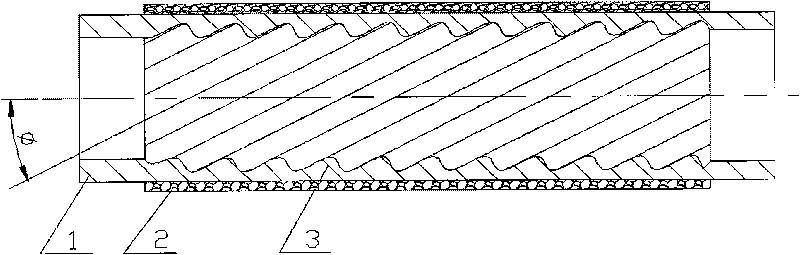

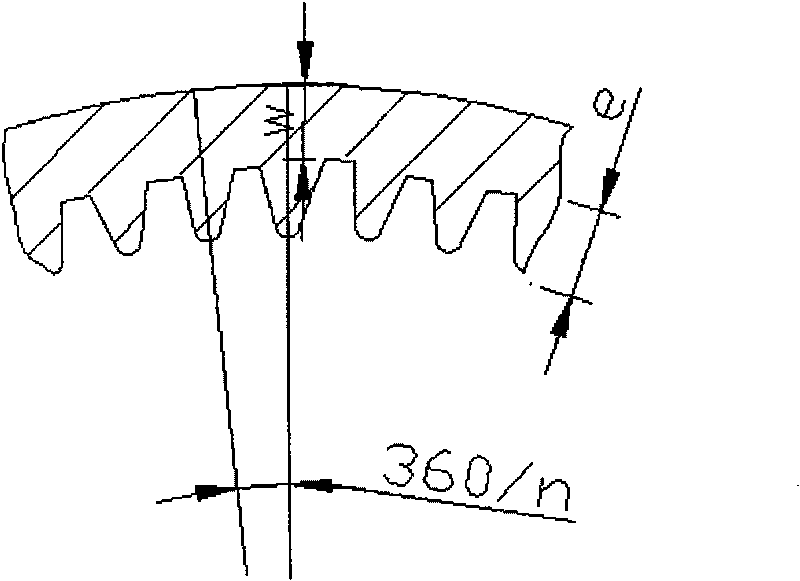

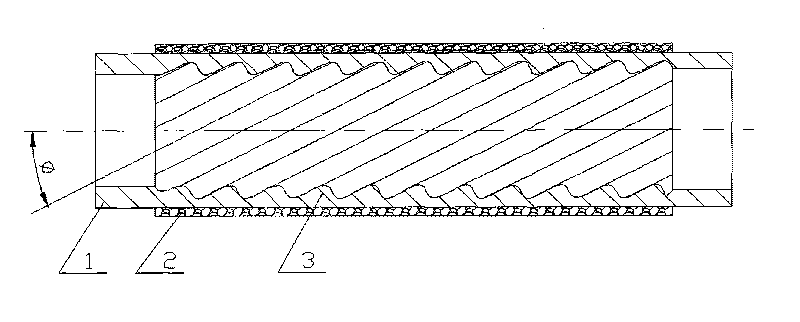

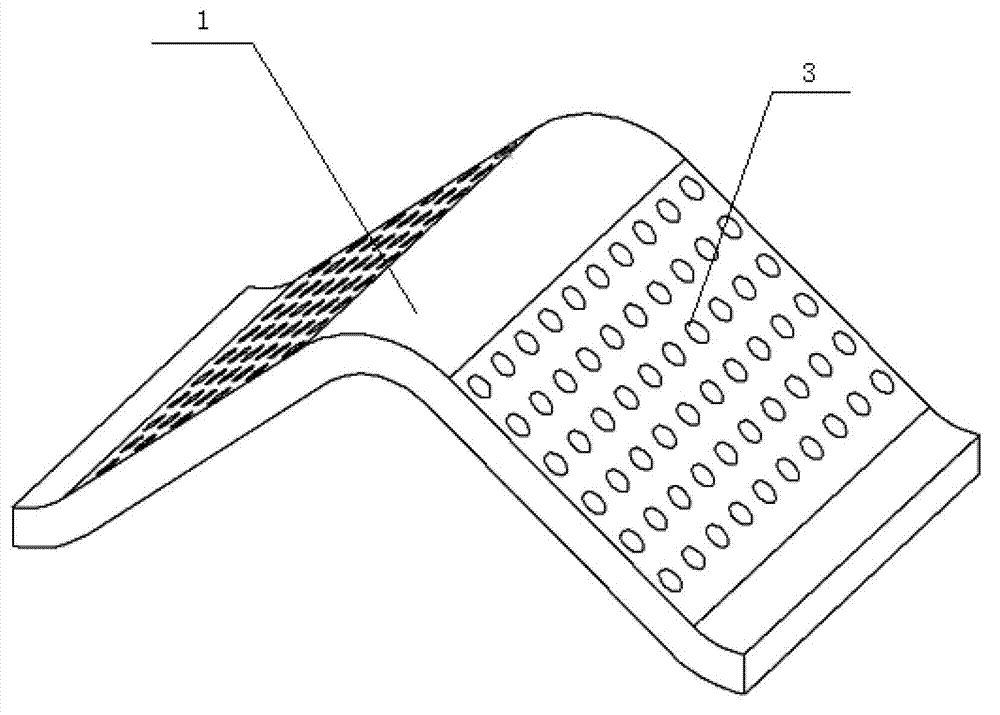

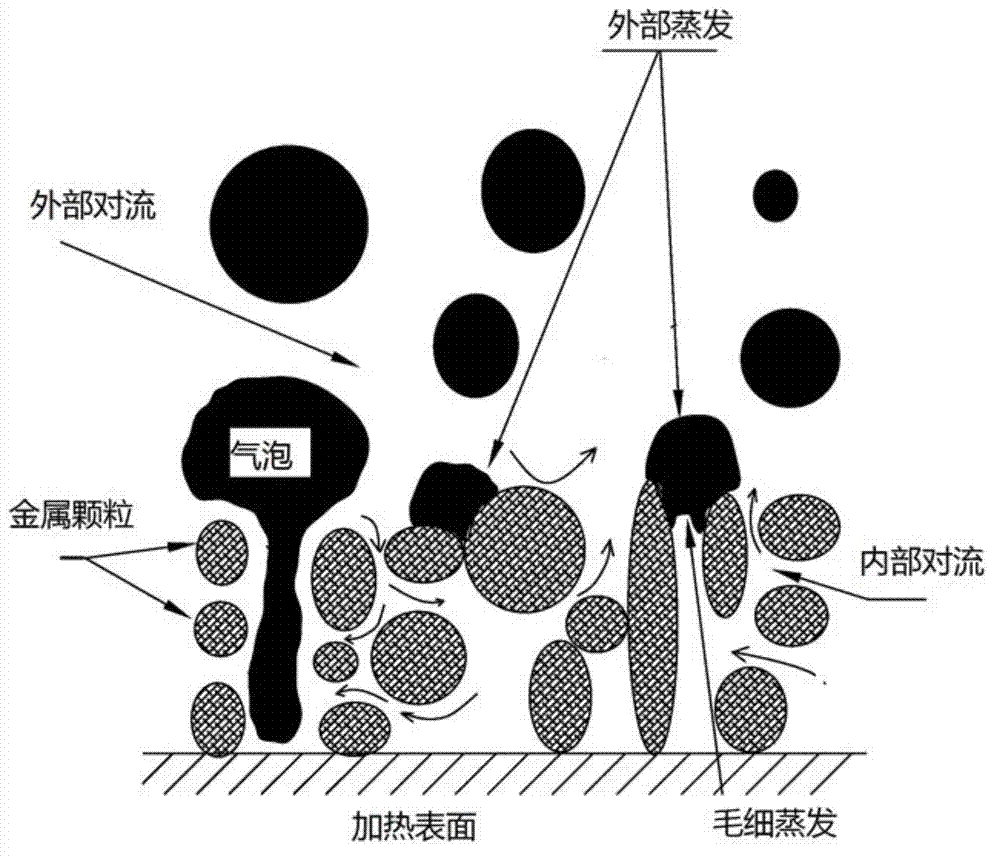

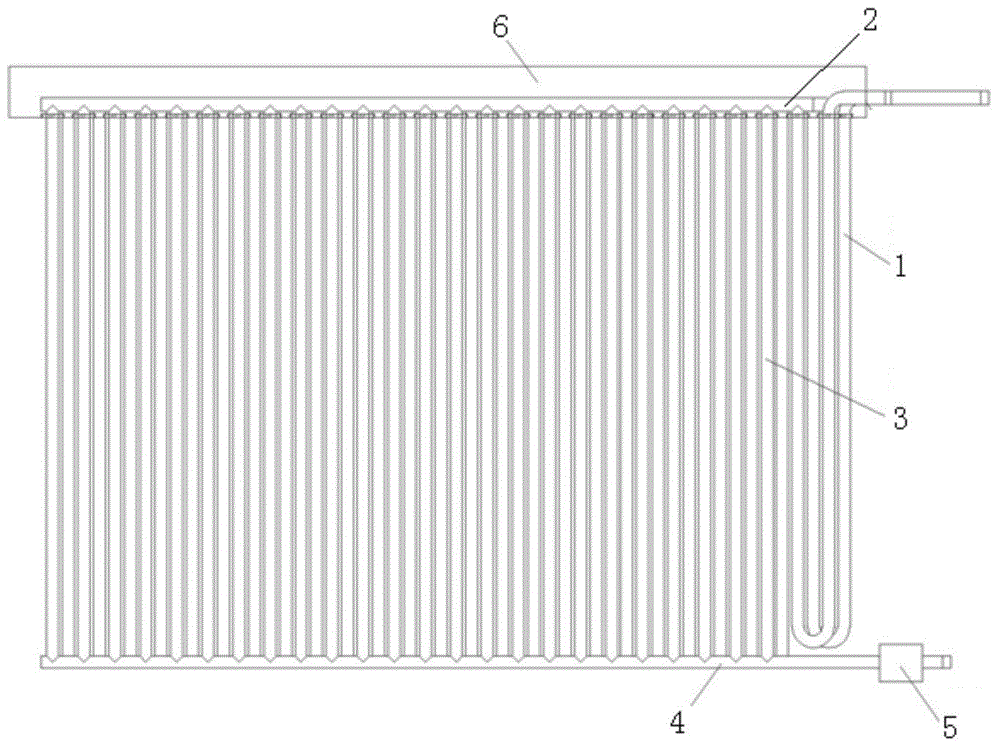

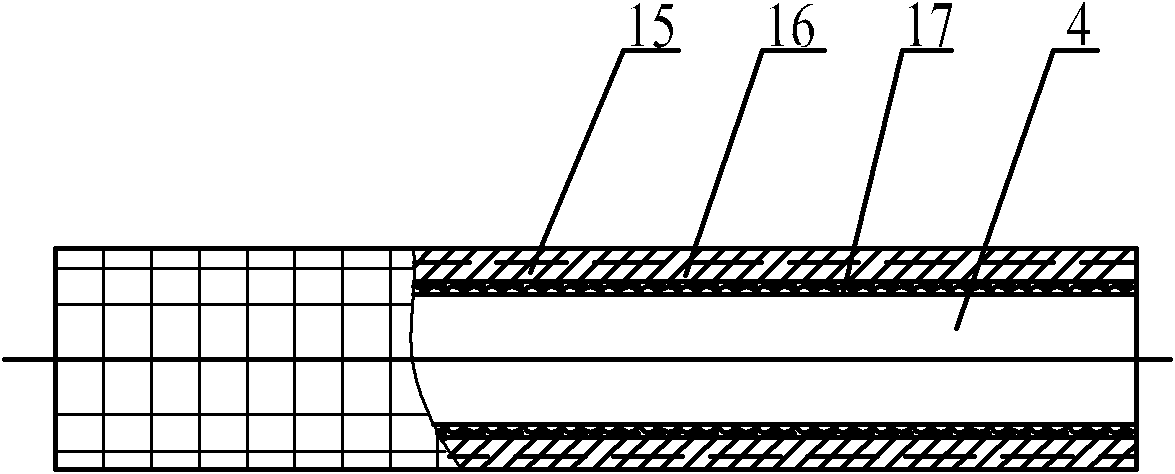

Inner fin externally sintered porouslayer heat exchange tube

InactiveCN101738124AHigh bonding strengthIncrease productivityHeat transfer modificationTubular elementsCondensation heat transferMaterials science

The invention relates to an inner fin externally sintered porouslayer heat exchange tube which comprises tube fitting segments with smooth circular sections at both ends, and a double strengthened heat exchange segment in the middle, wherein the internal surface of the double strengthened heat exchange segment is a spiral low fin surface, and the external surface is a metallic porous surface. Compared with the prior art, the inner fin externally sintered porouslayer heat exchange tube can simultaneously strengthen condensing heat exchange in the tube and boiling heat exchange outside the tube. In the tube, the condensing coefficient of heat exchange can be doubled by increasing heat exchange area, disturbing fluid flowing states, reducing temperature boundary layers, etc.; the boiling heat exchange efficiency can be improved by an order of magnitude with the method of increasing the nucleus of boiling outside the tube. The strengthening effects inside and outside the tube are obvious. The heat exchange tube belongs to a double-surface strengthened heat exchange tube. The inner fin externally sintered porouslayer heat exchange tube has the characteristics of good strengthened heat exchange effect, low flowing resistance, high production efficiency, low cost, etc.

Owner:SHANGHAI RES INST OF CHEM IND

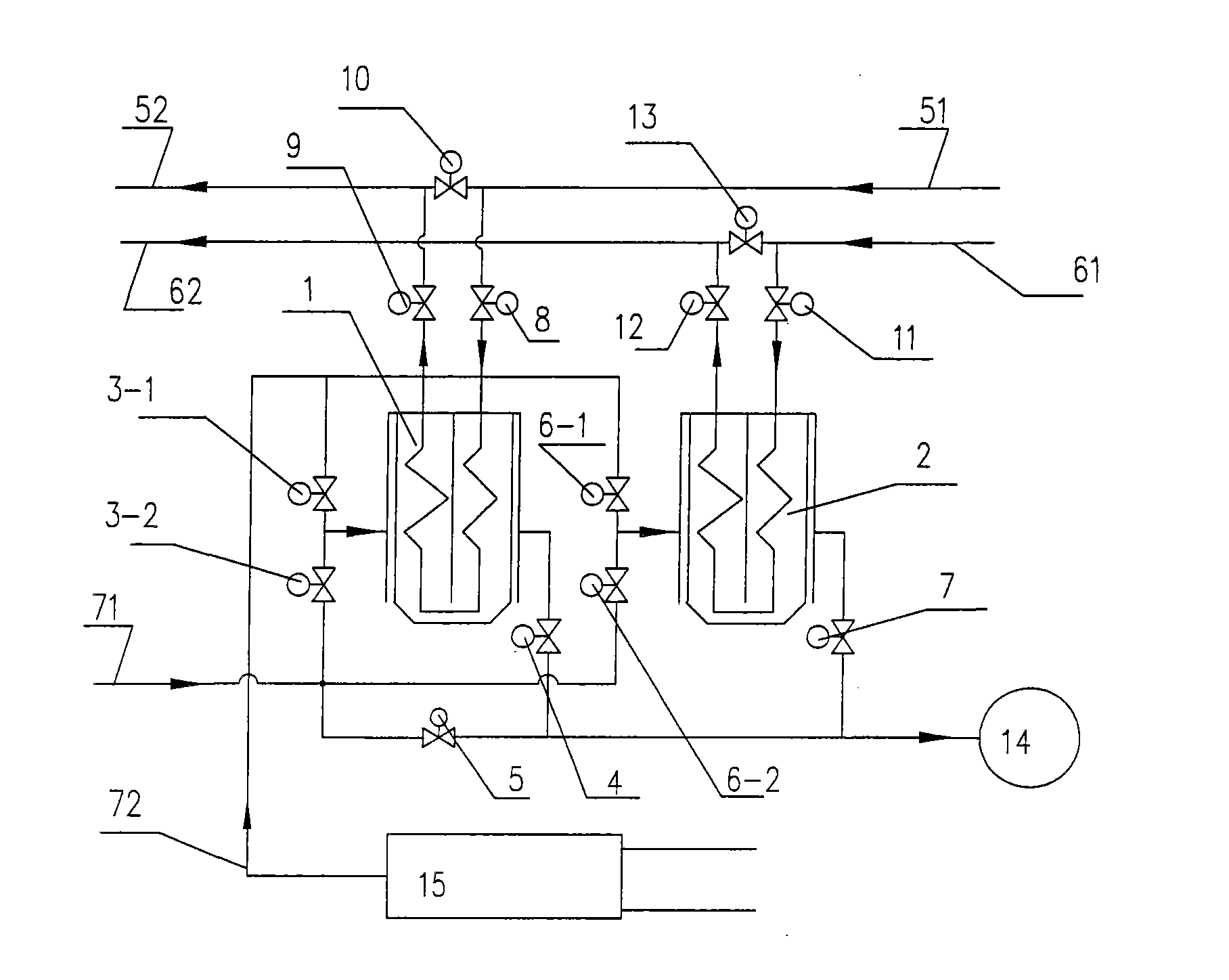

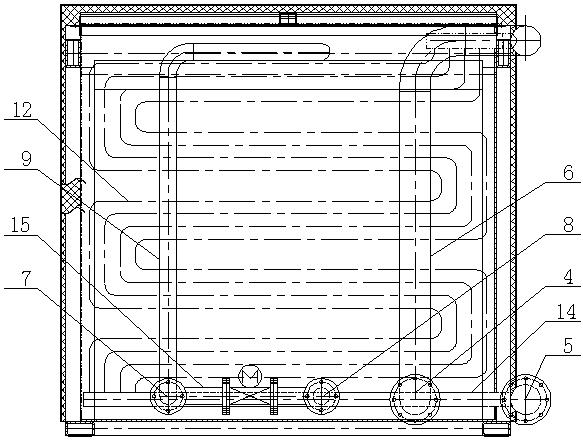

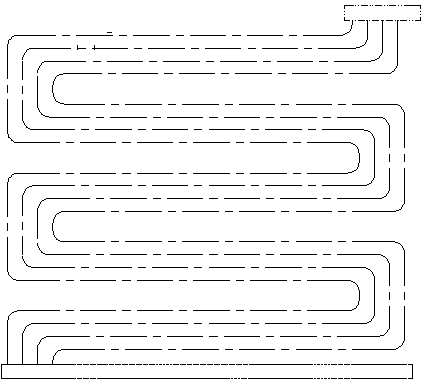

Efficient movable phase change heat storage heating device

ActiveCN103528122AImprove recycling efficiencyReasonable structural designHeat storage plantsSpace heating and ventilation detailsEngineeringPhase change

The invention relates to an efficient movable phase change heat storage heating device. At present, a movable phase change heat storage heating device which does not require a pipe network and is high in heat energy recovery efficiency does not exist. The efficient movable phase change heat storage heating device is characterized by comprising a heat storage tank, a heat storage assembly, a steam pipe, a cold water pipe, a plurality of heating pipe rows, a bottom hot water pipe, a condensed water pipe, a hot water thermoregulation pipe and an air exhaust pipe. The heat storage assembly comprises a plurality of heat storage aluminum foil bags, phase change materials are arranged in the heat storage aluminum foil bags, the heat storage aluminum foil bags are installed inside the heat storage tank, each heating pipe row comprises a plurality of steam branch pipes, the heating pipe rows are perpendicularly installed inside the heat storage tank, the cold water pipe comprises a main pipe body and a plurality of branch pipe bodies, the branch pipe bodies are all perpendicularly fixed to the main pipe body and arranged in parallel, the bottom hot water pipe is located on the lower middle portion of the heat storage tank, and the two ends of the hot water thermoregulation pipe are connected to the cold water pipe and the bottom hot water pipe respectively. The efficient movable phase change heat storage heating device is reasonable in structural design and high in heat energy recovery efficiency.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD +1

