Plate-type adsorption and desorption device for purifying and recovering volatile organic matters in exhaust gas

A technology for volatile organic compounds and waste gas, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem of insufficient contact between waste gas and adsorbent, slow flow rate of cooling or heating agent, and low mass transfer and heat transfer efficiency. problems, to achieve the effect of easy mobile operation, low consumption of metal materials, and improved heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

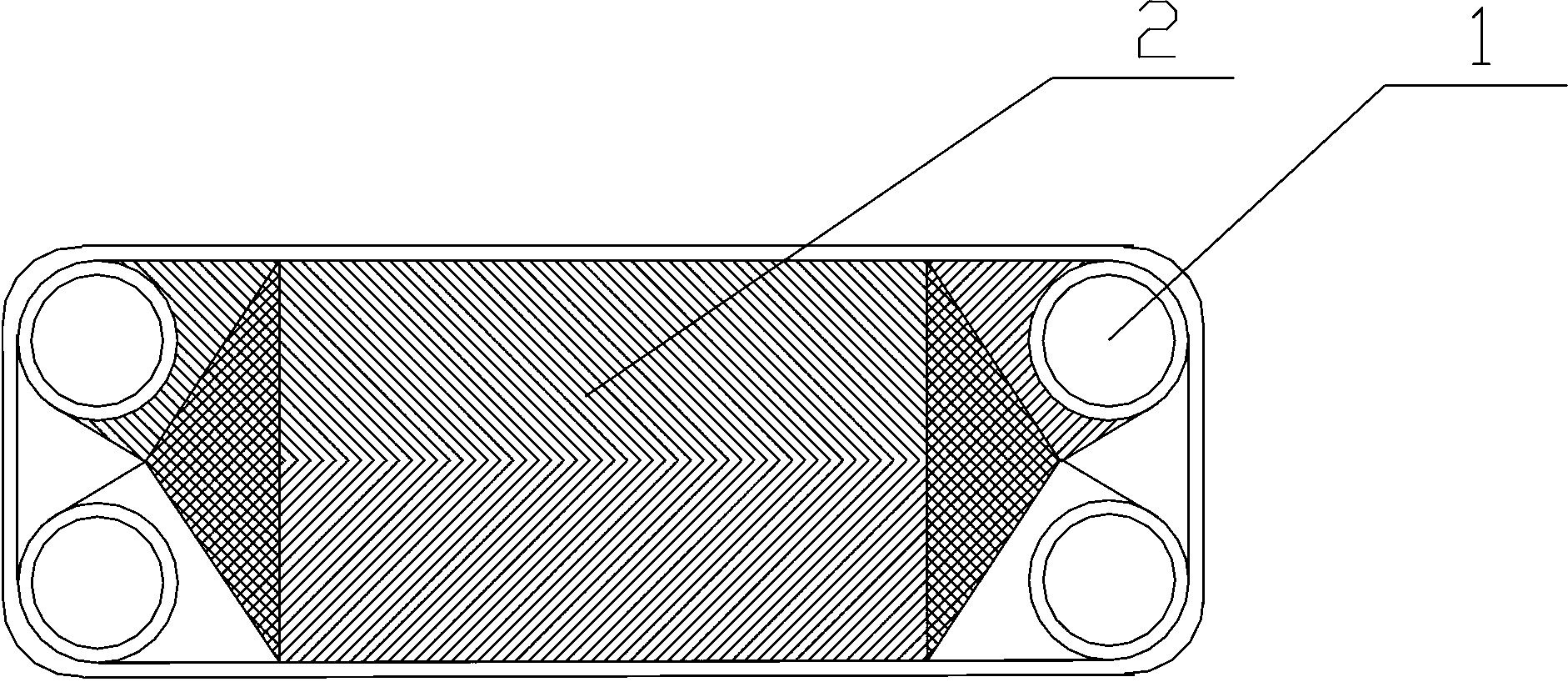

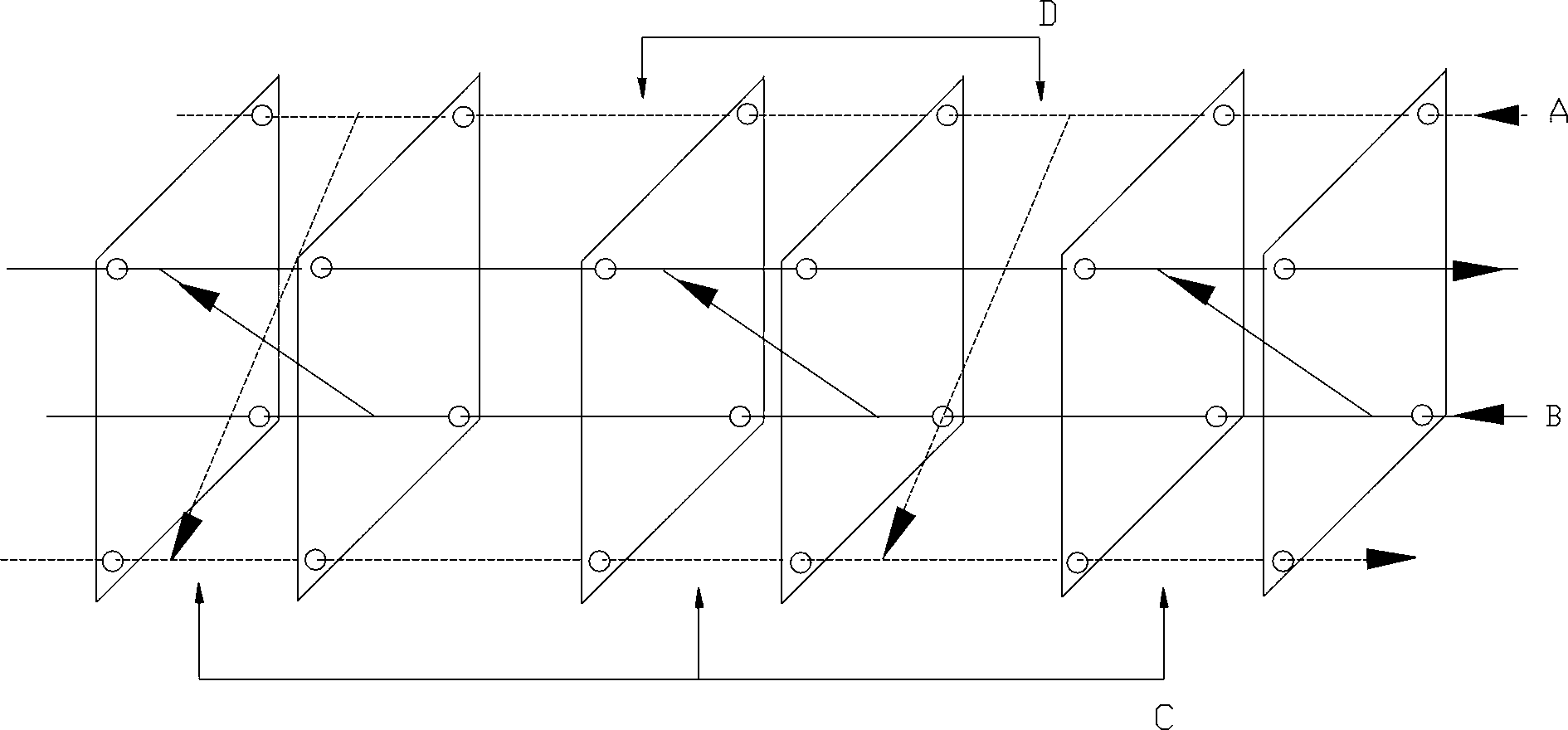

[0017] A plate-type adsorption-desorption device for purifying and recovering volatile organic compounds in waste gas, including a frame and a plurality of thin metal heat transfer plates 2, the thin metal heat transfer plates are fixed on the frame in turn, and the edges of two adjacent thin metal heat transfer plates are lined with The rubber gasket is pressed tightly, and the four corners of the thin metal heat transfer plate are respectively provided with through holes 1 to form two channels, in which the waste gas containing volatile organic compounds, cold and hot liquid or steam pass alternately on both sides of the thin metal heat transfer plate. holes for heat exchange.

