Patents

Literature

30results about How to "Play a role in enhancing heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

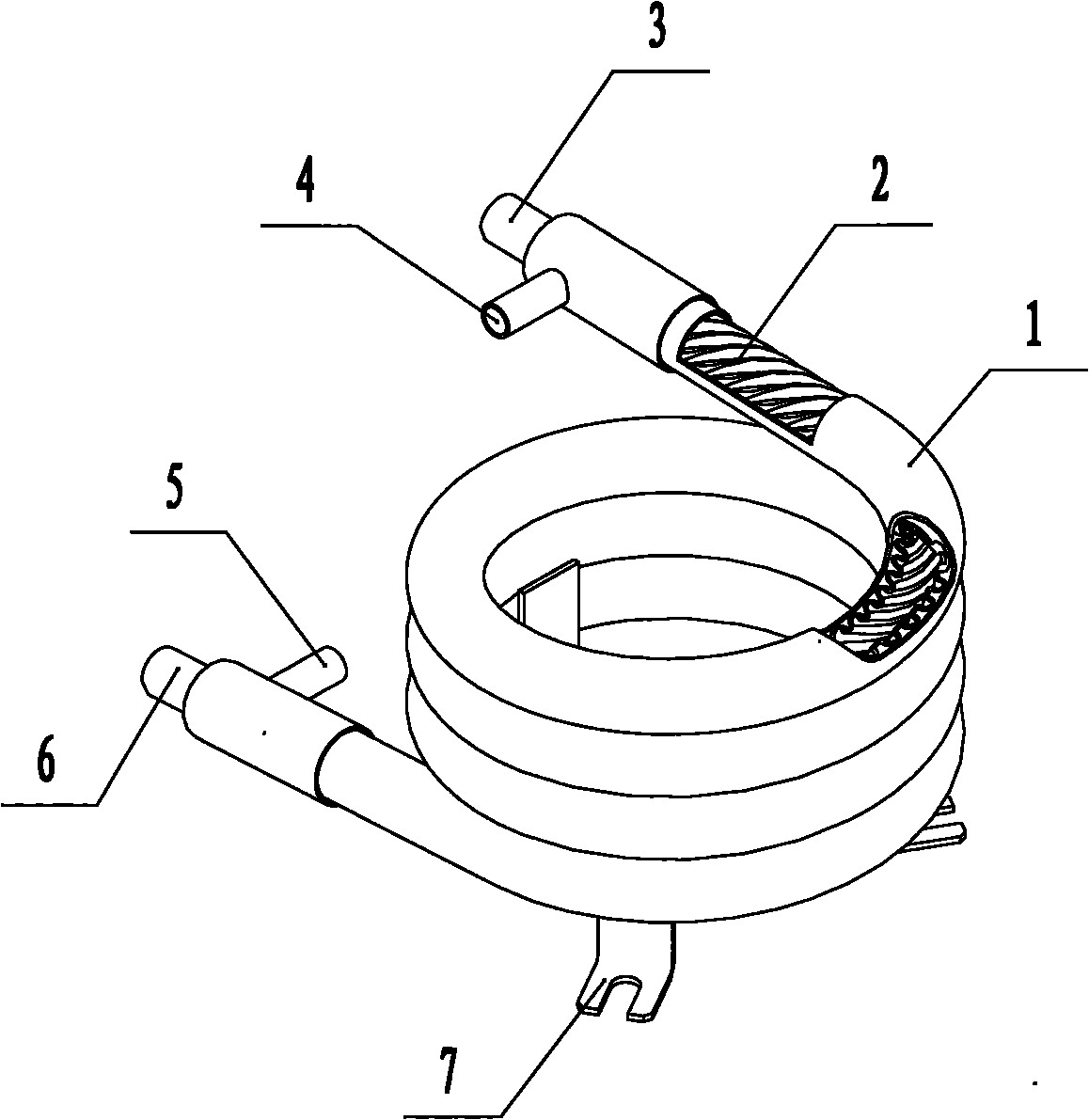

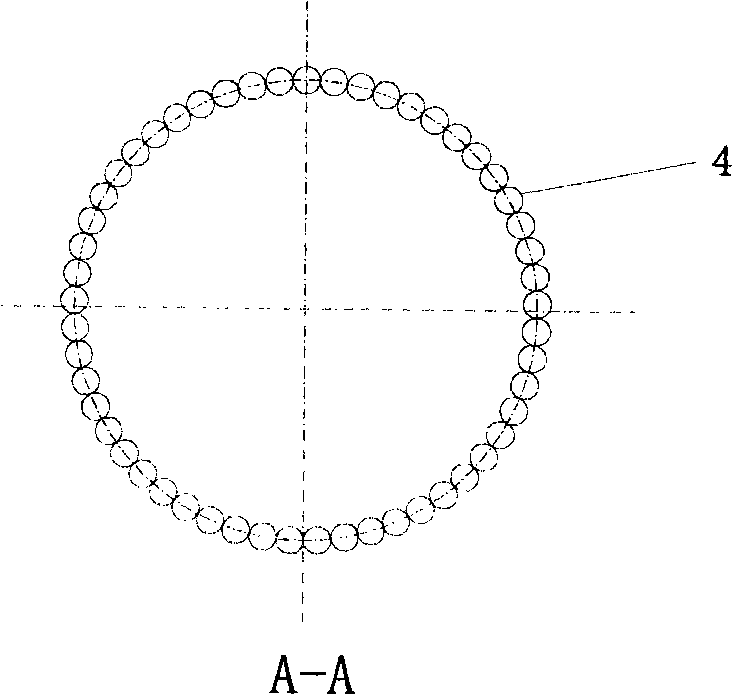

Coaxial heat exchanger

InactiveCN102116585AReduce consumptionImprove heat transfer effectHeat exhanger conduitsStationary tubular conduit assembliesEngineeringHigh heat

The invention provides a coaxial heat exchanger. The coaxial heat exchanger comprises an outer tube and an inner tube which are sleeved coaxially; the main body section of the inner tube is a multi-head spiral tube with a plurality of parallel spiral slot structures; both ends of the inner tube are used as a first fluid inlet and a first fluid outlet respectively; both ends of the outer tube are used as a second fluid inlet and a second fluid outlet respectively; a first fluid passageway is formed in the inner tube; a second fluid passageway consisting of a plurality of parallel spiral slots is formed between the outer tube and the inner tube; the second fluid passageway uniformly encircles the first fluid passageway; first fluid flows into the inner tube and flows out of the inner tube through the first fluid passageway; second fluid flows in the second fluid passageway; and the two kinds of fluid flows reversely so as to exchange heat through the tube wall of the inner tube. The coaxial heat exchanger provided by the invention has a large heat exchange area and high heat exchange efficiency; and the metal consumption of unit heat exchange area is low and the volume of the heat exchanger can be reduced, so the whole structure is compact and rational, and the coaxial heat exchanger is easy and convenient to operate and install.

Owner:EXTEK ENERGY EQUIP ZHEJIANG

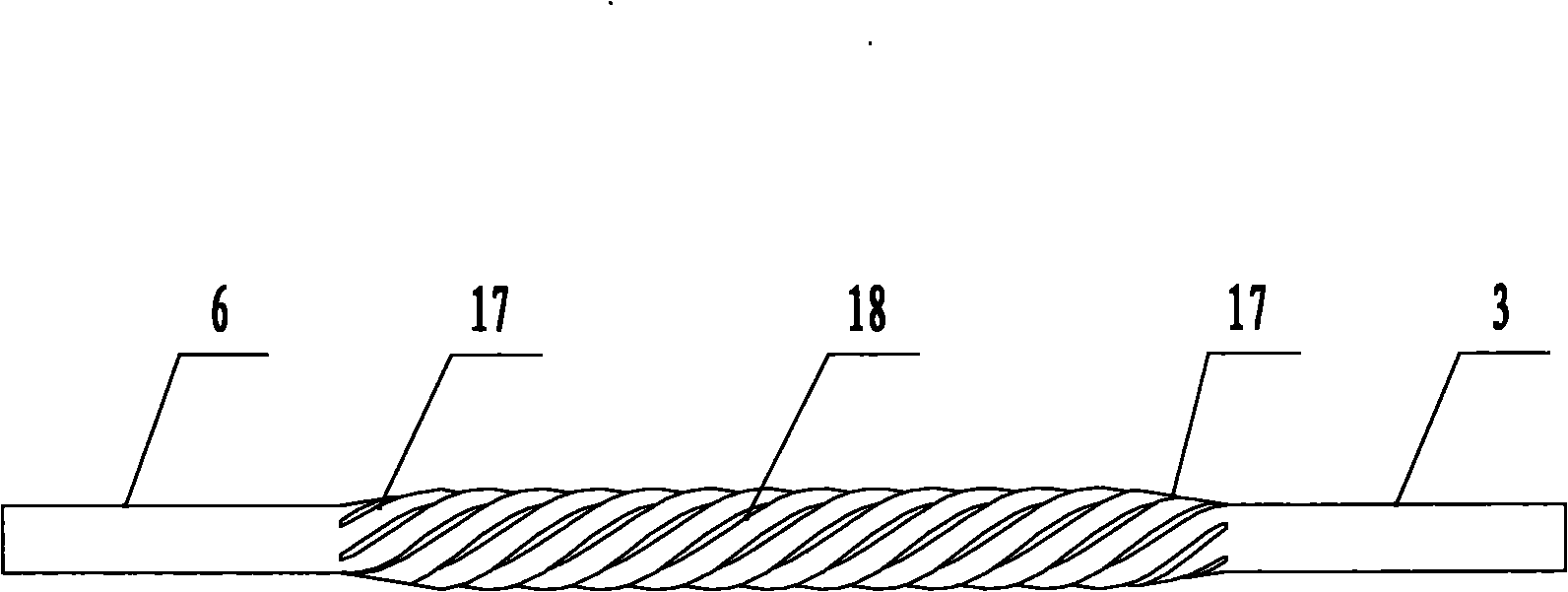

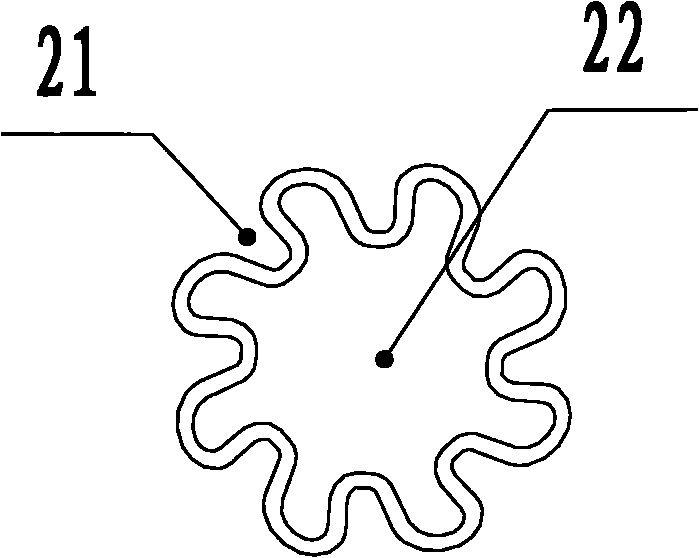

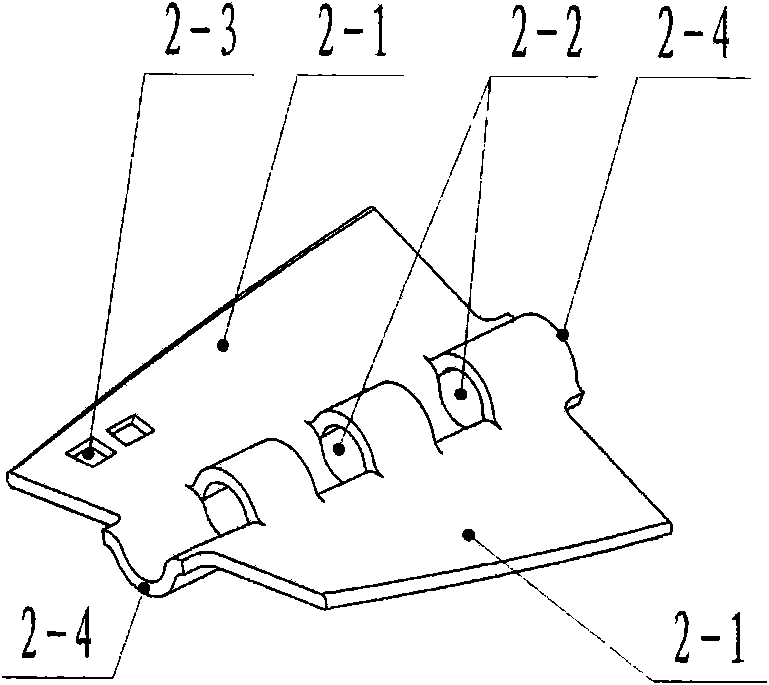

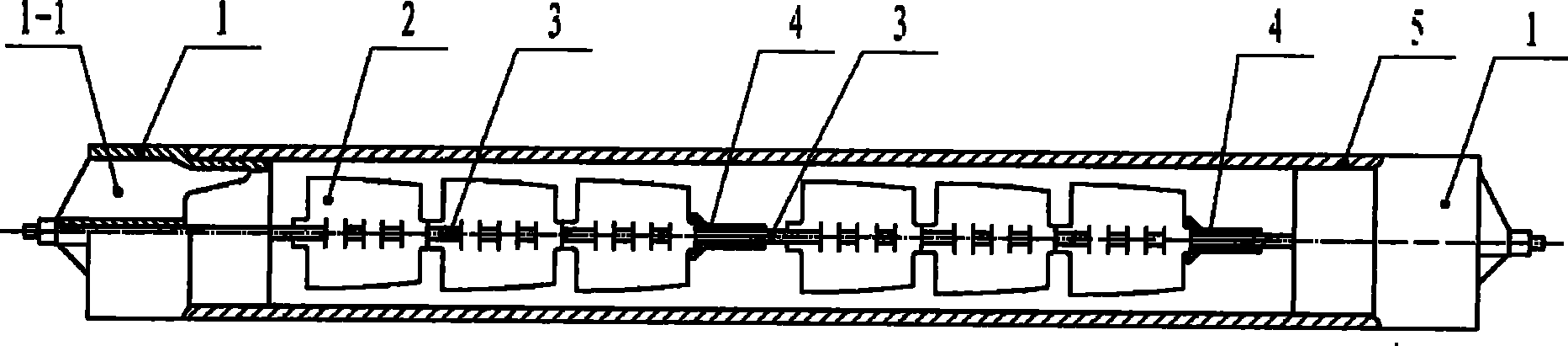

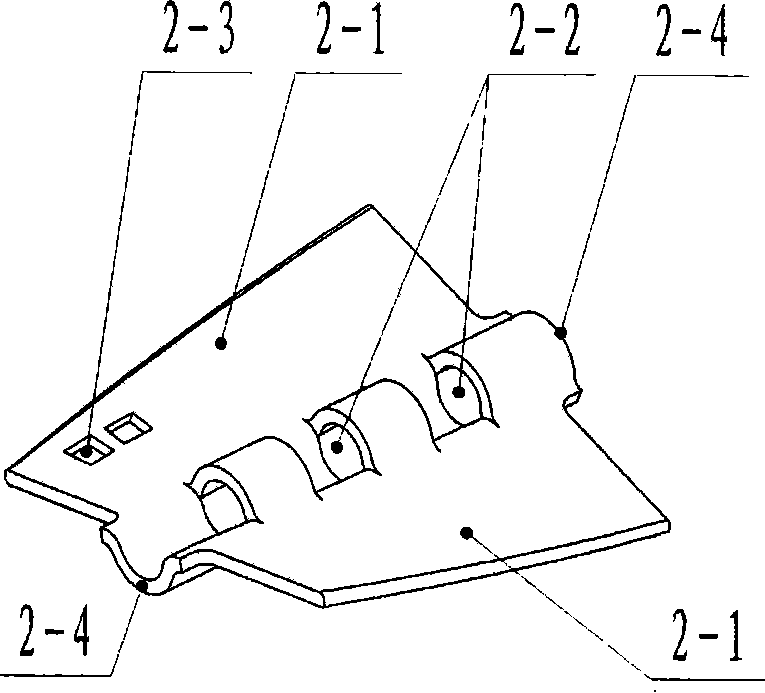

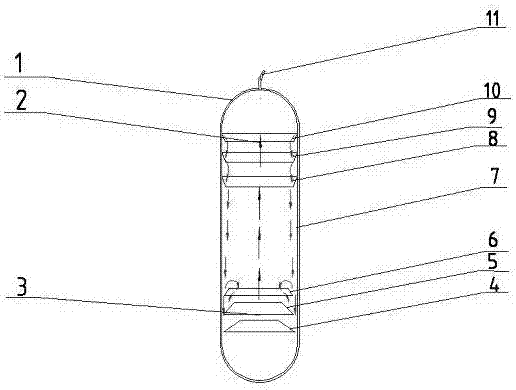

Rotating piece type automatic-cleaning and heat-transfer enhancing device

InactiveCN101551214ALow rotational resistanceSave materialHeat transfer modificationRotary device cleaningDual functionScale control

The invention relates to a rotating piece type automatic-cleaning and heat-transfer enhancing device, in particular to a device used for a heat transfer pipe for a tubular heat exchange device. The device comprises one or more rotating piece(s), hanging parts, an axial line and limiting rivets and is used by being placed in a heat exchanger, wherein the number of the hanging parts is two, and the two hanging parts are respectively fixed at both ends of the heat transfer pipe; the rotating pieces are placed in the heat transfer pipe of the heat exchanger; the rotating pieces are used and arranged in groups, and the limiting rivets are arranged between each group of the rotating pieces at intervals; the axial line penetrates through an axle holes of the rotating pieces and the limiting rivets, and both ends of the axial line are fixed on the two hanging parts; the rotating pieces are of screw twisted shapes, concavo-convex slot structures are alternatively arranged at the position of the axial line at intervals and are axle holes of the axial line, the friction between the rotating pieces and the axial line can be effectively reduced, thus the service life of the rotating pieces is prolonged; and the rotating pieces have simple molds, can be made of plastics or metal and can be molded by pressing or by injection according to the different materials. The device has the dual functions of automatic on-line cleaning and scaling control and enhancing heat transfer in the heat transfer pipe and is convenient to manufacture, assemble, use and replace.

