Novel heat exchange tube

A technology of heat exchange tubes and heat exchange pipes, applied in the direction of tubular elements, heat transfer modification, heat exchange equipment, etc., can solve the problems of increased system energy consumption, complicated processing technology, and increased loss along the process, and achieve the goal of exchanging Increased thermal coefficient, enhanced heat transfer effect, and reduced resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

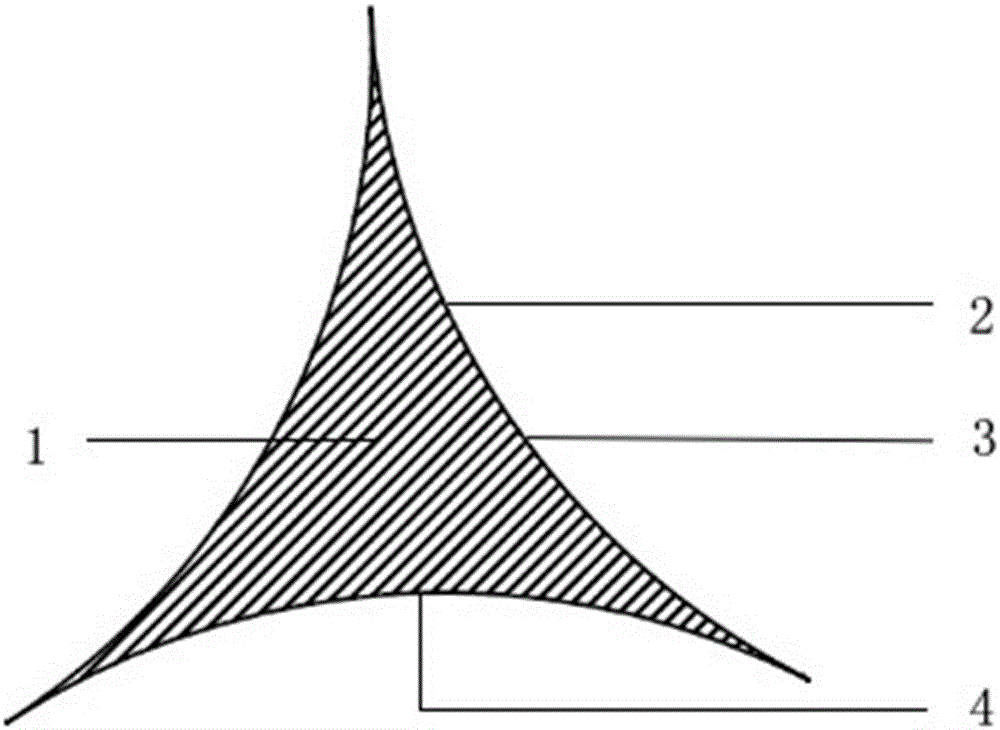

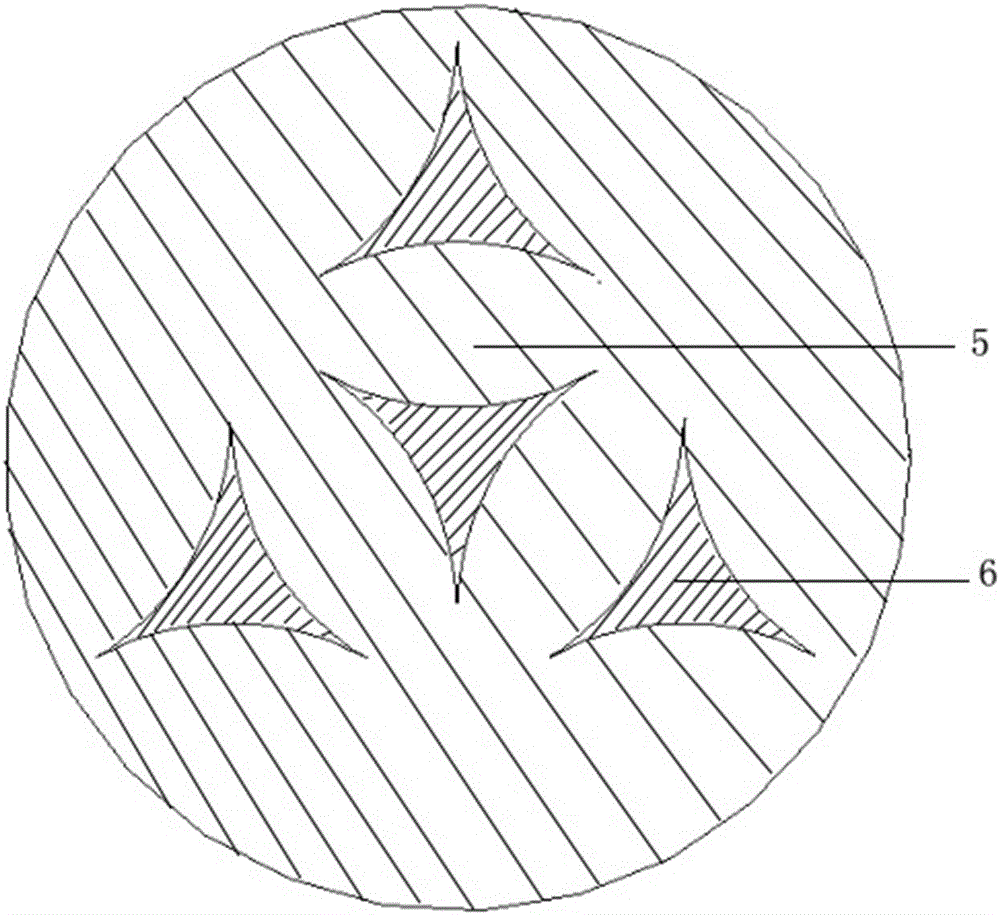

[0023] The cross-sectional shape of the pipe is formed by three equal circles with a radius of 25mm circumscribed in pairs; if the design requires that the B range is 550-1994m 2 / m 3 , the arrangement method 1 is adopted: equilateral triangle arrangement, the positional relationship between the pipe walls is as follows: take any one pipe geometric center as the rotation center, and the remaining three adjacent pipes are arranged rotationally symmetrically at a rotation angle of 120°, and the two adjacent pipes The axial center distance d is 30-40mm, and the length of the heat exchange tube is determined according to the design requirements of the heat exchanger. When the length of the heat exchange tube is less than 2m, the thickness of the tube wall