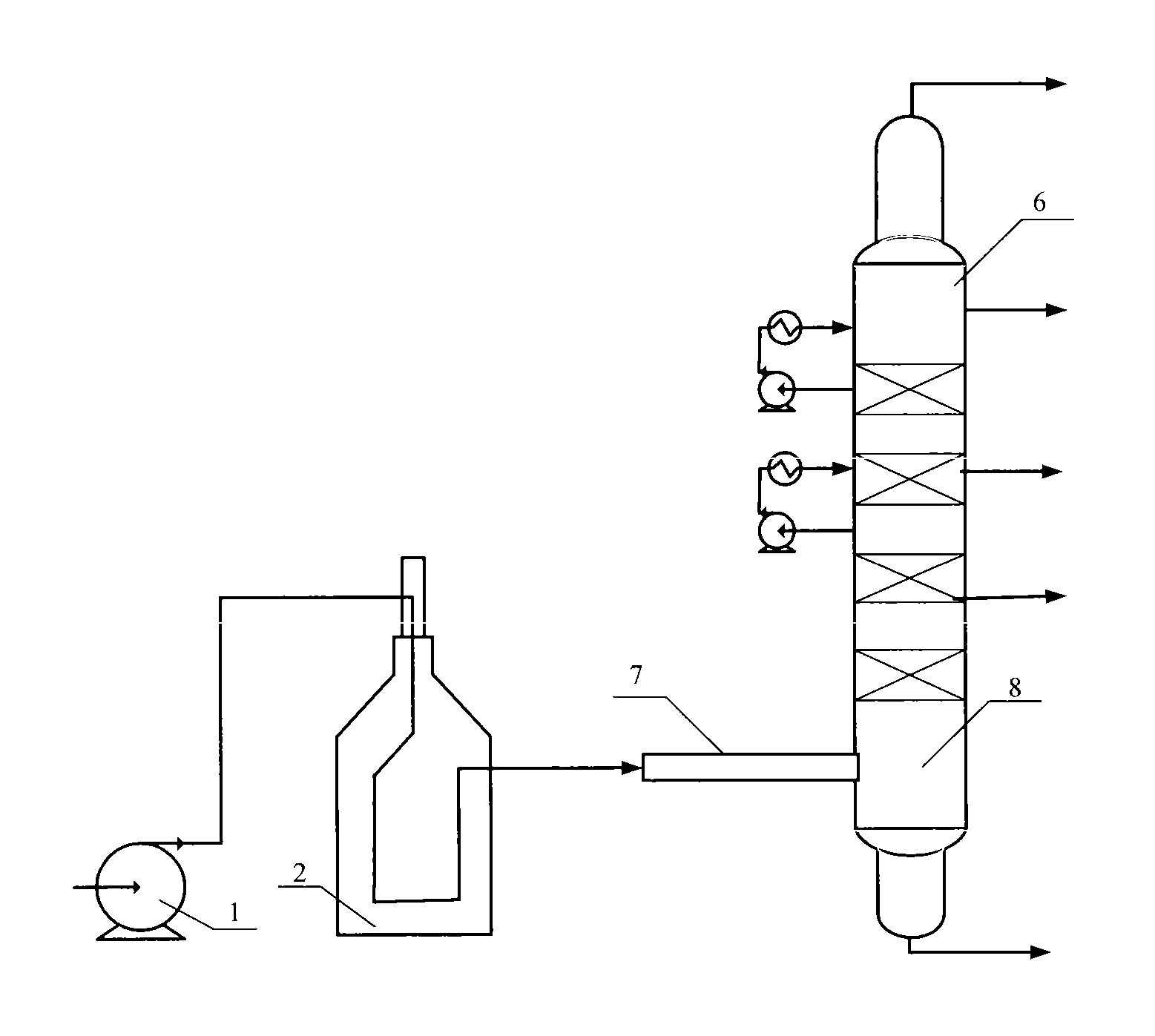

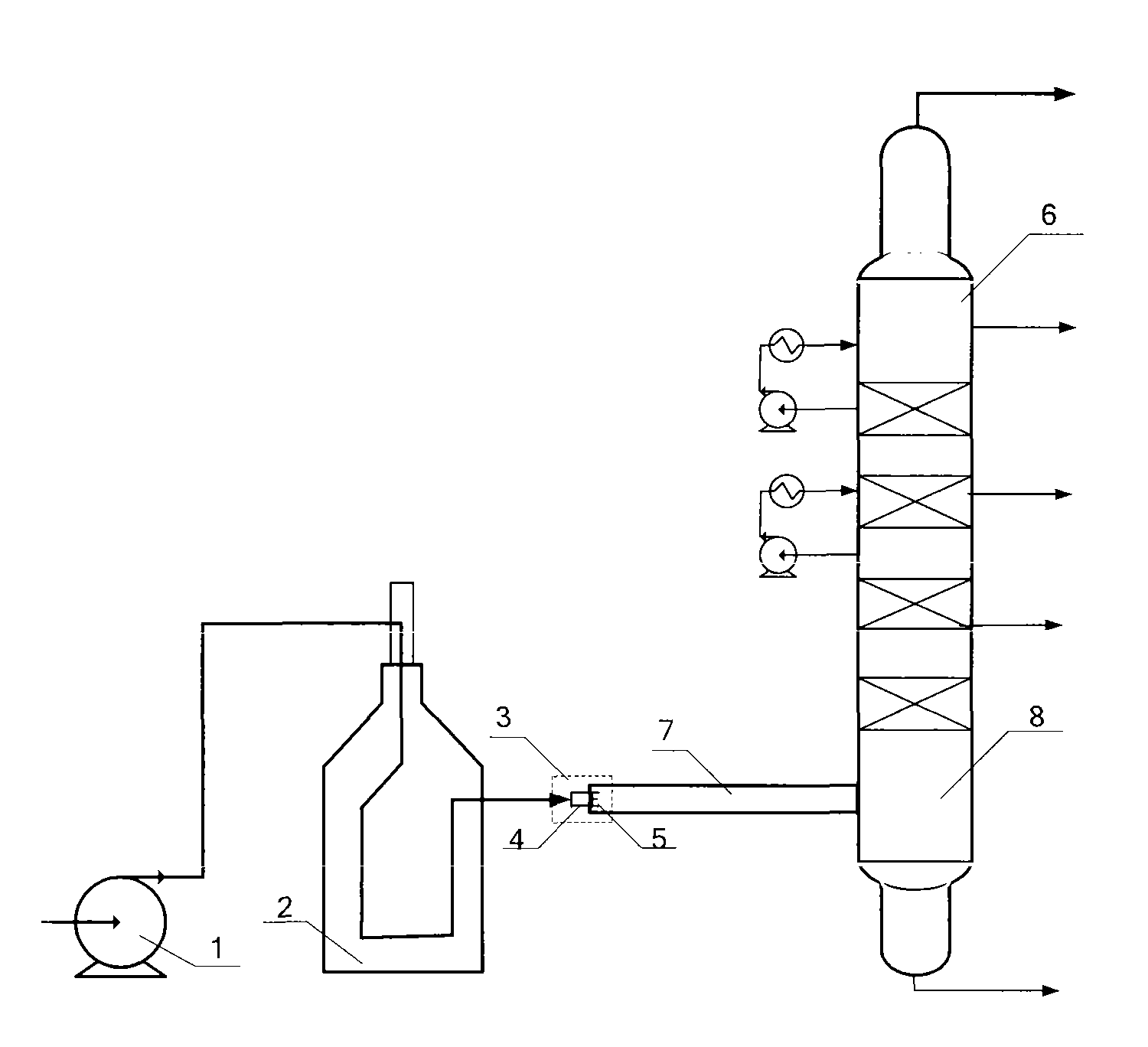

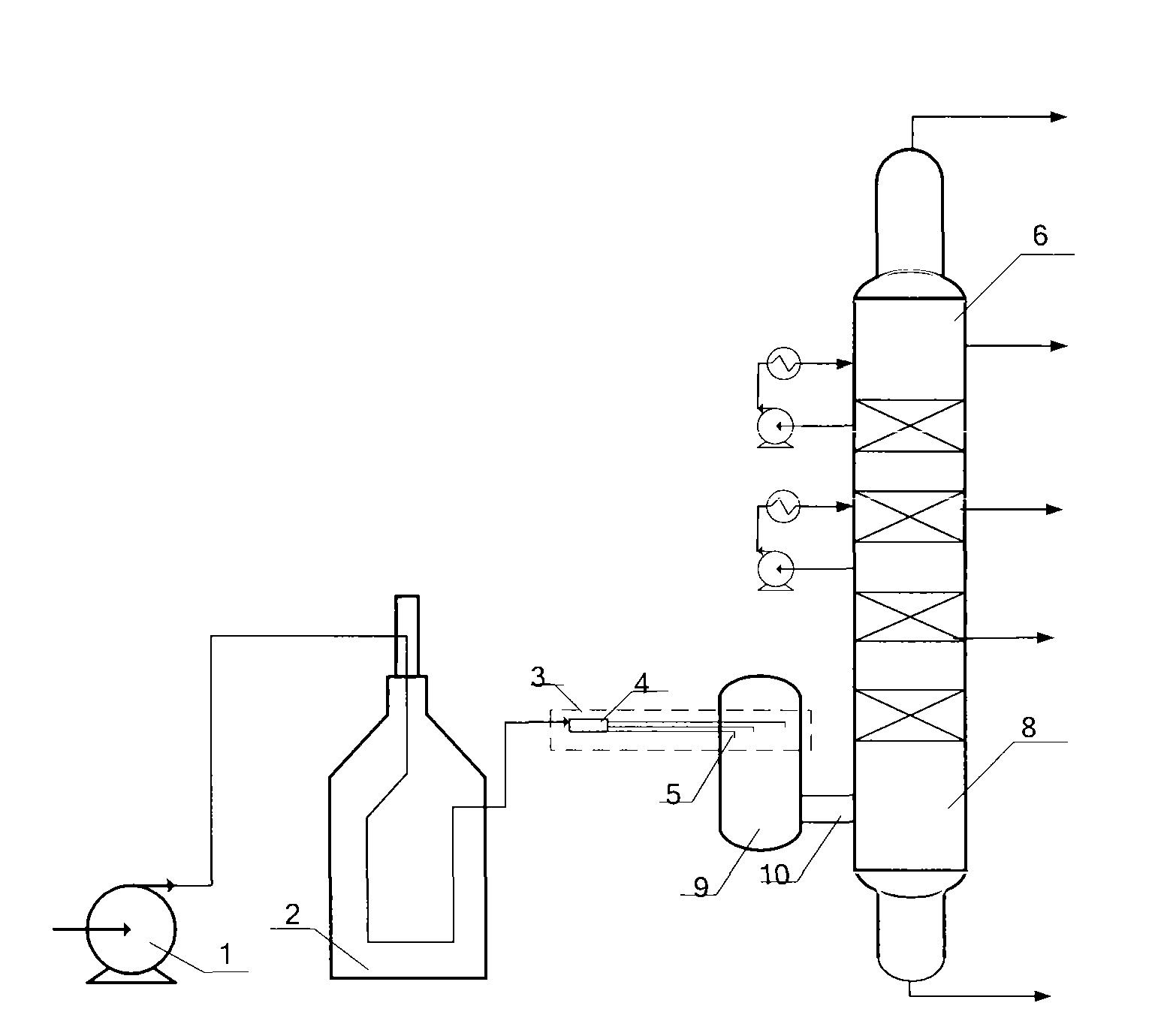

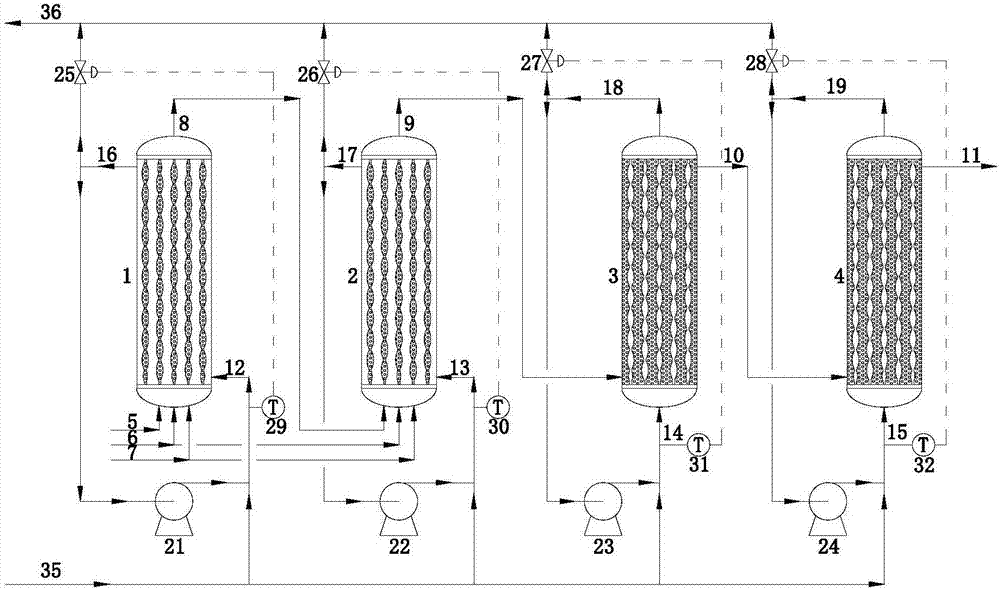

Fractionating column feed method for improving distillate yield

ActiveCN102079984AImprove distillate yieldHigh yieldHydrocarbon distillationSmall dropletFractionating column

Disclosed is a fractionating column feed method for improving distillate yield, which comprises the following steps: preheating petroleum hydrocarbon raw oil to be fractionated by a heating furnace; spraying the preheated raw oil into a atomization container under the pressure of 100.0-1000.0kPa higher than the pressure of the atomization container and atomizing into small droplets with the particle size of 0.0001-10 millimeters and vaporizing partly; and introducing the small droplets into a fractionating column for distillation separation; leading out the distillate products from the top ofthe fractionating tower and / or the lateral line and the residues from the bottom. In the method provided by the invention, the vaporization process of the raw oil is accelerated through atomization in order to fully vaporize the distillate in an extreme short period of time, minimize the distillate content in the residual oil to the great extent and increase the yield of distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

