Patents

Literature

37results about How to "Large mixing range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency feed mixing device

InactiveCN107376746AWell mixedEvenly distributedShaking/oscillating/vibrating mixersFeeding-stuffEngineeringMotor shaft

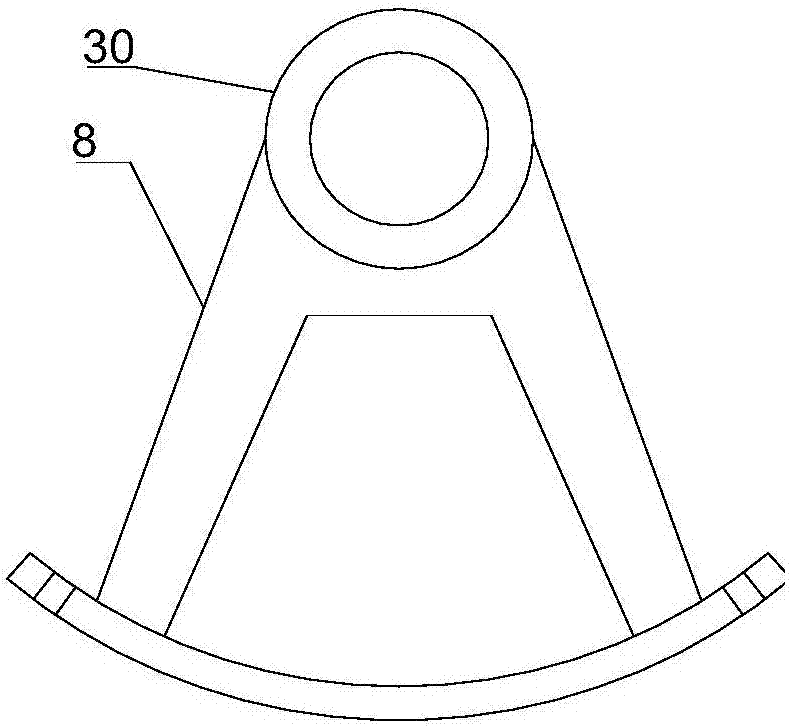

The invention discloses a high-efficiency feed mixing device, which comprises a base, wherein the base is fixedly provided with a first sliding rail; the upper part of the first sliding rail is connected with a first rack and a mixing box through a slide block in a sliding manner; the right end of the first rack is connected with the mixing box through a connecting rod; the base is also provided with a fixed seat; a first gear motor is also fixedly arranged at the front end of the fixed seat; a motor shaft at the front end of the first gear motor is connected with a first belt pulley; a fixed shaft is arranged on the front end surface of the first belt pulley; the front end surface of the fixed seat is also rotationally connected with a sector gear through a pin shaft; the sector gear is meshed with the first rack; the top end of the sector gear is fixedly connected with a rocking bar; a rectangular opening is formed in the rocking bar; and the fixed shaft is matched with the rectangular opening in the rocking bar. The sector gear swings from side to side to drive the mixing box to move left and right, so that the feed sways from side to side in the mixing process, and uniform distribution of the feed is ensured.

