Filling adaptive water control screen pipe

A self-adaptive, water-screening technology, applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., which can solve the problems of increasing the filling displacement, the inability to pass the displacement, and the inability of the passive flow control valve to be adjusted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

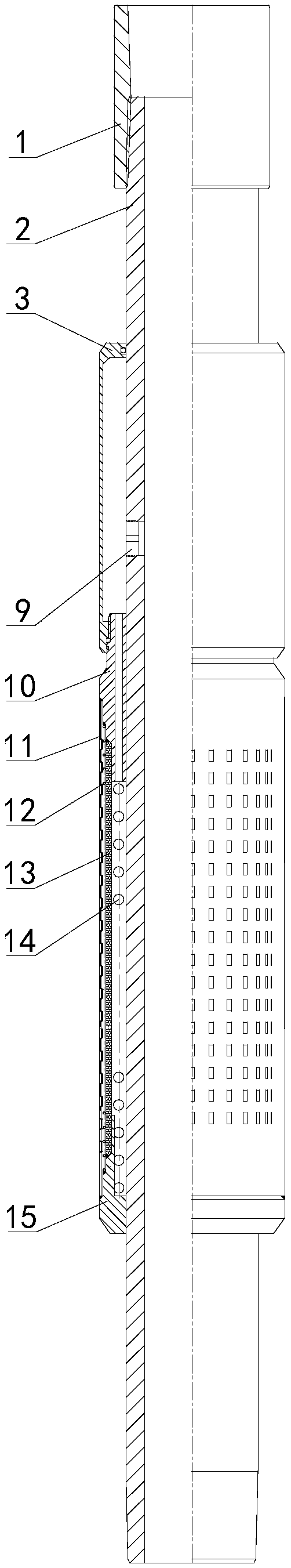

Embodiment 1

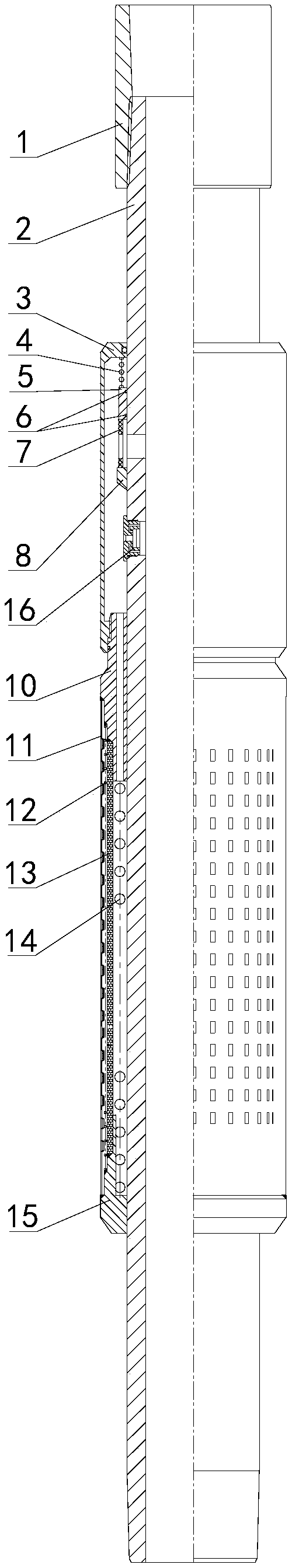

[0029] Such as figure 2 and image 3 As shown, this embodiment discloses a fillable self-adaptive water control screen. On the basis of the above water control screen in the prior art, an adaptive flow control valve 16 is used to replace the passive flow control valve 9, and an additional Large displacement filling hole 2-1 and self-resetting filling mechanism.

[0030] The self-adaptive flow control valve 16 can adopt a viscosity-sensitive flow control valve disclosed in the Chinese patent whose publication number is CN105840894B. Make adaptive adjustments.

[0031] The large-displacement filling hole 2-1 is set on the side wall of the base pipe 2 above the adaptive flow control valve 16, and is used to allow the filling fluid to enter the interior of the base pipe 2 and circulate out of the well after passing through the large-displacement filling hole 2-1. Large displacement filling hole 2-1 can meet 2m 3 Filling displacement requirements within / min.

[0032]The self...

