Patents

Literature

92results about How to "Has a diversion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

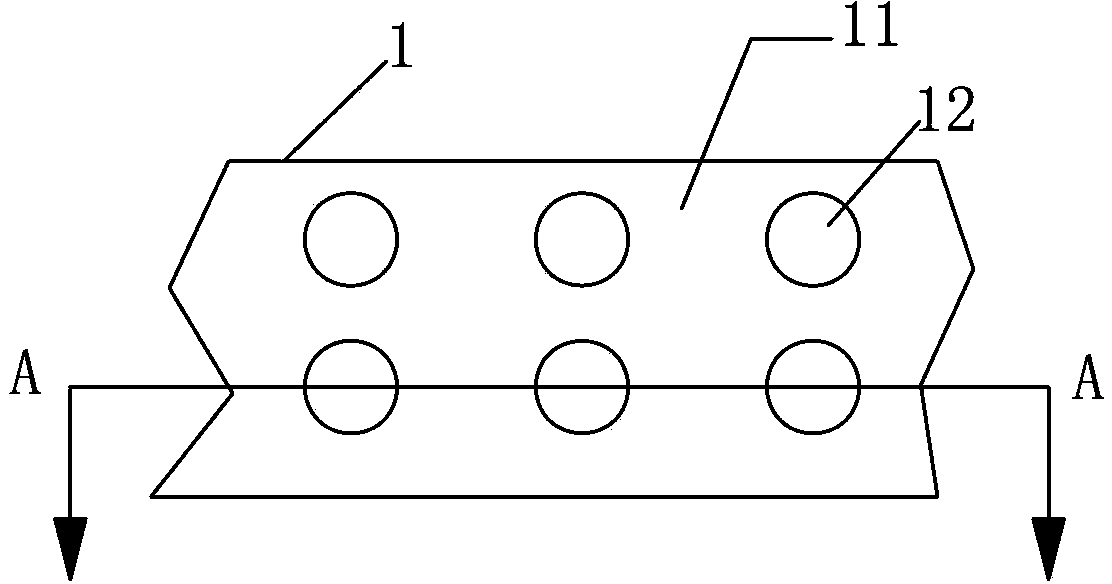

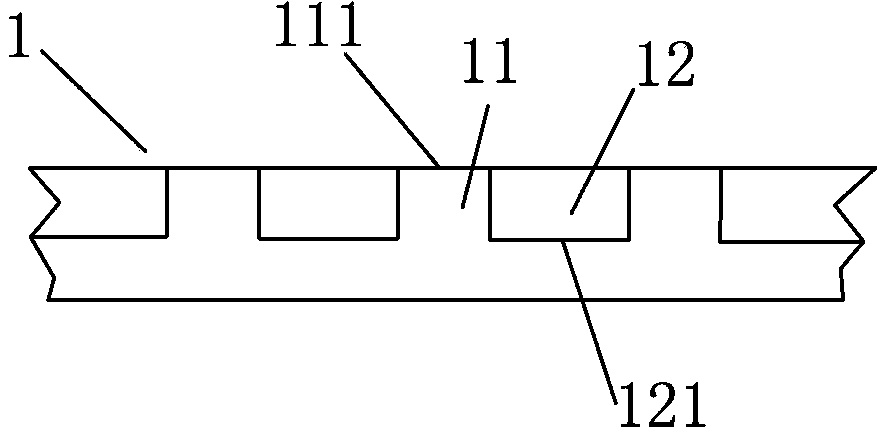

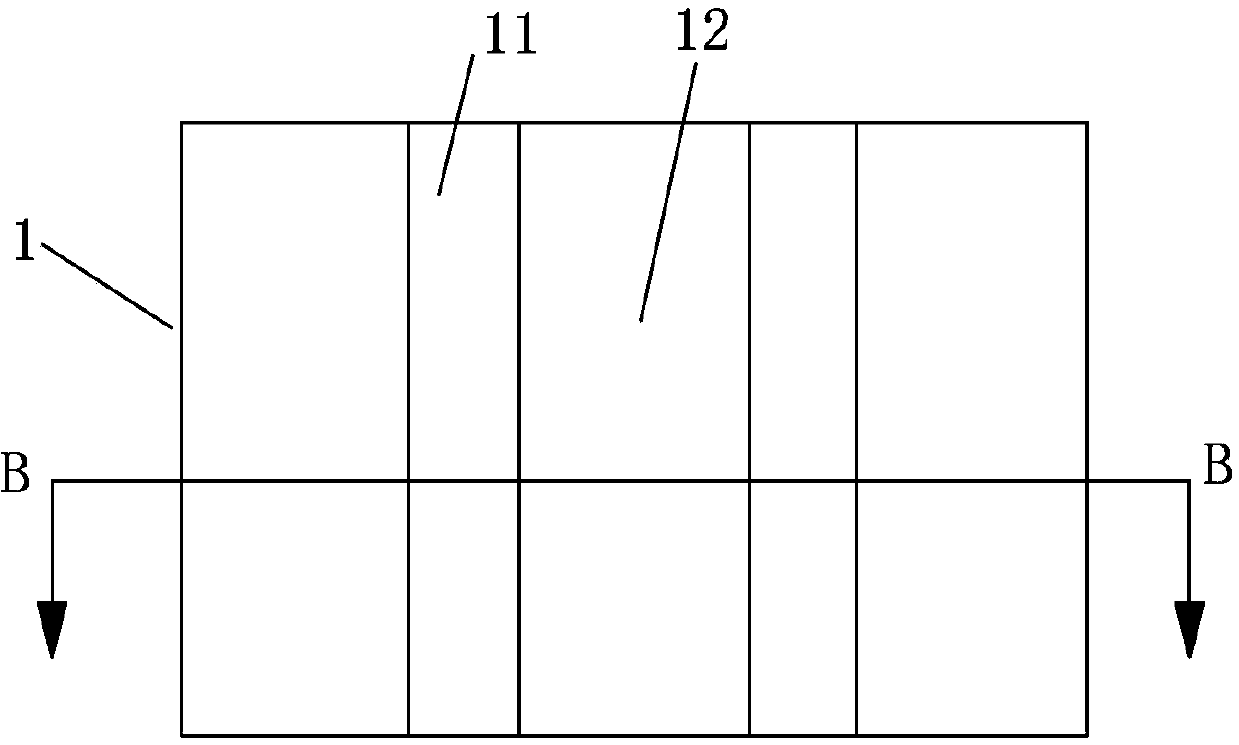

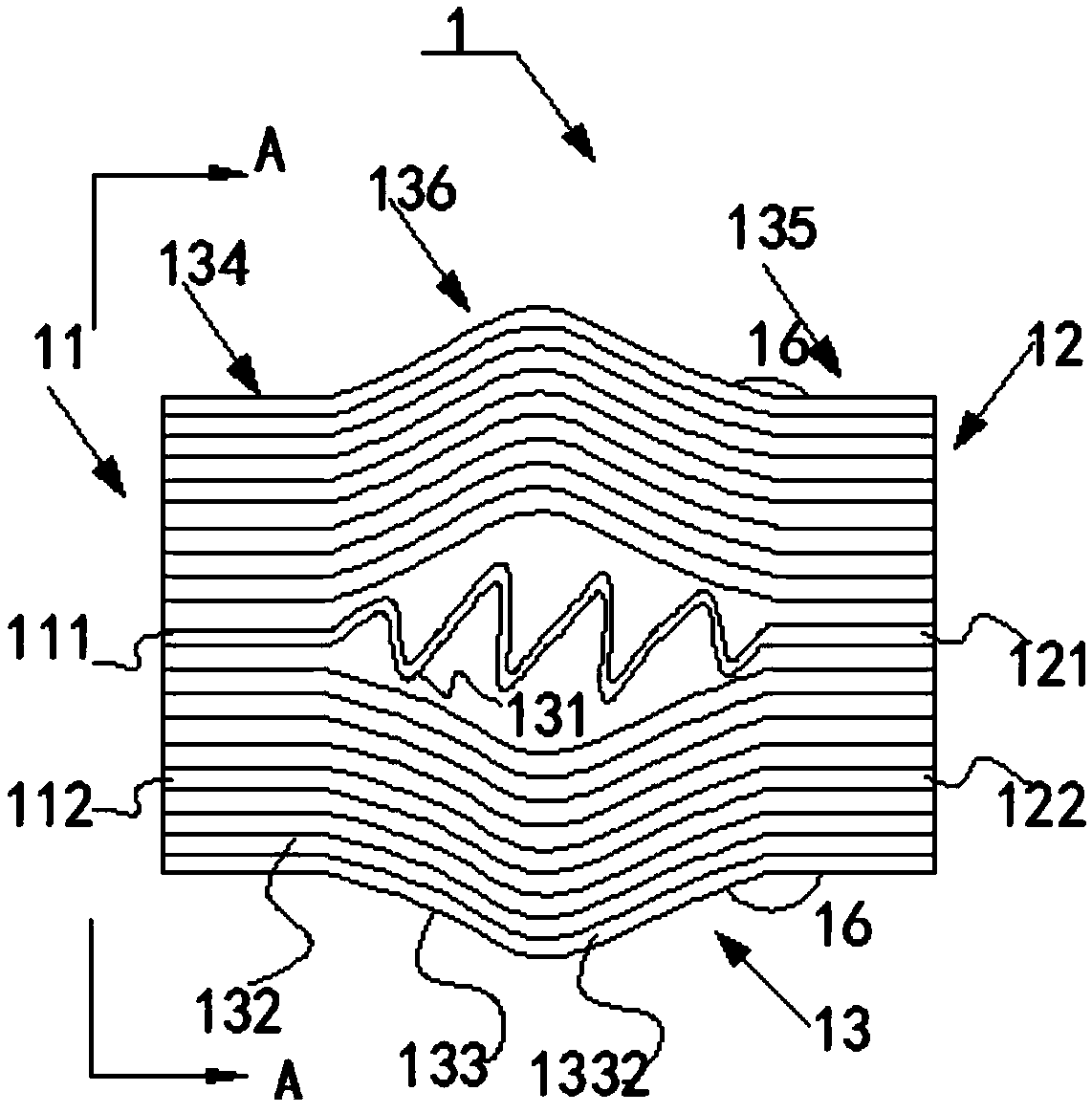

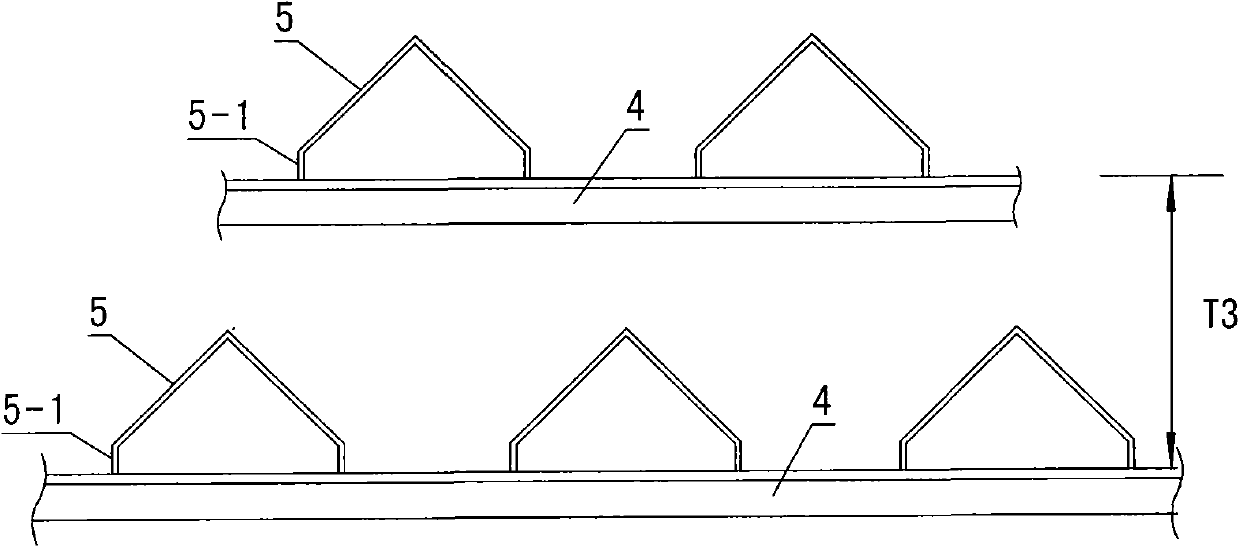

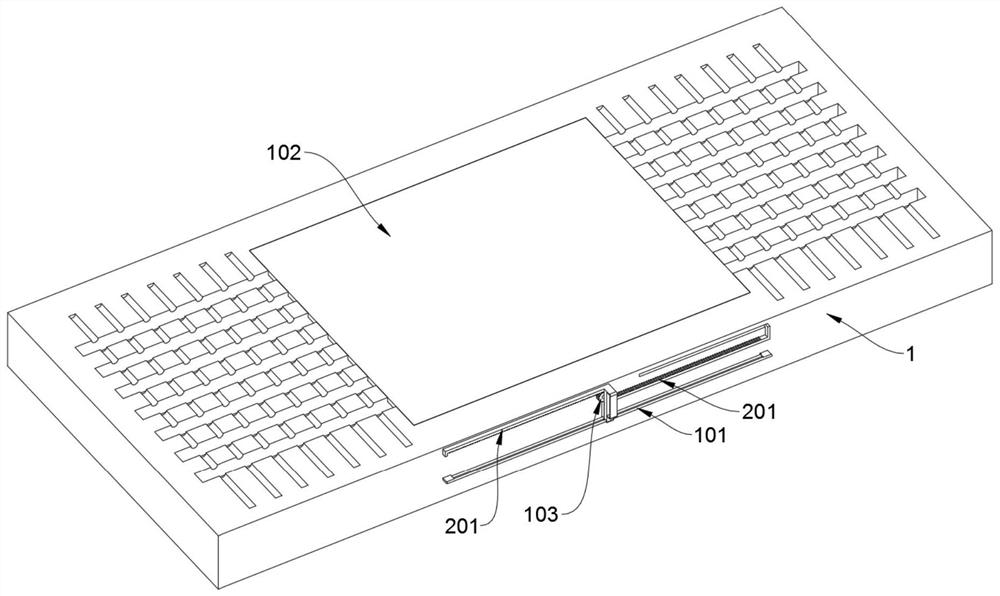

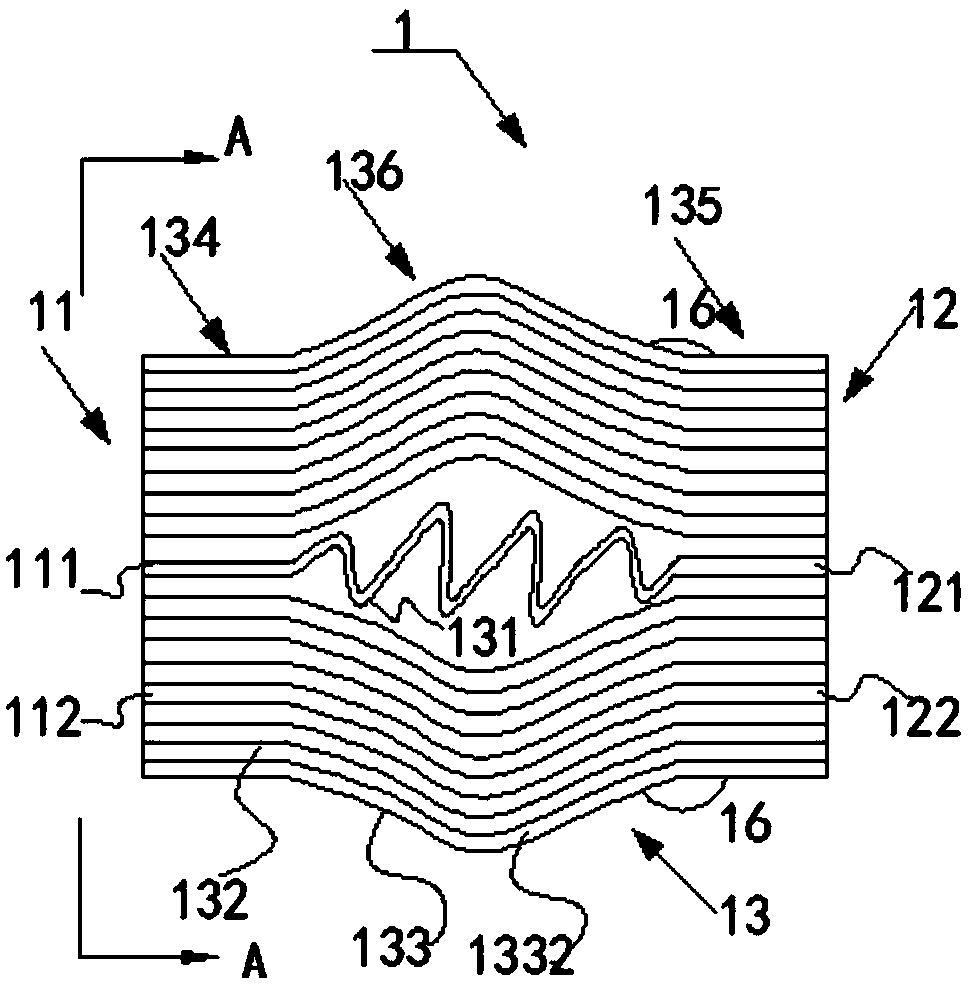

Three-dimensional non-woven fabric

ActiveCN103417338AIncrease the effective use areaPromotes rapid absorptionNon-woven fabricsBandagesWoven fabricEngineering

The invention discloses three-dimensional non-woven fabric. The surface of the three-dimensional non-woven fabric comprises a plurality of convex parts and a plurality of concave parts. The convex parts and the concave parts are arranged at intervals and are made of the same material. The contact angle of 20% to 100% area of each convex part and water is larger than 70 degrees, and the contact angle of 20% to 100% area of each concave part and the water is smaller than 70 degrees. The three-dimensional non-woven fabric has the advantages of being dry and comfortable.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

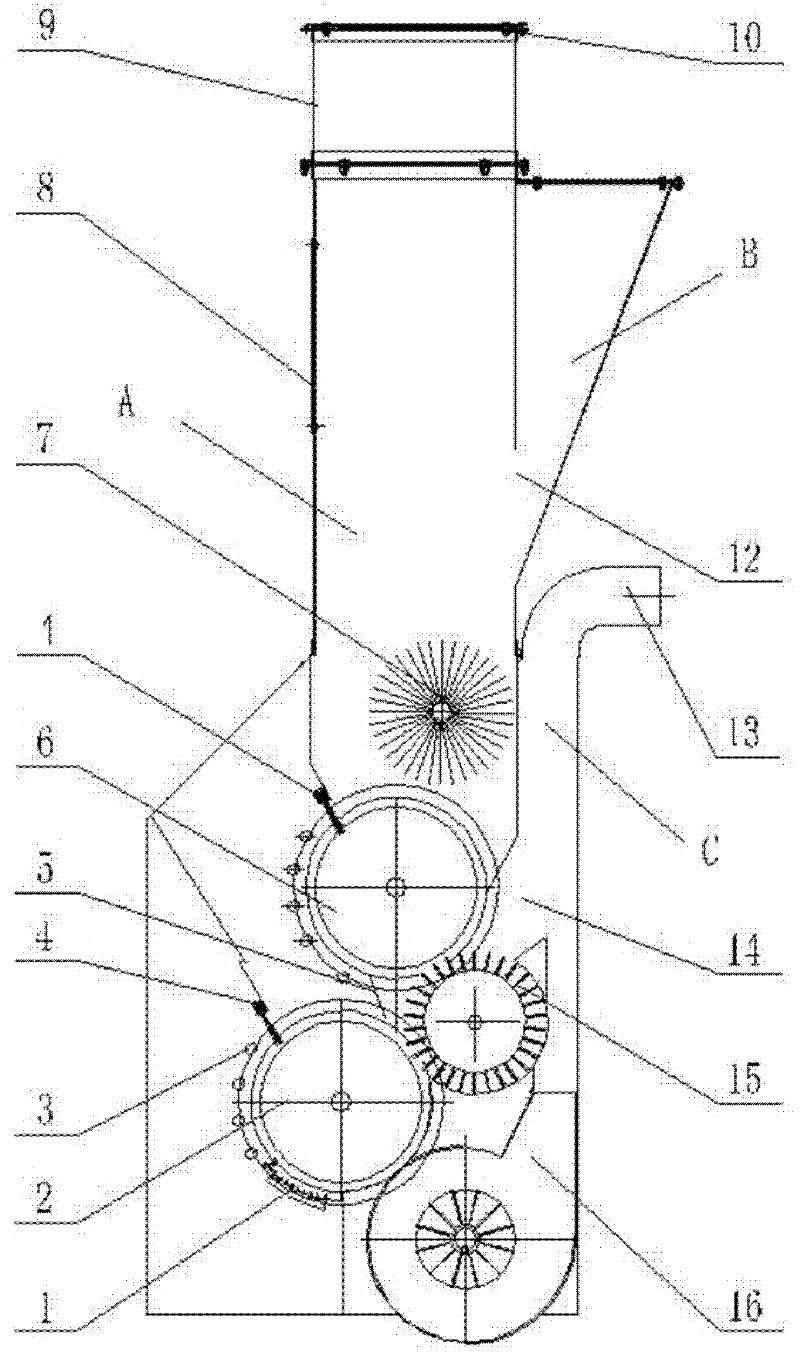

Onboard efficient cotton cleaning device

ActiveCN102577752AAvoid lostAvoid clogging and can't rule out fine impuritiesPicking devicesHoneycombEngineering

The invention relates to an onboard efficient cotton cleaning device, which belongs to the technical field of agricultural machinery and comprises a vertical flow channel with an input hole in the middle of one side. A cellular box with honeycomb holes on the lateral wall is installed on the top of the vertical flow channel, an upper toothed roller and a lower toothed roller supported inside a lower casing are installed on the lower portion of the vertical flow channel, an upper brush and a lower brush radially extending towards the upper toothed roller and the lower toothed roller are respectively mounted at the same-side lower ends of the vertical flow channel and the input hole and on the lower casing, beating rods are distributed at intervals on the sides, corresponding to the input hole, of the upper toothed roller and the lower toothed roller along circular tracks, a cotton collection channel for delivering air flow from bottom to top is arranged at the bottom of the casing. A suction hole on the side, opposite to the beating rods, of the upper toothed roller is reserved in the middle of the cotton collection channel, a return hole lower than the input hole is reserved on the side, opposite to the input hole, of the vertical flow channel, and a distribution channel extends up diagonally from the return hole and out of the vertical flow channel. The onboard efficient cotton cleaning device is capable of preventing unginned cotton from being blown out of an impurity hole and impurities from directly entering a cotton collection box in a short-pass manner, and accordingly the rate of impurities is lowered effectively.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Filter with particulate matter separation function for oil field demulsifier production

ActiveCN114042347AAvoid excessive accumulationAvoid blockingMoving filtering element filtersDemulsifierParticulates

The invention relates to the technical field of demulsifier production, in particular to a filter with a particulate matter separation function for oil field demulsifier production. The technical problems that separated particle impurities are inconvenient to discharge out of a filtering device, normal use of the filtering device is reduced, and the filtering efficiency of a demulsifier is reduced are solved. According to the technical scheme, the filter with the particulate matter separation function for oil field demulsifier production comprises a supporting shell, a feeding mechanism, a vibration filtering mechanism and the like, the inner side face of the bottom of the supporting shell is provided with a protrusion, the feeding mechanism is arranged above the supporting shell, and the vibration filtering mechanism is arranged on the upper portion of the inner side face of the supporting shell. By designing the feeding mechanism, non-uniform discharging of an oil field demulsifier caused by different pressures of the oil field demulsifier to the bottom of the material containing shell is avoided, by designing the vibration filtering mechanism, the filtering efficiency of the sieve plate is improved, and meanwhile, the situation that too many impurity particles are accumulated, and filtering holes in the sieve plate are blocked is avoided.