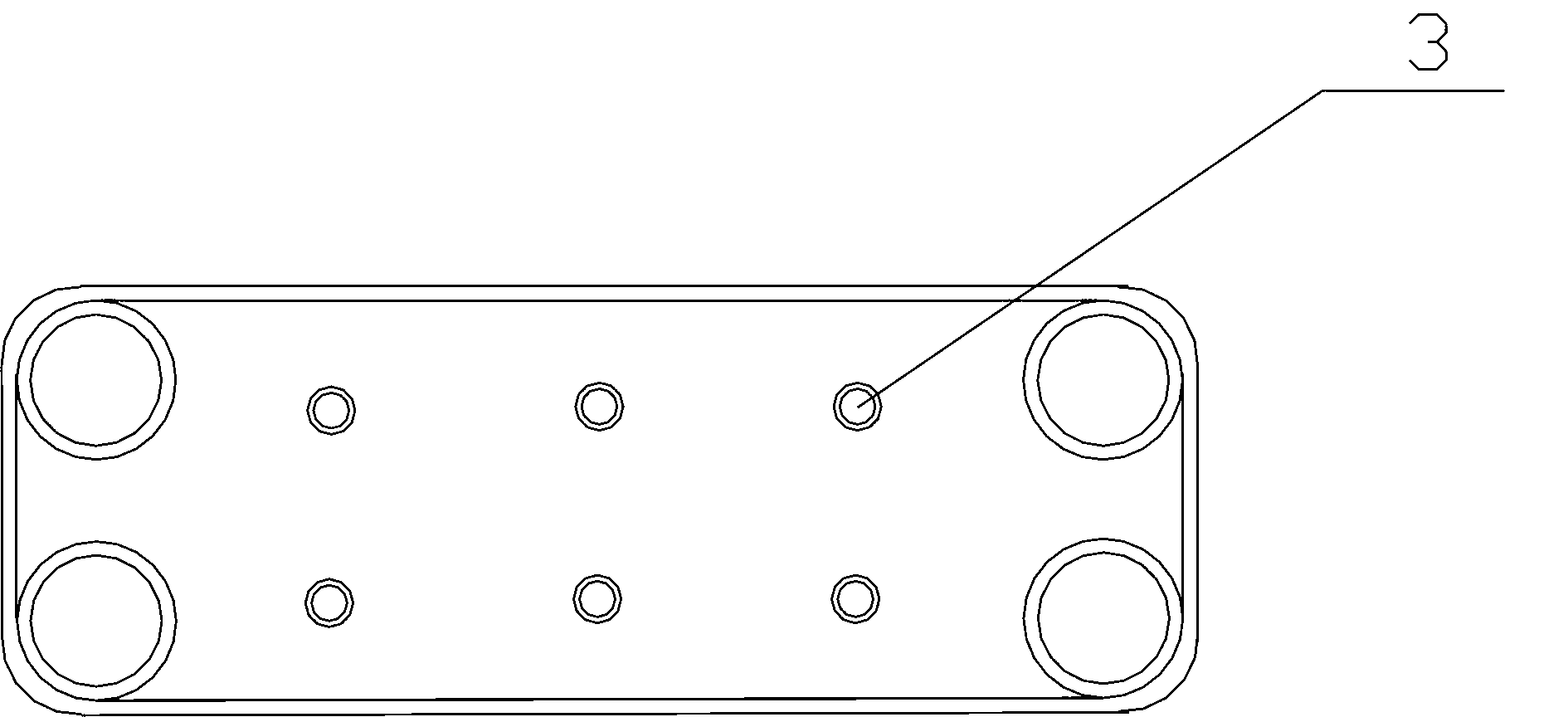

[0018] Such as Figure 1-2 , the thickness of the thin metal heat transfer plate is 3-5 mm, one of the surfaces is grooved or corrugated, and the other side is evenly welded with short piles 3 perpendicular to the plane, with a diameter of 10-25 mm and a height of 20-40 mm. Evenly distributed. The ...

Embodiment 2

[0025] A chemical plant unloads VOC from tank trucks S To the receiving tank, move the independent unit car composed of plate adsorption-desorption device and suction fan to VOC S At the loading and unloading site, it is connected with the exhaust port of the receiving tank, and the VOC is unloaded S At the same time, the independent unit passes cooling water, draws air, and completes exhaust gas purification, and then assembles this independent unit into the plate adsorption-desorption device to implement VOC in the whole process. S Desorption recovery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com