Use method of spiral step fin tower for purifying VOCs (volatile organic compounds) waste gas

A waste gas and spiral technology, which is applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve the problems of failing to purify VOCs waste gas, and the electric heating purification filter element has no solution, so as to achieve efficient utilization and continuous purification, increase Time of contact mass transfer, effect of increasing ventilation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

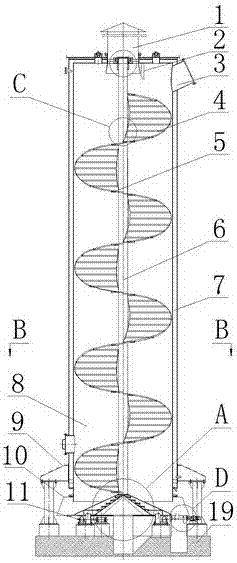

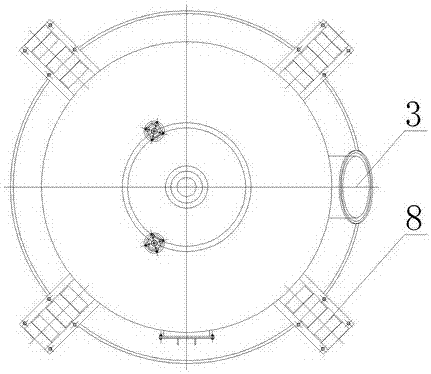

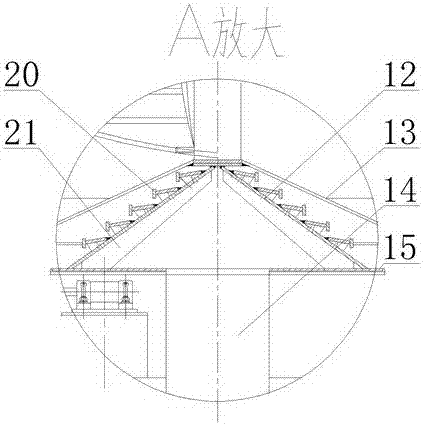

[0026] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, a method for purifying VOCs waste gas spiral stepped fin tower is characterized in that:

[0027] Step 1. First, collect relevant data in the laboratory on the adsorption of VOCs exhaust gas to saturation by the adsorbent under simulated site conditions. A 1L syringe can be used to extract exhaust gas samples from the production site. For less than 8 exhaust gas samples, use a balance to weigh 100g of adsorbent and fill it into an empty glass tube. One end of the empty glass tube is connected to an air bag, and the other end is connected to a syringe that has been sampled, and then the exhaust gas is injected into the glass tube filled with adsorbent at a uniform speed. The glass tube adsorbent packing is changed. When oil stains appe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com