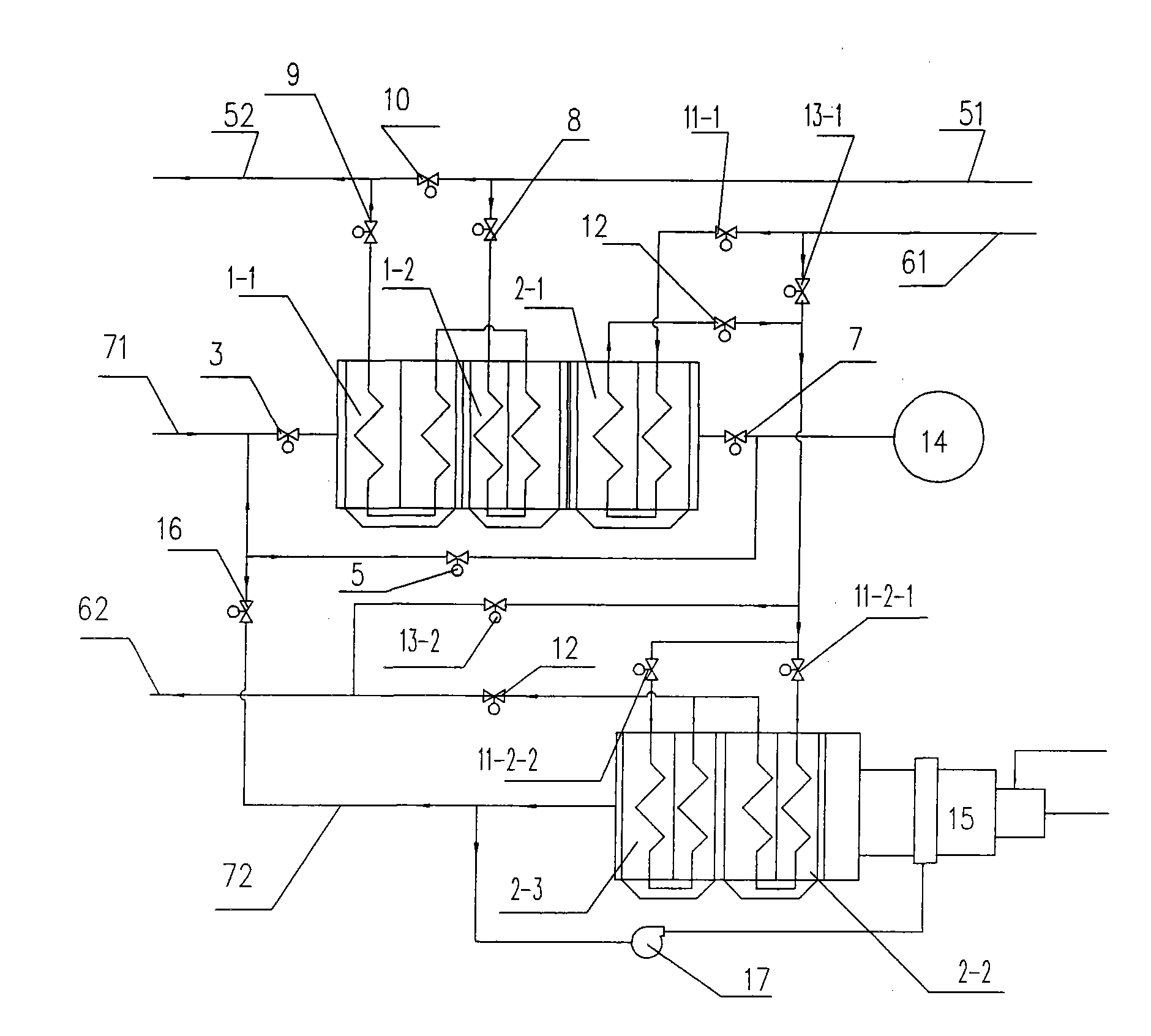

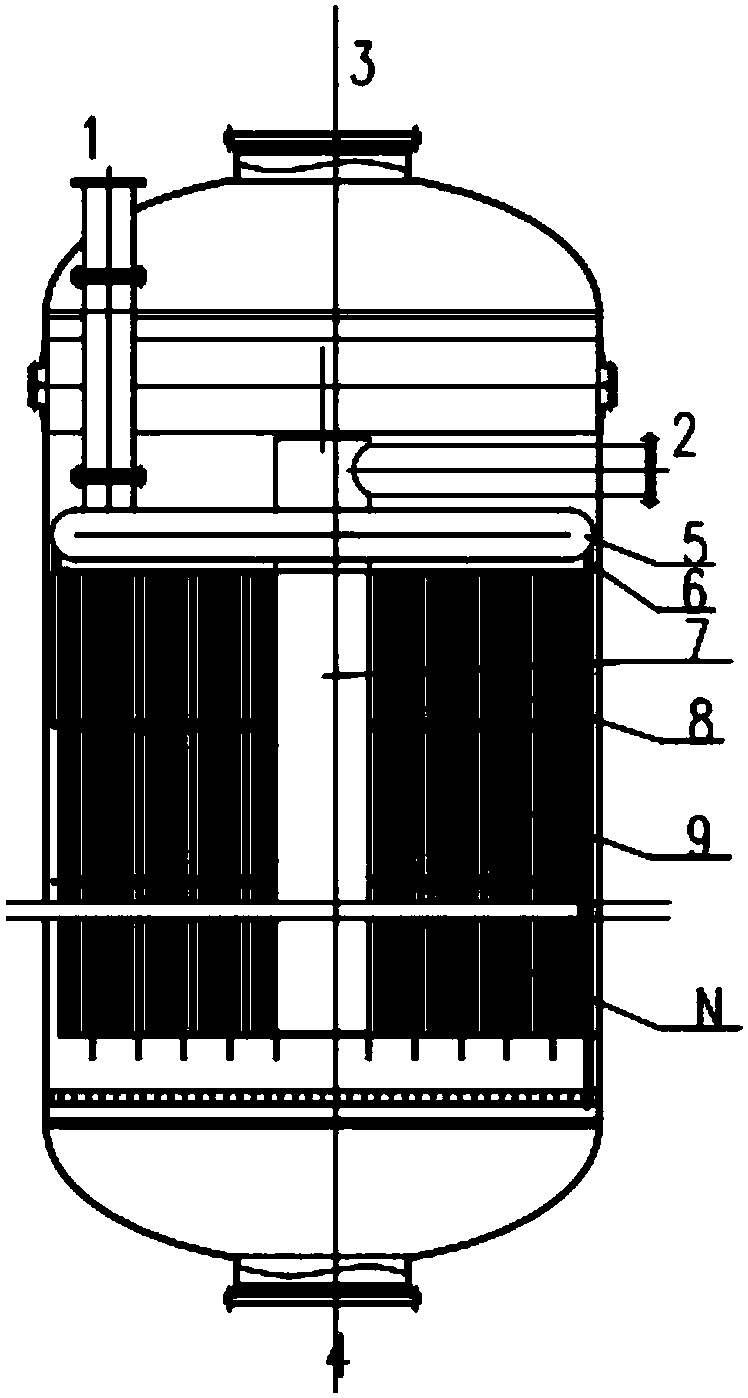

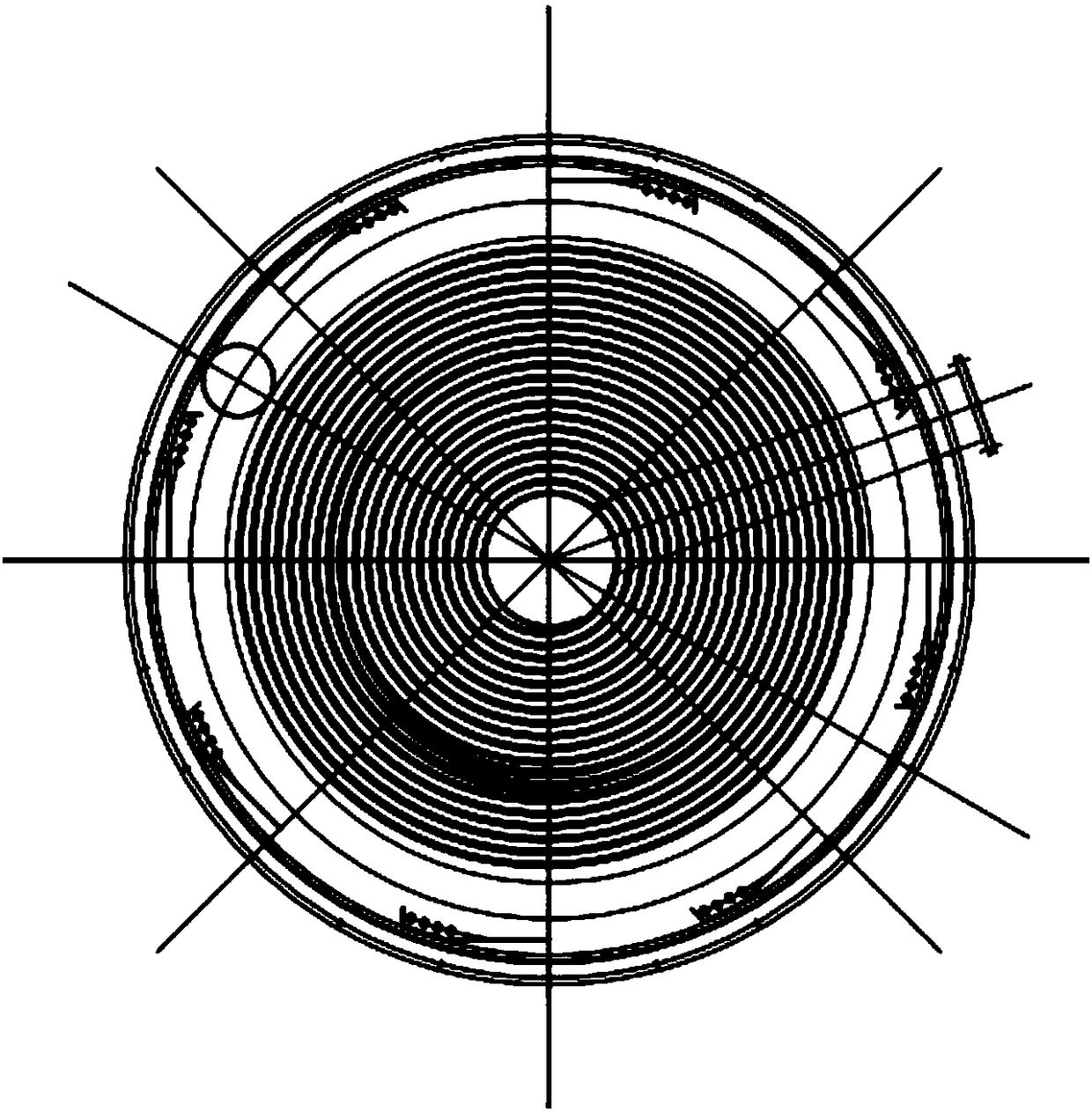

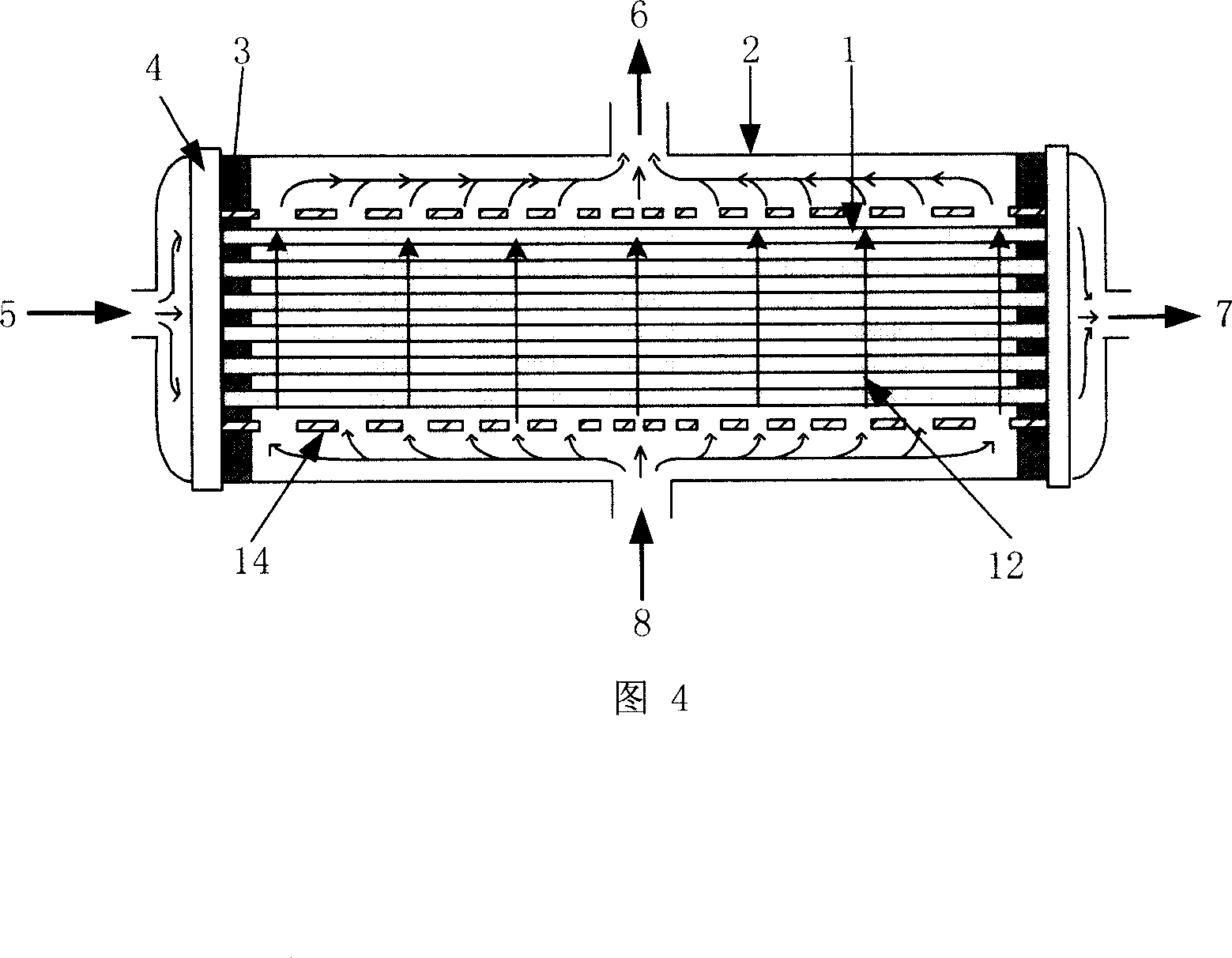

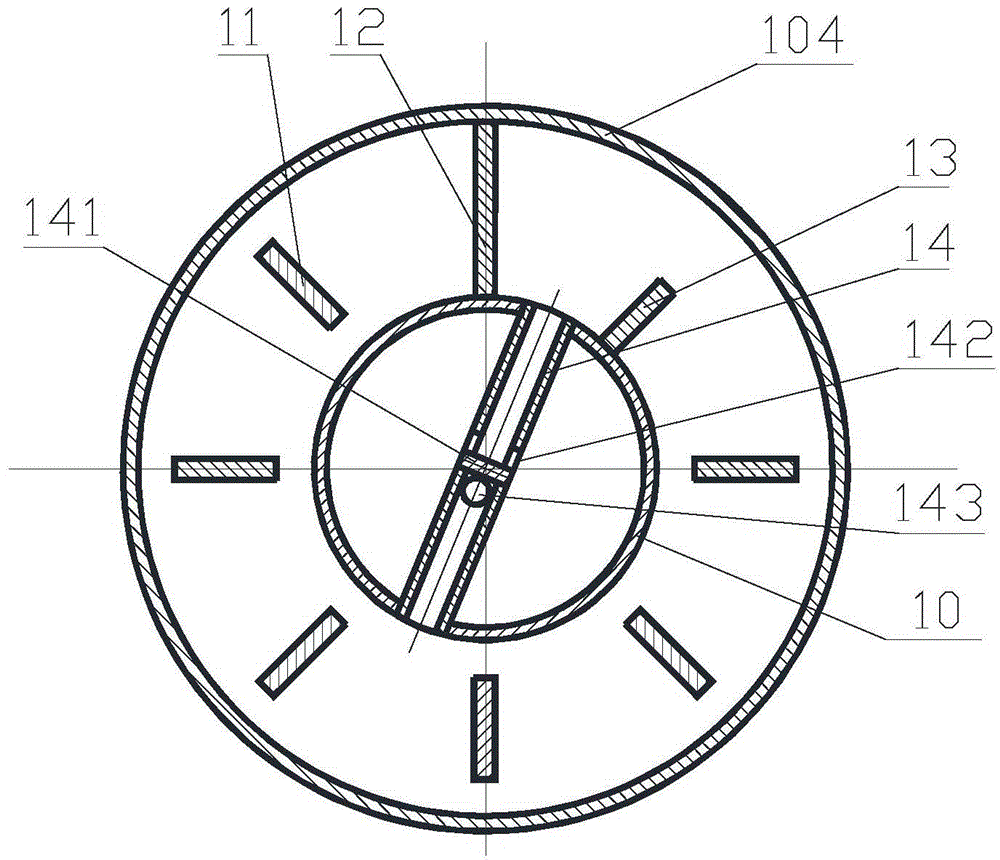

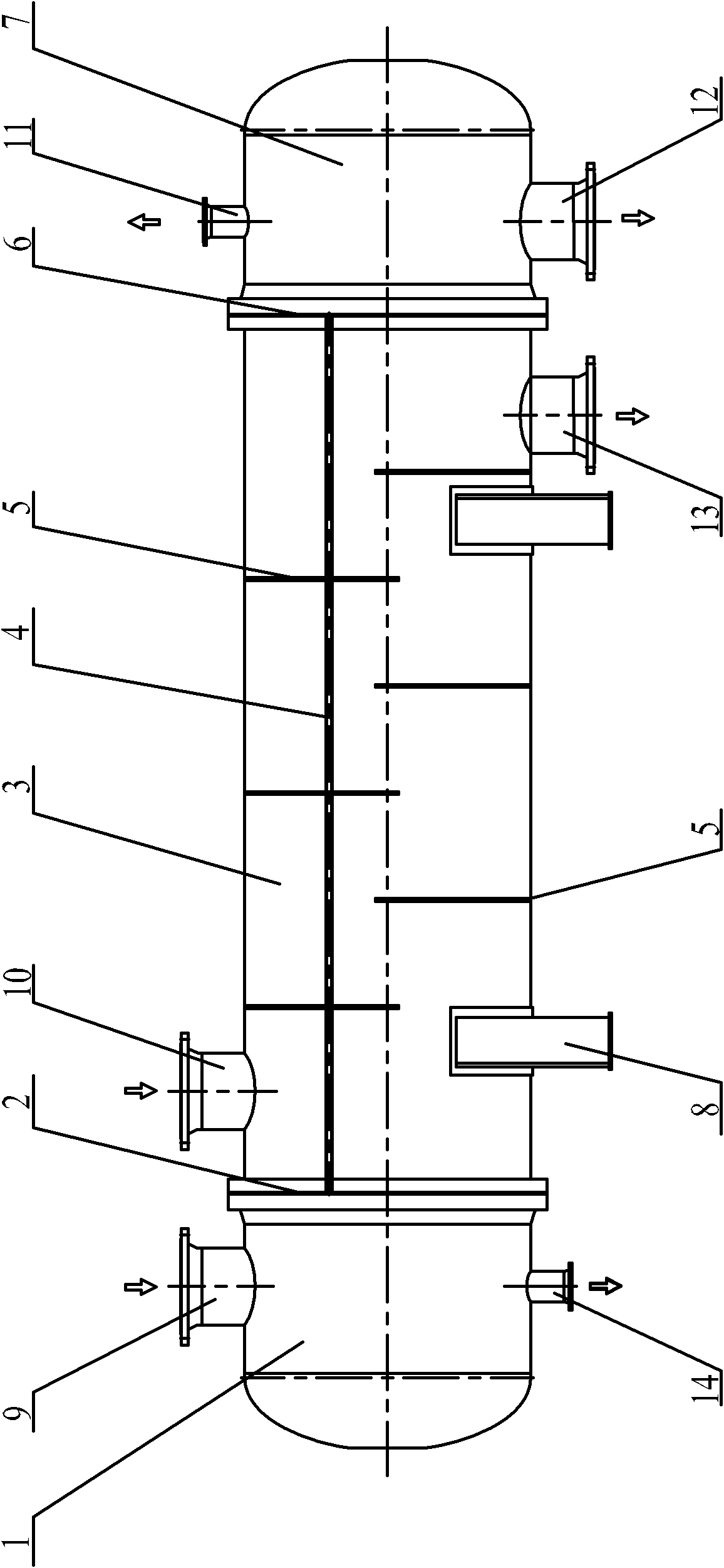

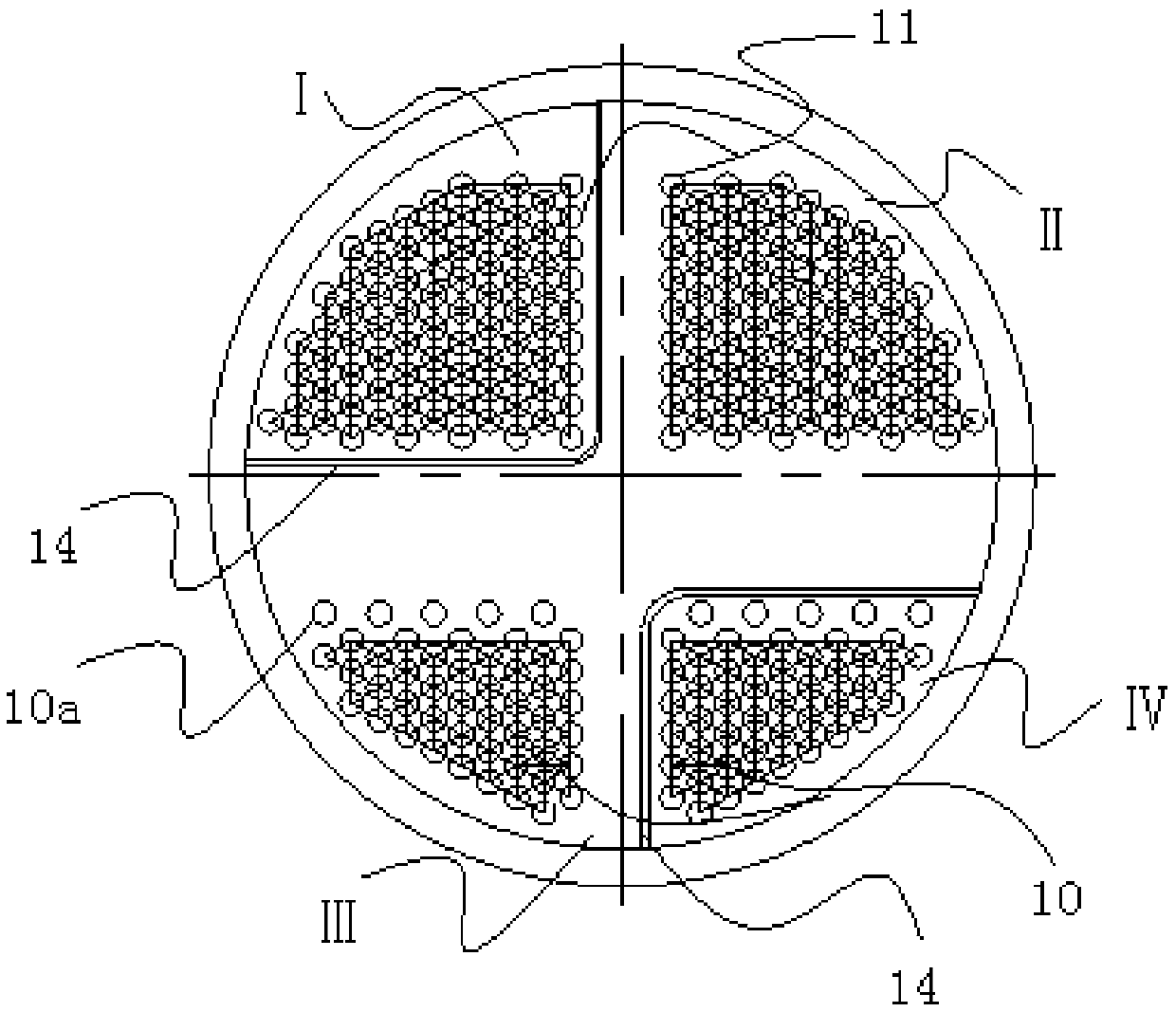

Soaking type screw plate fixed-bed reactor for gas-solid catalytic reaction

ActiveCN108114672ATemperature uniformity and controlFlexible control distanceChemical/physical processesGas solidGas phase

The invention relates to a soaking type screw plate fixed-bed reactor for a gas-solid catalytic reaction. The soaking type screw plate fixed-bed reactor comprises a gaseous phase and an inlet / outlet of a heat exchange medium; one or more screw plate fixed-bed reaction sections are arranged in the reactor. The soaking type screw plate fixed-bed reactor disclosed by the invention has the advantagesthat firstly, a shell pass heat exchange coefficient is remarkably increased, a total heat transfer coefficient is enabled to be increased, a heat transfer effect is intensified and heat transfer temperature difference is reduced; secondly, heat transfer distance and heat transfer area can be flexibly controlled and uniformity and control of the temperature of a reaction bed layer are facilitated;thirdly, the volume utilization rate is high (the maximum can reach 70 percent or higher, and the maximum of a shell and tube reactor is about 40 percent), the capacity of single equipment is high, and the occupied area and the investment are obviously reduced; fourthly, a heat exchange medium channel has a self-cleaning effect, so that dirt and block are not easily generated.

Owner:QINGDAO UNIV OF SCI & TECH

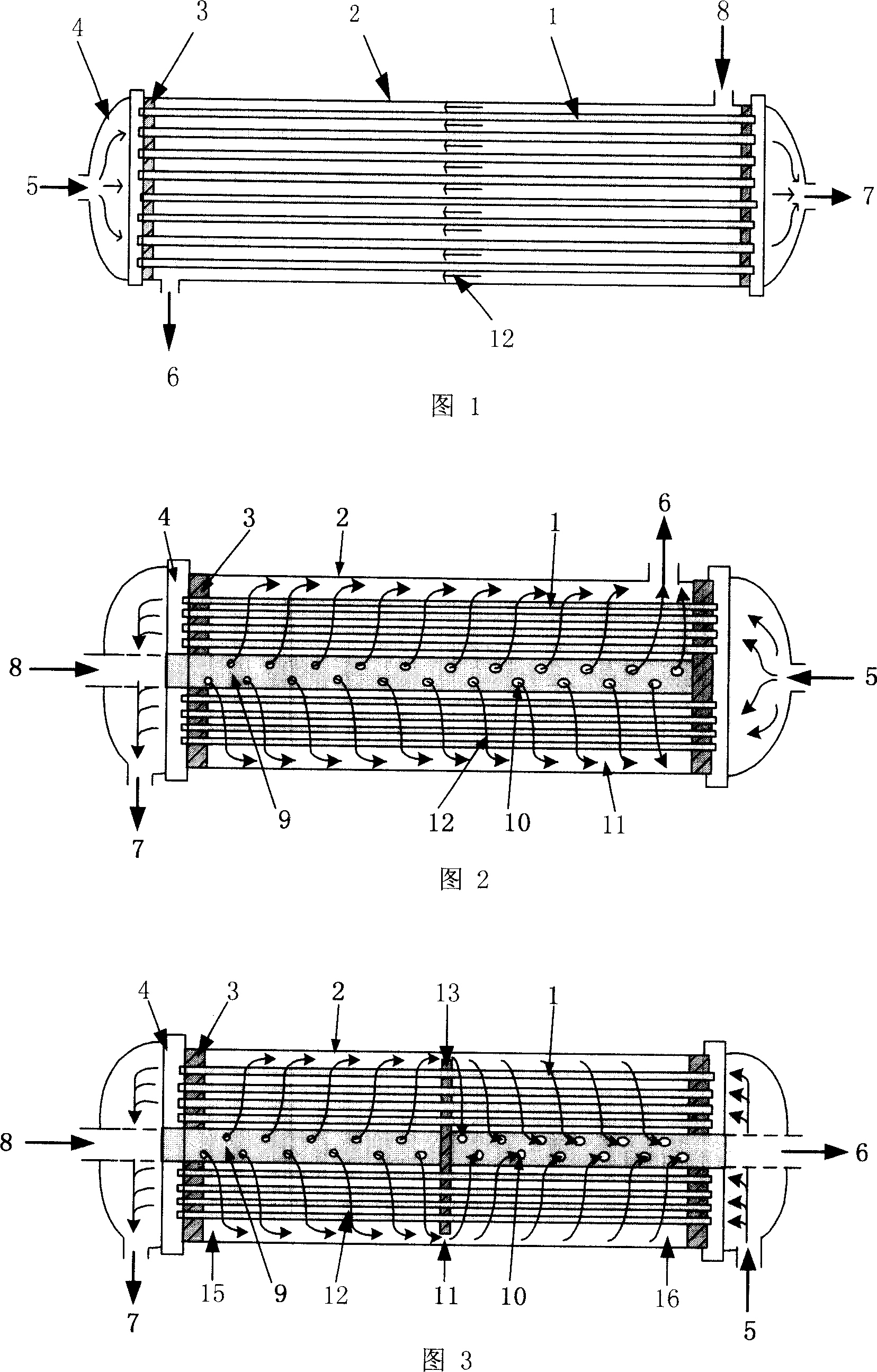

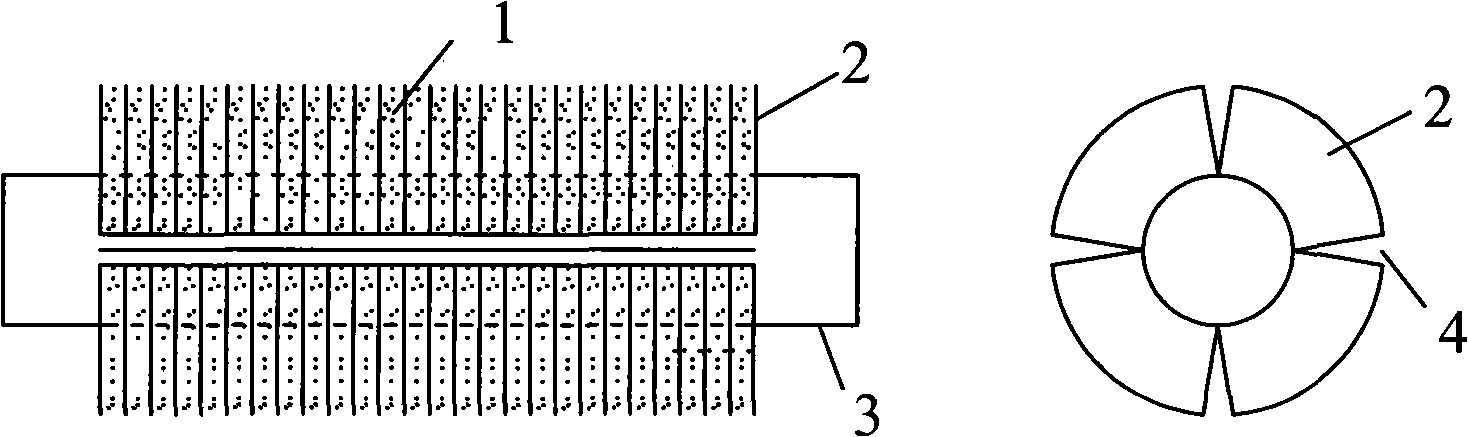

Hollow fibre heat-exchange device and method

ActiveCN101105380AImprove heat transfer efficiencyImprove overall heat transfer coefficientHeat exchange apparatusHollow fibreFiber

The invention relates to a hollow fiber heat exchanger, which comprises hollow fiber, a component enclosure, and a flow rate distribution system. Structurally, the hollow fiber heat exchanger has parallel counter current and cross current two basis modes. In the components of different modes of heat exchanger, the hollow fiber is parallelly and uniformly arranged in the enclosure of component, the two ends of the hollow fiber is fixed in the component enclosure by binder, and the two ends of the component enclosure are respectively connected with a tail cap with fluid inlet / outlet port. The inventive heat exchanger is suitable for heat exchange between gas, steam and liquid system, and has the advantages of high overall heat transfer coefficient, salinity tolerance, acid resistance, alkali resistance, low volume, light weight, easy production, low production cost, and broad application range.