Owner:东营市宝泽能源科技有限公司 +1

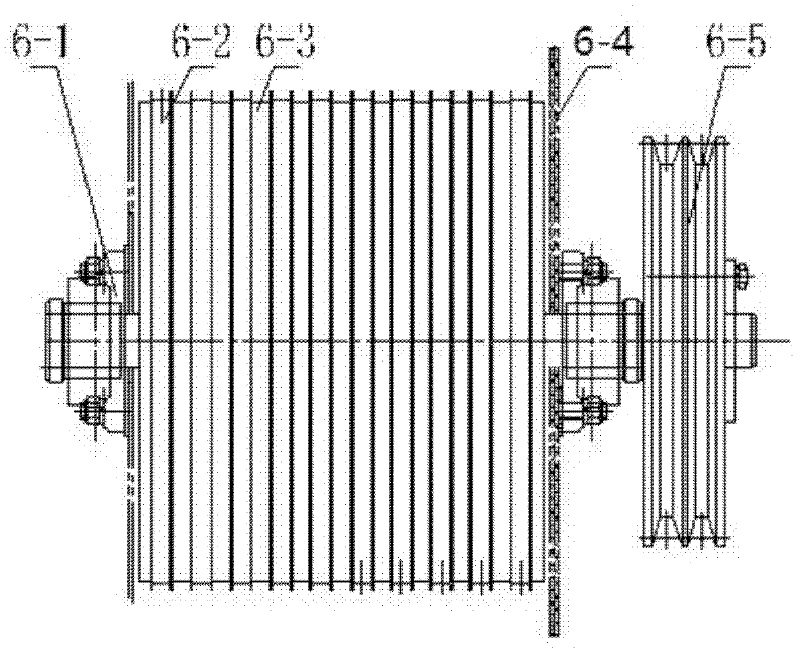

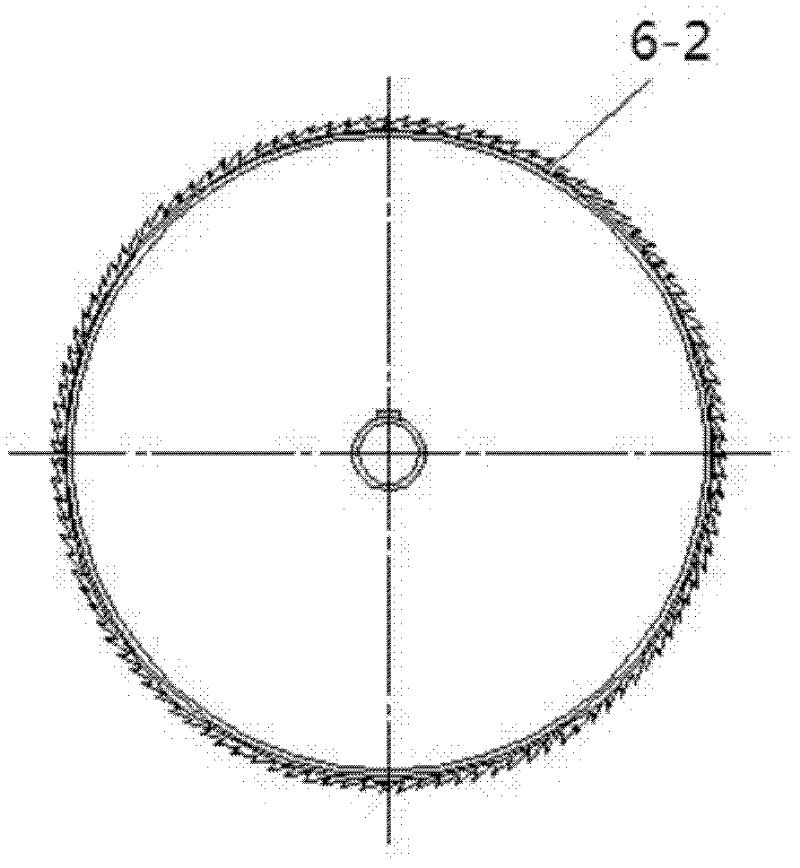

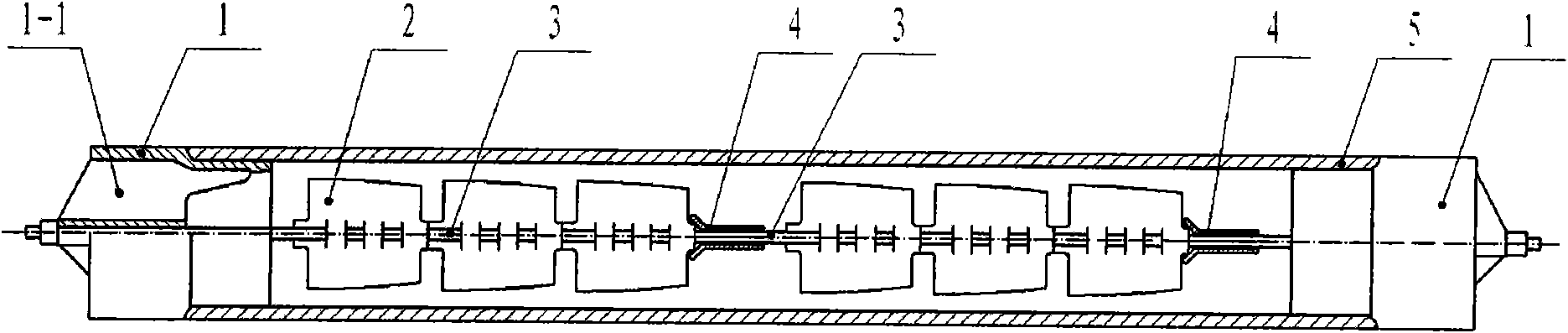

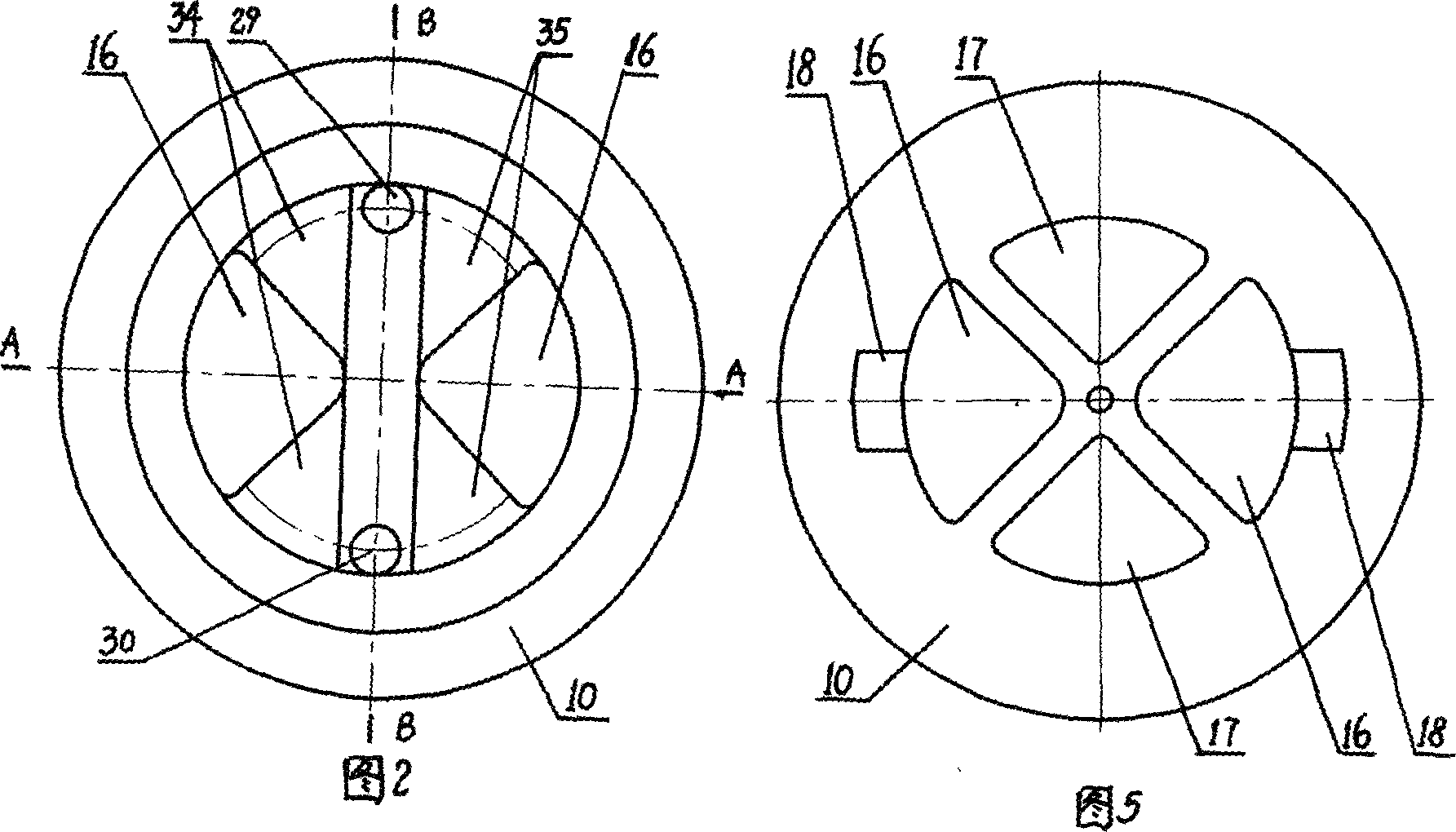

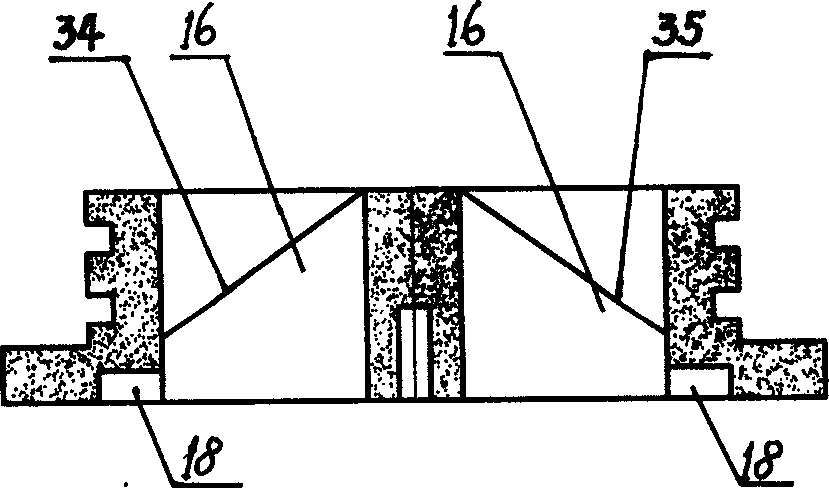

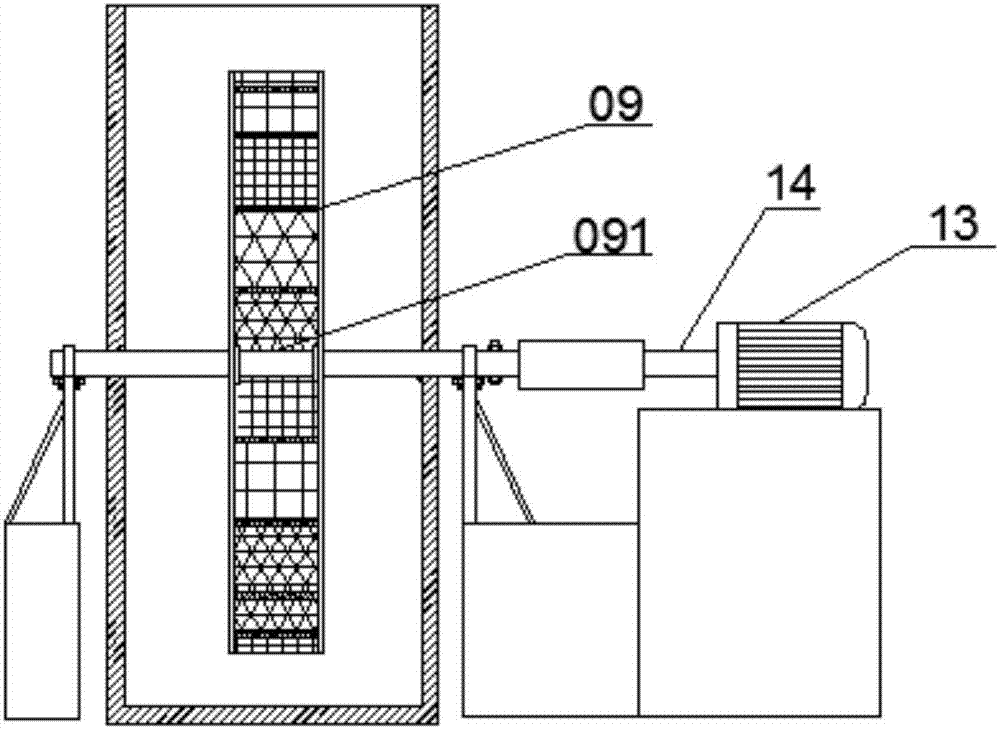

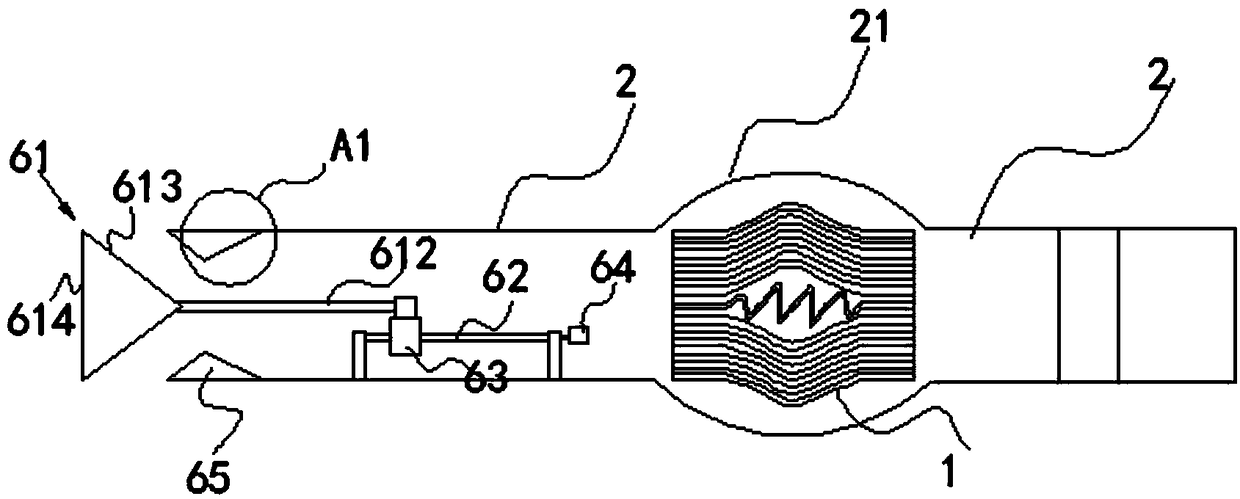

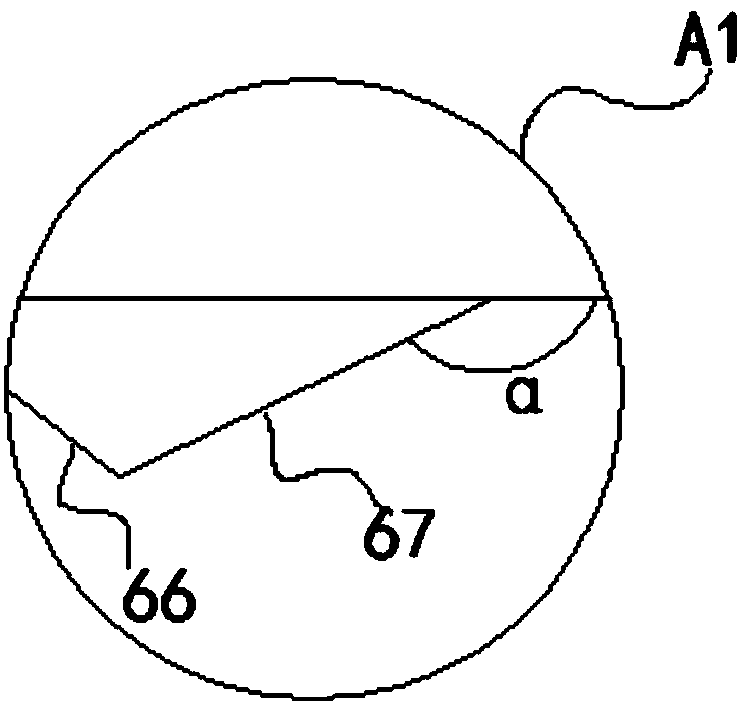

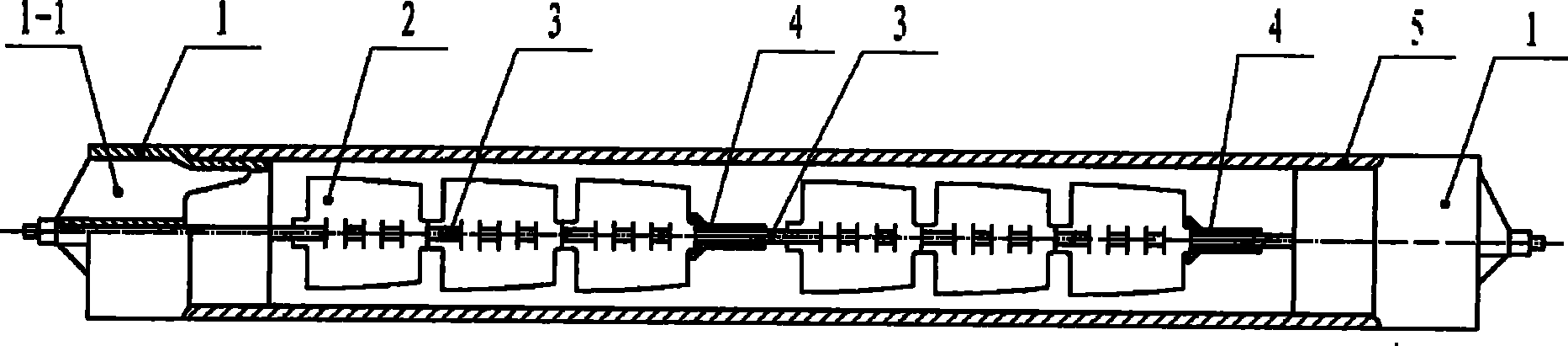

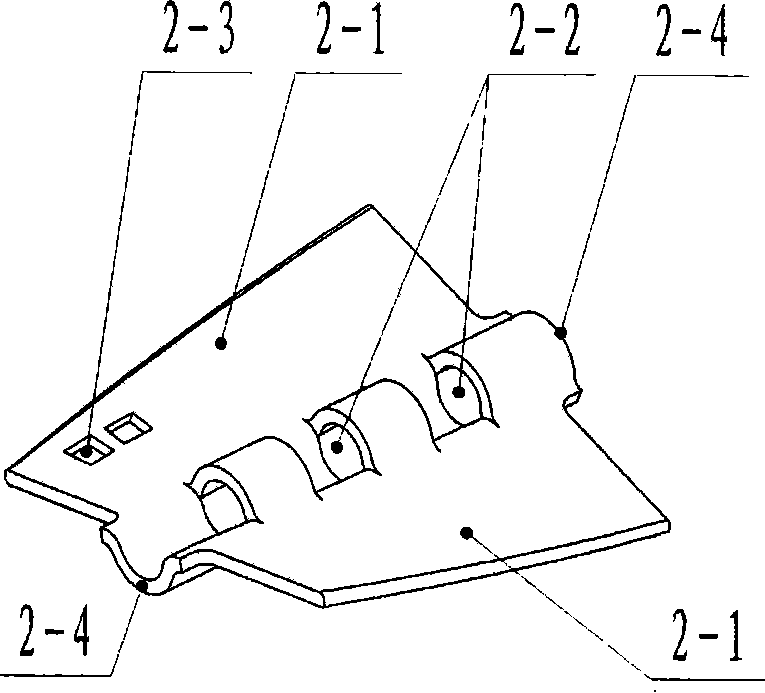

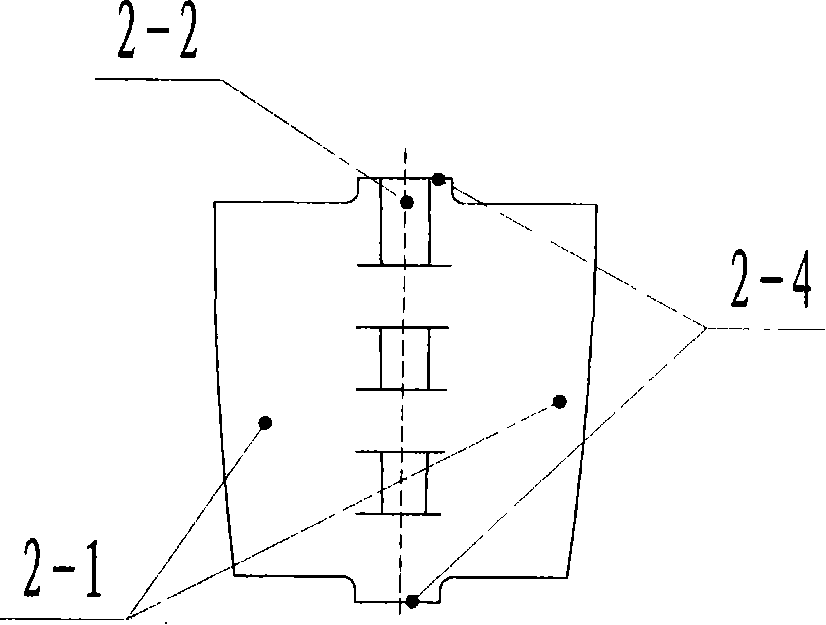

Rotating piece type automatic-cleaning and heat-transfer enhancing device

InactiveCN101551214ALow rotational resistanceSave materialHeat transfer modificationRotary device cleaningDual functionScale control

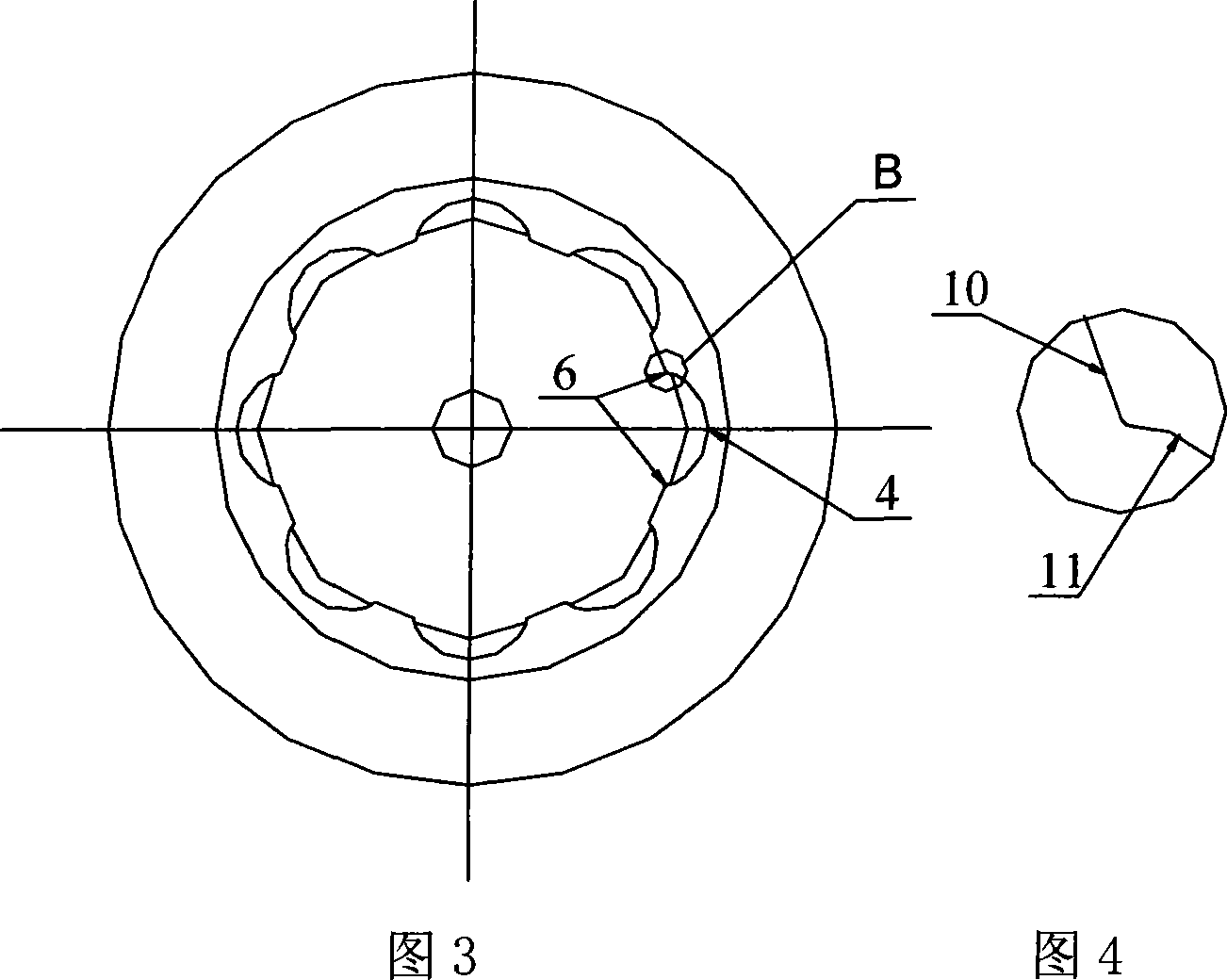

The invention relates to a rotating piece type automatic-cleaning and heat-transfer enhancing device, in particular to a device used for a heat transfer pipe for a tubular heat exchange device. The device comprises one or more rotating piece(s), hanging parts, an axial line and limiting rivets and is used by being placed in a heat exchanger, wherein the number of the hanging parts is two, and the two hanging parts are respectively fixed at both ends of the heat transfer pipe; the rotating pieces are placed in the heat transfer pipe of the heat exchanger; the rotating pieces are used and arranged in groups, and the limiting rivets are arranged between each group of the rotating pieces at intervals; the axial line penetrates through an axle holes of the rotating pieces and the limiting rivets, and both ends of the axial line are fixed on the two hanging parts; the rotating pieces are of screw twisted shapes, concavo-convex slot structures are alternatively arranged at the position of the axial line at intervals and are axle holes of the axial line, the friction between the rotating pieces and the axial line can be effectively reduced, thus the service life of the rotating pieces is prolonged; and the rotating pieces have simple molds, can be made of plastics or metal and can be molded by pressing or by injection according to the different materials. The device has the dual functions of automatic on-line cleaning and scaling control and enhancing heat transfer in the heat transfer pipe and is convenient to manufacture, assemble, use and replace.

Owner:BEIJING UNIV OF CHEM TECH

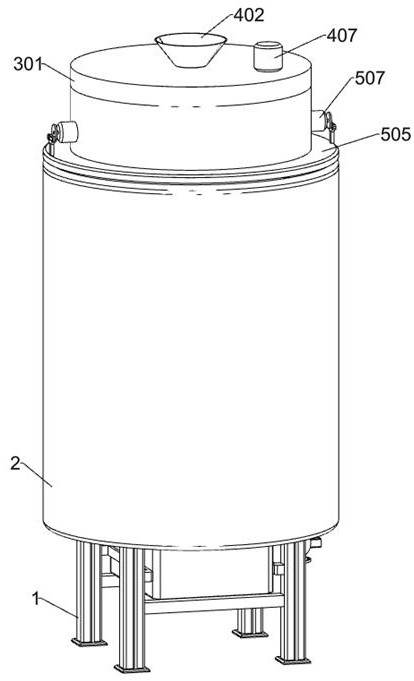

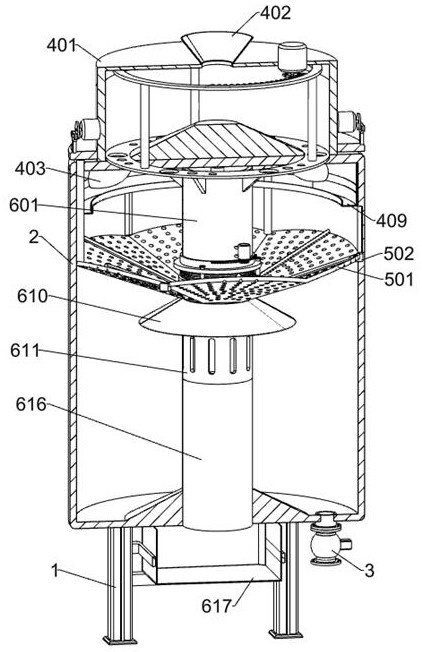

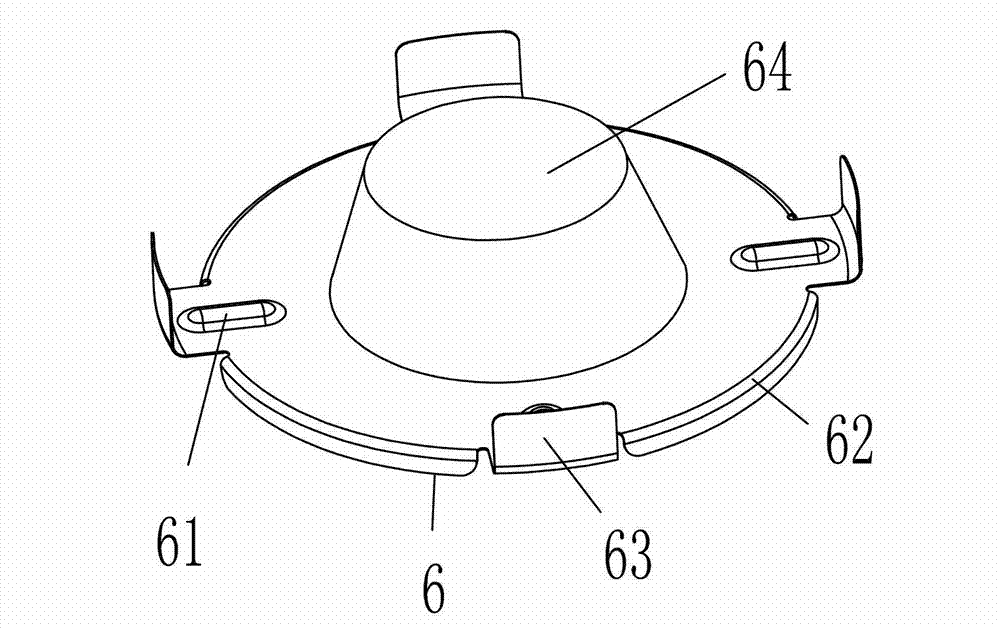

Heating container of water dispenser and control method thereof

InactiveCN103110358AProtection against dry burn damageSimple control methodBeverage vesselsThermodynamicsEngineering

The invention relates to the field of accessories of a water dispenser and provides a heating container of the water dispenser and a control method thereof. The heating container of the water dispenser comprises a heating container body, an installation support fixedly connected at the upper end of the heating container body, at least one water temperature control device for controlling temperature of water inside the heating container body, a water inlet pipe, a water outlet pipe, a buffer disk located in the heating container body and fixedly connected with the inner side of the heating container body, an electric heating disk provided with a heating element and fixedly connected with the lower end of the heating container body, a high temperature controller and a temperature fuse, wherein the high temperature controller and the temperature fuse are fixed on the electric heating disk, the buffer disk divides the heating container body into an upper cavity and a lower cavity and is provided with a plurality of through holes, the water inlet pipe is communicated with the upper cavity, and the water outlet pipe is communicated with the lower cavity. An electric heater of the heating container of the water dispenser can be effectively protected, not prone to dry burning and be damaged, and cold water can not directly flow to the water outlet pipe after entering the heating container body through the water inlet pipe so that water outlet temperature decreases slowly. The control method of the heating container of the water dispenser is simple, practical and good in safety.

