Wave plate pipe heat exchanger with transerse rib

A tubular heat exchanger and wave plate technology, applied in the direction of heat exchanger types, indirect heat exchangers, fixed plate conduit components, etc., can solve the problems of inability to strengthen the heat transfer of fluids on both sides of the cold and hot, and can not be applied well. , to achieve the effect of promoting turbulent flow and enhancing heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

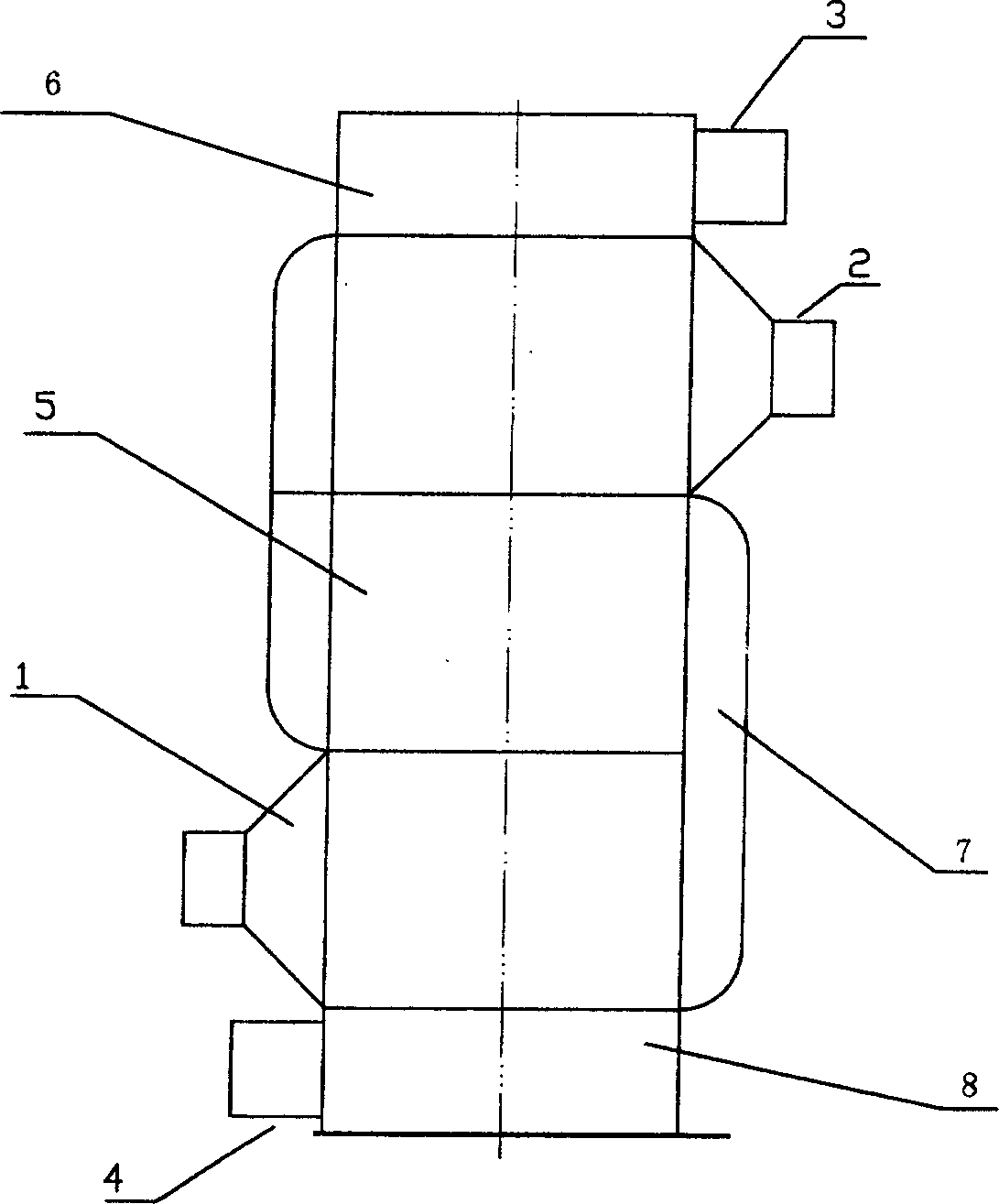

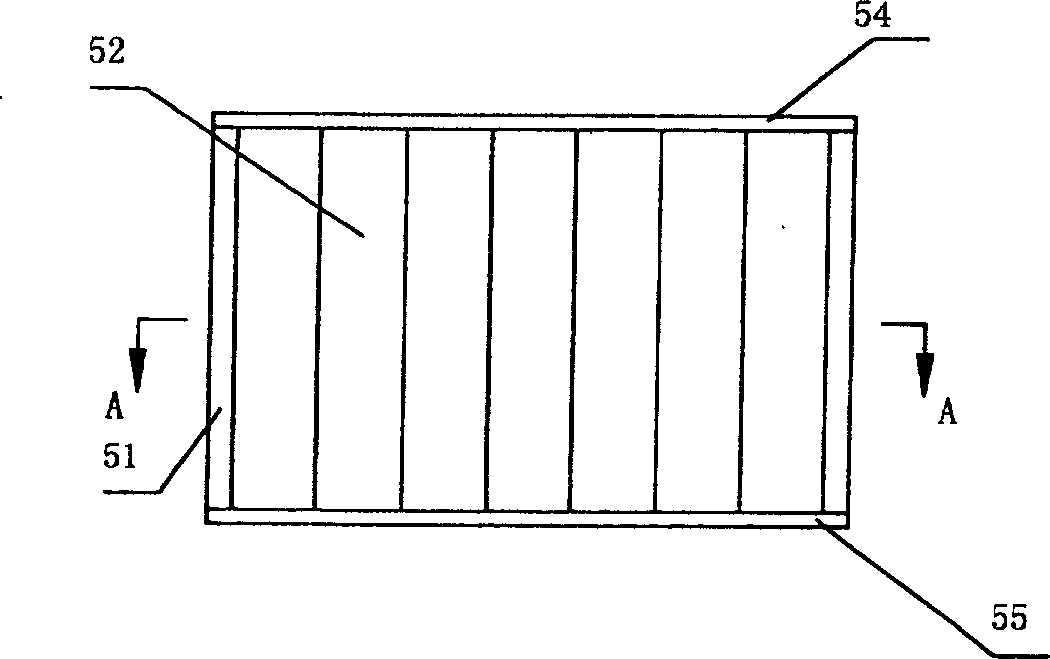

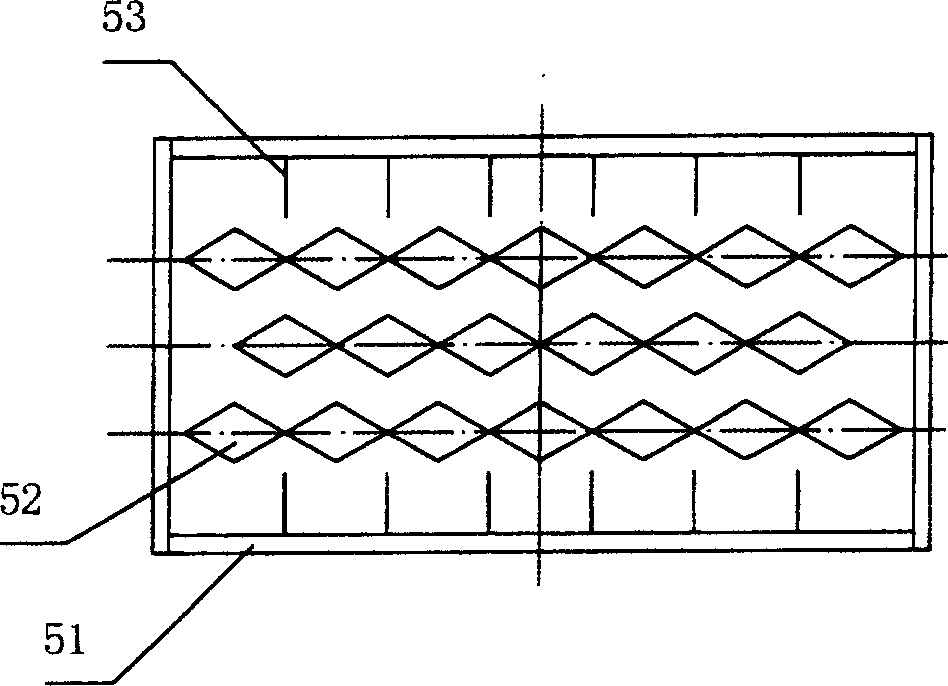

[0023] figure 1 Among them, it consists of cold fluid inlet 1, cold fluid outlet 2, hot fluid inlet 3, hot fluid outlet 4, heat exchange unit 5, upper head 6, cold fluid connecting air duct 7 and lower head 8; heat exchange unit 5 The schematic diagram of the structure is attached figure 2 , attached image 3 As shown, it is composed of a shell 51, a plate tube 52, an edge spoiler 53, an upper tube plate 54 and a lower tube plate 55. The plate tube 52 is composed of two stacked and connected special-shaped plates with wave grooves. , in the heat exchanger shell 51, there are special-shaped plates with repeated and continuous transverse ribs and longitudinal wave grooves, and the crests of the wave grooves of two adjacent special-shaped plates are overlapped and connected to form a plate tube 52. For every two special-shaped plates in one special-shaped plate, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com