Owner:TIANJIN MOKELI TECH

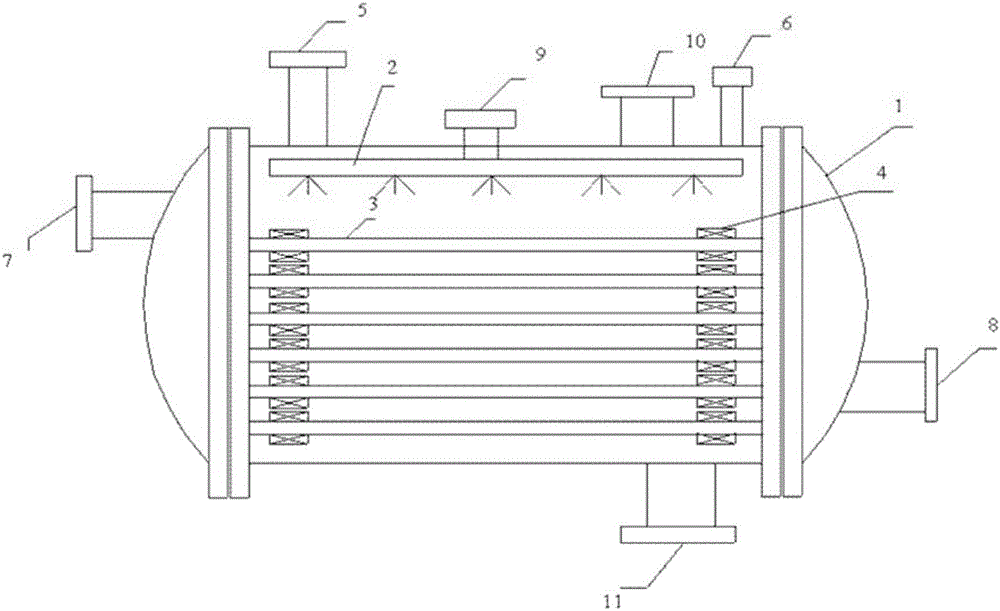

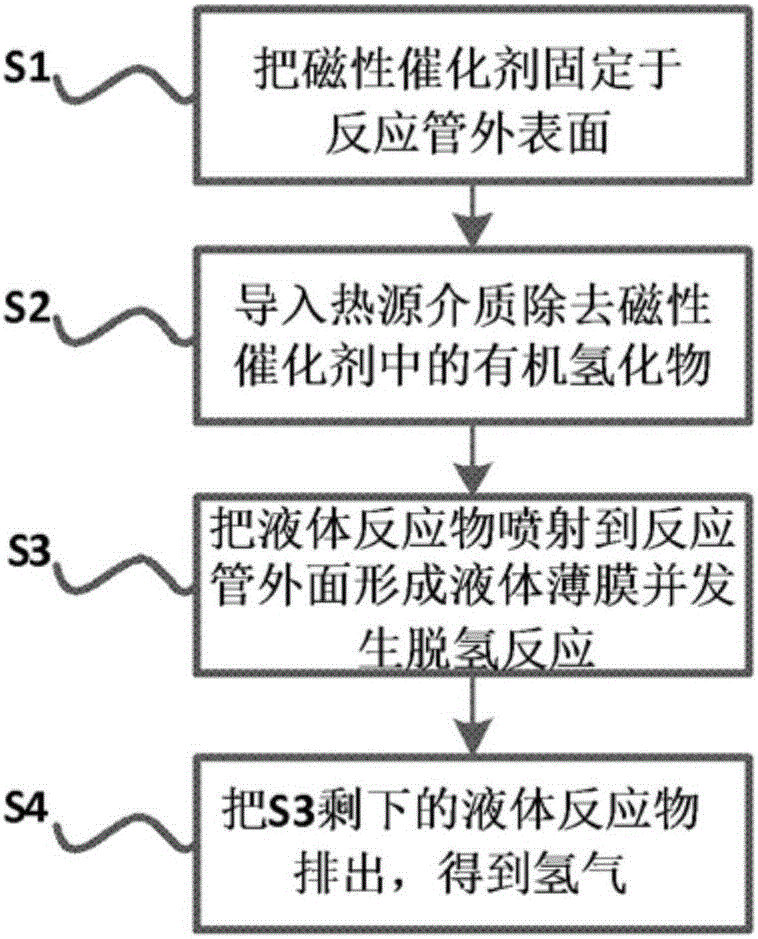

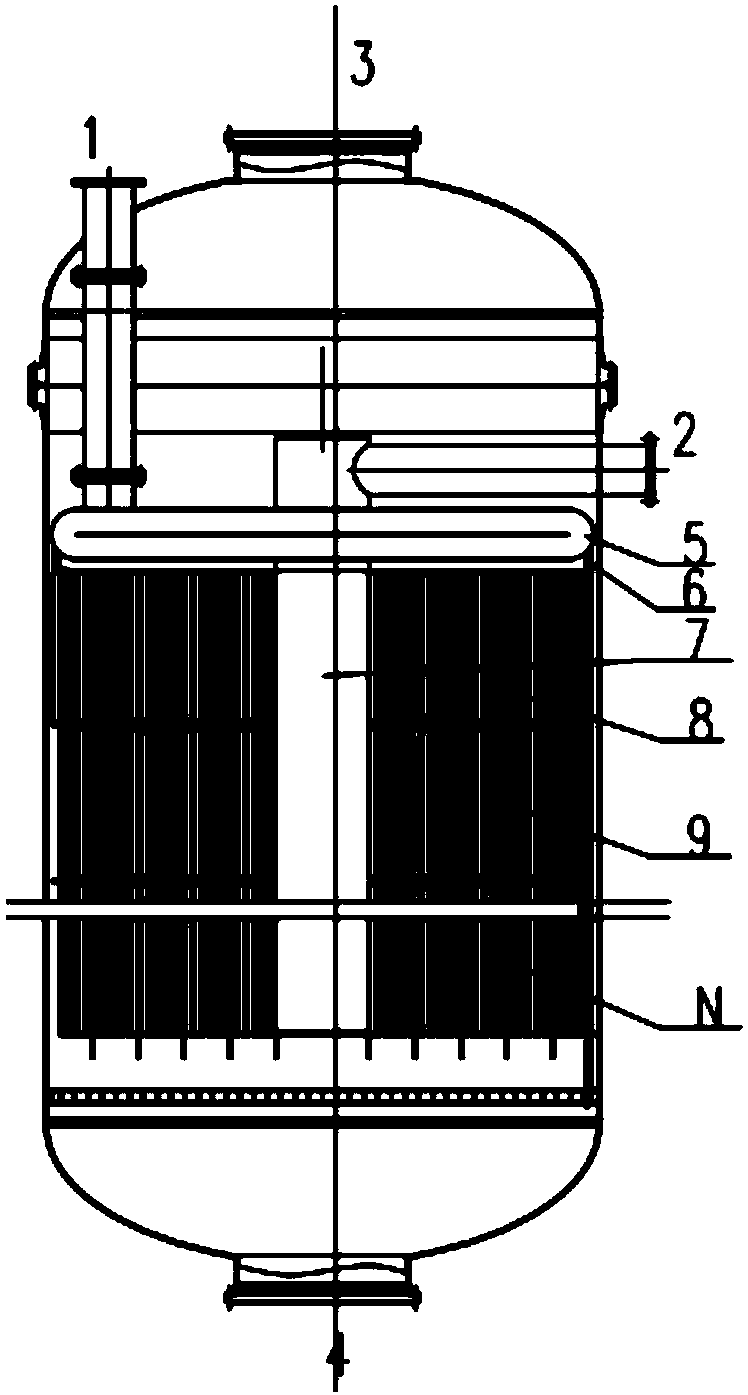

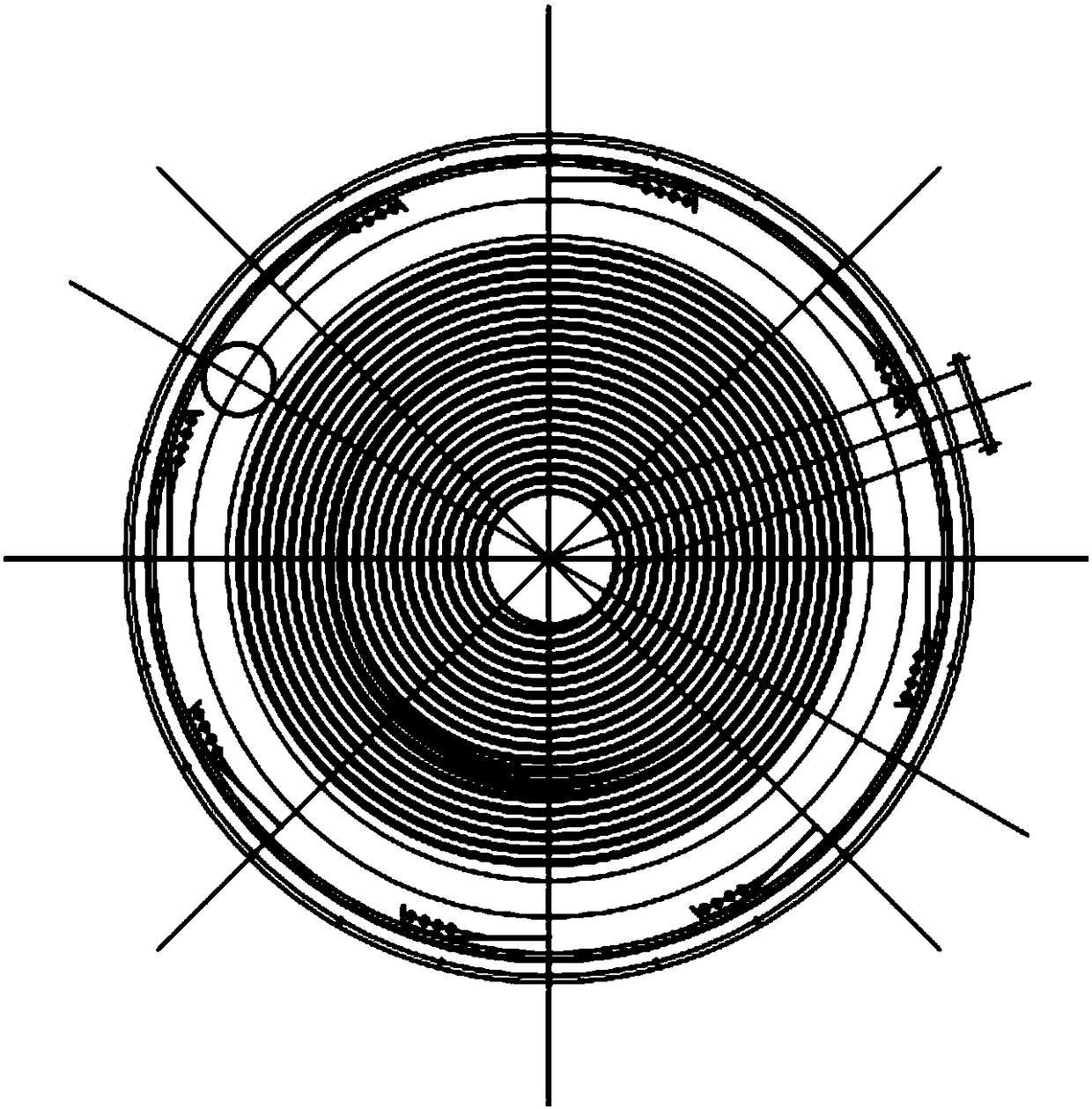

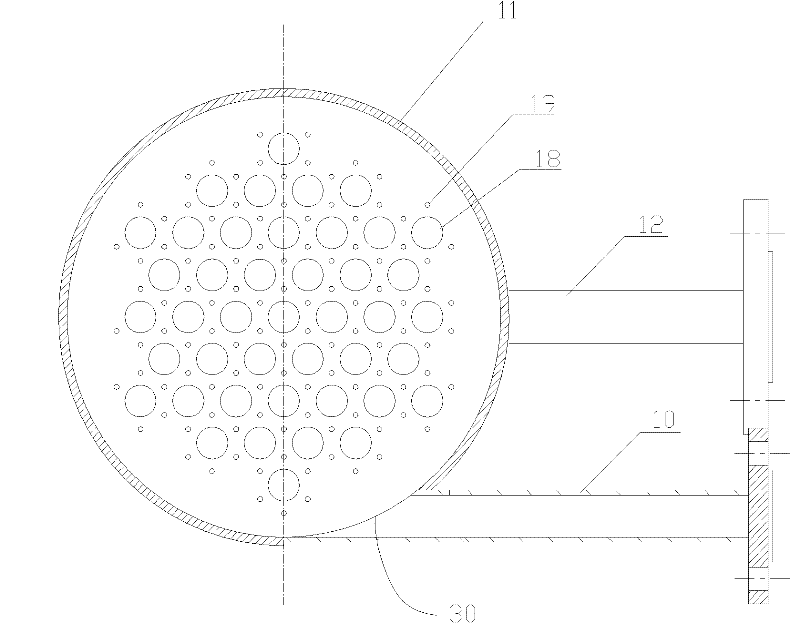

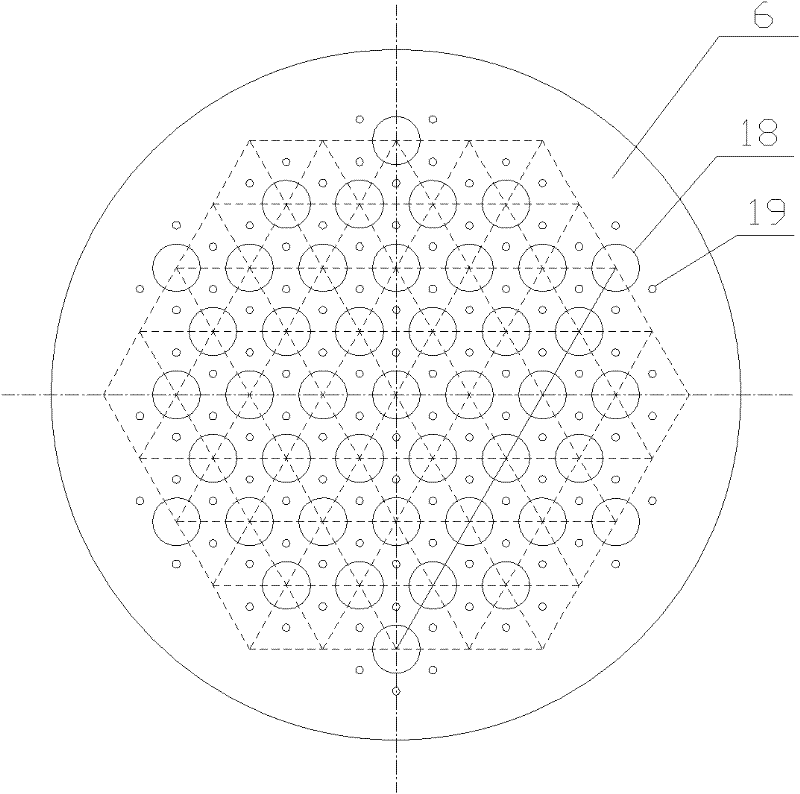

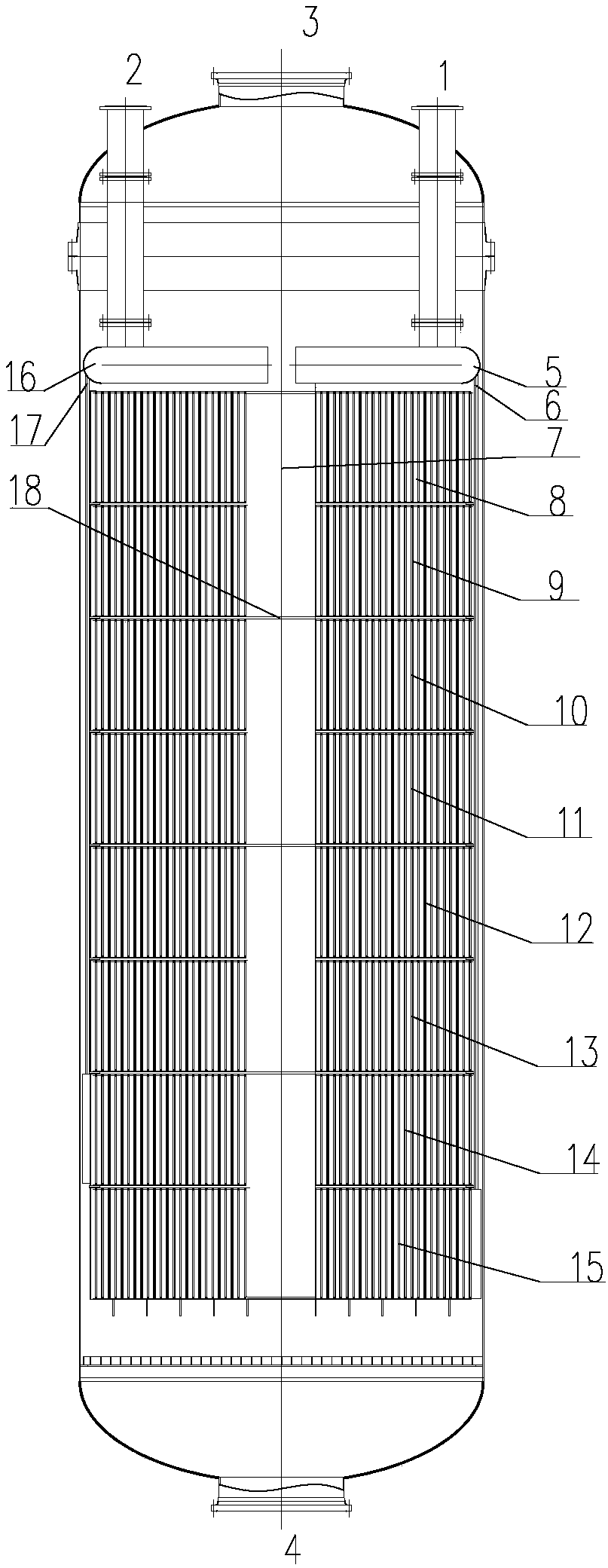

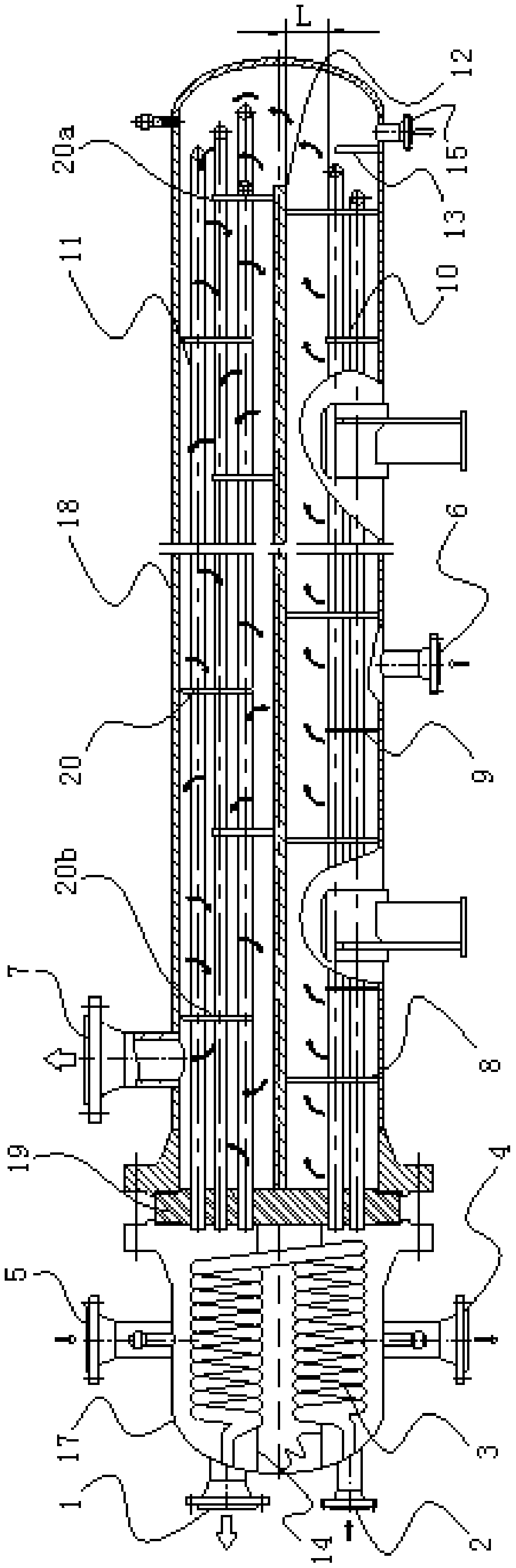

Device for dehydrogenating liquid organic hydride

ActiveCN106698339AImprove overall heat transfer coefficientImprove utilization efficiencyHydrogenHydrogen/synthetic gas productionReaction tubeContinuous production