Owner:ELECTROTEMP TECHNOLOGIES CHINA INC

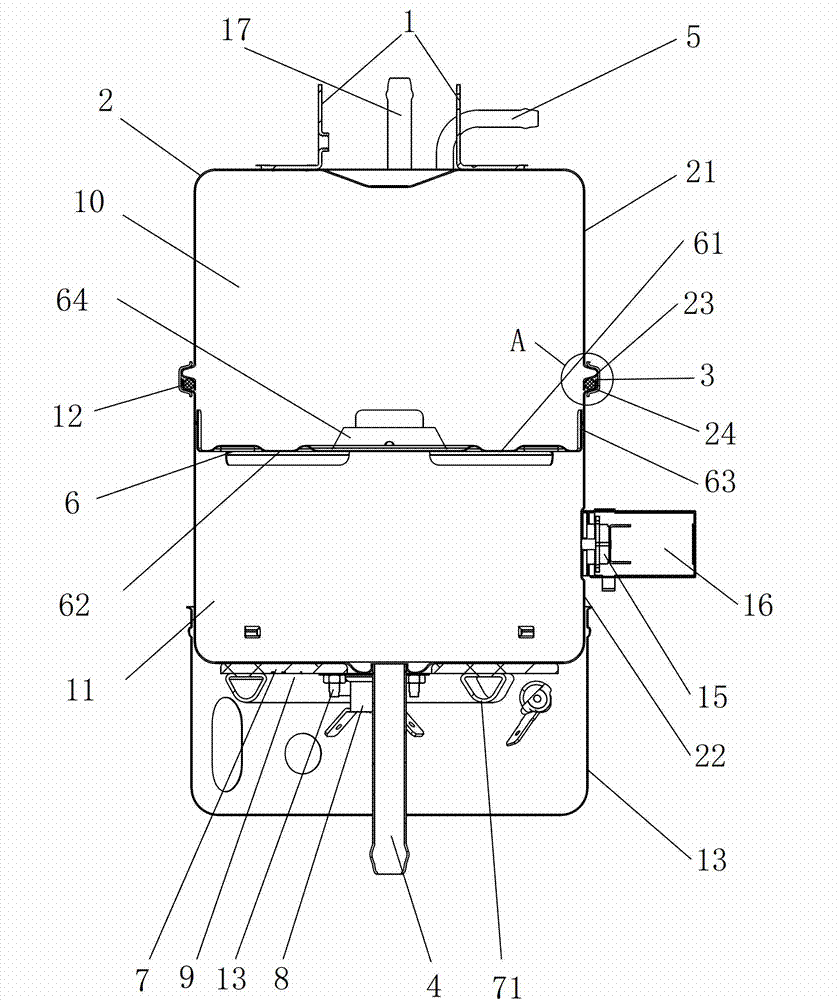

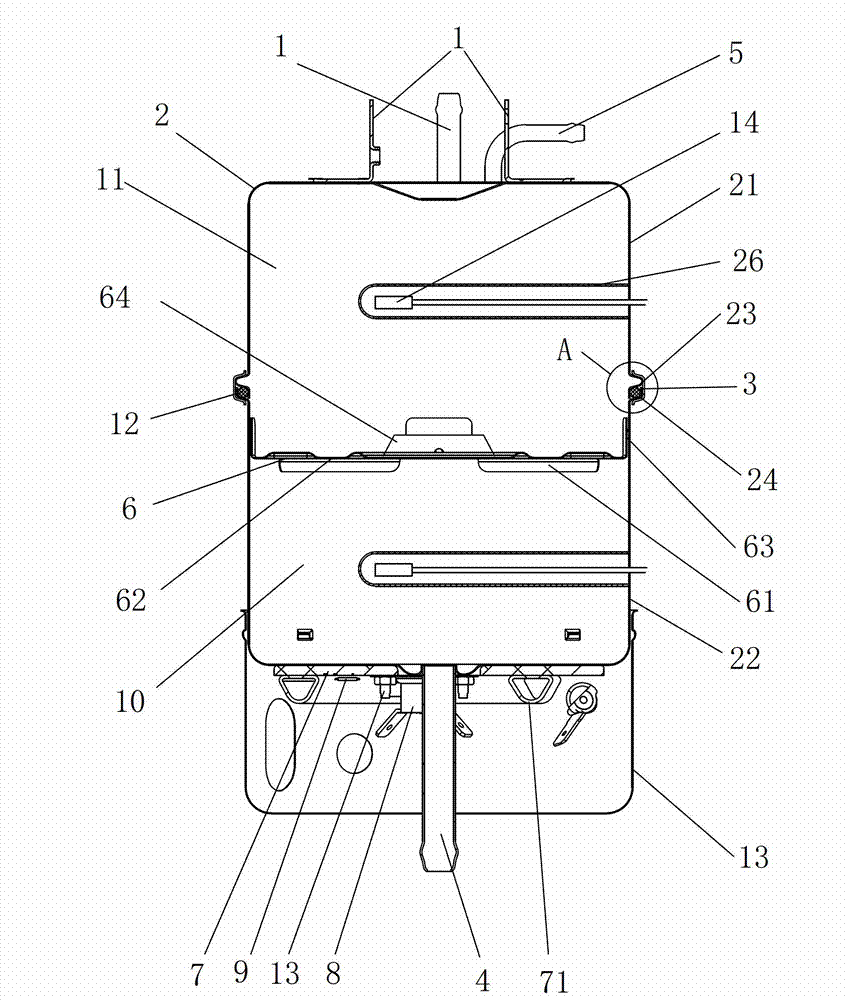

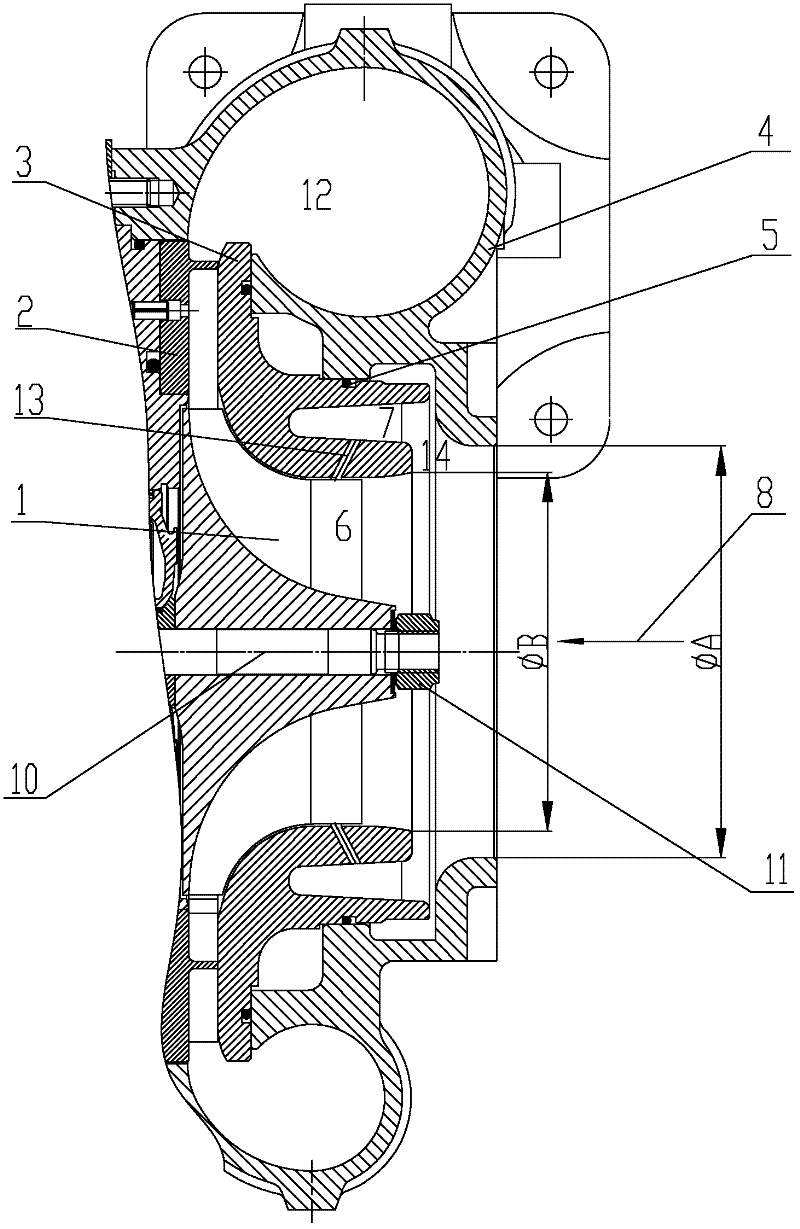

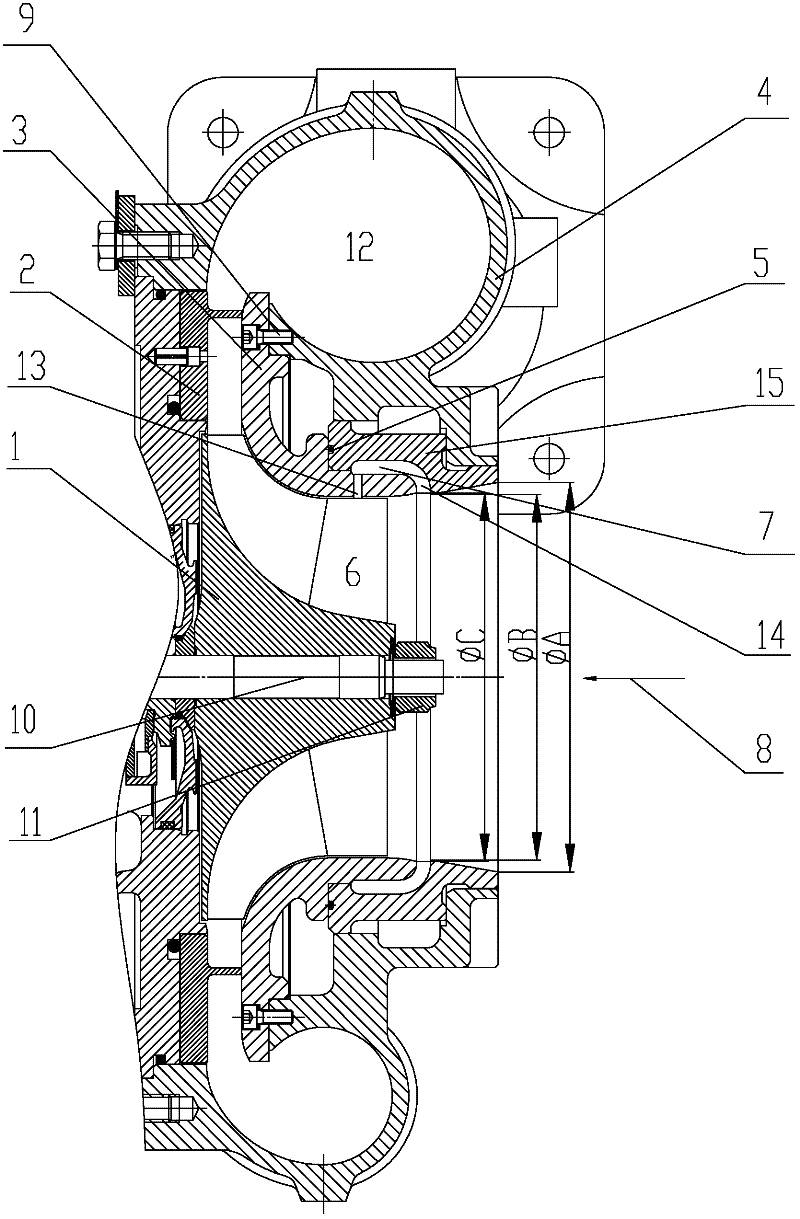

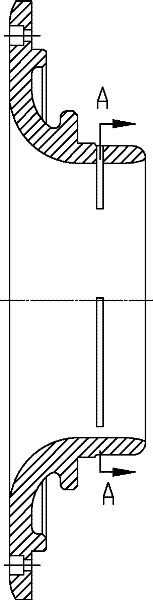

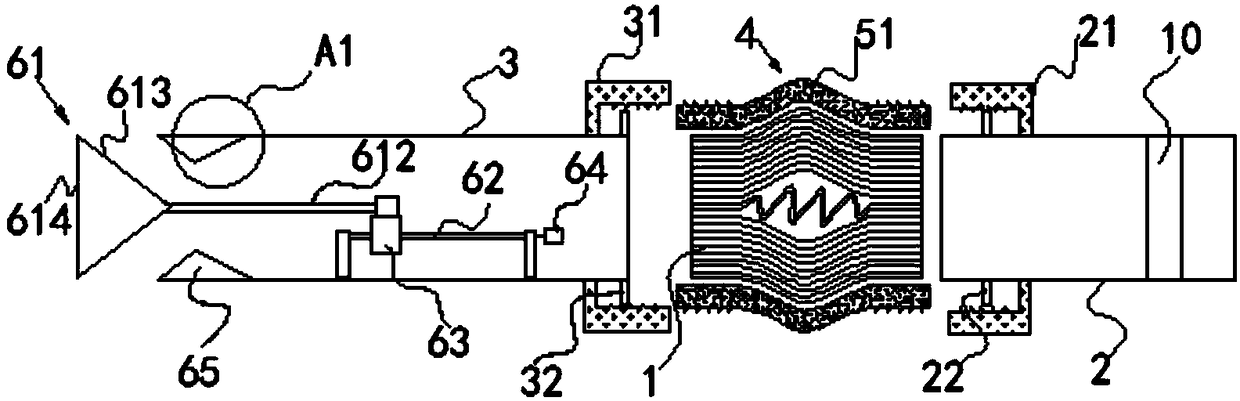

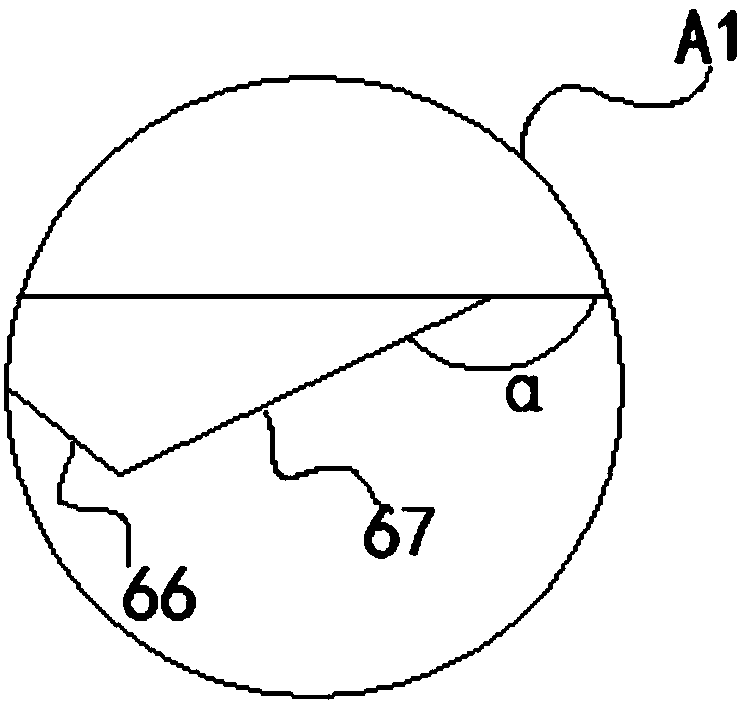

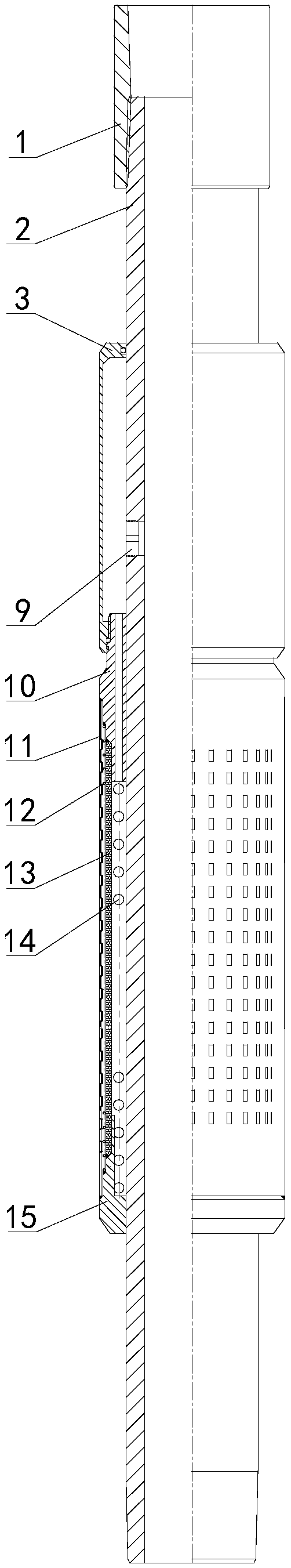

Low-noise device for centrifugal compressor of turbocharger

InactiveCN102588351AReduce secondary flow lossSpeed up the flowPump componentsPumpsLow noiseInlet channel

The invention discloses a low-noise device for a centrifugal compressor of a turbocharger, aiming at overcoming the defect of serious airflow turbulence after an air guide wheel air incoming re-circulating structure is adopted by a turbocharger with the lowest cost so as to lower noise and improve the efficiency of the compressor. The low-noise device has the following technical scheme that based on the prior art, a space is formed between a shell 4 of an air compressor and an air guide sleeve 3, and a flow guide cover 15 is arranged in the low-noise device so as to form secondary air inlet passages 7 and 14; and arc flow guide treatment is carried out at the turning of the channel of related parts, and the air guide sleeve 3 is provided with 3 grooves or 3-20 circular holes at the radial circumference corresponding to an impeller 1 of the air compressor. The low-noise device can be widely applied to compressors to lower the noise and has wide application prospect.

Owner:大同北方天力增压技术有限公司

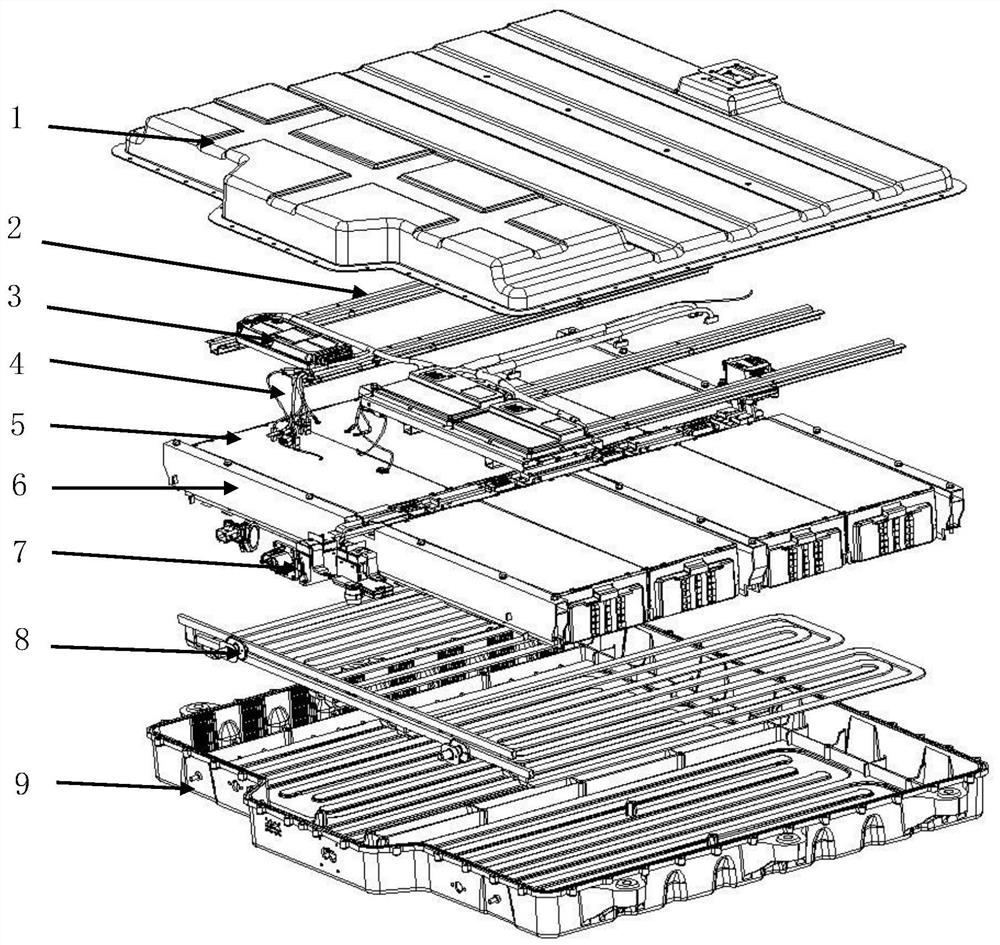

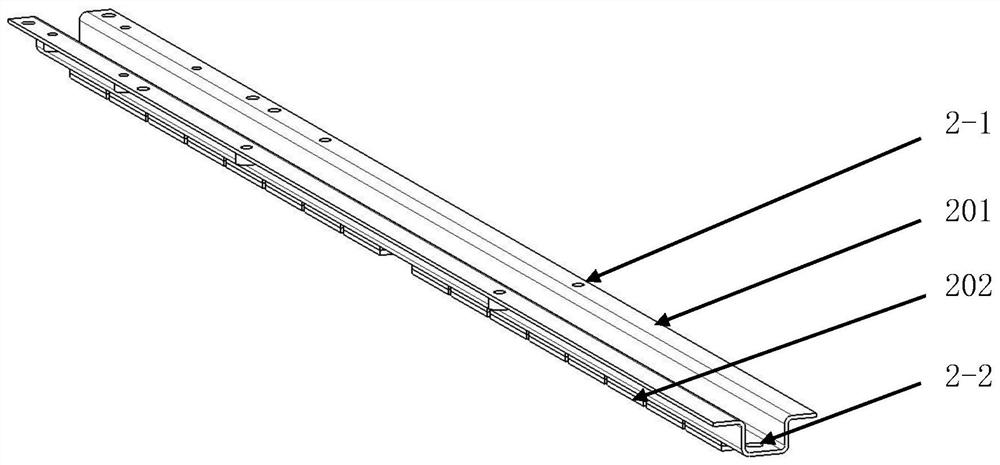

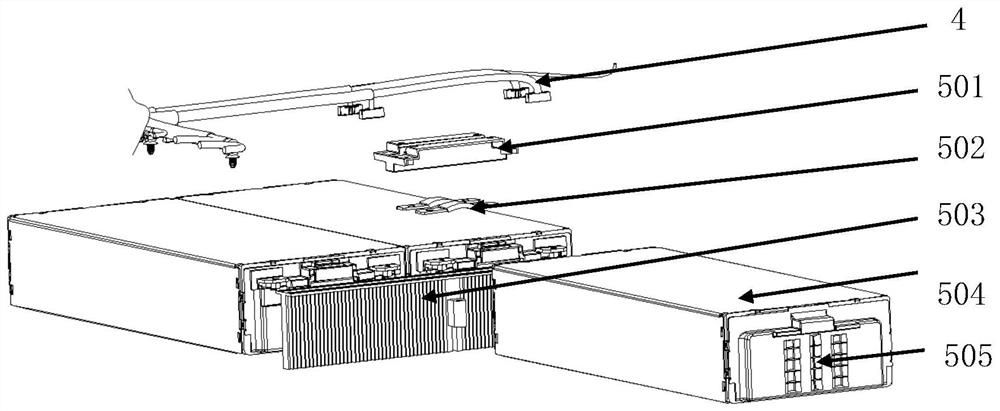

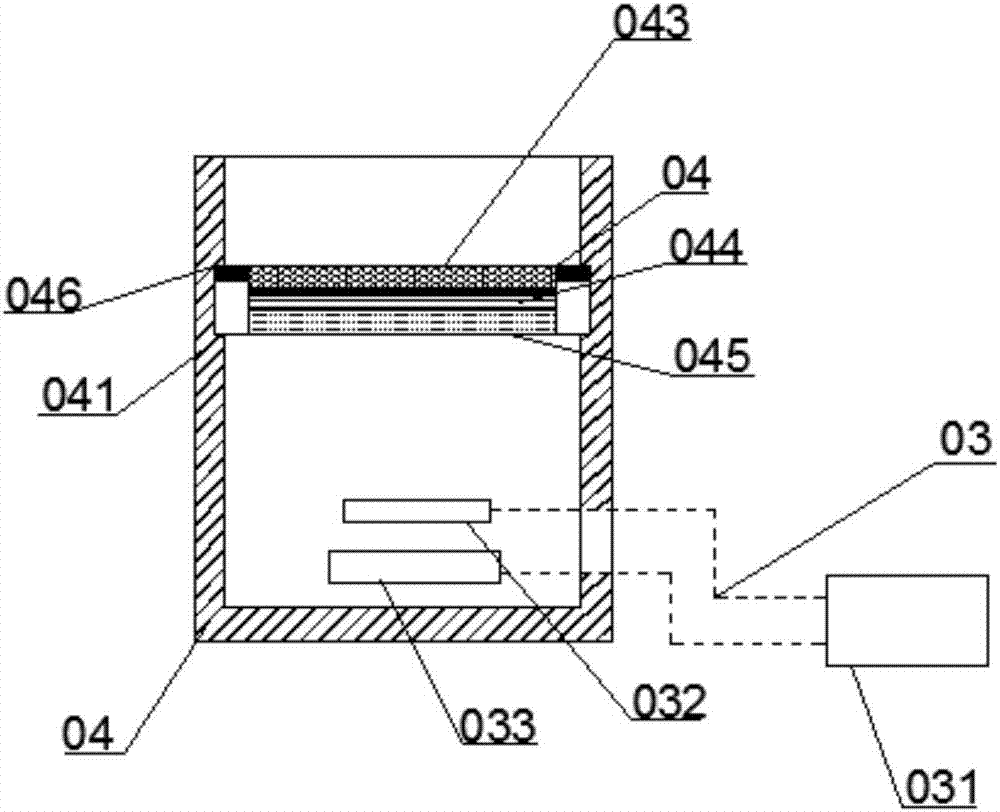

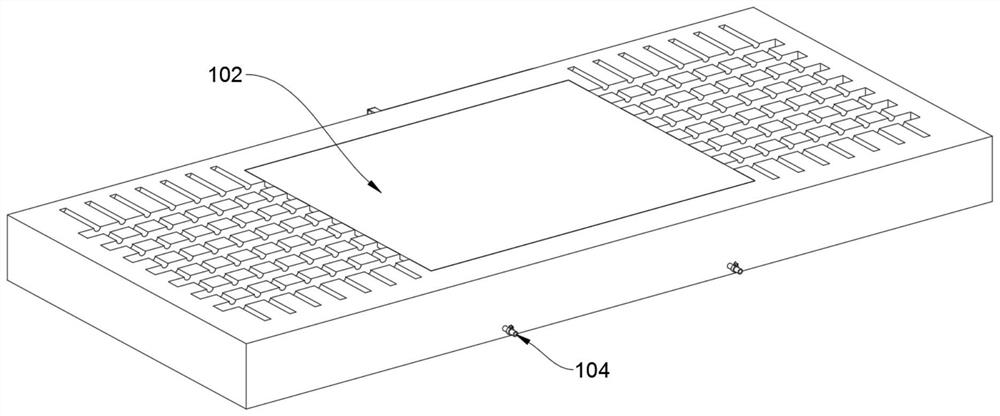

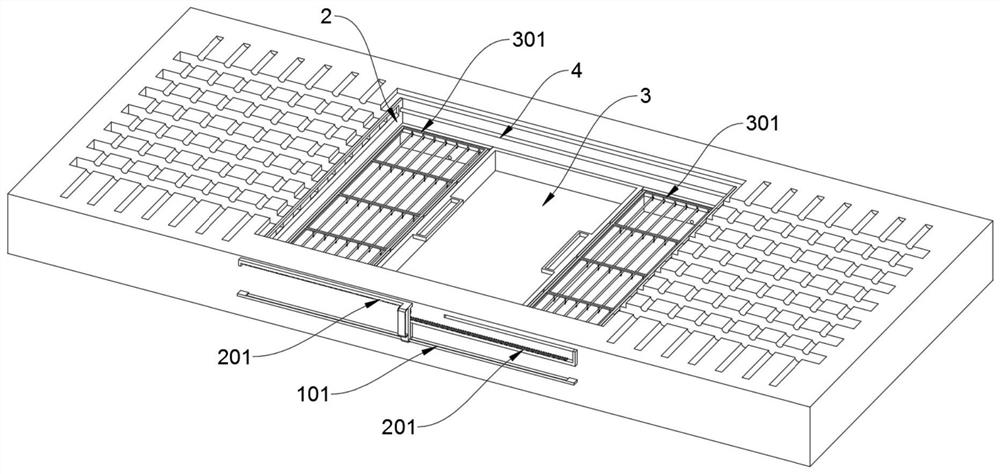

Soft package non-modular power battery system

ActiveCN112397828AReduce assembly errorsSimple processSecondary cellsCell component detailsPower batteryLiquid cooling system

The invention discloses a soft package non-modular power battery system which comprises an upper cover and a lower box body assembly which are fixedly connected, and a battery management system, a pressing rod assembly, a low-voltage wiring harness, a soft package battery cell assembly, a high-voltage assembly, a cross beam assembly and a liquid cooling system are sequentially arranged between theupper cover and the lower box body assembly from top to bottom. According to the technical scheme, a modular structure is avoided, soft package battery cells are directly integrated into the batterybox, the process of integrating the battery cells into a module is omitted, the assembly error caused by intermediate integration of the module is omitted, the process is simplified, and the cost is reduced; the system is non-modular, materials such as a module shell, a module end plate and a heat conduction structural adhesive are omitted, the weight is obviously reduced, the cost is obviously reduced, a heat exchange path is changed into a battery cell, heat conduction structural adhesive and liquid cooling pipe, the heat transfer path is shortened, and the efficiency is improved.