Owner:BEIJING UNIV OF CHEM TECH

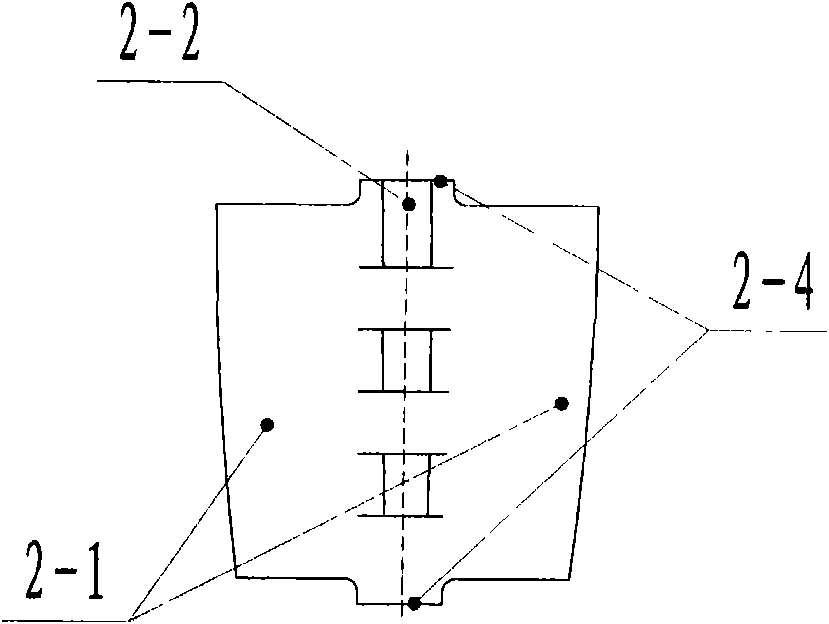

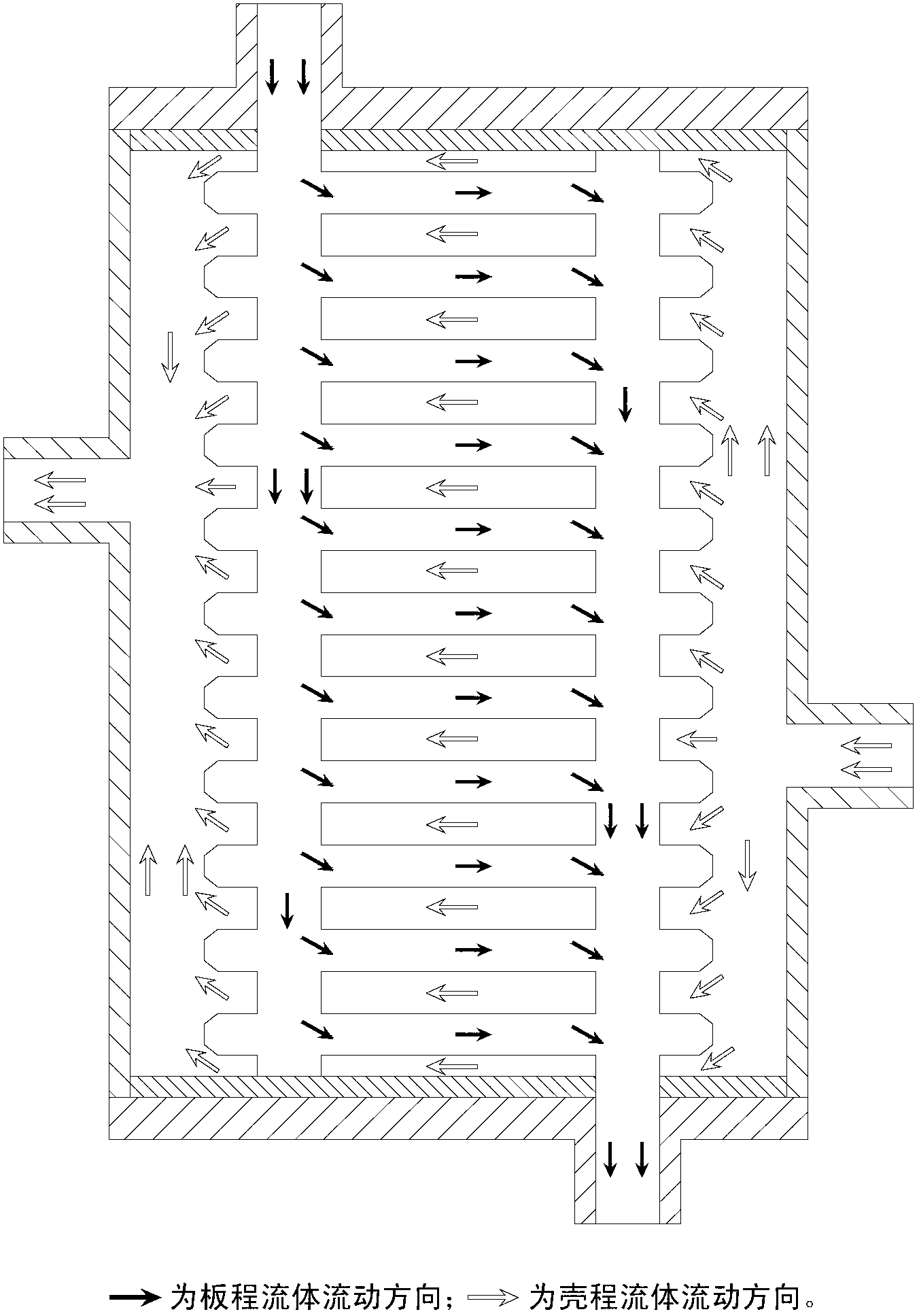

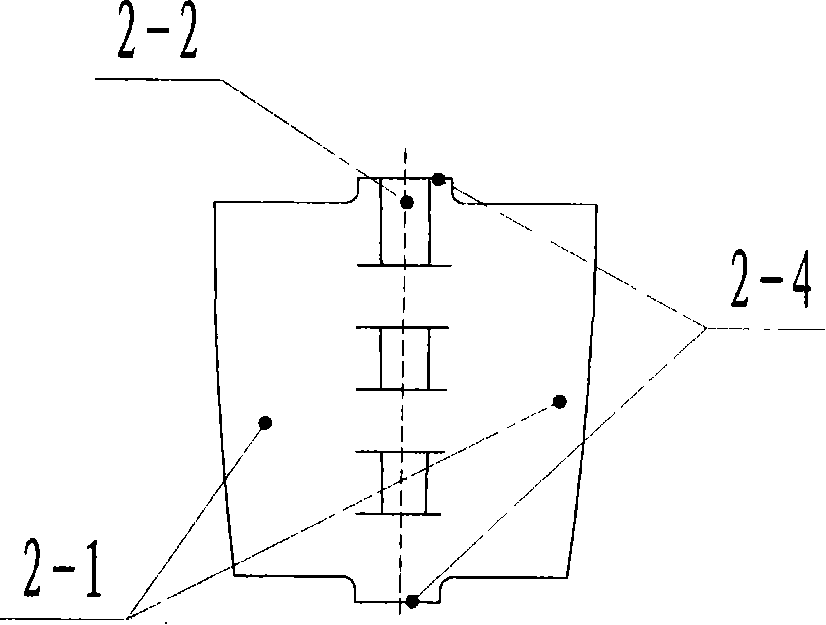

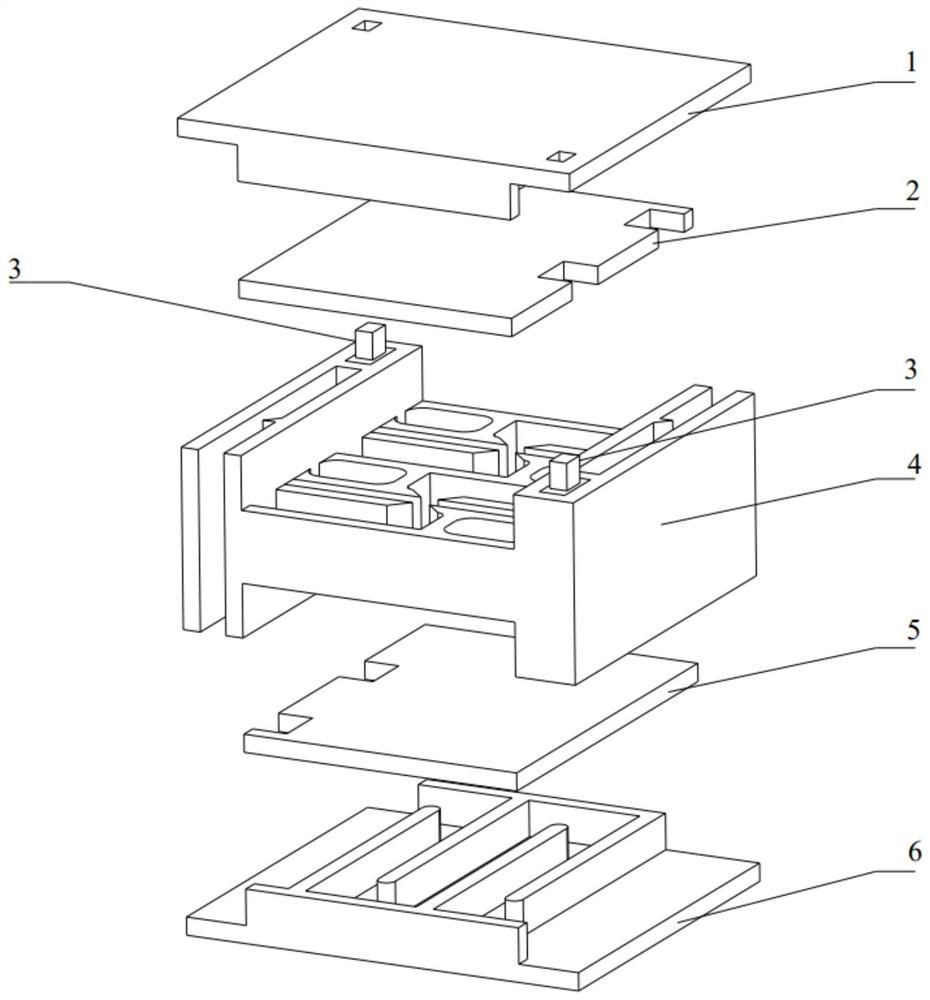

High-pressure resistant lamella heat exchanger adopting round corrugated plates

InactiveCN102706188AUniform stress distributionStrong pressure capacityLaminated elementsStationary plate conduit assembliesEngineeringHigh pressure

The invention aims to provide a high-pressure resistant lamella heat exchanger adopting round corrugated plates, which includes a shell, cover plates, a corrugated plate lathed bundle, flow guiding blocks and support plates, wherein the corrugated plate lathed bundle includes corrugated plates and is fixed in the shell through the support plates; the two ends of the shell are sealed by the cover plates; a shell side outlet and a shell side inlet are arranged in the shell; a plate side inlet and a plate side outlet are arranged in the cover plates; an annular zone between the shell and the corrugated plate lathed bundle is divided into a shell side inlet chamber and a shell side outlet chamber through the flow guiding blocks; the shell side inlet is communicated with the shell side inlet chamber; the shell side outlet is communicated with the shell side outlet chamber; angular holes are formed in the corrugated plate lathed bundle; and the plate side inlet is communicated with the plate side outlet through the angular holes in the corrugated plate lathed bundle. The high-pressure resistant lamella heat exchanger provided by the invention has the advantages of high pressure bearing capability, high heat exchange efficiency, compact structure, big heat transfer area in a unit volume, wide material selection range, wide application range, as well as simplicity in processing and installation.

Owner:HARBIN ENG UNIV

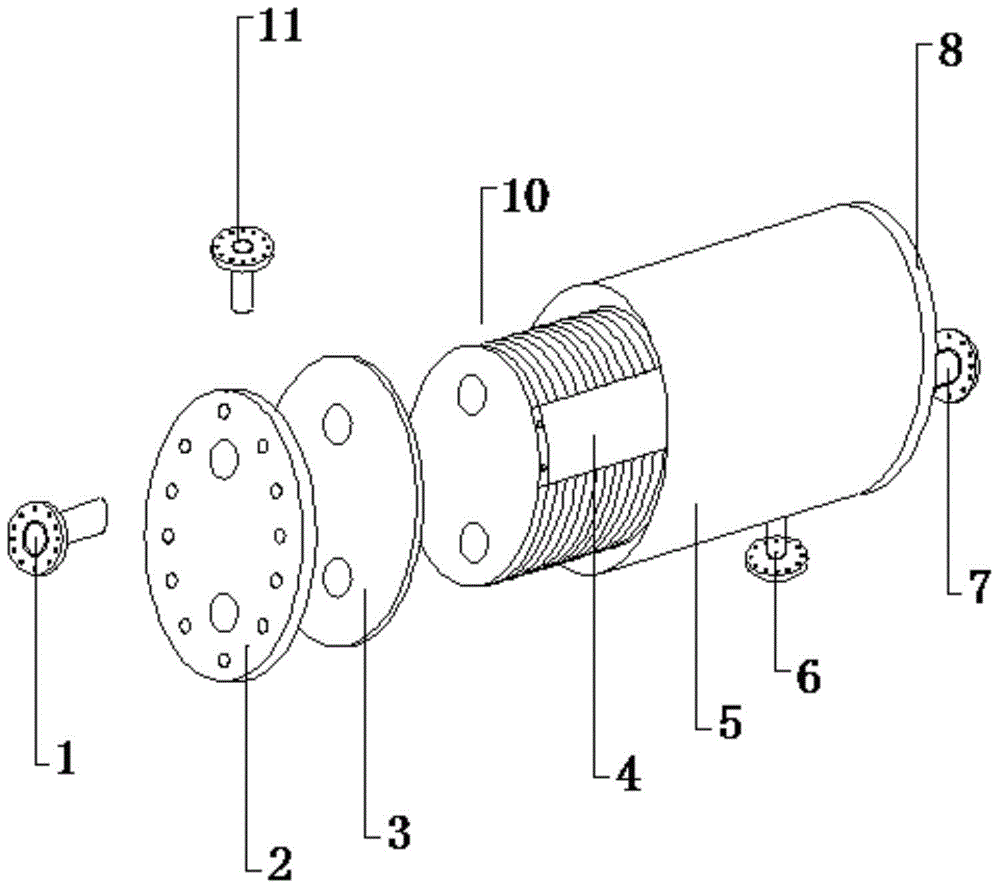

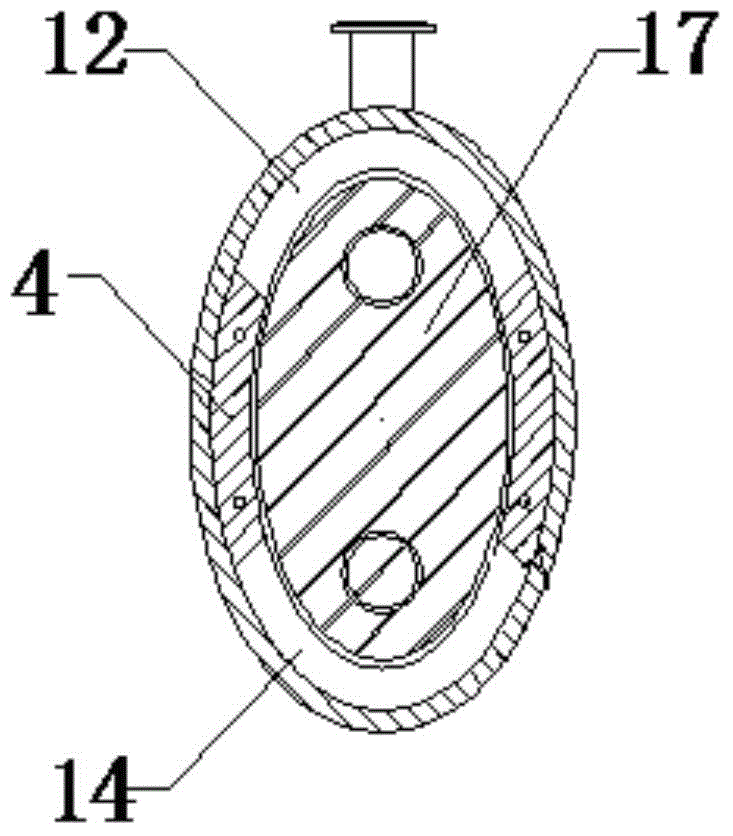

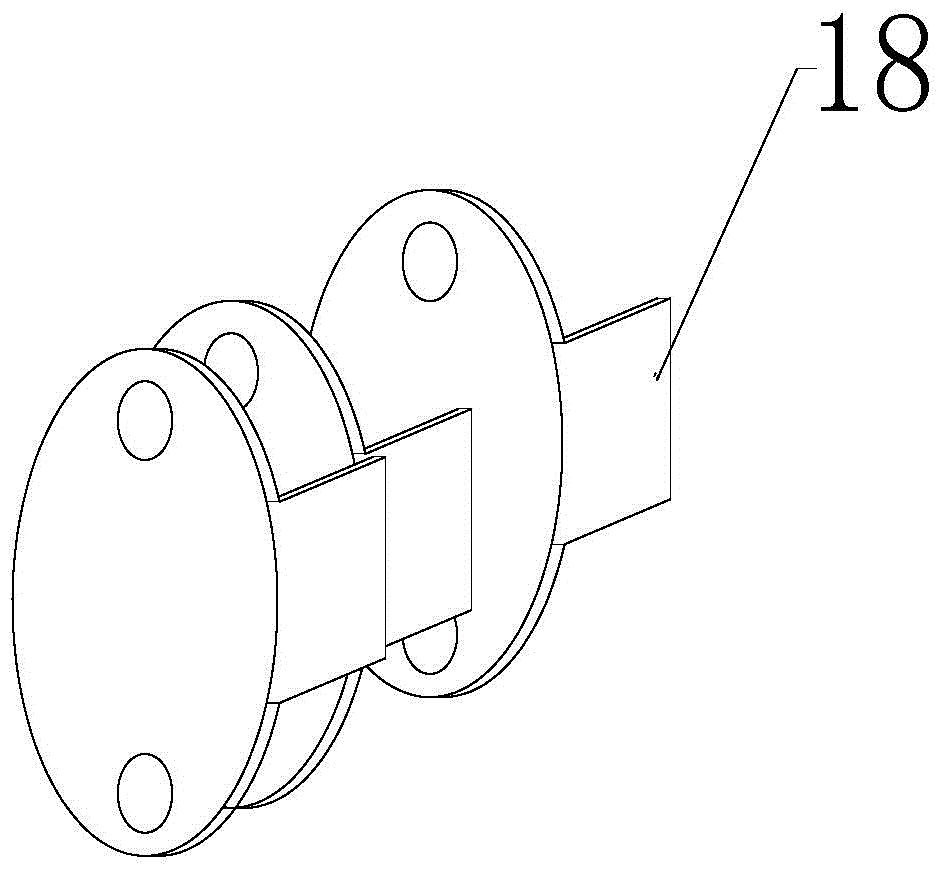

Plate-shell heat exchanger with oval corrugated plates

InactiveCN104089503AImprove heat transfer efficiencyReduce leakageLaminated elementsStationary plate conduit assembliesPlate heat exchangerEngineering

The invention relates to a plate-shell heat exchanger with oval corrugated plates. The multiple oval corrugated plates form a corrugated plate bundle, each corrugated plate is provided with two corner holes correspondingly, the corrugated plate bundle is arranged in a shell, the shell is provided with a plate pass inlet and a plate pass outlet, and the plate pass inlet and the plate pass outlet are communicated through the corner holes in the corrugated plates; a guide block is formed between the corrugated plate bundle and the shell and divides the annular area between the corrugated plate bundle and the shell into a shell pass inlet cavity and a shell pass outlet cavity; the shell is provided with a shell pass inlet and a shell pass outlet correspondingly. The plate-shell heat exchanger is characterized in that the corrugated plates are oval, and the two corner holes of each corrugated plate are formed in the upper portion and the lower portion of the corrugated plate respectively.

Owner:HARBIN ENG UNIV

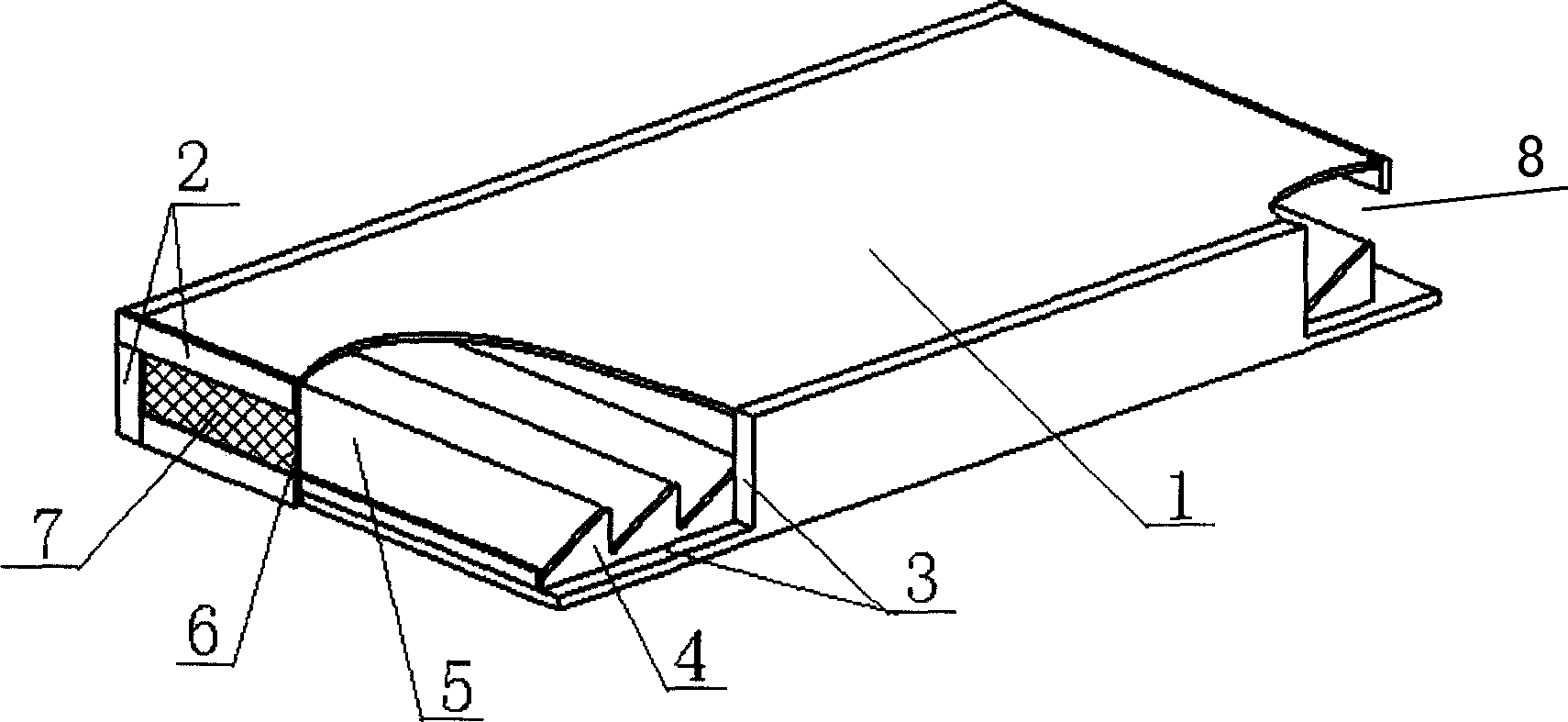

Solar air thermal collector with shutter type heat absorption plate core

InactiveCN101520239AAdjustable lengthAdjustable widthSolar heating energySolar heat devicesAir filtrationInsulation layer

The invention relates to the technical field of solar energy utilization, in particular to a solar air thermal collector which comprises a transparent cover plate, a sealed frame, a heat-insulation layer, a sawtooth-shaped bracket of a heat receiver strip, a strip plated with an anodic oxidation selective coating, an air filtering layer, an inlet of the air thermal collector and an outlet of the air thermal collector. The solar air thermal collector is mainly used for drying occasions with high flow, low running resistance and high efficiency. Air directly flows through a channel between a heat absorption plate core and the glass cover plate, and the heat receiver formed by the shutter type heat absorption plate core and the sawtooth-shaped bracket of the heat receiver strip not only have larger heat absorption area, but also cause perturbation to the flowing of air; the perturbation has less integral resistance for the flowing of air but has sufficient heat exchange, so that heat transfer is strengthened; the shutter type heat absorption plate core and the heat receiver strip are used as the heat receiver, therefore a reflect light part projected to a next heat absorption plate core strip is absorbed by a former heat absorption plate core strip, and the reflect ratio of a heat absorption surface is reduced; in addition, the heat absorption strips can be arranged to be at different inclination angles on the sawtooth-shaped bracket according to the requirement, and the inclination angles of the bracket can also be reduced in the practical application so as to save the material of the heater collector bracket. The air filtering layer is additionally arranged at an air inlet so as to make air in the thermal collector keep as clean as possible.

Owner:YUNNAN NORMAL UNIV

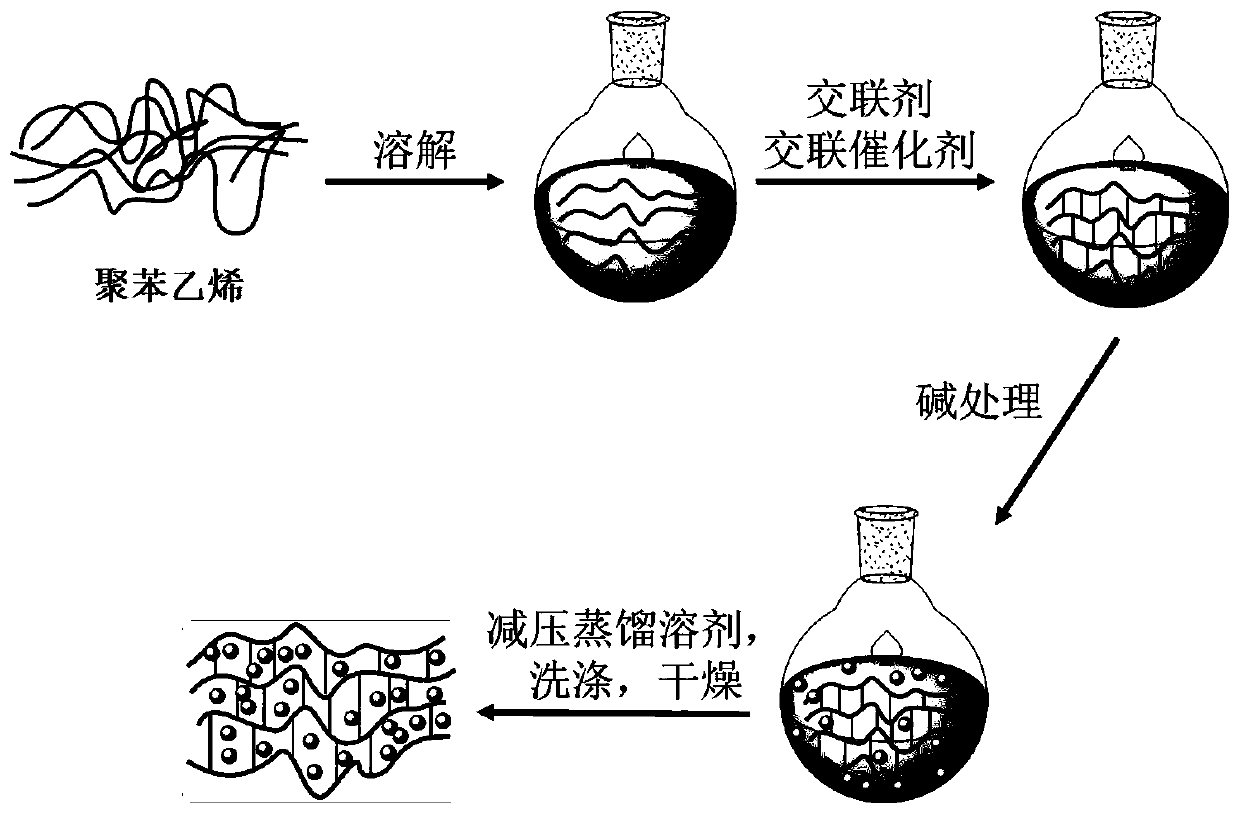

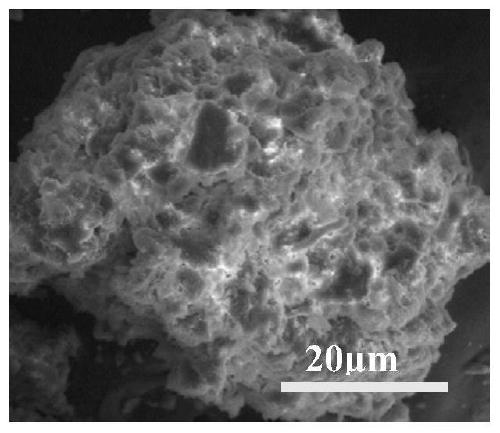

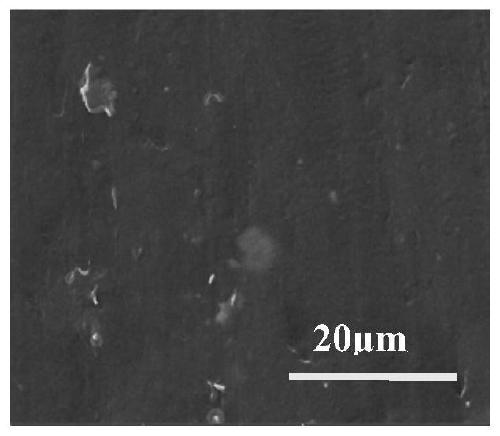

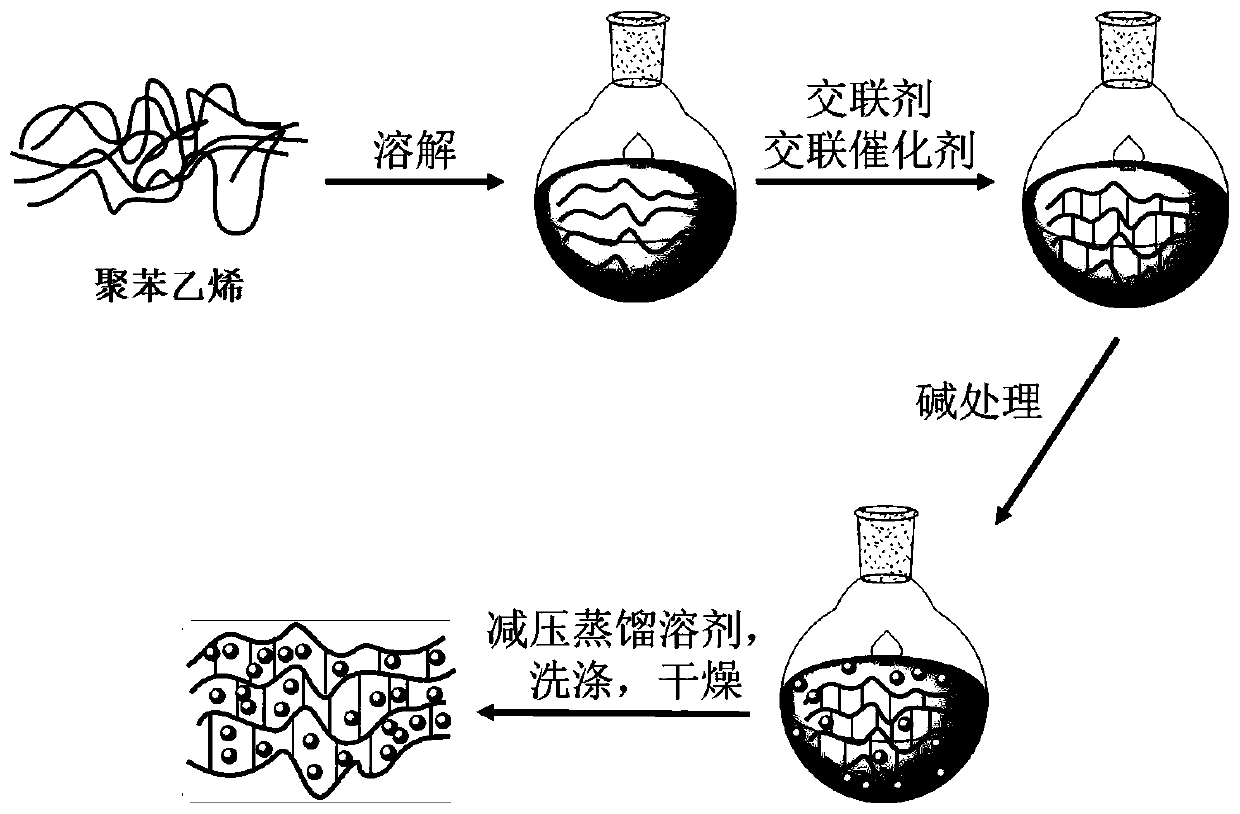

Preparation method of super-crosslinked polystyrene-supported organic phase change material and composite phase change material prepared by preparation method