The invention discloses a device for dehydrogenating liquid organic hydride. The device is composed of a shell, a liquid distributor, reaction tubes, electromagnetic coils, and a fluid inlet / outlet adapter tube; the reaction tubes are evenly arranged in the device, a thermal medium flowing in each tube provides heat for reaction; the electromagnetic coil is an electrified coil wound on two ends of each reaction tube according to a certain direction, each reaction tube can be magnetized after the electronic coil is electrified; a catalyst is adsorbed to the outer side of the tube, and an organic hydride thin liquid film is formed to generate the dehydrogenation reaction. Compared with the prior art, the device disclosed by the invention has the following advantages that the filling and replacing of the catalyst are extremely simple and convenient by performing power on / power off operation on the electromagnetic coils, and the continuous production requirement can be satisfied.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

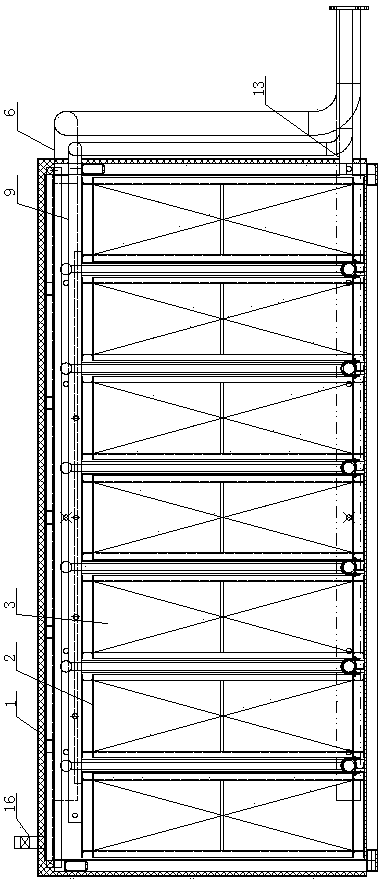

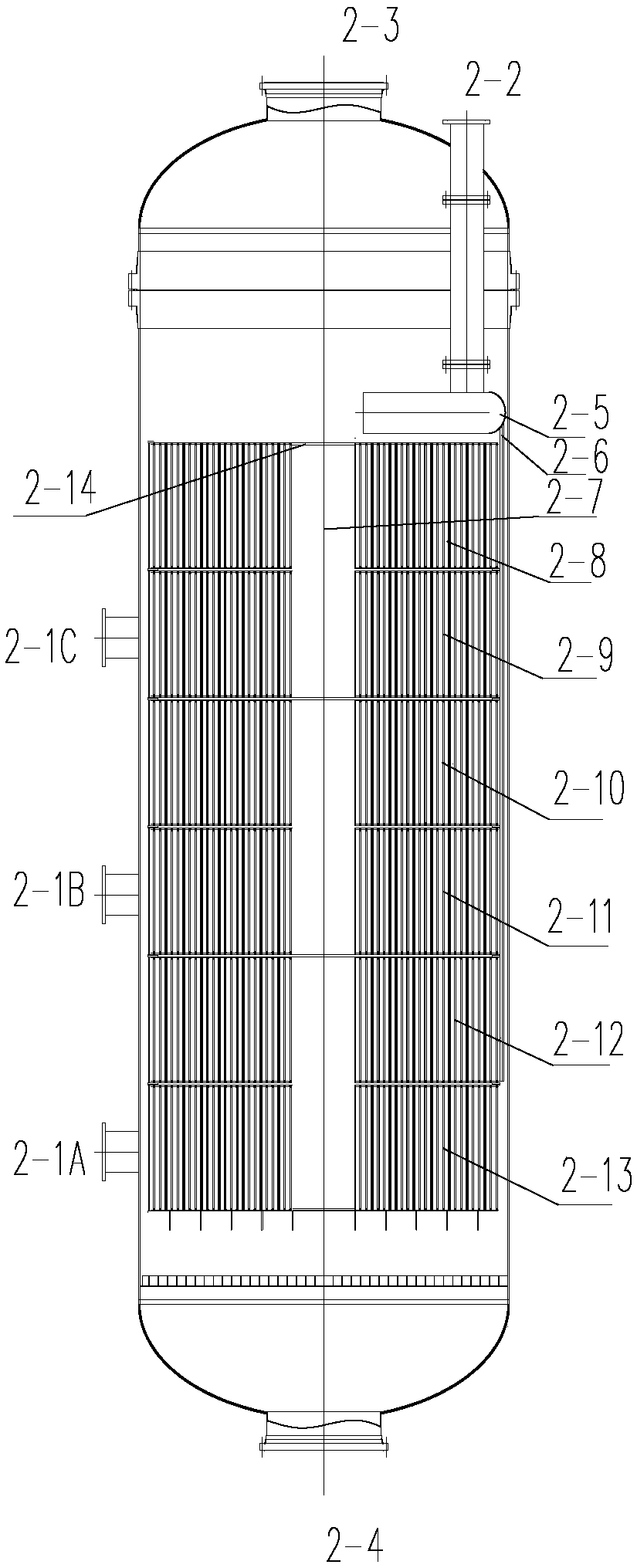

Uniform heating type spiral plate fixed bed reactor for gas-solid catalytic reaction

InactiveCN108421503ATemperature uniformity and controlFlexible control distanceOrganic compound preparationCarboxylic acid esters preparationGas solidGas phase

The invention relates to a uniform heating type spiral plate fixed bed reactor for a gas-solid catalytic reaction. The uniform heating type spiral plate fixed bed reactor for a gas-solid catalytic reaction comprises a gas phase inlet, a gas phase outlet, a heat exchange medium inlet and a heat exchange medium outlet; one or more spiral plate fixed bed reaction sections are arranged in the reactor.The uniform heating type spiral plate fixed bed reactor for the gas-solid catalytic reaction has the advantages that: (1) a shell pass heat exchange coefficient is remarkably increased, so that the total heat transfer coefficient is increased, a heat transfer effect is enhanced, and the heat transfer temperature difference is reduced; (2) the heat transfer distance and the heat transfer area canbe controlled flexibly, which is beneficial to the uniformity and the control of the temperature of a reaction bed layer; (3) the capacity utilization rate is highest (the highest capacity utilizationrate can reach 70 percent or above, and the highest capacity utilization rate of a shell and tube reactor is about 40 percent), the capacity of a single set of equipment is high, and the occupied area and the investment are remarkably reduced; (4) a heat exchange medium channel has a self-cleaning effect, and dirt and blockage are not produced easily.

Owner:QINGDAO KEDA LONGTENG TECH DEV +2

Tubular heat exchanger in glass lining kettle

InactiveCN102102953AImprove axial circulationImprove overall heat transfer coefficientStationary conduit assembliesCoatingsPlate heat exchangerWater vapor

The invention relates to a tubular heat exchanger in a glass lining kettle, which is welded by a plurality of tube bundles and liquid collecting bags at both ends, wherein water vapor inlets or cooling water outlets are formed at upper and lower ends of the liquid collecting bags; glass is enameled on the welded surface; the lower part or the upper part of a glass lining sleeve is sealed by using an upper filler box or a lower filler box; a heat exchanger body is pressed on the lower filler box by a teflon pad; and the upper part of the heat exchanger body is in bolted connection with the glass lining sleeve.

Owner:淄博三田机械密封有限公司

Paint slag drying and thermal oxidizing system

ActiveCN107671107ASolve sticking problemsImprove drying and oxidation efficiencySolid waste disposalTransportation and packagingSlagLacquer

The invention discloses a paint slag drying and thermal oxidizing system. The paint slag drying and thermal oxidizing system comprises a paint slag pool, a paint slag pump, a paint slag filter press,a filter press crushing mechanism, a drying and oxidizing mechanism, an exhaust gas dedusting mechanism and a paint slag finished product recycling mechanism, wherein a discharging outlet of the paintslag pool is connected with a feeding inlet of the paint slag filter press through the paint slag pump, and a slag outlet of the paint slag pool is connected with the paint slag crushing mechanism; aslag outlet of the paint slag crushing mechanism is connected with the drying and oxidizing mechanism, the drying and oxidizing mechanism comprises a drying and oxidizing barrel, a barrel body of thedrying and oxidizing mechanism barrel is provided with a thermal bypass connector used for being externally connected with a heat source, and a stirrer is arranged in the barrel body; the drying andoxidizing barrel is used for drying and oxidizing paint slag in the barrel, exhaust gas obtained after drying and oxidizing are conducted is conveyed to the exhaust gas dedusting mechanism, and the paint slag is conveyed to the paint slag finished product recycling mechanism; and the exhaust gas dedusting mechanism is used for filtering the exhaust gas, obtained residual paint slag is conveyed tothe paint slag finished product recycling mechanism, and the filtered exhaust gas is exhausted through a gas outlet. According to the paint slag drying and thermal oxidizing system, drying and thermaloxidizing treatment can be conducted on the paint slag, the decomposing treatment efficiency can be improved, generation of toxic substances can be reduced, and the carbon emission can be reduced.

Owner:苏州克兰茨环境科技有限公司

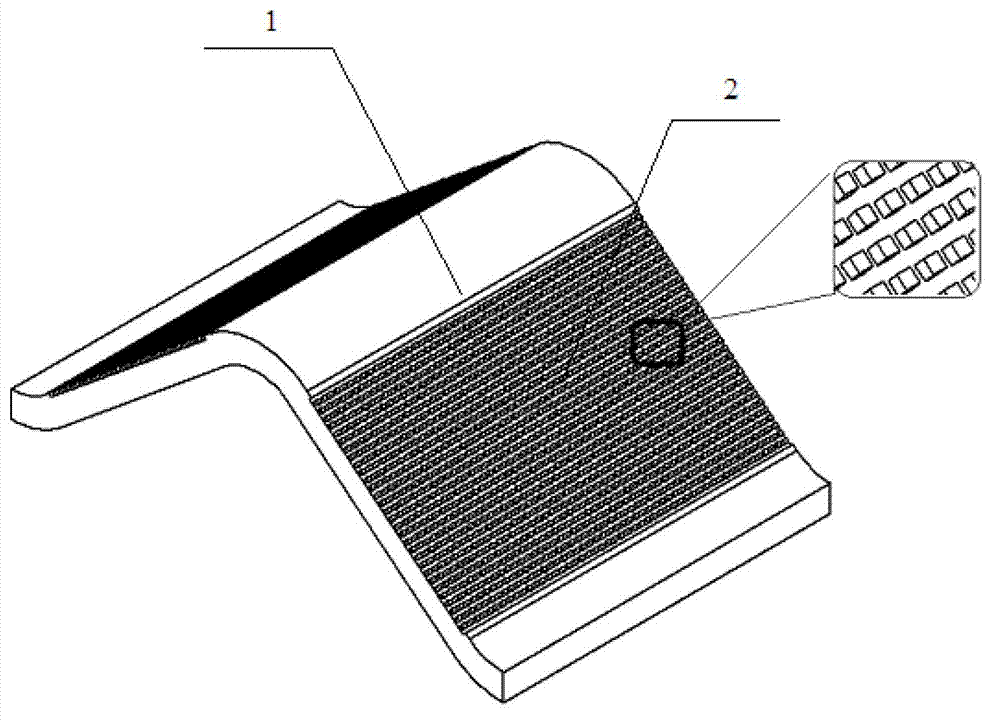

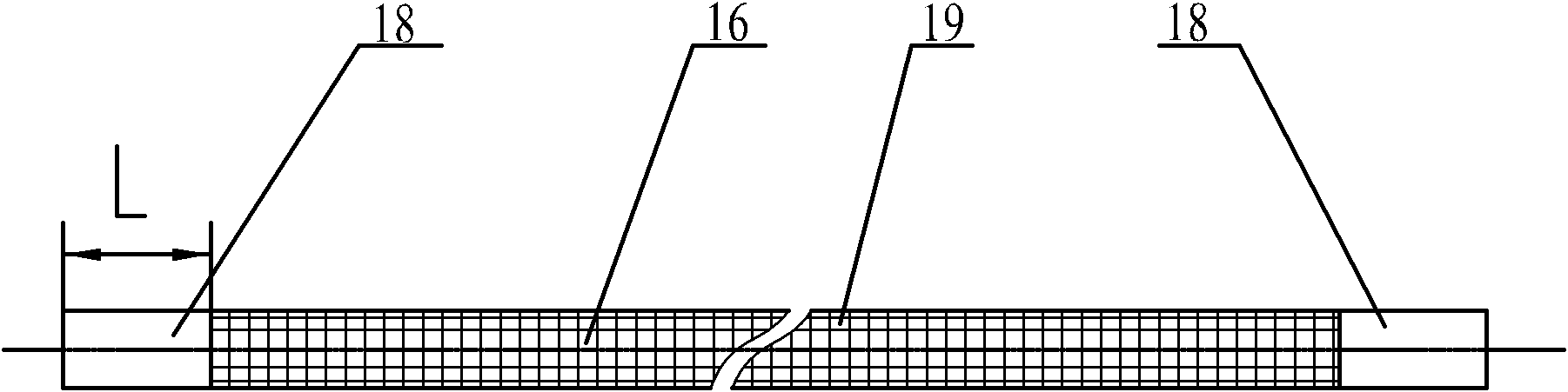

Method for preparing zeolite molecular sieve single finned tube for sintering shell type adsorbent bed

InactiveCN101274266AIncrease filling volumeImprove effective thermal conductivityOther chemical processesAbsorbers/adsorbersMolecular sieveSorbent

The invention relates to a fin adsorption single tube which disposably and integrally sinters zeolite molecular sieves with low temperature on a fin pipe and leads the zeolite molecular sieves to be solidified and formed, and realizes the combination of sintering of composite adsorbent and solidification of the composite adsorbent and the fin pipe wall. The fin adsorption single tube of the invention replaces light pipe sintering with the fin pipe, improves the filling quantity of the adsorbent on the unit length pipe wall and increases the heat exchanging area; the adsorbent adopted by the invention has high thermal conducting coefficient, has small resistance of the contact with the metal wall surface and fast mass transfer speed, thus improving the heat transmission and mass transfer performance of an adsorption bed, increasing the adsorption circulation quantity, and shortening the circulation time.

Owner:EAST CHINA UNIV OF SCI & TECH

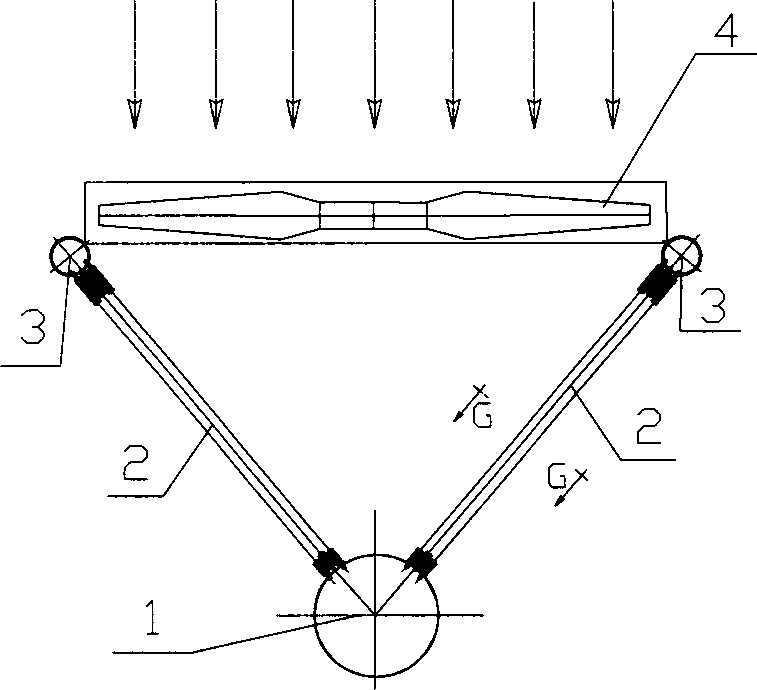

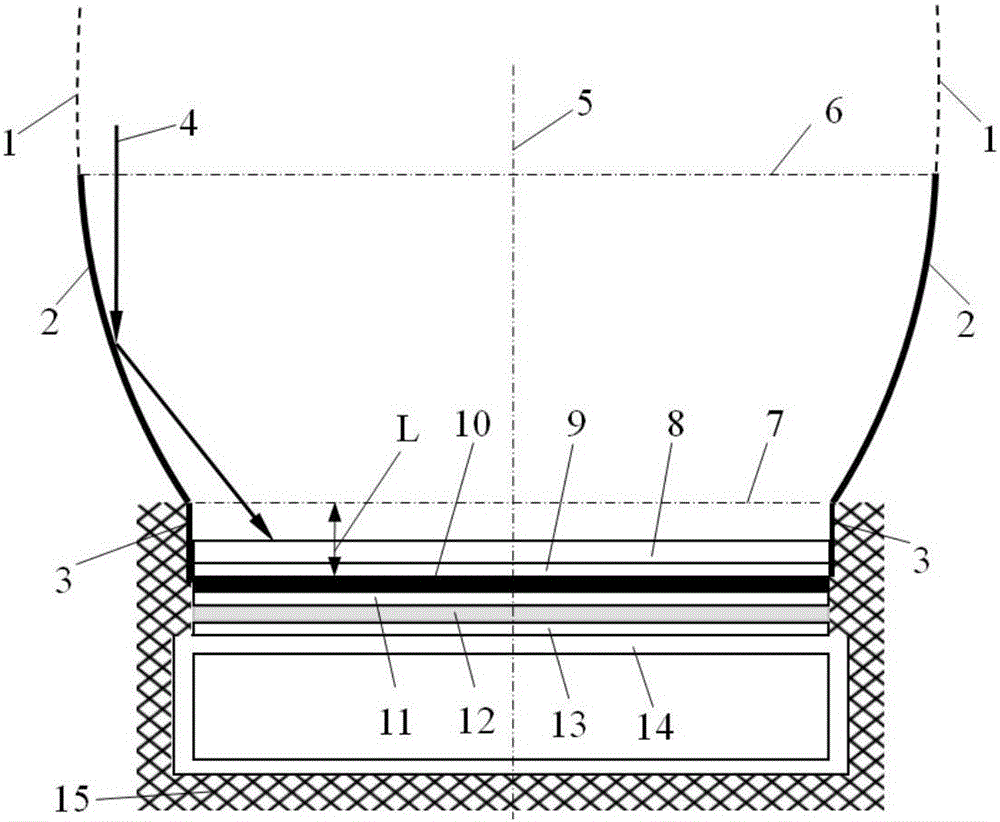

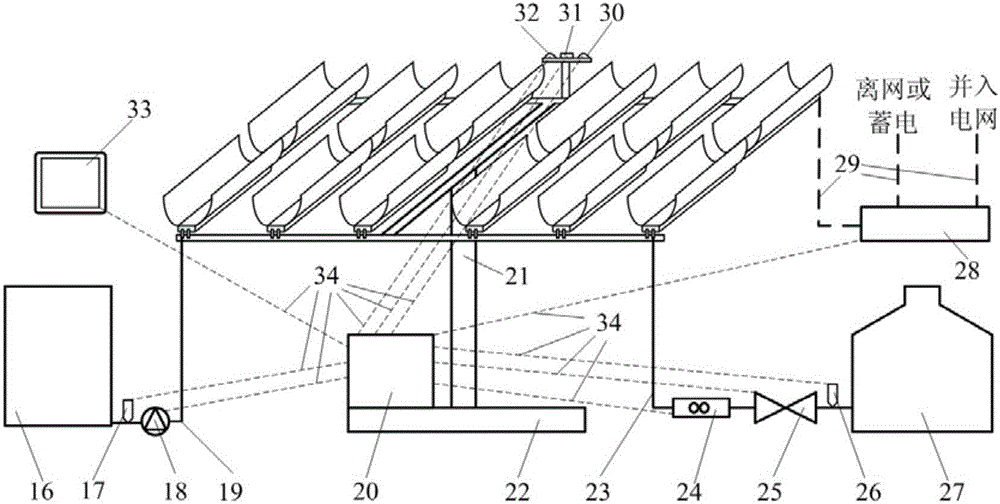

Cogeneration device for light condensation of single-reflection compound parabolic condenser and application method

ActiveCN105024629AImprove light gathering efficiencySolve the problem of reduced light-gathering efficiencyPV power plantsPhotovoltaic energy generationThermal energyGlass cover

The invention relates to a cogeneration device for light condensation of a single-reflection compound parabolic condenser and an application method. The cogeneration device comprises a concentrating photovoltaic photothermal unit array, a tracking unit, an electricity recovery unit, a heat recovery unit and a control and monitor unit, direct sunlight parallel to the axis of the single-reflection compound parabolic condenser is reflected in one time by the single-reflection compound parabolic condenser, then sequentially passes through an ultra-white glass cover plate and an upper layer ethylene vinyl acetate (EVA) from top to bottom, and is converged to a crystalline silicon photovoltaic cell, the crystalline silicon photovoltaic cell generates electric energy and heat energy, the electric energy passes through a cable, is modulated by a photovoltaic inverter and then is incorporated into a power grid or used or stored in an off-grid way, and the heat energy is absorbed by a fluid passing through a cooling square pipe and then is introduced out for storage or application. The single-reflection compound parabolic condenser adopted by the invention is shorter than the traditional compound parabolic condenser and the traditional short and abrupt compound parabolic condenser, cost is low, high-quality electric energy can be generated, meanwhile, the heat energy can be provided, and high performance cost ratio is achieved.

