Preparation method of rubber waterstop and rubber waterstop

A rubber waterstop, rubber technology, applied in belts, building components, applications, etc., can solve problems such as damage, excessive length, and inability to pull out sticks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

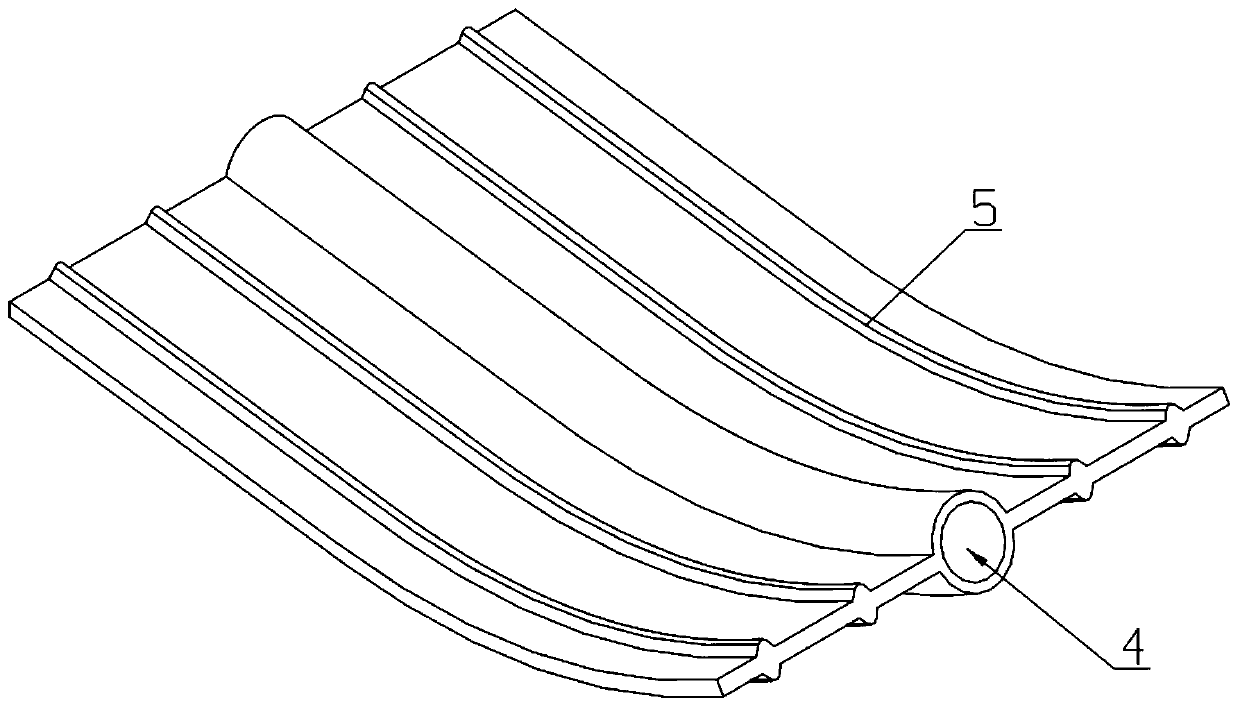

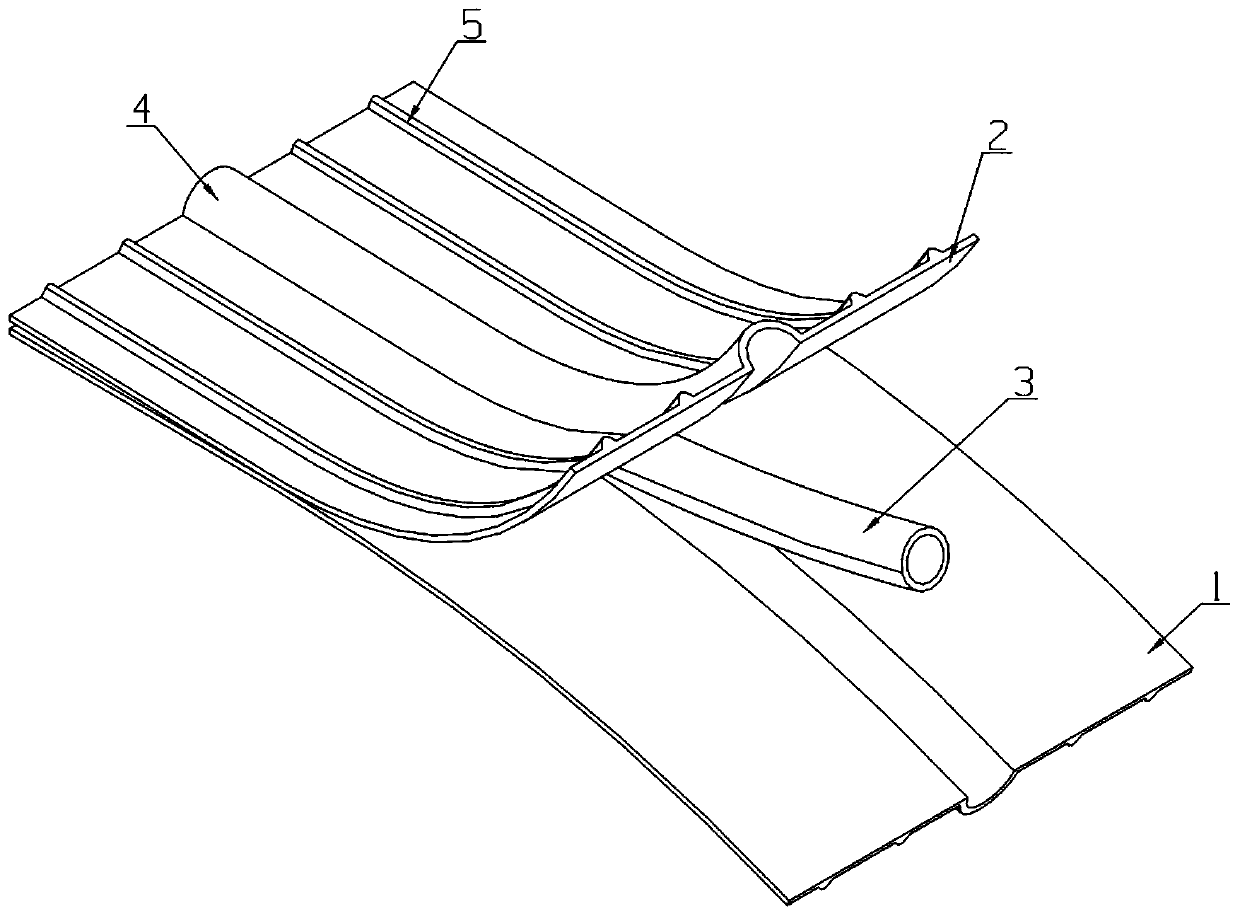

[0051] This embodiment provides a kind of preparation method of rubber waterstop, see figure 2 , is a schematic decomposition diagram of the structure of the rubber waterstop prepared in the preparation method.

[0052] This embodiment specifically includes the following steps:

[0053] In the first step of mixing, the raw materials for rubber production are mixed to obtain a rubber compound.

[0054] In the second step of calendering, the mixed rubber is calendered to form a strip-shaped first cover rubber 2 and a second cover rubber 1 .

[0055] As an alternative embodiment, in the second step, an extruder can also be used to produce strip-shaped first cover glue 2 and second cover glue 1 .

[0056] The third step is to bury the core, the pre-prepared hose 3, the hose 3 is pre-wound on the unwinding mechanism, and the hose 3 follows the calendered first cover rubber 2 and the second cover rubber 1 for synchronous unwinding. Lay the first cover rubber 2 and the second cov...