ActiveCN109836598AHigh latent heatFully covered and efficientHeat-exchange elementsPolystyreneLewis acid catalysis

The invention discloses a preparation method of a super-crosslinked polystyrene-supported organic phase change material and a composite phase change material prepared by the preparation method. The preparation method comprises the following steps: dissolving polystyrene in a halogenated hydrocarbon solvent, then adding an organic phase change material into the dissolved polystyrene, stirring untilcompletely dissolved so as to obtain a mixed solution; adding a crosslinking agent and a Lewis acid catalyst to the mixed solution, stirring and reacting for 12-24 h, distilling off the excess solvent under reduced pressure after the reaction; dissolving residual solid in ethanol, carrying out ultrasonic dispersion under alkaline conditions for 0.5-1 h, and stirring for 10-18 h; and distilling off the solvent under reduced pressure after the reaction, and drying to obtain the product. By carrying out the forming step of the super-crosslinked high molecular weight skeleton and the coating stepof the phase change material simultaneously, efficient coating of the phase change material is guaranteed, and the material obtained has high latent heat and is not easy to leak; and the super-crosslinked catalyst is converted to a corresponding metal oxide under an alkaline condition without the need of removing the metal catalyst. The metal oxide obtained acts to enhance heat transfer.

Owner:CHINA UNIV OF MINING & TECH

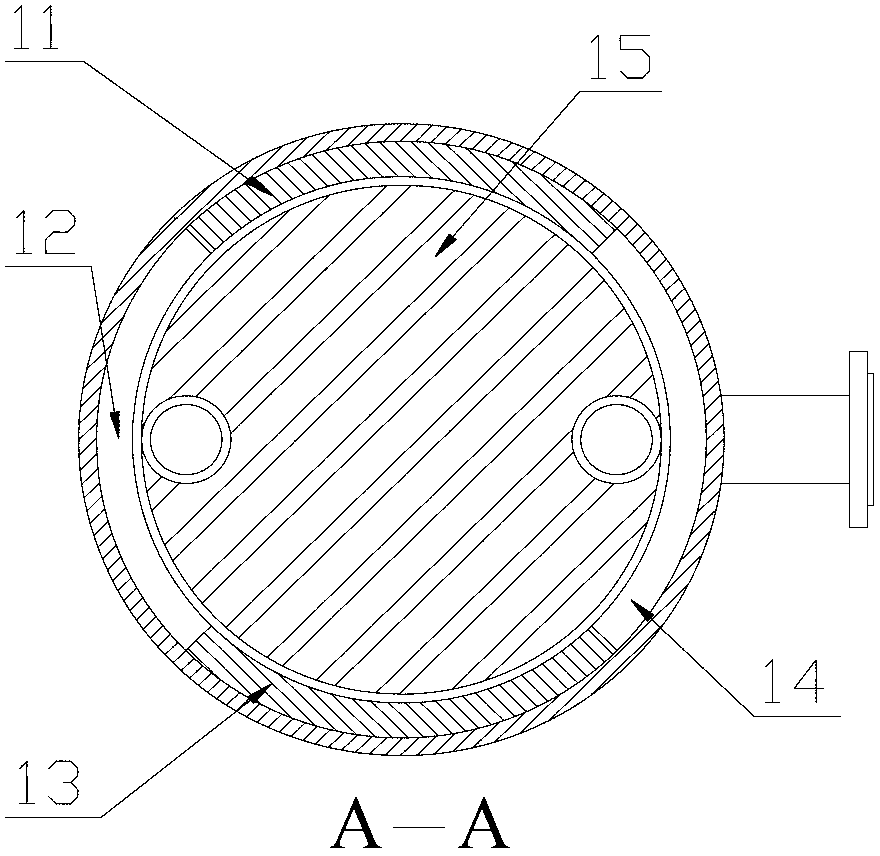

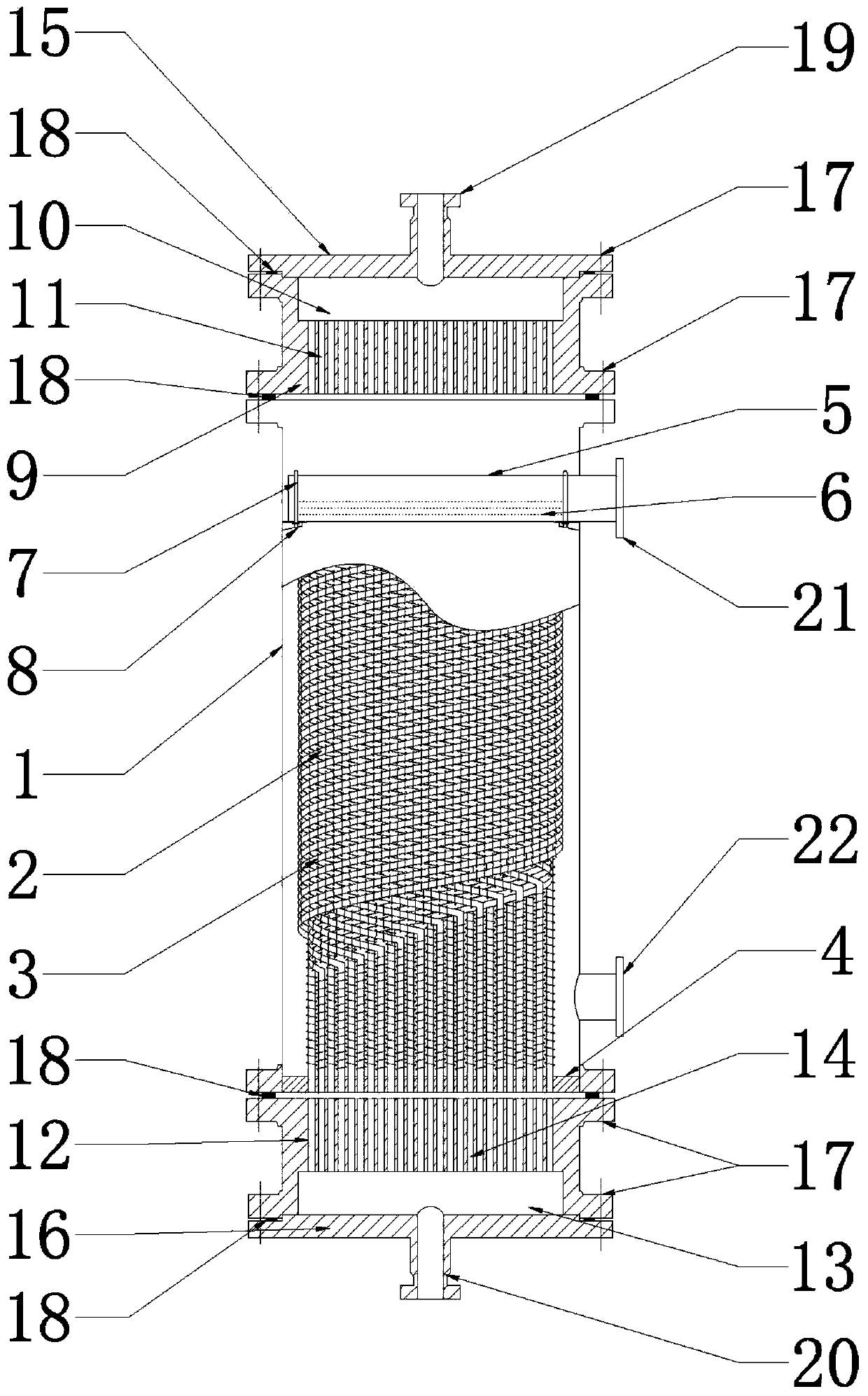

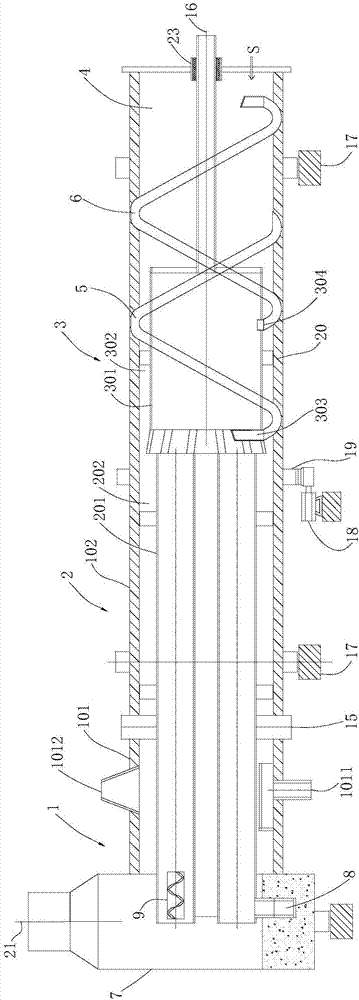

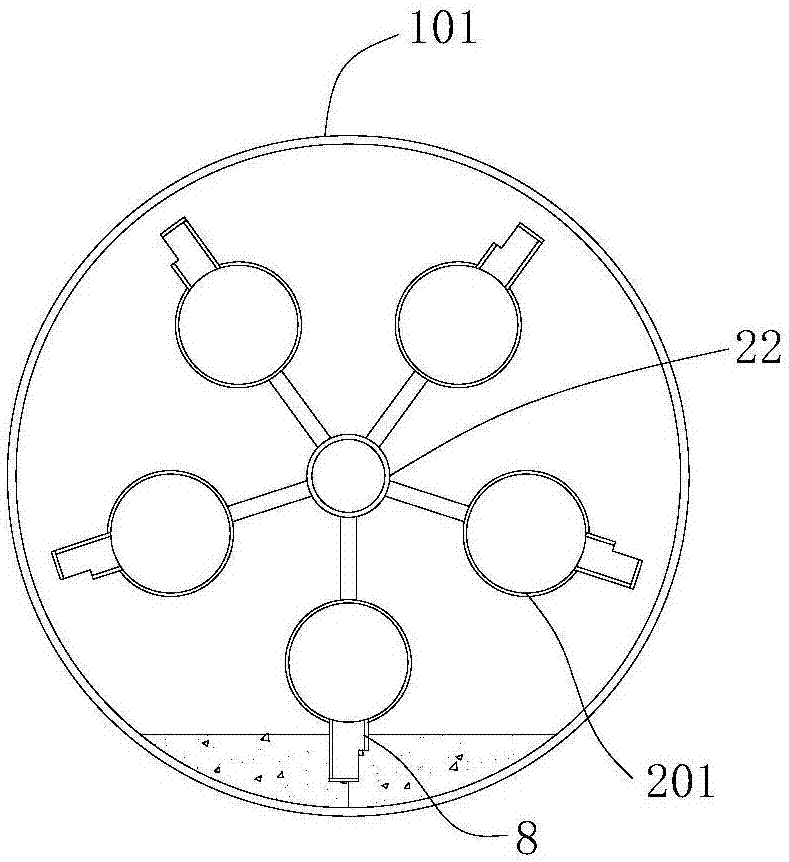

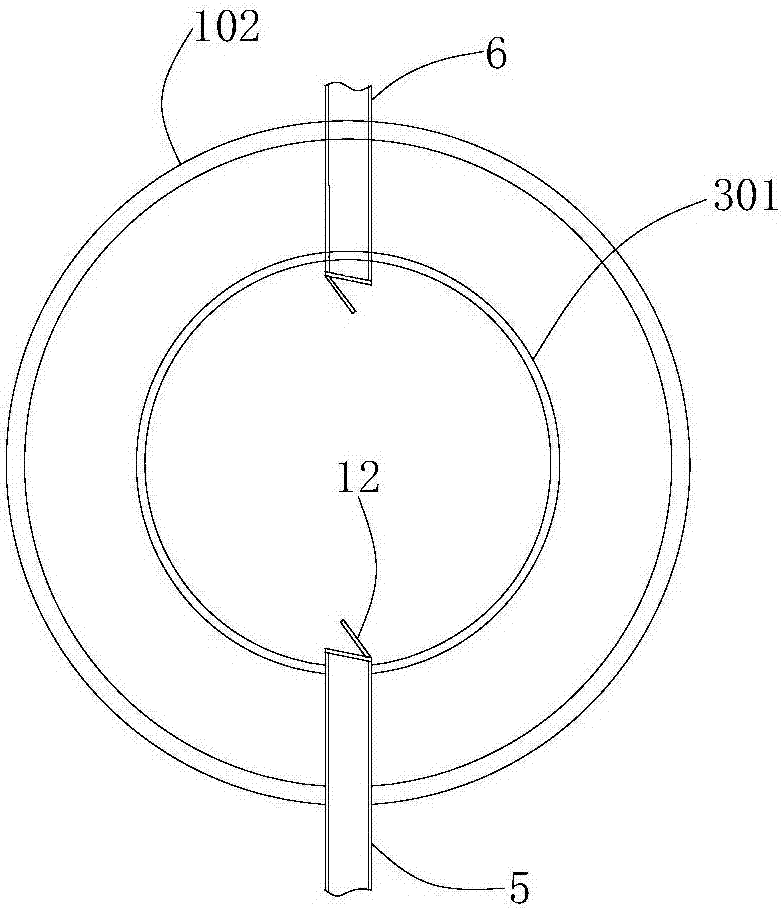

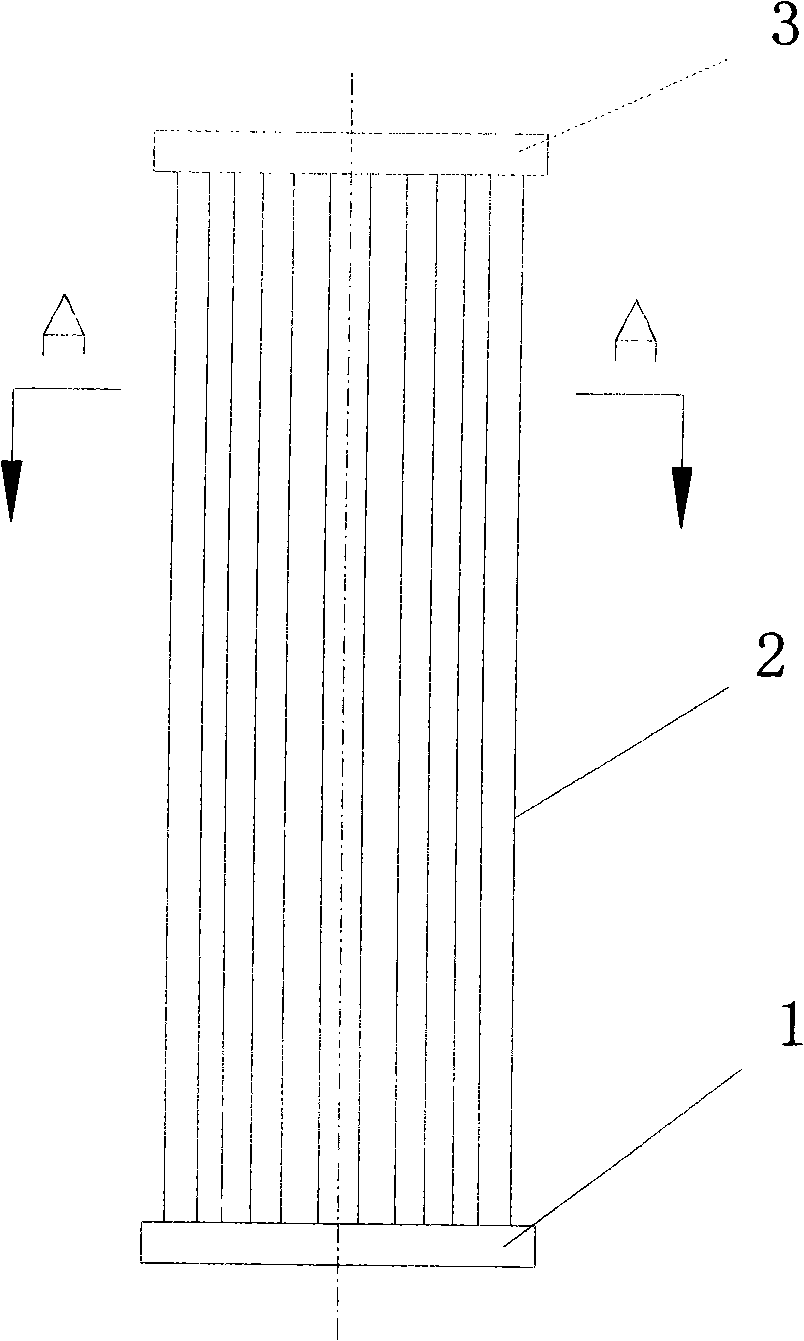

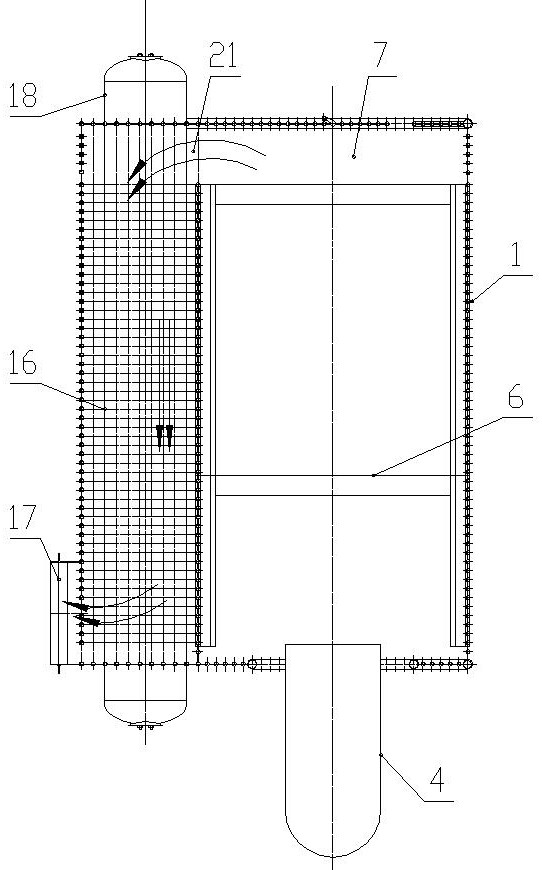

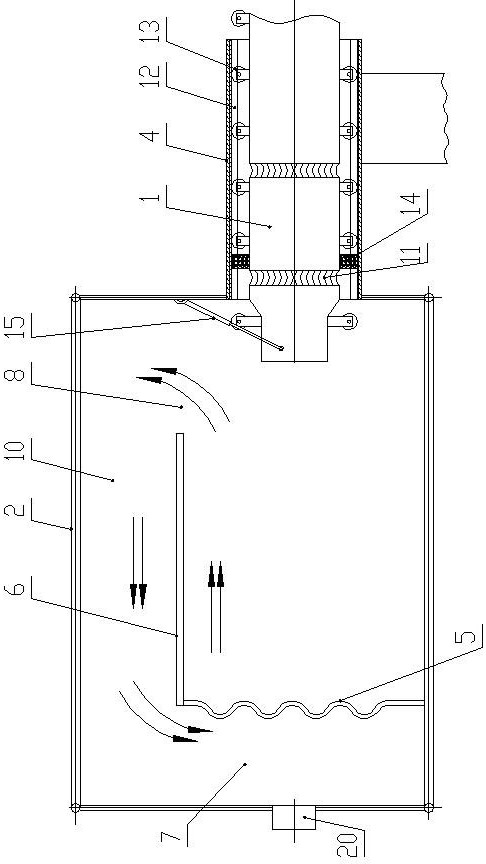

Spirally wound type quencher used for supercritical hydrothermal synthesis of nano powder

InactiveCN111521038ASmall footprintEnhanced heat transferStationary conduit assembliesHeat exchanger casingsPhysicsEngineering

The invention provides a spirally wound type quencher used for supercritical hydrothermal synthesis of nano powder. The spiral wound type quencher used for the supercritical hydrothermal synthesis ofthe nano powder comprises a cylinder, a plurality of layers of spirally wound heat exchange tubes are arranged in the cylinder, a spray pipe with a downward spray hole is arranged on the upper portionin the cylinder, the bottom end of each heat exchange tube communicates with a hot fluid inlet, the top end of each heat exchange tube communicates with a hot fluid outlet, the spray pipe is connected with a cooling water inlet, and the lower portion of the cylinder is provided with a cooling water outlet. Each layer of heat exchange tubes consists of a plurality of pipelines which are wound upwards or downwards in an inclined mode, the inclined directions of every two adjacent layers of heat exchange tubes are opposite, and spirals formed by winding are coaxial with the cylinder. Fins of a spiral structure can be arranged on the heat exchange tubes, a diversion collection box can be arranged at the bottom end of the cylinder, and a gathering collection box can be arranged at the top endof the cylinder. A spirally wound type heat exchanger structure is adopted, a spray structure is additionally arranged, heat exchange is enhanced, and the cooling efficiency of the quencher is improved. The heat exchange area is fully utilized, the occupied area of the quencher is greatly reduced, and the quenching requirement of the supercritical hydrothermal synthesis of the nano powder is met.

