Device for dehydrogenating liquid organic hydride

A hydride and organic technology, which is applied in the field of reaction devices for producing hydrogen, can solve the problems of low reaction conversion rate and huge equipment, and achieve the effects of improving the total heat transfer coefficient, increasing utilization efficiency, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

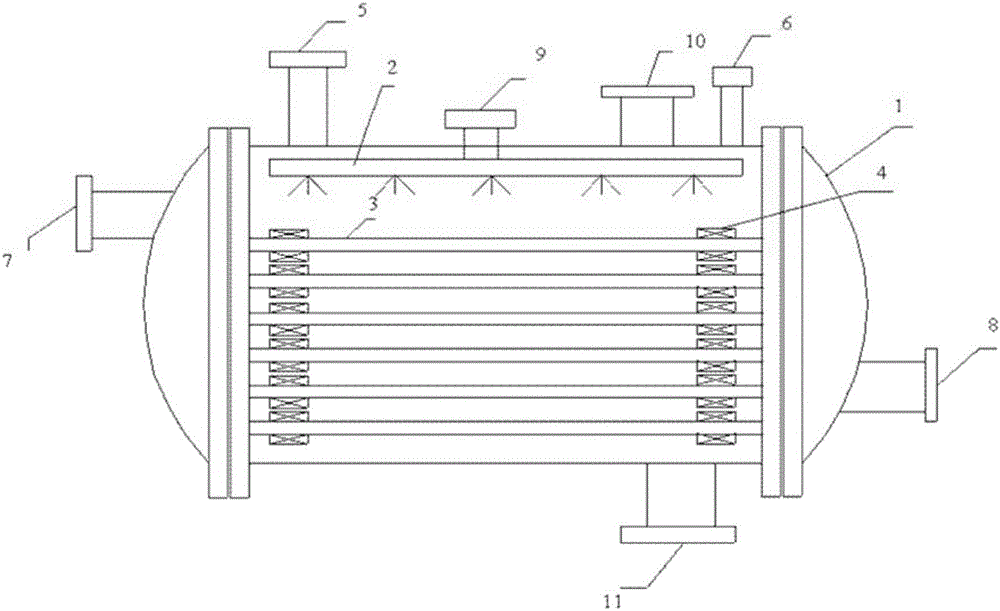

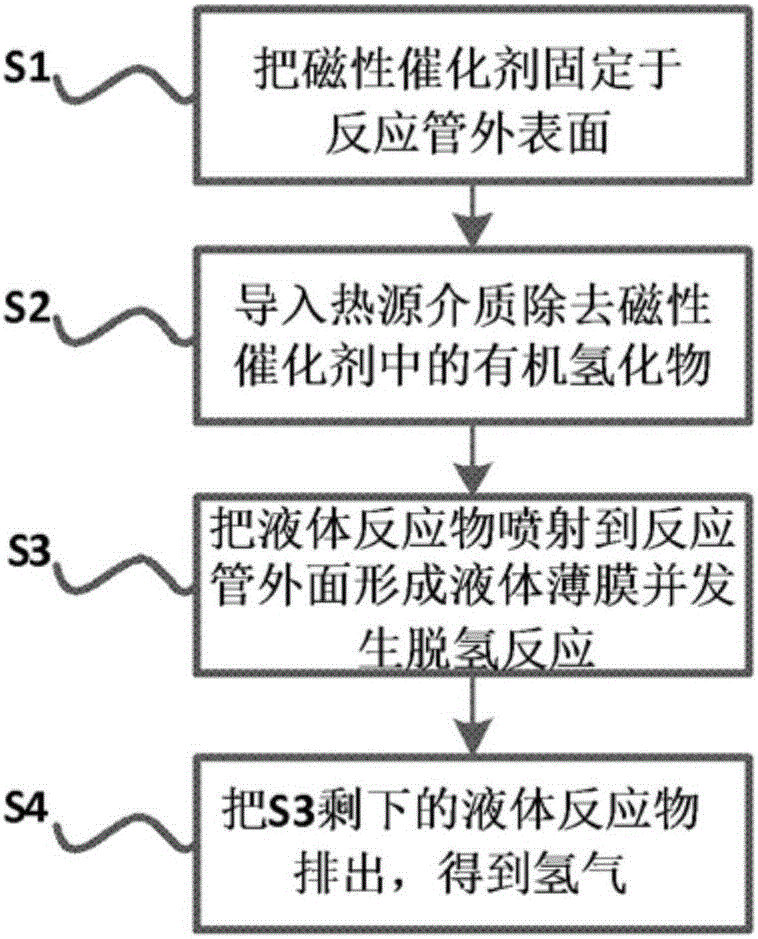

[0023] The device for dehydrogenating liquid organic hydrides of the present invention has a shell, a reaction tube, a liquid distributor and an electromagnetic coil. The housing serves as a reaction vessel for the dehydrogenation of liquid organic hydrides. The reaction tube is used for heating the liquid organic hydride to make it undergo dehydrogenation reaction on the surface of the reaction tube. A heat source medium can be introduced into the reaction tube to provide heat for the hydrogenation reaction. The reaction tubes are preferably uniformly arranged in the device, so that the liquid organic hydride is evenly distributed on the outer surface of the reaction tubes. The material of the reaction tube can be selected from metals that are easy to magnetize and demagnetize, such as soft iron. The shape of the reaction tube is preferably a circular tube, but not limited thereto.

[0024] The liquid distributor is used to spray the organic hydride liquid onto the outer s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com