Owner:WANXIANG 123 CO LTD

Through-wall purification ventilation pipe with induced draft fan

ActiveCN108180592AAir volume adjustmentEasy to useDucting arrangementsMechanical apparatusVentilation tubeAir volume

The invention discloses a through-wall purification ventilation pipe with an induced draft fan. The through-wall purification ventilation pipe comprises a ventilation pipe, a filter device and a pipefan; the ventilation pipe comprises a first section of ventilation pipe and a second section of ventilation pipe; the pipe fan is arranged on the first section of ventilation pipe; the filter device comprises a filter screen and a filter screen mounting shell; the filter screen mounting shell comprises two half mounting shells with the same structures; the first section of ventilation pipe is provided with a first mounting cover; and the second section of ventilation pipe is provided with a second mounting cover. The through-wall purification ventilation pipe is provided with the induced draftfan for achieving a suction function; the novel filter screen is arranged in the ventilation pipe to achieve a filter function; through extension of a gas filter path, the designed filter screen achieves the purpose of prolonging the contacted time of gas with the filter screen, so that the purifying efficiency of the filter screen is high, and the filter screen can be singly used by deviating from a purifier when the air purifying effect is improved; and in addition, an air volume adjusting device is designed to achieve less mounting space, simple operation, reliable structure and high automation degree.

Owner:KUNSHAN SILAIMU ENERGY SAVING TECH CO LTD

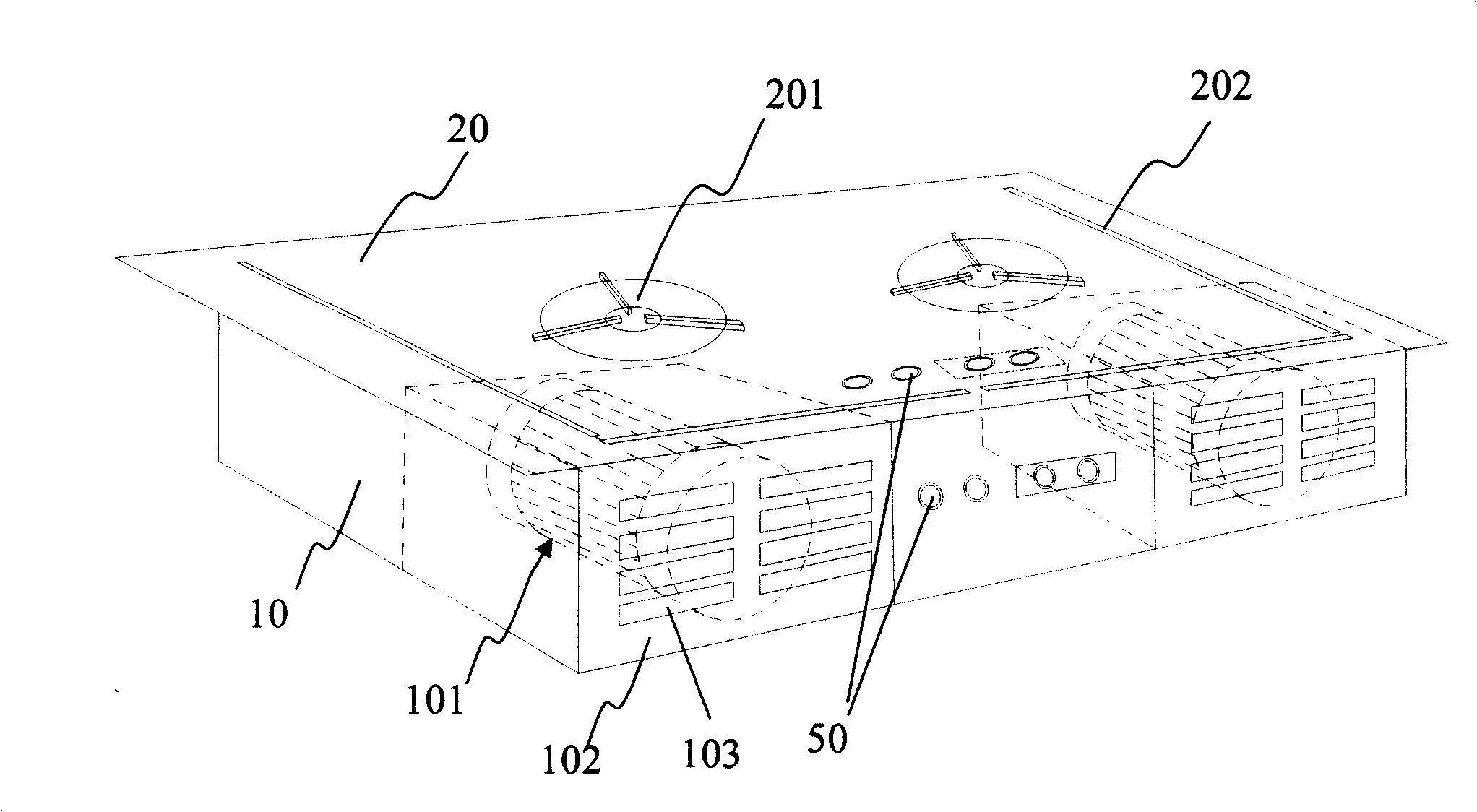

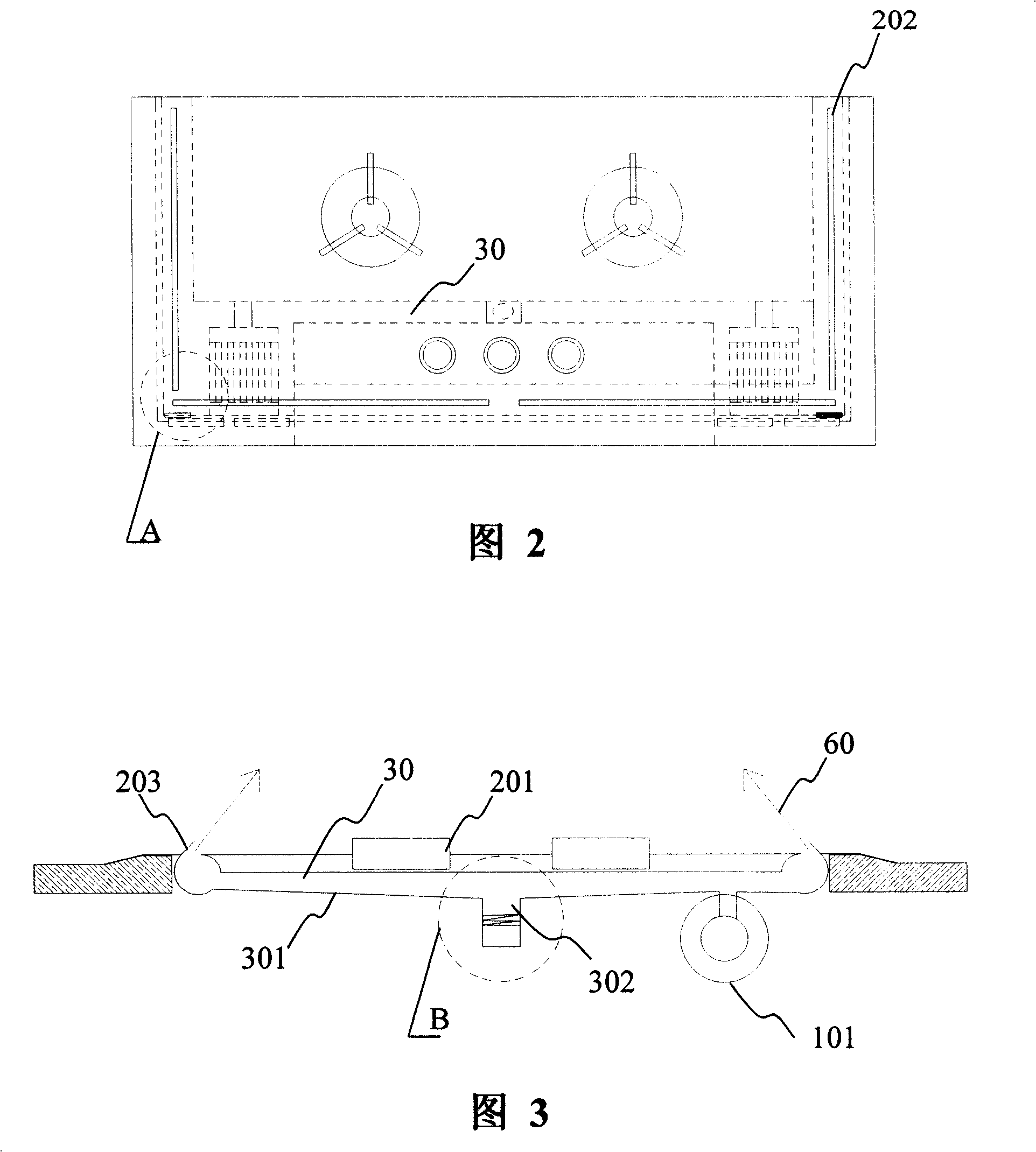

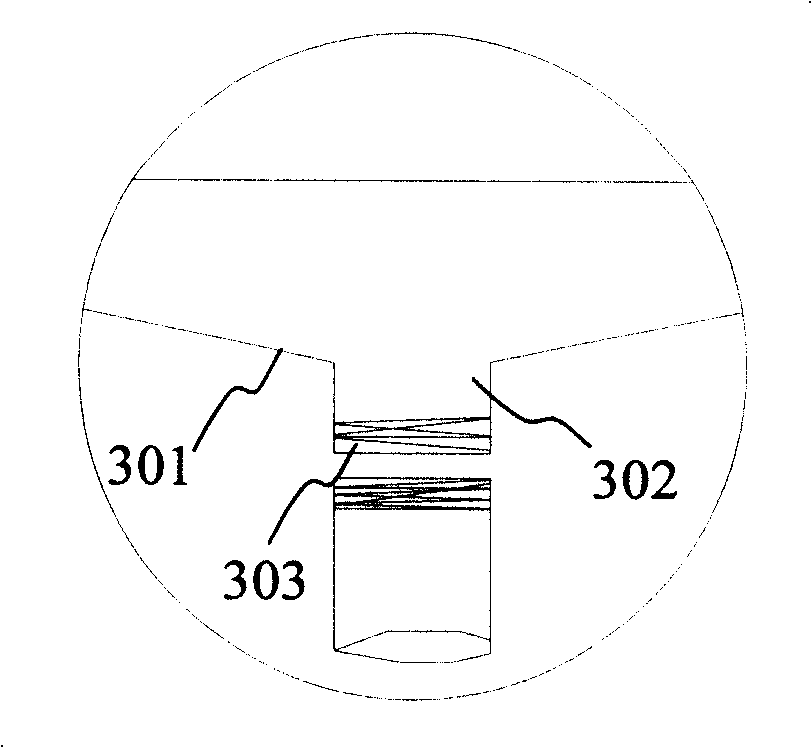

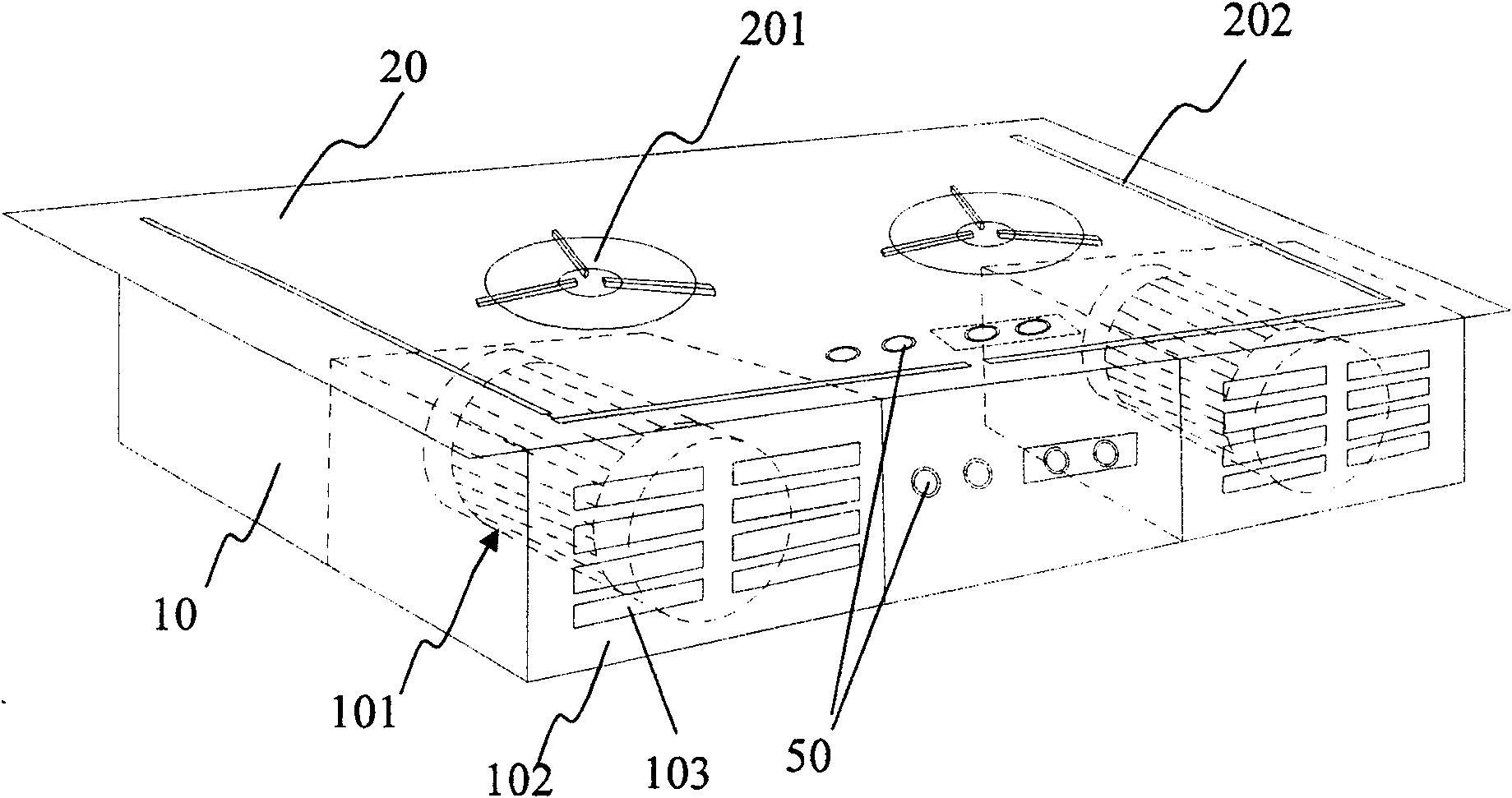

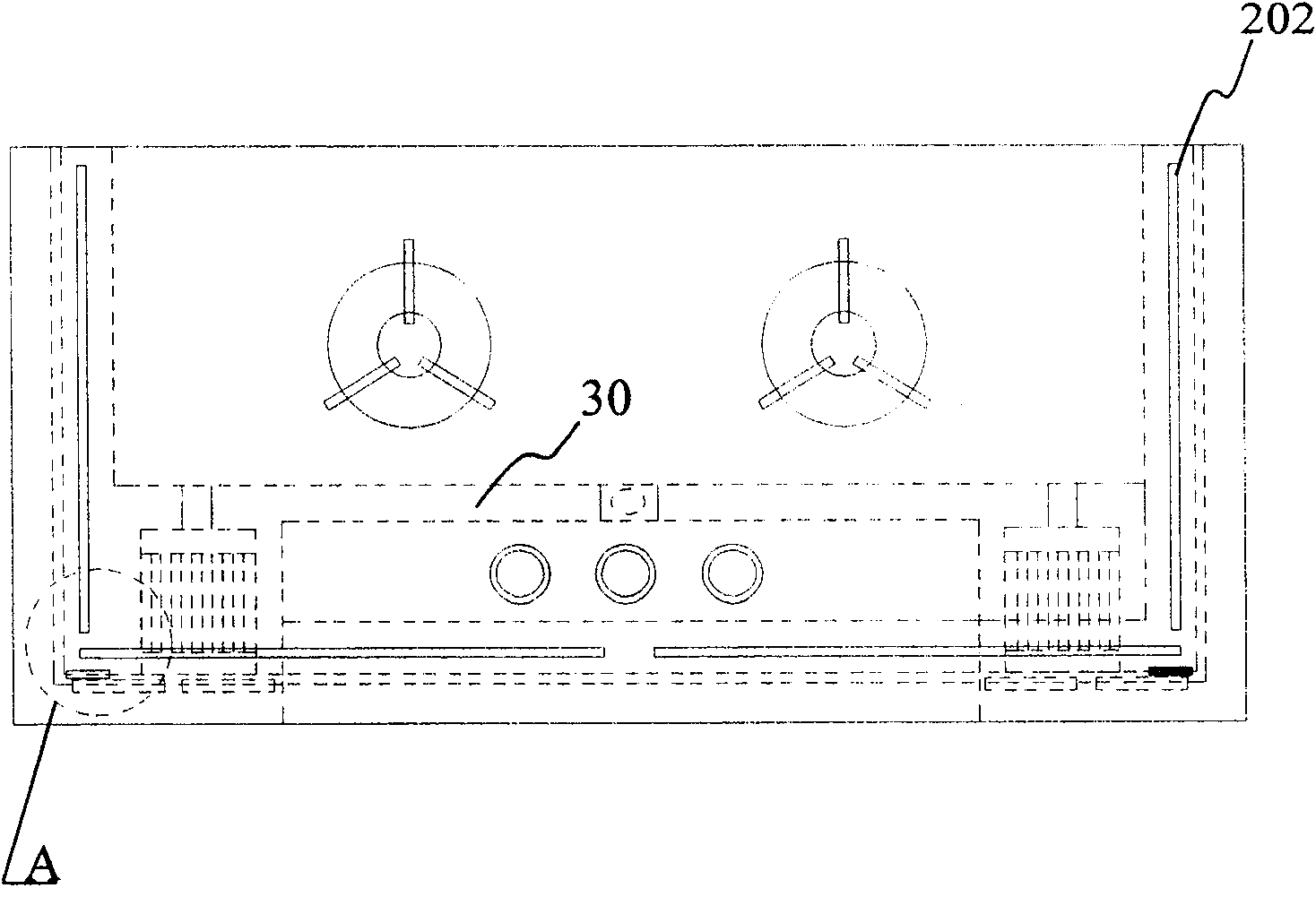

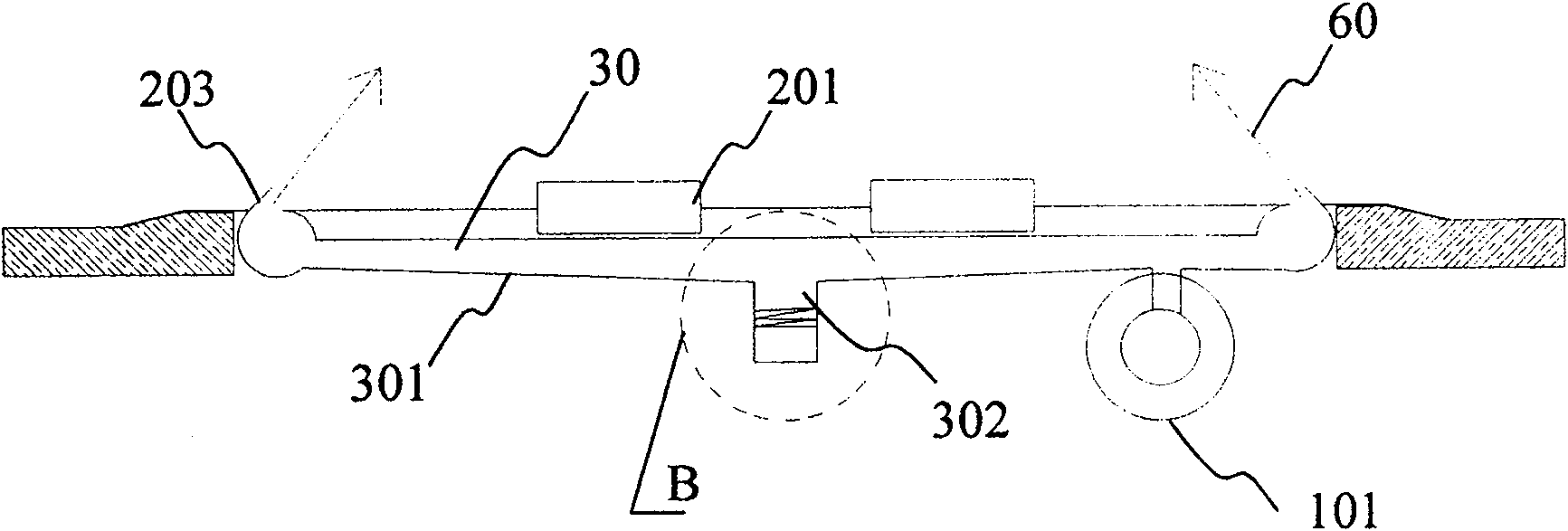

Air curtain gas range

ActiveCN101256001AAvoid incongruityNice appearanceDomestic stoves or rangesLighting and heating apparatusCombustionEngineering

The invention discloses an air curtain gas range comprising a gas range body, a range plate disposed on the upper surface of the gas range body, and a range core and an electromagentic furnace disposed in the gas range plate, wherein an air blaster and an air pipe are disposed in the gas range body, an air vent is disposed at the periphery of the range core on the range plate, the air blaster communicates with the air vent through the air pipe, and air flow generated by the air blaster flows through the air pipe and the air vent to form an air wall at the periphery of the range core. The air curtain and the gas range are provided integrally with a beautiful external form and convenient installation, water-proof and supply of combustion air are considered sufficiently to avoid external form incoordination caused by fussy installation process of the separate air curtain and separate installation.

Owner:ZHEJIANG SHUAIKANG ELECTRIC

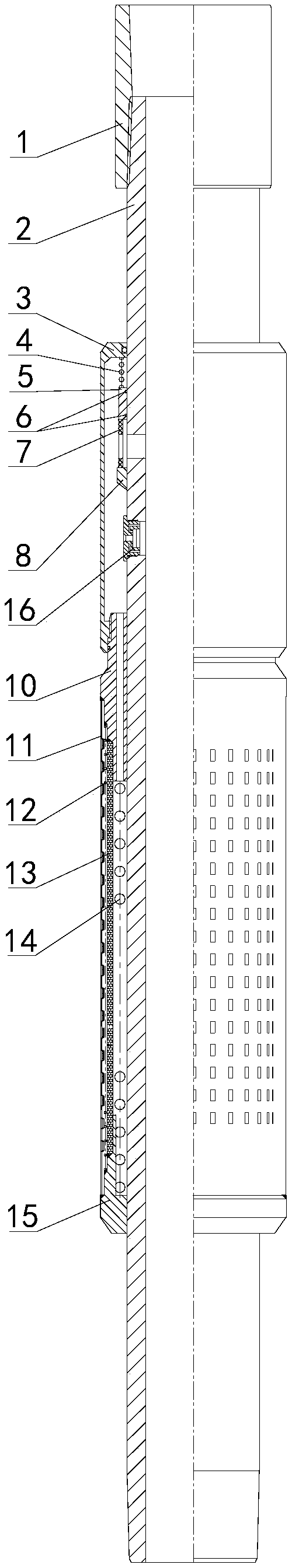

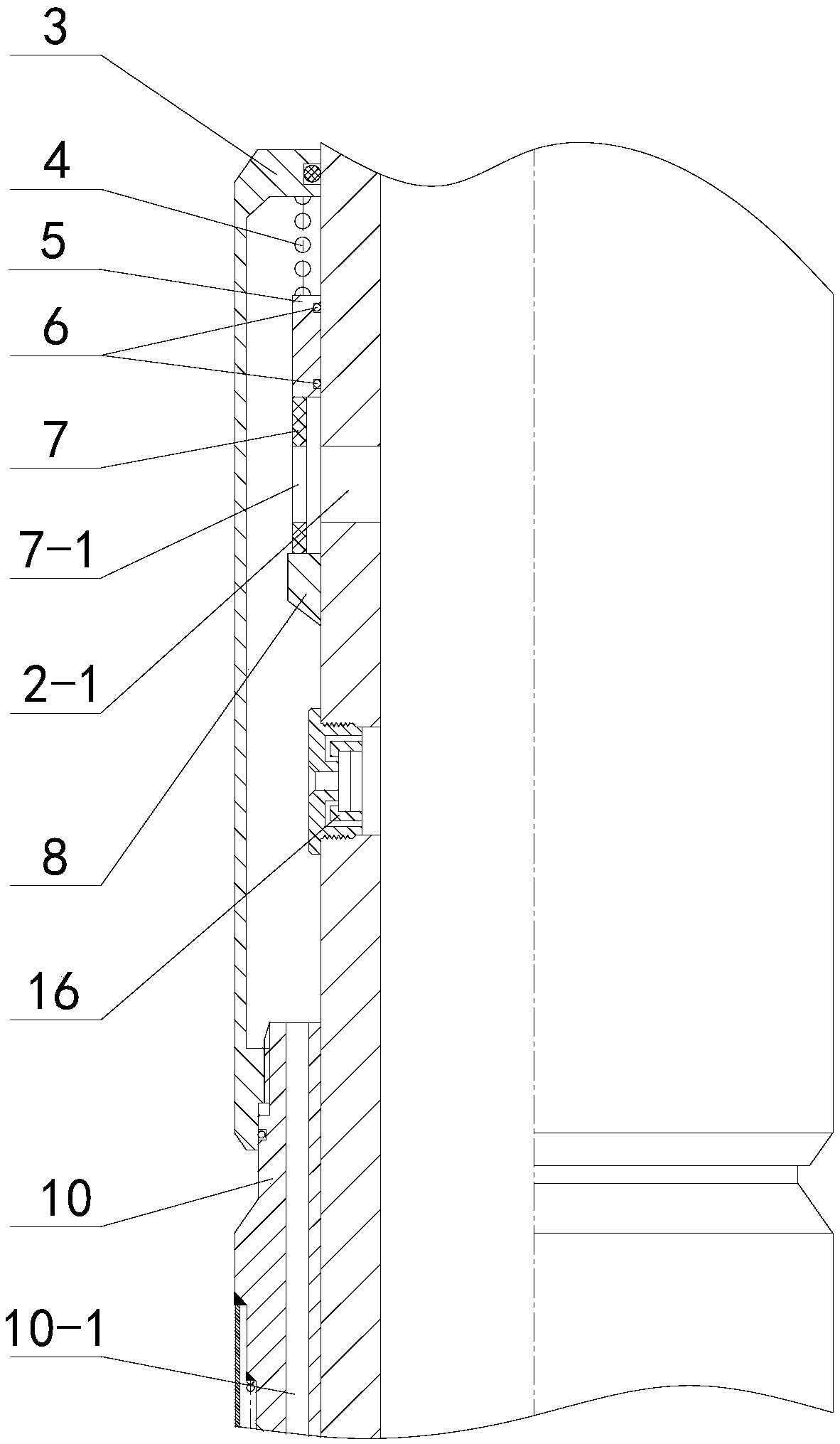

Filling adaptive water control screen pipe

The invention belongs to the oil and gas exploration technology field and discloses a filling adaptive water control screen pipe. A base pipe in a valve shield is provided with a large displacement filling hole and an adaptive flow control valve. The external portion of the large displacement filling hole is provided with a self-reset filling mechanism. Or a water-swelling rubber is arranged in anannulus between the base pipe and the valve shield. The self-reset filling mechanism is formed by a spring, a slide sleeve, a sealing ring, a soluble support sleeve and a positioning ring. When the soluble support sleeve supports the slide sleeve, the large displacement filling hole is in an open state. After the soluble support sleeve is corroded by water, the slide sleeve closes and seals the large displacement filling hole. After the water-swelling rubber is swelled in the water, a filling channel between the overflow hole channel of an overflow end ring and the large displacement fillinghole of the base pipe is closed. In the invention, the adaptive flow control valve and a large displacement filling mechanism are effectively combined in the screen pipe so that the large displacementdemand of filling work is satisfied and effective sand prevention and water control during a production process can be realized; and a water control completion effect is effectively improved, and a water control validity period is prolonged.