Owner:XI AN JIAOTONG UNIV

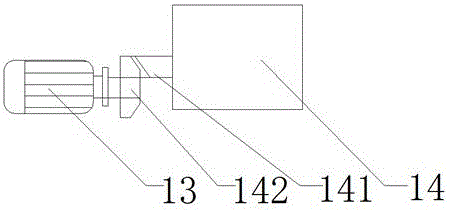

Efficiency natural gas directional flow heating system

PendingCN108468897AImprove heating efficiencyEffective destructionThermal insulationPipe heating/coolingEngineeringThermal efficiency

The invention discloses an efficient natural gas directional flow heating system, and relates to the technical field of heating systems. The efficient natural gas directional flow heating system comprises an adjusting module and an induction coil wound outside a heat exchange tube. The heat exchange tube comprises a natural gas inlet and a natural gas outlet, the heat exchange tube is provided with a temperature detection instrument at the natural gas outlet, and the adjusting module detects the temperature according to the temperature detected by the temperature detection instrument to adjustthe working current, power and other parameters of the induction coil. A directional flow device for guiding natural gas to the position of a heat exchange wall is arranged inside the heat exchange tube. According to the scheme, compared with other methods heating from outside, the efficient natural gas directional flow heating system has advantage that the heating speed is fast, the heating timeis only 10% -20% of that of other heating methods, the heating uniformity is high, and the heat efficiency is high.

Owner:辽宁华燃新能源科技有限公司

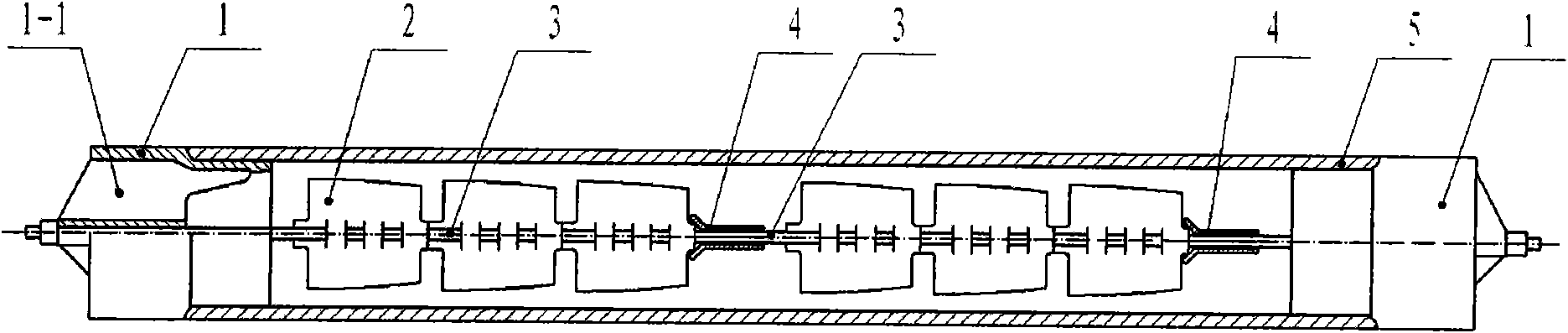

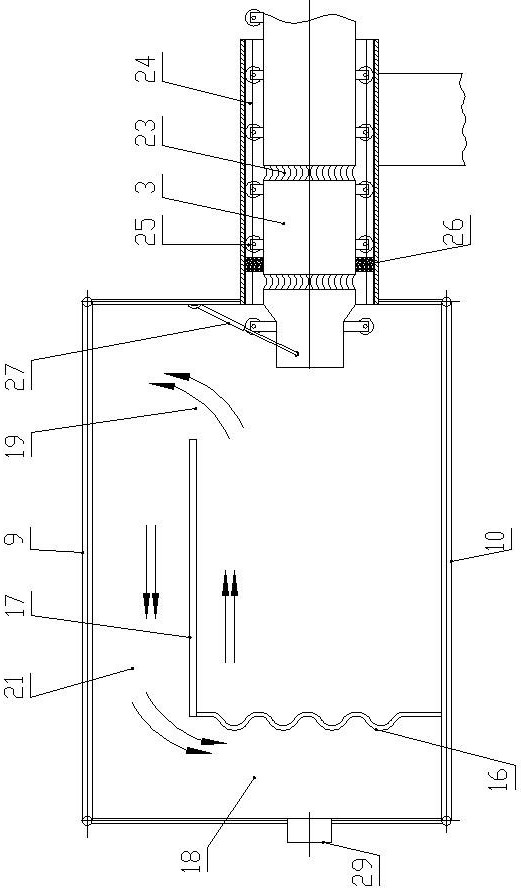

Overall rotary type solid thermal carrier retort

InactiveCN107384456AAvoid secondary decompositionFast pyrolysisIndirect and direct heating destructive distillationSpecial form destructive distillationCombustion chamberBiochemical engineering

The invention relates to the technical field of powdered coal pyrolysis equipment, and in particular discloses an overall rotary type solid thermal carrier retort which comprises a retort outer cylinder, wherein a preheating chamber, a destructive distillation chamber and a combustion chamber are arranged inside the retort outer cylinder; the destructive distillation chamber comprises an inner cylinder fixedly connected with the retort outer cylinder; at least one preheating tube is arranged inside the preheating chamber; one end of the preheating tube is communicated with the inner cylinder of the destructive distillation chamber; a high-temperature semicoke feeding hole is formed in one end, close to the preheating tube, of the inner cylinder; a pyrolysis semicoke discharge hole is formed in the other end of the inner cylinder; the high-temperature semicoke feeding hole is communicated with a first return material channel; the other end of the first return material channel is communicated with the combustion chamber; the pyrolysis semicoke discharge hole is connected with a second return material channel; the other end of the second return material channel is communicated with the combustion chamber. By adopting the overall rotary type solid thermal carrier retort disclosed by the invention, powdered coal is preheated in an indirect heating mode with heat conduction intensification measures, and rapid pyrolysis of the powdered coal is achieved through direct blending and mixing of a solid thermal carrier and preheated raw coal.

Owner:北京广厦环能科技股份有限公司

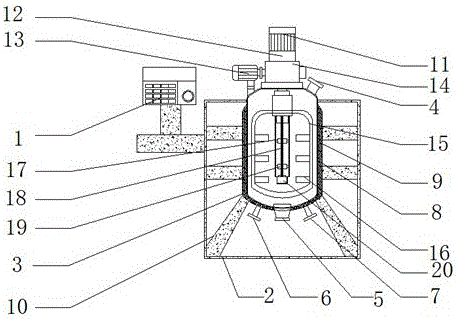

Uniform mixing and stirring apparatus of pesticide emulsion containing surfactant

InactiveCN106422826AControl reaction temperatureImprove stabilityMixing methodsTransportation and packagingEmulsionDrive shaft

The invention discloses a uniform mixing and stirring apparatus of a pesticide emulsion containing a surfactant. A heat exchange coil tube is arranged on the inner wall of a stirring apparatus body, a heat insulation jacket is arranged on the outer wall of the stirring apparatus body, a high-shear emulsifying machine is arranged at the upper end of a gear device, and is in transmission connection with a driving shaft, a gear speed reducer is arranged at the left side of the upper end of the stirring device and is arranged at the left side of the gear device, an outer frame stirrer is arranged in the stirring apparatus body, a stirring shaft is arranged in the middle of the upper end of the outer frame stirrer, the output shaft of the high-shear emulsifying machine is arranged at the inner side of the stirring shaft, a propeller blade is fixedly connected with the output shaft of the high-shear emulsifying machine, and an emulsifying head is arranged at the lower end of the stirring shaft. The uniform mixing and stirring apparatus of the pesticide emulsion containing the surfactant has the advantages of good safety and reliability, production cost reduction, uniformity in stirring, no blind angles, and simplicity in operation.

Owner:李芹

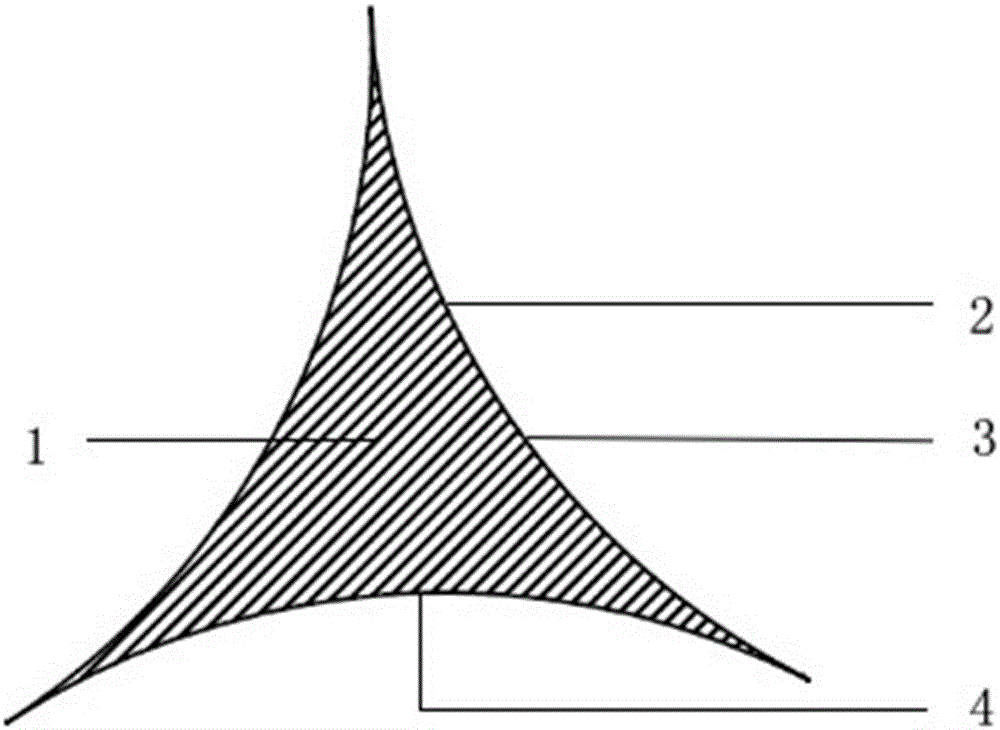

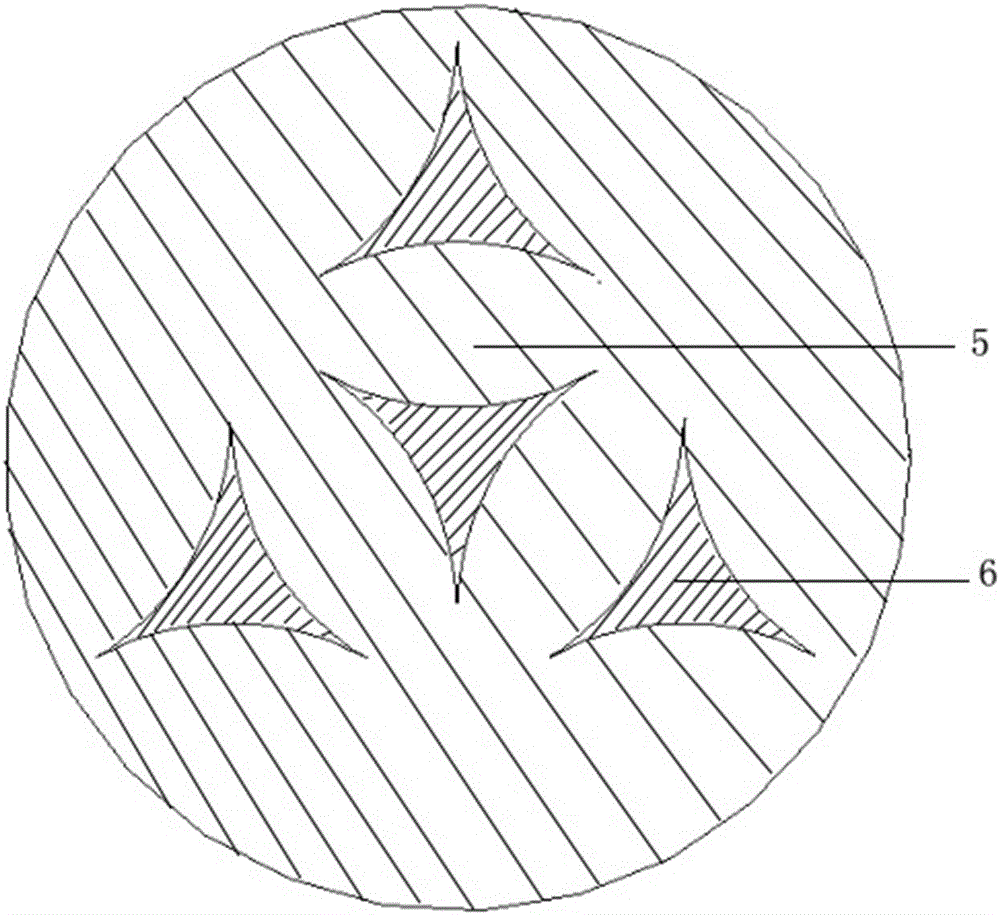

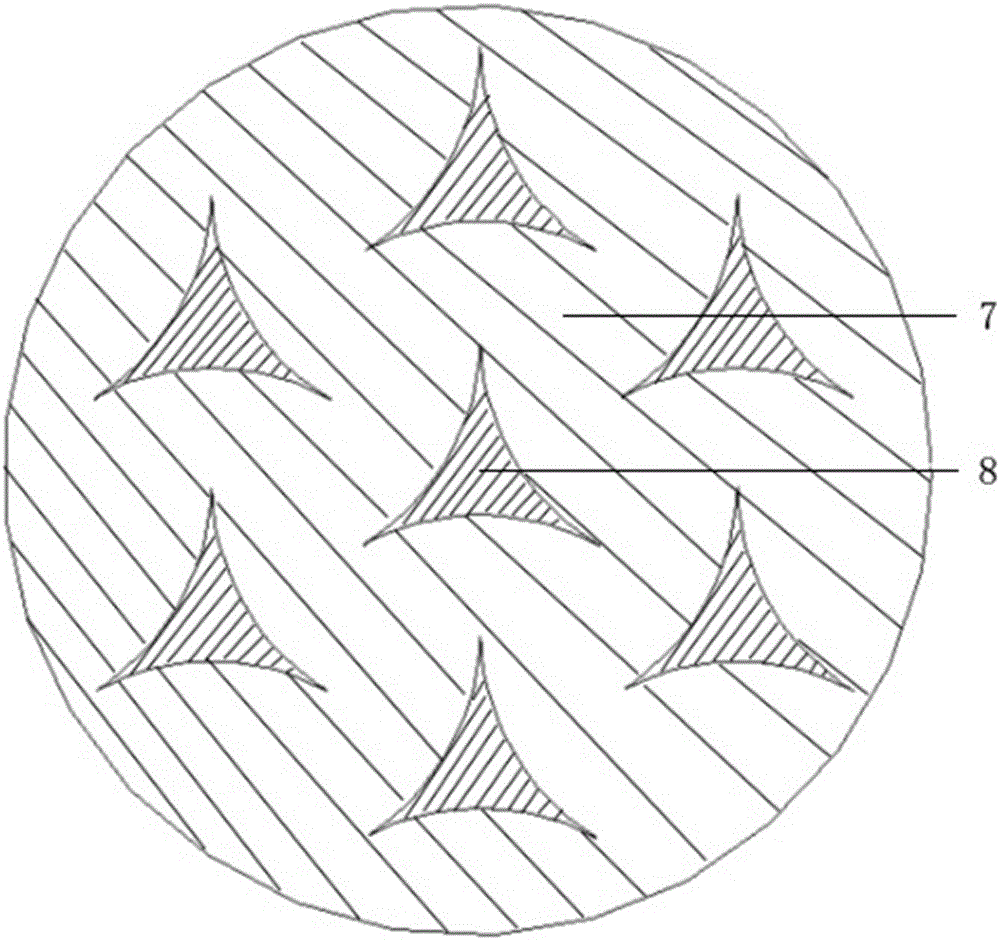

Novel heat exchange tube

InactiveCN105698583AImprove compactnessIncrease the areaCorrosion preventionHeat transfer modificationTrombe wallEngineering

A new type of heat exchange tube, the heat exchange tube includes: flow channel (1), tube wall (2), tube wall (3), tube wall (4); the cross-sectional shape of the tube is composed of three equal circles with a radius of 25mm Formed by two circumcisions; the heat exchange tubes are composed of two different arrangements: regular triangle arrangement and regular hexagonal arrangement. The unique shape of the heat exchange pipe of the invention can increase the intensity of turbulent flow, strengthen the heat exchange effect, and improve the heat exchange performance. Compared with ordinary round pipes, the heat exchange coefficient is increased by nearly 50%. At the same time, the structure is relatively simple, it is not easy to scale, and it is more convenient to clean after scaling.