Owner:曹欢

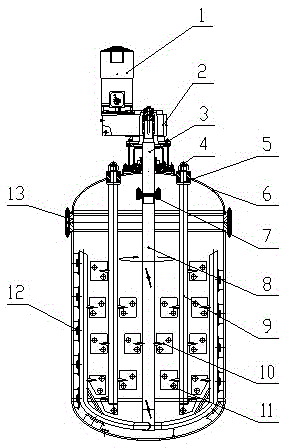

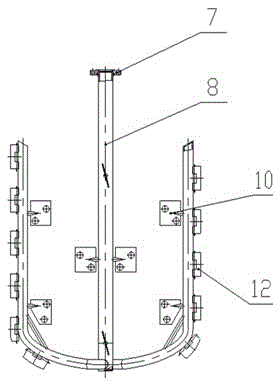

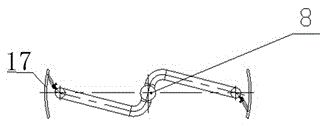

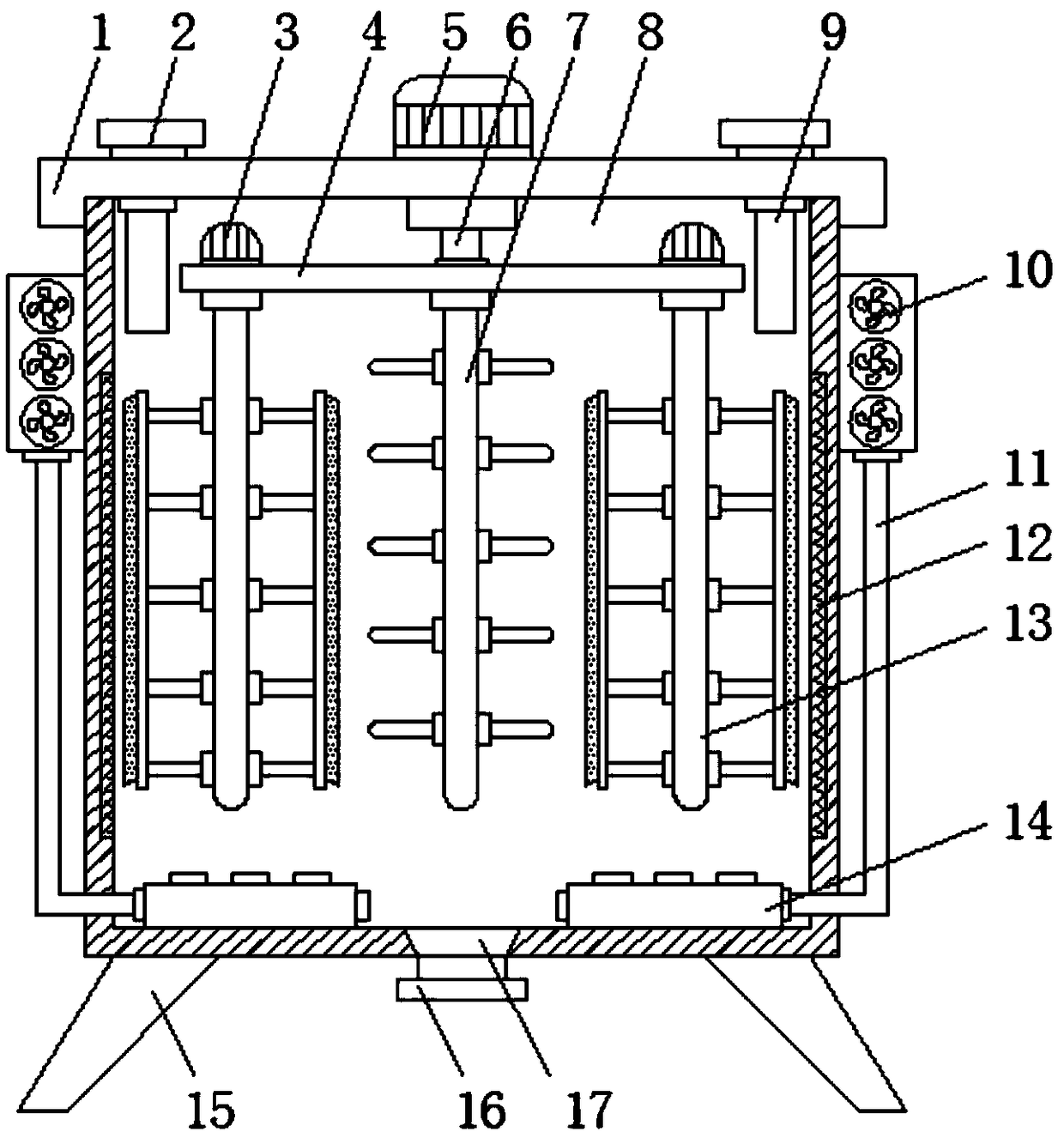

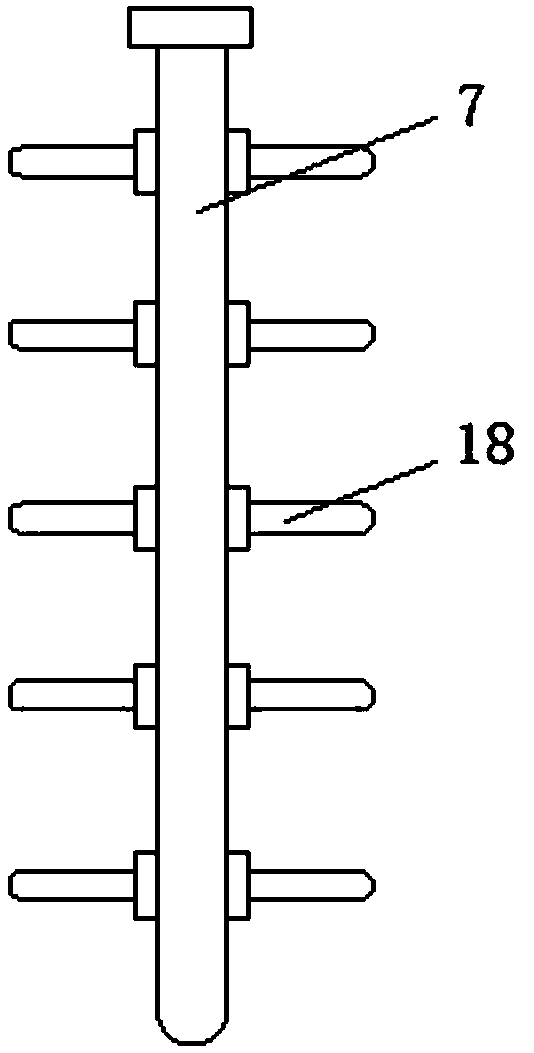

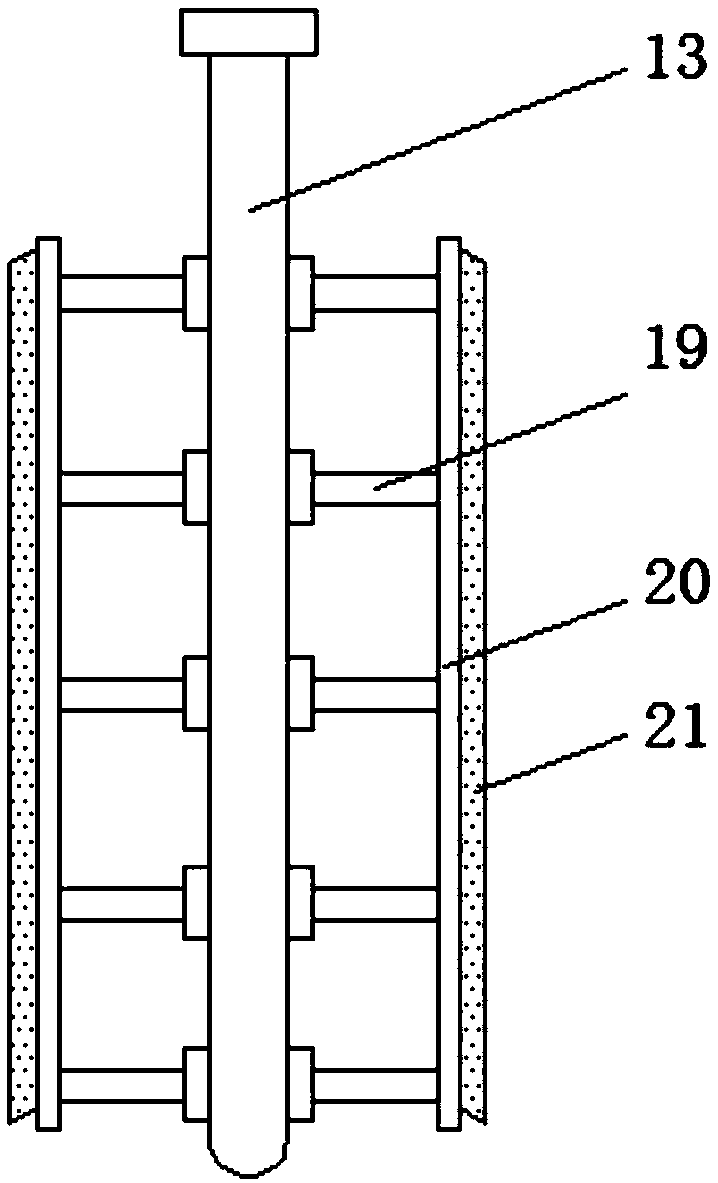

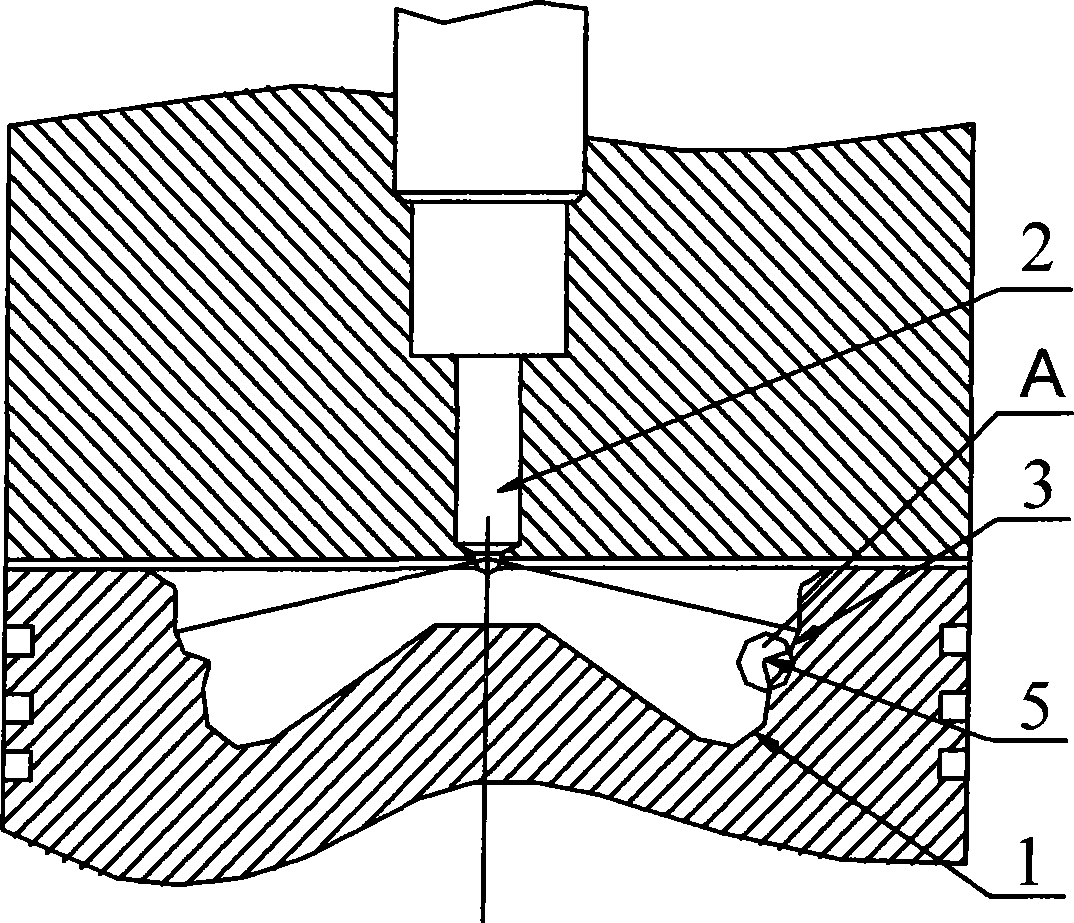

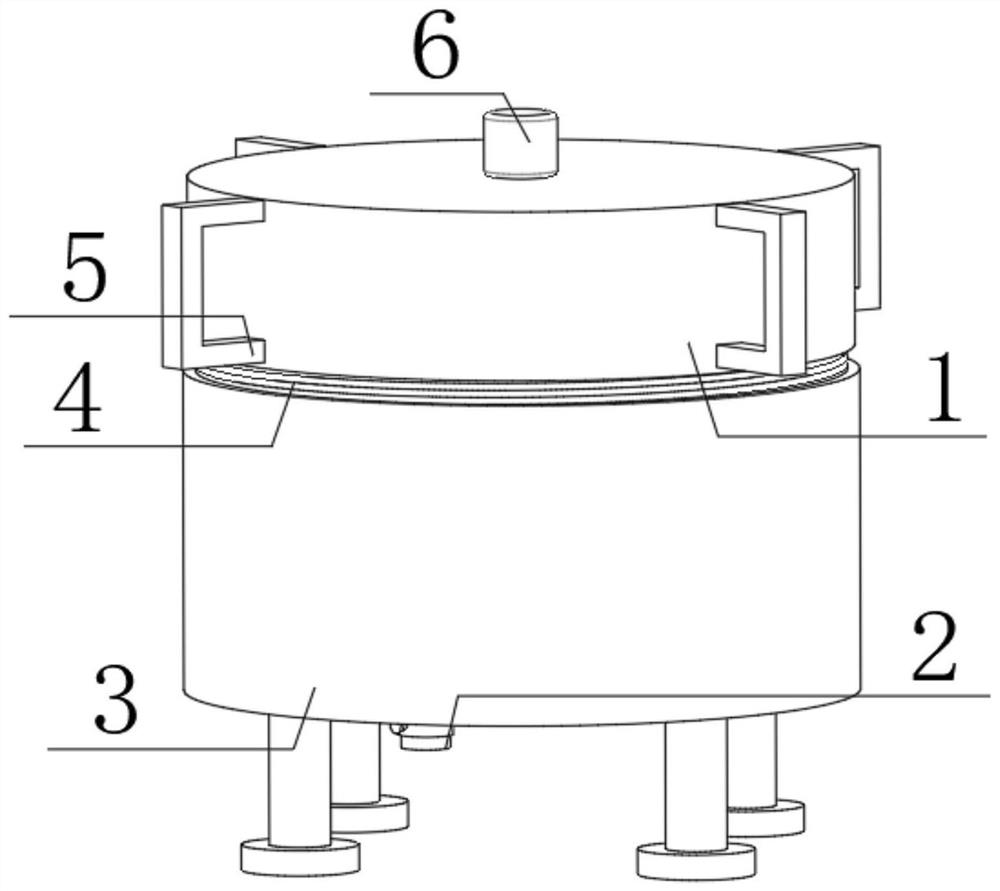

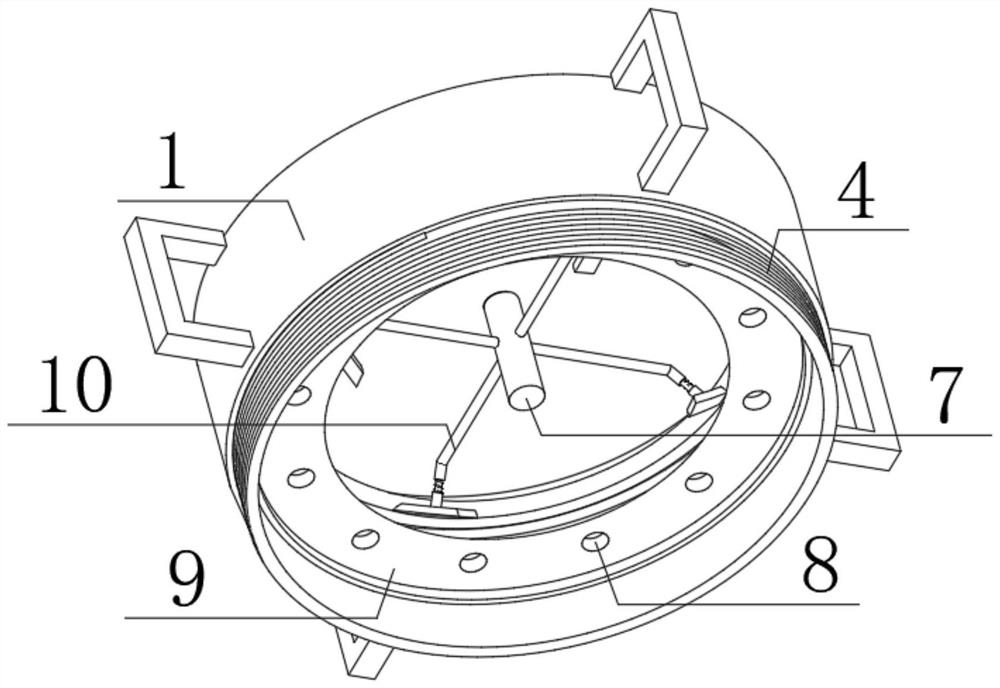

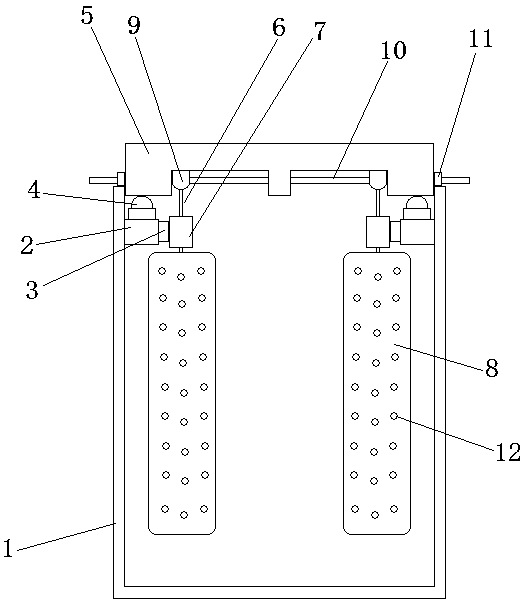

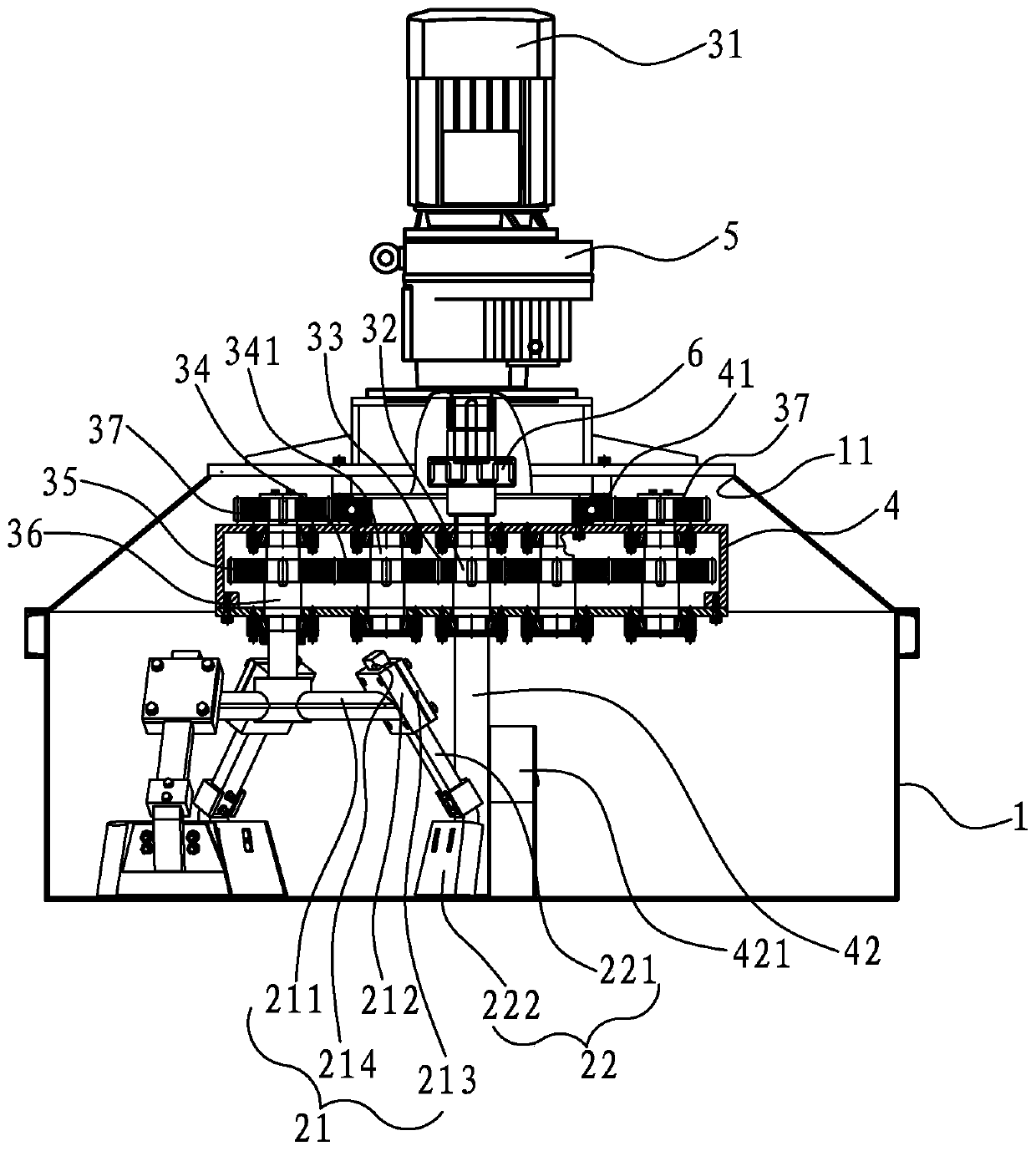

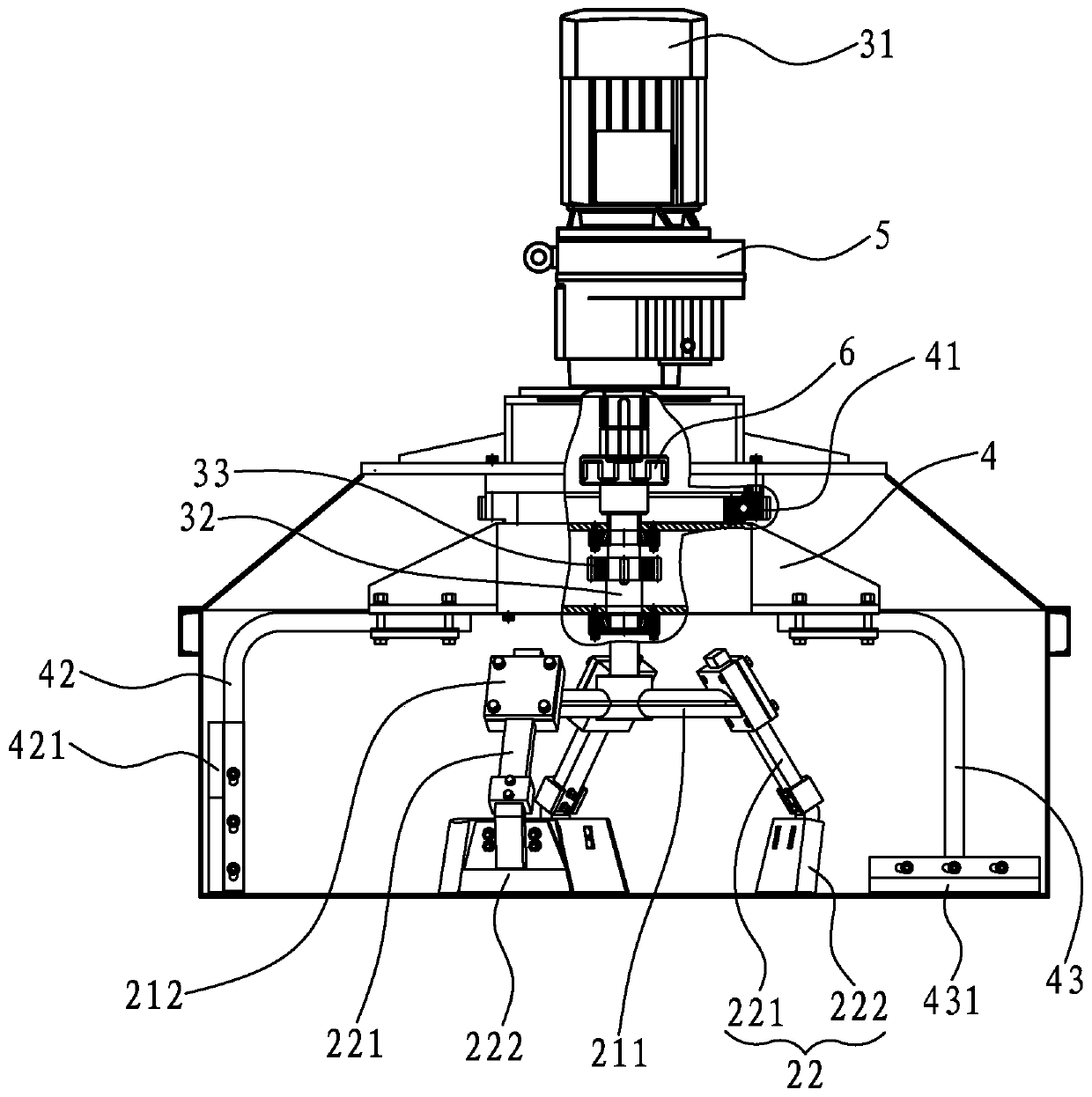

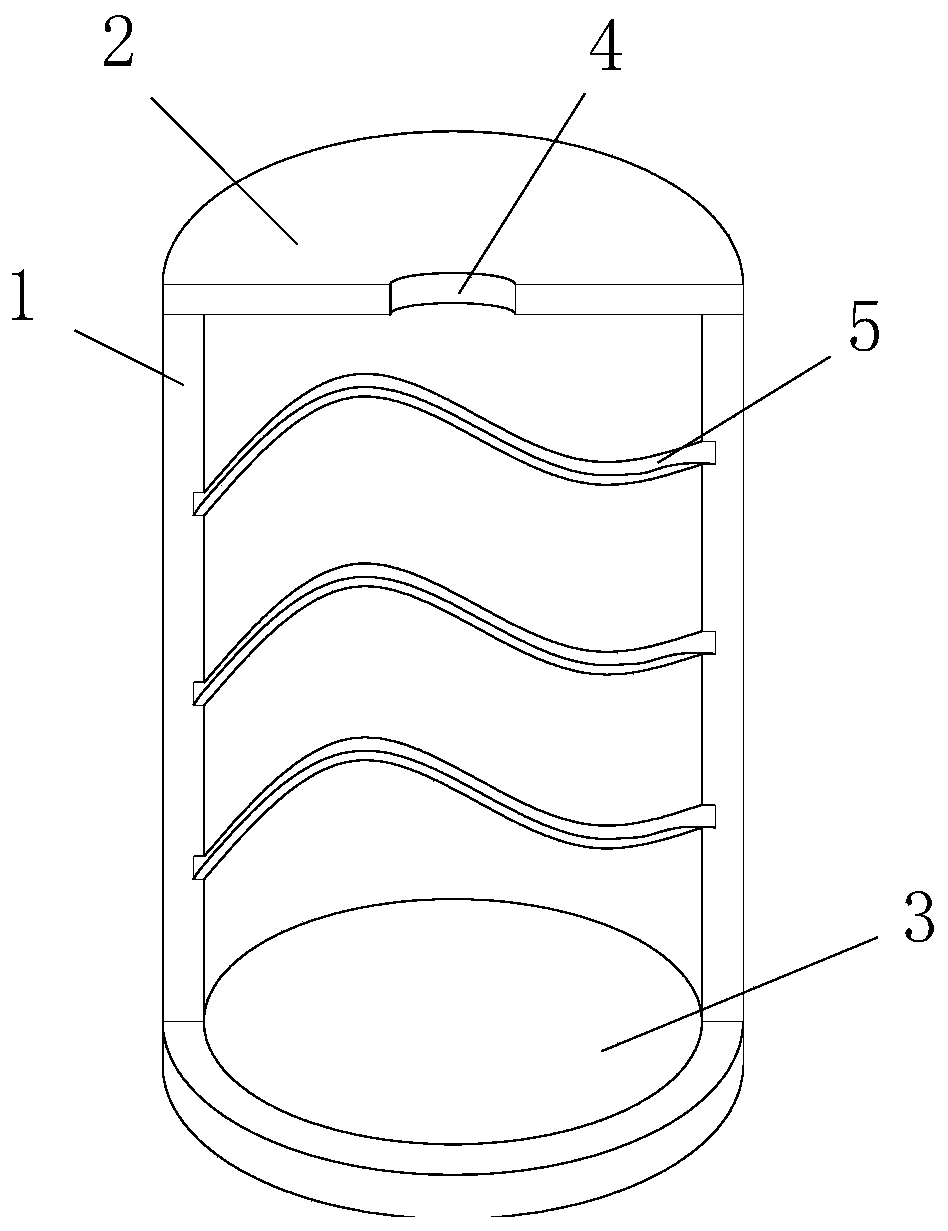

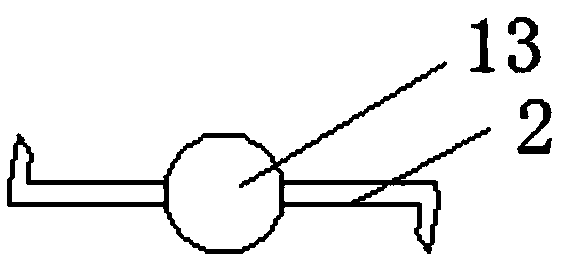

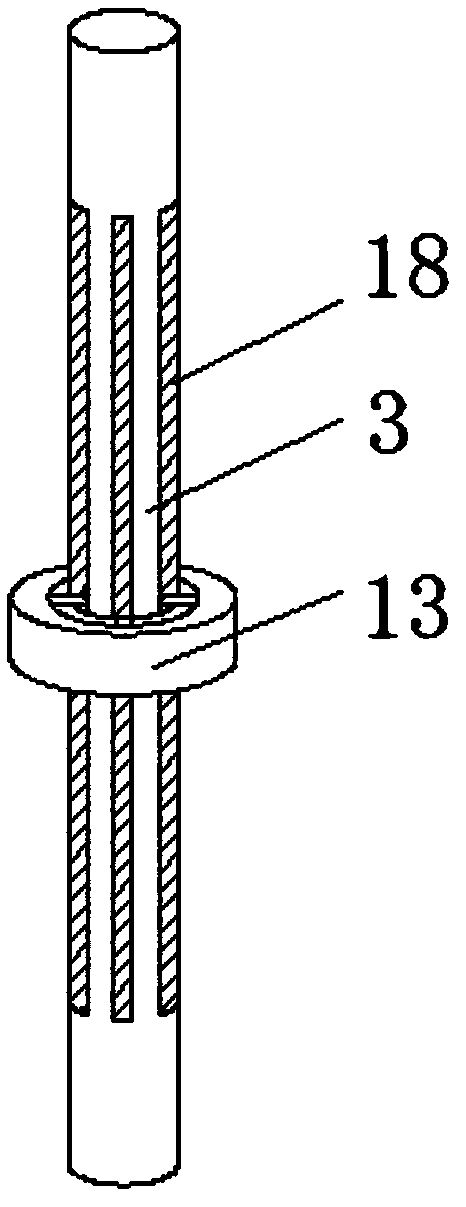

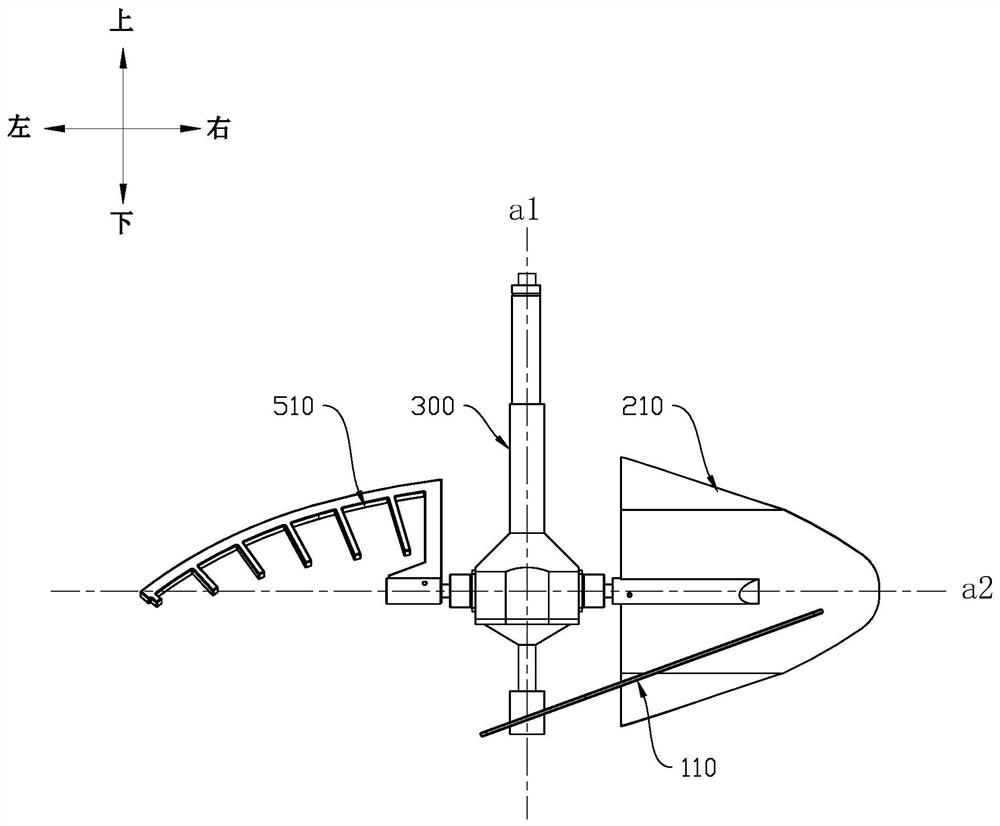

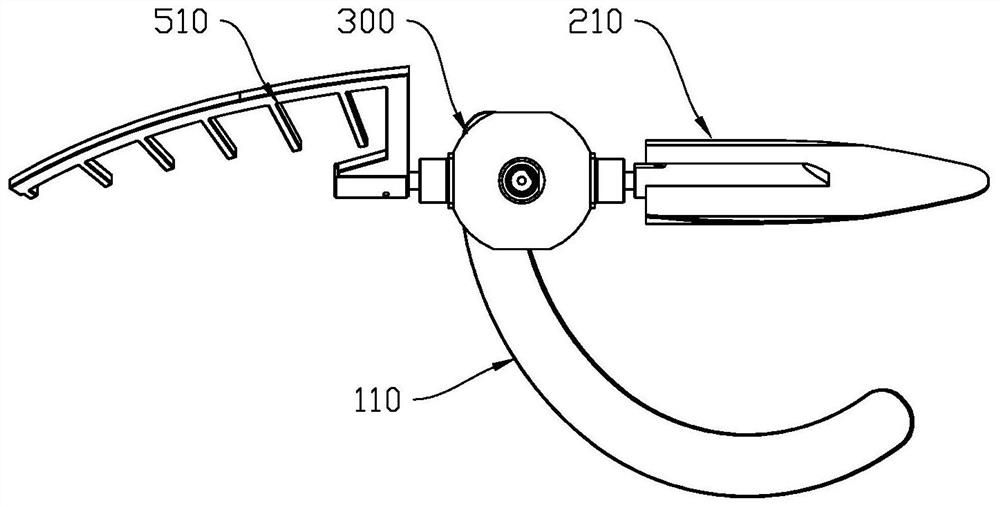

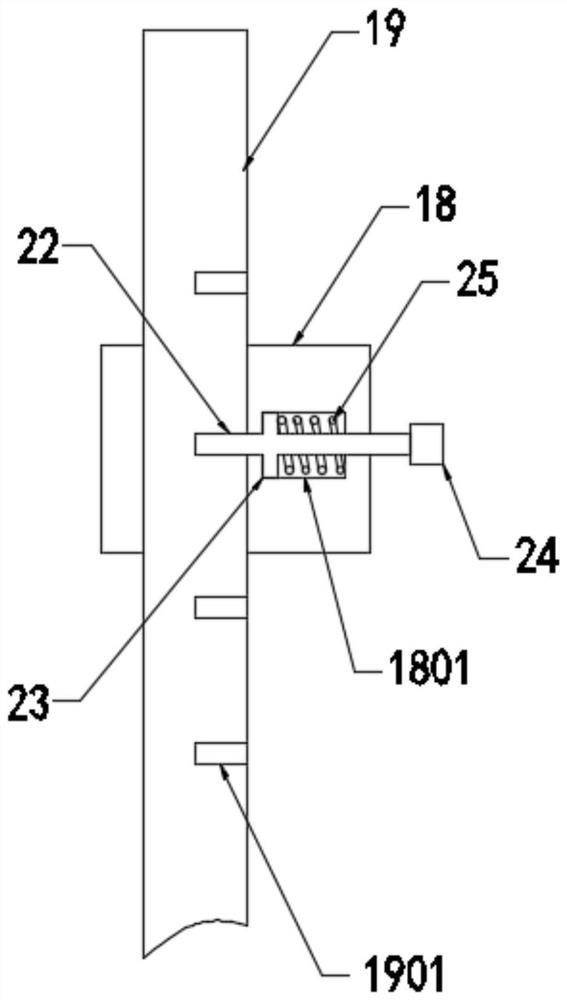

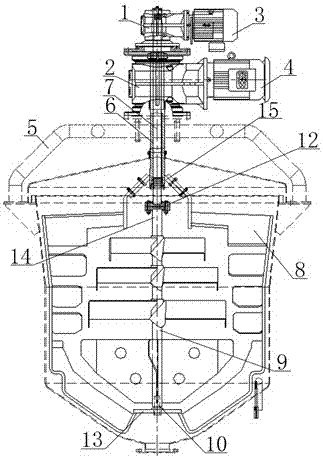

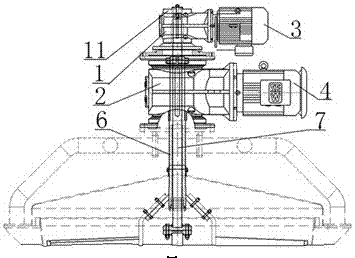

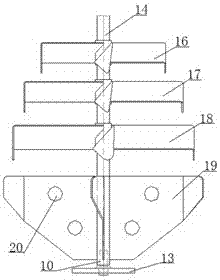

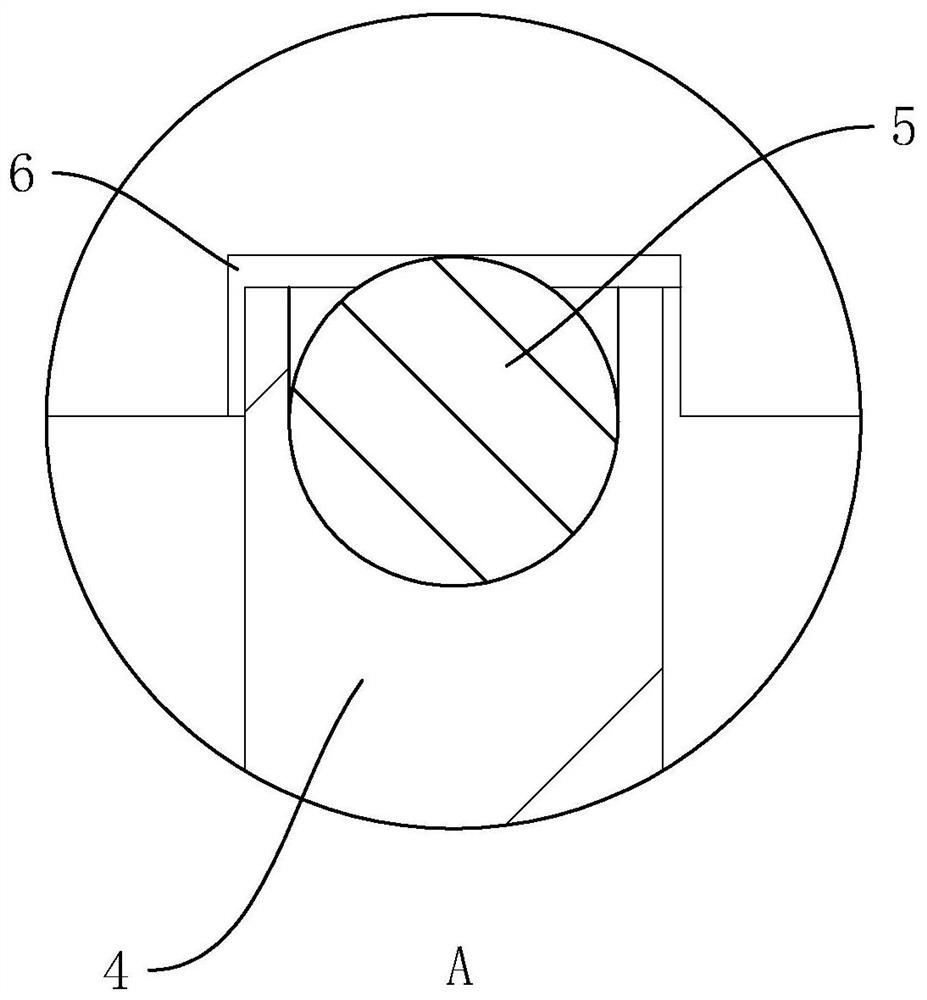

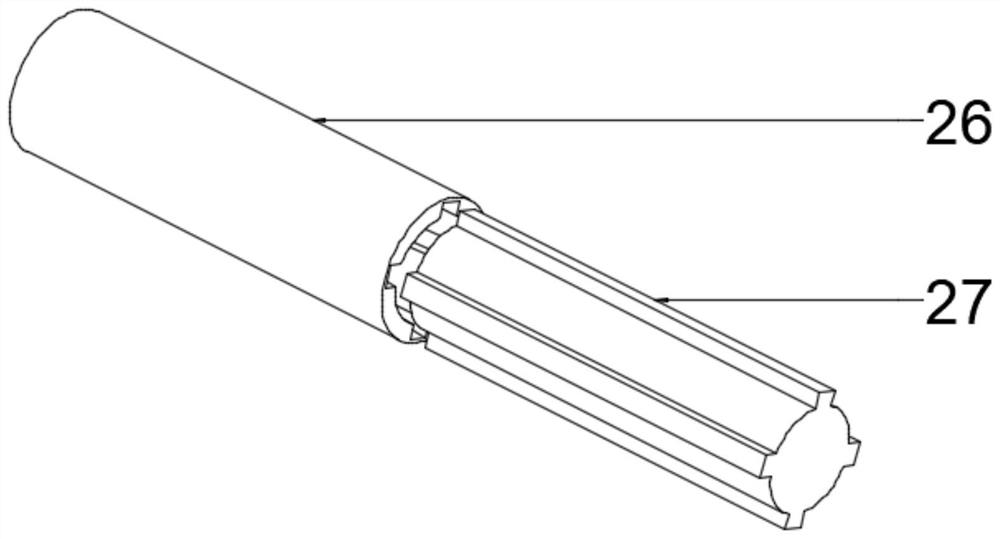

Hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer

InactiveCN105561841ALarge mixing rangeStir wellTransportation and packagingRotary stirring mixersElectric machineryReducer

The invention relates to a hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer. The hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer comprises a motor, a speed reducer, a transmission shaft, cover-type nuts, fixing bases, end sockets, a coupler, a rotating-anchor-type stirrer body, fixing-type stirrer bodies, rotating stirrer blades, fixing stirrer blades, scratch boards, device flanges and a tank. The fixing-type stirrer bodies are installed at the top ends of the end sockets on the two sides of a stirring shaft of the rotating-anchor-type stirrer body, the scratch boards are installed on the outer sides of supports on the two sides of the rotating-anchor-type stirrer body, and the rotating stirrer blades and the fixing stirrer blades are correspondingly and alternately installed on the stirring shaft and fixing shafts. The hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer has the advantages that the angle positions of all the blades can be installed according to the requirement of technology operation to meet the requirements of the different working conditions; the stirring range of the stirrer is wide and almost free of dead corners, and full stirring can be guaranteed; when materials with different production technologies are stirred, the device is flexible in assembling, reliable in fixing and quite convenient to disassemble, assemble, replace, wash and maintain.

Owner:SHANGHAI SANQIANG VESSEL NANTONG CO LTD

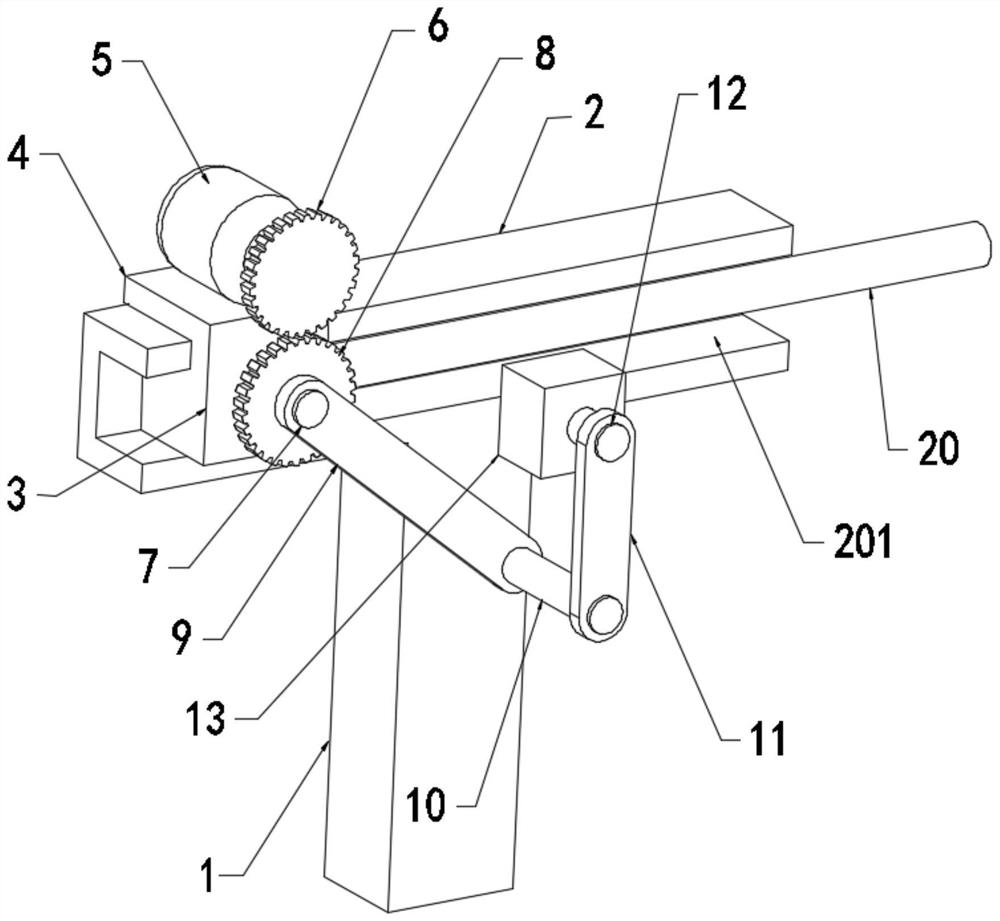

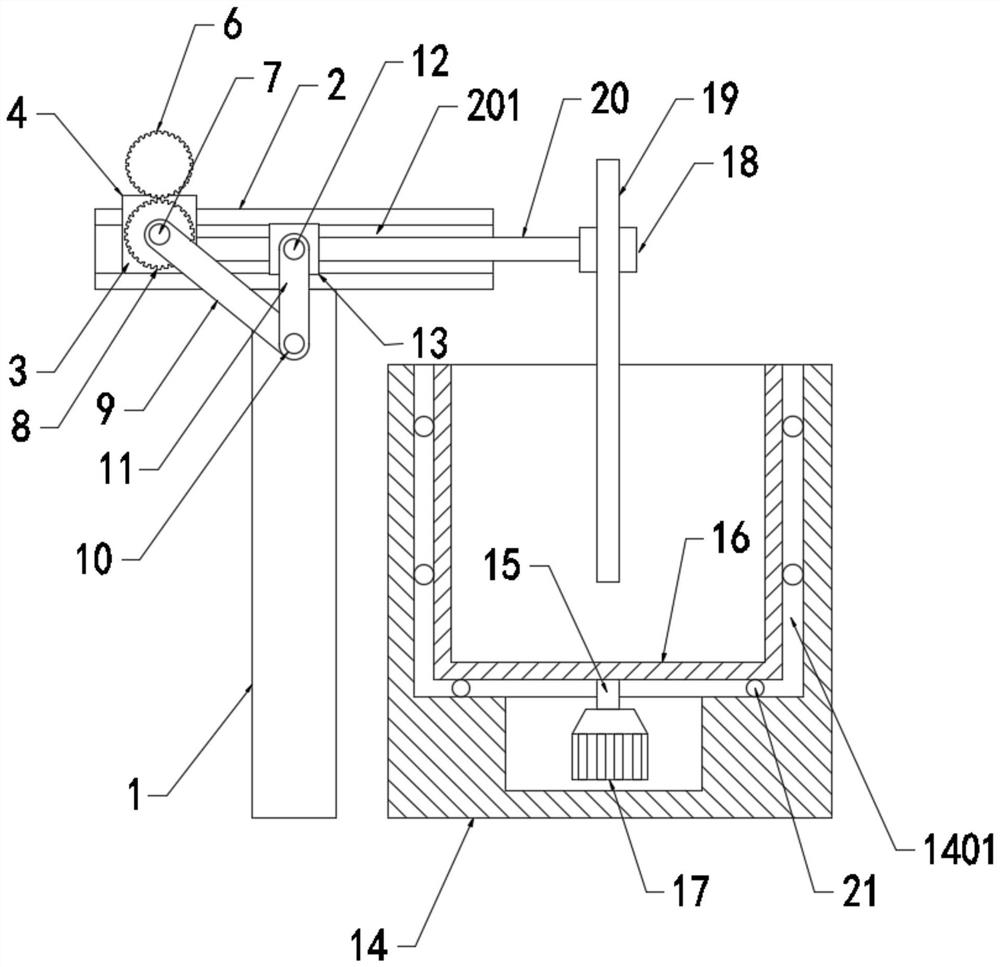

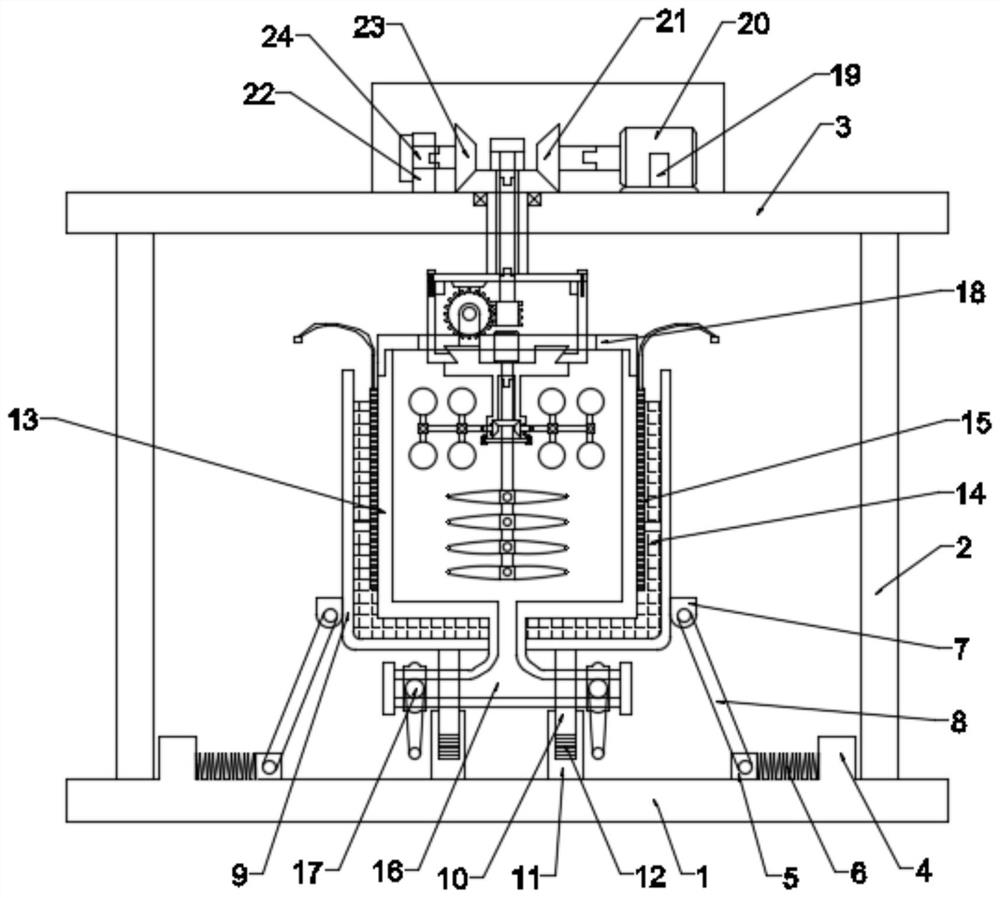

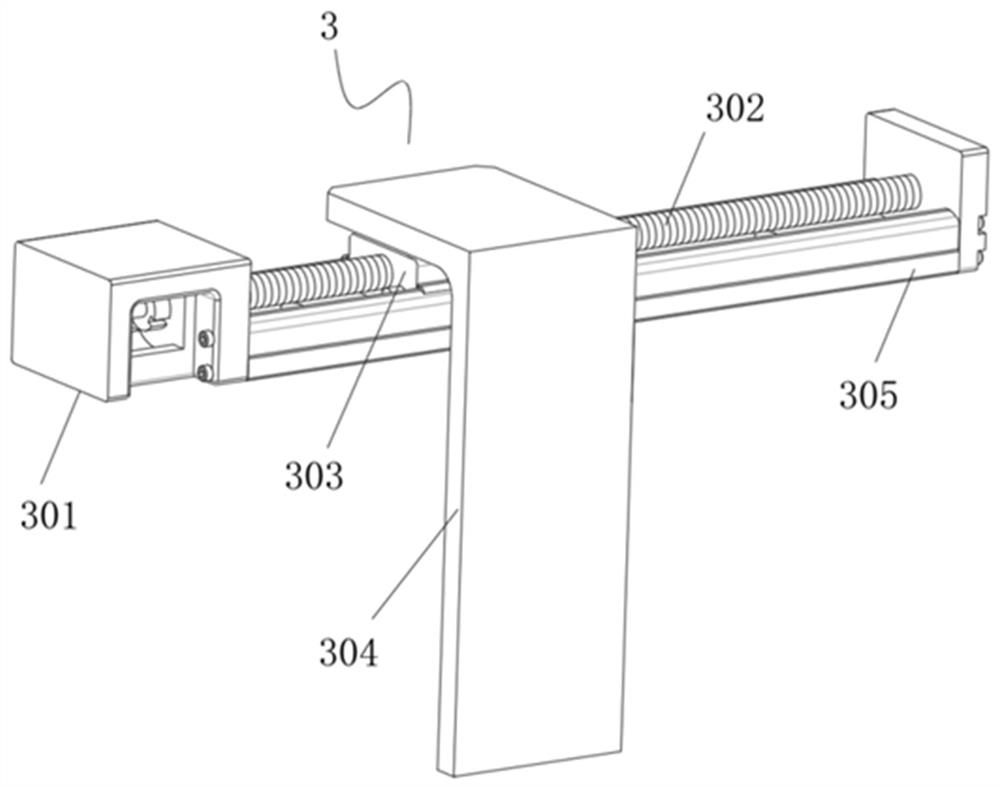

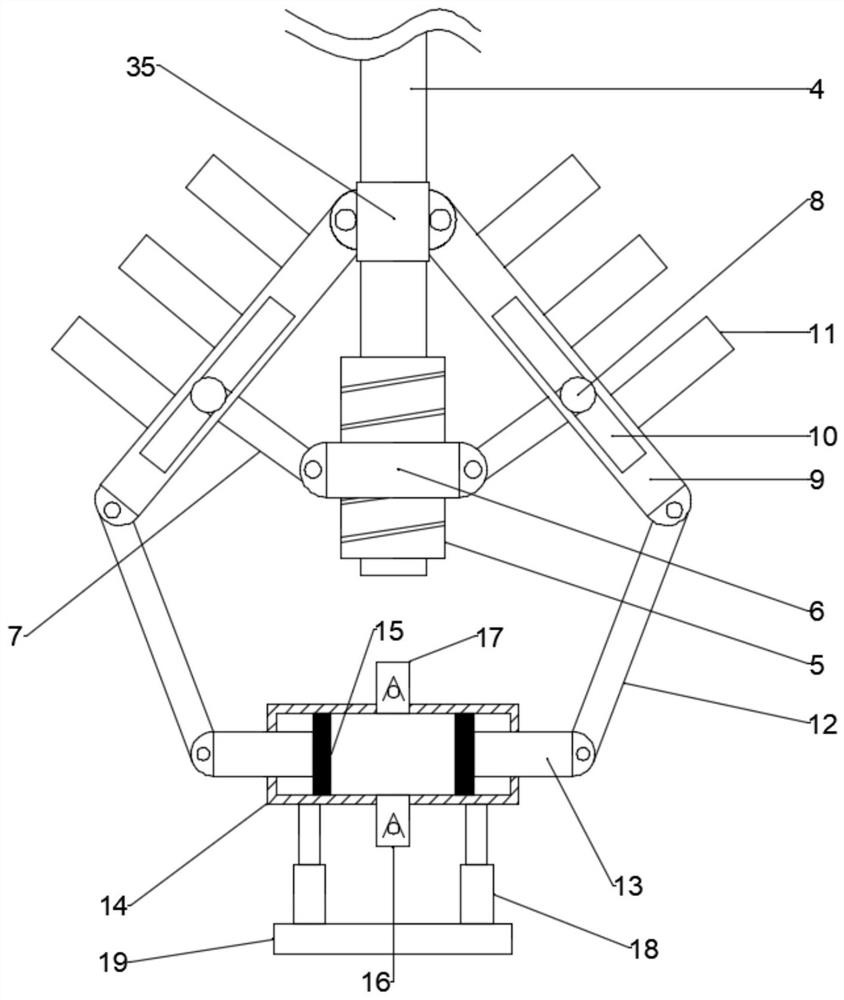

Rapid building mortar stirring device

InactiveCN107379257AVersatileImprove integrityCement mixing apparatusSold ingredients supply apparatusEngineering

The invention discloses a fast mixing device for building mortar, which comprises a supporting installation module, a multiple mixing module and a sand screening feeding module. The support column, the main agitation transmission structure is inlaid inside the support installation plate, and the main agitation transmission structure includes a transmission protection cavity inlaid inside the support installation plate, and multiple agitation modules are arranged on the upper end of the support installation plate, and the multiple agitation The module includes multiple mixing barrels installed on the top of the supporting installation plate. The upper end of the multiple mixing barrels is horizontally equipped with a material guide installation plate. The middle position of the material guide installation plate is provided with a bearing sleeve in conjunction with the main stirring shaft. The invention has a compact and novel mechanism. , perfect function, strong integration, wide stirring range and high stirring efficiency.