is 2mm; When the ratio of the diameter a of the fluid inlet on the shell side of the heat exchanger to the length b of the heat exchange tube is less than 0.2, the included angle of the wall of the heat exchange tube shall be arr...

specific Embodiment 2

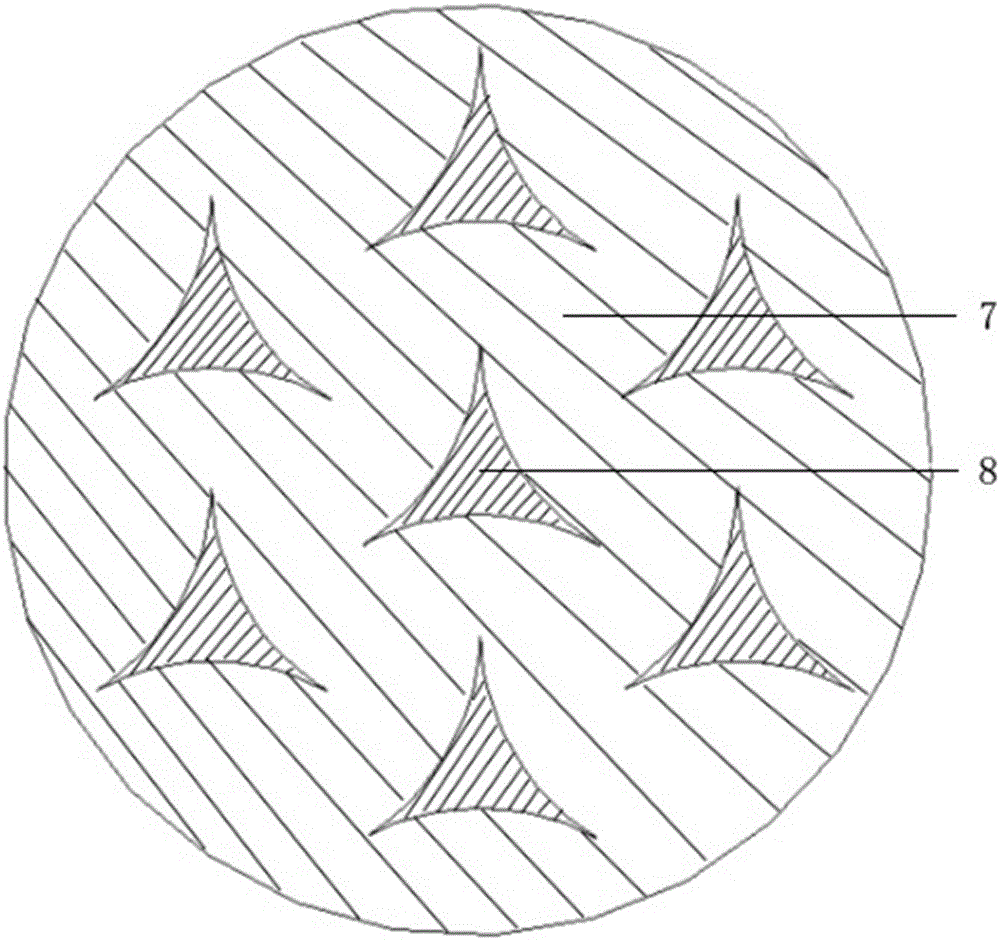

[0026] The cross-sectional shape of the pipe is formed by three equal circles with a radius of 25mm circumscribed in pairs; if the design requires that the range of B is 500-636m 2 / m 3 , using the second arrangement: regular hexagonal arrangement, with any one pipe geometric center as the center of rotation, and the other 6 adjacent pipes are arranged rotationally symmetrically at a rotation angle of 120°, and the axial center distance d of two adjacent pipes is 37- 45mm, the length of the heat exchange tube is determined according to the design requirements of the heat exchanger. When the length of the heat exchange tube is less than 2m, the thickness of the tube wall is 2mm; when the length of the heat exchange tube is greater than 2m, the thickness of the tube wall is 3mm; When the ratio of a to the length b of the heat exchange tube is less than 0.2, the included angle of the wall of the heat exchange tube shall be arranged in the direction of the incoming flow; the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com