Owner:SHANGHAI OCEAN UNIV

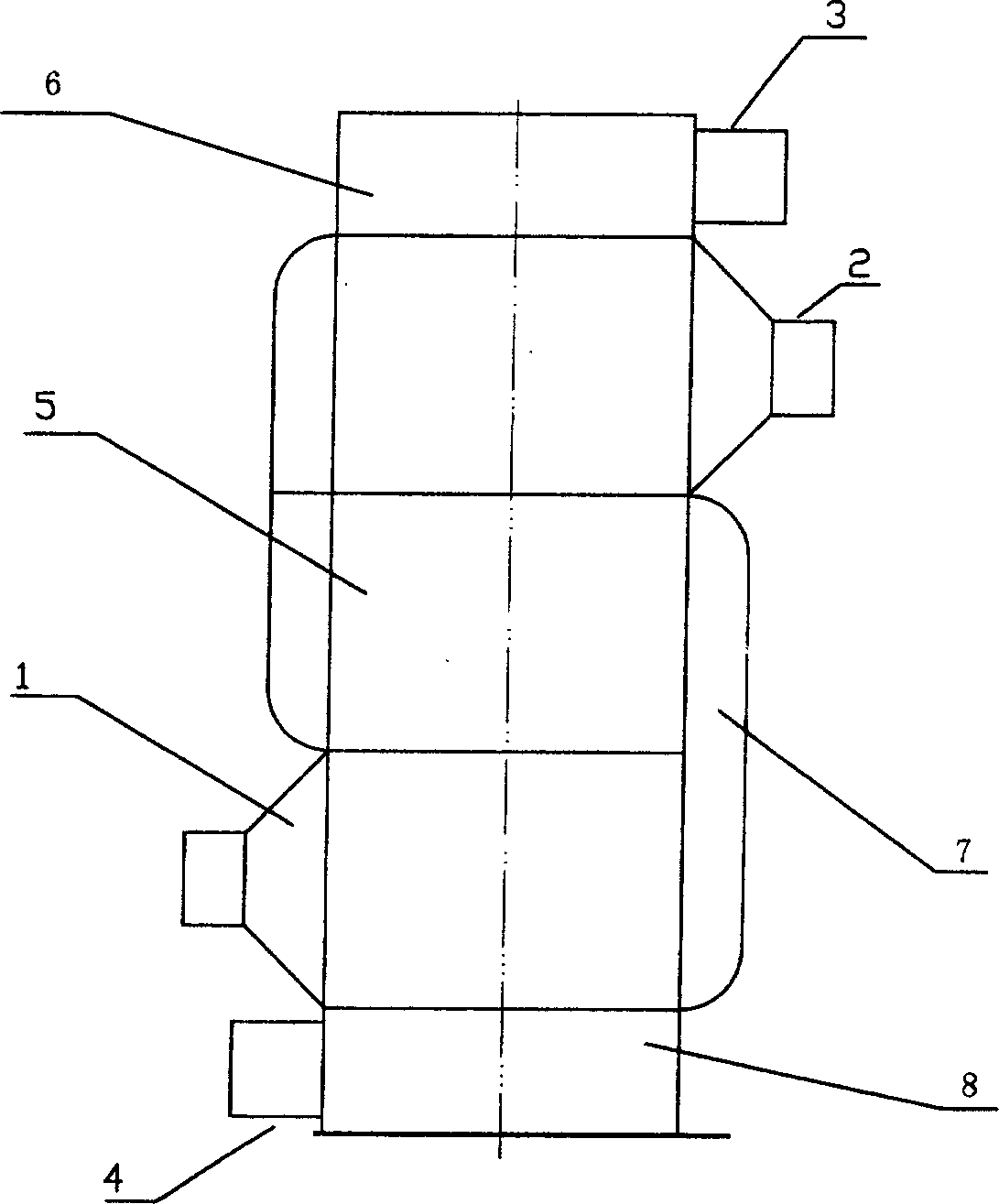

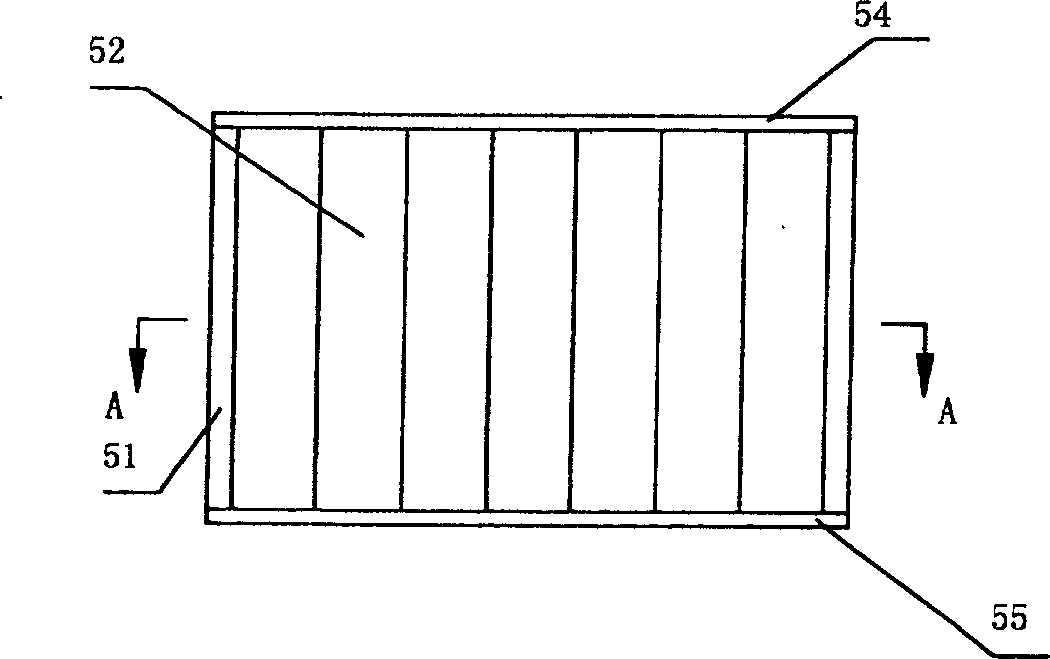

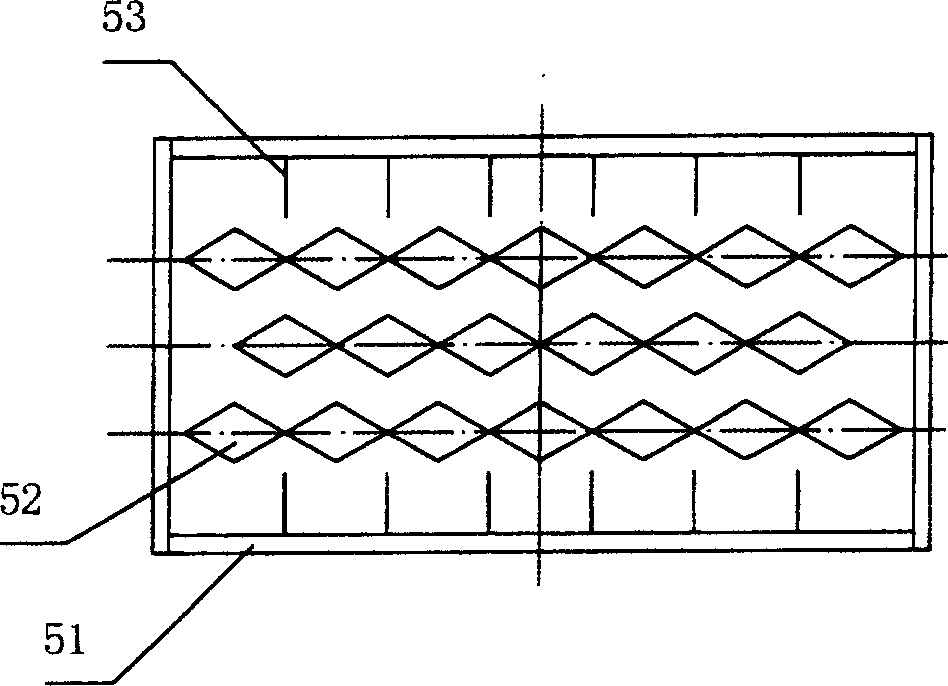

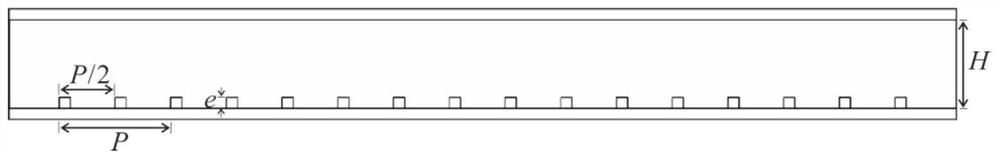

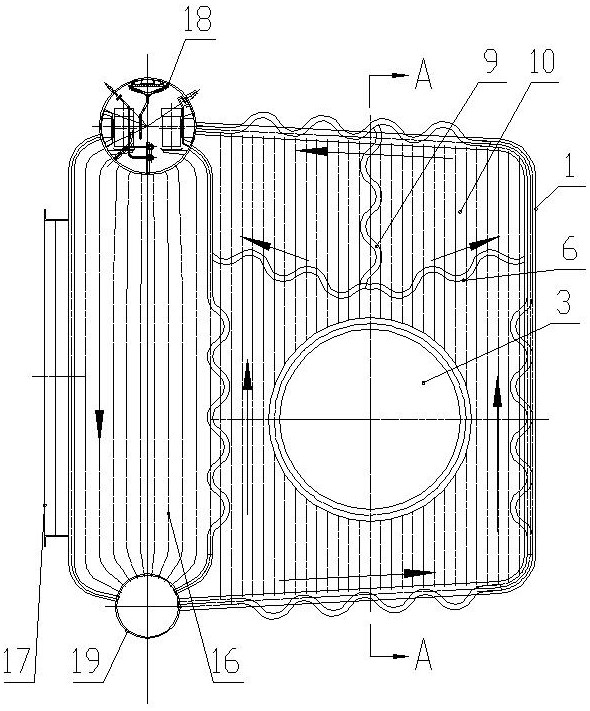

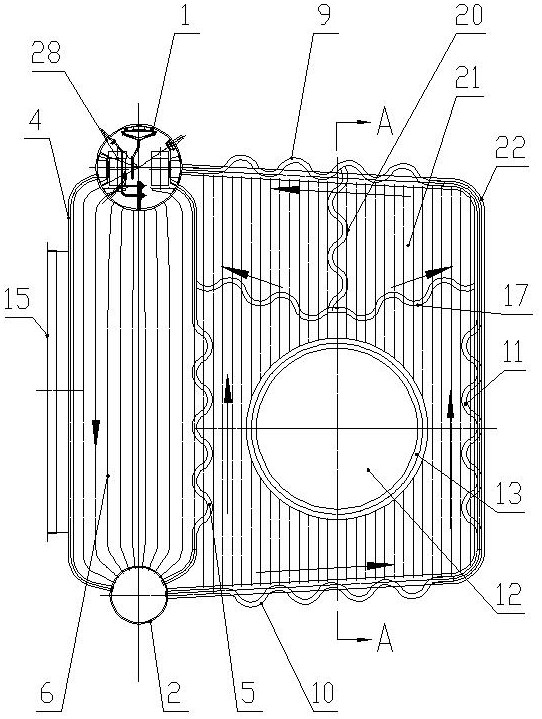

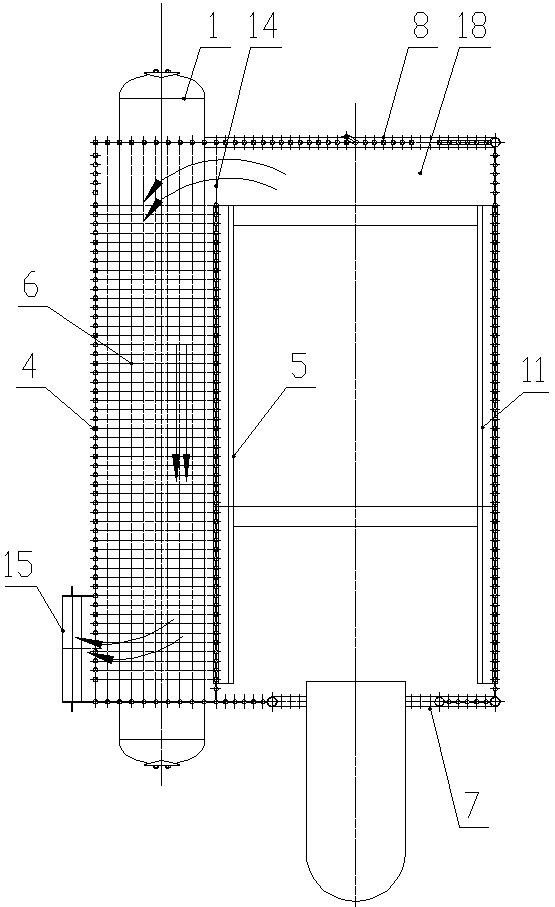

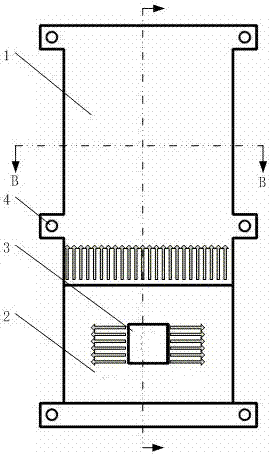

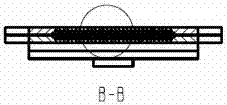

Wave plate pipe heat exchanger with transerse rib

InactiveCN1587883APlay a role in enhancing heat transferPromotes turbulent flowLaminated elementsStationary plate conduit assembliesRough surfaceWave shape

The invention provides a wave-shaped plate with cross rib tubular type heat exchanger, comprising shell, wave-shaped plate with cross rib, upper and lower tube plates which are connected together, fluid state inside and outside the wave-shaped plate with cross rib both flows along rough rib surface optimized which can promote turbulent flow of fluid on boundary layer and intensification of heat transfer effect to the fluid. The invention with wide plate spacing, is suitable for heat exchange between hot-cold gas fluid with low ordinary pressure and large volume, and has the advantages that overall coefficient of heat transfer is high, heat exchange effect is excellent, materials needed are few, investment to apparatus is low, convenient to produce and apply.

Owner:SOUTH CHINA UNIV OF TECH

Rotating piece type automatic-cleaning and heat-transfer enhancing device

InactiveCN101551214BLow rotational resistanceSave materialHeat transfer modificationRotary device cleaningEngineeringDual function

The invention relates to a rotating piece type automatic-cleaning and heat-transfer enhancing device, in particular to a device used for a heat transfer pipe for a tubular heat exchange device. The device comprises one or more rotating piece(s), hanging parts, an axial line and limiting rivets and is used by being placed in a heat exchanger, wherein the number of the hanging parts is two, and thetwo hanging parts are respectively fixed at both ends of the heat transfer pipe; the rotating pieces are placed in the heat transfer pipe of the heat exchanger; the rotating pieces are used and arranged in groups, and the limiting rivets are arranged between each group of the rotating pieces at intervals; the axial line penetrates through an axle holes of the rotating pieces and the limiting rivets, and both ends of the axial line are fixed on the two hanging parts; the rotating pieces are of screw twisted shapes, concavo-convex slot structures are alternatively arranged at the position of theaxial line at intervals and are axle holes of the axial line, the friction between the rotating pieces and the axial line can be effectively reduced, thus the service life of the rotating pieces is prolonged; and the rotating pieces have simple molds, can be made of plastics or metal and can be molded by pressing or by injection according to the different materials. The device has the dual functions of automatic on-line cleaning and scaling control and enhancing heat transfer in the heat transfer pipe and is convenient to manufacture, assemble, use and replace.

Owner:BEIJING UNIV OF CHEM TECH

Downcomer having membrane type wall structure

InactiveCN101298570AAvoid burnsIncrease contactCombustible gas productionManufacturing cost reductionEngineering

In a film wall-structure falling pipe, the pipe wall of the falling pipe adopts film wall structure, i.e. the pipe wall of the falling pipe is completely or partially constructed by arranging a plurality of thin pipes. The upper and lower ends of the thin pipe constructing the film wall are connected with an upper header and a lower header respectively. Circulating cooling water is communicated in the upper header, the thin pipes and the lower header. The thin pipes are smooth straight pipes or corrugated pipes, and the adopted arrangement mode is vertical arrangement, or horizontal arrangement, or serpentine circuitous arrangement. The thin pipes are sequentially connected or connected at intervals by a welding method; the thin pipes connected at intervals are connected by using flat steel. By adopting the film wall-structure falling pipe, the pipe wall can be effectively prevented from the damage of high temperature gas or melting slag. The surface area of the film wall-structure falling pipe is larger than that of the existing barrel-type falling pipe, thus enlarging the contact between a falling liquid film and the high temperature gas and playing the role of heat transfer enhancement. The film wall-structure falling pipe can be manufactured by adopting common steels, thus dramatically reducing the manufacturing cost.