Owner:CHINA NAT OFFSHORE OIL CORP +1

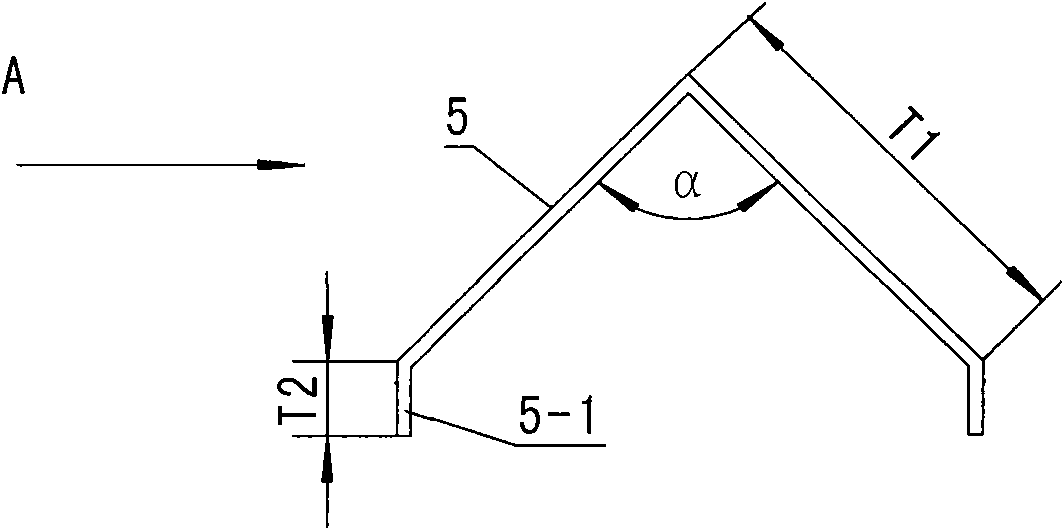

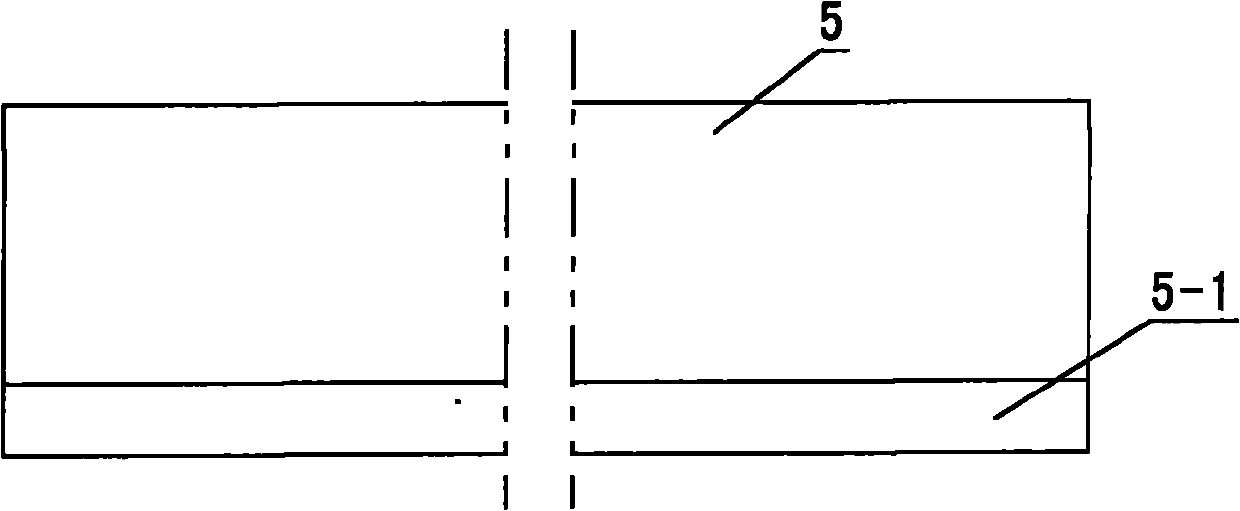

Flow crossing-baffling composite gasoline fractionating tower of ethylene device

InactiveCN101785931AAvoid cloggingNo clogging will occurGasoline stabilisationFractional distillationTO-18Gasoline

The invention discloses a flow crossing-baffling composite gasoline fractionating tower of an ethylene device. Micro baffling plates which are arrayed in an interlaced manner are arranged in parallel up and down at a quenching oil circulating section, and a vertex angle of each micro baffling plate is within 90 to 139 DEG; symmetrical bevel edges at the two sides of the vertex angle of the baffling plate are provided with symmetrical vertical folded edges; flow-crossing sieve plates with the diameter of sieve holes within Phi18 to 24mm are arrayed up and down at a medium oil circulating section; flow-crossing sieve plates with the diameter of the sieve holes within Phi13 to 24mm are arrayed up and down at a diesel oil separating section; and flow-crossing sieve plates with the diameter of sieve holes within Phi13 to 18mm are arrayed up and down at a gasoline separating section. The gasoline fractionating tower of the invention overcomes the problem of polymer blockage frequently occurring in the present plate-type fractionating tower and has the remarkable advantages of strong impact and vibration resisting capability, low tower pressure, high ethylene yield, obvious energy saving effect and long-term stable running.

Owner:TIANJIN UNIVTECH CO LTD

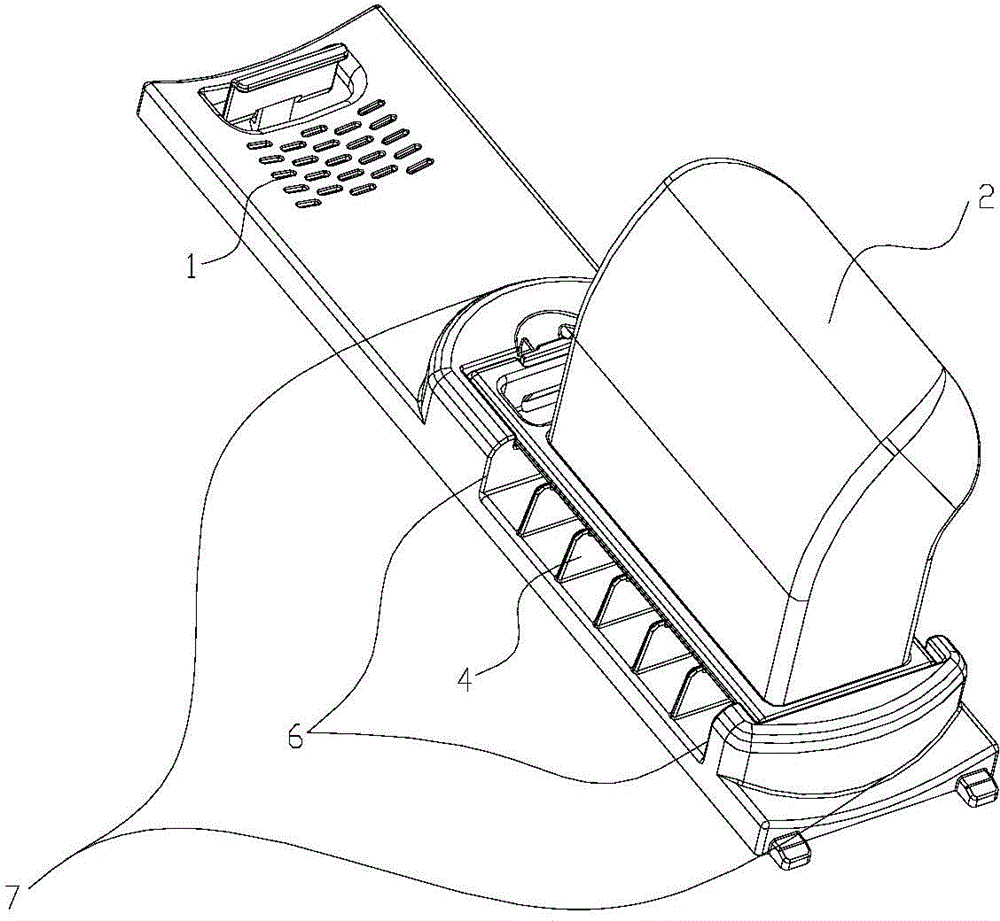

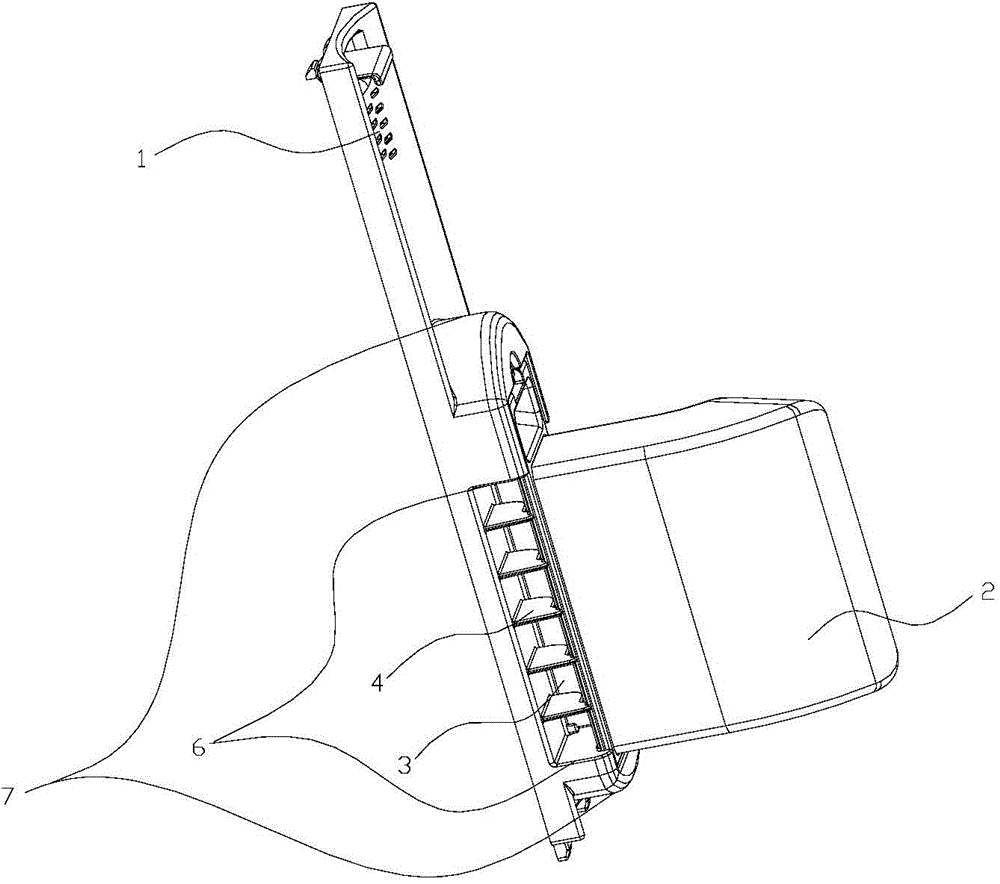

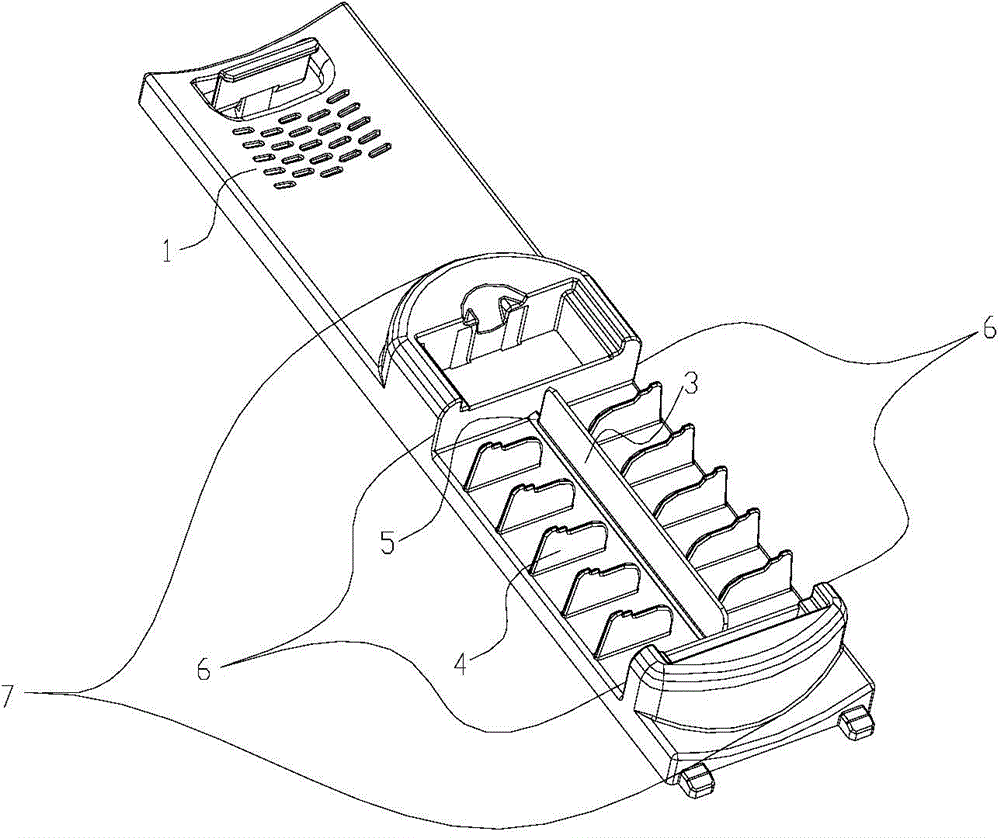

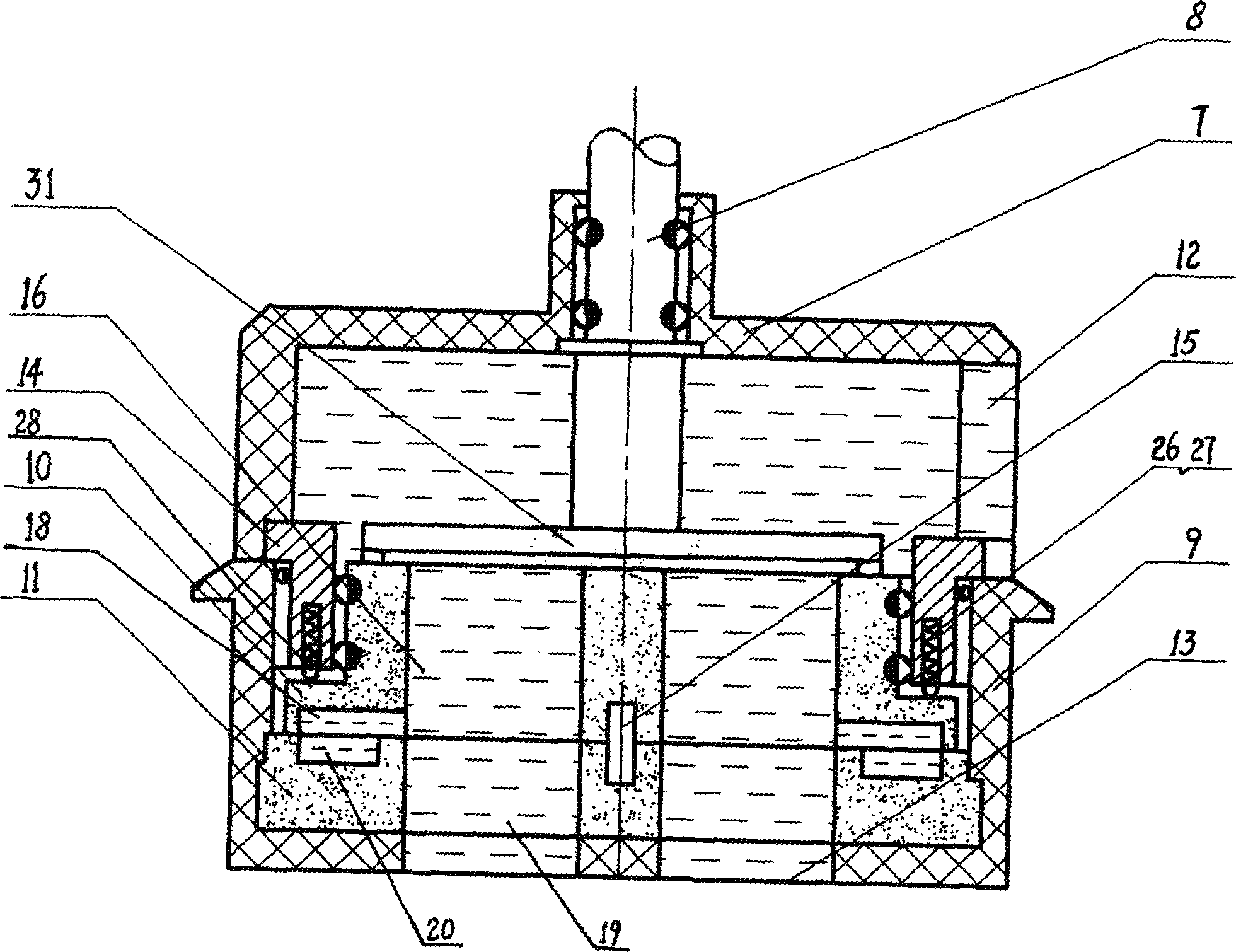

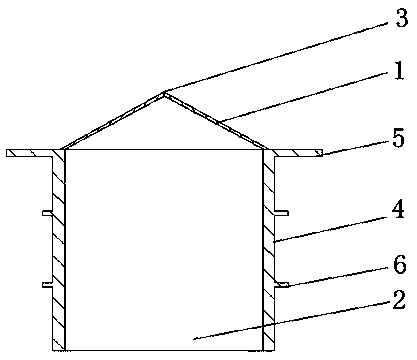

Self-ventilation motor fan housing capable of enhancing capacities of heat dissipation and protection

InactiveCN103138455AAvoid enteringHas a diversion effectSupports/enclosures/casingsFailure rateWater leakage

The invention provides a self-ventilation motor fan housing capable of enhancing the capacities of heat dissipation and protection and resolves the problems that an existing self-ventilation motor is poor in protective capability of an air inlet-outlet and low in reliability when temperature rise of the motor is overhigh. The self-ventilation motor fan housing capable of enhancing the capacities of the heat dissipation and the protection comprises a fan housing body which is arranged on the air inlet-outlet of the motor, the fan housing body comprises a shell body, an arch-shaped plate is arranged at the upper end of the shell body, wherein a hole is formed in the middle of the arch-shaped plate, the arch-shaped plate is connected with an outer shell of the motor in a matched mode, a plurality of louver-type wind plates are arranged on the front side and the back side of the shell body, air ports are formed in the lower portions of the plurality of louver-type wind plates, and a water leakage hole is formed in the bottom of the shell body. The self-ventilation motor fan housing capable of enhancing the capacities of the heat dissipation and the protection is reasonable and reliable in structural design and capable of improving cooling effect, meanwhile, the motor is good in the protective capacity, high in reliability and low in a failure rate. Due to the fact that the temperature rise of the motor is lowered, the core length of an effective part of the motor can be reduced, the size is reduced, the weight is reduced, cost is lowered, the demands for low-floor and light weight of the motor of users can be satisfied.

Owner:CRRC YONGJI ELECTRIC CO LTD

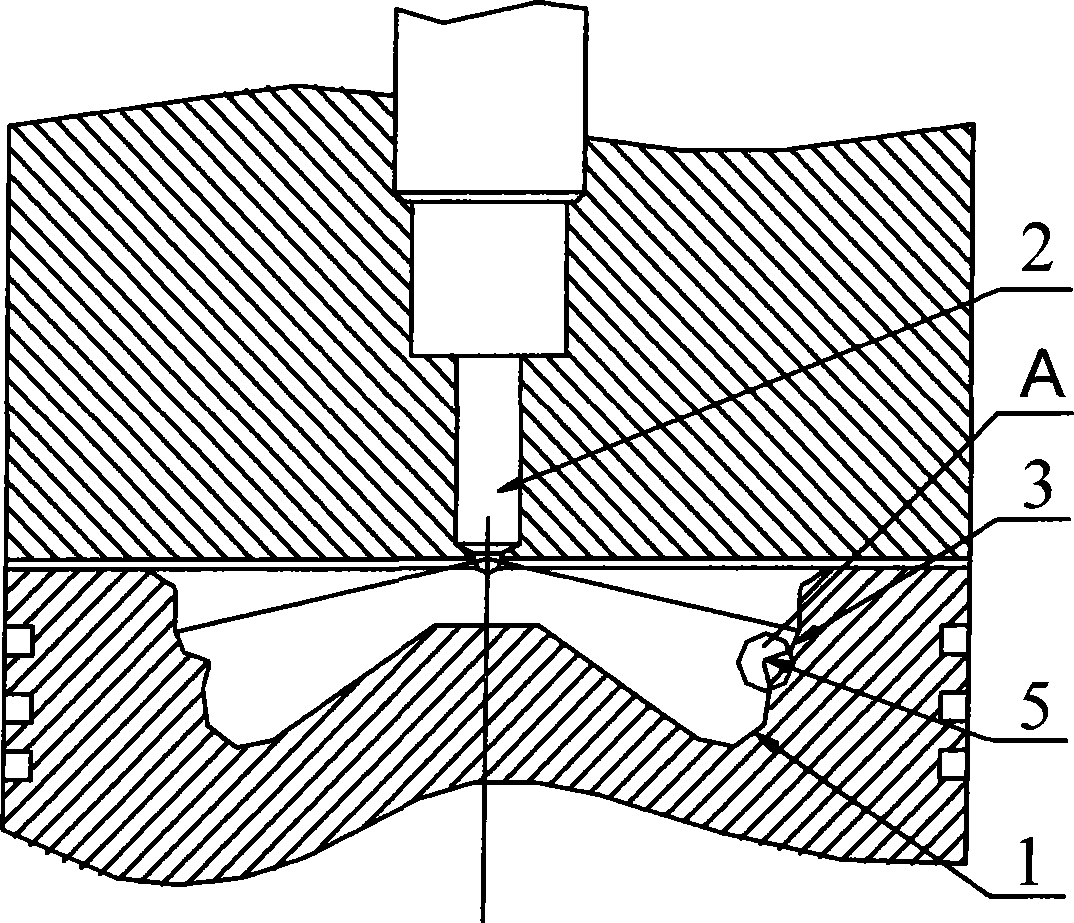

Combustion system applied in direct injection diesel

InactiveCN101446225AFacilitated DiffusionLarge mixing rangeInternal combustion piston enginesCombustion systemCombustion chamber

The invention discloses a combustion system applied in a direct injection diesel, comprising a W-shaped combustion chamber and an oil atomizer that is used for injecting high-pressure fuel oil into the combustion chamber. A plurality of arc concave pits which have the same number with oil beams of the oil atomizer and correspond to the injecting direction thereof are uniformly arranged on the inner wall of the W-shaped combustion chamber along the peripheral direction, the lower edge of every arc concave pit is connected with the inner wall of the combustion chamber in a first change structure way by the transition of small round corners, and the two side edges of every arc concave pit are connected with the intersection of the inner wall surfaces of the combustion chamber in a second change structure by the transition of the small round corners. By adopting the structure of the invention, separation between the fuel oil and the wall surface of the combustion chamber is realized in two directions, therefore, the fuel oil precipitated on the wall surface of the combustion chamber is greatly reduced, meanwhile, two spraying jets expand the range for the fuel oil to be mixed in the combustion chamber and the air is more fully utilized, thus being beneficial to reducing harmful emission.