Owner:张大伟

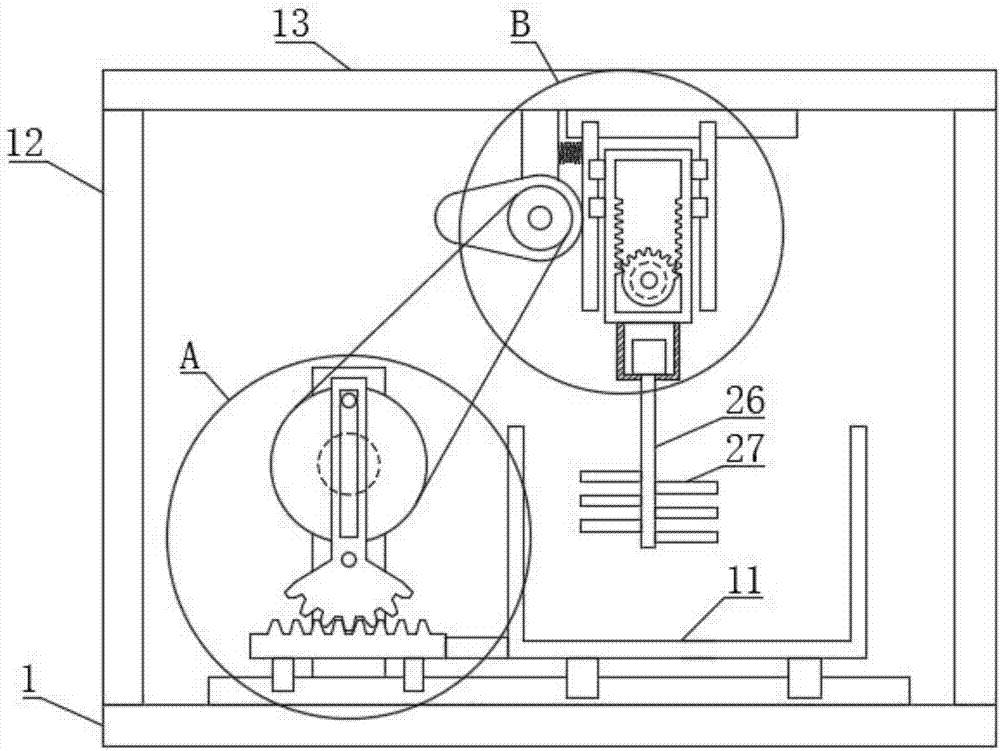

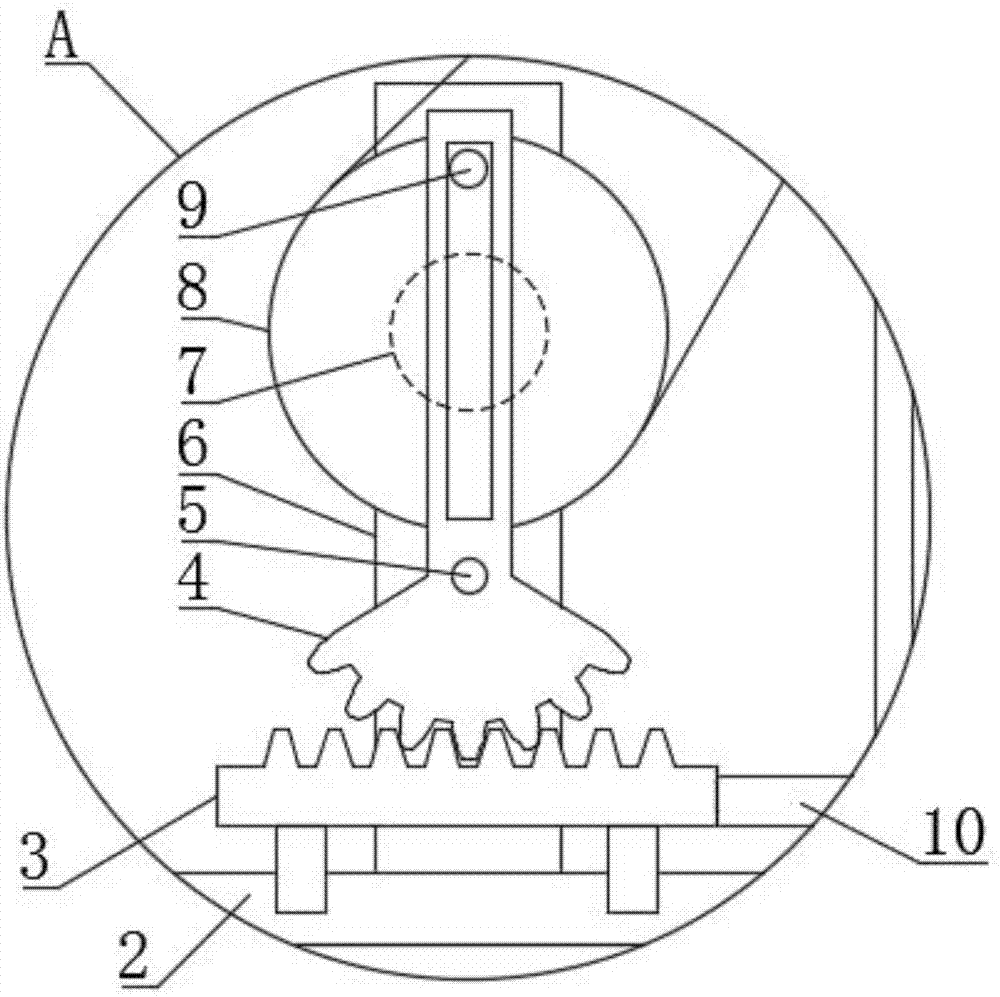

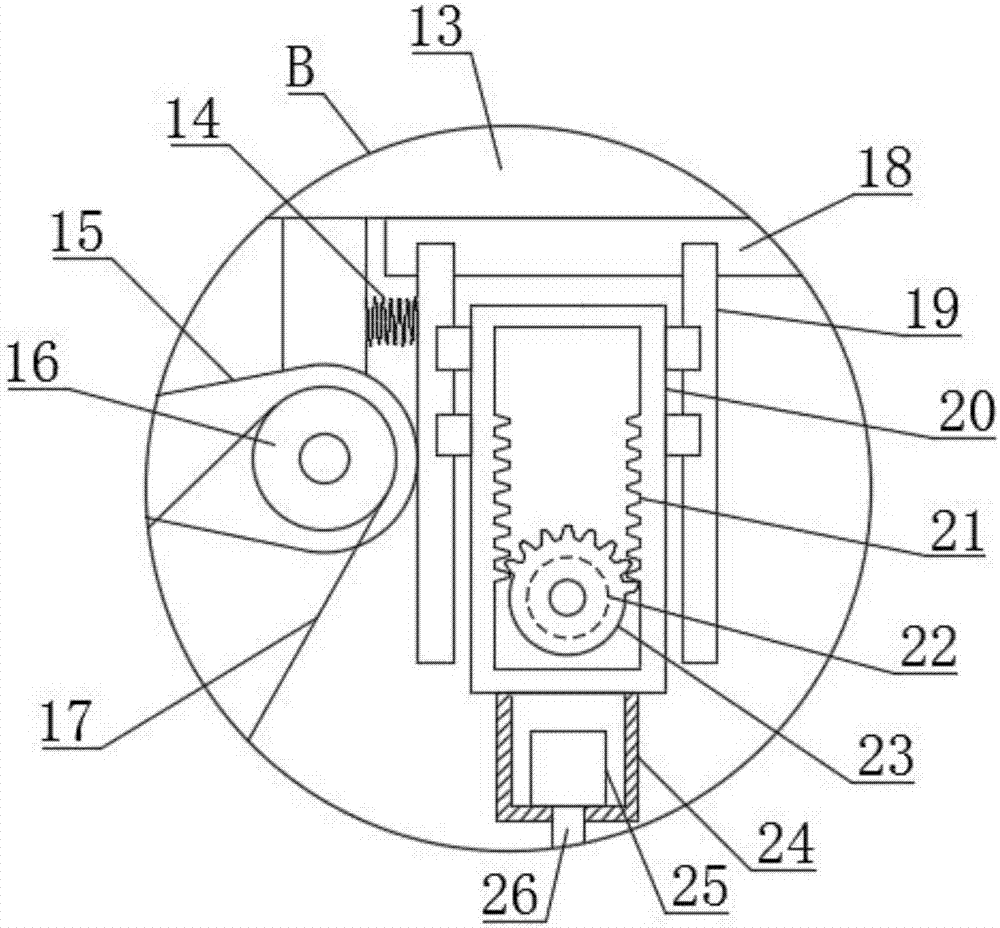

Concrete mortar stirring and mixing device for building construction

InactiveCN107901227AStir completely and evenlyStirring effect is sufficientCement mixing apparatusGear driveReciprocating motion

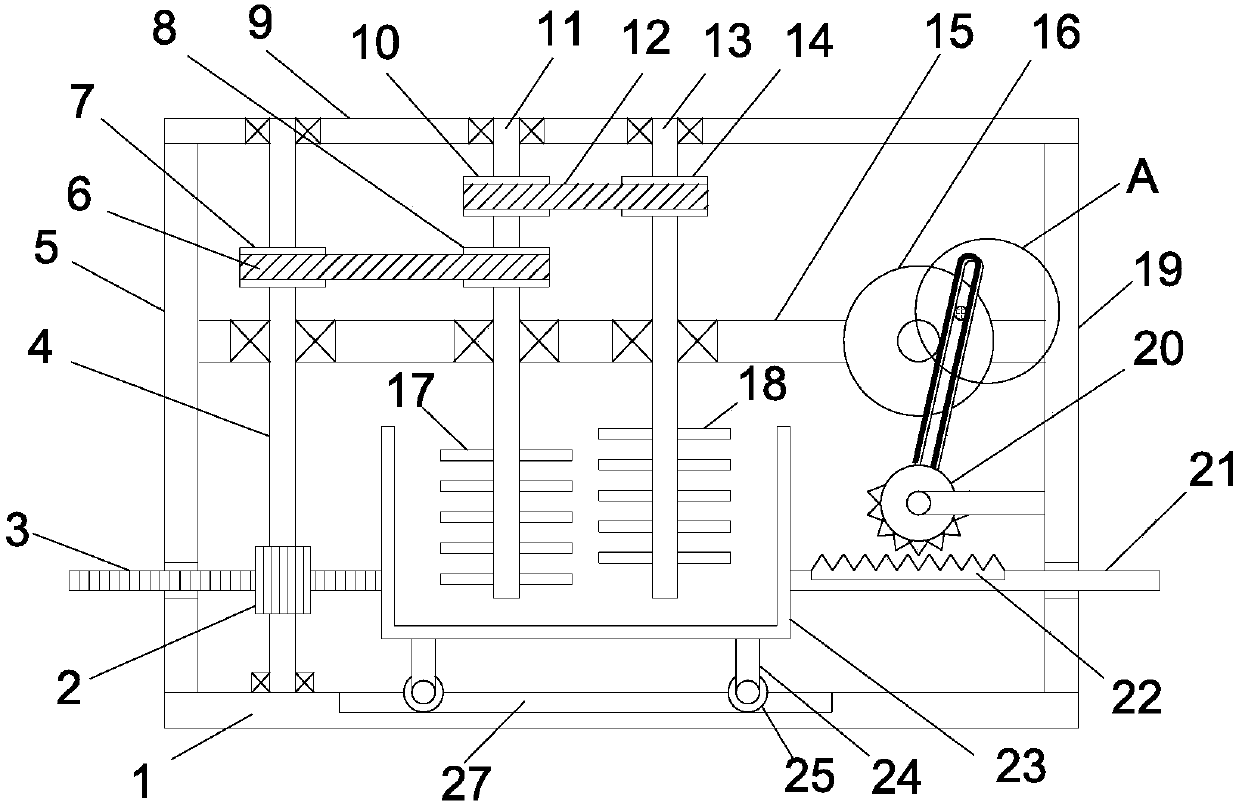

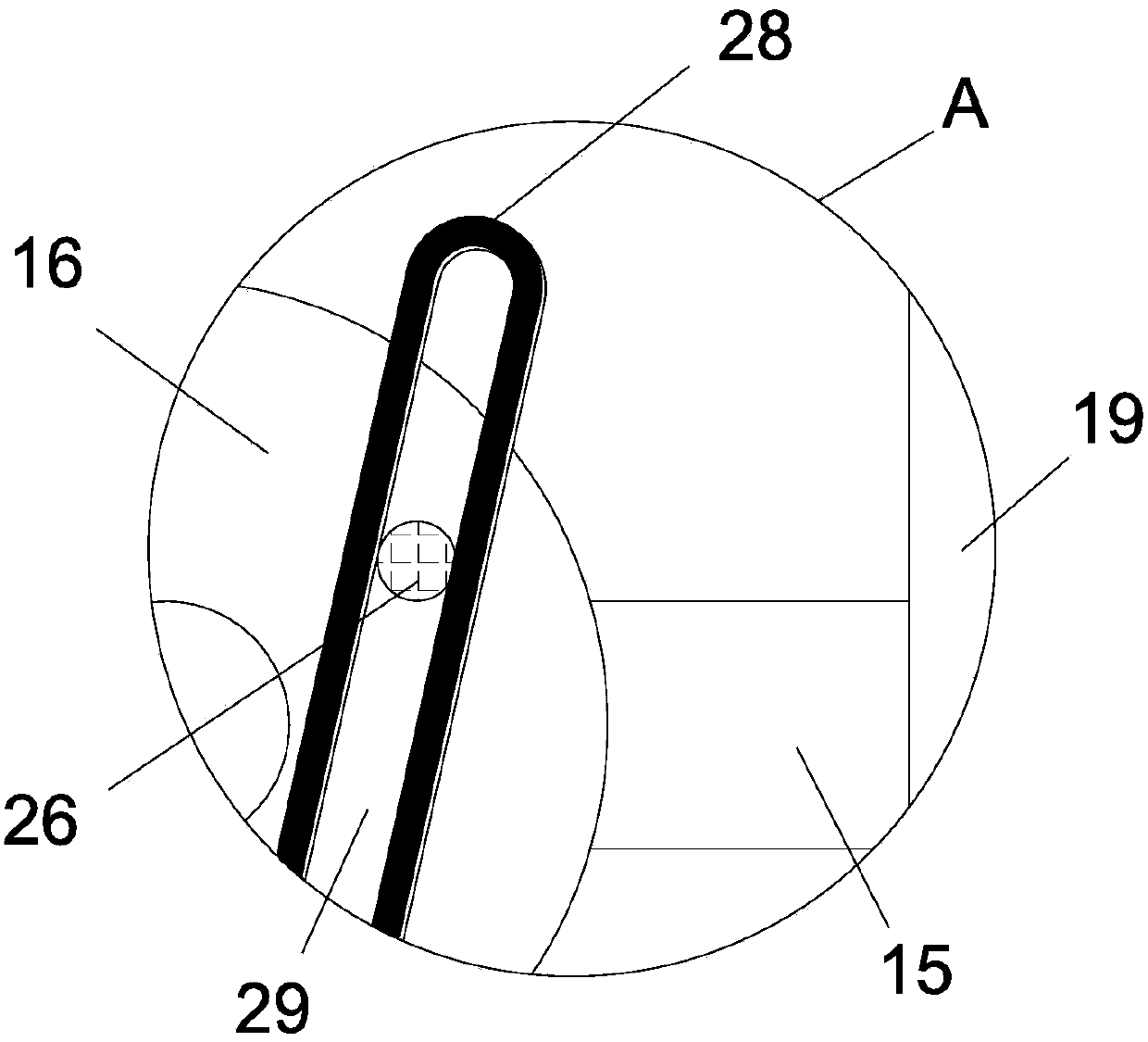

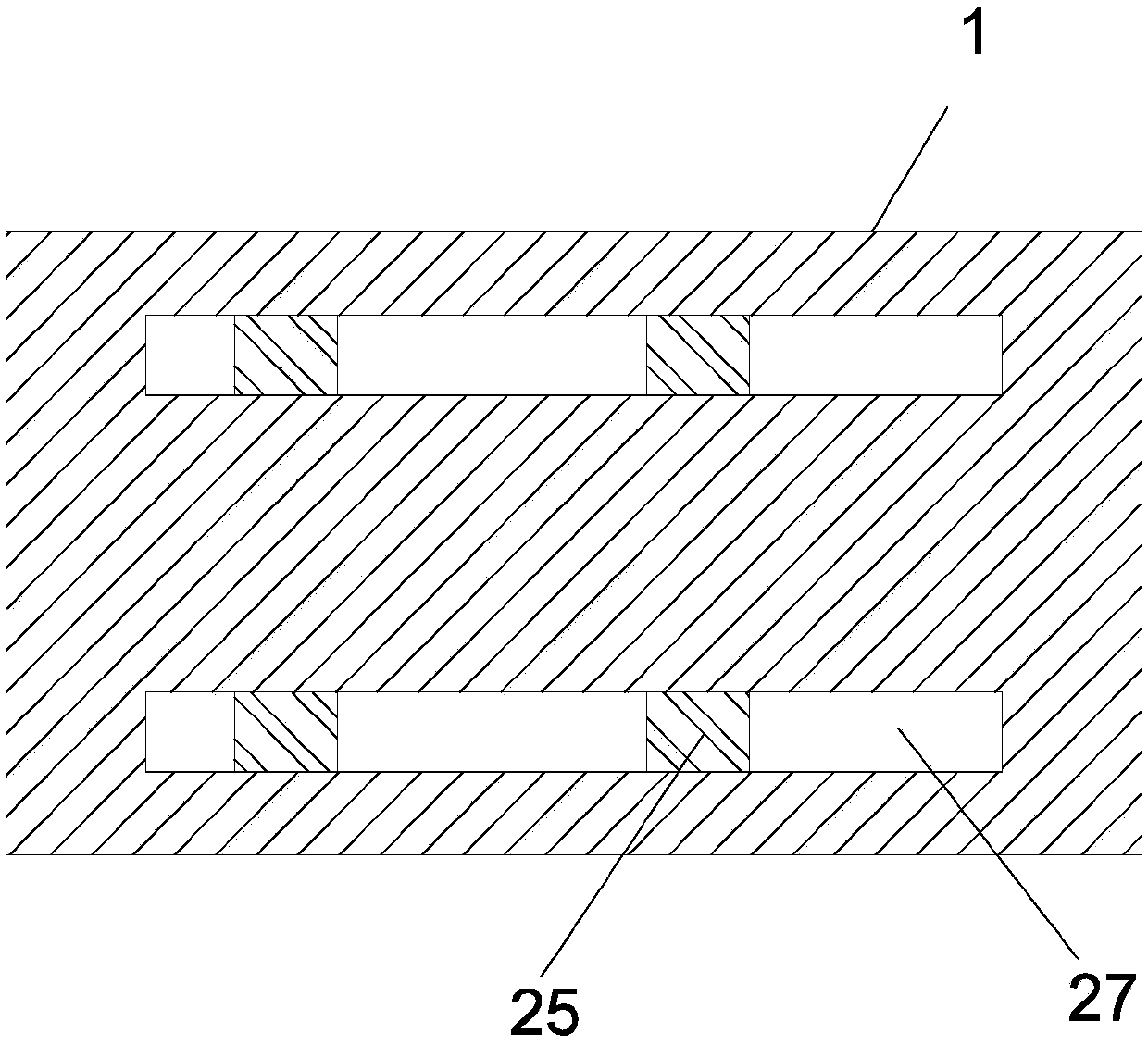

The invention discloses a concrete mortar stirring and mixing device for building construction. The concrete mortar stirring and mixing device comprises a bottom plate. A left vertical plate and a right vertical plate are vertically fixedly mounted on the bottom plate, a limiting pin is eccentrically fixedly mounted on the obverse side of a rotary wheel, and the left side wall of the right vertical plate is rotatably provided with a sector gear through a support. A sliding rod which slidably penetrates through the right vertical plate is fixedly mounted on the right side wall of a mixing groove, and a transmission rotary shaft is fixedly provided with a cylindrical gear in a sleeved mode, wherein the cylindrical gear is engaged with a first rack. According to the concrete mortar stirring and mixing device, rotating of a first stirring shaft and a second stirring shaft drives a first stirring blade and a second stirring blade to rotate, and concrete mortar in the mixing groove is sufficiently stirred accordingly; meanwhile, clockwise and anticlockwise rotation of the sector gear drives the sliding rod to make reciprocating movement in the left-right direction through a second rack engaged with the sector gear, reciprocating movement in the left-right direction of the mixing groove is achieved accordingly, and the concrete mortar at different positions in the mixing groove is stirred, and thus the stirring range is wider.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Electric coating stirring device

InactiveCN109225013AImprove mixing effectStirring speed is fastTransportation and packagingRotary stirring mixersElectric machineryCoating

The invention discloses an electric coating stirring device which comprises a stirring barrel main body; a barrel cover is arranged on the upper end of the stirring barrel main body; a first motor isarranged on the barrel cover; a rotating shaft is connected with an output end of the first motor; a fixed plate is connected with the lower end of the rotating shaft; a first stirring shaft is arranged at the center of the bottom of the fixed plate; a stirring blade is arranged on the first stirring shaft; second stirring shafts are arranged on the two sides of the first stirring shaft; second motors are arranged on the two ends of the surface of the fixed plate; stirring rods are arranged on the two sides of the second stirring shafts; brush plates are arranged on the stirring rods; electricheating plates are arranged in the two sides of an inner wall of the stirring barrel main body; air exhaust pipes are arranged on the two ends of the bottom in the stirring barrel main body; air blowers are arranged on the two sides on the exterior of the stirring barrel main body. In the electric coating stirring device, the first stirring shaft and the second stirring shafts are matched with each other, so that the stirring scope is expanded, the stirring is uniform and thorough, the time of stirring is reduced and the stirring efficiency is effectively increased.

Owner:合肥瀚鹏新能源有限公司

Mixing and high-efficient cooling device for chemical raw materials

InactiveCN106925171AWell mixedReduce the temperatureShaking/oscillating/vibrating mixersDomestic cooling apparatusFan bladeMaterials science

The invention relates to a cooling device, in particular relates to a mixing and high-efficient cooling device for chemical raw materials. The technical problem to be solved is to provide the mixing and high-efficient cooling device for the chemical raw materials which can mix the chemical raw materials more evenly and simultaneously can reduce the temperature of the raw materials during mixing. In order to solve the technical problem, the mixing and high-efficient cooling device for the chemical raw materials is provided. The device comprises a base, a sliding rail, sliding blocks, a support, a processing tank, a gear, a stirring blade, a rack, a fan blade, a flat belt, a second belt pulley, a second rotating shaft, a bearing block and the like, wherein the top of the base is connected with the sliding rail in a bolt connection way; the sliding rail is connected with the sliding blocks in a sliding manner; the sliding rail cooperates with the sliding blocks; the top part of each sliding block is welded with the processing tank. According to the device disclosed by the invention, the effects that the chemical raw materials can be mixed more evenly and the temperature of the raw materials during mixing can be simultaneously reduced can be achieved, and the processing tank moves continuously leftwards and rightwards while the stirring blade continuously rotates positively and negatively.