Embodiment 2

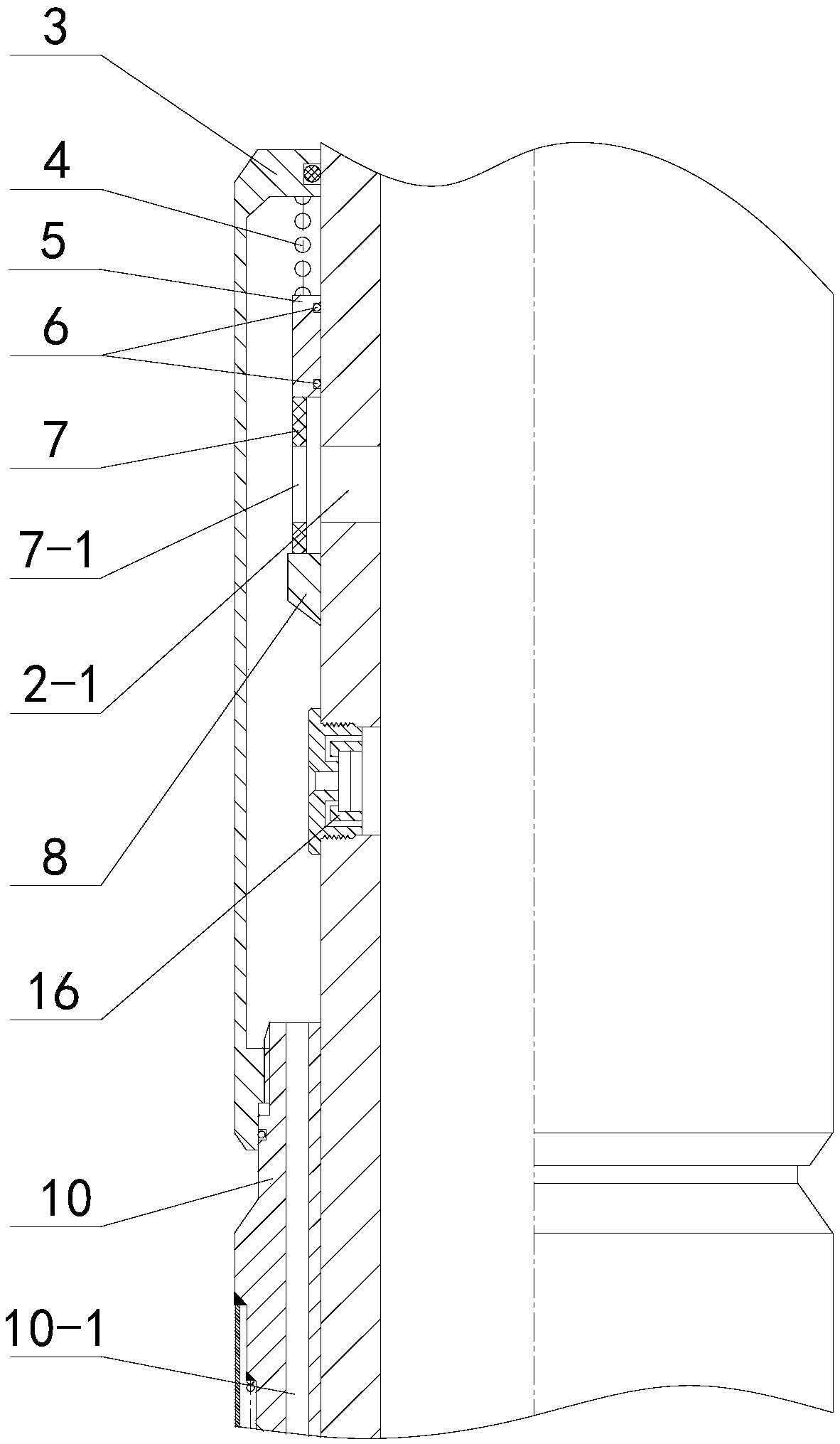

[0036] Such as Figure 4 and Figure 5 As shown, this embodiment discloses a fillable self-adaptive water control screen. On the basis of the above water control screen in the prior art, an adaptive flow control valve 16 is used to replace the passive flow control valve 9, and an additional Large displacement filling hole 2-1 and water-swellable rubber 17.

[0037] Both the self-adaptive flow control valve 16 and the large displacement filling hole 2-1 are completely the same as those in the first embodiment. The difference from Embodiment 1 is that the water-swellable rubber 17 is used instead of the self-resetting filling mechanism.

[0038] The water-swellable rubber 17 is arranged in the annular space between the base pipe 2 and the valve shield 3, and is glued and fixed on the inner rotary surface of the valve shield 3, and is located at the large displacement filling hole 2-1 and the self-adaptive flow control valve Between 16. The water-swellable rubber 17 can adopt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com