Owner:TIANJIN UNIV

Device for extracting water from air

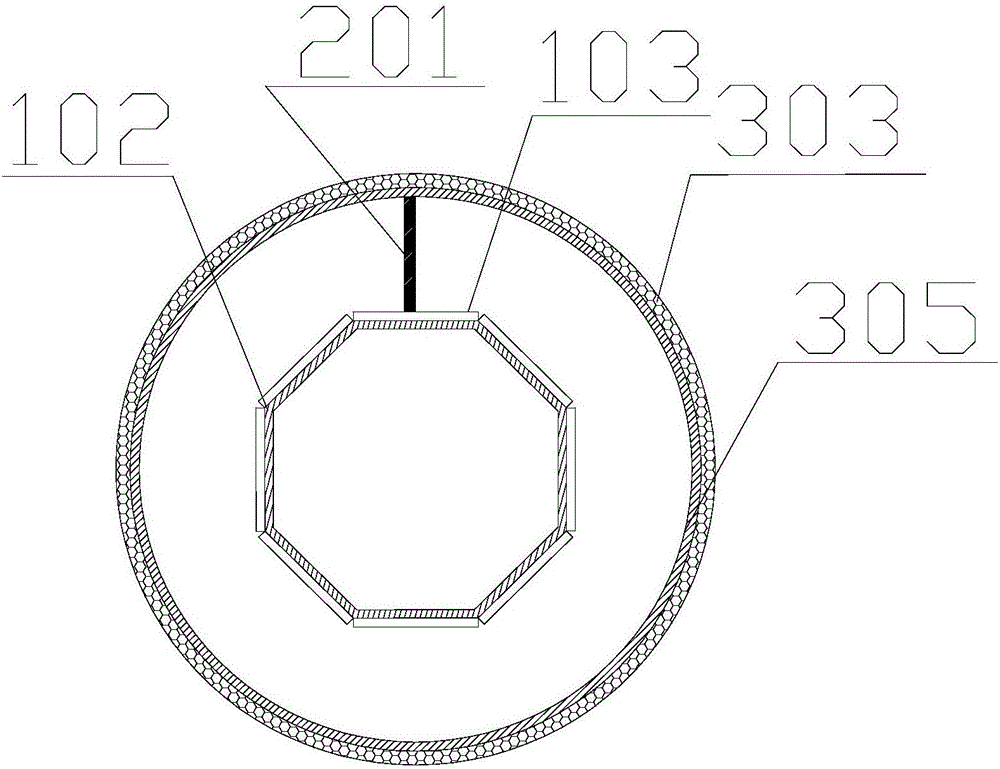

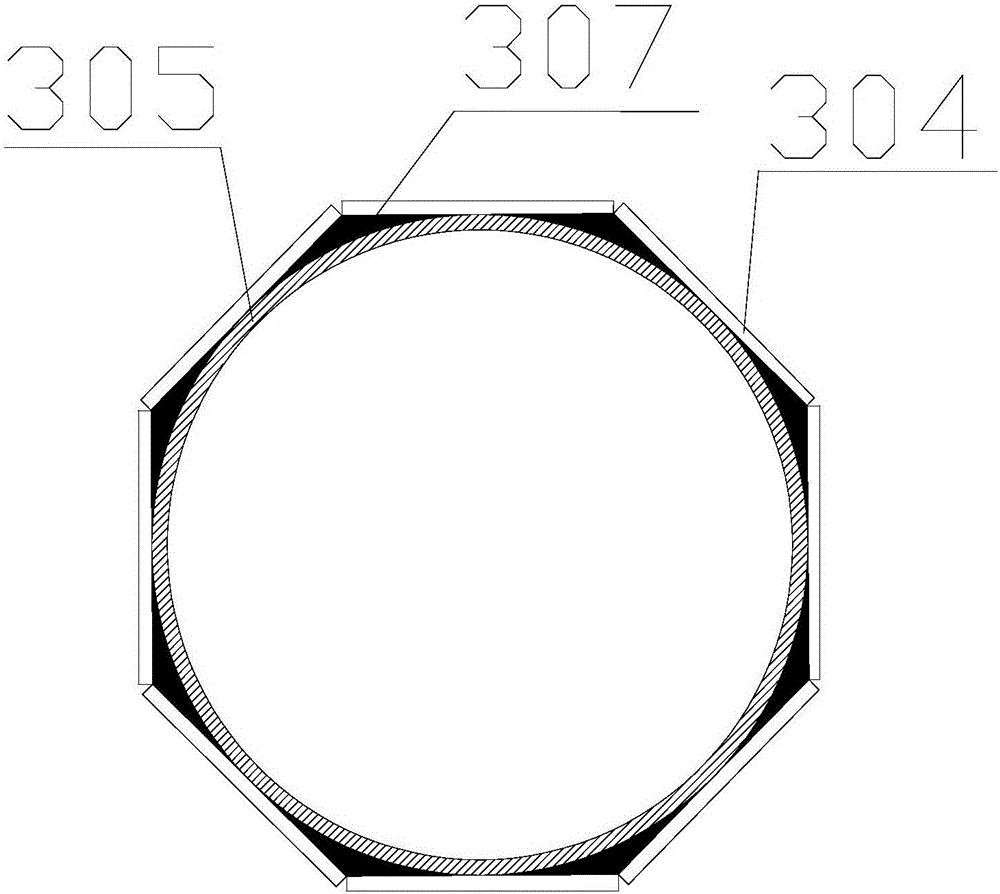

ActiveCN106368267AFull exposure to condensationImprove condensation efficiencyDrinking water installationWater vaporFresh water

The invention discloses a device for extracting water from air. The device is characterized in that the device comprises an inner cylinder assembly, an outer cylinder assembly, a heat dissipation and diversion assembly and a water collecting assembly, the inner cylinder assembly is located inside the outer cylinder assembly, the inner wall of the inner cylinder assembly is a metal polygonal cylinder, an inner side thermoelectric chip attaches to the corresponding outer wall of the metal polygonal cylinder, the inner wall of the outer cylinder assembly is a metal cylinder, an outer side thermoelectric chip attaches to the outer wall of the metal cylinder, the inner cylinder assembly and the outer cylinder assembly are connected through the heat dissipation and diversion assembly, and the bottom of the outer cylinder assembly is connected with the water collecting assembly. The inner side thermoelectric chip of the inner cylinder and the outer side thermoelectric chip of the outer cylinder are utilized to condense water vapor in air for water taking, the heat dissipation and diversion assembly makes the air fully in contact with a condensation face, an air exhausting pipe is utilized to perform waste heat recovery, and the condensing efficiency is improved. The device has the advantages of being convenient to carry, high in efficiency and compact in structure, saving energy and the like, facilitates relieving of the fresh water resource shortage problem and has practicability and convenience.

Owner:HUNAN UNIV

Air curtain gas range

ActiveCN100559082CAvoid incongruityNice appearanceDomestic stoves or rangesLighting and heating apparatusCombustionEngineering

The invention discloses a gas curtain gas cooker, which comprises a gas cooker body, a cooker board arranged on the upper surface of the cooker body, and a stove core or an induction cooker arranged in the cooker board, wherein the inside of the body is provided with A fan and an air duct, an air outlet is arranged around the stove core on the cooktop, the fan is connected to the air outlet through the air duct, and the air generated by the fan passes through the air duct and the air duct. The air outlet forms an air wall around the stove core. The air curtain machine and the gas stove in the present invention are integrated with each other, beautiful in appearance, convenient to install, fully consider waterproof and supply of combustion-supporting air, and avoid cumbersome installation process of separate air curtain machine and uncoordinated appearance caused by separate installation.

Owner:ZHEJIANG SHUAIKANG ELECTRIC

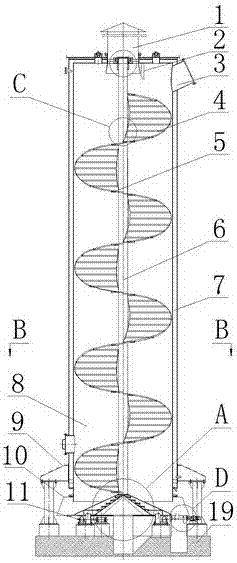

Use method of spiral step fin tower for purifying VOCs (volatile organic compounds) waste gas

ActiveCN106861363AEfficient use ofImprove mass transfer efficiencyGas treatmentDispersed particle separationSorbentSlag

The invention relates to the technical field of control on VOCs (volatile organic compounds) waste gas, in particular to a use method of a spiral step fin tower for purifying the VOCs waste gas. The use method is characterized by comprising use methods of a tower body assembly, a slag discharge rotary disc assembly, a support roll assembly and a support table. The use method has the advantages that the spiral conveying is effectively combined with a tower reaction working principle, and the spiral conveying is utilized, so that the sustained moving of an adsorbent under the sealing condition is realized, the interphase contact area with a tower reactor is large, and the mass transfer efficiency is high; the adsorbent filler can continuously maintain interphase contact with the VOCs waste gas; under the saturation condition, the contact is timely disengaged, and the technical problem of difficulty in realizing continuous purifying of the VOCs waste gas under the condition of continuous production is solved.

Owner:SHENZHEN YUANTONG ROBOT AUTOMATION CO LTD

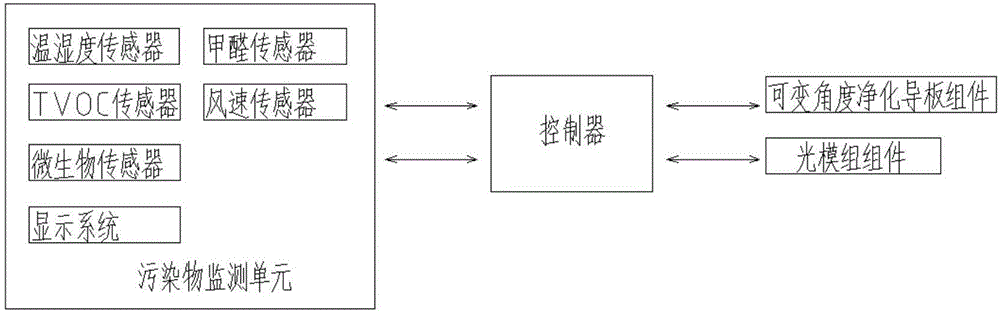

Air pipe with purifying and guide effects

InactiveCN106440285AHigh intensity processing effectGood processing effectDucting arrangementsMechanical apparatusPhotocatalysisActivated carbon

The invention relates to the technical field of indoor air purifying, and develops a novel air conditioning assembly which is small in resistance, is low in noise, is good in treatment effect and does not generate secondary pollution so as to achieve the purpose of improving quality of indoor air. The invention discloses a purifying air duct which utilizes a photocatalysis technology; a pulse xenon lamp is taken as a light source, and nano zinc oxide co-mixed with activated carbon is taken as a catalyst, so that VOCs can be purified, microorganisms are removed, and guide and noise reduction effects are achieved; the air pipe has the characteristics of high purifying efficiency, low noises and no secondary pollution, and is very wide in application prospect. With the adoption of the technical scheme, the air pipe with purifying and guide effects consists of a reflecting air duct, a variable-angle type purifying guide plate assembly, a light module unit, a pollutant monitoring unit and a control unit. The air pipe is mainly used for designing and manufacturing air purifying equipment.

Owner:TIANJIN UNIV

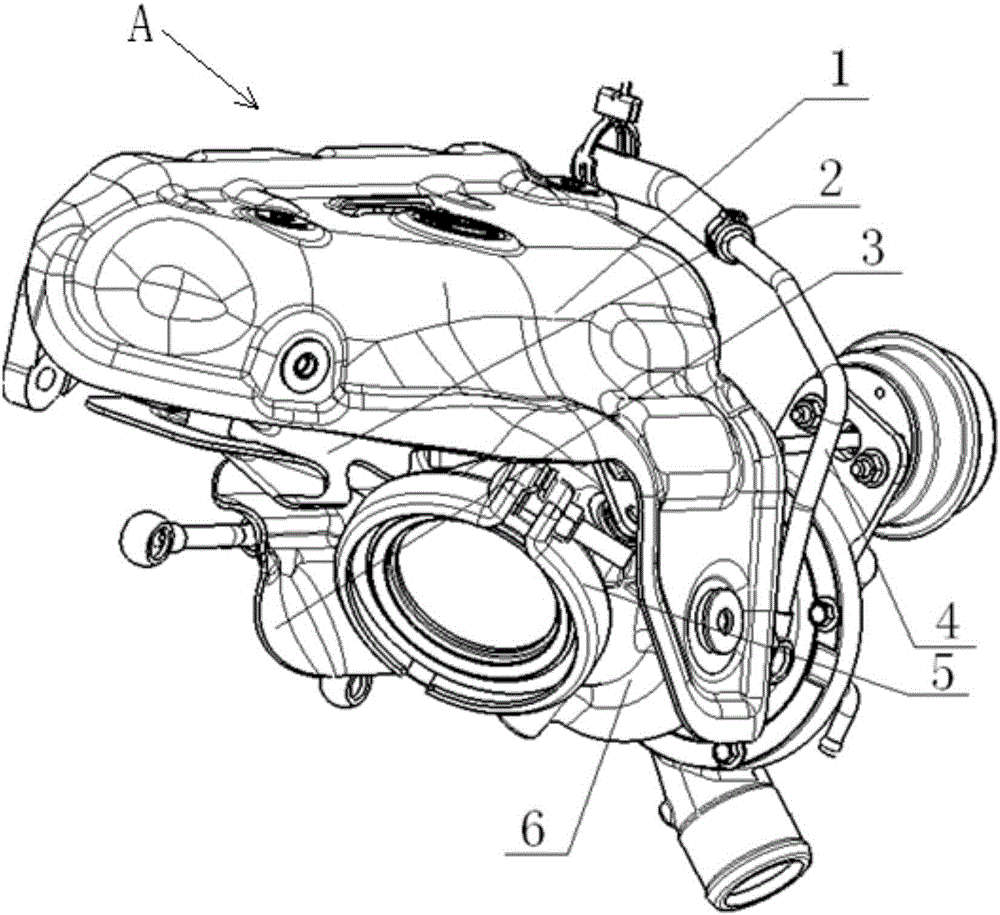

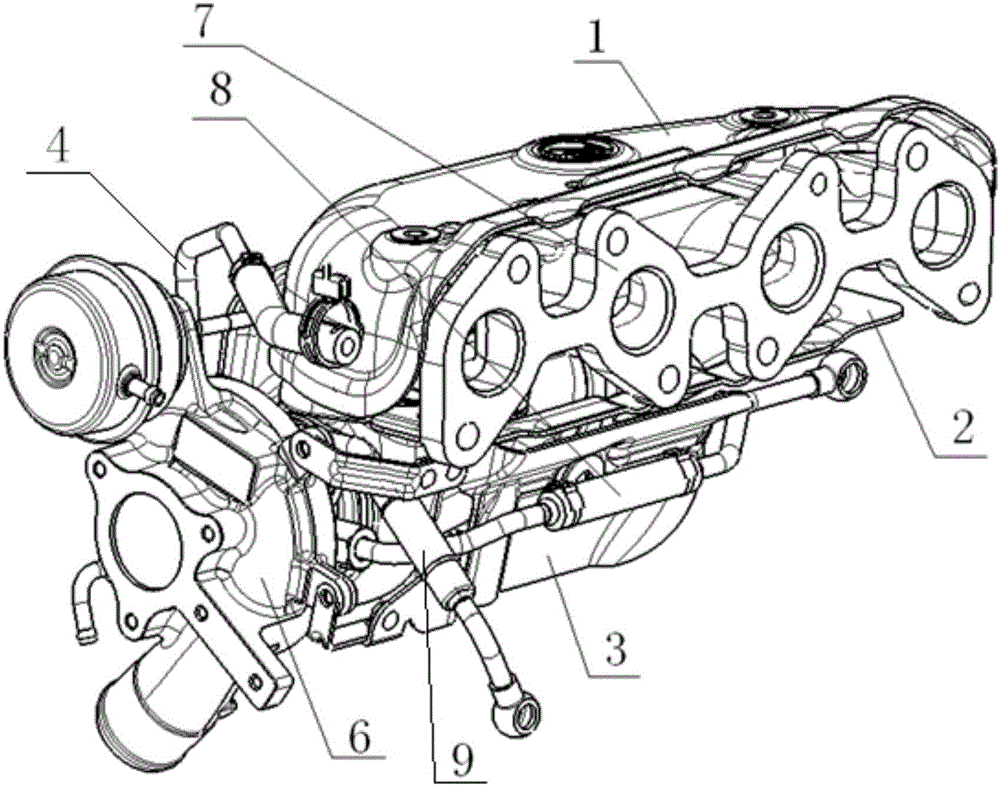

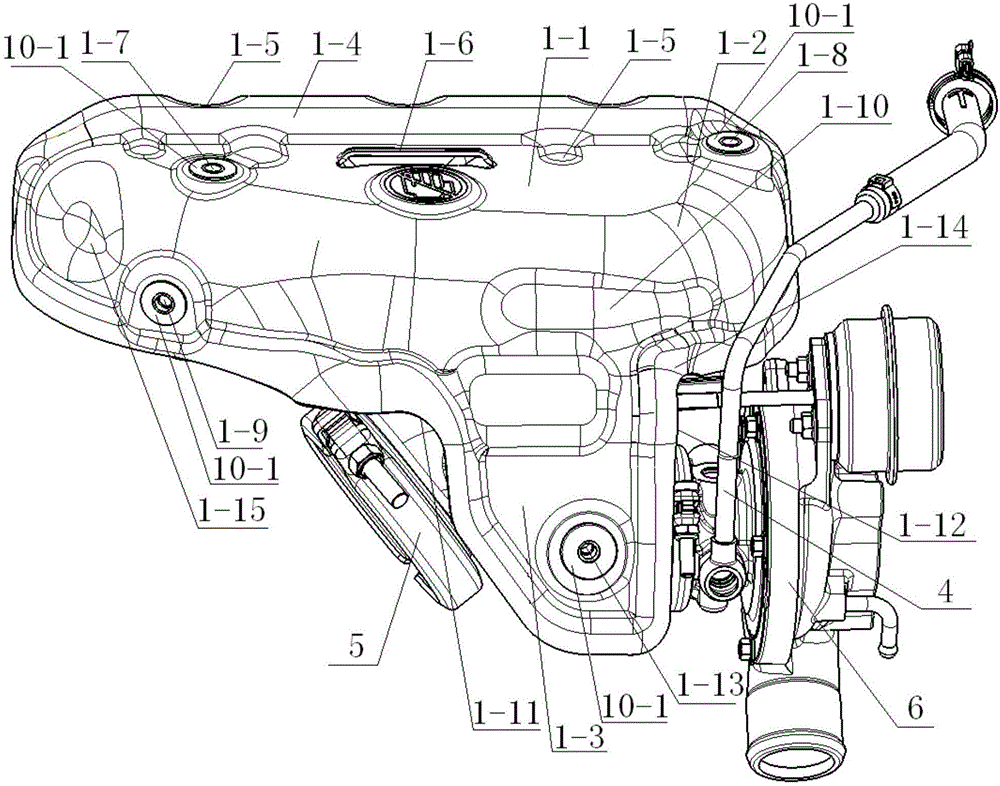

Thermal shroud assembly of supercharged engine

ActiveCN106703963AGood NVH performanceWith vibration reductionExhaust apparatusNon-rotating vibration suppressionNoise, vibration, and harshnessEngineering

The invention discloses a thermal shroud assembly of a supercharged engine. The thermal shroud assembly comprises an upper exhaust manifold shroud, a lower exhaust manifold shroud and a lower supercharge shroud, wherein the upper exhaust manifold shroud consists of a flat plate, a transition arc-surface plate and a rear side plate; an arc convex rib is arranged on the front edge of the flat plate; a vent hole is formed in the middle of the flat plate; an avoiding bulge is arranged on the right side of the transition arc-surface plate; a hoop avoiding notch is formed in the left part of the rear side plate; a return water tube avoiding notch is formed in the right part of the rear side plate; an abdication groove is formed in the front side of the lower exhaust manifold shroud; an abdication arc surface is arranged on the left part of the rear side of the lower exhaust manifold shroud; an avoiding arc surface is arranged at the right part of the rear side of the lower exhaust manifold shroud; the lower supercharger shroud comprises a first bracket, a second bracket and a lower shroud body; an abdication notch is formed in the right side of the lower shroud body; a connecting arm is arranged at the right end of the upper side of the lower shroud body; a triangular connecting plate is arranged at the right end of the lower side of e lower shroud body; an arc avoiding groove is formed in the lower side of the lower shroud body. By adopting the thermal shroud assembly, thermal conduction can be effectively cut off under the condition that a sufficient part assembling space is ensured, and meanwhile the thermal shroud assembly has good NVH (Noise Vibration and Harshness) performance.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Spilling water filtration device

ActiveCN104594001AStructural innovationSolve the problem of hanging clothesOther washing machinesTextiles and paperFiltrationWater flow

The invention provides a spilling water filtration device which comprises a spilling water portion and a filtration portion. A lint filter is arranged on the filtration portion, a filtration cavity is formed between the filtration portion and the lint filter, water inlets are formed in the two sides of the filtration cavity respectively, water deflection baffles which swing in the filtration cavity water inflow direction are arranged in the filtration cavity, and the water deflection baffles deflect water currents which enter the filtration cavity from the water inlets into the lint filter. By means of the spilling water filtration device, the lint collection rate can reach to about 90%. The spilling water filtration device has the advantages that the structure is simple, the production cost is low, the filtration effect is good, and the spilling water filtration device is worth popularizing and applying.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Mini-consumption electric controlling valve

InactiveCN1598372ASimple structureImprove reliabilityOperating means/releasing devices for valvesSlide valveEngineeringPower consumption

The invention refers to a micro power dissipation electric control valve. Driving shaft is equipped on the middle of the up bear frame. The upside of the down bear frame is equipped with motion valve plate. And the downside is fixed with fixed valve plate. The up end surface of the motion valve plate is connected to the down end surface of the driving shaft. The inter-space between the motion valve plate and the fixed valve plate is actively oriented by the central shaft of the valve plate. Blowhole and drain-hole, which are connected to fillister, are set on the motion valve plate. And blowhole and drain-hole are also set on the constant valve plate, of which the up end surface of the none-hole region is set with annular blowhole fillister and annular drain-hole fillister that connects to the fillister of the down end surface of the motion valve plate. The outer force caused by the open and close process of the invention has no direct relationship with the pressure of the air and liquid in the pipe. Thus, it can satisfy the design request of the micro power dissipation but mass flow. It has been verified that the invention could save more than 80% energy compared with the same type electric control valve driven by electric mini-motor.

Owner:杨晖 +1

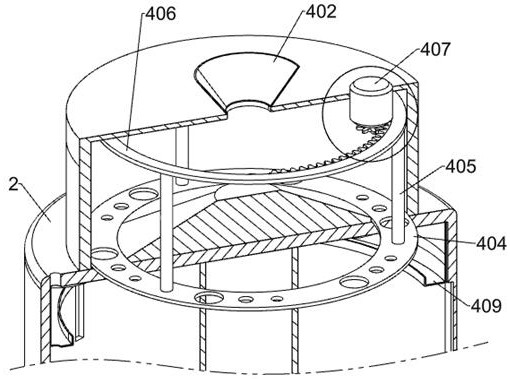

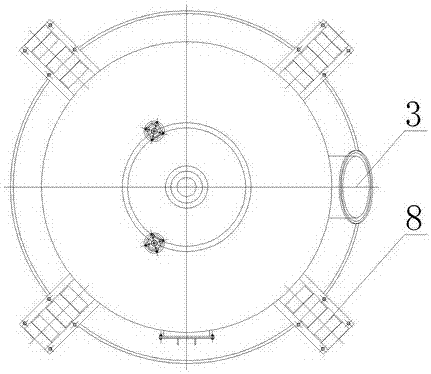

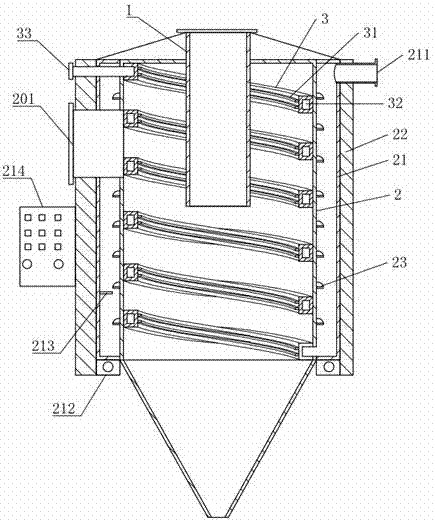

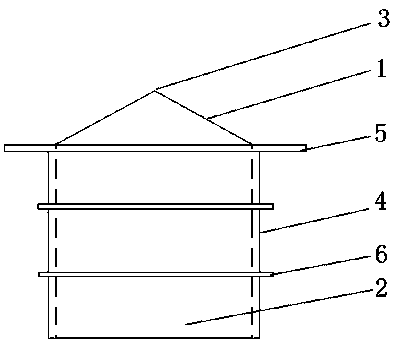

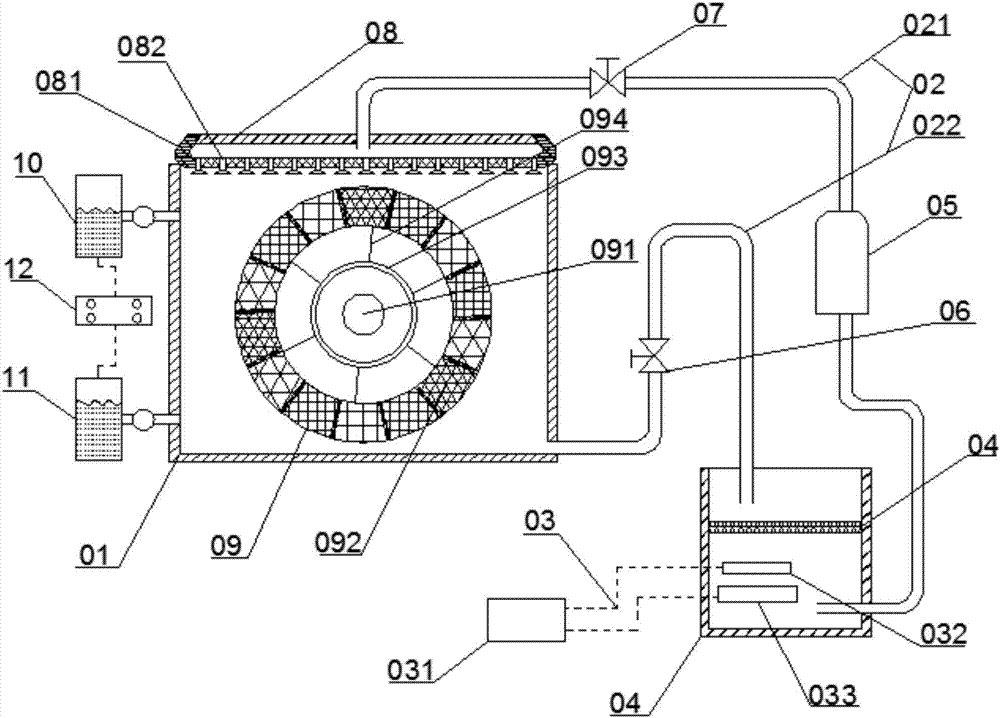

Waste heat recycle cyclone dust collector

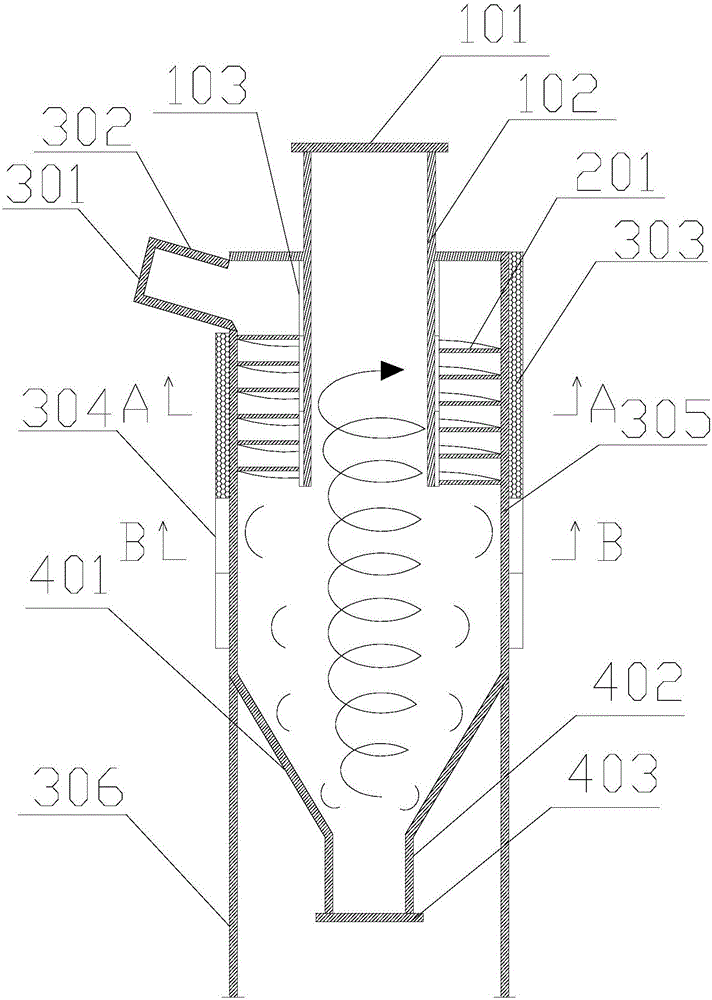

PendingCN107376523AIncrease profitHas a diversion effectRecuperative heat exchangersDispersed particle separationEnvironmental geologySmoke

The invention discloses a waste heat recycle cyclone dust collector which comprises an inner cylinder and an outer cylinder, wherein the outer cylinder is externally provided with a water jacket; a spiral flow guide body is arranged on an inner wall of the outer cylinder; the flow guide body is hollow; a flow guide groove is formed in the middle of the flow guide body; the upper end of the flow guide groove extends to the outside of the outer cylinder; a water inlet is formed at the upper end of the flow guide groove; the lower end of the flow guide groove is communicated with the bottom of the water jacket; and an air outlet is formed at the upper part of the water jacket. The waste heat recycle cyclone dust collector can increase heat absorption area of phenol water and a waste heat conversion rate of smoke.