Owner:刘燕

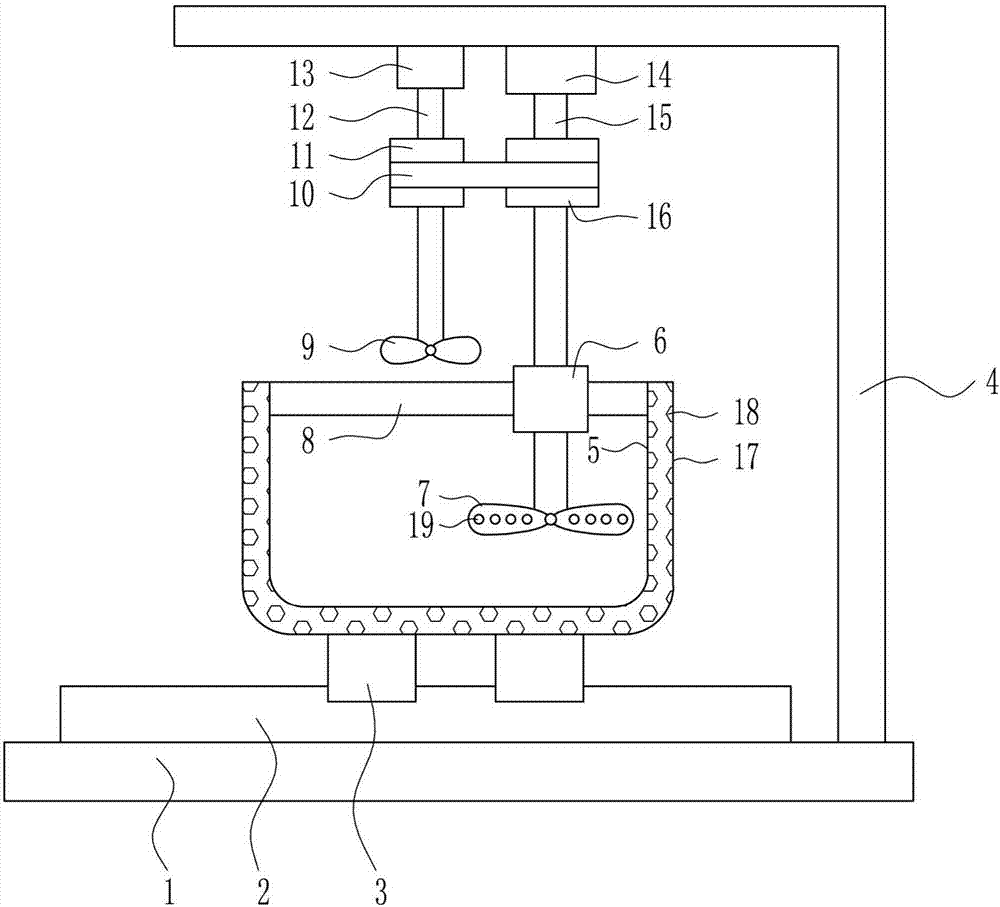

Combustion system applied in direct injection diesel

InactiveCN101446225AFacilitated DiffusionLarge mixing rangeInternal combustion piston enginesCombustion systemCombustion chamber

The invention discloses a combustion system applied in a direct injection diesel, comprising a W-shaped combustion chamber and an oil atomizer that is used for injecting high-pressure fuel oil into the combustion chamber. A plurality of arc concave pits which have the same number with oil beams of the oil atomizer and correspond to the injecting direction thereof are uniformly arranged on the inner wall of the W-shaped combustion chamber along the peripheral direction, the lower edge of every arc concave pit is connected with the inner wall of the combustion chamber in a first change structure way by the transition of small round corners, and the two side edges of every arc concave pit are connected with the intersection of the inner wall surfaces of the combustion chamber in a second change structure by the transition of the small round corners. By adopting the structure of the invention, separation between the fuel oil and the wall surface of the combustion chamber is realized in two directions, therefore, the fuel oil precipitated on the wall surface of the combustion chamber is greatly reduced, meanwhile, two spraying jets expand the range for the fuel oil to be mixed in the combustion chamber and the air is more fully utilized, thus being beneficial to reducing harmful emission.

Owner:TIANJIN UNIV

Chemical paint stirring device with heating function

InactiveCN112023752AStir wellLarge mixing rangeShaking/oscillating/vibrating mixersRotary stirring mixersCouplingElectric machinery

The invention belongs to the technical field of paint stirring, and particularly relates to a chemical paint stirring device with a heating function. The invention aims to solve the problems that an existing stirrer consumes considerable time and labor, the stirrer cannot be guaranteed to perform stable stirring when held by hand all the time, and if the stirrer touches the inner wall of a paint bucket, paint may splashes everywhere, or even the paint bucket is likely to be broken and harm is posed to human beings. According to a scheme provided by the invention, the chemical paint stirring device comprises a stirring bucket, wherein a first threaded groove is formed in the outer wall of the top of the stirring bucket, and a box cover is connected to the inner wall of the first threaded groove through threads; and a motor is fixed to the outer wall of the top of the box cover through bolts, and an output shaft of the motor is connected with a rotating rod through a coupling. Accordingto the chemical paint stirring device, a mixing plate is inclinedly arranged on the rotating rod to form an upward angle of 30 to 50 degrees; and by means of the arrangement, paint at the bottom of aninner bucket can be stirred upwards while the mixing plate rotates, and therefore, all the paint in the inner barrel can be fully stirred.

