Integrated combined heat exchanger

A technology of shell-and-tube heat exchangers and heat exchangers, applied in the direction of indirect heat exchangers, heat exchanger types, fixed tubular conduit assemblies, etc., which can solve the problems of low utilization rate of reboilers and reduce maintenance The effect of operating cycle, improving utilization rate and improving overall heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

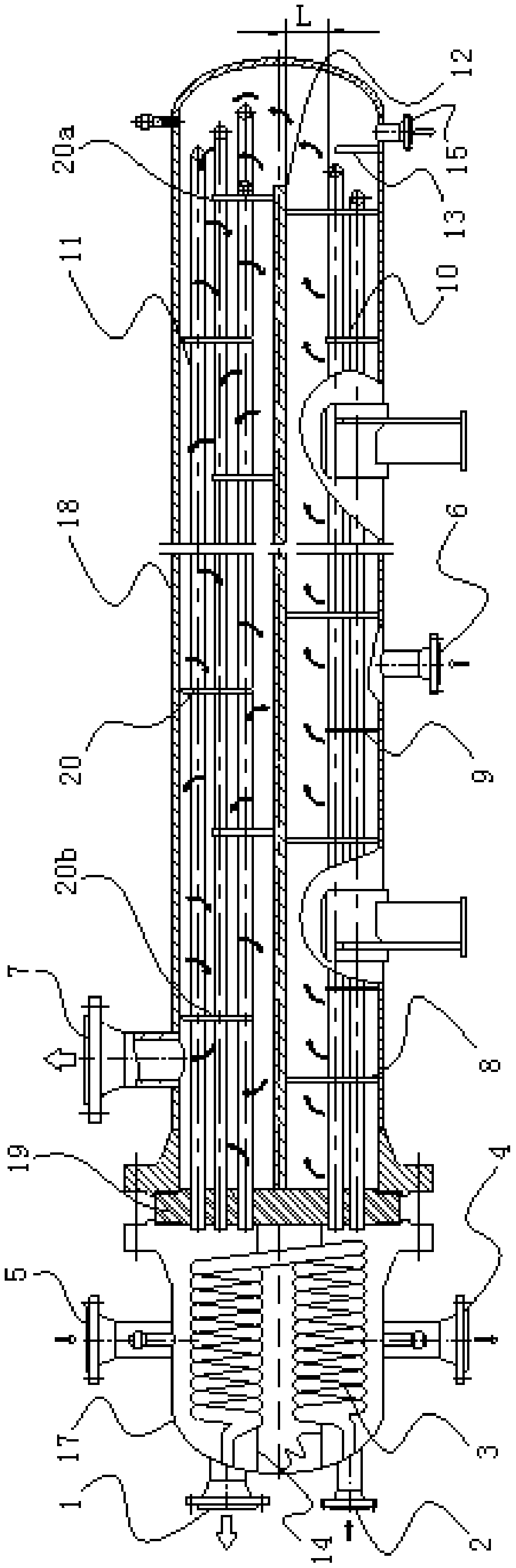

[0026] The present invention will be further described below in conjunction with accompanying drawing.