Owner:SOUTHEAST UNIV

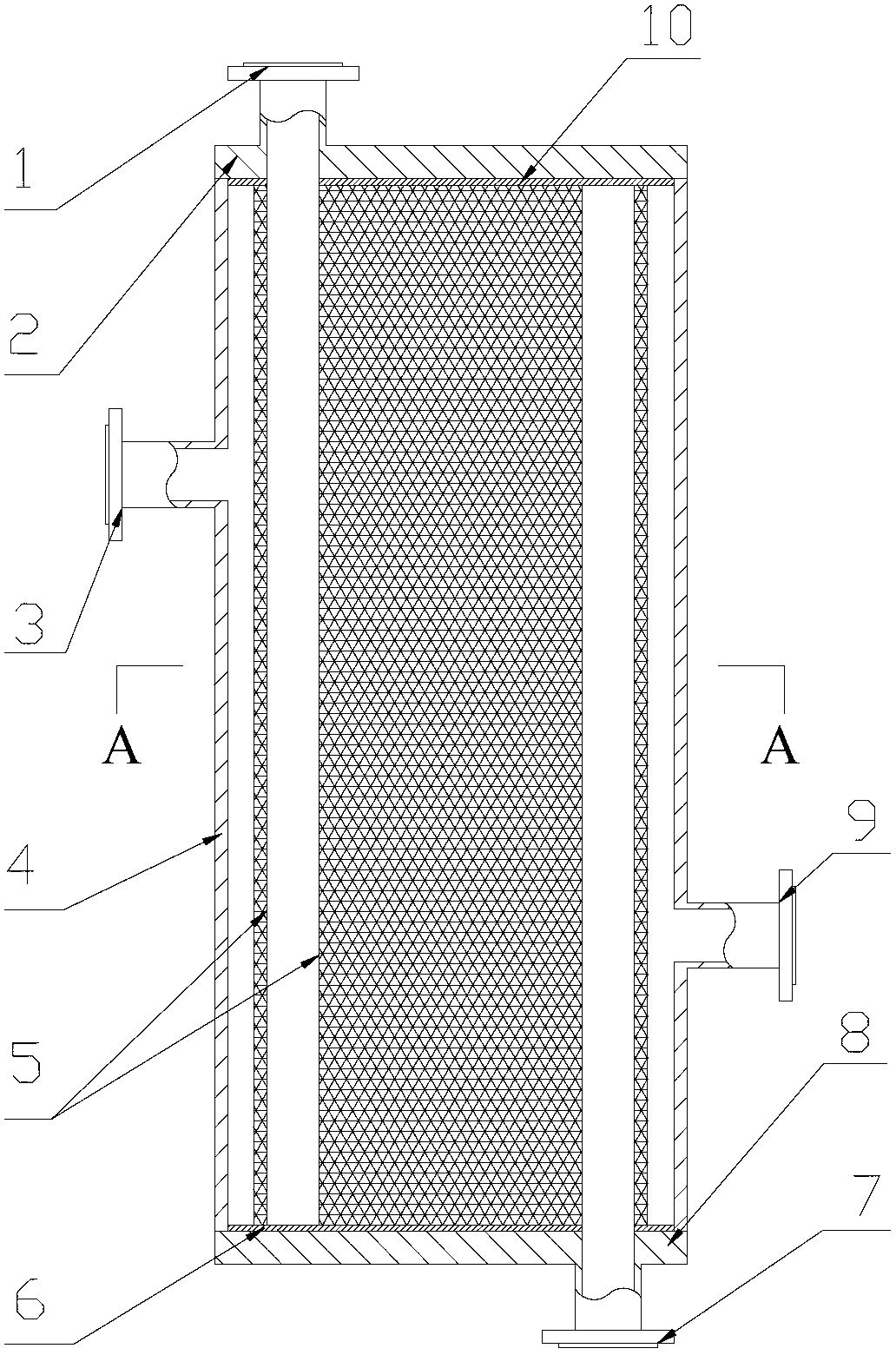

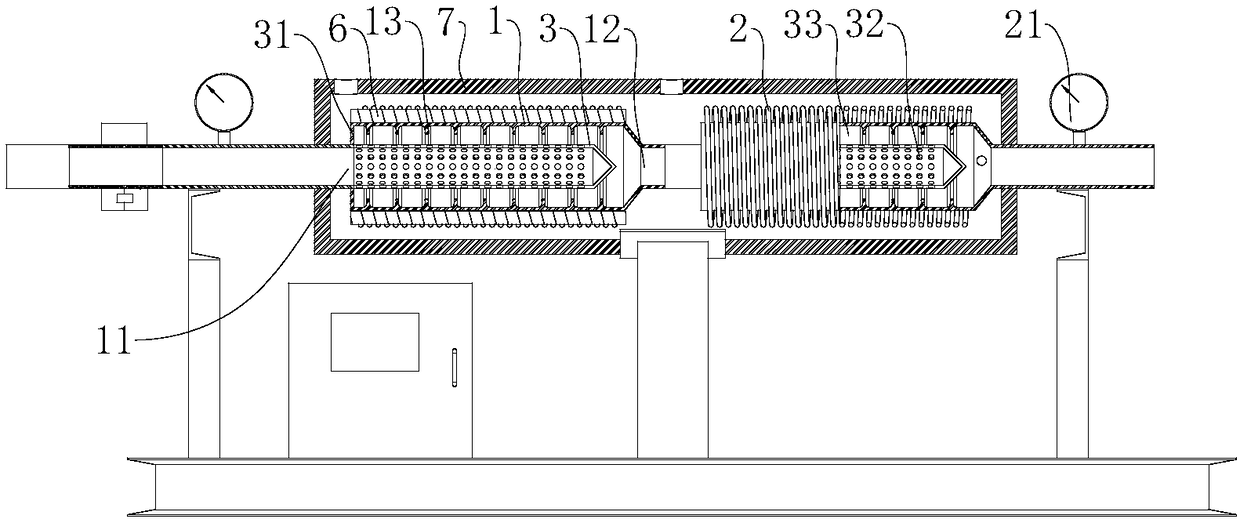

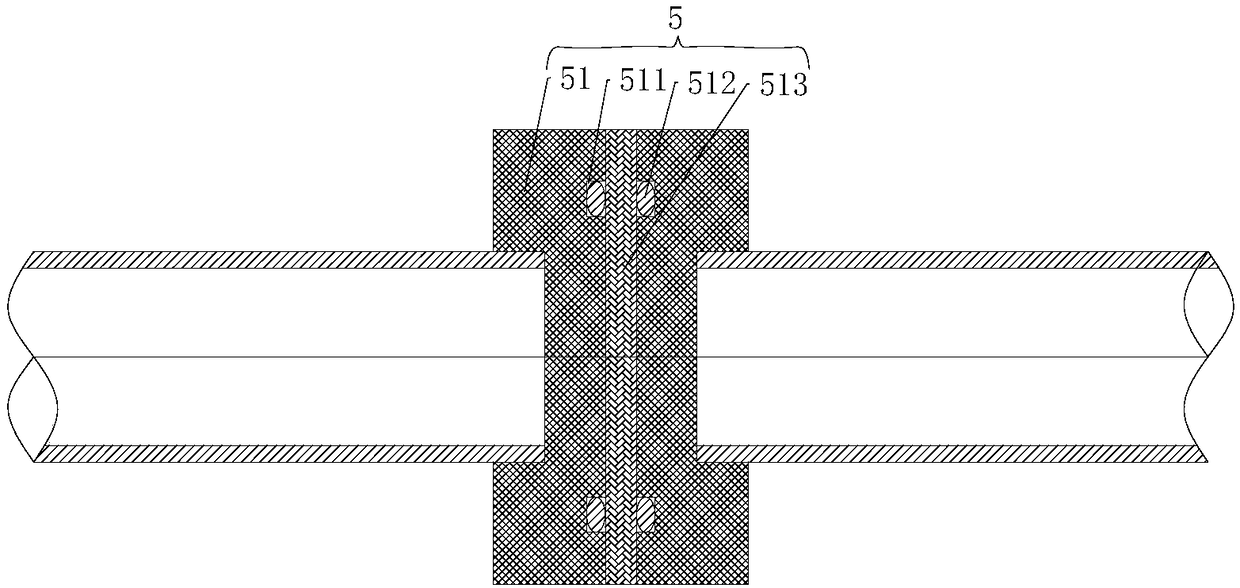

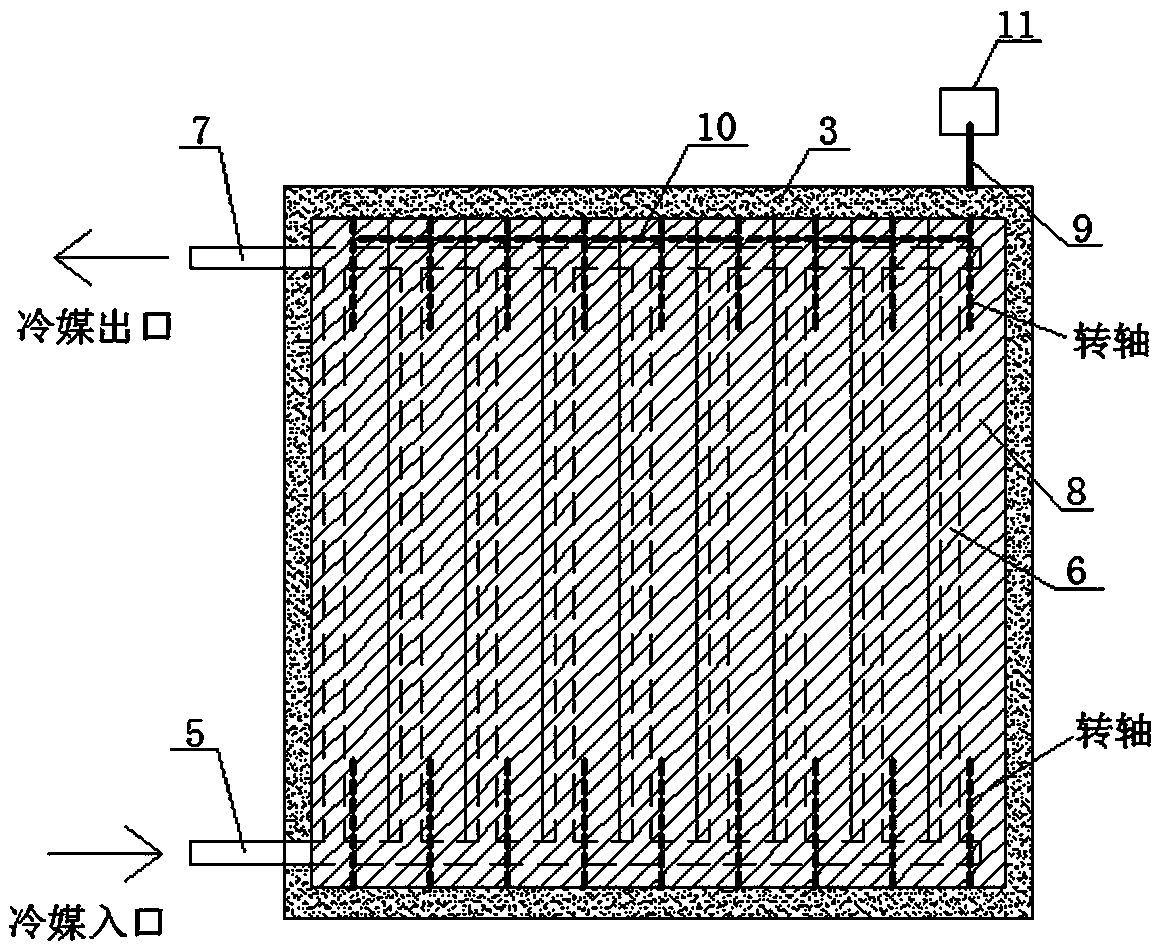

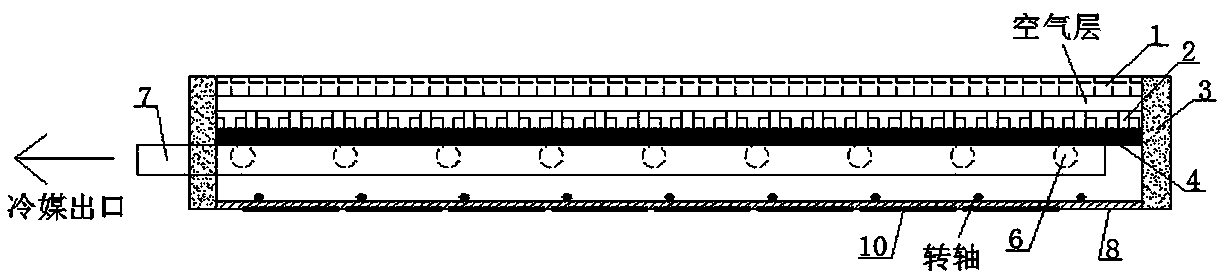

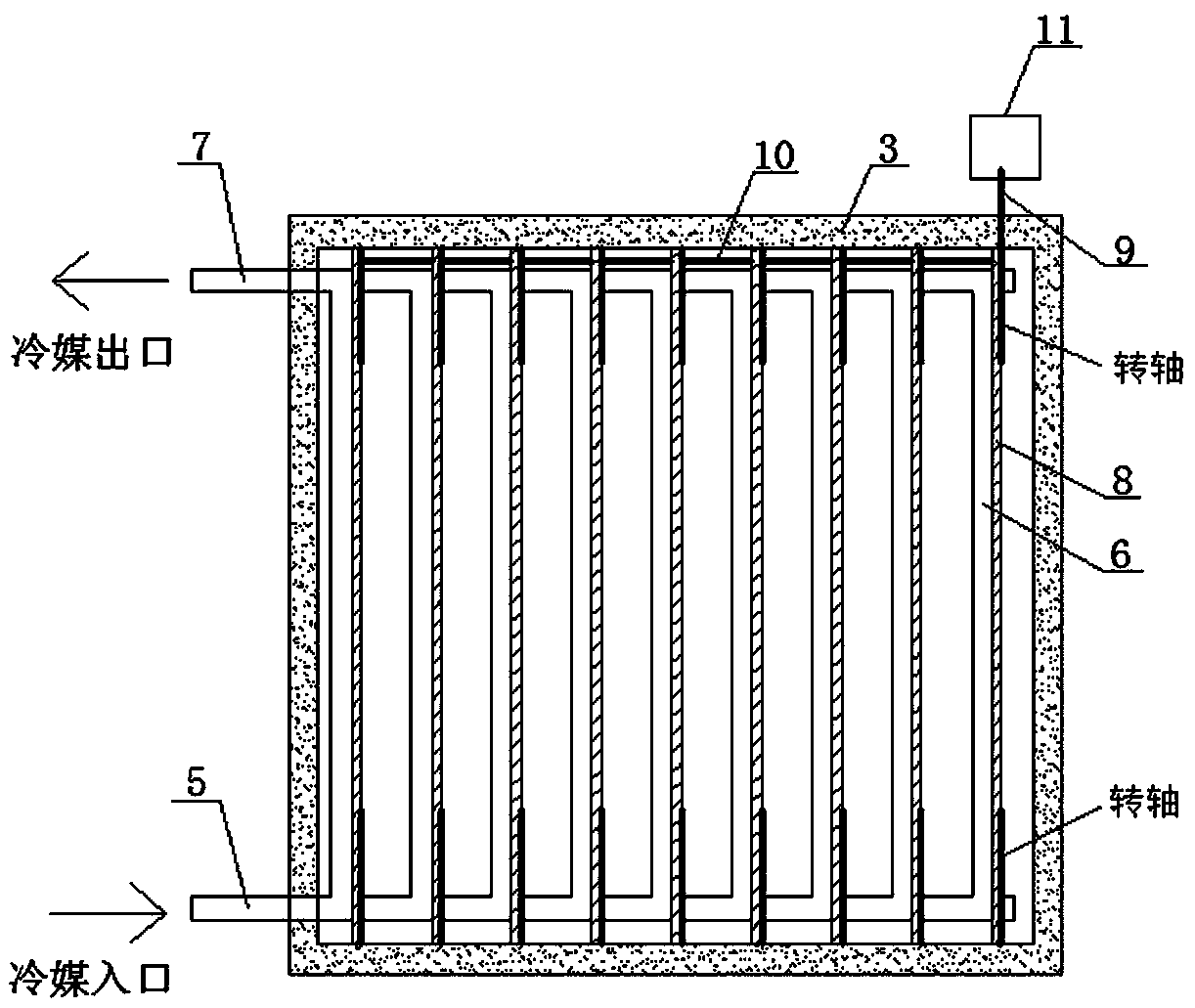

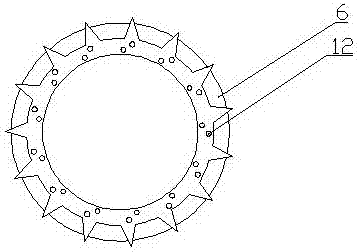

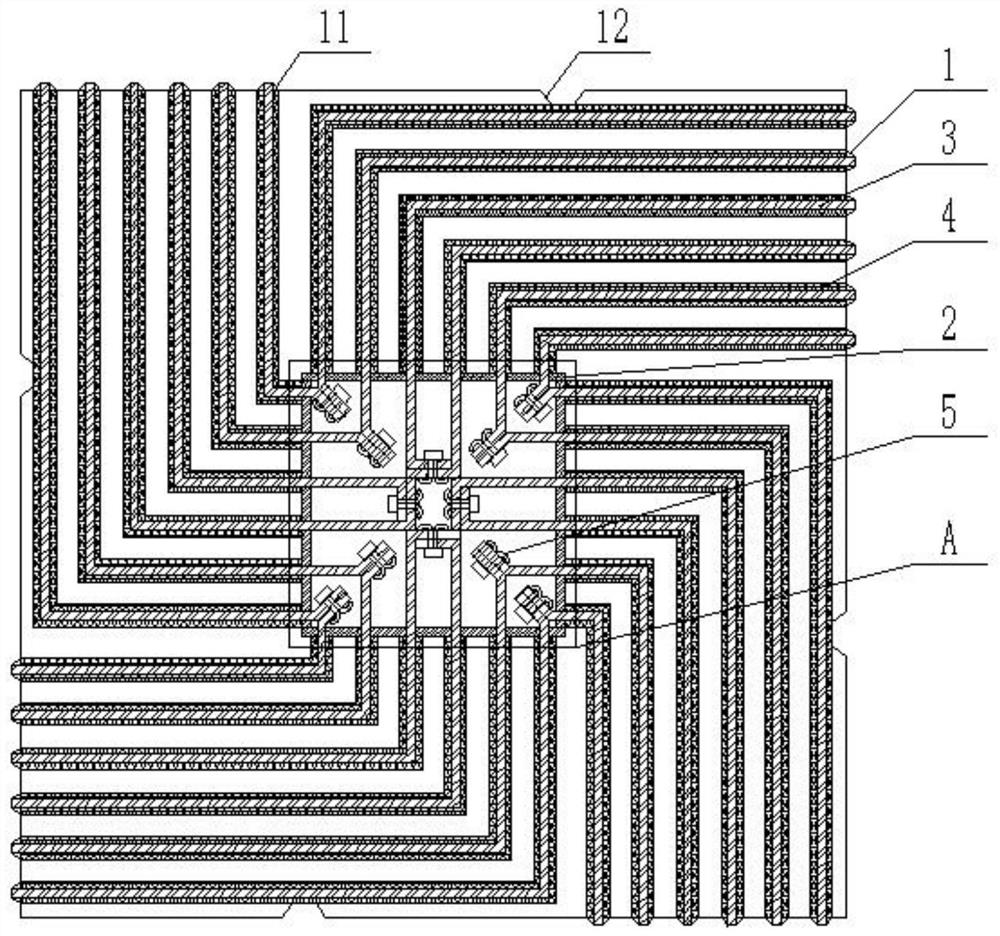

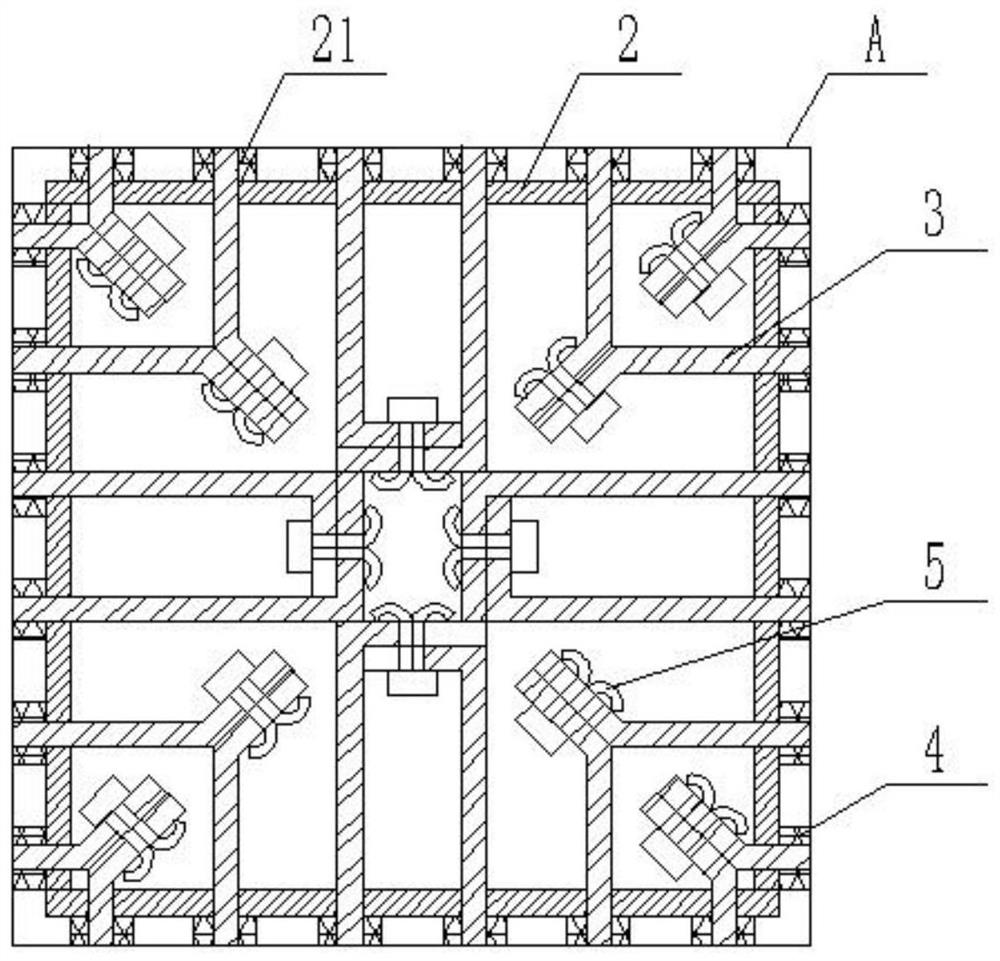

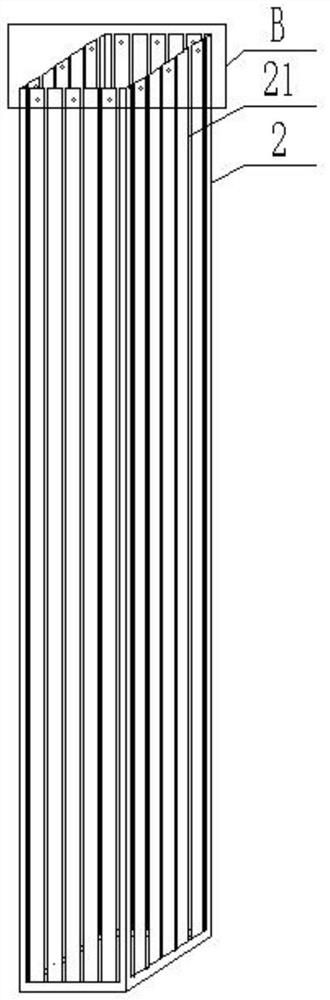

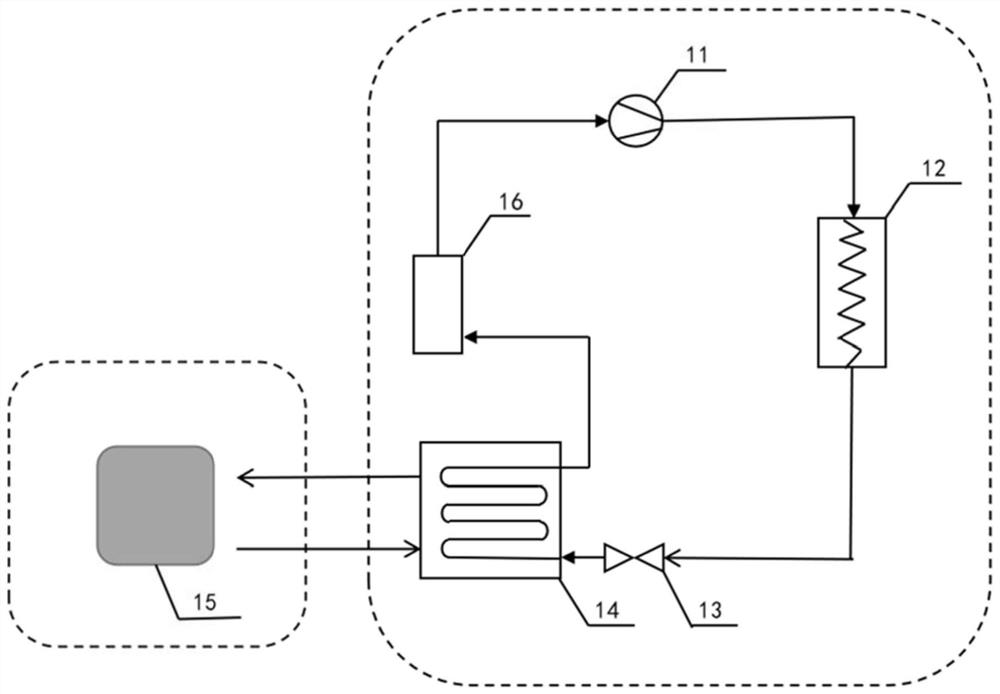

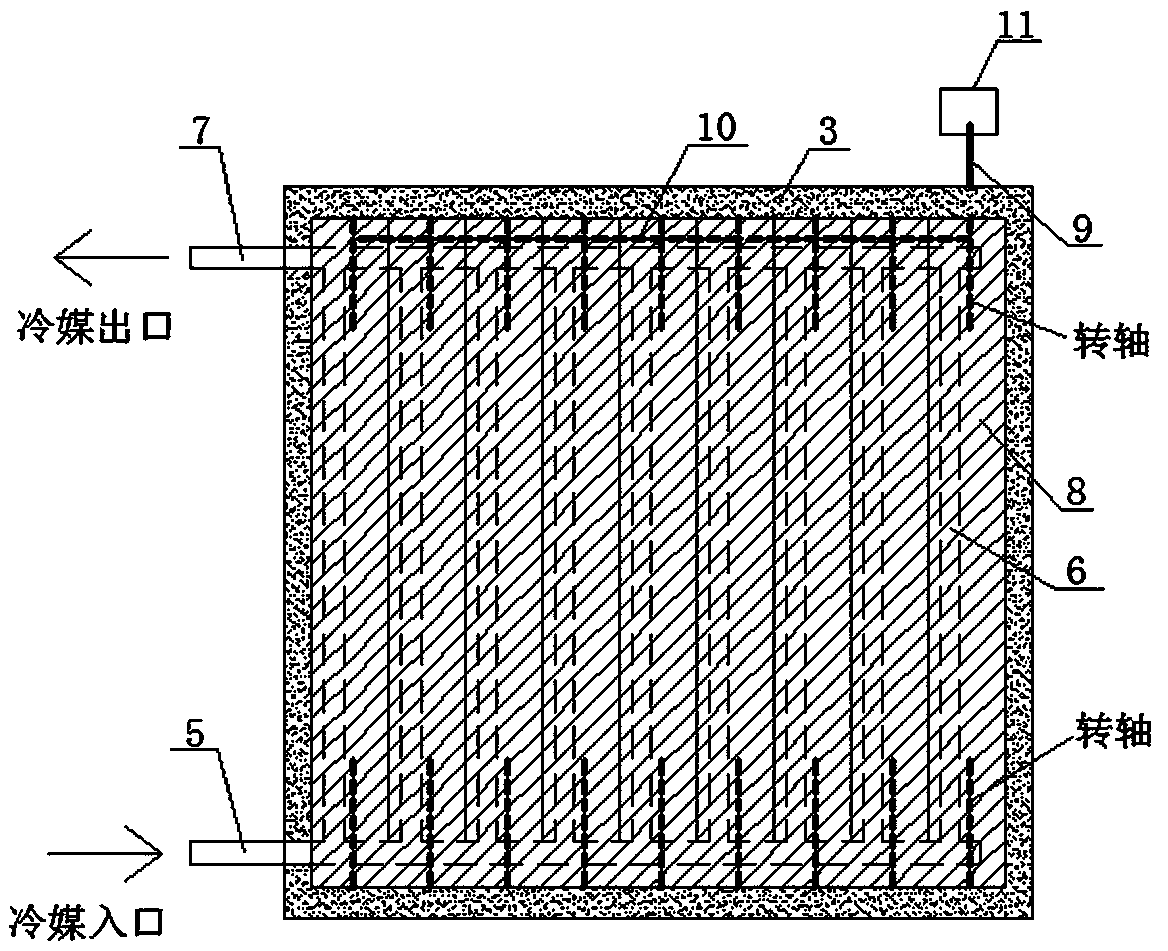

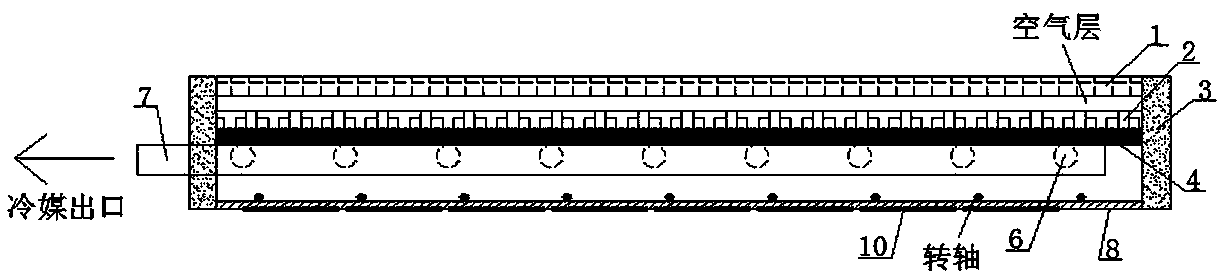

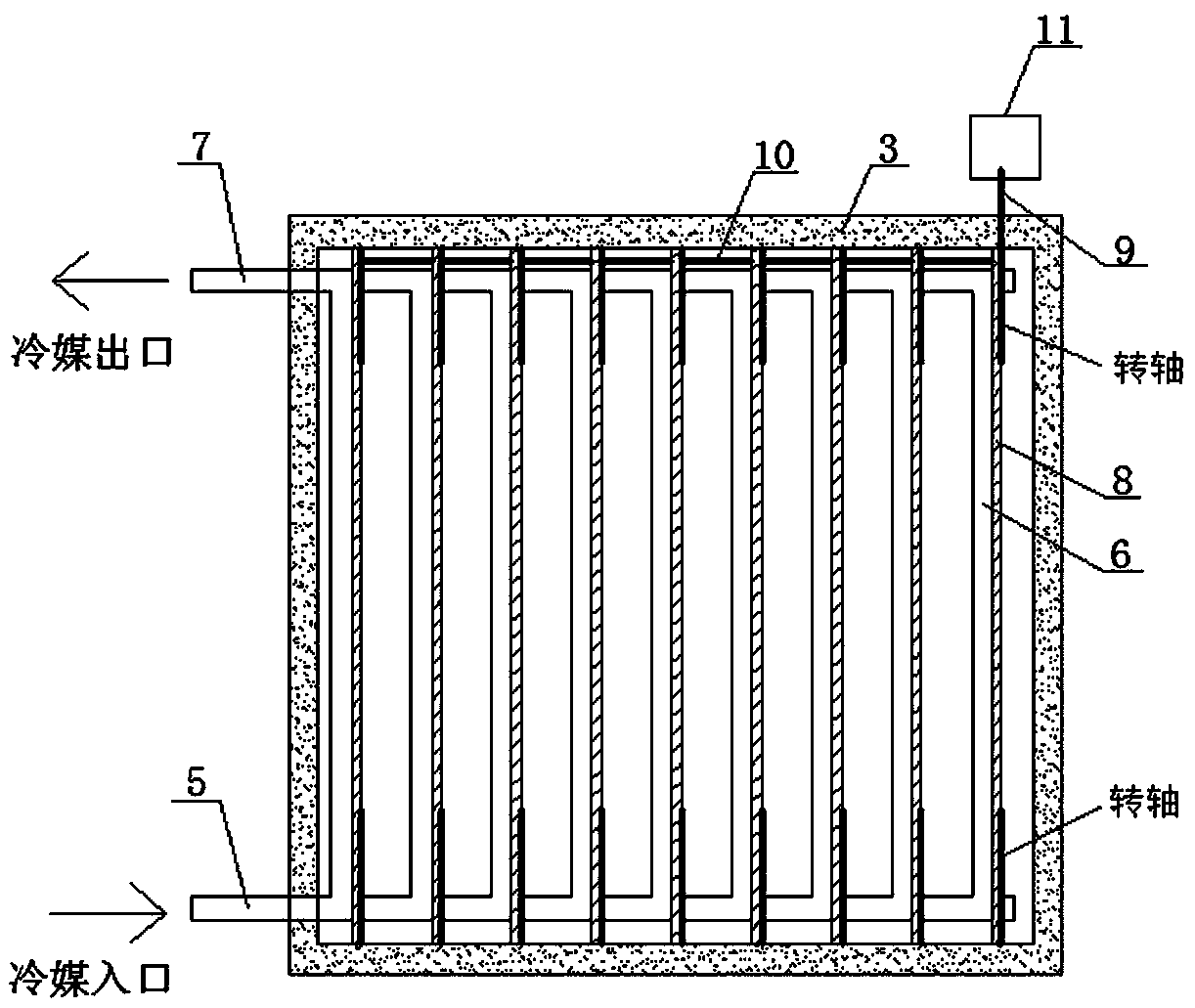

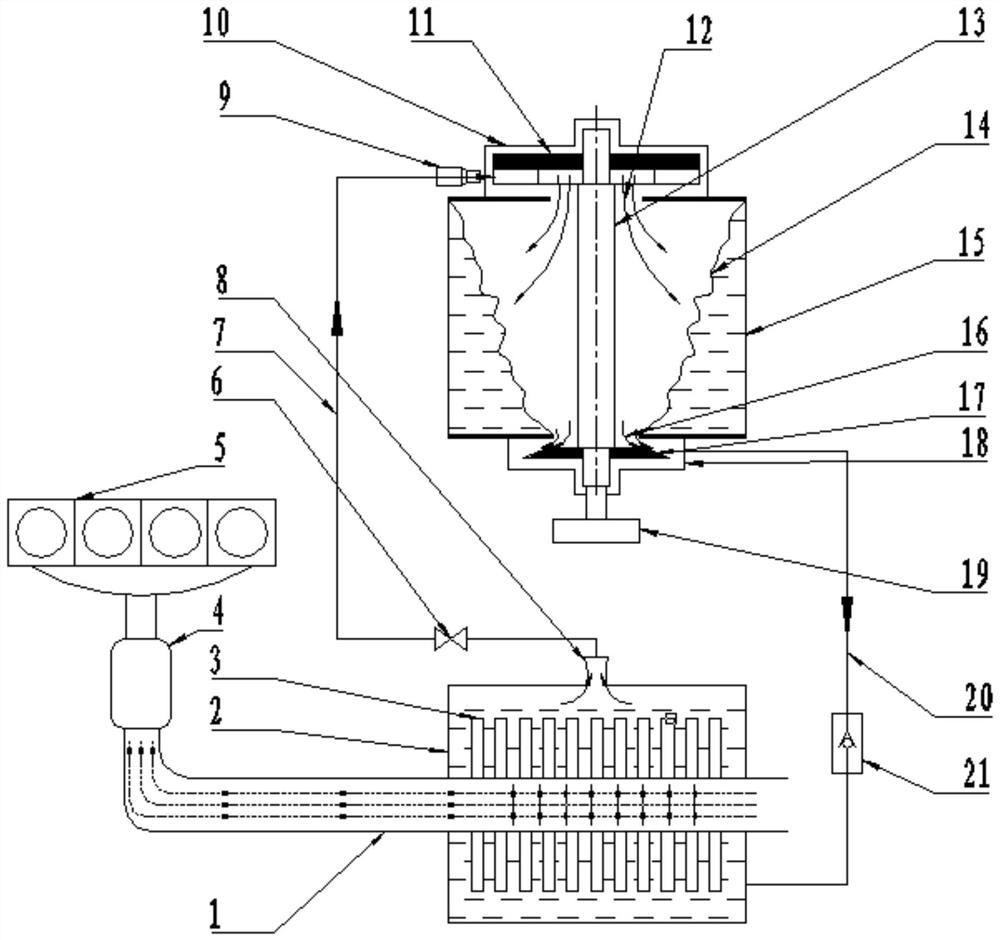

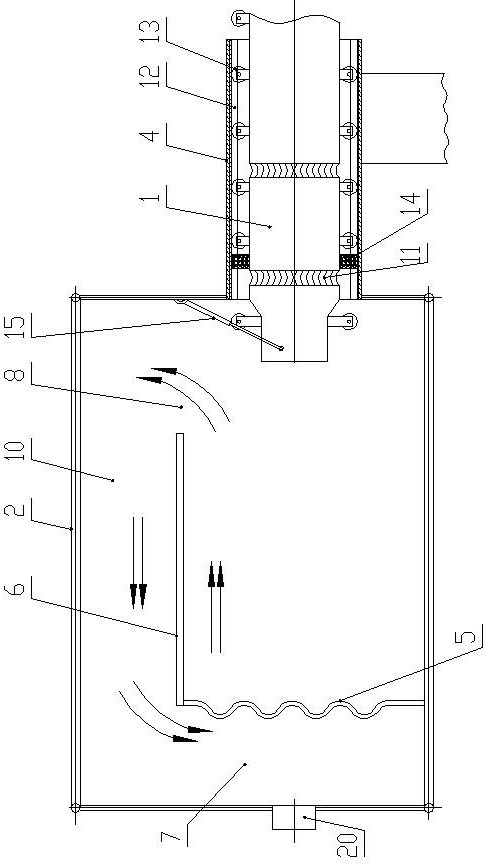

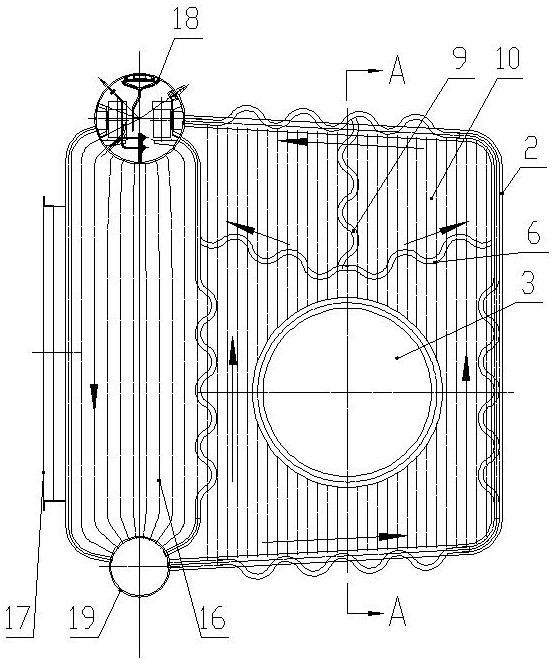

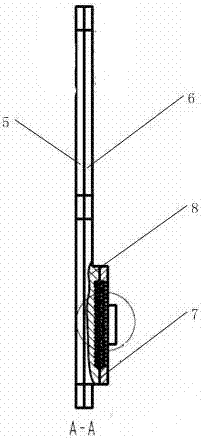

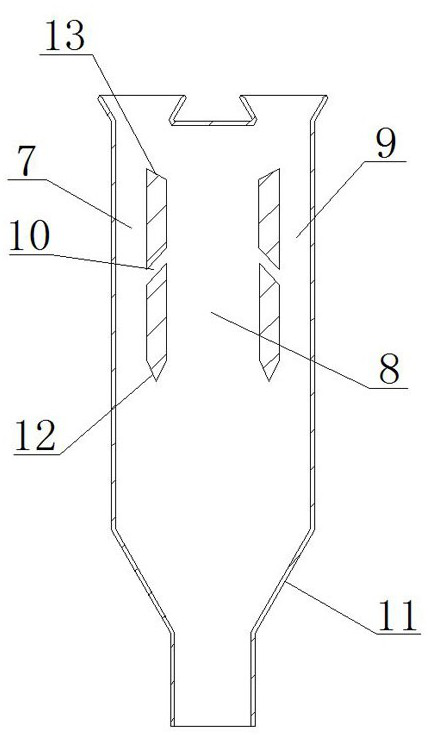

Photovoltaic and photo-thermal integrated device capable of drawing on advantages and avoiding disadvantages