Owner:XI AN JIAOTONG UNIV

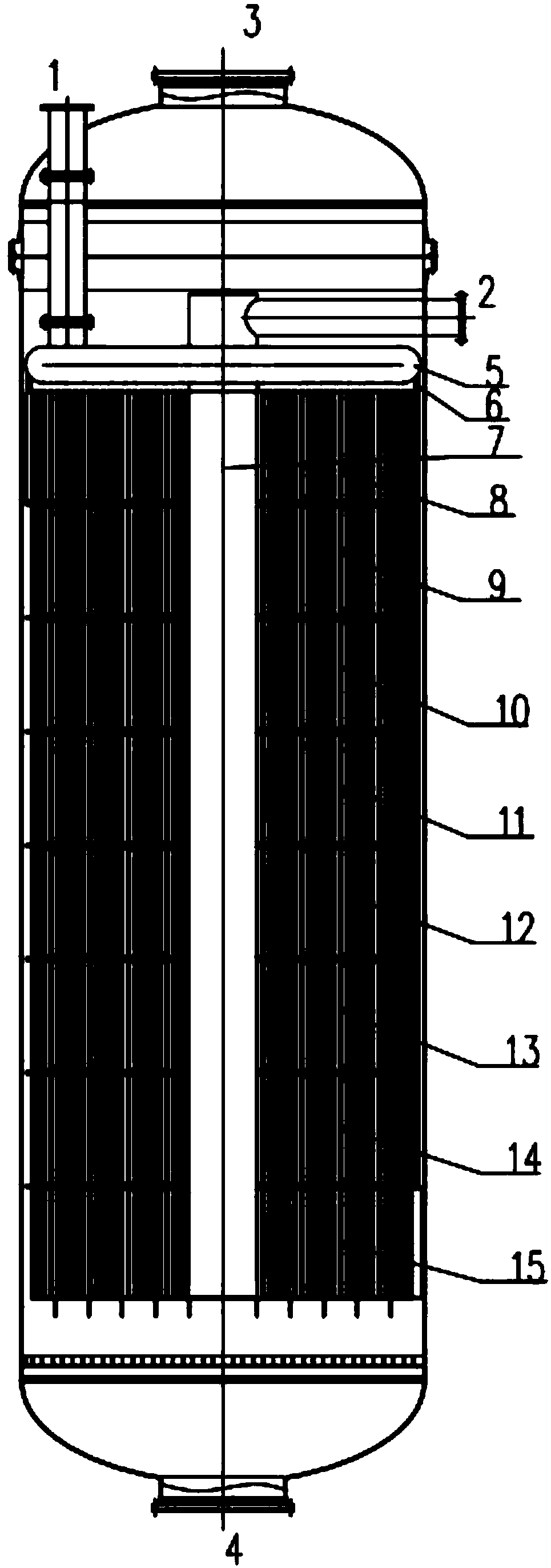

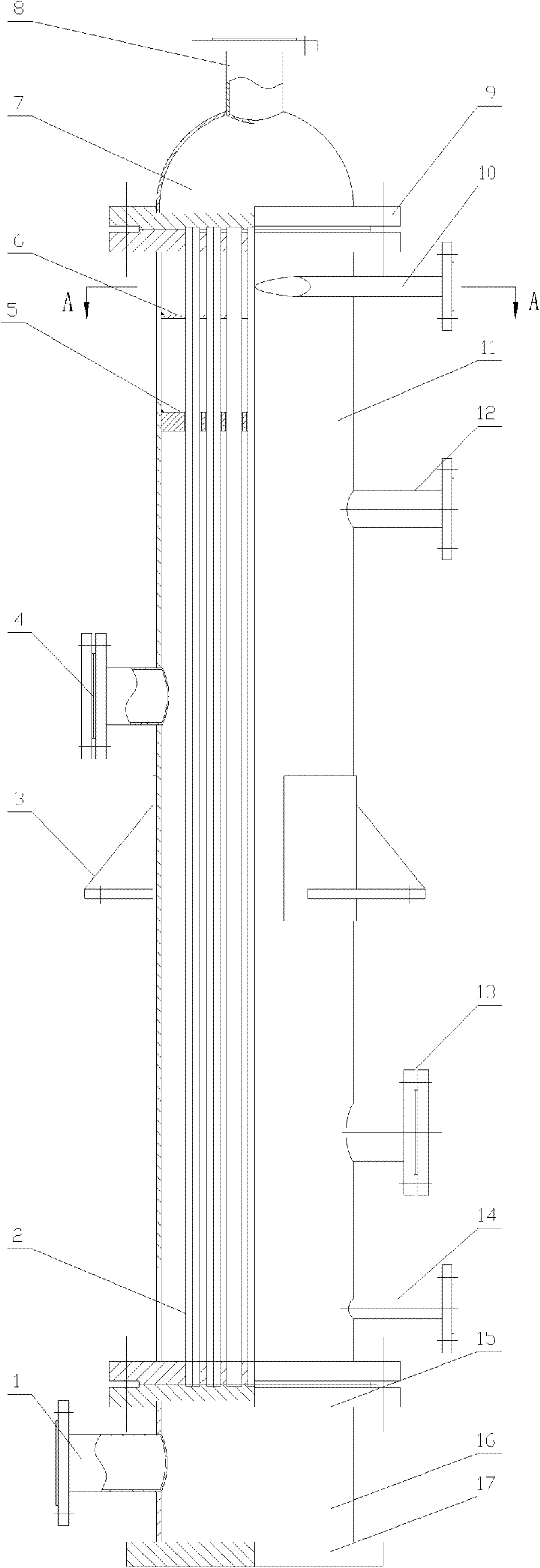

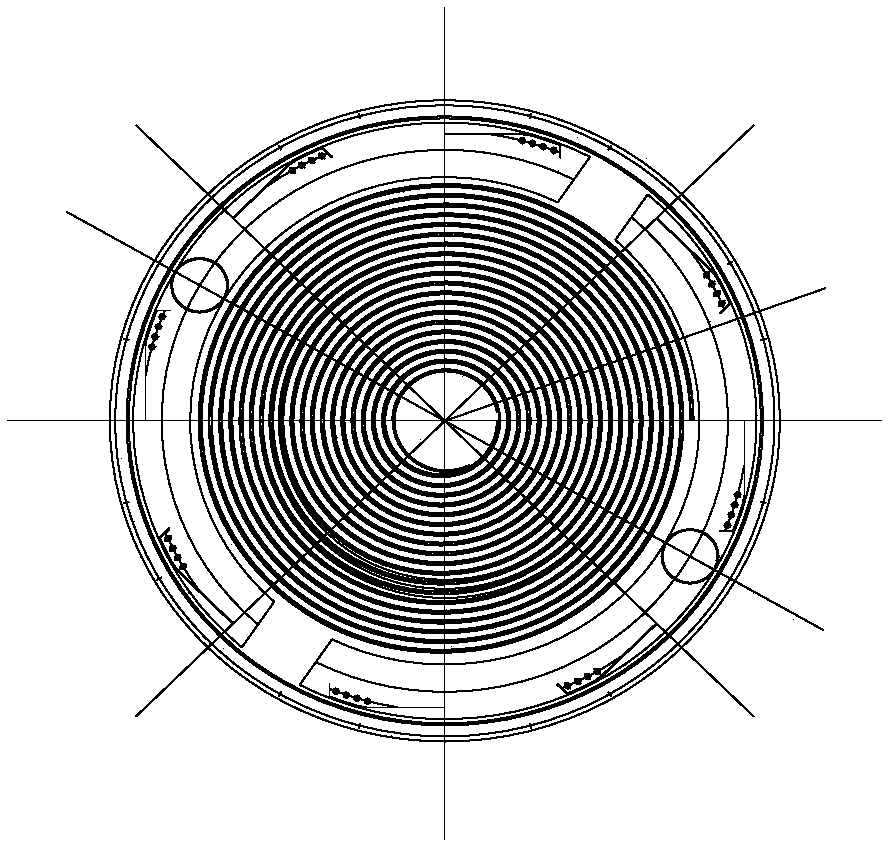

Vertical falling-film heat exchanger outside pipe

ActiveCN102155854BUniform film formationIncrease the heat exchange areaStationary conduit assembliesTrickle coolersChemical industryWater desalination

The invention discloses a vertical falling-film heat exchanger outside a pipe, which comprises a heat exchanger shell, a reinforced heatexchange tube bundle, a film distributing device, a tube pass accommodating chamber, sight glasses, a fluid inlet and outlet pipeline and the like. The double-layer film distributing device is arranged at the top of a heat exchanger; and a fluid flows down uniformly along the outer wall of a pipe in a film shape through the film distributing device to take away heat of another fluid in a heat exchange tube or transfer the heat to another fluid in the heat exchange tube so as to realize heat exchange of two different fluids. Because a tangential-flow liquid introducing manner and the unique double-layer film distributing device are adopted for the heat exchanger, the problems of nonuniform film distribution, low effective heat exchange area and the like of the traditional falling-film heat exchanger are solved. By adopting the device, the mass transferresistance of the fluid can be effectively reduced, the heat transfer and mass transfer capacities of the heat exchanger are remarkably improved, and the device can be widely applied to the industries, such as chemical industry, thermotechnical industry, light industry, food, pharmacy, metallurgy, sea water desalination and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

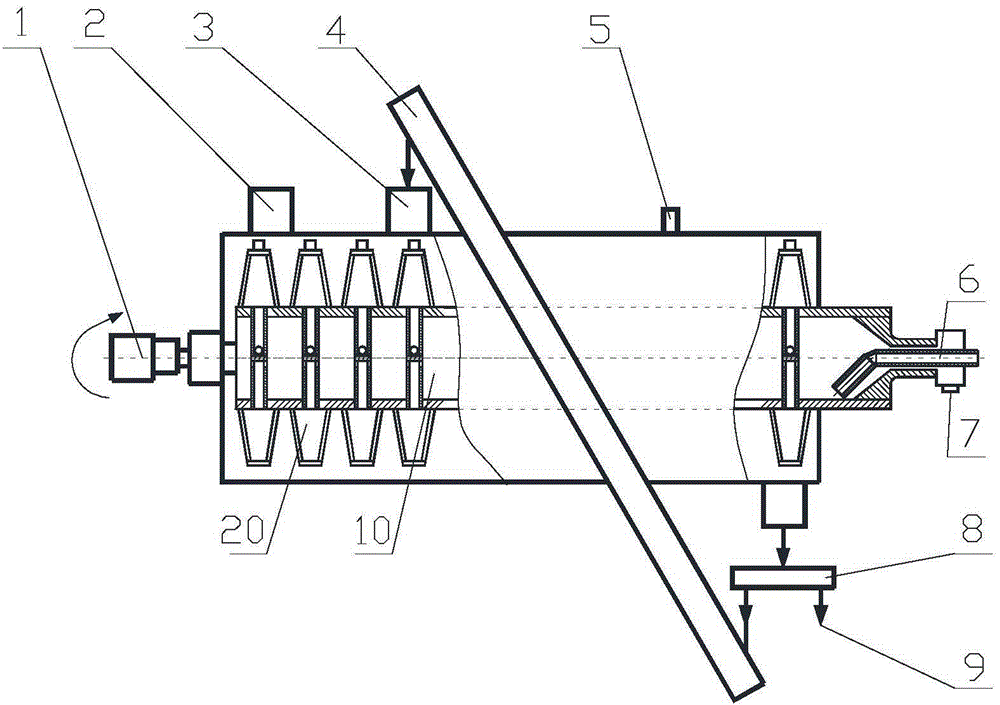

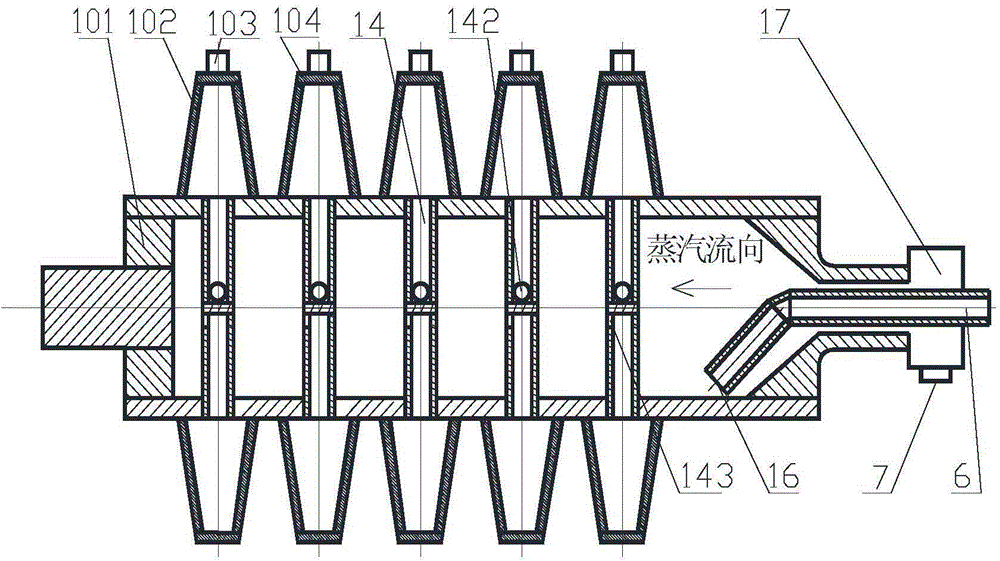

Steam rotating heat conduction sludge drying device

ActiveCN104803576AImprove thermal efficiencyReal-time adjustment of mud return volumeSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesDraining tubeSludge

A steam heating type sludge drying device comprises a rotating heat conduction drier, a dried sludge distributor, a dried sludge lifter and the like, wherein dried sludge returns to a variable sludge return opening; the dried sludge distributor is utilized for precisely controlling the sludge moisture at the back of the sludge return opening to be lower than the moisture in a viscous area; a plurality of blades are connected onto a hollow shaft; a blade closure plate, a blade water collecting plate and blade reinforcing ribs are arranged in each blade; specially designed blade steam inlet water discharge pipes penetrate through the hollow shaft between the blade closure plates and the blade water collecting plates, so that blade steam inlet pipes and water discharge openings are all close to the center of the hollow shaft, condensate water in the hollow shaft is prevented from backwards flowing into the blades, and water flowing from the blades is prevented from directly entering blade steam inlets. In the frame structure of the steam heating type sludge drying device, the hollow shaft is high in rigidity and strength; the backward flowing of the condensate water is avoided; the dried sludge return amount is small; the unit area dry sludge amount is large.

Owner:WUXI GUOLIAN ENVIRONMENTAL SCI & TECH

A spiral plate fixed bed reactor for gas-solid phase contact catalytic reaction

InactiveCN109382045AImprove heat transfer coefficientImprove overall heat transfer coefficientOrganic compound preparationCarboxylic acid esters preparationGas solidGas phase

Owner:QINGDAO KEDA LONGTENG TECH DEV +2

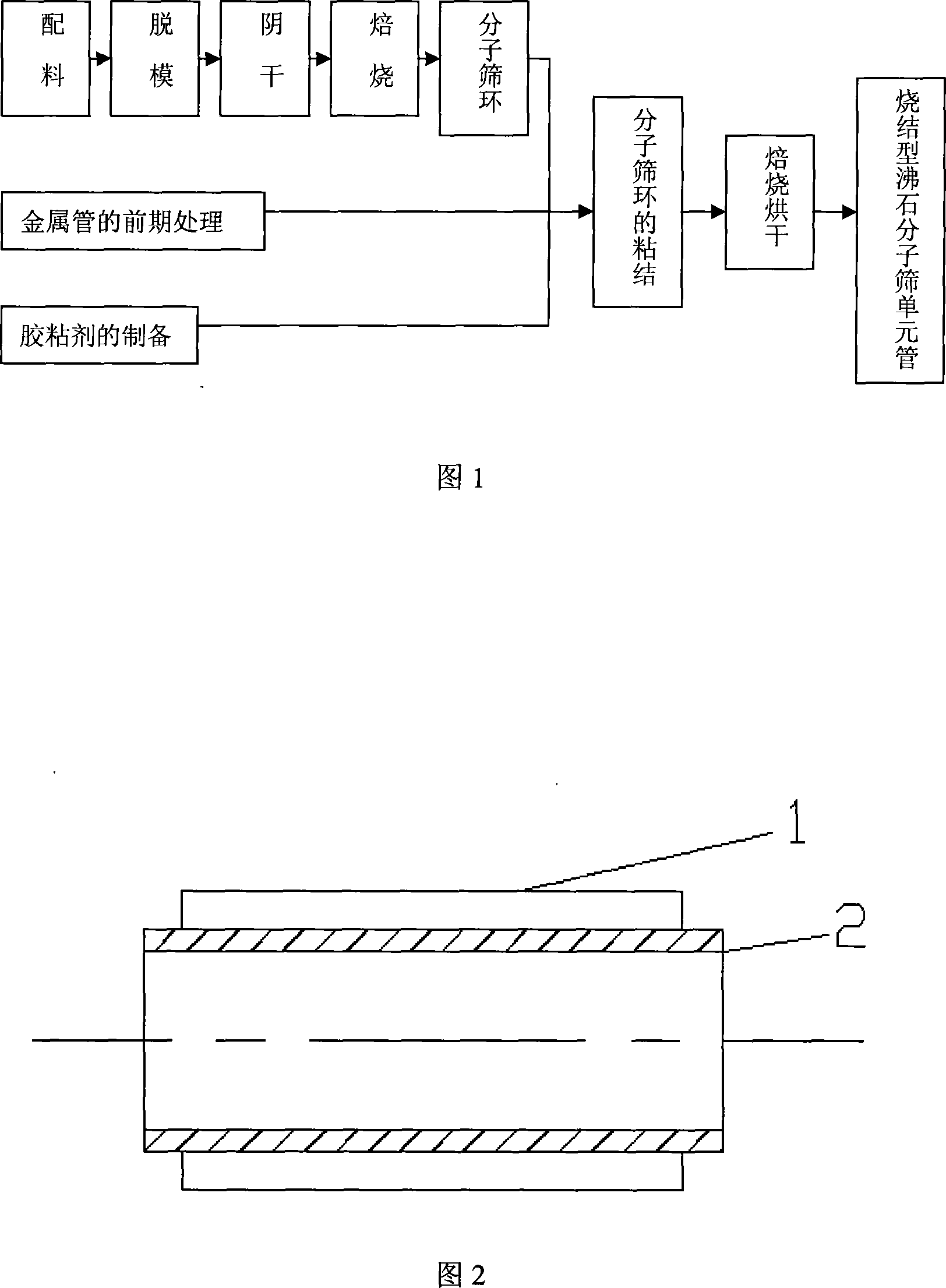

Sintering type zeolite molecular sieve adsorption refrigeration unit tube preparation process

InactiveCN101144664AImprove thermal conductivityImprove overall heat transfer coefficientEnergy efficient heating/coolingClimate change adaptationMolecular sieveAdsorption refrigeration

The invention designs a preparation process of a sintering type zeolite molecular sieve adsorption refrigeration unit tube, and aims at enhancing the heat conductivity coefficient of the molecular sieve, and reducing the contact thermal resistance between the molecular sieve and a metal wall surface, thereby strengthening the heat transfer of an adsorption bed. The preparation process comprises the molding of the sintering type zeolite molecular sieve and the solidification and combination of the metal wall surface. The first part includes that a zeolite molecular sieve ring is sintered through the steps of raw material disposition, mold unloading, drying in shade and roasting, etc., to accomplish the molding process of the zeolite molecular sieve; the second part includes that a sintering type zeolite molecular sieve unit tube is made through the steps of preparation of an adhesion agent, adhesive bonding of the molecular sieve ring, roasting and drying, to realize the sintering and solidification of the zeolite molecular sieve and the metal wall surface.