Owner:邢强

Air insulating container material discharging mouth

InactiveCN111483693AReduce convectionLow peroxide valueLarge containersSealingEngineeringMaterials science

The invention discloses an air insulating container material discharging mouth. The air insulating container material discharging mouth comprises a material discharging mouth and a container opening sealing body. The lower part of the material discharging mouth is in a shape of bell mouth; the top of the material discharging mouth is in a shape of a slit; the bottom of the material discharging mouth is connected with the container opening sealing body; the top of the material discharging mouth is higher than the container opening sealing body; in a normal state, the top of the material discharging mouth is in an automatic closed state; during discharging, the material discharging mouth is automatically opened under the pressure; after discharging, the material discharging mouth is automatically closed; and the slit-shaped top has a flow guide effect. The container opening sealing body comprises a sealing pad plug, a cover body seat and a sealing ring. According to the air insulating container material discharging mouth, the inside and outside air convection of a container can be reduced, and the slit-shaped top of the material discharging mouth has the flow guide effect during discharging. The container opening sealing body has the advantages of simple structure, good sealing performance and low production cost.

Owner:武欣辰

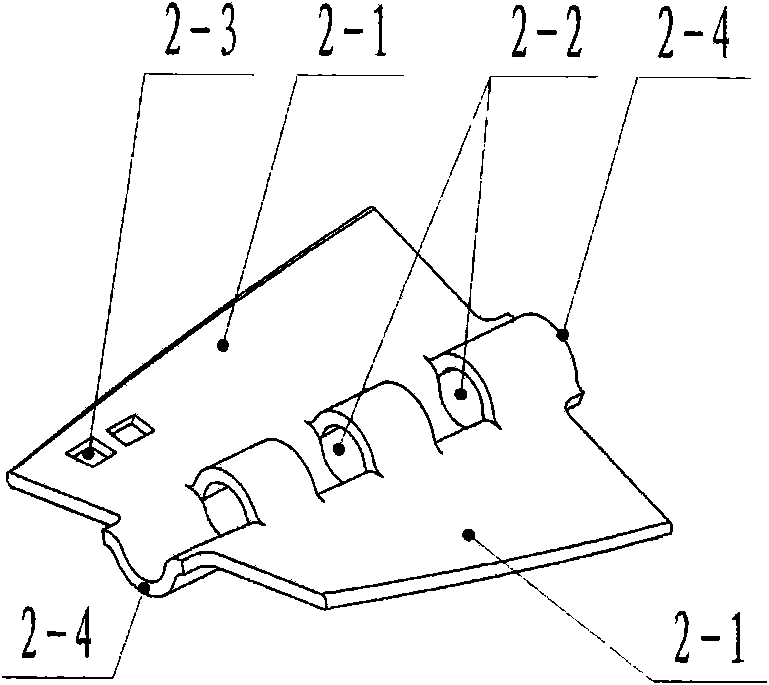

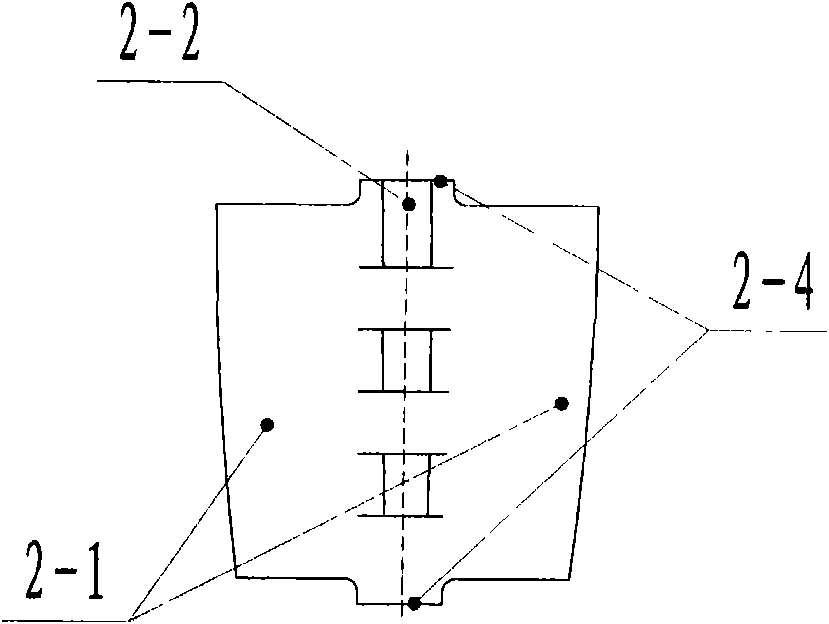

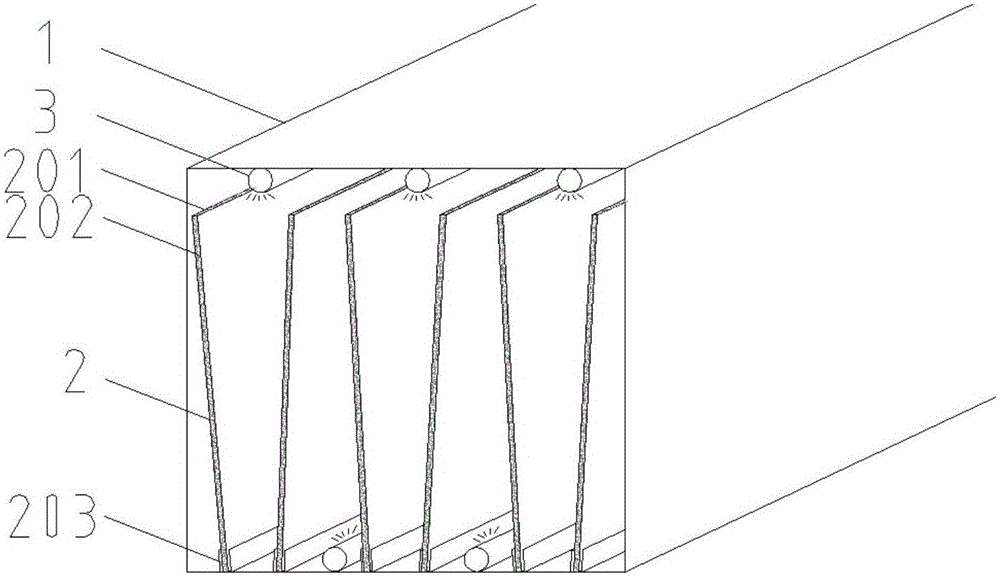

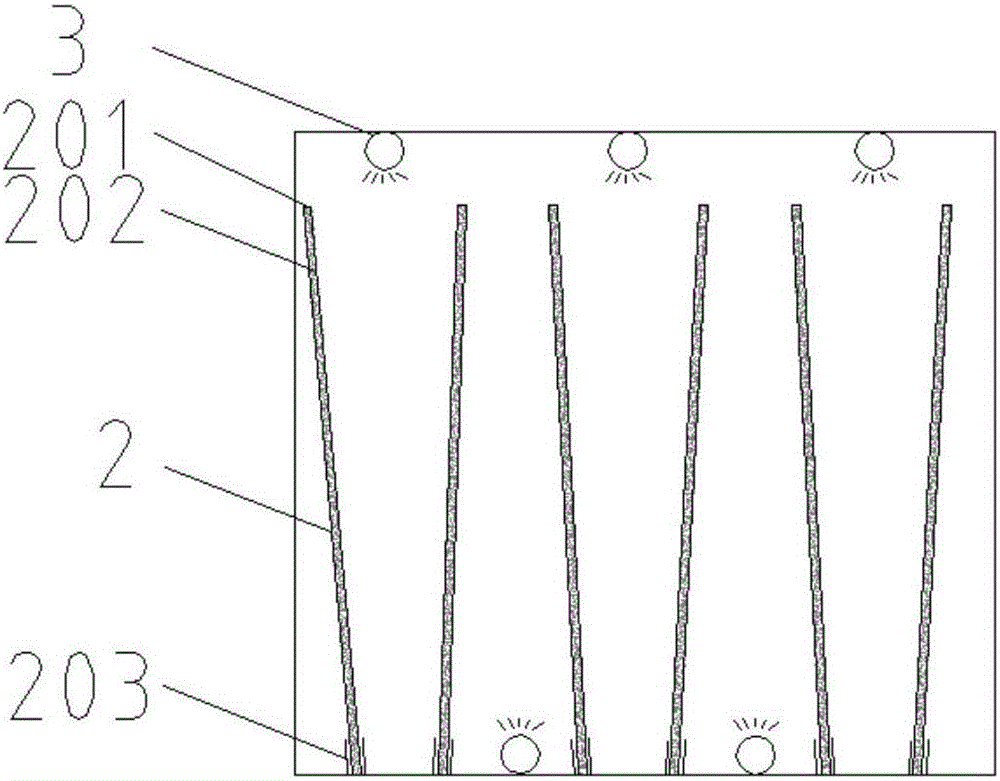

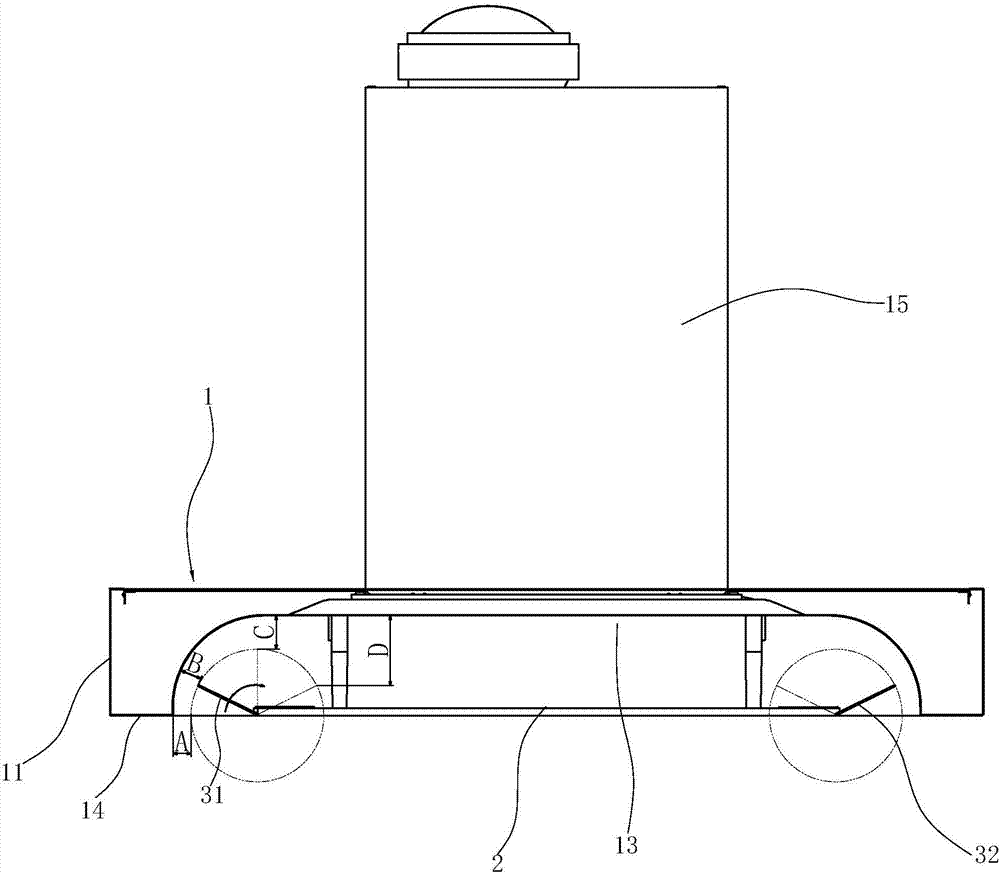

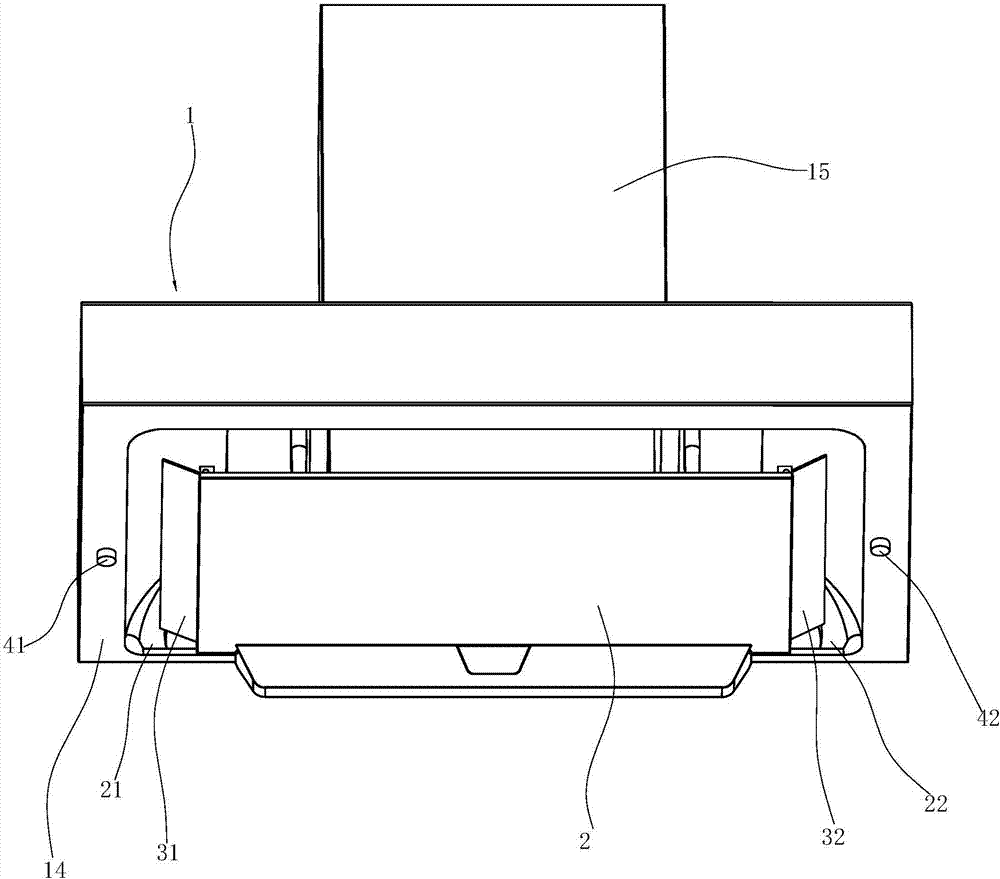

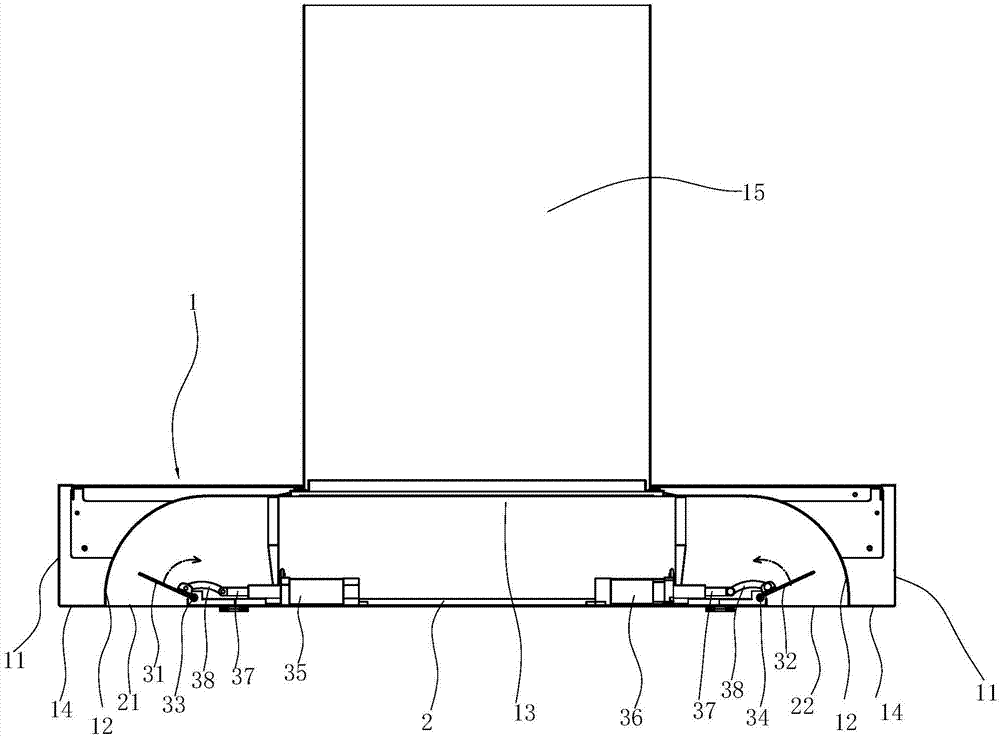

Stepless speed governing range hood

ActiveCN107975846AStepless speed regulation suction effectGreat suctionDomestic stoves or rangesLighting and heating apparatusEngineeringAirflow

The invention relates to a stepless speed governing range hood which comprises a smoke collecting hood (1) and a flow rectification plate (2) which corresponds to an oil smoke suction inlet; a first air inlet (21) is formed between the edge of the left side of the flow rectification plate (2) and an inner side wall (12) of the smoke collecting hood (1); and a second air inlet (22) is formed between the edge of the right side of the flow rectification plate (2) and an inner side wall (12) of the smoke collecting hood (1). The stepless speed governing range hood is characterized in that a firstwind adjustment plate (31) corresponding to the first air inlet (21) and a second wind adjustment plate (32) corresponding to the second air inlet (22) are rotationally connected with the flow rectification plate (2); the inner side walls (12) of the smoke collecting hood (1) are arc-shaped in the longitudinal sections; and when the flow rectification plate (2) rotates from a smoke collecting hoodinlet to the oil smoke suction inlet, in the direction of the extension line of the flow rectification plate (2) in the longitudinal section, the distance between the edge of the left side or right side of the flow rectification plate (2) and the corresponding inner side wall (12) of the smoke collecting hood (1) is increased gradually. Stepless speed governing can be carried out on the oil smokesuction velocity, and the range of a negative pressure smoke drawing zone is changed, so that the oil smoke suction and discharge effects are improved; and the flow guide effect on an oil smoke flowis significant and the oil and gas separation effect is good.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

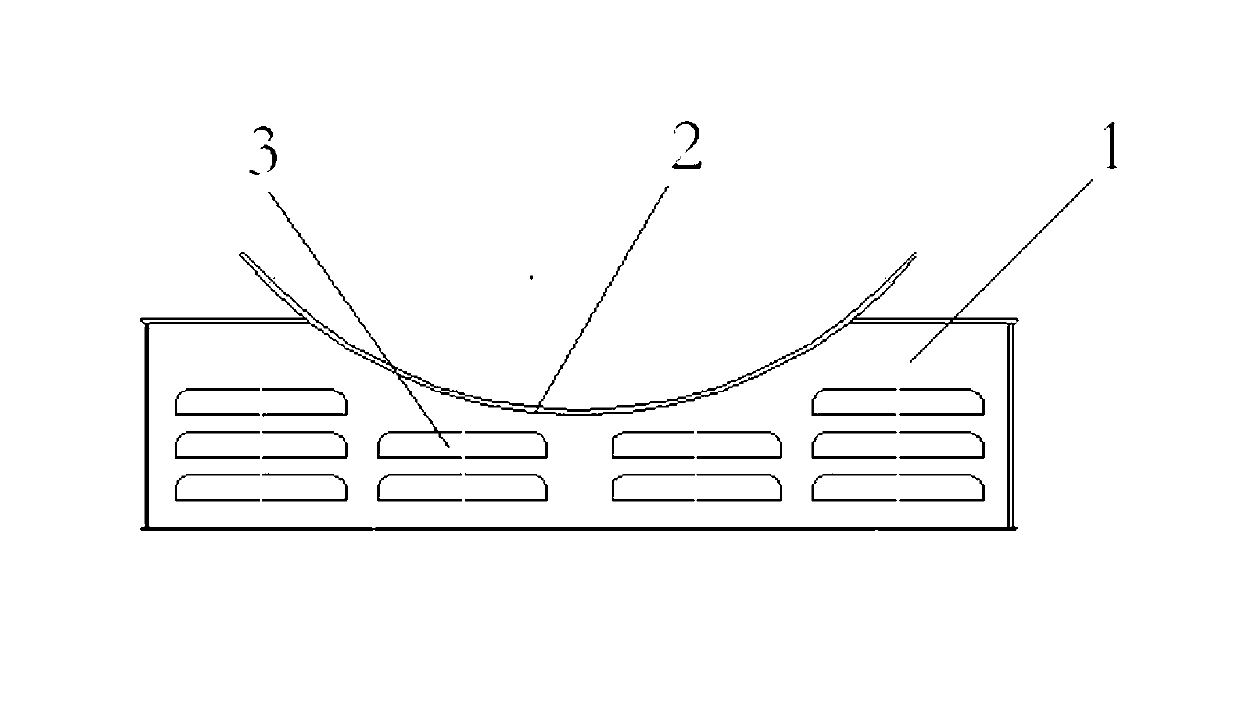

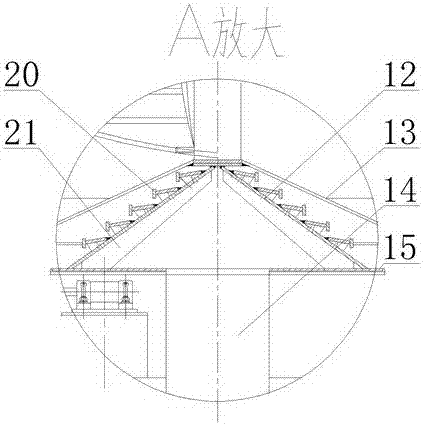

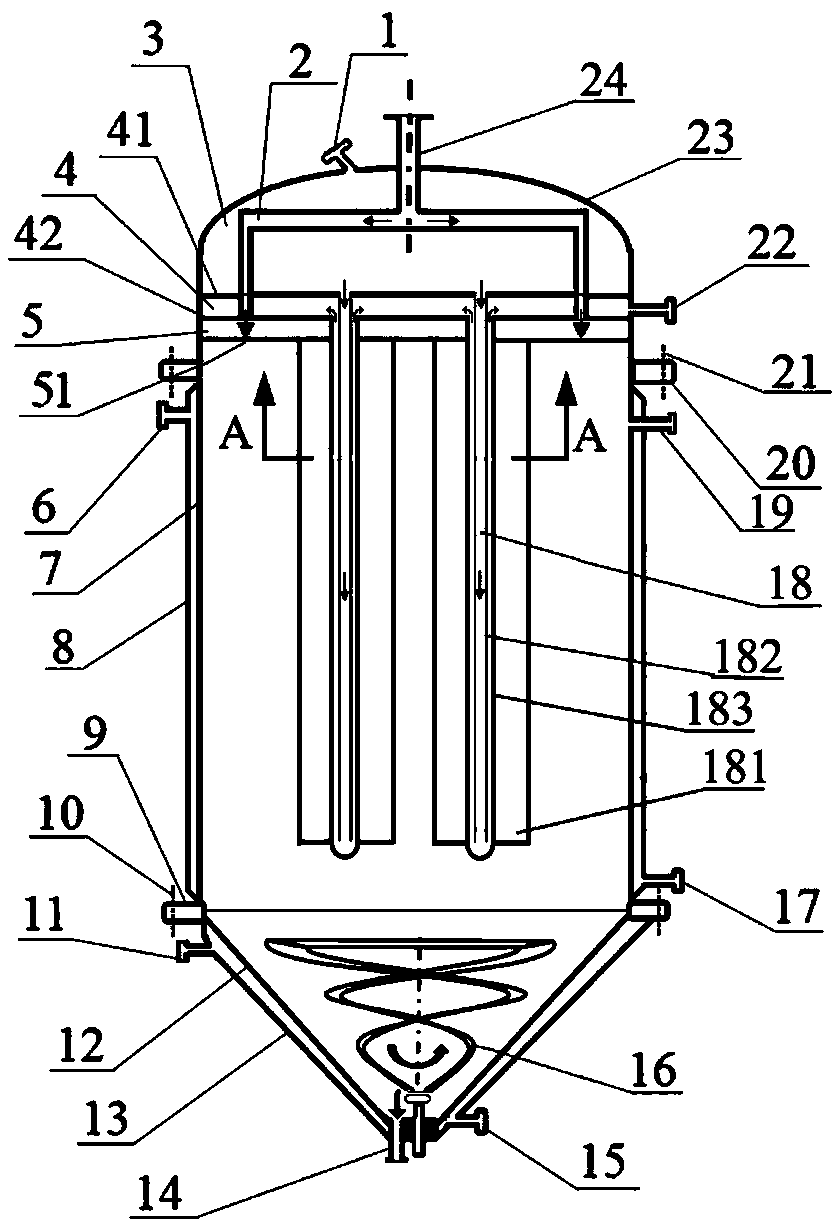

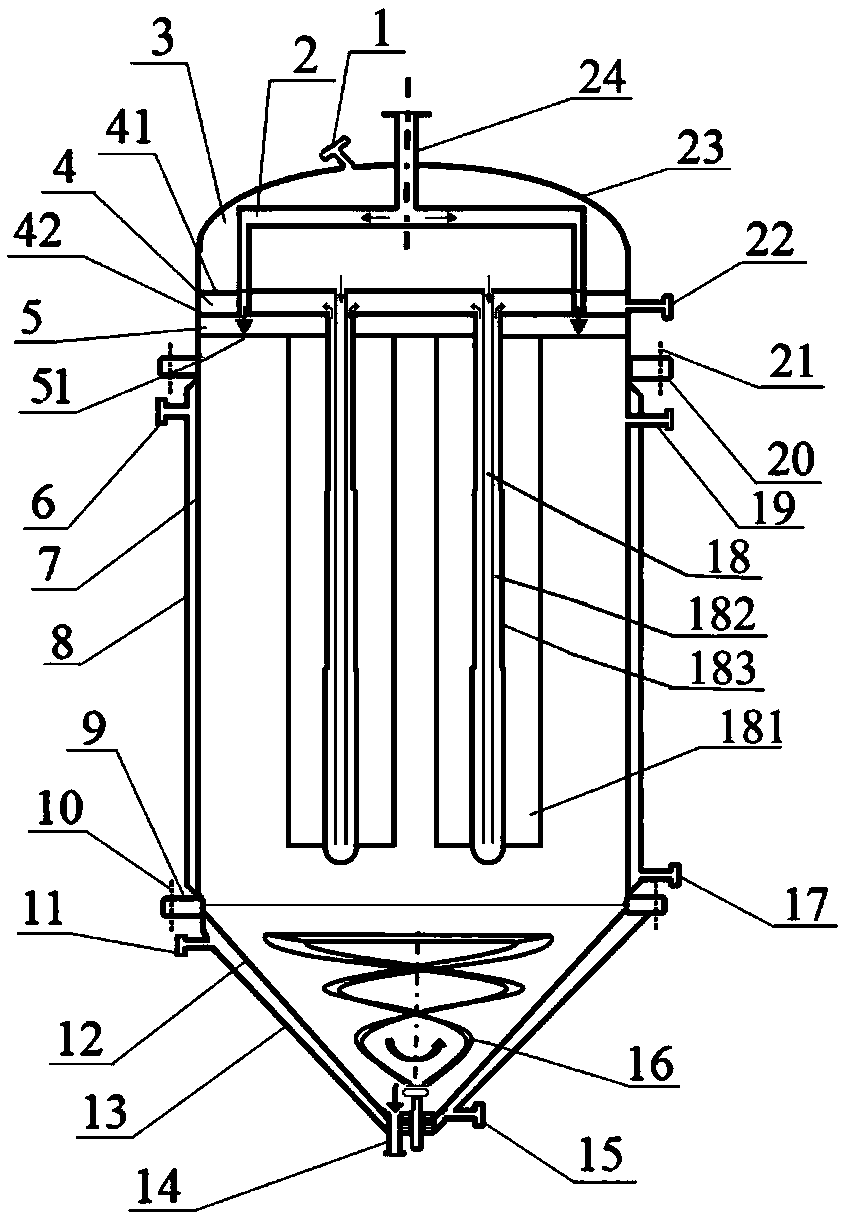

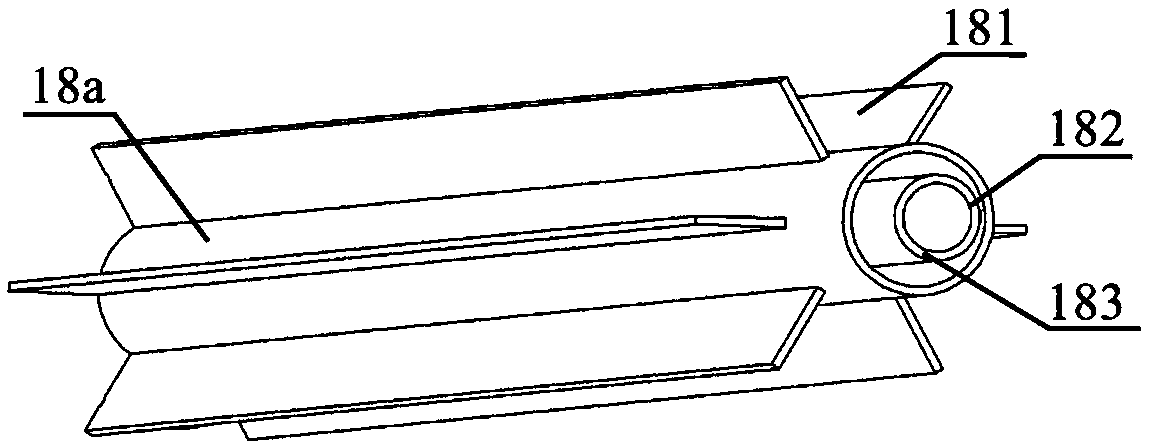

Falling film type devolatilizer and falling film element thereof

PendingCN110639461AEasy to adjust residence timeEasy to control liquidityChemical/physical/physico-chemical stationary reactorsPolymer sciencePolymer chemistry

The invention relates to a falling film type devolatilizer and a falling film element thereof. The falling film type devolatilizer comprises a vertical shell, a seal head connected with the upper endof the vertical shell, and a bottom shell connected with the lower end of the vertical shell; a material box body and at least one falling film element are arranged in the devolatilizer; the falling film element is provided with a plurality of falling film flow channels; a bottom plate of the material box body is a film distribution plate; and film distribution structures are distributed on the film distribution plate for all the falling film flow channels. The devolatilizer has the advantages of large film forming area, controllable film forming form, wide flow regulation range and the like,and is suitable for devolatilization processes such as high-viscosity polymer production, spinning solution deaeration, solution concentration and the like.

