Downcomer having membrane type wall structure

A membrane wall and thin tube technology, applied in the field of energy utilization, can solve problems such as the inability to fundamentally effectively protect the downcomer, and achieve the effects of increasing contact, preventing burning damage, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

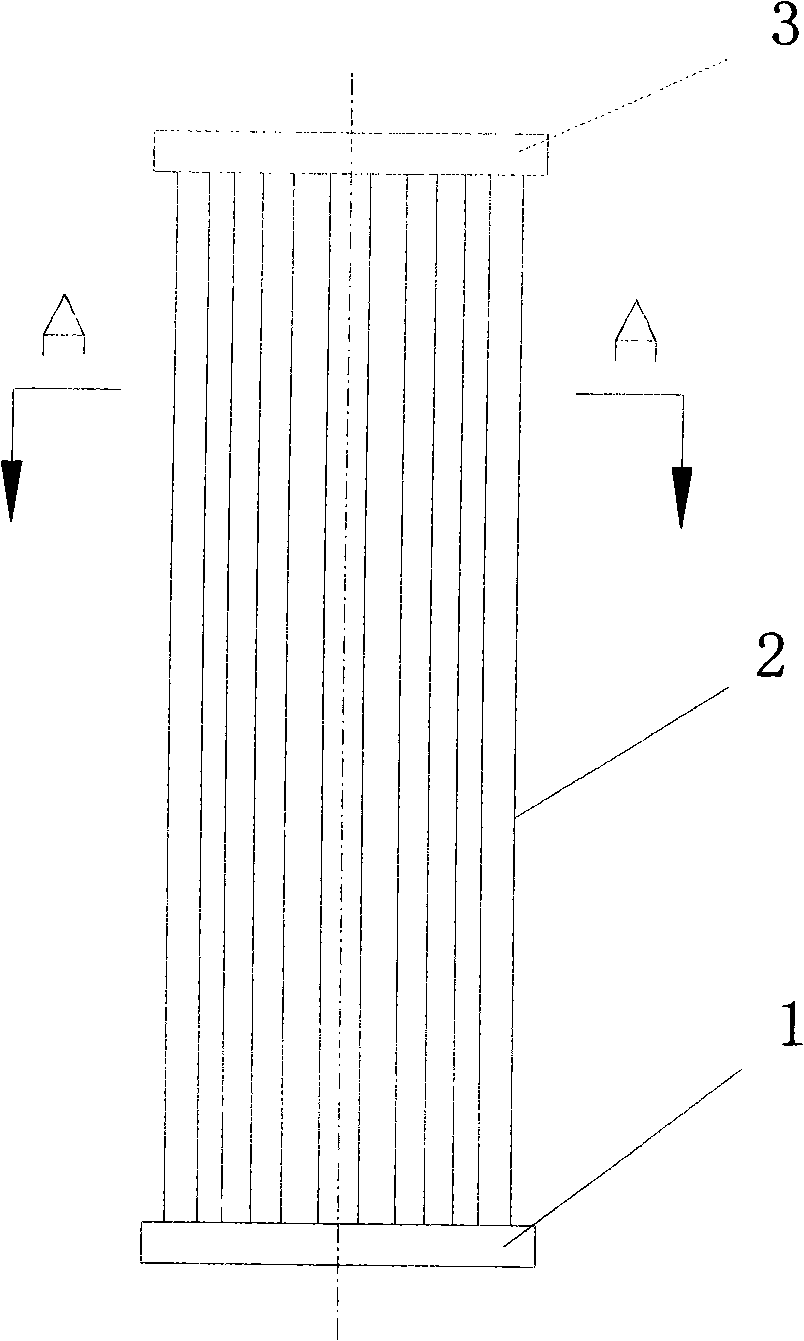

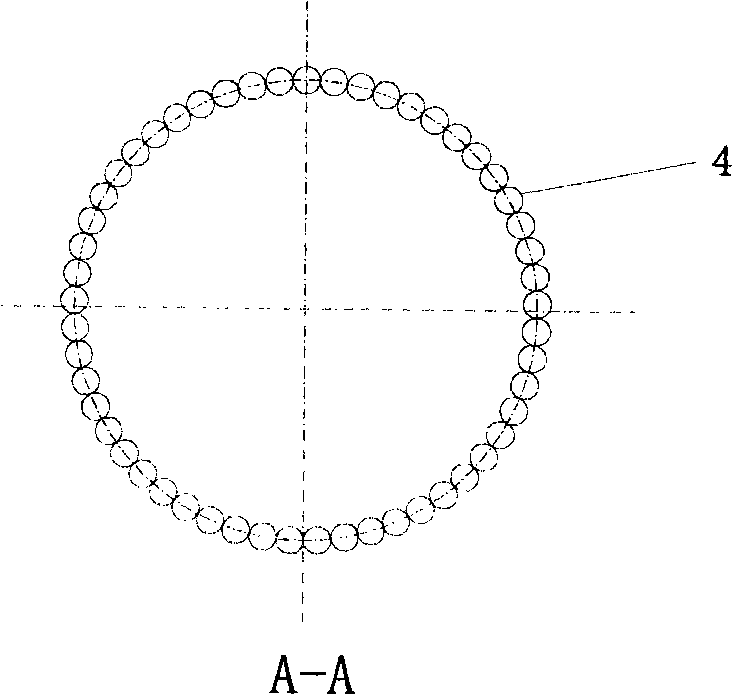

[0011] Such as figure 1 , 2 As shown, the present invention is a downcomer with a membrane wall structure, and the tube wall 2 of the downcomer is composed of a plurality of thin tubes 4 arranged in whole or in part. The upper and lower ends of the thin tube 4 constituting the membrane wall are respectively connected with the upper header 1 and the lower header 3 . Cooling water circulates in the upper header 1, thin tube 4 and lower header 3. The thin tube 4 is a smooth straight tube or a corrugated tube, and the arrangement that can be adopted is: vertical arrangement, horizontal arrangement, or spiral winding. The narrow tubes 4 are sequentially or occasionally connected by welding, and the thin tubes 4 that are occasionally connected are connected by flat steel.

[0012] When the membrane wall structure downcomer is in operation, the cooling water is introduced into the upper header 1 by the pump and distributed to each narrow tube 4, and the cooling water flowing in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com