Reactor for performing continuous multiphase catalytic reaction and separation

A technology of heterogeneous catalysis and reactors, which is applied in the field of reactors and can solve problems such as inappropriate heterogeneous catalysis reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

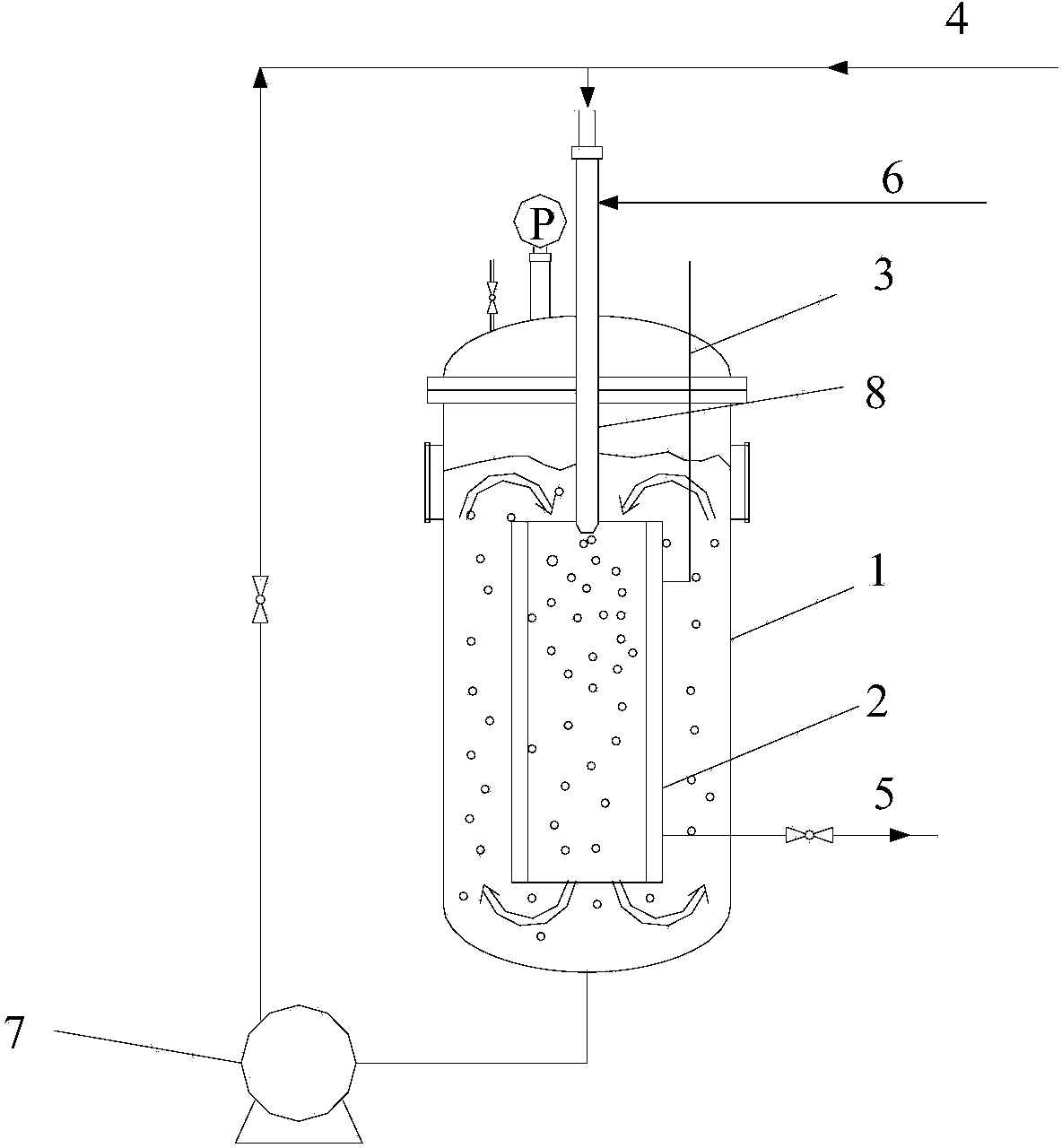

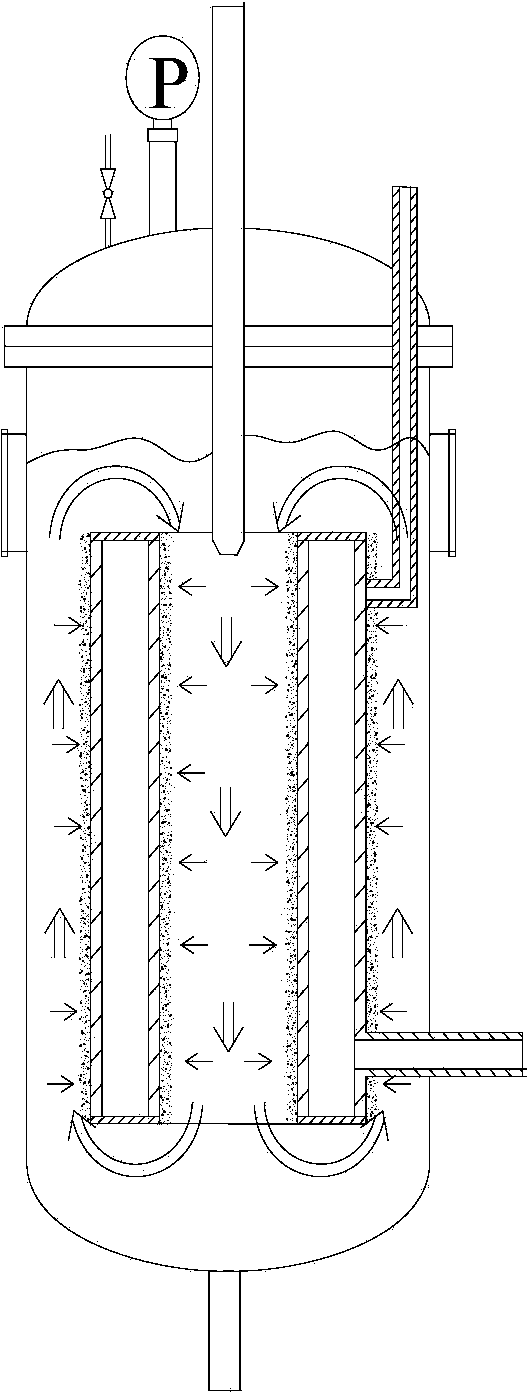

[0023] The invention discloses a continuous heterogeneous catalytic reactor capable of realizing liquid-solid separation in the reactor. Taking advantage of the characteristics of the jet loop reactor such as sufficient mixing, good mass transfer and heat transfer effect, the coupled liquid-solid separation process realizes continuous multiphase