Gravity heat pipe with annular element

A technology of gravity heat pipes and components, applied in the field of heat exchange, can solve problems such as unfavorable promotion, inability to maintain bead condensation for a long time, and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

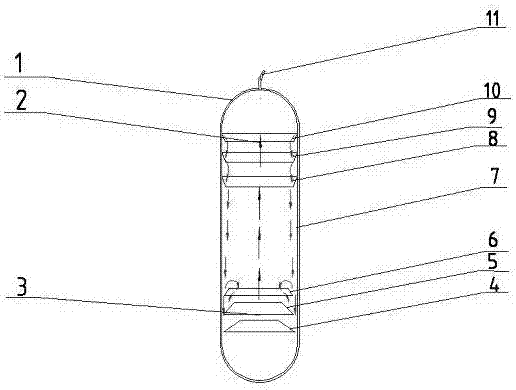

[0012] The technical solutions of the present invention will be described below through specific embodiments in conjunction with the accompanying drawings.

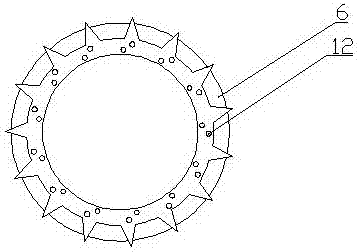

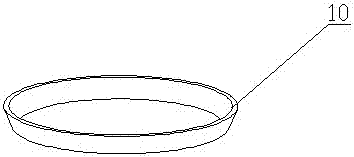

[0013] see figure 1 , and combined with figure 2 and image 3 , a gravity heat pipe with annular components, including a shell 1, a condensation section 2, an evaporation section 3, a heat preservation section 7, a process port 11, and n evaporation section annular components 4 installed in the evaporation section 3 and installed in the condensation section n condensing section ring elements 8 of section 2. Set n ring components in the evaporation section as needed, and set n ring components in the condensation section as needed, and n is an integer greater than or equal to 1. The annular component 10 of the condensation section and the pipe wall of the condensation section 2 are fixed together through interference fit. The inner central hole of the annular component 10 in the condensation section is not only the des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com