Owner:EAST CHINA UNIV OF SCI & TECH

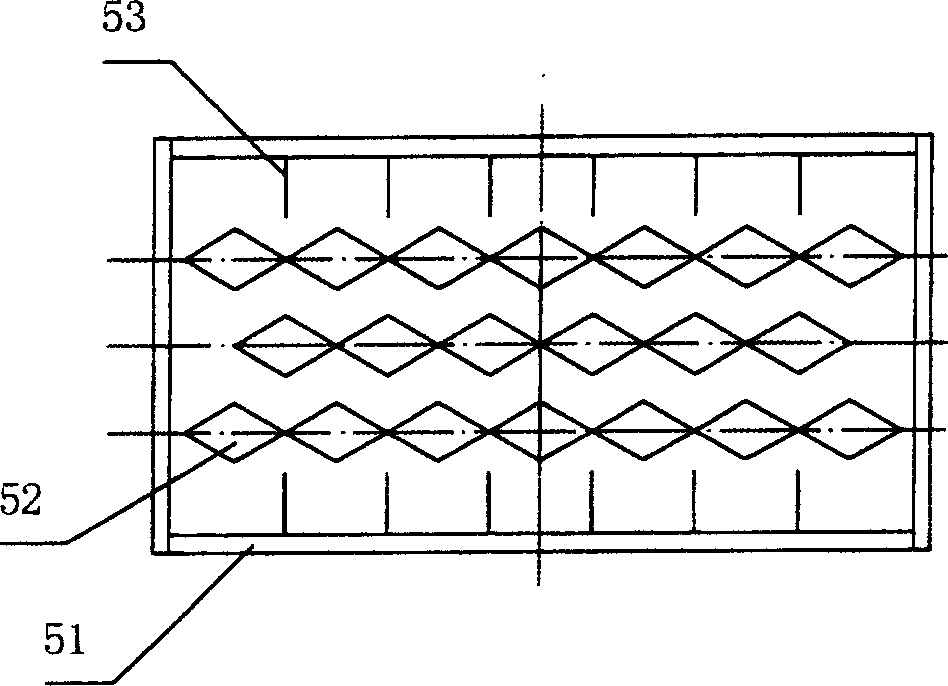

Heat exchange plate for plate-type evaporator

InactiveCN103175432AIncrease the number ofReduce superheatLaminated elementsRough surfaceHeat transmission

The invention belongs to the technical field of heat transmission, and relates to a heat exchange plate, in particular to a heat exchange plate for a plate-type evaporator. On the basis of a heat exchange plate substrate, the upper end face of the heat exchange plate substrate is provided with micro ribs and micro grooves, and alternatively, the surface of the heat exchange plate substrate is provided with rough structures. The heat exchange plate has the advantages that multiple rough surfaces can increase vaporization core number, reduce the degree of superheat of the wall surface, strengthen boiling heat transfer, and further improve the total heat transfer coefficient of the evaporator.

Owner:NO 711 RES INST CHINA SHIPPING HEAVY IND GRP

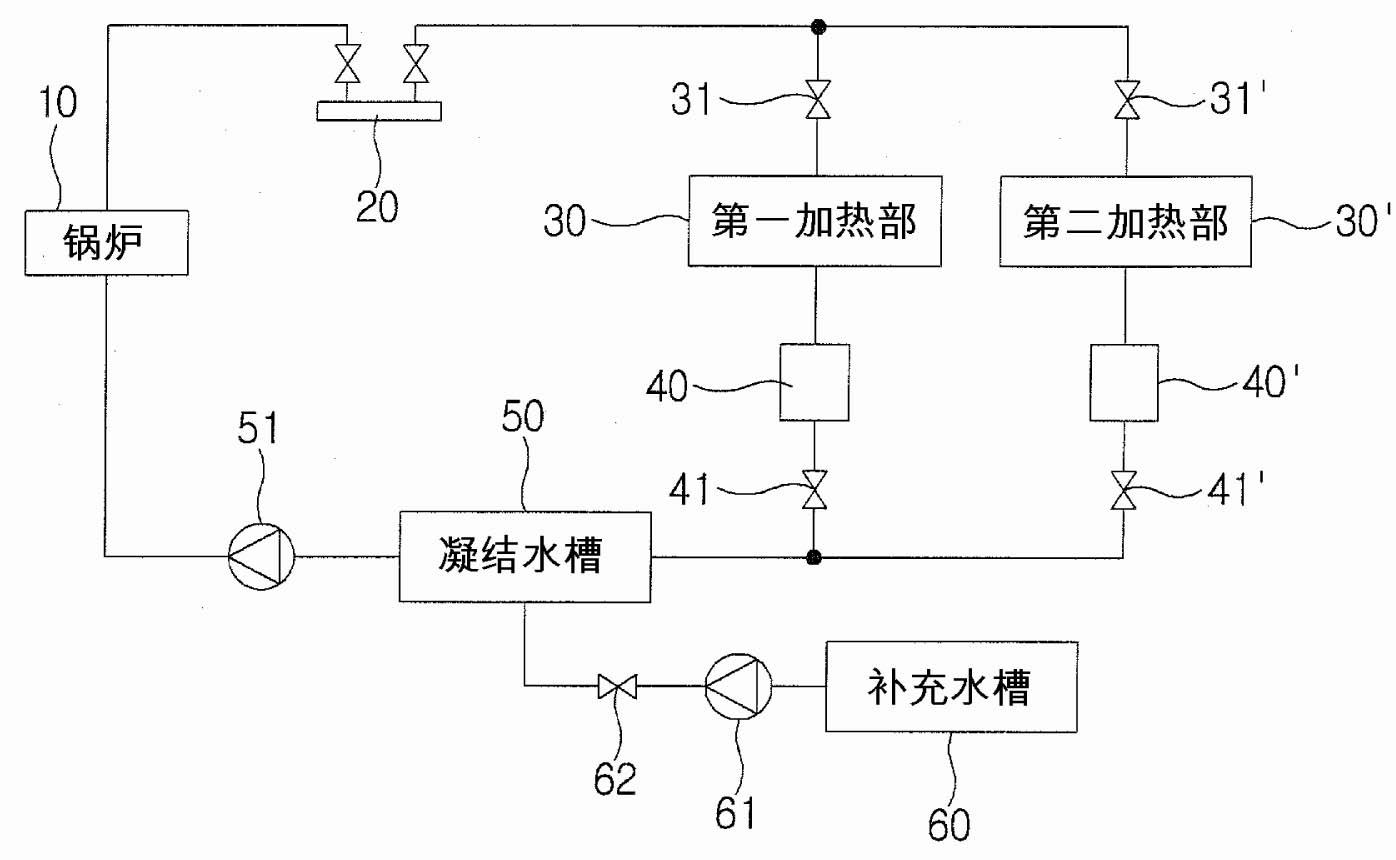

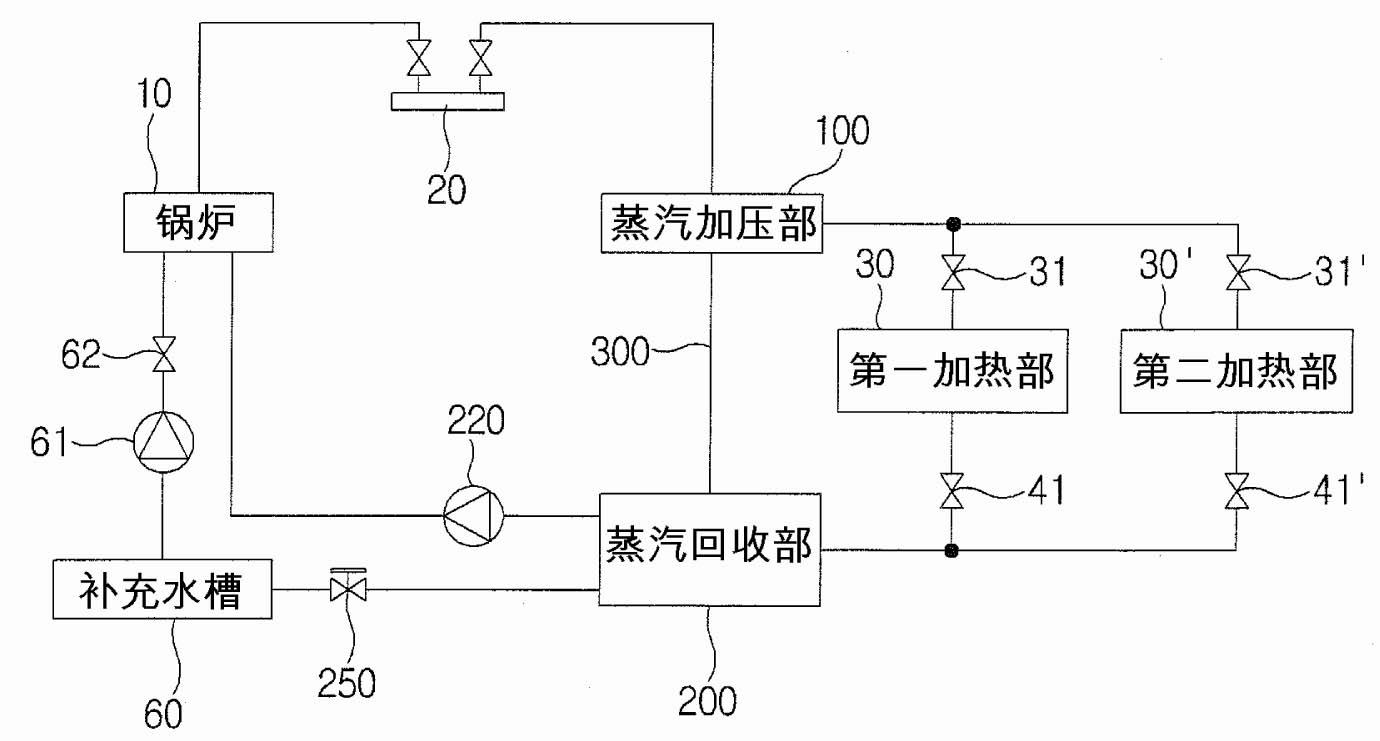

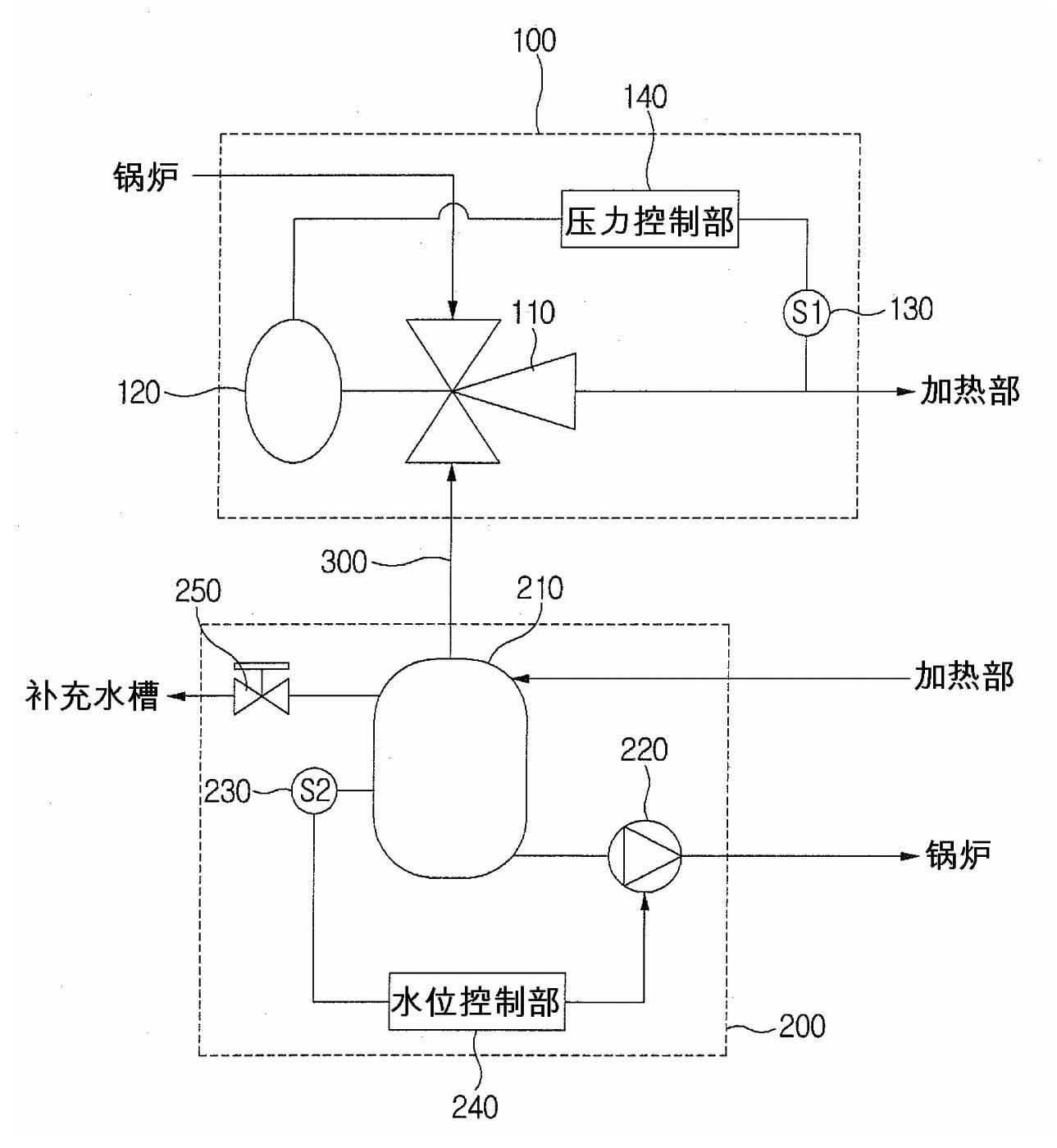

Apparatus for recovering vent steam and drain

ActiveCN102149985AImprove efficiencyReduce usageWater heatersSteam engine plantsAtmospheric airEngineering

Owner:YEONGIL PUMPTECH

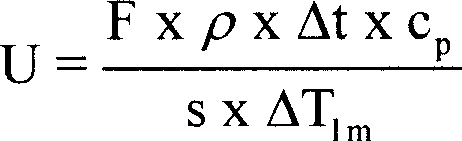

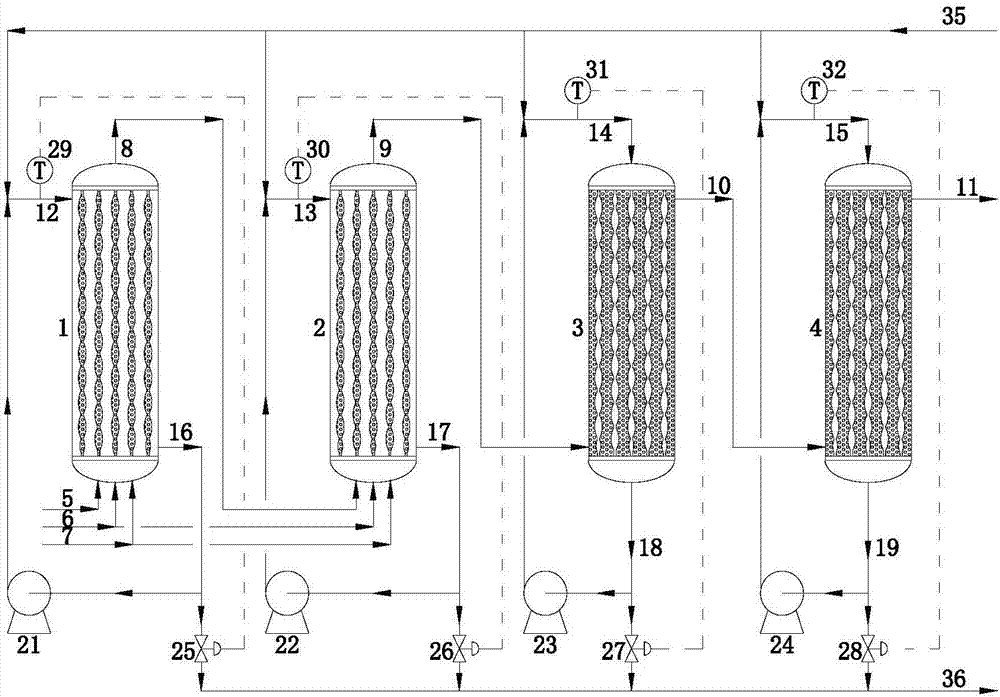

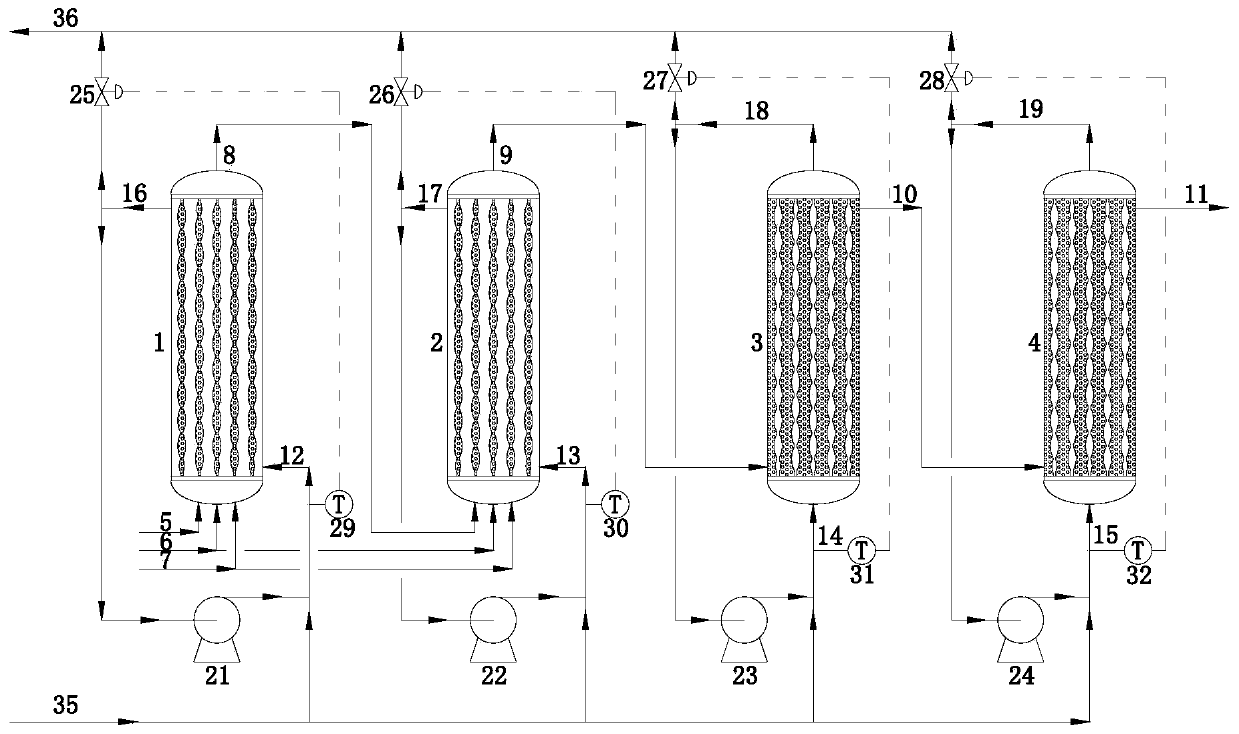

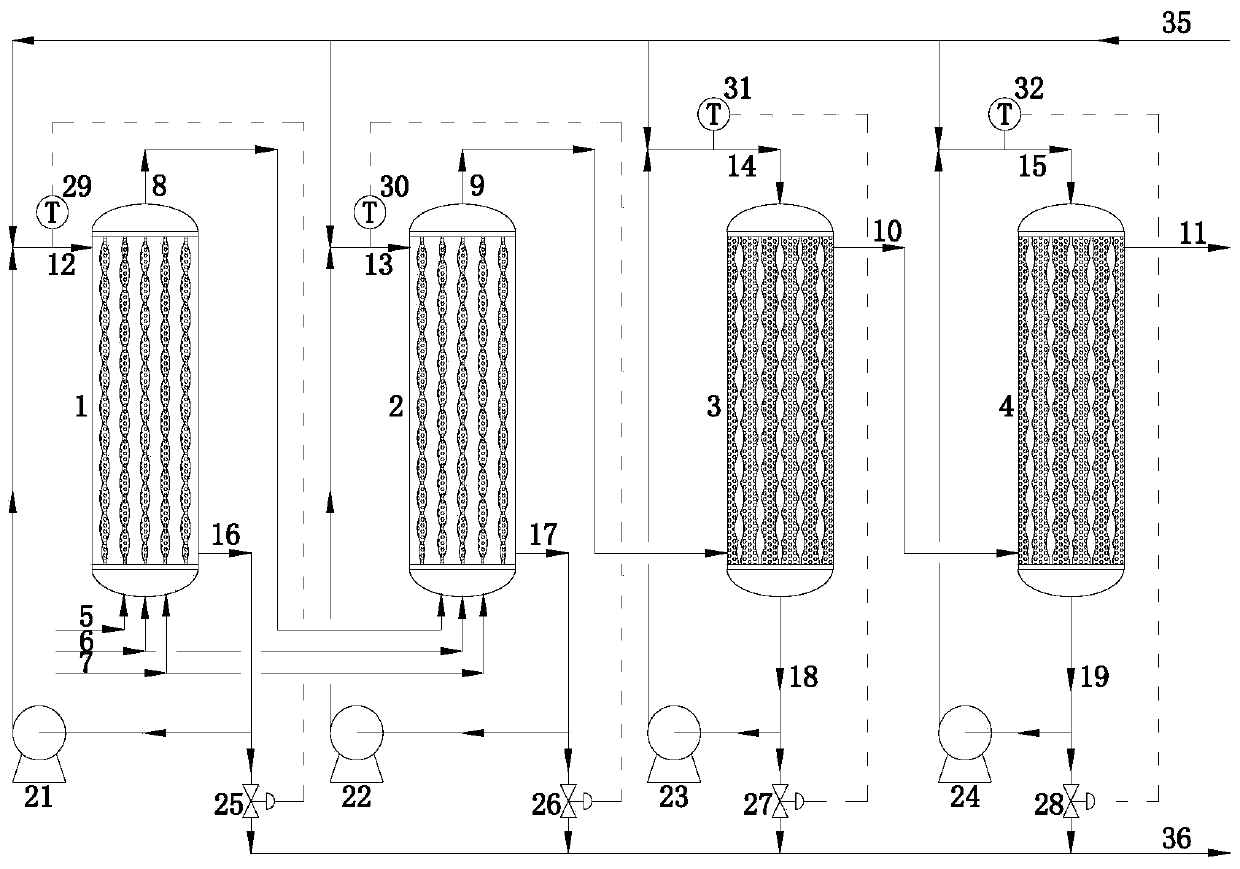

Reactor process control method of HPPO (hydrogen peroxide to propylene oxide) device

ActiveCN107417645AHigh selectivityGood technical effectOrganic chemistryBulk chemical productionProcess engineeringThermometer

The invention relates to a reactor process control method of an HPPO (hydrogen peroxide to propylene oxide) device and mainly solves the problems that a heat transfer effect is poor, the reaction temperature is not uniform and the temperature in a reactor is difficult to control in the prior art. By means of the reactor process control method of the HPPO device, four serially connected corrugated plate reactors are adopted, circular cooling water is forced to circulate to optimize heat removing, and the temperature of the circular cooling water is controlled through a thermometer and an adjusting valve, so that the reaction temperature is uniform. Accordingly, by means of the technical scheme that the total heat transfer coefficient K is increased to 2,400-2,800 w / m<2>k, the service life of a catalyst is prolonged to 4.8-5.0 years and the selectivity of epoxypropane is improved to 97.2%-97.3%, the problems are better solved, and the reactor process control method can be used in the HPPO device.

