High-pressure resistant lamella heat exchanger adopting round corrugated plates

A corrugated plate and heat exchanger technology, applied in the field of heat exchangers, can solve the problems of design waste, volume and material waste, design mismatch, etc., and achieve the effect of wide material selection, strong applicability, and simple and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

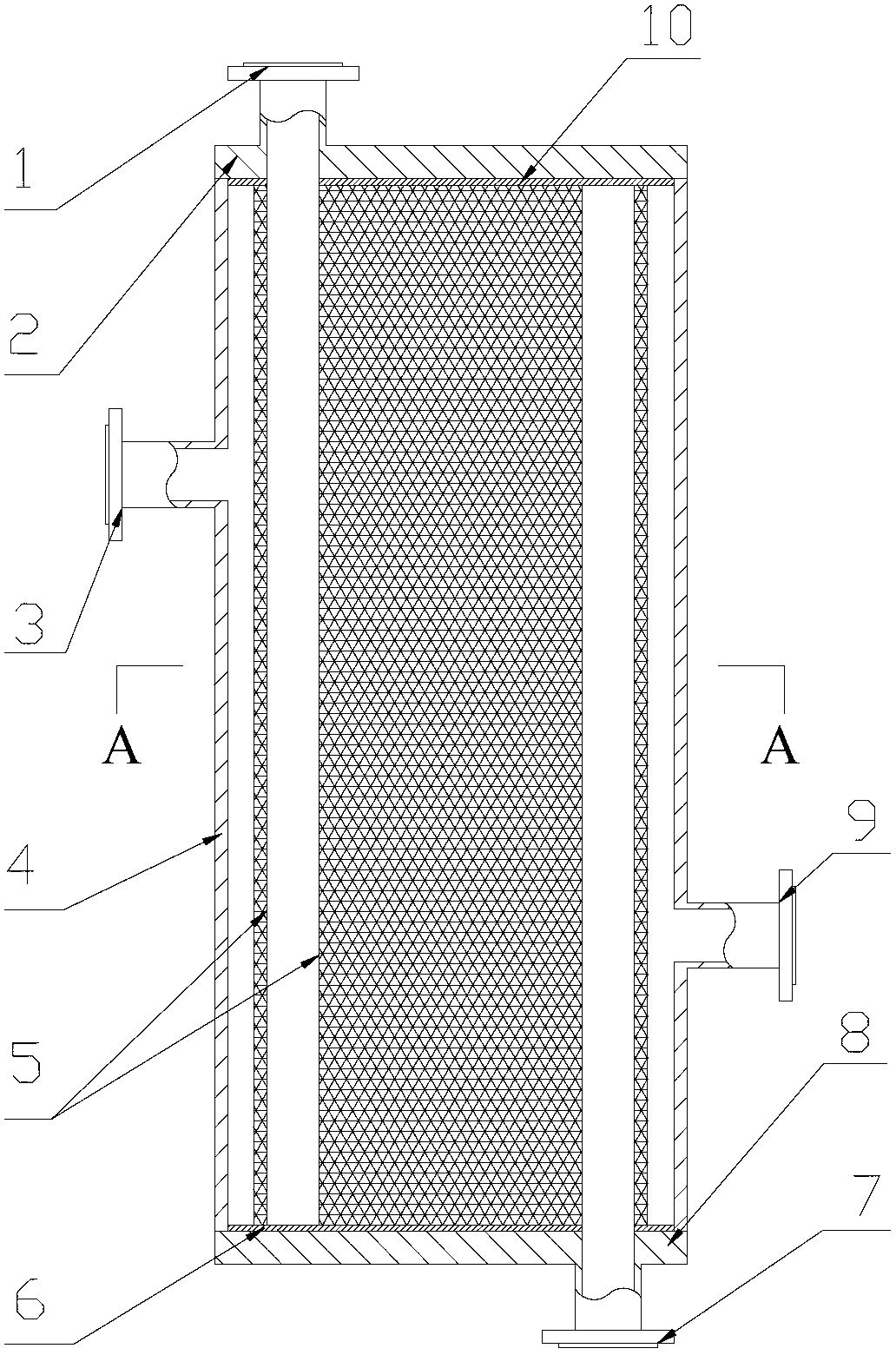

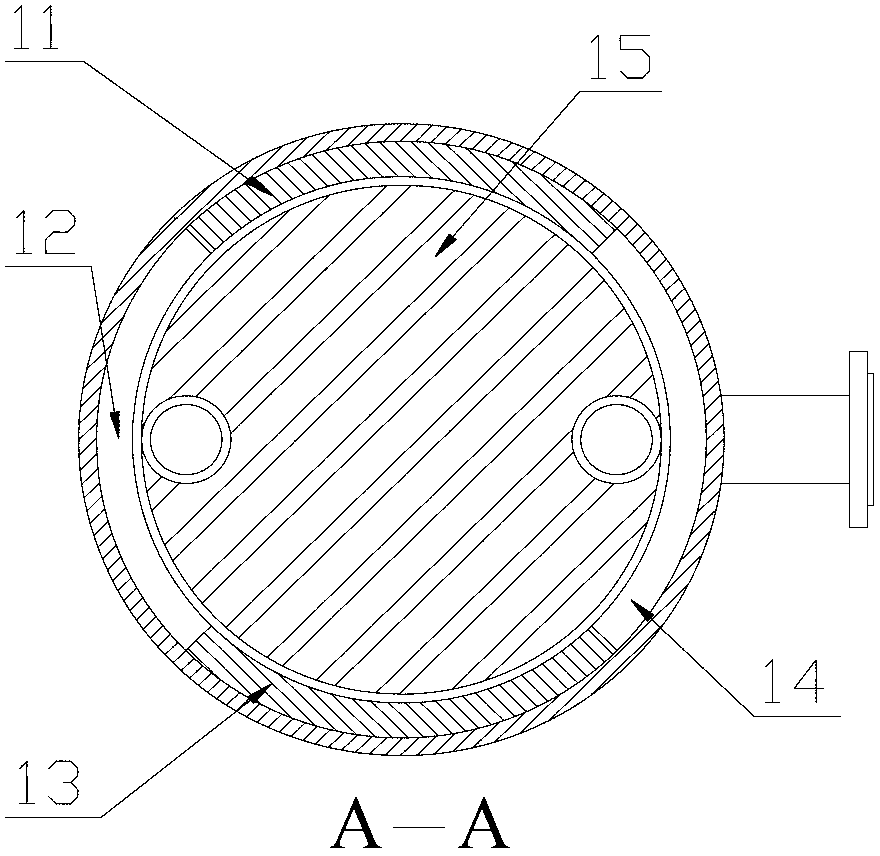

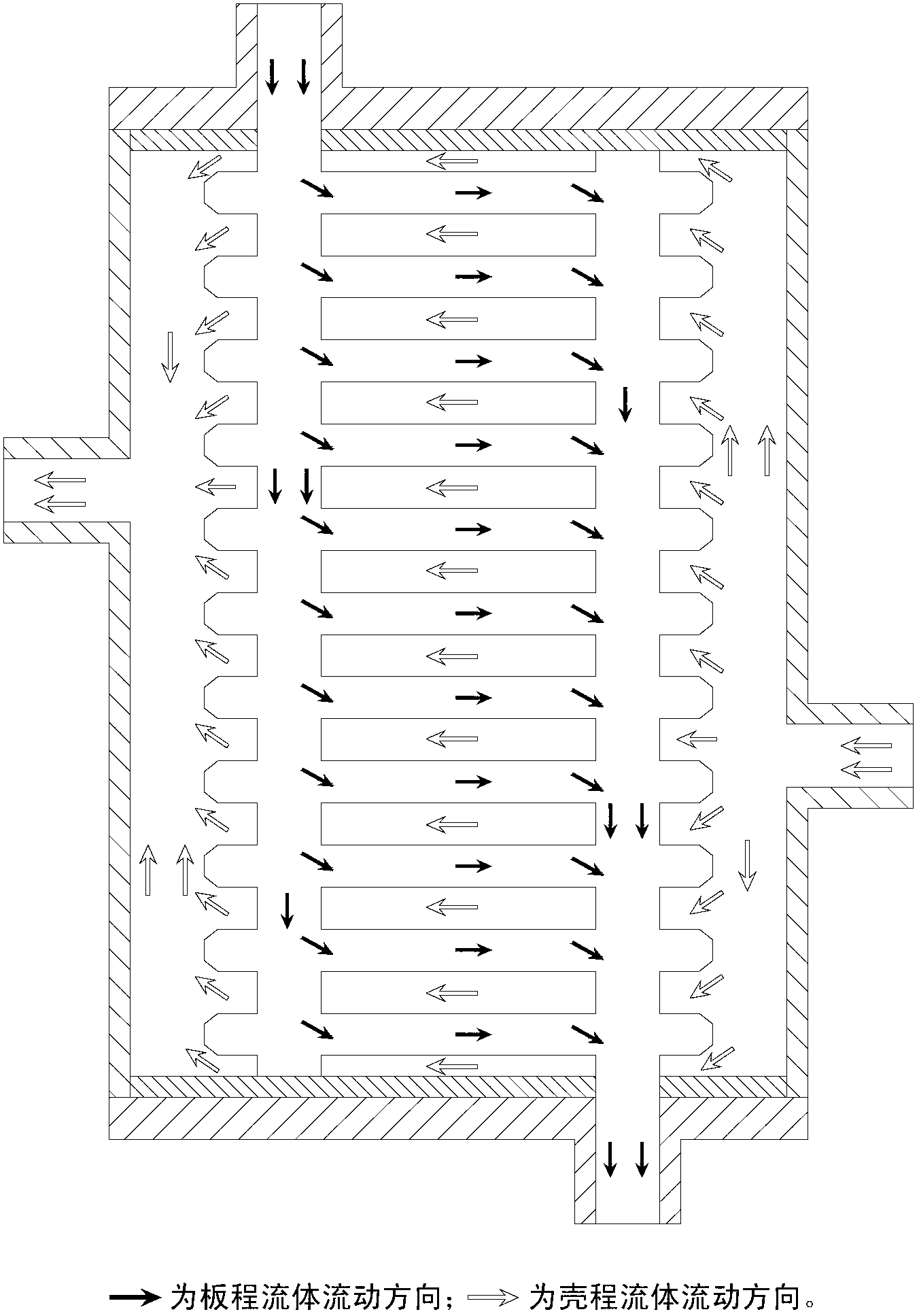

[0025] combine Figure 1~5 , the present invention is made up of board pass inlet 1, board pass outlet 7, shell pass import 9, shell pass outlet 3, shell pass inlet chamber 14, shell pass outlet chamber 12, corrugated plate bundle 5, support plates 6, 10, The deflector blocks 11 and 13, the cover plates 2 and 8 on both sides, and the housing 4 are composed of components. The corrugated plate bundle 5 is welded to the support plates 6, 10 through corner holes, and placed in the housing 4 through the support plates 6, 10. The two ends of the plate bundle 5 are compressed and fixed by the cover plates 2 and 8 . The cover plates 2, 8 are welded with the shell 4 to form a complete shell, which encloses the corrugated plate bundle 5 and the supporting plates 6, 10 inside. The annular area between the shell and the plate bundle is divided into a shell-side inlet chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com