Embodiment 2

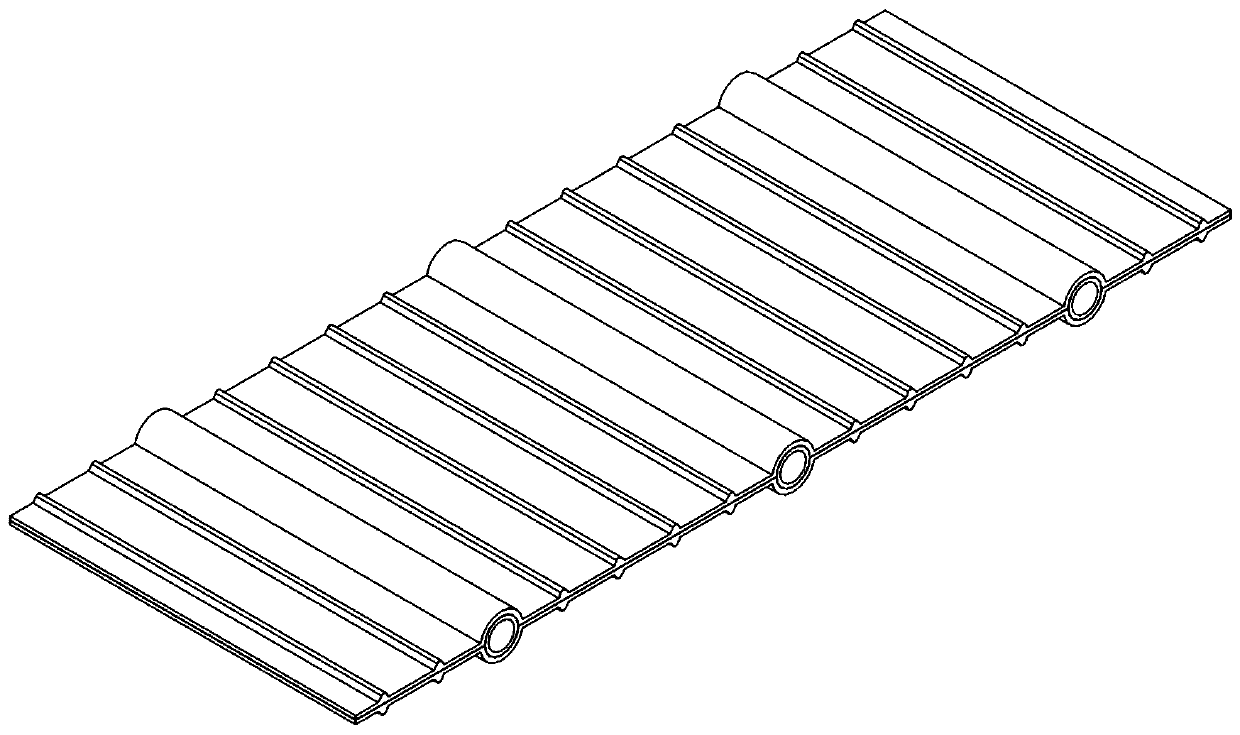

[0063] This embodiment provides a rubber waterstop, the structure diagram of the rubber waterstop is shown in figure 2 , including a belt body, a tubular structure 4 is arranged on the belt body along the extending direction of the belt body, a hose 3 is arranged inside the tubular structure 4, and the outer wall of the hose 3 is attached to the inner wall of the outer layer. On the one hand, the above-mentioned rubber waterstop can be produced by the preparation method in the above technical solution, so the length of a single rubber waterstop is longer than that of the prior art, and the production process is also simplified. On the other hand, since the tubular structure 4 of the rubber waterstop includes the inner hose 3 and the outer rubber, when the outer rubber is aged and cracked after long-term use, the inner hose 3 can still function. Therefore, the service life of the rubber waterstop is longer than that of the traditional rubber waterstop, and the water-proof effe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com