Owner:张行江

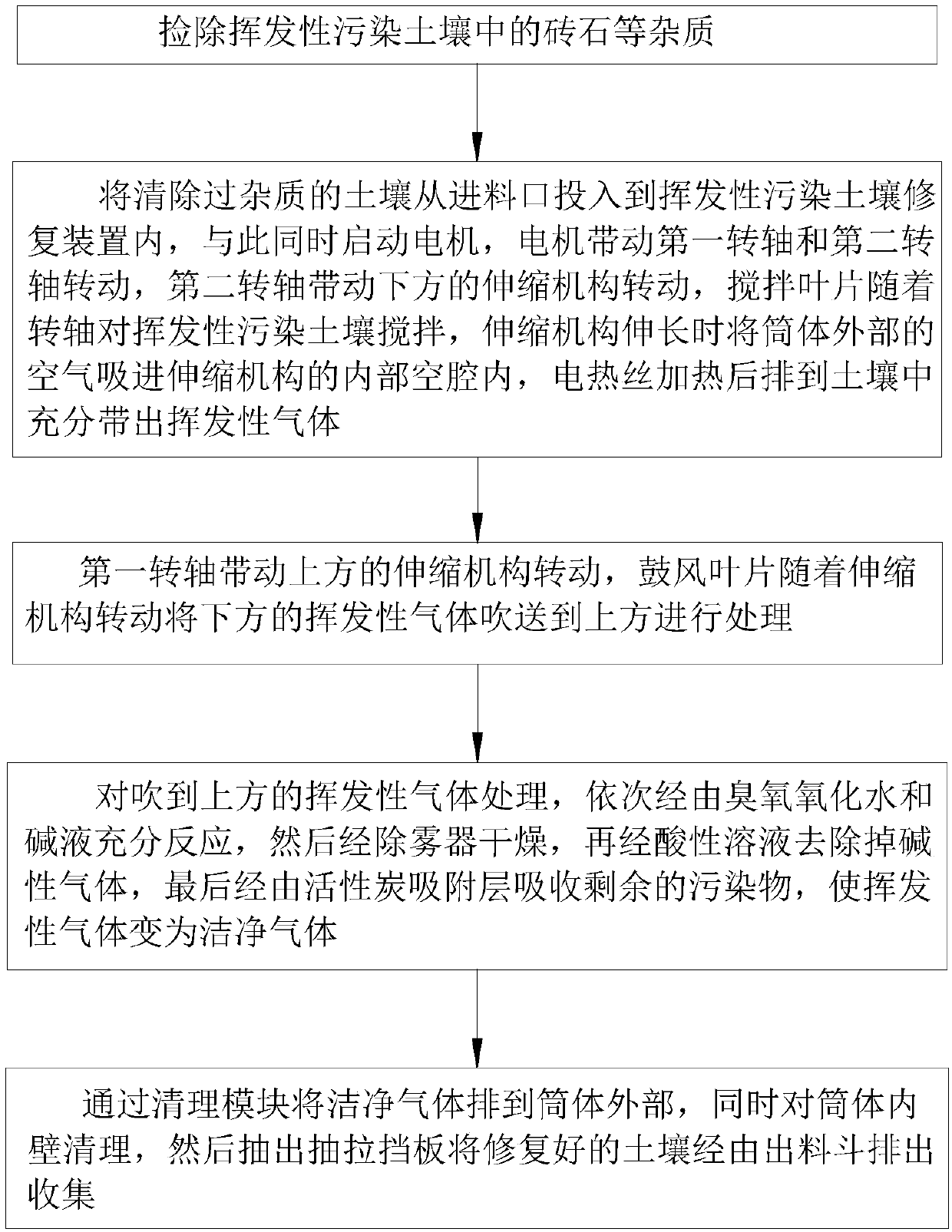

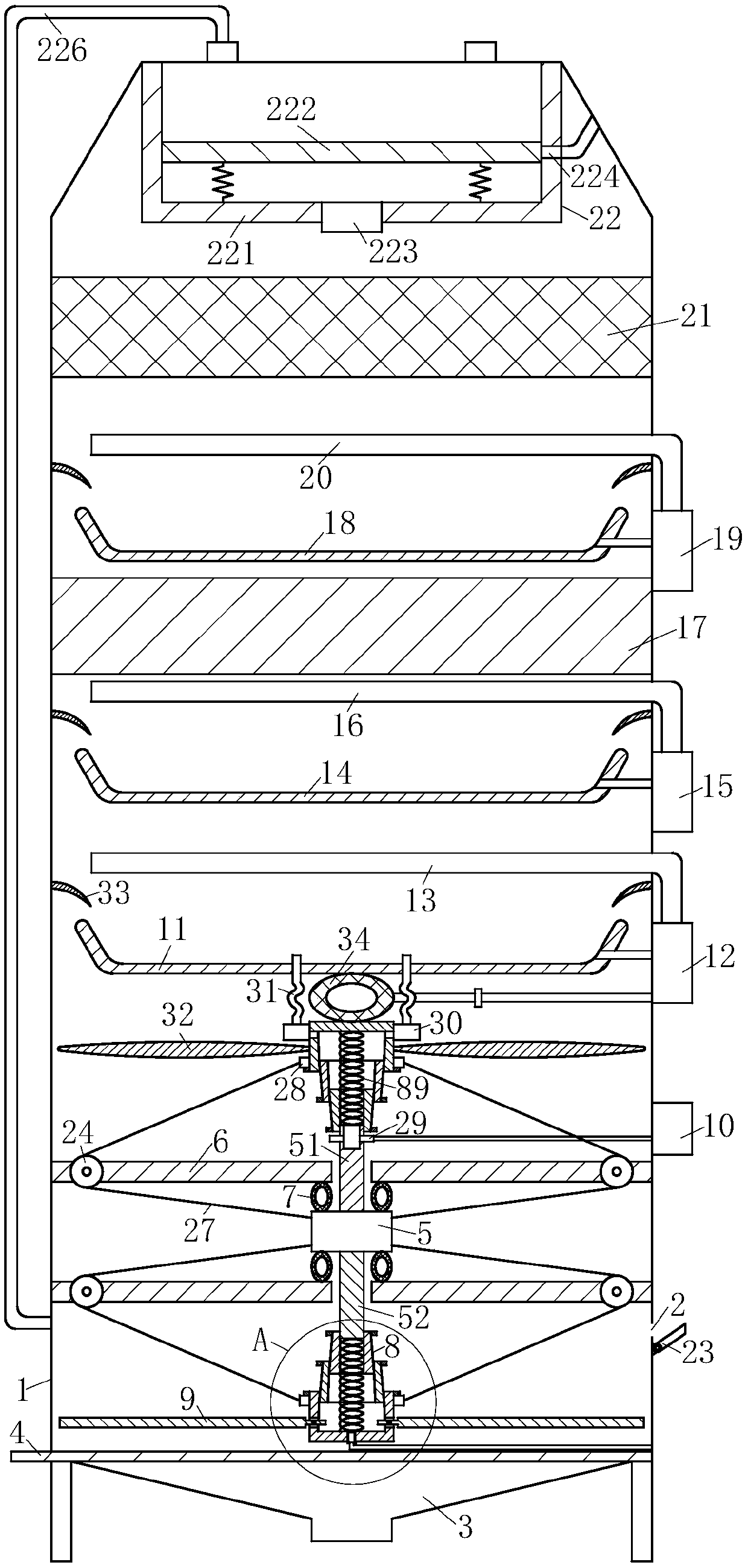

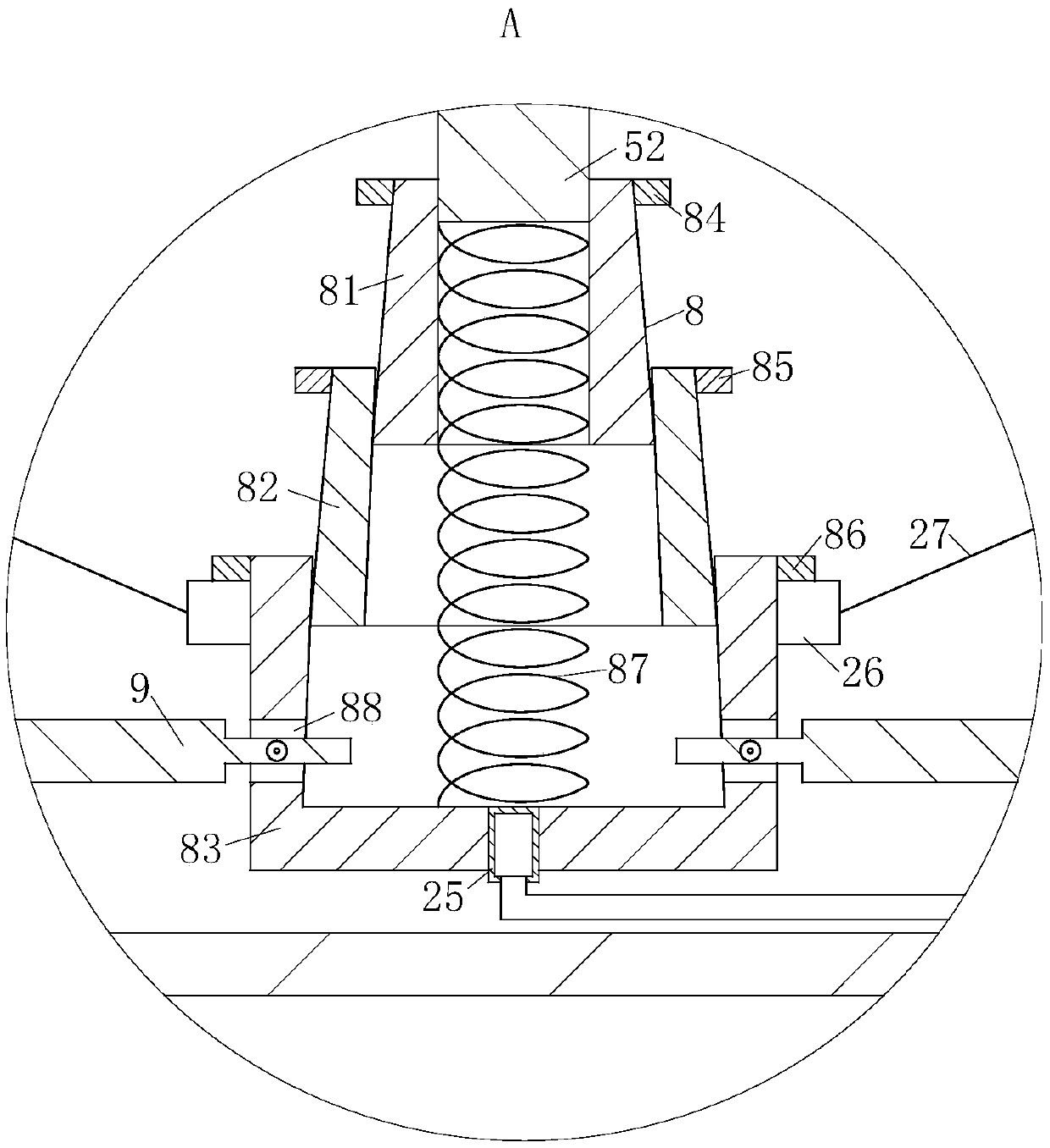

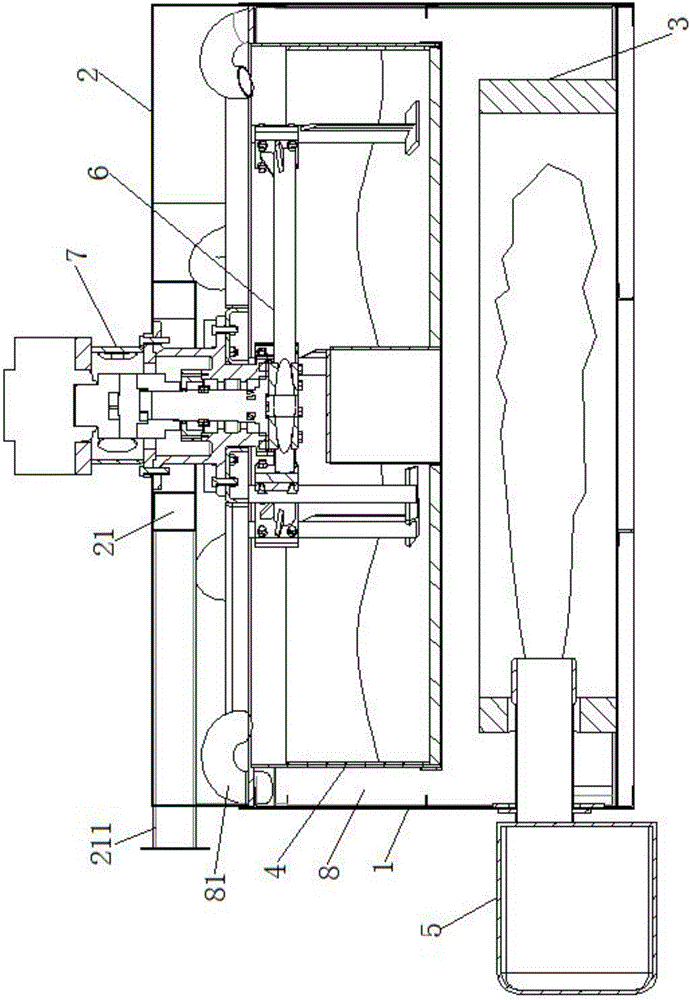

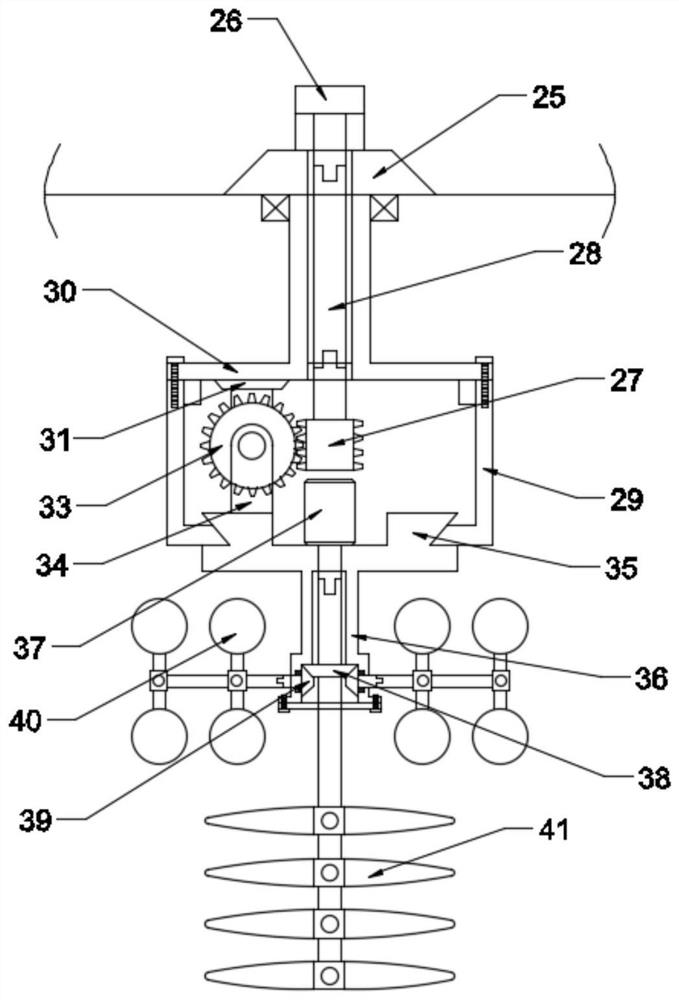

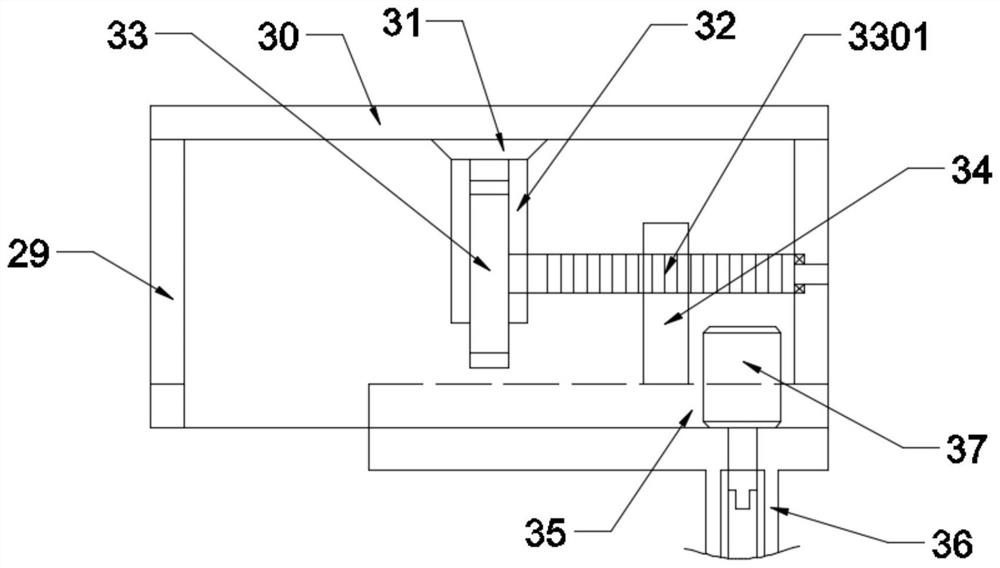

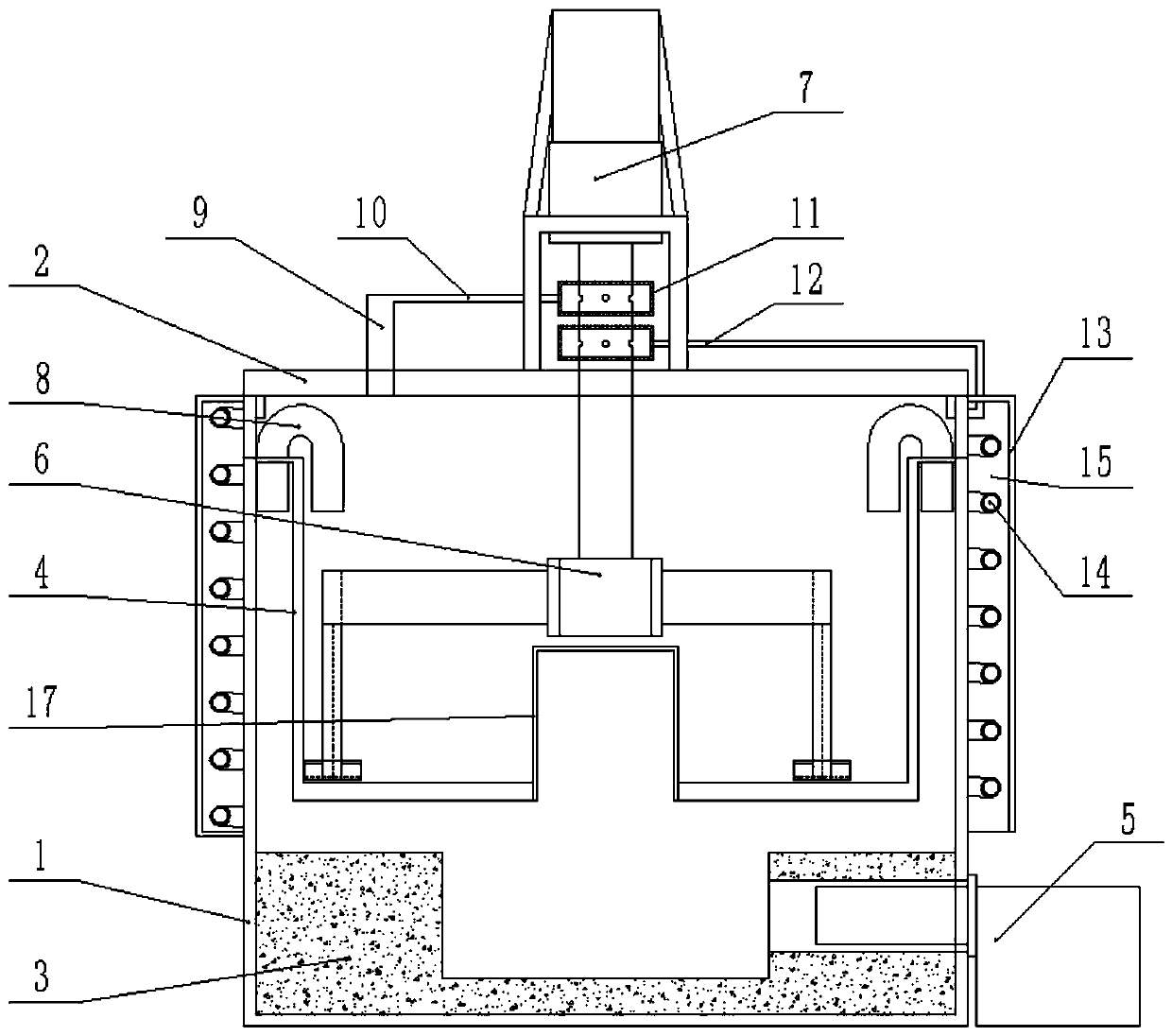

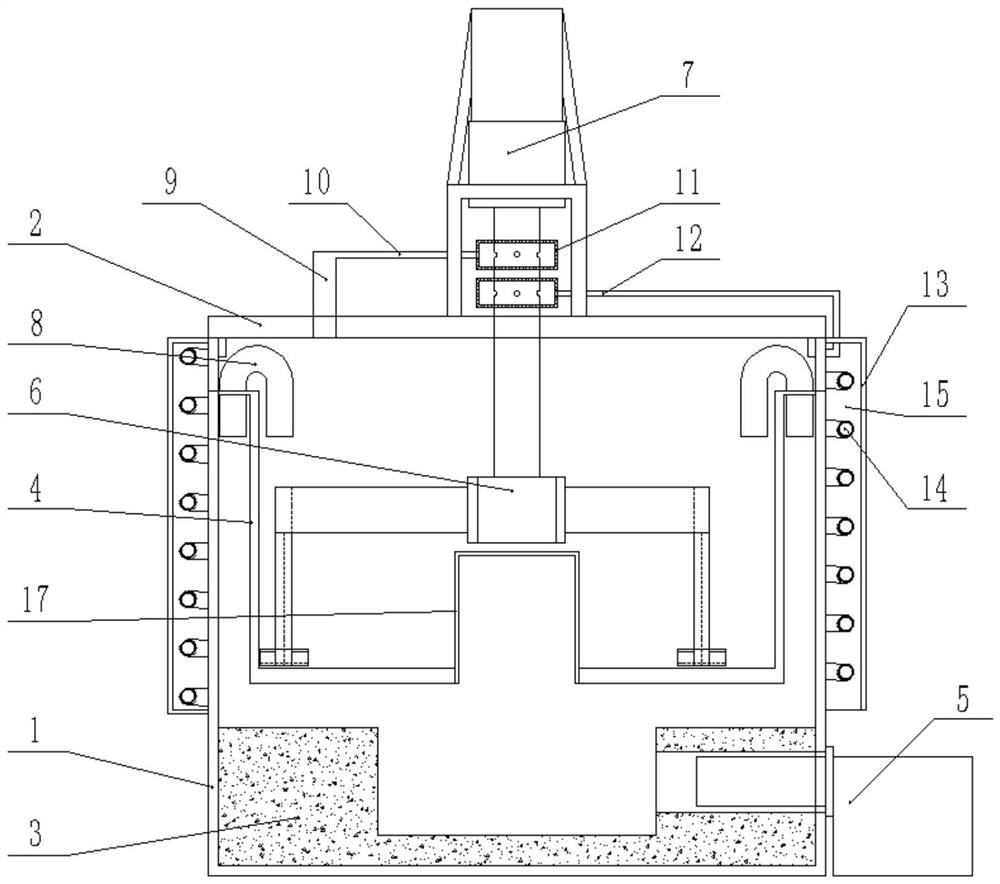

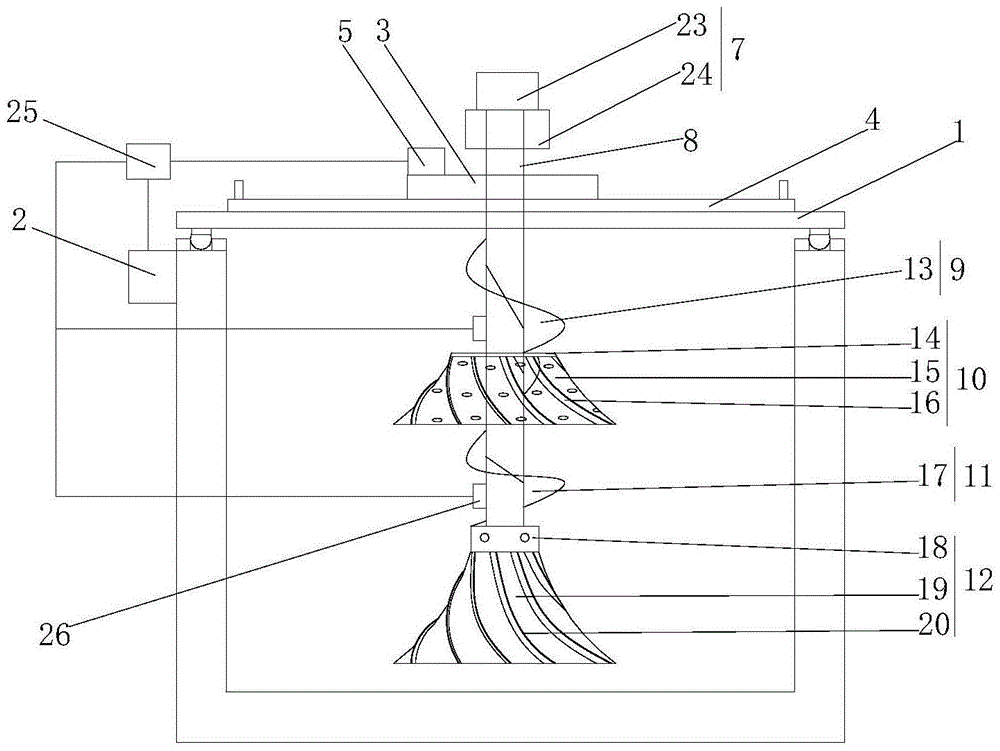

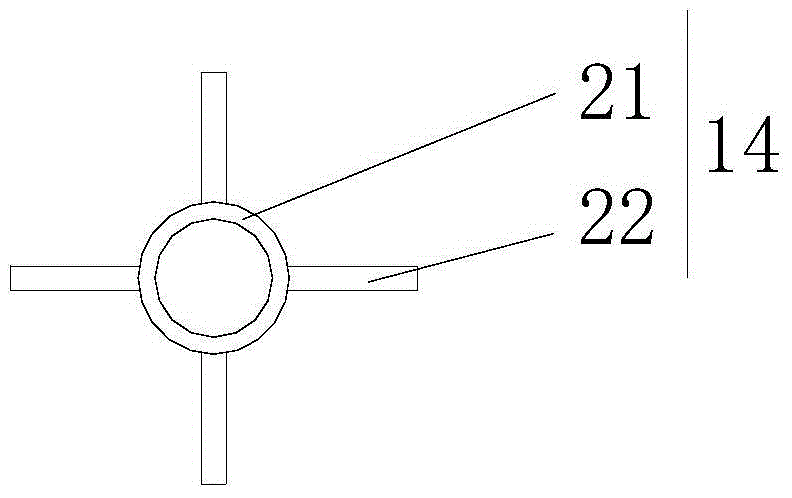

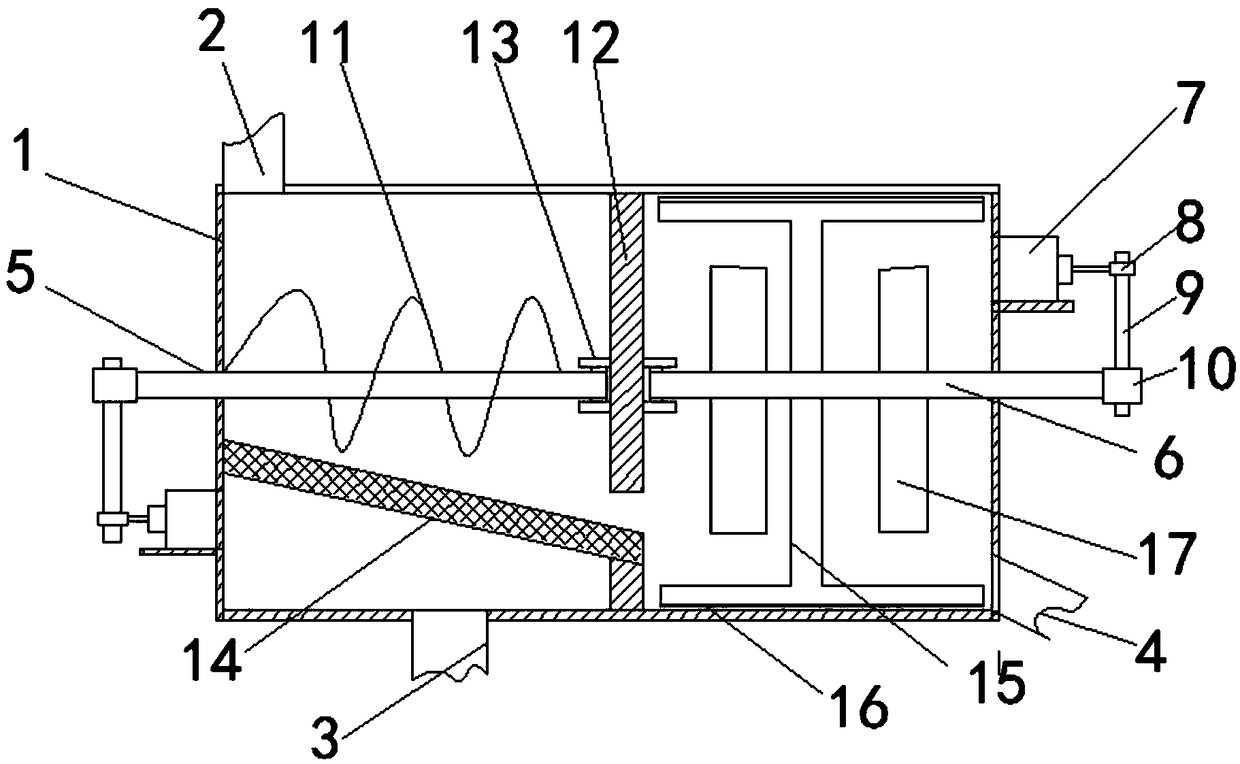

Volatile polluted soil repairing method

PendingCN109663807ASave energyRealize circulating air supplyDispersed particle separationContaminated soil reclamationBrickEngineering

The invention relates to the technical field of polluted soil restoration and treatment, particularly to a volatile polluted soil repairing method. The volatile polluted soil repairing method comprises the following steps of picking off impurities in volatile polluted soil such as bricks and stone; feeding the impurity-cleaned soil into a volatile polluted soil repairing device via a feeding port,and meanwhile, starting a motor to drive a first rotating shaft and a second rotating shaft to rotate so that the second rotating shaft drives an extending mechanism beneath to rotate, mixing bladescan mix the volatile polluted soil along with the rotating shafts, the extending mechanism extends to absorb air outside a barrel into the inner cavity of the extending mechanism, and then the air isheated by heating wires and discharged into the soil to take out volatile gas. By preprocessing the polluted soil, the volatile polluted soil repairing method can ensure protection over parts inside the volatile polluted soil repairing device; the volatile polluted soil repairing device is simple in structure, convenient to operate, low in manufacturing cost and high in soil repairing efficiency.