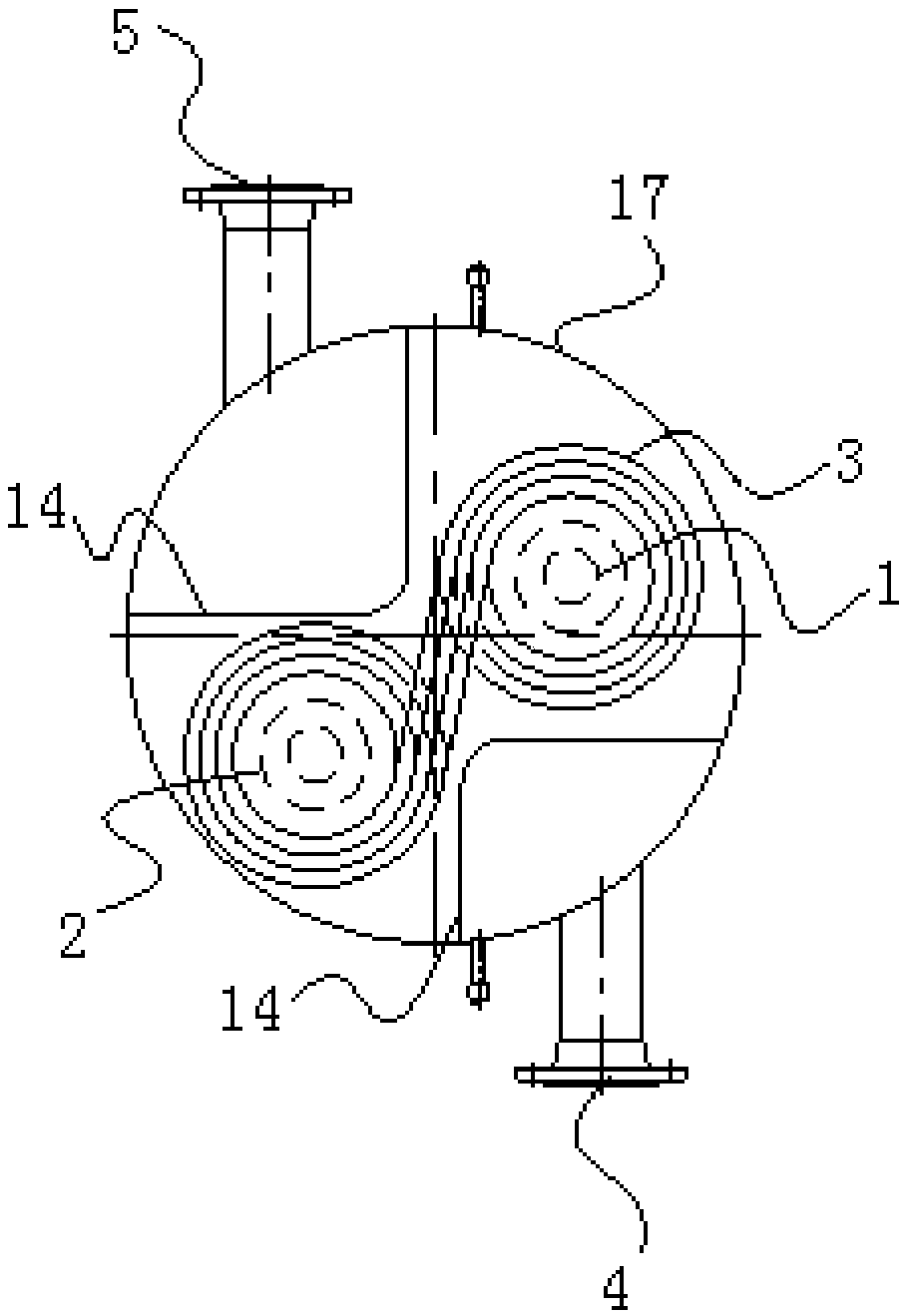

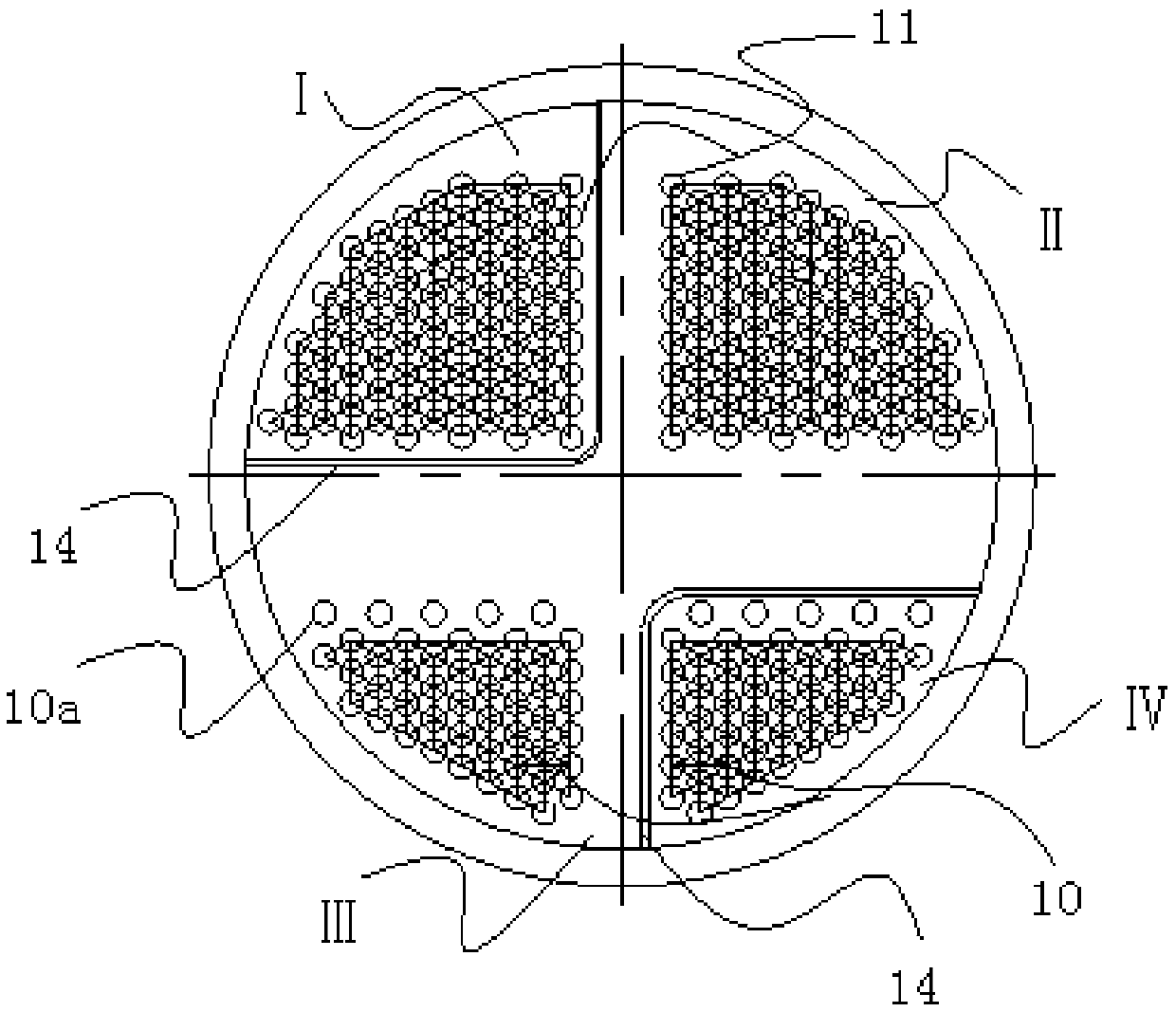

[0027] see Figure 1 to Figure 4 , The integrated combined heat exchanger of the present invention is a horizontal four-tube shell-and-tube heat exchanger, which mainly includes a tube box 17, a coiled tube bundle 3 or a coiled tube bundle, a shell 18, a U-shaped heat exchange tube bundle, and the like.

[0028] The tube box 17 is cylindrical in shape, and the tube box 17 is divided into three spaces by two tube side partitions 14, so that the number of tube passes of the heat exchanger is four tube passes, and the head of the tube box 17 is provided with a winding inlet Connecting pipe 2 and winding outlet connecting pipe 1, the wall surface of pipe box 17 is provided with pipe pass outlet connecting pipe 4 and a pipe pass inlet connecting pipe 5.

[0029] The coiled tube bundle 3 or the coiled tube bundle is arranged in the tube box 17 (the following takes the coiled tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com