Owner:ZHEJIANG SCI-TECH UNIV +1

Washing device for recycling sterilization of medical apparatus

InactiveCN107570472AThe function of sterilization and disinfection is weakenedIncrease the function of sterilization and disinfectionLavatory sanitoryCleaning using liquidsElectricityProcess engineering

The invention provides a washing device for recycling sterilization of medical apparatus, and relates to the technical field of medical machinery and equipment. The washing device comprises a washingand disinfecting tank and a washing fluid arranged in the washing and disinfecting tank and further comprises a liquid purifying tank, a circulating pump and a circulating pipeline. The circulating pipeline leads the washing liquid into the liquid purifying tank for being purified, and the washing liquid is conveyed into the washing and disinfecting tank again through the circulating pump. The liquid purifying tank is internally provided with a filter plate and a discharge generator. The discharge generator is arranged below the filter plate. The discharge generator comprises a power supply part, a cathode and an anode, wherein the cathode and the anode are electrically connected with the power supply part. The washing liquid output from the bottom of the liquid purifying tank comprises hydrogen peroxide produced by streamer discharge in the washing liquid through the voltage applied by the power supply part to the cathode and the anode. By means of the technical scheme, the problems that with long-term using of the washing fluid, the sterilization and disinfection functions of the washing liquid are gradually weakened, even the washing fluid is recycled and reused, and the medicalapparatus cannot be qualified in sterilization are solved.

Owner:弘毅天承知识产权股份有限公司

Cutting fluid treatment and regeneration device for machine manufacturing

ActiveCN112569653AHas a diversion effectAvoid intercept aggregationLoose filtering material filtersGravity filtersMachine buildingGear wheel

The invention discloses a cutting fluid treatment and regeneration device for machine manufacturing, relates to the technical field of cutting fluid treatment devices, and solves the problems that theexisting cutting fluid regeneration device easily accumulates iron slag mixed in cutting waste fluid on the periphery of a filtering part, the stacked iron slag needs to be frequently and manually scraped or cleaned, and the operation and the use are labor-consuming and inconvenient. The cutting fluid treatment and regeneration device for machine manufacturing comprises a rectangular bottom plate, the rectangular bottom plate comprises a rail shaft, a cover plate, a gear and a fluid outlet pipe, a square fluid containing groove is formed in the middle of the rectangular bottom plate in an inwards-concave mode, water guide grooves are longitudinally and transversely formed in the plate faces of the left side and the right side of the square fluid containing groove in a densely-distributedmode, and a rectangular bottom plate is integrally installed at the bottom of a machine tool to serve as a base of the machine tool. The filter cotton can be inserted, blocked and positioned by the two pressing frames through the five rows of conical tip inserting rods at the bottoms of the pressing frames, so that the two pieces of filter cotton are more stably fixed and prevented from sliding and moving along with the two scraping plates.

Owner:大连博斯特科技有限公司

Through-wall purifying ventilating pipe with ventilating flow adjusting structure

ActiveCN108168007AGuaranteed cleanlinessExtended service lifeMechanical apparatusSpace heating and ventilation safety systemsAir volumeContact time

The invention discloses a through-wall purifying ventilating pipe with a ventilating flow adjusting structure. The through-wall purifying ventilating pipe comprises a ventilating pipe and an air volume adjusting device comprising a valve and a transmission unit. The transmission unit comprises a screw rod, a nut and a driving motor. A circle of retaining flanges is arranged on the inner side of the ventilating pipe. Four limiting sensors, a PLC, a PM2.5 sensor and a CO2 sensor are further arranged. The through-wall purifying ventilating pipe with the ventilating flow adjusting structure is small in mounting space, easy to operate and reliable in structure; and a filter net of a novel structure is arranged in the ventilation pipe, the purpose of prolonging the contact time of gas and the filter net is achieved by prolonging the filter path of the gas, and the purifying efficiency of the filter net is high.

Owner:KUNSHAN SILAIMU ENERGY SAVING TECH CO LTD

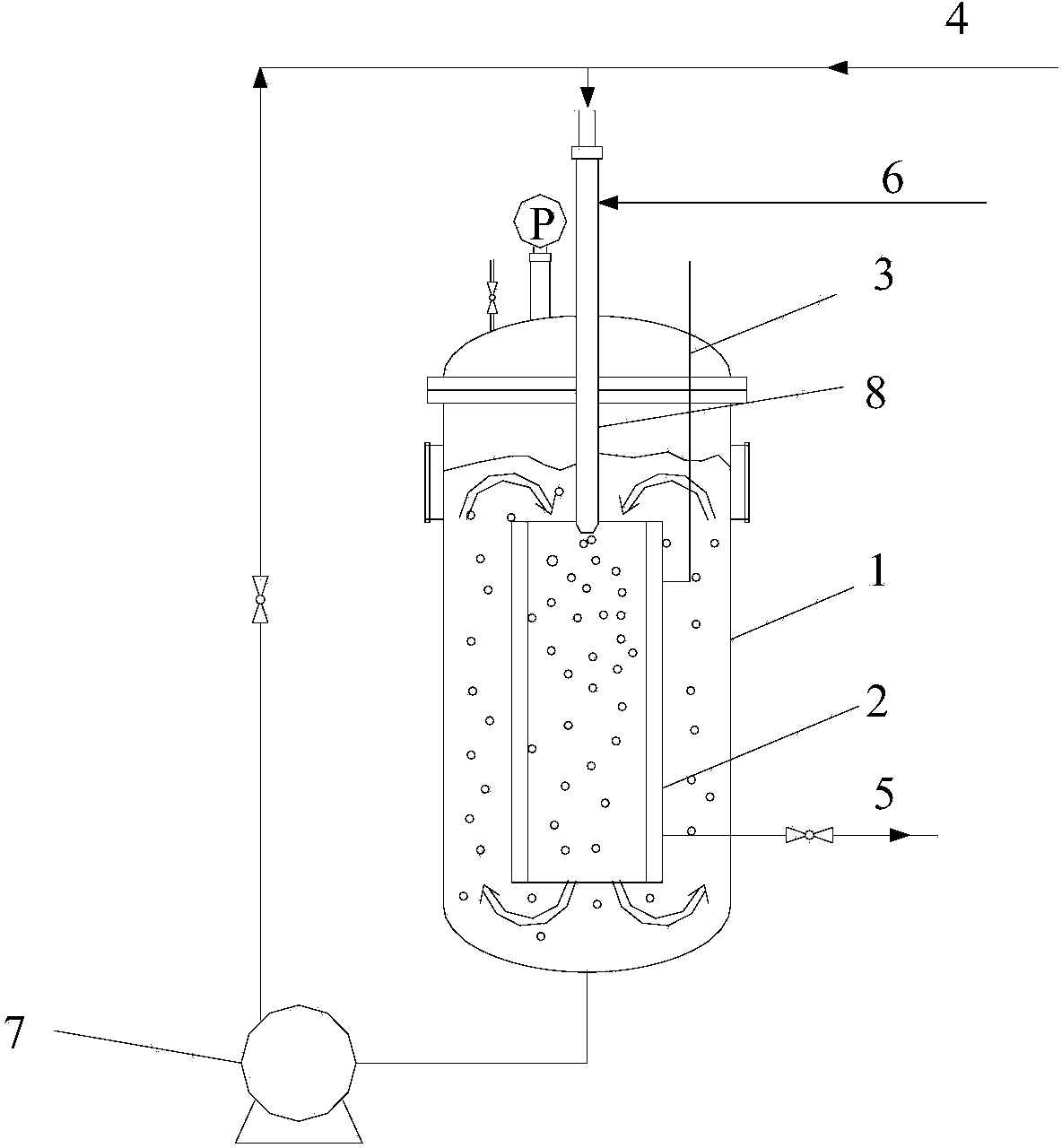

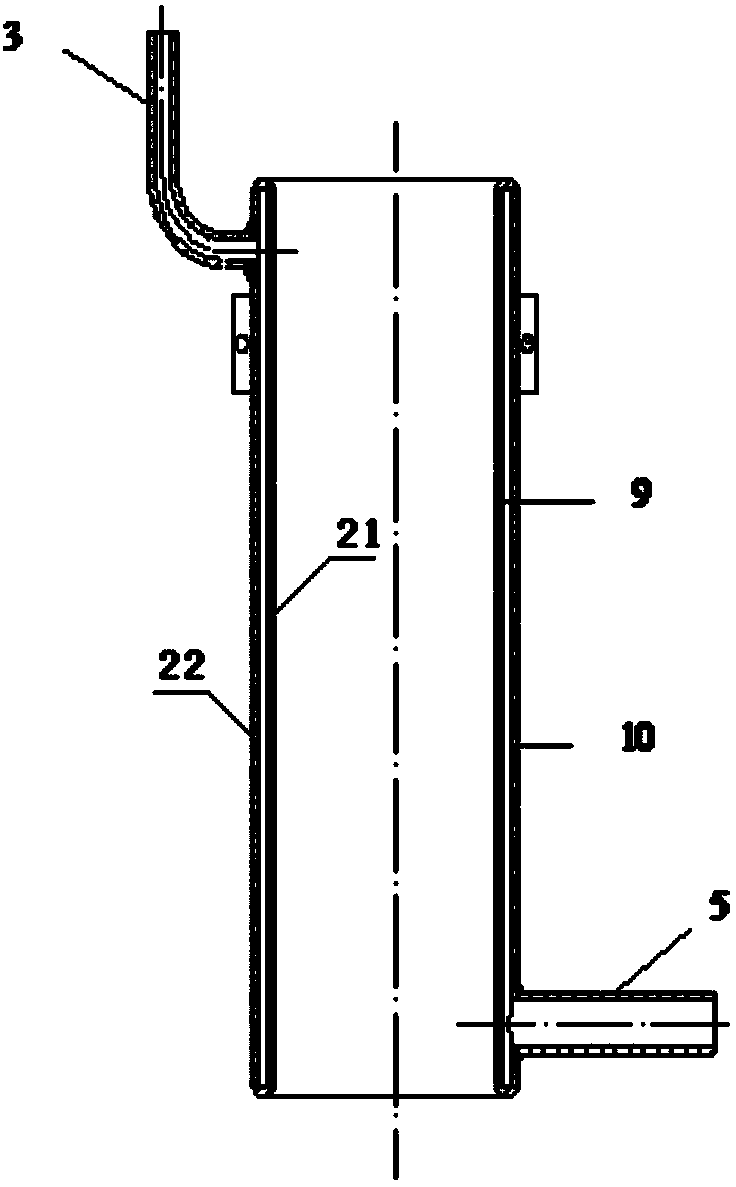

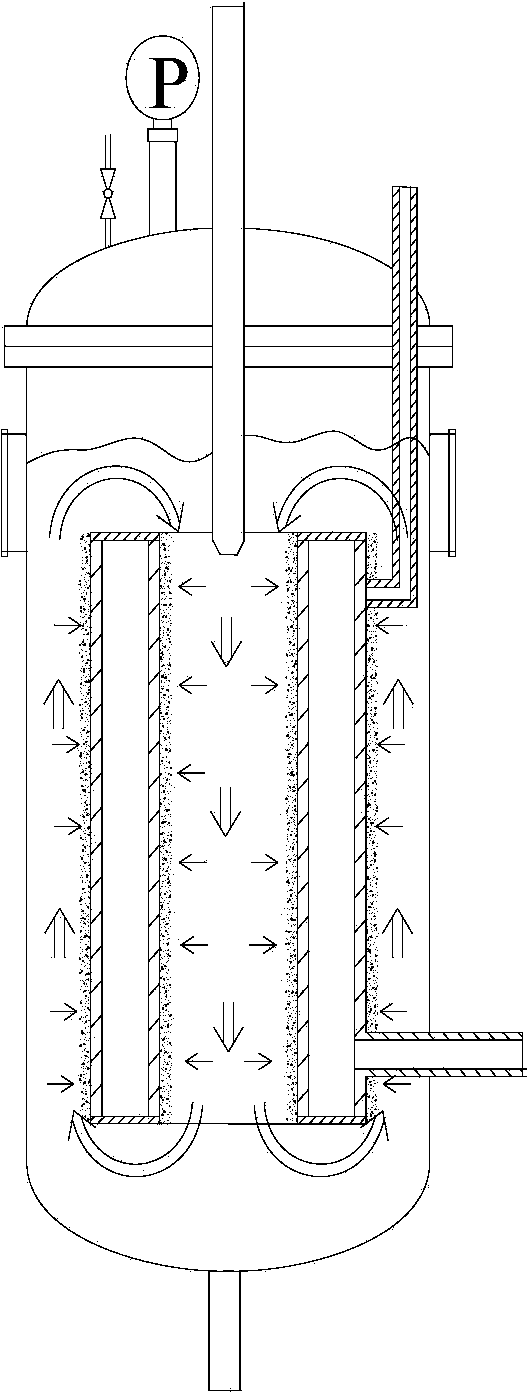

Reactor for performing continuous multiphase catalytic reaction and separation

ActiveCN103877915AImprove efficiencyHas a diversion effectChemical/physical processesStationary filtering element filtersEngineeringSlurry

The invention discloses a reactor for performing continuous multiphase catalytic reaction and separation. The reactor comprises a reactor shell, a nozzle and a filtering-type guiding device, wherein the nozzle is connected with a liquid reactant and a gas reactant; the reactor is characterized in that the filtering-type guiding device is arranged in the reactor shell and is immersed in a serous fluid of the reactor, the filtering-type guiding device is composed of inner and outer concentric cylinders, at least one of the cylinders is a filtering-type cylinder, the upper and lower ends of the two cylinders are connected and sealed, and an annular space arranged between the inner and outer concentric cylinders is a liquid filtering region; the filtering-type guiding device is provided with an exhaust hole and a liquid filtering discharging hole, and the nozzle is aligned to the interior of the filtering-type guiding device and can form a serous fluid ring current which can fold back from the interiors of the cylinders of the filtering-type guiding device to the bottoms of the cylinders and can pass through a space arranged between the filtering-type guiding device and the reactor shell to arrive the top of the filtering-type guiding device; the region of the serous fluid ring current is a reacting region, a liquid enters the liquid filtering region from the reacting region, and a filter cake is formed on the surface of a filtering cylinder of the filtering-type guiding device.

Owner:嘉善县临沪新城实业有限公司

Rotating piece type automatic-cleaning and heat-transfer enhancing device

InactiveCN101551214BLow rotational resistanceSave materialHeat transfer modificationRotary device cleaningEngineeringDual function

The invention relates to a rotating piece type automatic-cleaning and heat-transfer enhancing device, in particular to a device used for a heat transfer pipe for a tubular heat exchange device. The device comprises one or more rotating piece(s), hanging parts, an axial line and limiting rivets and is used by being placed in a heat exchanger, wherein the number of the hanging parts is two, and thetwo hanging parts are respectively fixed at both ends of the heat transfer pipe; the rotating pieces are placed in the heat transfer pipe of the heat exchanger; the rotating pieces are used and arranged in groups, and the limiting rivets are arranged between each group of the rotating pieces at intervals; the axial line penetrates through an axle holes of the rotating pieces and the limiting rivets, and both ends of the axial line are fixed on the two hanging parts; the rotating pieces are of screw twisted shapes, concavo-convex slot structures are alternatively arranged at the position of theaxial line at intervals and are axle holes of the axial line, the friction between the rotating pieces and the axial line can be effectively reduced, thus the service life of the rotating pieces is prolonged; and the rotating pieces have simple molds, can be made of plastics or metal and can be molded by pressing or by injection according to the different materials. The device has the dual functions of automatic on-line cleaning and scaling control and enhancing heat transfer in the heat transfer pipe and is convenient to manufacture, assemble, use and replace.

Owner:BEIJING UNIV OF CHEM TECH

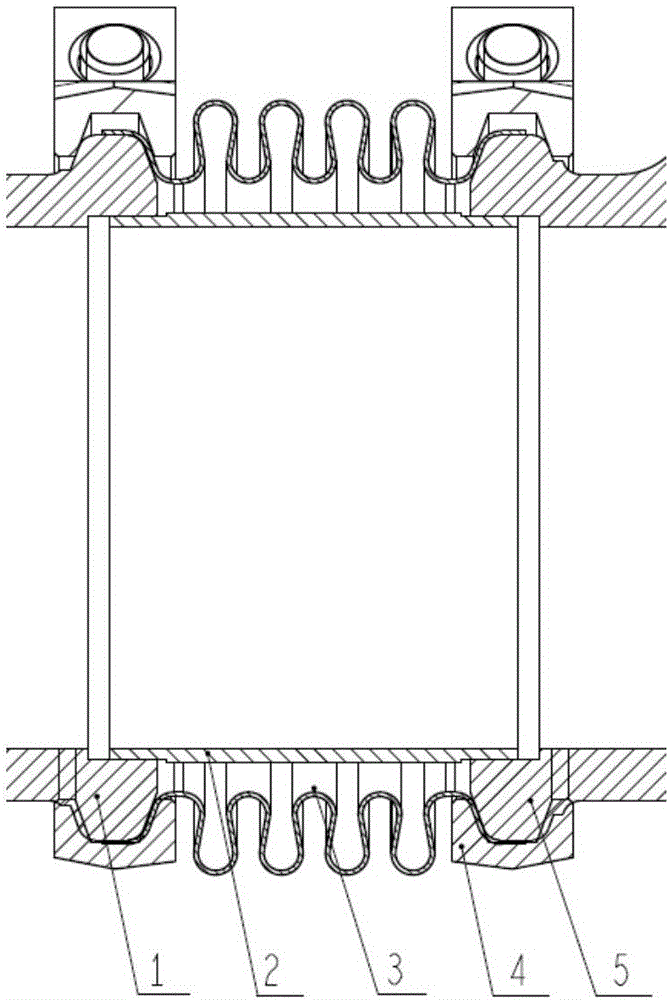

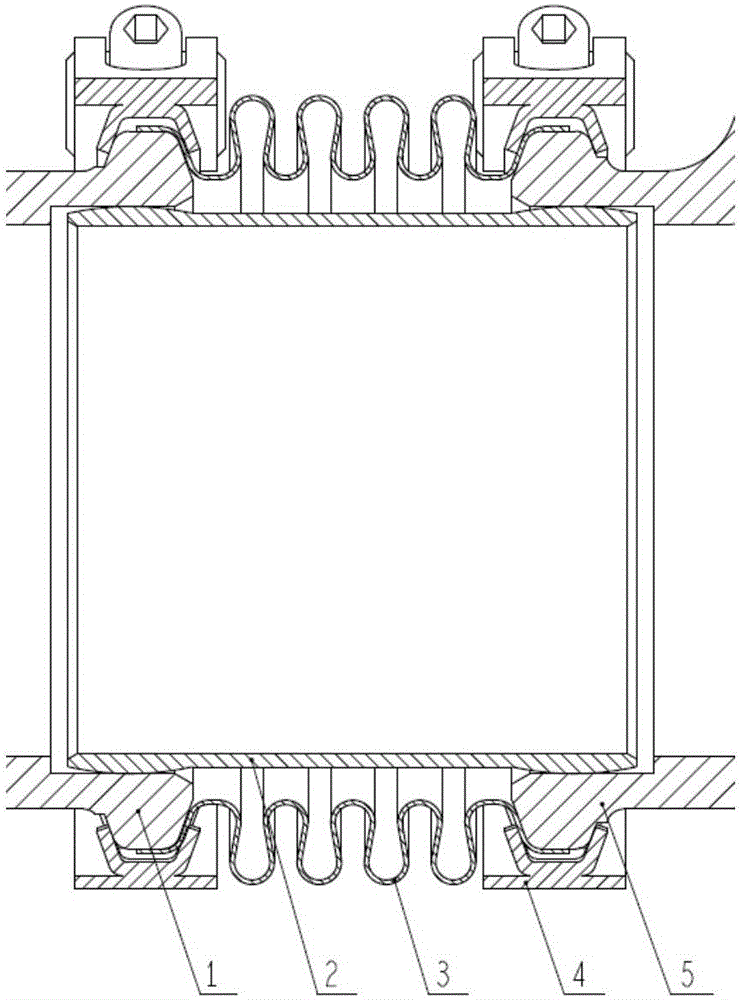

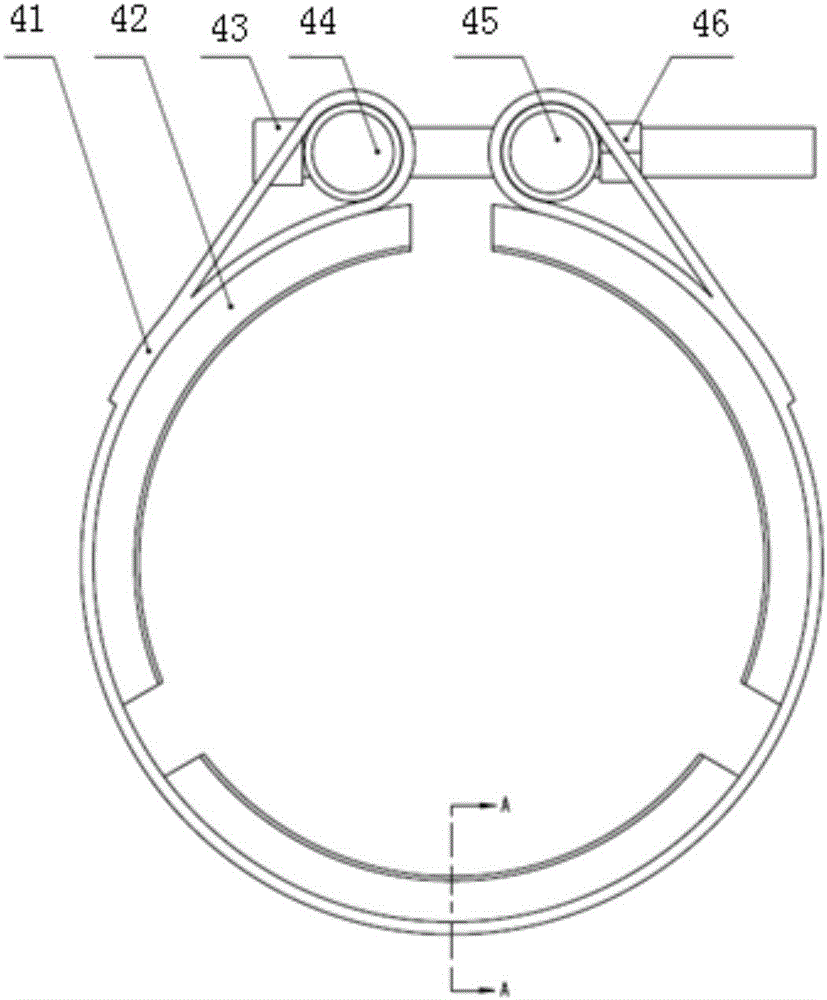

Adjustable diesel engine exhaust pipe connecting device

InactiveCN106545394AHas a diversion effectRealize flexible connectionExhaust apparatusSilencing apparatusDiesel engineExhaust pipe

The invention provides an adjustable diesel engine exhaust pipe connecting device. The adjustable diesel engine exhaust pipe connecting device comprises a lining pipe, a corrugated pipe and a clamp. The two ends of the lining pipe are of a spherical structure. The spherical structures of the two ends of the lining pipe are connected to a first exhaust pipe connector and a second exhaust pipe connector correspondingly. The corrugated pipe is connected between the outer portions of the first exhaust pipe connector and the second exhaust pipe connector and fixed through the clamp. According to the adjustable diesel engine exhaust pipe connecting device, flexible exhaust pipeline connection is achieved, the purpose of adjustable assembling is achieved, and the design tolerance and the processing and manufacturing error are effectively offset; and the sealing reliability of an exhaust system is improved, the air leakage probability of an engine is reduced, exhaust energy losses of a flow guiding barrel are effectively avoided through the lining pipe of the spherical structure, and the energy utilization rate is increased.

Owner:CHINA NORTH ENGINE INST TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com