Owner:陈泽欣

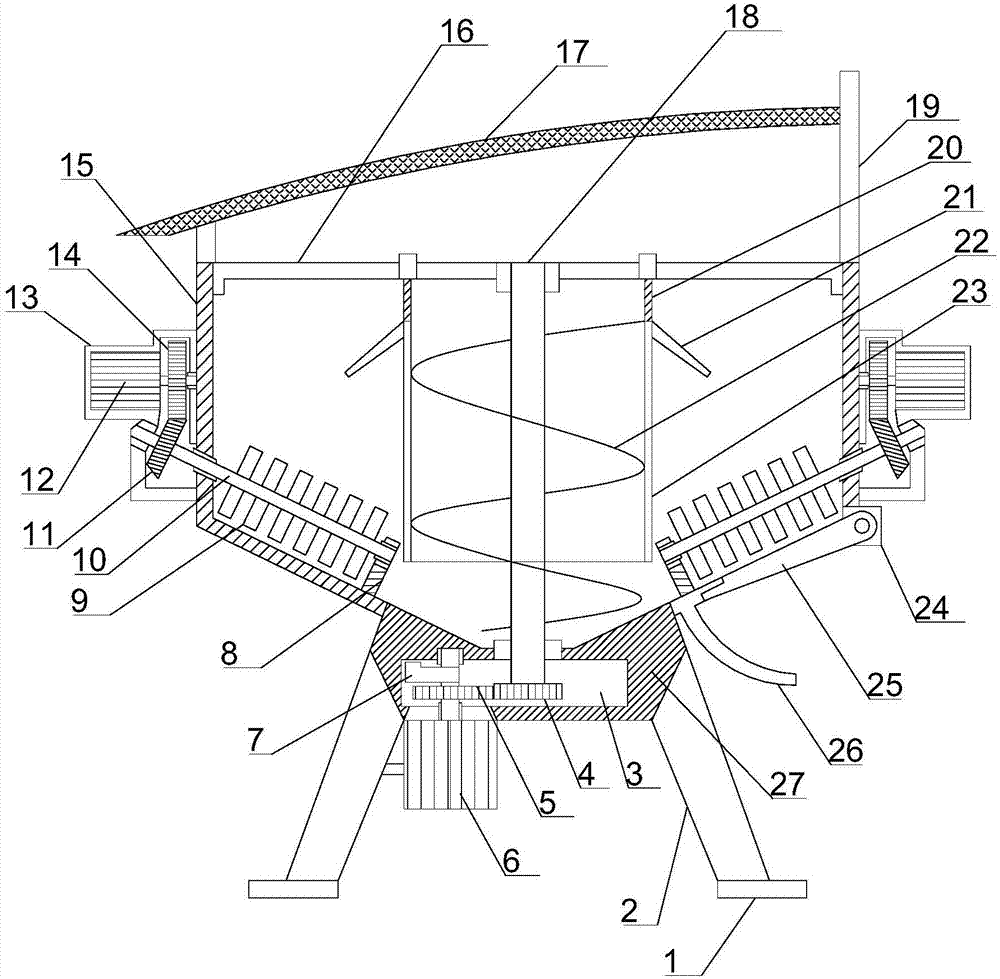

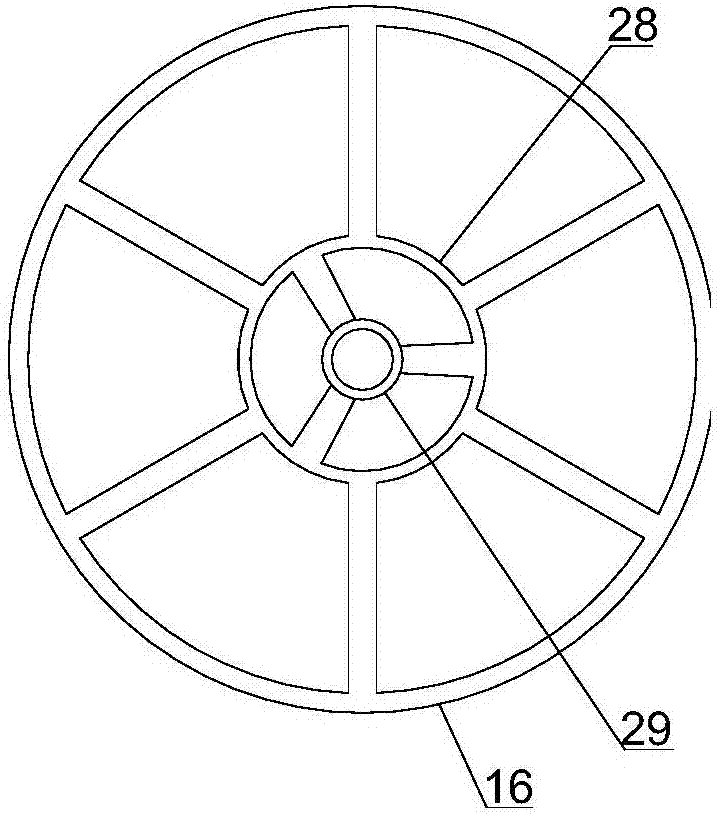

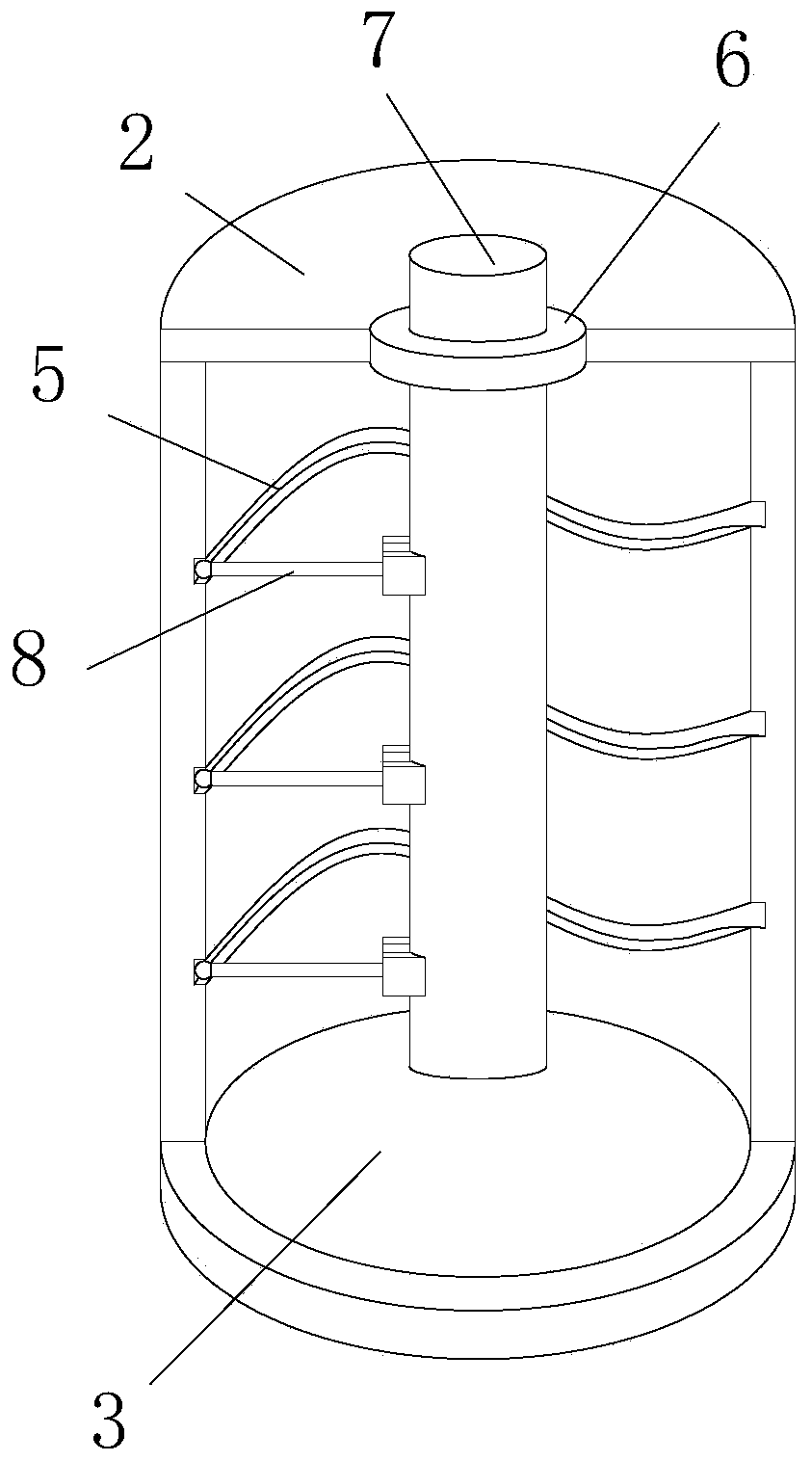

Vertical type mixing and heating device capable of mixing stirred materials

The invention relates to a vertical type mixing and heating device capable of mixing stirred materials. The vertical type mixing and heating device comprises a tank body, an upper cover, a hearth, a stirring reactor, a burner, a stirring cutting assembly and a power driving device. The upper end of the tank body is open, and the upper cover is detachably installed at the open end of the tank body. The hearth is installed on the inner bottom wall of the tank body. The stirring reactor is fixed to the inner wall of the tank body through a support and located above the hearth. The burner is installed outside the tank body, and a sprayer portion of the burner sequentially penetrates through the tank wall of the tank body and the lateral wall of the hearth and extends into the hearth. The stirring cutting assembly is arranged inside the stirring reactor. The power driving device is fixed to the upper cover and located above the stirring cutting assembly. The driving end of the power driving device extends downwards into the stirring reactor to be connected with the stirring cutting assembly. The vertical type mixing and heating device has the advantages that the structure is simple, usage is convenient, the stirred materials are evenly heated in the stirring process, the heat utilization rate of the burner is high, the crushing effect on the stirred materials is good, the uniformity and heating uniformity of the stirred materials are improved, and the stirring effect is excellent.

Owner:DONGYUE SPECIAL PURPOSE AUTOMOBILE SHANDONG MFG

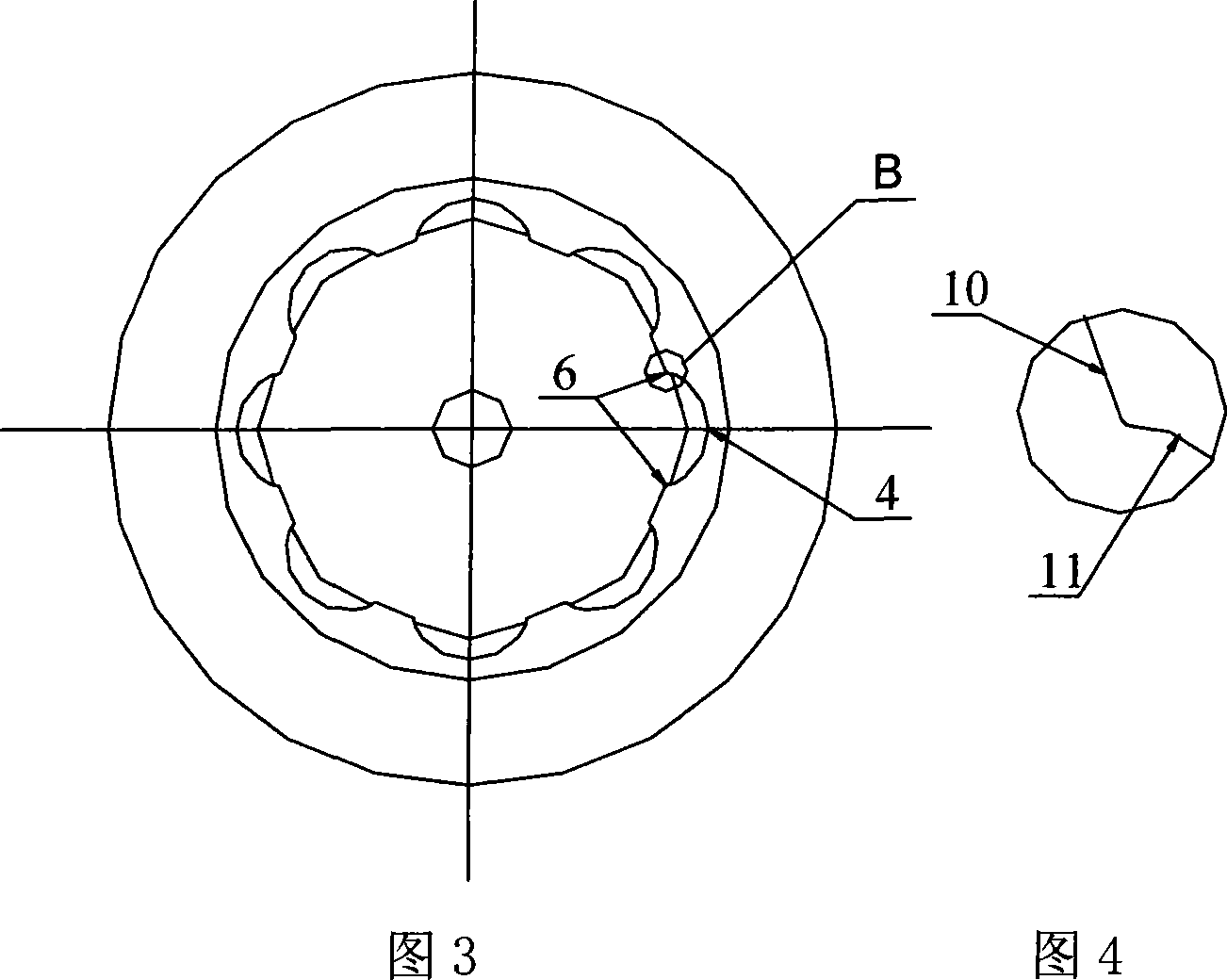

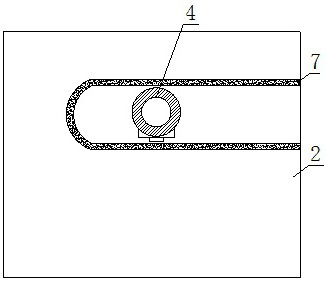

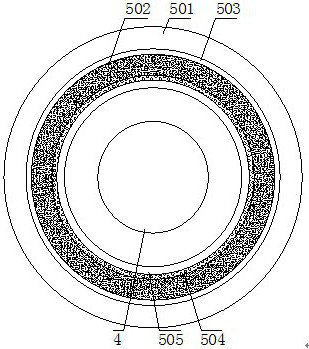

Continuous stirring device for cloth dyeing liquid

PendingCN109056252ALarge mixing rangeIncrease stirring speedTextile treatment machine arrangementsDyeingEngineering

The invention discloses a continuous stirring device for cloth dyeing liquid. The device comprises a stirring barrel with an opening in the upper portion, the portion, close to the opening, of the stirring barrel is provided with a circle of bosses, a circle of an inner ring of each boss is provided with an inner gear ring, a rolling ball is limed at the upper portion of each boss, a rotating plugis installed above the bosses, rotating shafts are arranged on the lower surface of the rotating plug and provided with gears meshed with the inner gear rings, and the lower end of each rotating shaft is provided with a stirring piece. Compared with the prior art, the continuous stirring device for the cloth dyeing liquid has the advantages that through the overall rotation of the rotating plug and the self-rotation of the stirring pieces, the double-stirring function is achieved to irregularly stir the dyeing liquid in the stirring barrel, the stirring range is wide, the stirring speed is high, the mechanization degree is high, the better effect of mixing the cloth dyeing liquid with various auxiliary material proportions is achieved, and the color and luster quality of the dyeing liquidis better.