reaction and separation inside the reactor at the same time. The liquid-solid separation is realized through the filter guide device in the reactor. The filtrate flow from the reaction zone into the filtrate zone can be kept constant for a long time, which can meet the requirements of continuous operation in industry.

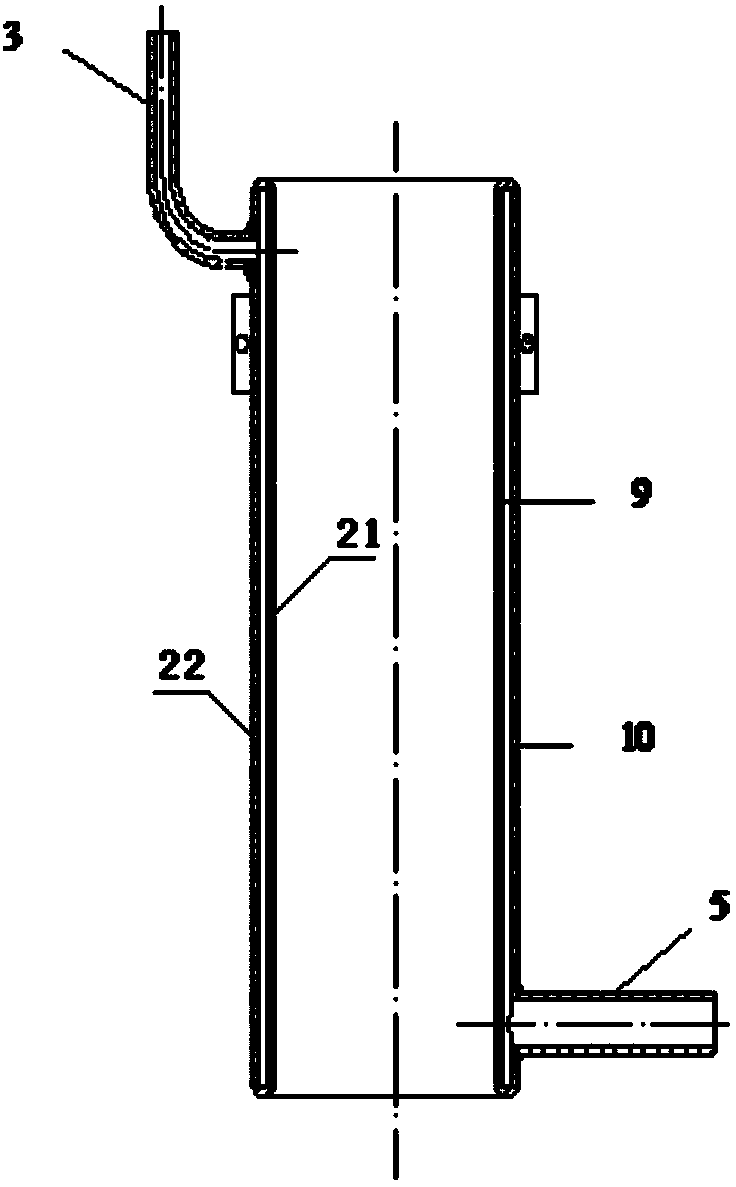

[0024] The jet loop reactor disclosed in the invention can be an up-spray type or a down-spray type. The filter guide device can be a single-tube filter or a double-tube filter. The structure and principle of the reactor will be introduced below by taking the internal filter downspray loop reactor as an example.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com