ActiveCN108954857AFlexible rotationIncrease temperatureSolar heating energyPhotovoltaicsGas collecting tubeGlass cover

The invention belongs to the field of photovoltaic and photo-thermal utilization and in particular relates to a photovoltaic and photo-thermal integrated device capable of drawing on advantages and avoiding disadvantages. The photovoltaic and photo-thermal integrated device capable of drawing on advantages and avoiding disadvantages comprises a glass cover plate (1), a photovoltaic power generation module (2), a side frame (3), a heat collecting plate (4), a liquid separating tube (5), heat exchange tubes (6), a gas collecting tube (7), blind fins (8), a transmission shaft (9), a blind connecting rod (10) and a reducing motor (11). The blind fins (8) can rotate to corresponding positions as needed to take away or utilize heat generated by solar energy and photovoltaic power generation quickly to play a role of enhancing heat transfer or insulating. The photo-thermal can be also improved while the photovoltaic power generation efficiency is improved, and photovoltaic and photo-thermal integration is achieved.

Owner:NORTHEAST DIANLI UNIVERSITY

Gravity heat pipe with annular element

ActiveCN107144162AIncrease the heat exchange areaSolve the problem that is not easy to weldIndirect heat exchangersEnhanced heat transferHeat conservation

The invention relates to a novel efficient heat exchanger gravity heat pipe, in particular to a gravity heat pipe for thinning a condensation film by changing a pipe wall structure, and belongs to the technical field of heat exchange. The gravity heat pipe is composed of three zones including an evaporation section, a heat preservation section and a condensation section. When a gravity heat pipe works, a working medium is heated to evaporate to reach the condensation section to form a thick liquid film on the wall face, thermal resistance is increased, and heat transfer is blocked. According to the novel efficient heat exchanger gravity heat pipe, the annular elements are additionally arranged in the pipe, the wall face structure is changed, and therefore the liquid film is thinned. The annular elements are additionally arranged in the evaporation section, and therefore the liquid film of the evaporation section is evenly distributed, and falling film evaporation is achieved; the annular elements are additionally arranged in the condensation section, and therefore the liquid film is thinned, and condensation heat exchange is strengthened. Meanwhile, the annular elements are additionally arranged, enhancement of heat transfer of heat exchange areas of the condensation section and the evaporation section is increased, the arrangement of the elements in the evaporation section can further solve the problem that overflowing liquid generated by too thick liquid films returns to a liquid pool again, and influences of cold and hot air flow joining on heat transfer are avoided.

Owner:QINGDAO UNIV +1

Multi-cavity regenerative combustion device suitable for non-premixed combustion

ActiveCN114216119ASimplify the ignition processAdjust the combustion stateIndirect carbon-dioxide mitigationGaseous fuel burnerCombustion chamberEngineering

The invention belongs to the related technical field of gas diffusion combustion, and discloses a multi-cavity regenerative combustion device suitable for non-premixed combustion, which comprises a first regenerative channel shell, a body upper cover plate, a piezoelectric fire maker, a combustion chamber body, a body lower cover plate and a second regenerative channel shell, the first backheating channel shell, the body upper cover plate, the combustion chamber body, the body lower cover plate and the second backheating channel shell are sequentially connected, and the piezoelectric fire maker is arranged on the combustion chamber body; a first groove and a second groove are formed in the two opposite ends of the combustion chamber body correspondingly, and an oxidizing agent channel, a first igniter chamber, a fuel channel and a second igniter chamber are formed in the other two opposite ends of the combustion chamber body correspondingly. The two piezoelectric igniters are partially accommodated in the first igniter chamber and the second igniter chamber, respectively. The technical effects of being good in mixing effect, wide in combustible range, high in combustion efficiency, easy and convenient to ignite and high in applicability can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

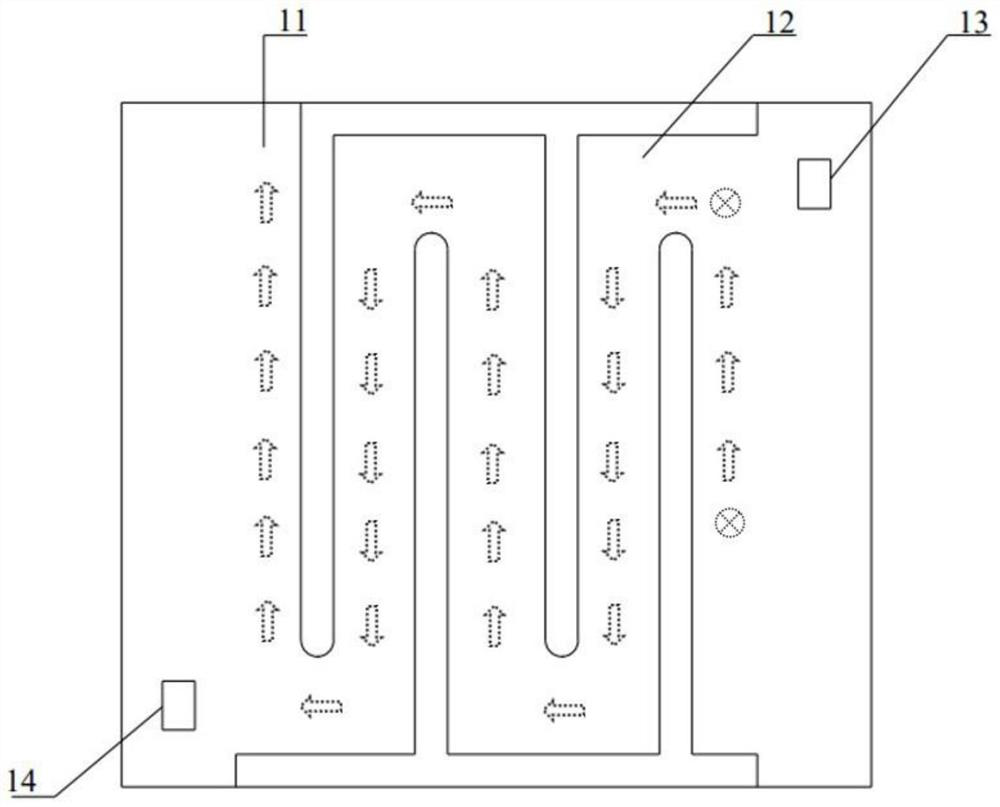

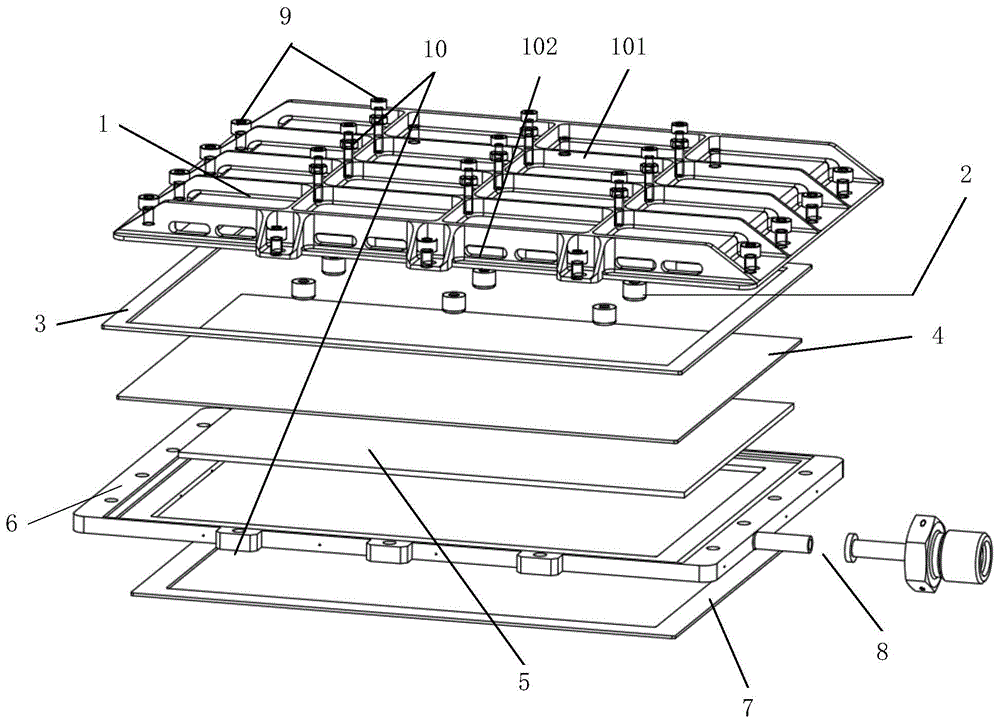

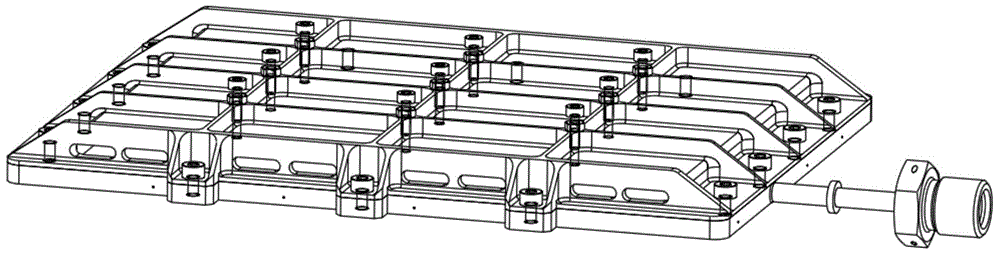

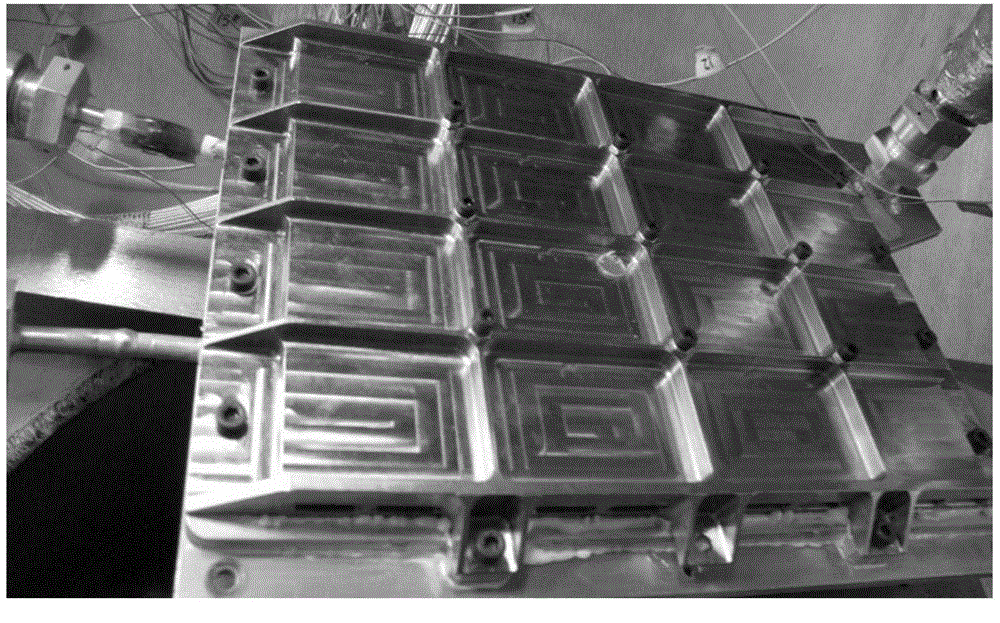

Flat-plate-type water sublimation cold plate for aerospace radiation

ActiveCN104019685BEnsure the uniformity of water supplyConvenience to workIndirect heat exchangersTriple pointCold plate

The invention provides a flat-type-type water sublimation cold plate for aerospace radiation. The flat-type-type water sublimation cold plate is composed of a cover plate, a teflon cushion block, a sealing ring, a perforated plate, a metal foam or micropore fin, a base body, a water supply channel sealing pressing plate, a water supply pipeline, a connecting bolt and a lock nut. A water supply channel is formed in the bottom face of the base body in the circumferential direction. The installation space matched with the metal foam or micropore fin, the perforated plate and the sealing ring is reserved in the upper surface of the base body. The metal foam or micropore fin is located inside the installation space, the perforated plate is located above the metal foam or micropore fin, and the metal foam or micropore fin is compressed onto the base body through welding of the perforated plate and the base body. A plurality of through holes are formed in the contact face of the base body and the metal foam or micropore fin in the thickness direction. The through holes are communicated with the water supply channel. A reinforcing rib and an air outlet channel are arranged on the cover plate. According to the flat-type-type water sublimation cold plate for aerospace radiation, the triple-point characteristics of water working media are utilized for sublimating the water working media through the structural design, and therefore the radiating function is achieved.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

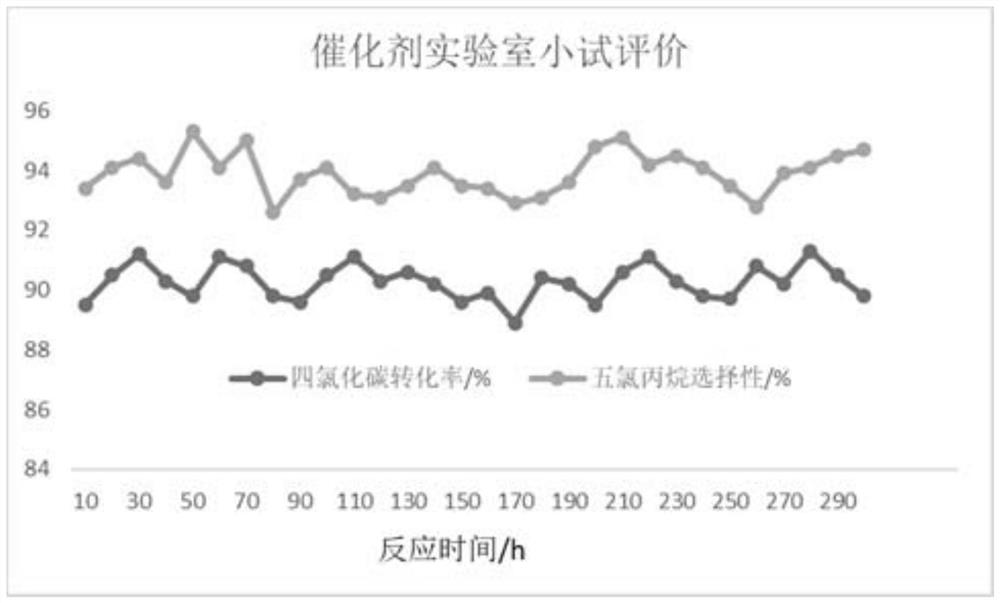

Method for continuously synthesizing 1, 1, 1, 3, 3-pentachloropropane

PendingCN114605225AReduce weightSimple process equipmentOrganic-compounds/hydrides/coordination-complexes catalystsHalogenated hydrocarbon preparationSide productConsecutive reaction

The invention discloses a method for continuously synthesizing 1, 1, 1, 3, 3-pentachloropropane, which comprises the following steps: uniformly mixing carbon tetrachloride and vinyl chloride raw materials according to a certain ratio, pumping the mixture into a tubular reactor filled with an iron catalyst by using a pump, cooling the reaction discharged material by using a cold trap, collecting a reaction crude product, and distilling and rectifying the crude product to obtain the product, namely the 1, 1, 1, 3, 3-pentachloropropane. Unreacted materials enter the reactor to be recycled. Compared with the existing kettle-type intermittent or continuous reaction process, the method has the advantages of high catalytic reaction activity, low catalyst cost, wider selection, short reaction time, low by-product content, no need of subsequent separation of the catalyst, simple reaction process and equipment, and suitability for continuous industrial production.

Owner:SHANGHAI INST OF ORGANIC CHEMISTRY - CHINESE ACAD OF SCI

Fin type SCR catalyst attachment skeleton structure and flue gas denitration system and method thereof

ActiveCN112973443AImprove denitrification performanceImprove sulfur resistanceGas treatmentDispersed particle separationPtru catalystFlue gas

The invention provides a fin type SCR catalyst attachment skeleton structure and a flue gas denitration system and a method thereof, and belongs to the technical field of low-temperature SCR denitration, the skeleton structure comprises: an outer box body, wherein each side wall of which is provided with a plurality of trapezoidal grooves formed by outward extrusion; an inner box body arranged in the outer box body, wherein each side wall of the inner box body is provided with a plurality of insertion grooves with openings in one ends; fin skeletons, wherein one end of each fin skeleton is inserted into the corresponding trapezoidal groove, the other end of each fin skeleton is inserted into the corresponding insertion groove, and the end parts of every two fin skeletons are fixedly connected through a pin; and two side walls of each fin skeletonare coated with an SCR catalyst; a plurality of baffle plates arranged at one end of the inner box body and used for fixing a plurality of fin skeletons. According to the system and the method, the normal-temperature air can be heated by using the molten salt solar condensation-heat storage system to overcome deactivation or poisoning of the SCR catalyst, and the flow speed of flue gas in the flue can be increased by increasing the flow speed of the high-temperature air.

Owner:山西清泽阳光环保科技有限公司

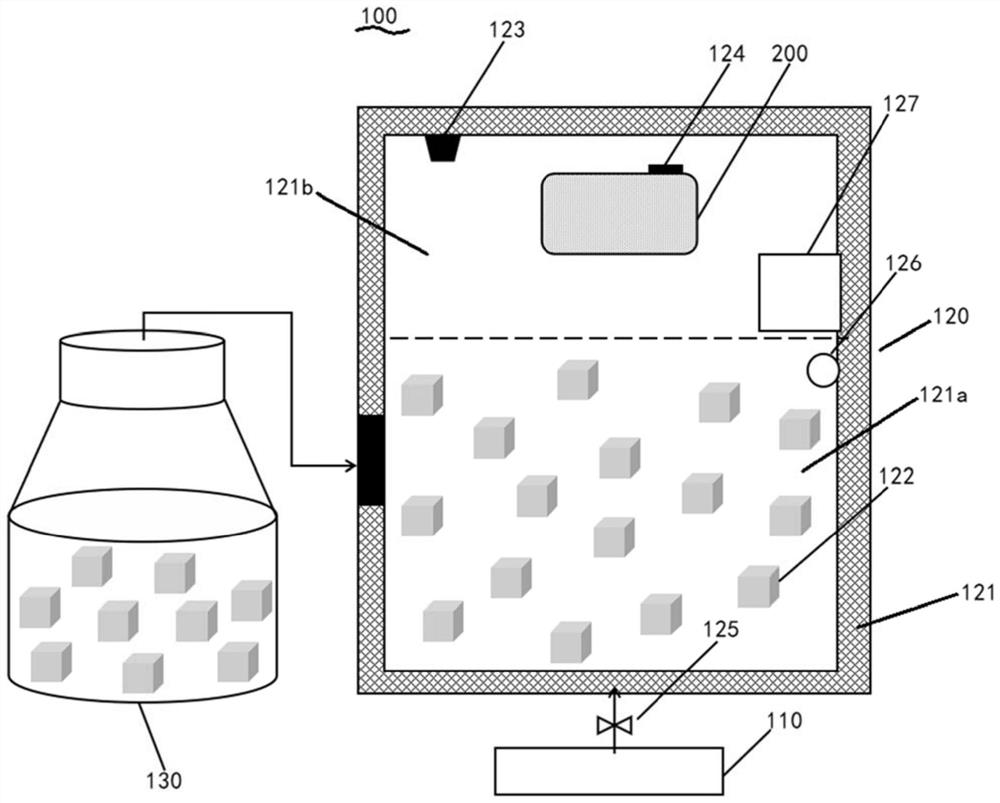

Compact type dry ice air cooling laser heat dissipation system and method

PendingCN112886369ACompact cooling structureSave spaceLaser cooling arrangementsErbium lasersHeat sink

The invention discloses a compact type dry ice air cooling laser heat dissipation system and method. A scheme adopted in the invention employs dry ice to cool forced convection air for heat dissipation, and employs the cooled forced convection air to carry out heat exchange on a laser heat sink. Compared with an existing scheme, the scheme of the invention has the advantages that the space structure of the laser heat dissipation system is optimized, the phase change cold storage mode is large in cold storage capacity, cold can be rapidly released, and the problem that the air cooling heat dissipation capacity is limited can be solved.

Owner:SHANGHAI FIRE RES INST OF MEM

A photovoltaic photothermal integrated device that can avoid disadvantages

ActiveCN108954857BFlexible rotationIncrease temperatureSolar heating energyPhotovoltaicsGas collecting tubeGlass cover

The invention belongs to the field of photovoltaic and photo-thermal utilization and in particular relates to a photovoltaic and photo-thermal integrated device capable of drawing on advantages and avoiding disadvantages. The photovoltaic and photo-thermal integrated device capable of drawing on advantages and avoiding disadvantages comprises a glass cover plate (1), a photovoltaic power generation module (2), a side frame (3), a heat collecting plate (4), a liquid separating tube (5), heat exchange tubes (6), a gas collecting tube (7), blind fins (8), a transmission shaft (9), a blind connecting rod (10) and a reducing motor (11). The blind fins (8) can rotate to corresponding positions as needed to take away or utilize heat generated by solar energy and photovoltaic power generation quickly to play a role of enhancing heat transfer or insulating. The photo-thermal can be also improved while the photovoltaic power generation efficiency is improved, and photovoltaic and photo-thermal integration is achieved.

