Plate-shell heat exchanger with oval corrugated plates

A corrugated plate and elliptical technology, which is applied in the field of elliptical corrugated plate and shell heat exchangers, can solve the problems of unsatisfactory heat transfer coefficient of circular corrugated plates, affecting heat transfer effect, affecting heat transfer, etc., to achieve overall Simple and compact structure, enhanced heat transfer, large heat transfer area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

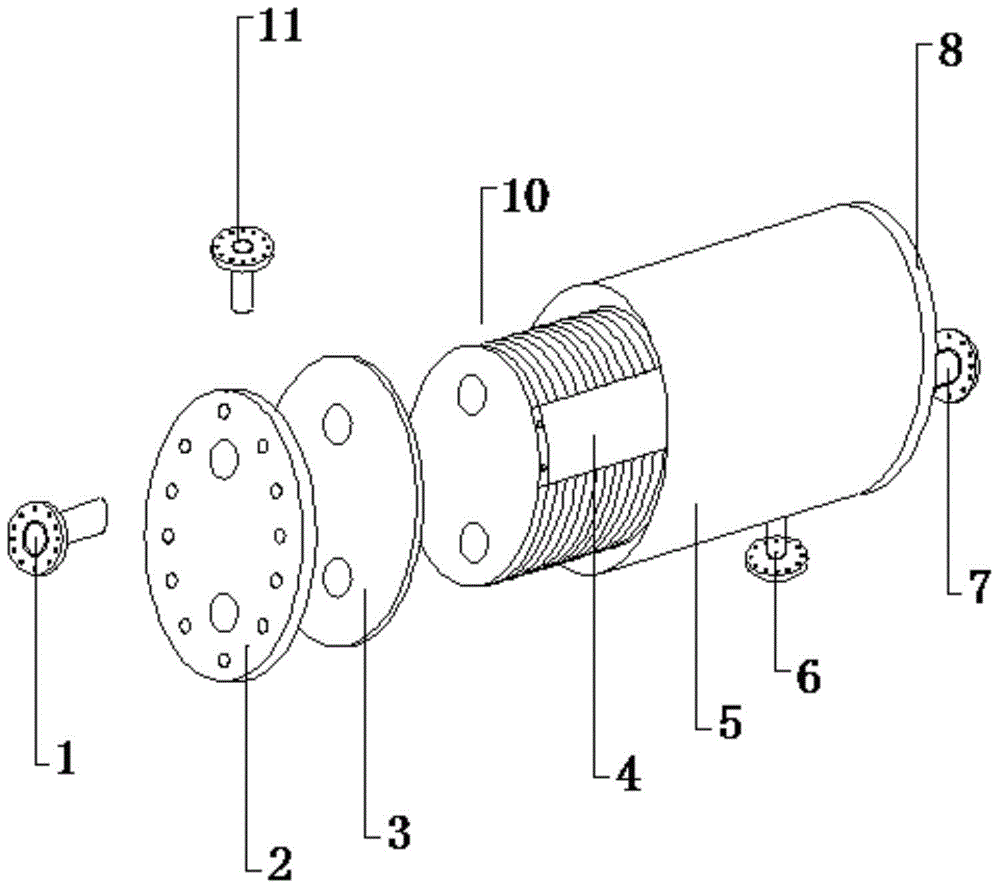

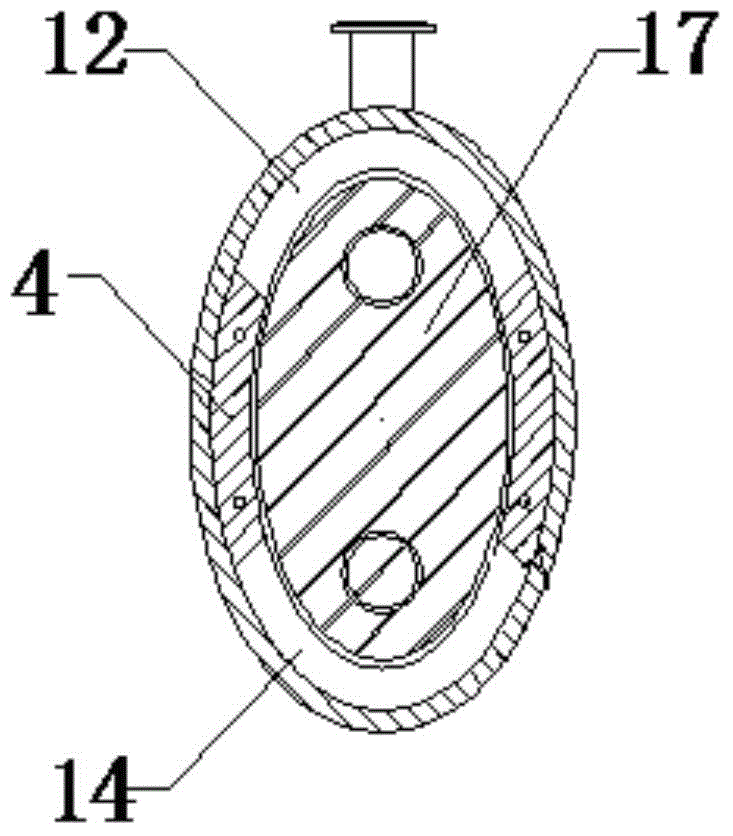

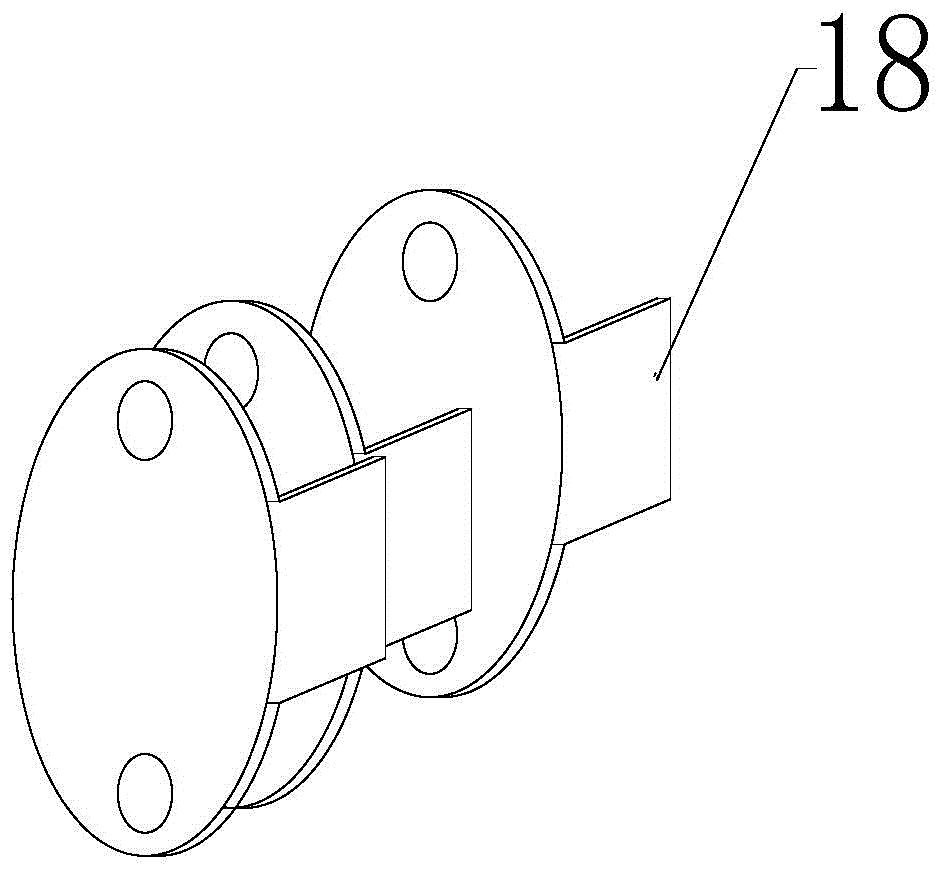

[0028] Such as figure 1 , figure 2 As shown, the elliptical corrugated plate plate-shell heat exchanger of the present invention consists of a plate-side inlet 1, a plate-side outlet 7, a shell-side inlet 6, a shell-side outlet 11, a shell-side inlet chamber 14, a shell-side outlet chamber 12, The corrugated plate bundle 10, the support plate 3 (a pair), the guide block 4 (a pair, which also has the function of a support), the cover plates 2 and 8 on both sides, and the shell 5 are composed of components such as the corrugated plate bundle A guide block 4 is provided between 10 and the shell 5, and the guide block 4 divides the annular area between the corrugated plate bundle 10 and the shell 5 into a shell-side inlet chamber 14 and a shell-side outlet chamber 12, The corrugated plate bundle 10 is welded to the support plate 3 (a pair) through corner holes, and is placed in the housing 5 through the support plate 3 (a pair) and the guide block 4 (a pair). The two ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com