Owner:CHINA PETROLEUM & CHEM CORP +1

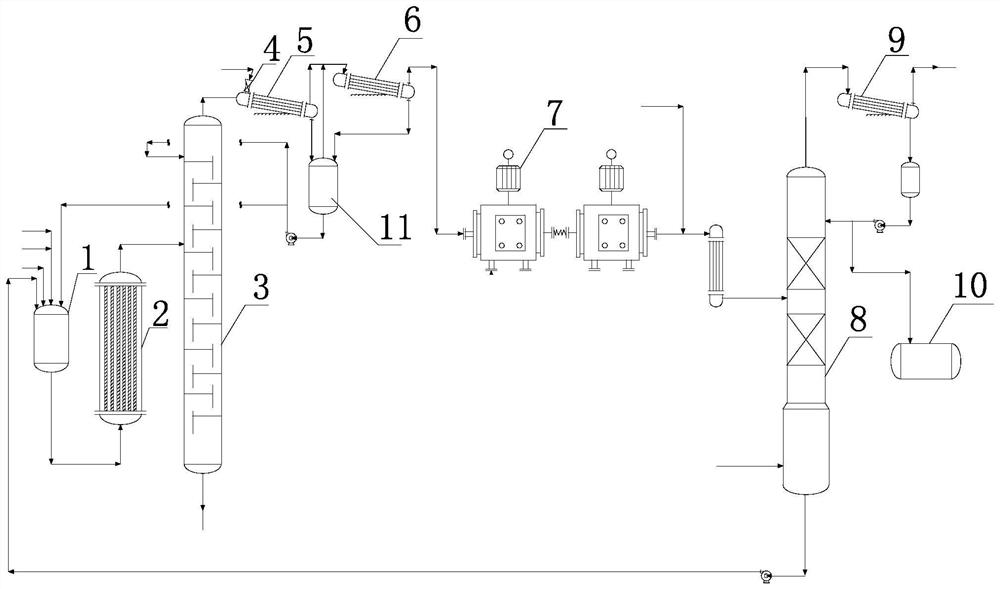

Method for separating and recycling acrolein in 1,3-propylene glycol preparation process

ActiveCN112920031ASimple processEasy to operateOrganic compound preparationChemical industryChemical industryPropanediol

The invention relates to the field of chemical industry, and discloses a method for separating and recycling acrolein in the process of preparing 1,3-propylene glycol, which comprises the following steps: adding a polymerization inhibitor into an acrolein solution to carry out hydration reaction; making a reaction product pass through an acrolein rectifying tower to separate acrolein from 3-hydroxyl propionaldehyde; introducing the 3-hydroxyl propionaldehyde solution into a hydrogenation reaction unit; after being discharged, mixing the steam with a polymerization inhibitor solution, atomizing, carrying out two-stage condensation, returning part of condensate to the acrolein rectifying tower, using part of the condensate for batching, pumping out fixed gas in vacuum, and introducing fixed gas into an acrolein recovery tower in a gas phase state; and after steam stripping, continuously discharging and refluxing the acrolein aqueous solution from the tower kettle for batching, extracting acetaldehyde liquid from the tower top, condensing and collecting. According to the method, the rectifying tower is adopted to separate the 3-hydroxyl propionaldehyde, so that the 3-hydroxyl propionaldehyde meets the requirements of subsequent hydrogenation reaction, a steam stripping method is applied to separation of acetaldehyde and acrolein, entrained acetaldehyde can be thoroughly separated, and recycling of the acrolein solution is facilitated.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD +1

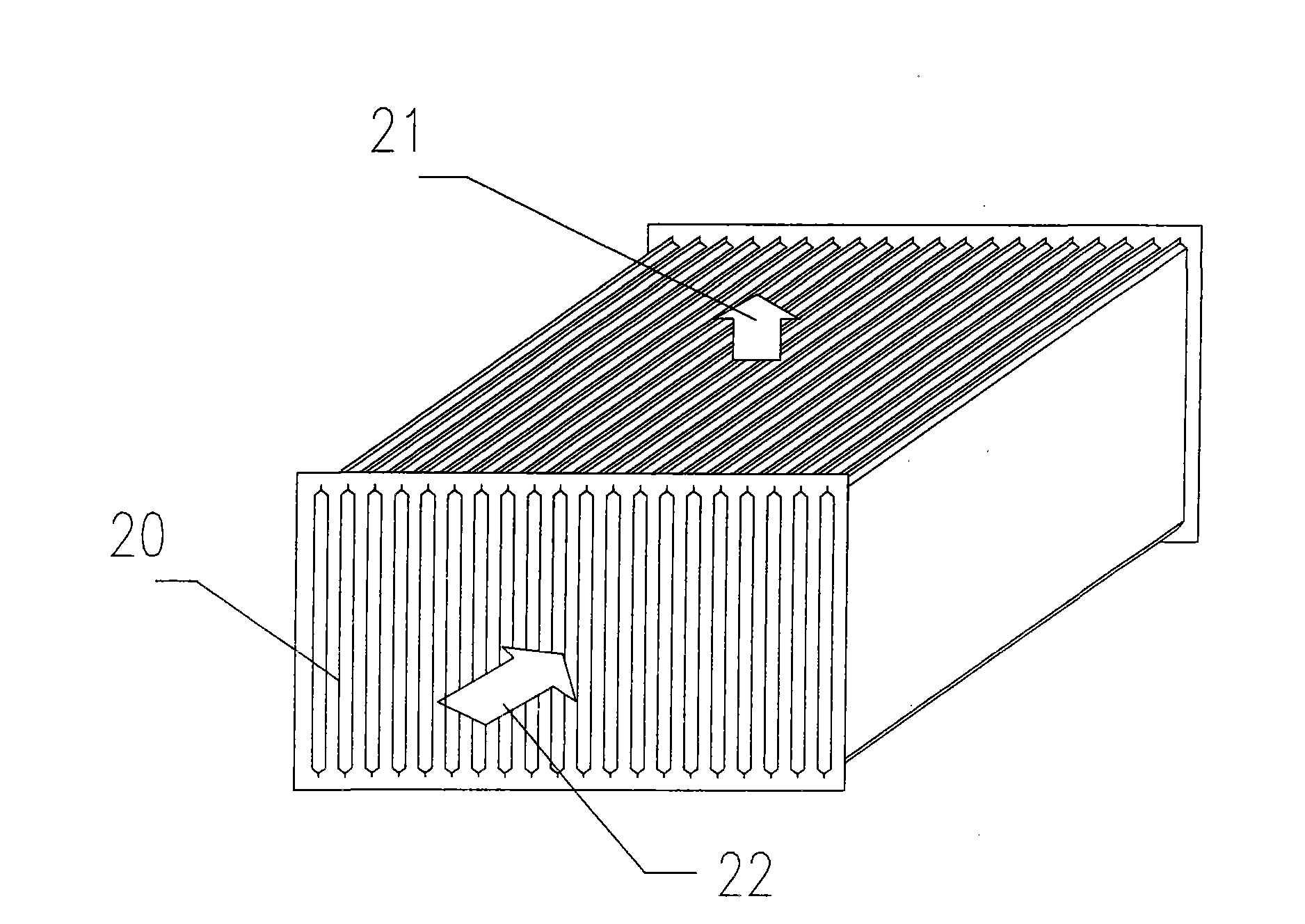

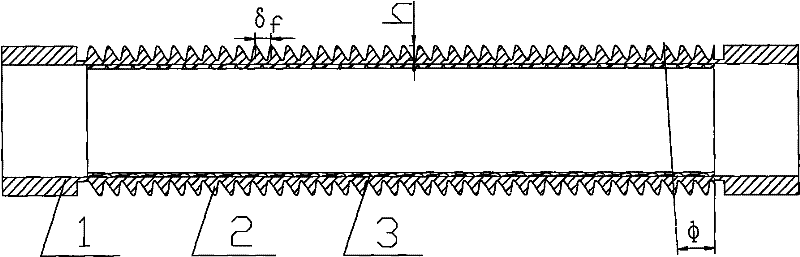

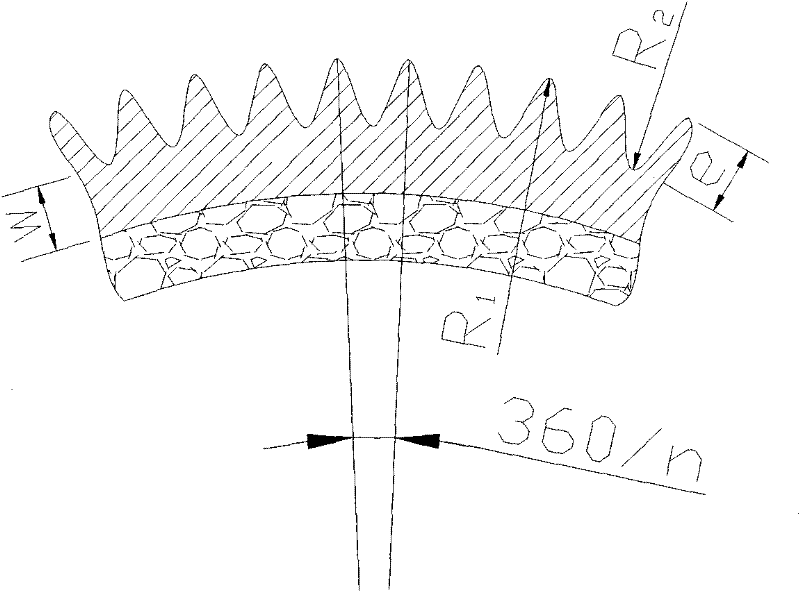

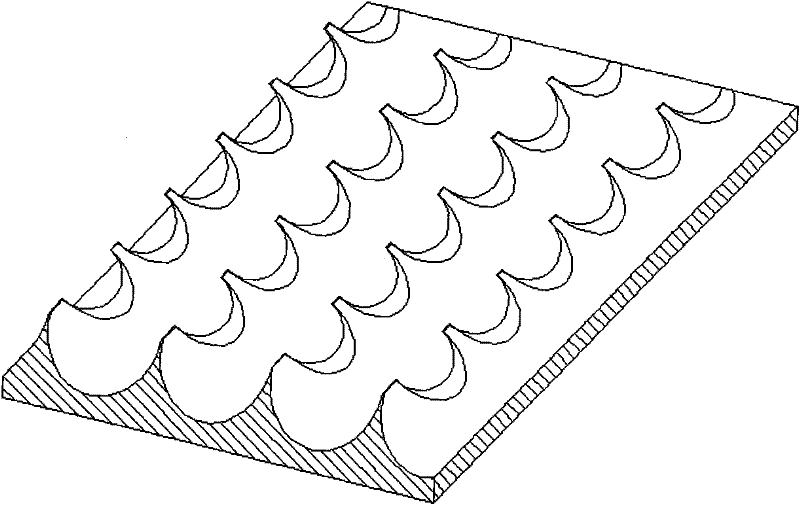

Heat exchange tube with two reinforced surfaces

ActiveCN101782344BImprove overall heat transfer coefficientImprove heat transfer performanceHeat transfer modificationTubular elementsSurface layerPorous layer

The invention relates to a heat exchange tube with two reinforced surfaces. The heat exchange tube comprises a sawteeth-shaped low-fin outer surface layer and an inner surface metal porous layer, wherein the low-fin outer surface layer is integrated with the tube wall. Compared with the prior art, the heat exchange tube strengthens the condensation of steam at the outside of the tube and the evaporation of liquid in the tube simultaneously; the surfaces of sawteeth-shaped fins of the outside of the tube are rough, and the sawteeth are mutually staggered, thus disturbing the flowing state of fluid; the surface tension is utilized to thin a liquid film on the fins so as to strengthen the condensation and heat transfer; and the number of vaporized cores is added on the porous layer at the inner surface of the tube, thus reducing the superheat degree needed by vaporization, strengthening the heat transfer of boiling, and improving the heat transfer of boiling by 10-15 times.

Owner:SHANGHAI RES INST OF CHEM IND

Superheat section and condensing section-separately arranged evaporation type condensation heat exchanger and method thereof

InactiveCN104990316ALarge forced convection heat transfer coefficientLower resistanceEvaporators/condensersEvaporationWater flow

The invention discloses a superheat section and x condensing section-separately arranged evaporation type condensation heat exchanger and a method thereof. The superheat section and condensing section-separately arranged evaporation type condensation heat exchanger includes an S-shaped superheated vapor cooling section, a horizontally-arranged upper gas collection pipe, a horizontally-arranged lower liquid collection pipe and vertical falling film condensation heat exchange pipes; a plurality of vertical falling film condensation heat exchange pipes are adopted and are distributed between the upper gas collection pipe and the lower liquid collection pipe at intervals; the S-shaped superheated vapor cooling section is U-shaped pipe; the inlet of the U-shaped pipe is connected with a compressor; the outlet of the U-shaped pipe is connected with the upper gas collection pipe; the upper ends of the vertical falling film condensation heat exchange pipes are respectively sleeved with a flow guide and water distributor with an oblique groove; and cooling water flows out through the oblique grooves along a tangential direction and is distributed on the outer surfaces of the vertical falling film condensation heat exchange pipes. The thickness of refrigerant condensed fluid films in the vertical falling film condensation heat exchange pipes of the heat exchanger is decreased, and the quantity of accumulated refrigerant fluid is decreased, and refrigerant charge can be decreased; and a refrigerant-side condensation heat exchange coefficient can be increased, and heat exchange efficiency can be improved.

Owner:SOUTH CHINA UNIV OF TECH

Plate-type adsorption and desorption device for purifying and recovering volatile organic matters in exhaust gas

ActiveCN102698561AFast flowIncrease or decrease the numberDispersed particle separationThin metalDesorption

The invention relates to a plate-type adsorption and desorption device for purifying and recovering volatile organic matters in exhaust gas, which comprises a framework and a plurality of thin metal heat transfer plates. The thin metal heat transfer plates are fixed on the framework in sequence; the edge lining of adjacent two thin metal heat transfer plates is compressed by a gasket; four corners of each thin metal heat transfer plate are provided with through holes so that two channels are formed; and the exhaust gas containing volatile organic matters, cold liquid and hot liquid or steam flow through the through holes on two sides of the thin metal heat transfer plate alternatively to exchange heat. The invention has the advantages that: (1) the flow velocity of the fluid on two sides of the surfaces of the thin metal heat transfer plates is high, the total heat transfer coefficient is high, and the heat transfer is changed; (2) the exhaust gas and the solid adsorbent can contact more fully, the flow velocity of the exhaust gas is high, and the transfer mass is strengthened; (3) the plate-type adsorption and desorption device has a compact structure, the number of the thin metal heat transfer plates can be increased and decreased according to needs of productivity, or the units can be connected in parallel; (4) the heat transfer area of unit volume is large, and the consumption of metal material is low; (5) the plate-type adsorption and desorption device has high operational flexibility and is convenient to move to work; and (6) the plate-type adsorption and desorption device has the operating pressure of 1.0MPa to 1.2MPa or 0.1MPa.

Owner:武汉旭日华环保科技股份有限公司

Process control method of hppo unit reactor

ActiveCN107417645BExtended service lifeHigh selectivityOrganic chemistryBulk chemical productionReaction temperatureProcess engineering

The invention relates to a reactor process control method of an HPPO (hydrogen peroxide to propylene oxide) device and mainly solves the problems that a heat transfer effect is poor, the reaction temperature is not uniform and the temperature in a reactor is difficult to control in the prior art. By means of the reactor process control method of the HPPO device, four serially connected corrugated plate reactors are adopted, circular cooling water is forced to circulate to optimize heat removing, and the temperature of the circular cooling water is controlled through a thermometer and an adjusting valve, so that the reaction temperature is uniform. Accordingly, by means of the technical scheme that the total heat transfer coefficient K is increased to 2,400-2,800 w / m<2>k, the service life of a catalyst is prolonged to 4.8-5.0 years and the selectivity of epoxypropane is improved to 97.2%-97.3%, the problems are better solved, and the reactor process control method can be used in the HPPO device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fixed tube-sheet heat exchanger with grooved parent tube surfaces

InactiveCN102121804AExtended flow timeIncrease the heat exchange areaTubular elementsHeat transfer efficiencyAxial length

The invention relates to a fixed tube-sheet heat exchanger with grooved parent tube surfaces, which particularly consists of heat exchange tubes, wherein the inner surface of the heat exchange tube is provided with a sintered layer, and the outer surface of the heat exchange tube is uniformly grooved both radially and axially. The fixed tube-sheet heat exchanger comprises a shell, wherein the left end of the shell is provided with a left channel box, and the right end of the shell is provided with a right channel box; the upper top of one end, adjacent to the left channel box, of the shell is provided with a thermal fluid inlet, and the lower bottom, adjacent to the right channel box, of the shell is provided with a thermal fluid outlet; the upper top of the left channel box is provided with a cold fluid inlet, and the lower bottom of the right channel box is provided with a cold fluid outlet; the heat exchange tubes distributed along the axial length of the shell are arranged in the shell, and each heat exchange tube comprises a parent tube; a porous layer is arranged on the inner peripheral surface of the parent tube, and a grooved layer is arranged on the outer peripheral surface of the parent tube; and the grooved layer comprises a plurality of grooves uniformly distributed along the axial direction and the circumferential direction of the parent tube. The fixed tube-sheet heat exchanger has a simple and compact structure, can improve the heat transfer efficiency of the heat exchanger, reduces the running energy consumption and equipment investment of the heat exchanger, and is safe and reliable.

Owner:WUXI CHEM EQUIP CO LTD

Wave plate pipe heat exchanger with transerse rib

InactiveCN1587883APlay a role in enhancing heat transferPromotes turbulent flowLaminated elementsStationary plate conduit assembliesRough surfaceWave shape

The invention provides a wave-shaped plate with cross rib tubular type heat exchanger, comprising shell, wave-shaped plate with cross rib, upper and lower tube plates which are connected together, fluid state inside and outside the wave-shaped plate with cross rib both flows along rough rib surface optimized which can promote turbulent flow of fluid on boundary layer and intensification of heat transfer effect to the fluid. The invention with wide plate spacing, is suitable for heat exchange between hot-cold gas fluid with low ordinary pressure and large volume, and has the advantages that overall coefficient of heat transfer is high, heat exchange effect is excellent, materials needed are few, investment to apparatus is low, convenient to produce and apply.

Owner:SOUTH CHINA UNIV OF TECH

Integrated combined heat exchanger

ActiveCN107606974BImprove heat transfer efficiencyIncrease profitStationary tubular conduit assembliesPlate heat exchangerStraight tube

The invention discloses an integrated combined heat exchanger. The integrated combined heat exchanger comprises a tube box, a shell and a U-shaped heat exchange tube bundle. The tube box is divided bytube pass partition plates into four tube passes, and a tube winding tube bundle is arranged. The shell is connected with the rear end of the tube box through a tube plate, and a tube pass dividing partition plate with the length smaller than the length of the shell is transversely arranged in the shell. The U-shaped heat exchange tube bundle comprises overheating section tube bundles and evaporation section tube bundles, all of which are arranged in an overheating section area and an evaporation section area in a one-to-one correspondence manner, the total length of the evaporation section tube bundles is equal to the length of the tube pass dividing partition plate, and the length of straight tube sections of the overheating section tube bundles is equal to the length of the tube pass dividing partition plate. The vertical distance between a row of tube bundles on the tops of the evaporation section tube bundles and the tube pass dividing partition plate is not smaller than 125 mm,at least one row of heat exchange tubes in the evaporation section tube bundles are higher than the liquid level in the shell, and the vertical distance between the row of heat exchange tubes and thenext row of heat exchange tubes is larger than the normal tube distance of the evaporation section tube bundles. The heat exchanger can be used for multiple occasions, and the utilization rate and heat transfer efficiency are improved.

Owner:SHANGHAI KAIREN GAS ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com