Owner:NORTHEAST DIANLI UNIVERSITY

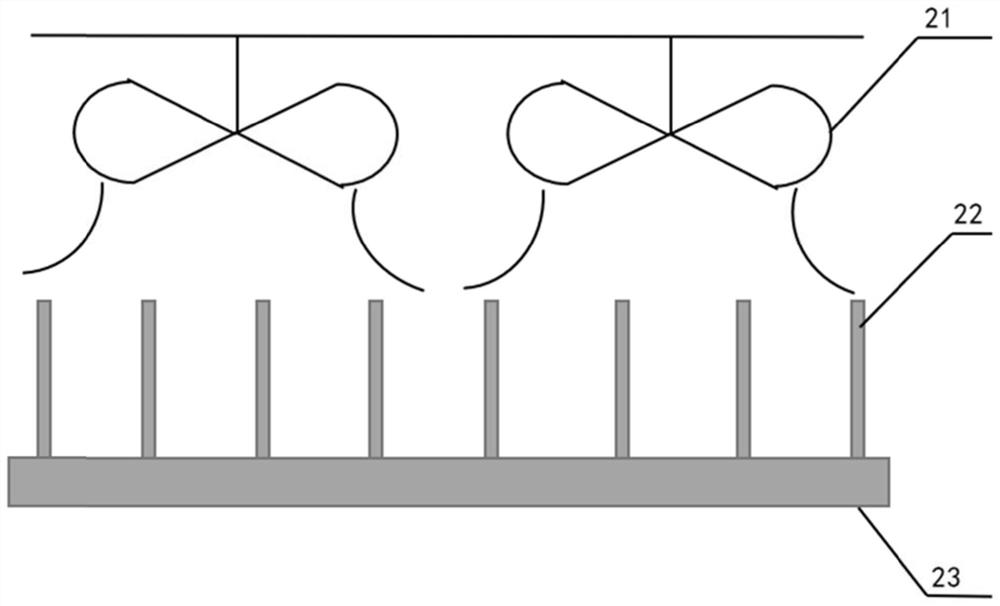

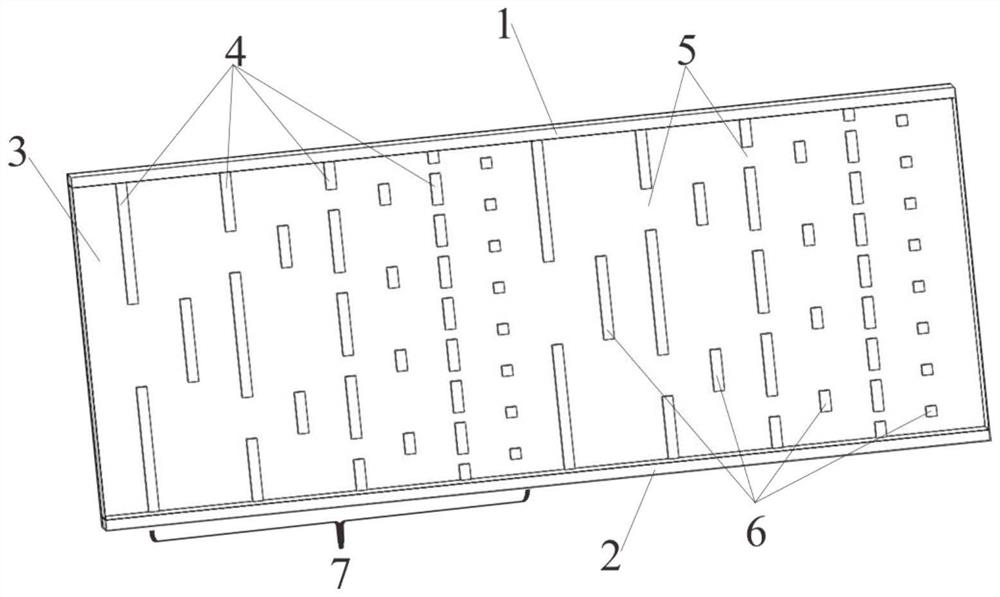

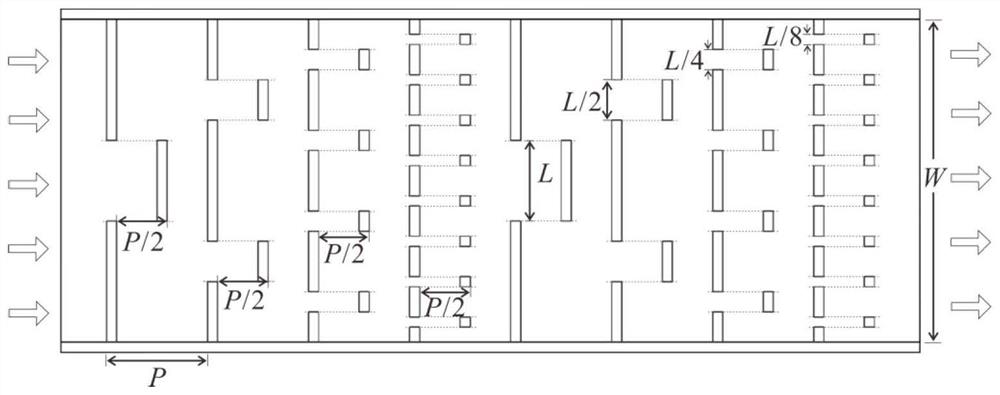

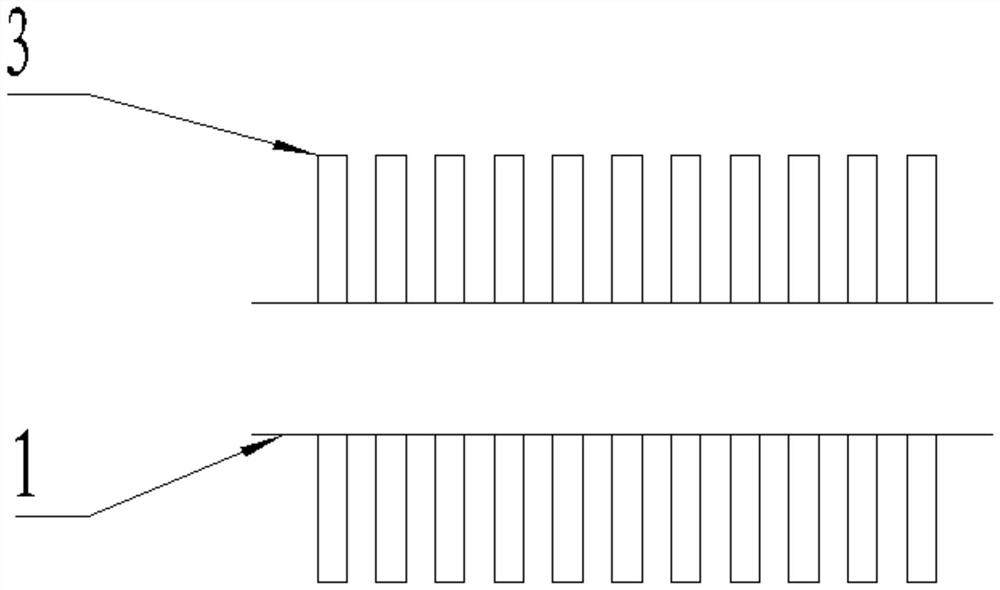

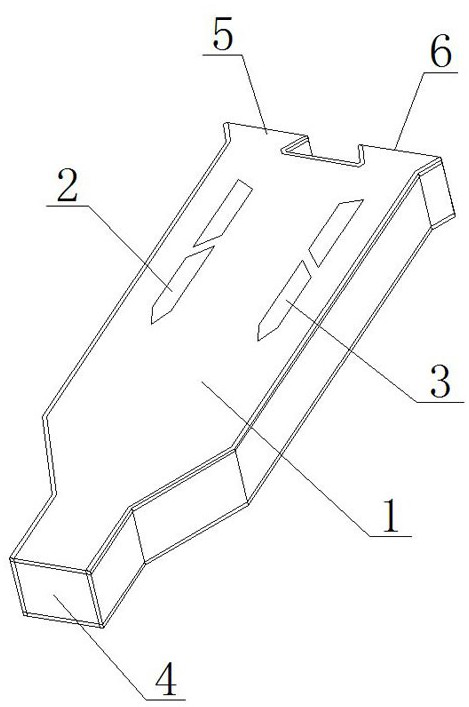

Constructal cut-off fin structure for enhancing overall thermal performance

PendingCN113847102AIncrease the heat exchange areaEnhanced convective heat transferEngine fuctionsBlade accessoriesThermodynamicsEngineering

The invention discloses a constructal cut-off fin structure for enhancing the overall thermal performance, and belongs to the technical field of heat exchange enhancement. Constructal cut-off fins are arranged in a cooling channel of a high-temperature component and evenly distributed in the length direction of the bottom wall face of the cooling channel periodically. Each period comprises eight rows of cut-off fins, the fins in the odd-numbered rows are cut-off in the airflow direction to form the cut-off fins and cut-off areas, the number of the cut-off fins and the cut-off areas in each row is gradually increased in the airflow direction, after the fins are cut off, the fin parts, located in the cut-off areas, in the odd-numbered rows horizontally move downstream in the airflow direction, and even-numbered rows in the period are formed. Compared with traditional continuous straight fins, the constructal cut-off fin structure generate transverse vortex in the cut-off areas to enable a near wall flowing structure to be changed, so that mixing of main flow and fluid on the boundary layer is enhanced, and the heat exchange performance and the overall thermal performance of the cooling channel are improved. The constructal cut-off fin structure is simple, reasonable in design and suitable for an internal cooling system and an enhanced heat exchange system of a high-temperature component.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

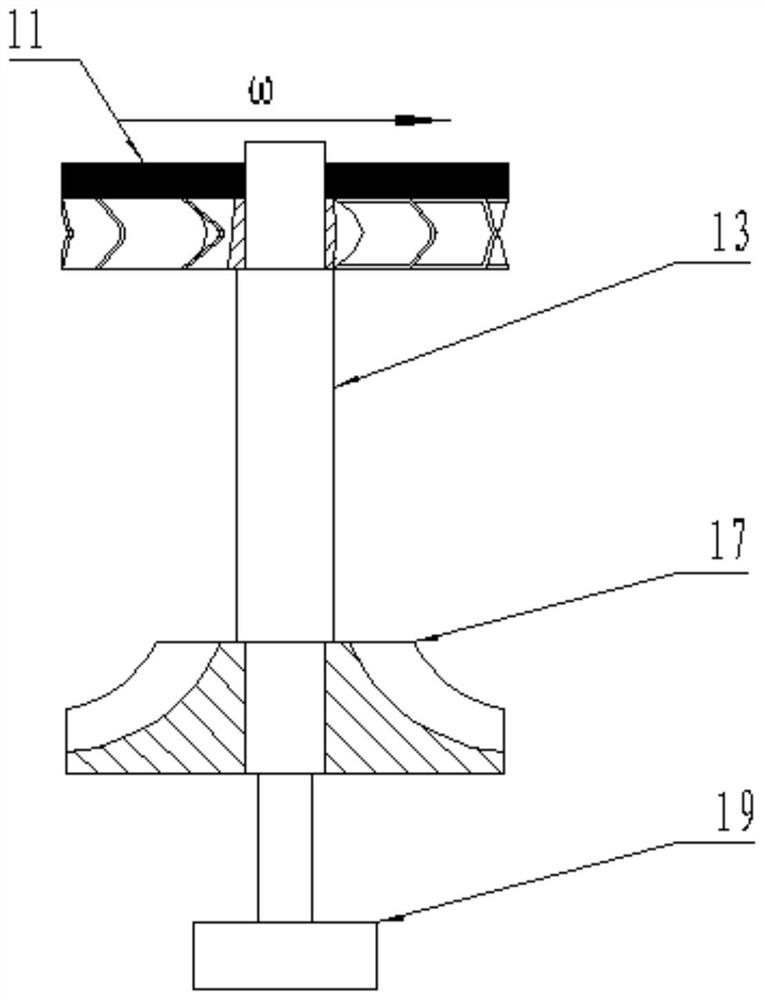

A vehicle exhaust waste heat recovery device based on loop heat pipe

ActiveCN109519261BPurification does not affectWon't block dischargeInternal combustion piston enginesExhaust apparatusPtru catalystThermal insulation

Owner:YANSHAN UNIV

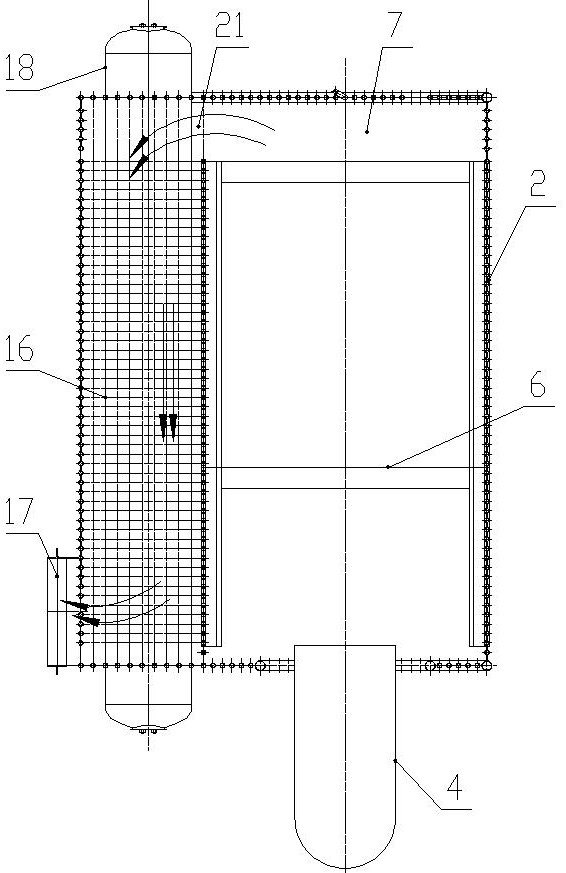

Curved surface hearth of natural gas burning boiler

ActiveCN111998331AReduce the size of the boilerEasy to scale upSteam boilersSteam boilers componentsFlueEngineering

The invention provides a curved surface hearth of a natural gas burning boiler. The curved surface hearth comprises a burner and a boiler body with a water-cooling membrane wall, wherein an installation guide pipe is fixedly arranged on the front side of the boiler body; a tail corrugated membrane wall is vertically arranged on the rear side in the boiler body; a top corrugated membrane wall is horizontally arranged in the boiler body; a tail water-cooling wet back flue is formed between the rear side of the tail corrugated membrane wall and the water-cooling membrane wall on the rear side ofthe boiler body; a top horizontal channel is formed between the top of the top corrugated membrane wall and the water-cooling membrane wall on the top of the boiler body; a smoke steering channel communicating with the front side of the top horizontal channel is formed between the front side edge of the top corrugated membrane wall and the water-cooling membrane wall on the front side of the boiler body; and the burner is arranged in the installation guide pipe. According to the curved surface hearth, the flowing time of smoke in the boiler is prolonged, meanwhile, the heating area can be multiplied in unit space through the corrugated water-cooling membrane walls, the boundary layer of the smoke can be well damaged through the design of the corrugated structure, the function of enhancingheat transfer is achieved, more heat can be absorbed, and the heat of the high-temperature smoke coming out of the hearth can be reduced.

Owner:HENAN YONGXING BOILER GRP

A preparation method of hypercrosslinked polystyrene loaded organic phase change material and the composite phase change material prepared therefrom

ActiveCN109836598BHigh latent heatFully covered and efficientHeat-exchange elementsHalohydrocarbonPtru catalyst

Disclosed are a method for preparing a super-crosslinked polystyrene supported organic phase change material and a composite phase change material prepared therefrom. The method comprises: dissolving polystyrene in a halogenated hydrocarbon solvent, then adding an organic phase change material to the dissolved polystyrene, and stirring same until same is completely dissolved to obtain a mixed solution; adding a crosslinking agent and a Lewis acid catalyst to the mixed solution, stirring and reacting same for 12 to 24 hours, and after the reaction is completed, evaporating same under reduced pressure to remove excess solvent; dissolving a residual solid in ethanol, ultrasonically dispersing same for 0.5 to 1 hour under alkaline conditions, and further stirring same for 10 to 18 hours; and after the reaction is completed, evaporating same under reduced pressure to remove the solvent and drying same to obtain the super-crosslinked polystyrene supported organic phase change material. According to the invention, the step of forming a super-crosslinked polymer skeleton and the step of coating same with the phase change material are synchronously carried out, ensuring that the efficiency of the coating with the phase change material is high and that the latent heat of the resulting material is high, with leakages being difficult; in addition, the catalyst for super-crosslinking is converted into a corresponding metal oxide under alkaline conditions, so that it is not necessary to remove the metal catalyst, and the resulting metal oxide serves to enhance heat transfer.

Owner:CHINA UNIV OF MINING & TECH

Water-cooled corrugated flue-fired natural gas boiler

ActiveCN111998330AReduce volumeReduce shipping costsSteam boilersSteam boilers componentsFlue gasEnhanced heat transfer

The invention discloses a water-cooled corrugated flue-fired natural gas boiler. The boiler comprises an upper drum, a lower drum, a burner, a convection side membrane wall, a left membrane wall, a convection tube bundle, a straight membrane wall at the front end, a straight membrane wall at the rear end, a top membrane wall, a bottom membrane wall, a right membrane wall, and a corrugated furnace;the straight membrane wall at the front end is fixed with a mounting duct, the burner is set in the mounting duct to spray flames into the corrugated furnace, an airflow turning channel into the convection tube bundle is provided between the rear side of the left side membrane wall and the straight membrane wall at the rear end, and the front side of the convection side membrane wall is providedwith a smoke exhaust port. The water-cooled corrugated flue-fired natural gas boiler makes full use of the existing furnace space, and is provided with the corrugated furnace, which significantly reduces the boiler volume, facilitates the enlargement of the boiler, and reduces the overall transportation cost. The corrugated structure can destroy a boundary layer of the flue gas, play the role of strengthening heat transfer, and absorb more heat to reduce the heat of high-temperature flue gas from the furnace, thereby increasing the operating time of the boiler, and reducing the maintenance cost of the boiler.

Owner:河南省永兴特种设备有限公司

A curved furnace of a natural gas-fired boiler

ActiveCN111998331BReduce volumeReduce shipping costsSteam boilersSteam boilers componentsFlue gasEnhanced heat transfer

A curved furnace of a natural gas-fired boiler, including a burner and a furnace body with a water-cooled membrane wall; The top corrugated membrane wall, the tail water-cooled wet back flue is formed between the back side of the tail corrugated membrane wall and the water-cooled membrane wall on the rear side of the furnace body, the top of the top corrugated membrane wall and the water-cooled membrane wall on the top of the furnace body A top horizontal passage is formed between the top horizontal passages, and there is a flue gas turning passage connected with the front side of the top horizontal passage between the front side of the top corrugated membrane wall and the water-cooled membrane wall on the front side of the furnace body, and the burner is arranged in the installation duct. The invention prolongs the flow time of the flue gas inside the boiler, and at the same time, these corrugated water-cooled membrane walls can double the heating area in a unit space, and the design of the corrugated structure can well destroy the boundary layer of the flue gas, It plays the role of enhancing heat transfer, which can absorb more heat and reduce the heat of high-temperature flue gas coming out of the furnace.

Owner:河南省永兴特种设备有限公司

A flat plate heat pipe with arrayed microchannels

ActiveCN103575144BIncrease the heat exchange areaImprove efficiencyIndirect heat exchangersHeat fluxEngineering

The present invention proposes a flat plate heat pipe with arrayed microchannels, including heat conduction microchannel plate heat pipes and heat uniform microchannel plate heat pipes. The pipeline axis of the heat pipe is perpendicular to the pipeline axis of the uniform heat microchannel flat heat pipe. The heat uniform microchannel plate heat pipe of the present invention is designed with a heat pipe with heat uniform function, which can make the heat pipe use under the condition of higher heat flux density, increase the heat exchange area and improve the efficiency.

Owner:SICHUAN JIUZHOU ELECTRIC GROUP

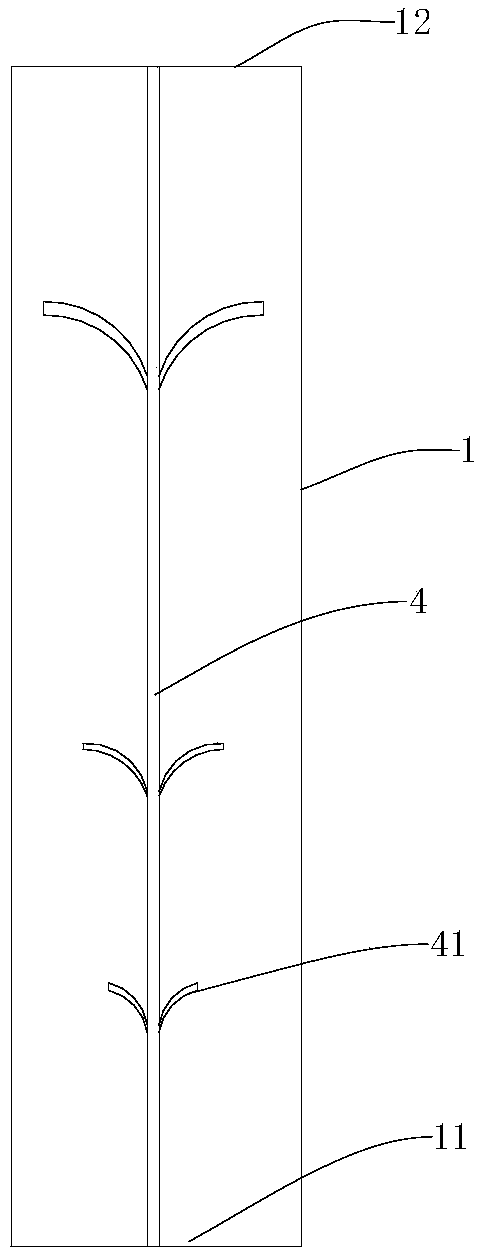

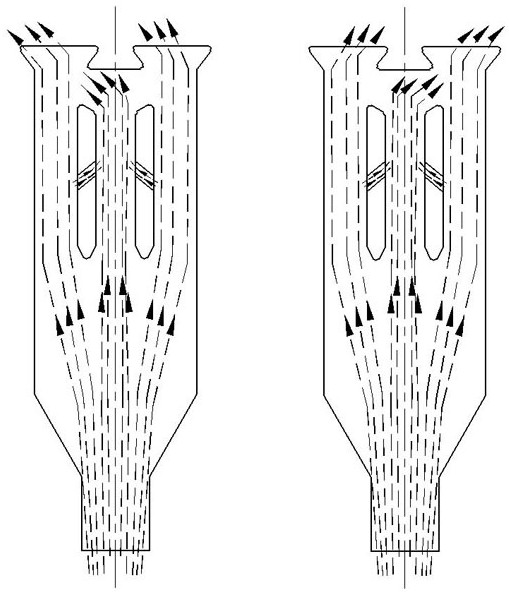

Enhanced heat transfer element capable of automatically and transversely scanning fluid

PendingCN114719661APlay a role in enhancing heat transferImprove heat transfer coefficientHeat transfer modificationSolar thermal energy generationEnhanced heat transferMechanical engineering

The invention discloses an enhanced heat transfer element capable of automatically and transversely scanning fluid, which comprises an enhanced heat transfer element shell, a first separator and a second separator, one end of the enhanced heat transfer element shell is provided with a fluid inlet, and the other end of the enhanced heat transfer element shell is provided with a first fluid outlet and a second fluid outlet; the first partition body and the second partition body are fixed in the enhanced heat transfer element shell and divide part of an inner cavity of the enhanced heat transfer element shell into a first side flow channel, a middle flow channel and a second side flow channel in the fluid flowing direction, and disturbance flow channels are further formed in the first partition body and the second partition body. Through the simple structural design, fluid automatically swings, so that a boundary layer on the heat exchange surface is eliminated, and the heat transfer enhancement effect is achieved.

Owner:南通中船机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com