Owner:YI HE STOCK

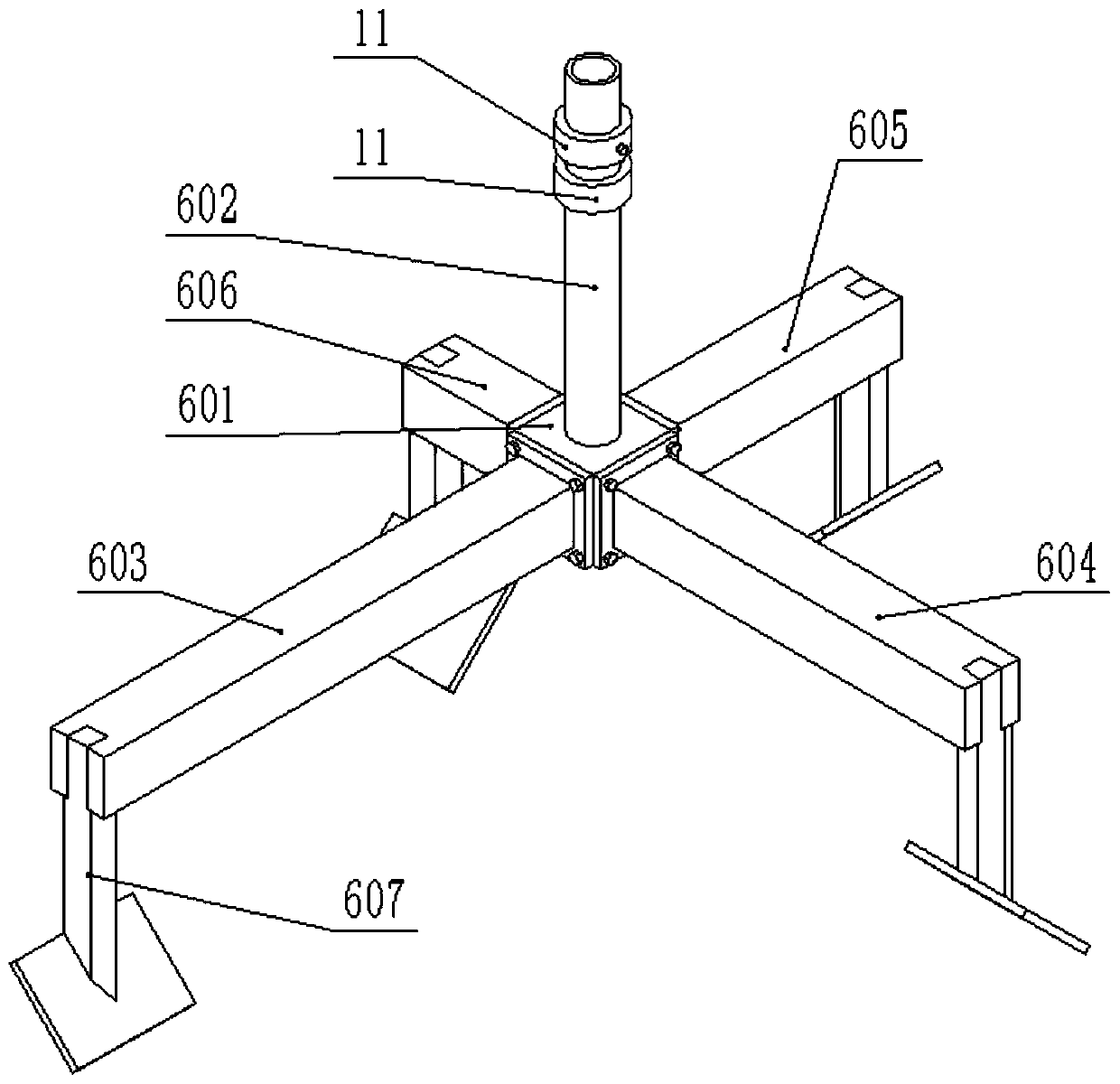

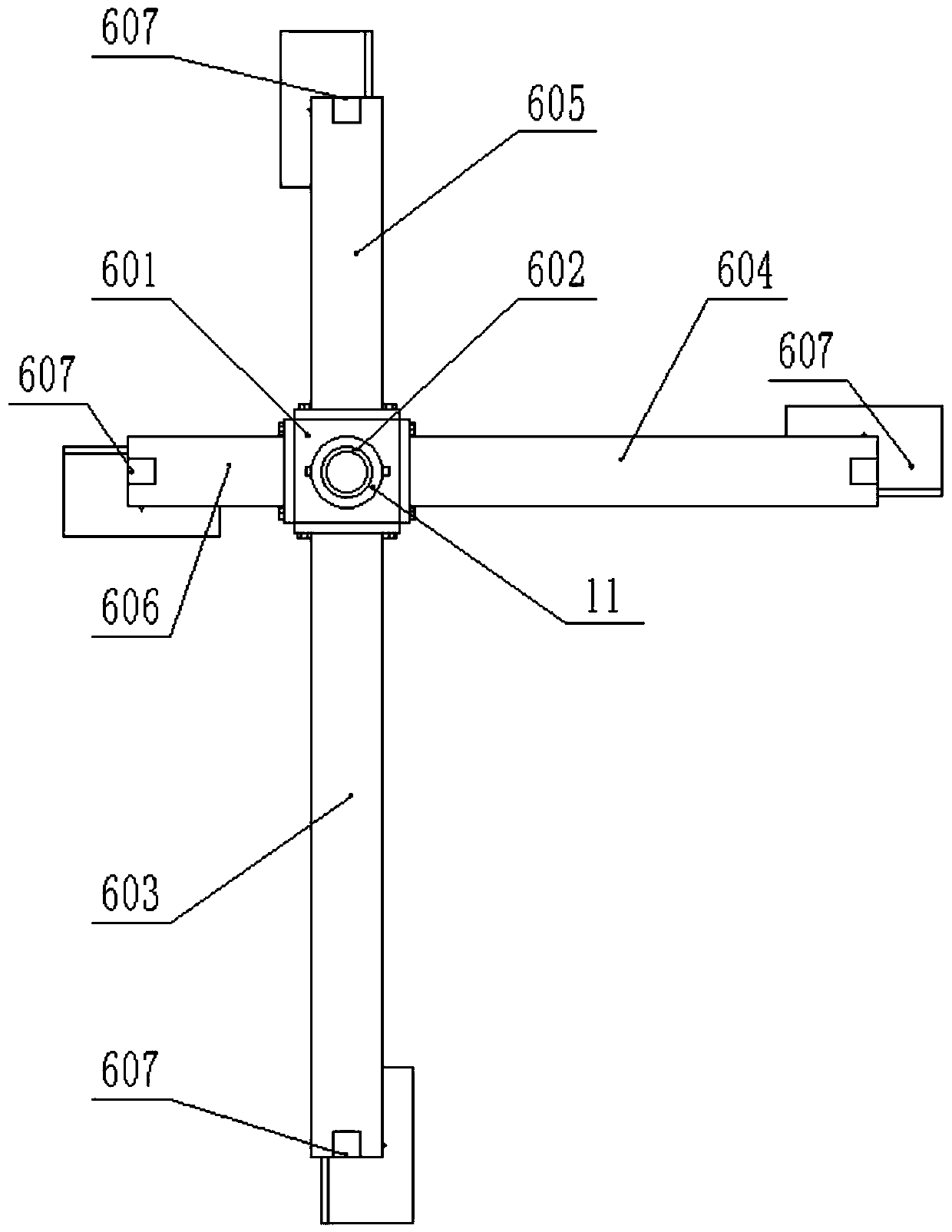

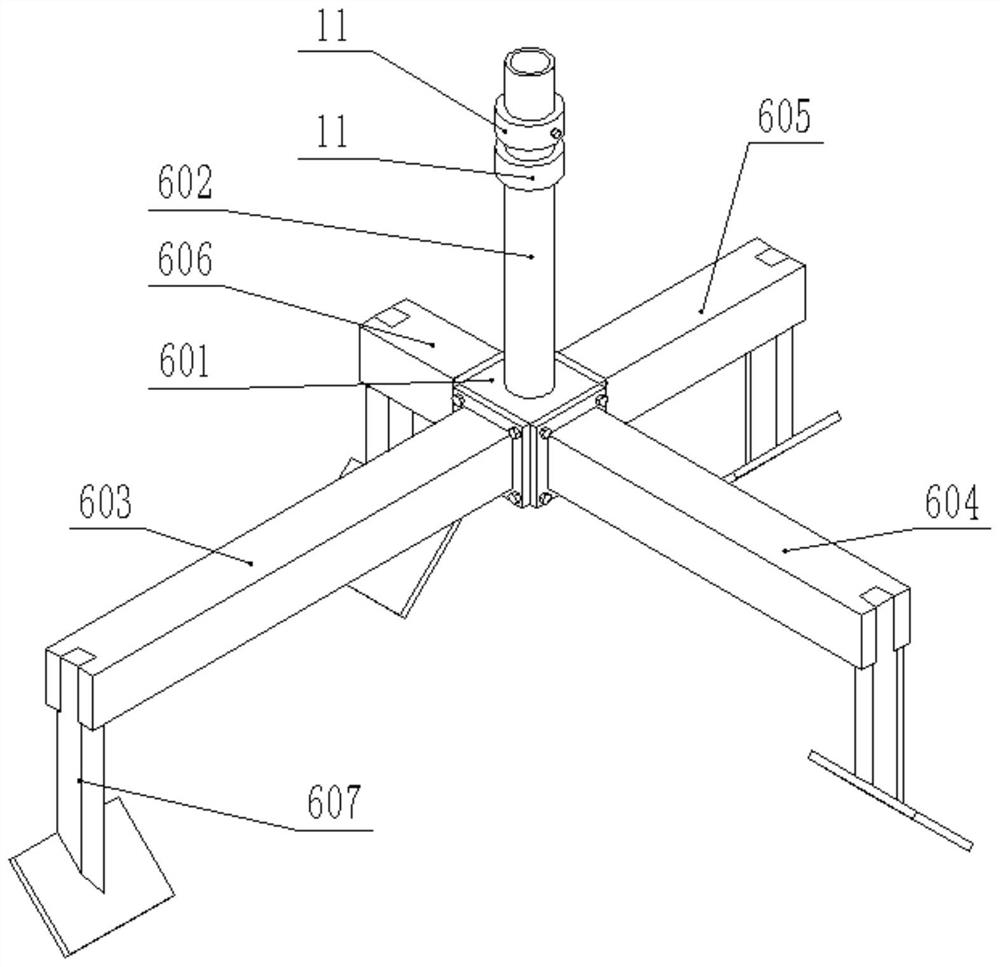

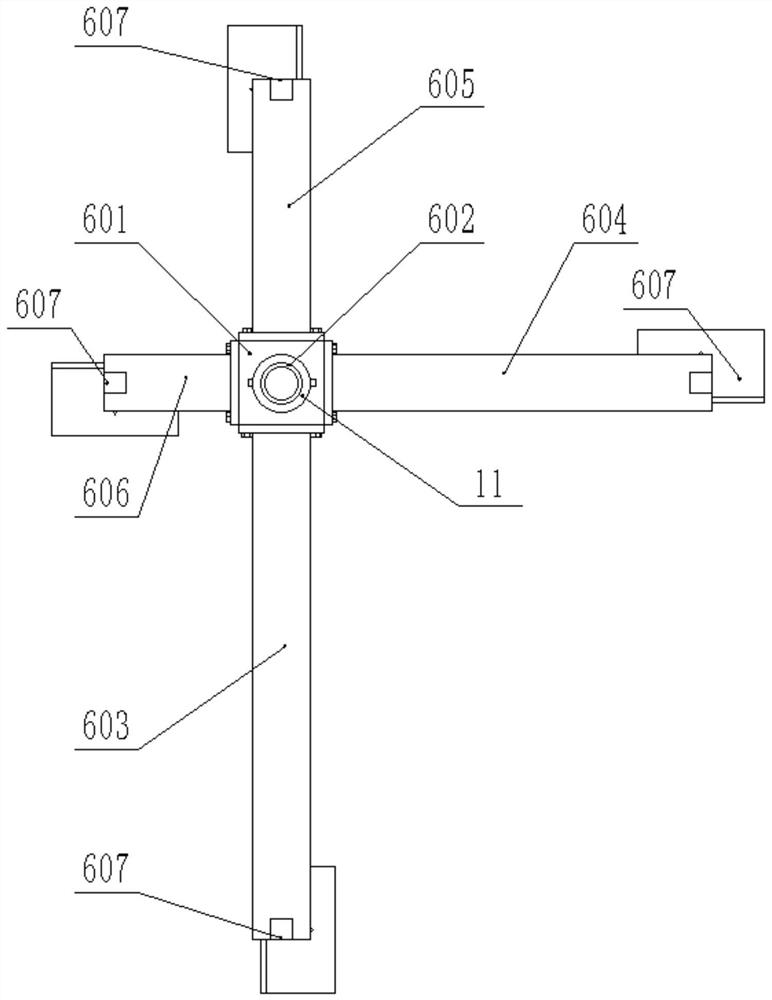

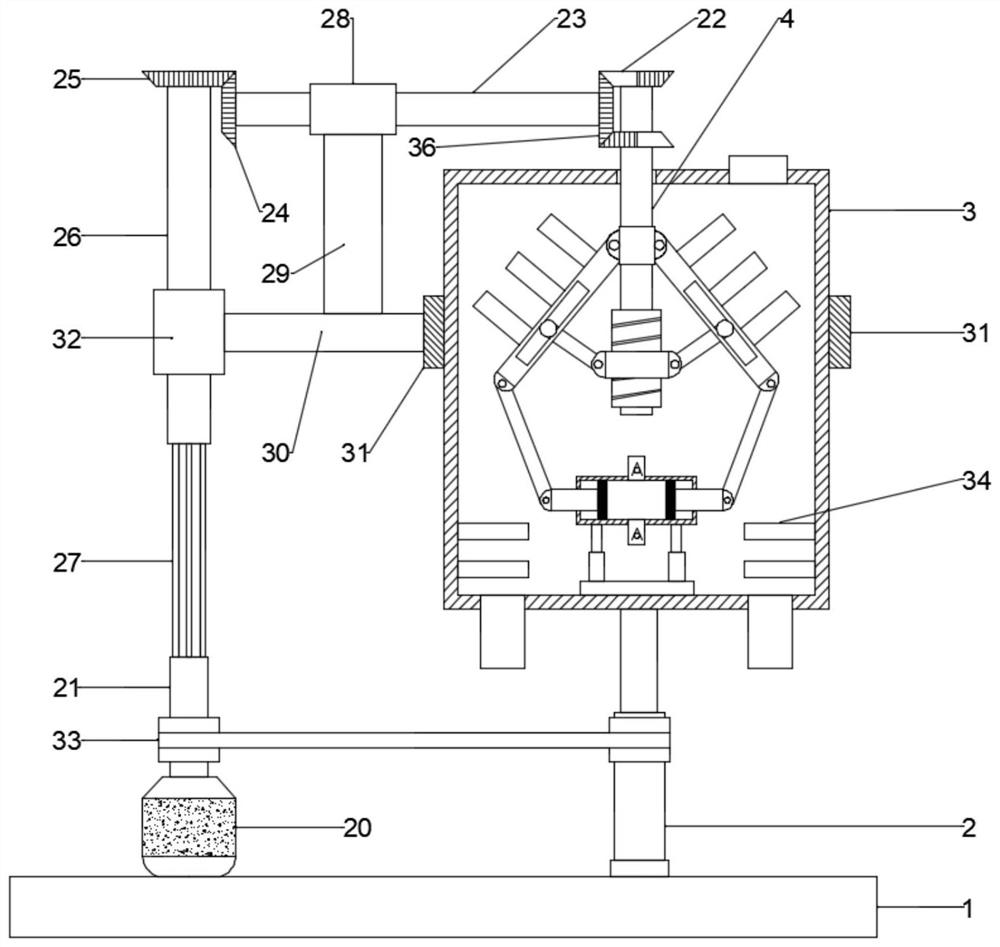

Stirrer combining revolution and rotation

PendingCN111546495AStirring trajectory is changeableRealize functionCement mixing apparatusElectric machineGear wheel

The invention discloses a stirrer combining revolution and rotation. The stirrer combining revolution and rotation comprises a stirring barrel body, a stirring arm assembly and a stirring power mechanism, wherein the stirring arm assembly is arranged below the stirring power mechanism and extends into the stirring barrel body, a stirring motor, a power main shaft, a driving gear, a transition gear, an autorotation gear, a stirring main shaft and a revolution gear are arranged in the stirring power mechanism, an output shaft of the stirring motor is connected with the upper end of the power main shaft, the driving gear is assembled on the power main shaft, the transition gear is correspondingly meshed with the driving gear and the autorotation gear, the autorotation gear is assembled at themiddle end of the stirring main shaft, the revolution gear is assembled at the upper end of the stirring main shaft, the stirring arm assembly is arranged at the lower end of the stirring main shaft,the stirrer is further provided with a revolution body, and a turntable bearing which is meshed with the revolution gear to rotate is arranged on the revolution body in a locked mode. By means of thestructure, the stirrer can integrate the revolution and the rotation to fully and uniformly stir materials, stirring dead corners are avoided, the stirring efficiency is high, and energy is saved.

Owner:NANAN CHANGSHENG BUILDING MATERIALS MACHINERY

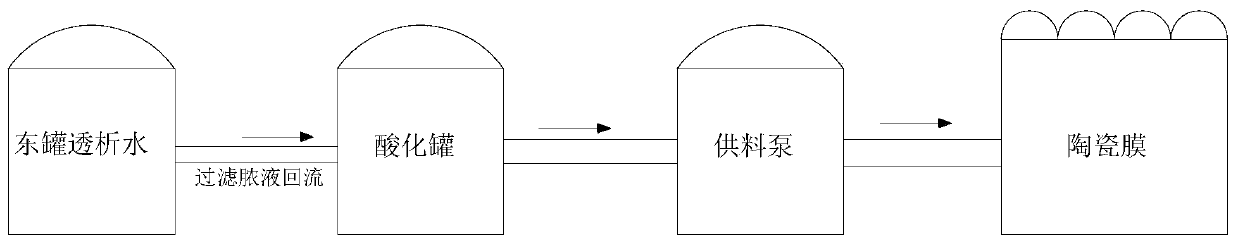

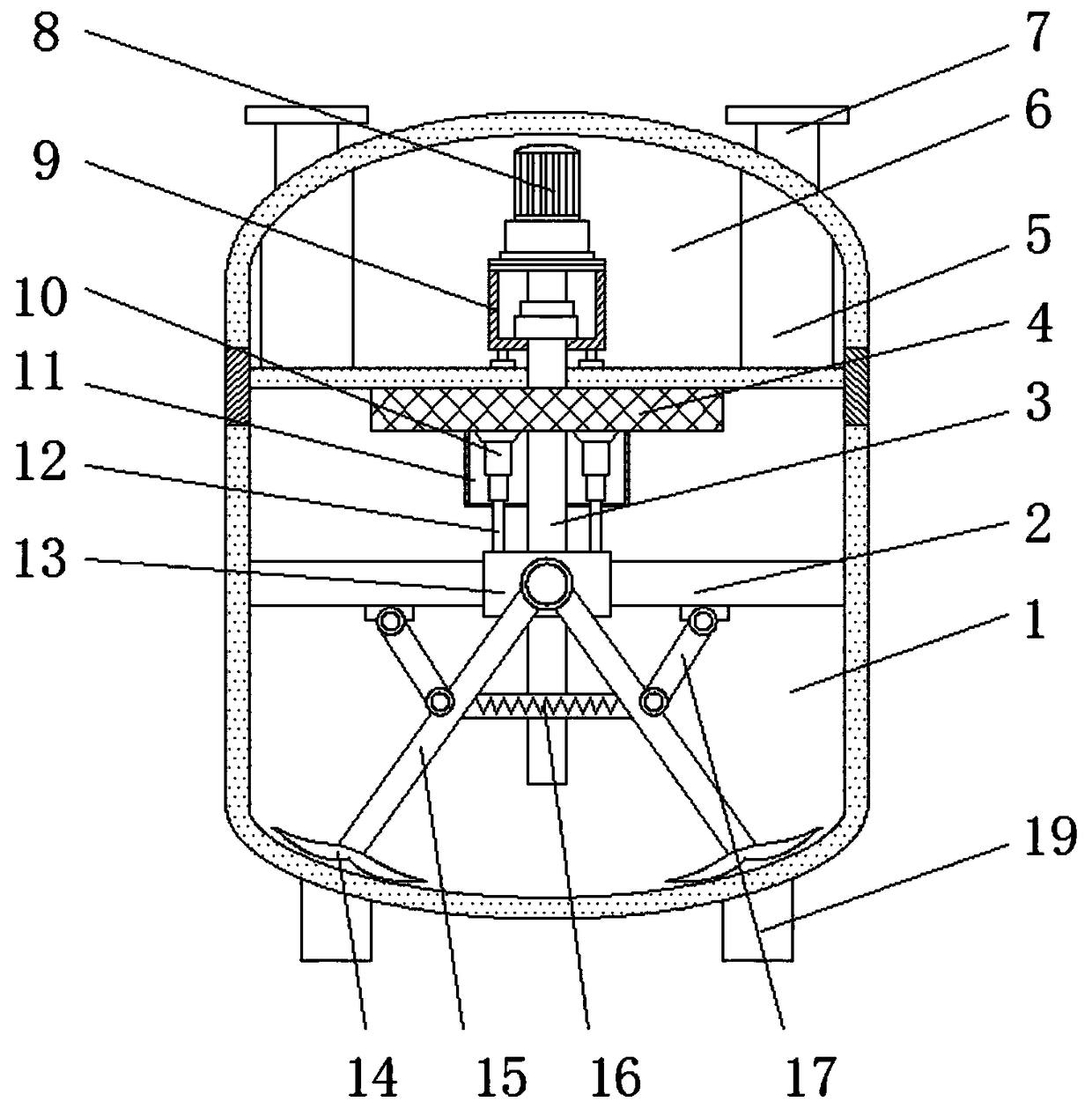

Material separation system based on cyclic separation in ceramic membrane separation process

ActiveCN111185117AEasy to diluteEasy to separateShaking/oscillating/vibrating mixersTransportation and packagingProcess engineeringCeramic membrane

The invention relates to the technical field of glucosamine manufacturing, and discloses a material separation system based on cyclic separation in a ceramic membrane separation process. The system comprises east tank dialysis water, wherein the east tank dialysis water and filtered concentrated liquid flow into an acidification tank through a pipeline, the mixed solution of the east tank dialysiswater and the filtered concentrated liquid in the acidification tank flows into a feeding pump through a pipeline, the feeding pump inputs the mixed solution into a ceramic membrane through a pipeline, a sealing cover and a bottom cover are fixedly connected to the top and the bottom of the tank body respectively, a round hole is formed in the center of the sealing cover, a first bearing is fixedly connected into the round hole, a rotating shaft is fixedly sleeved with the inner ring of the first bearing, and three stirring devices are movably connected to the outer wall of the rotating shaft. According to the invention, dialysis water and materials can be mixed through the acidification tank so as to conveniently dilute the concentration of the materials, and then the materials can be pumped into the ceramic membrane through the feeding pump to be separated, so that pressure can be applied to the materials, and the separation effect is improved.

Owner:SHANDONG RUNDE BIOTECH CO LTD

Vacuum rake dryer

The invention relates to a vacuum rake dryer which comprises a drying cylinder. A stirrer is arranged in the drying cylinder, the stirrer comprises an installation shaft and a stirring rod arranged on the installation shaft, a short rod vertical to the stirring rod is arranged at one end of the stirring rod, and the stirring rod is arranged on the installation shaft in staggered and crossed modes. The vacuum rake dryer is wide in stirring scope, even in stirring and ideal in stirring effect.

Owner:金伟均

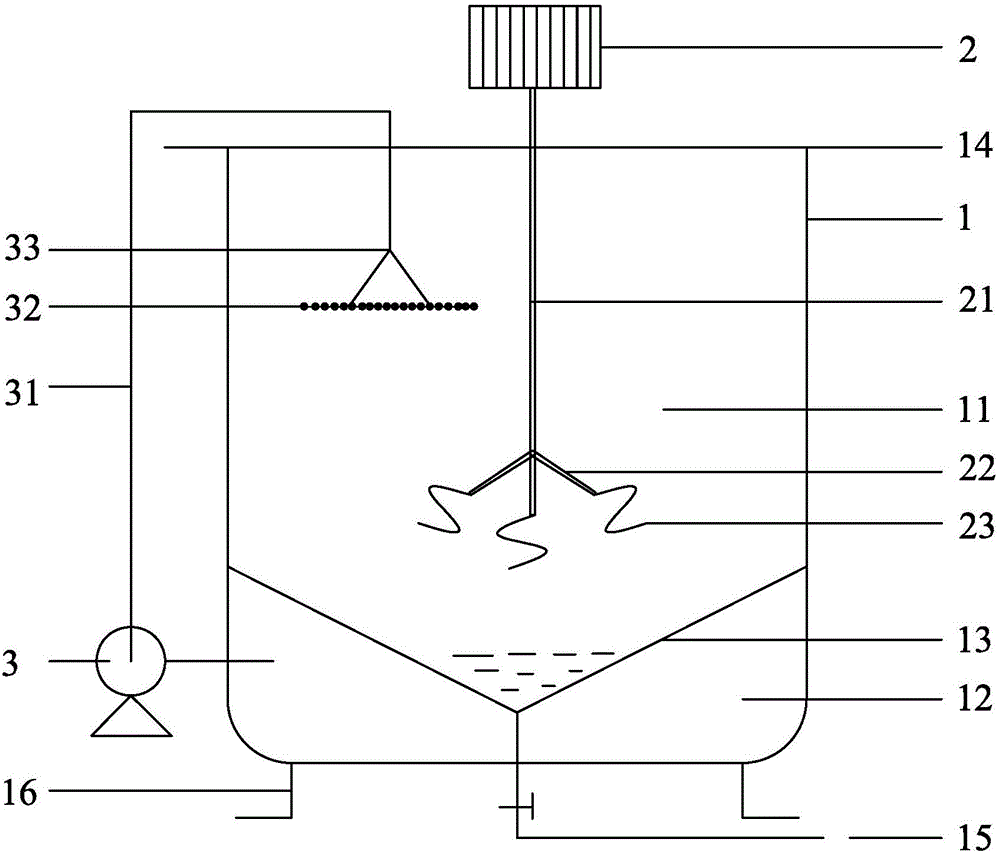

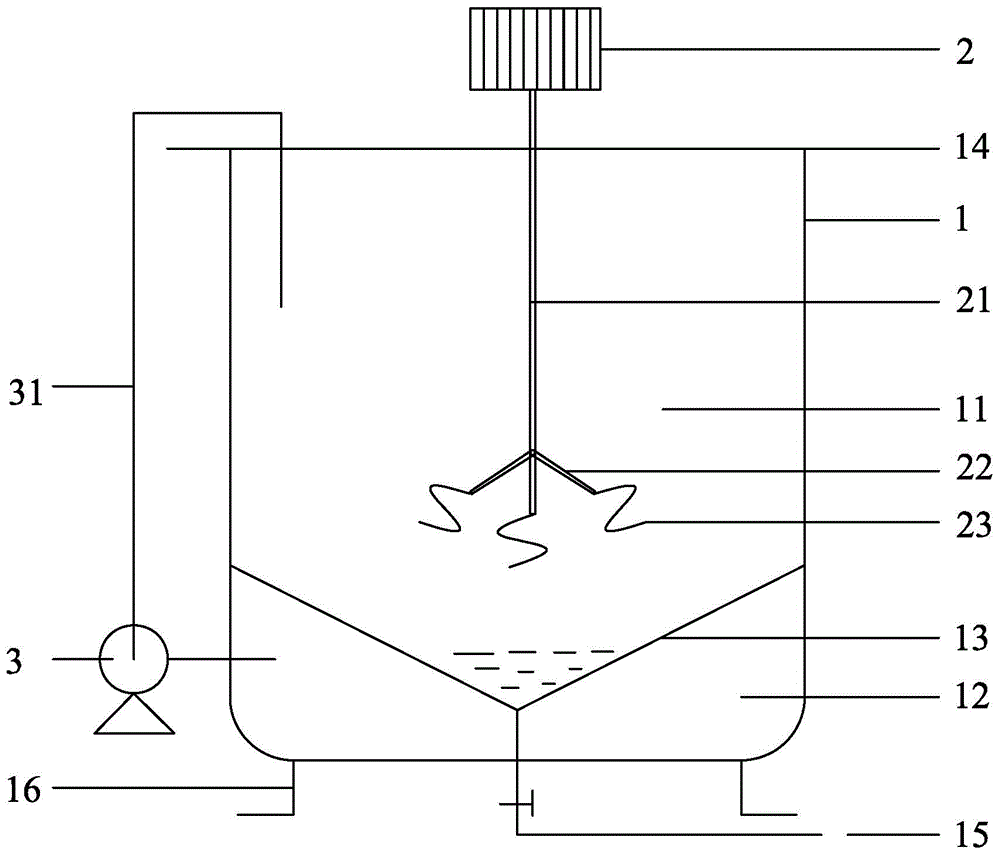

Spray type filtering and stirring tank

InactiveCN104549028AAverage speed landingLarge mixing rangeMixersPulp and paper industryFilter effect

The invention discloses a spray type filtering and stirring tank; the spray type filtering and stirring tank disclosed by the invention comprises a tank body and a motor, wherein the motor is arranged at the upper end of the tank body; a stirring shaft is connected to the lower end of the motor; three variable-angle stirring rods are arranged at the lower end of the stirring shaft; at least two bases are arranged at the bottom of the tank body; the spray type filtering and stirring tank is characterized in that the interior of the tank body is divided into a stirring area and a filtering area through a conical filter net arranged at the lower end of the tank body; a drainage pipe with a valve is communicated at the lowest position of the filter net; an output pipeline communicated with the pump is arranged on the side wall in the filtering area of the tank body; the pump is used for returning liquid pumped from the filtering area into the tank body through a backflow pipeline; a flow dividing pipe for dividing a flow through a connection joint is arranged at the liquid outlet end of the backflow pipeline; and a spray head with uniformly distributed umbrella type nozzles is connected to the liquid outlet end of the flow dividing pipe. The spray type filtering and stirring tank disclosed by the invention has the advantages of being simple in structure, high in practicability, convenient to operate, good in filtering effect and the like.

Owner:DALIAN 858 INNOVATION WORKS TECH SERVICE

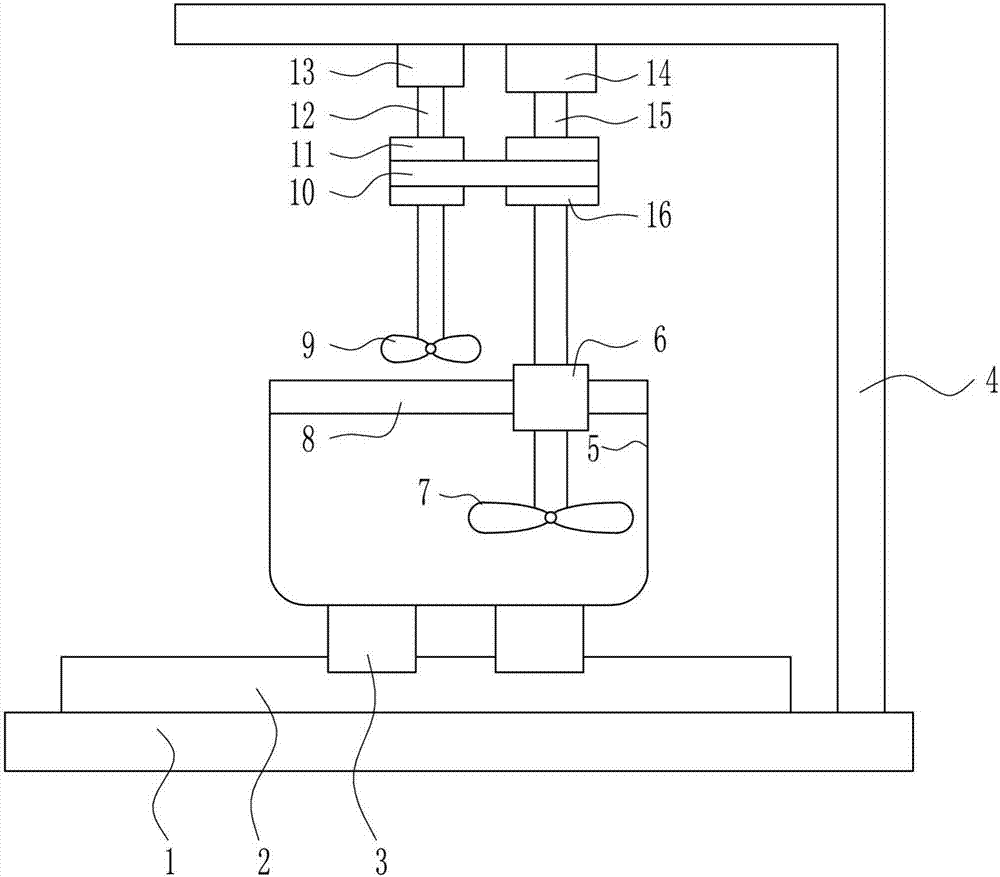

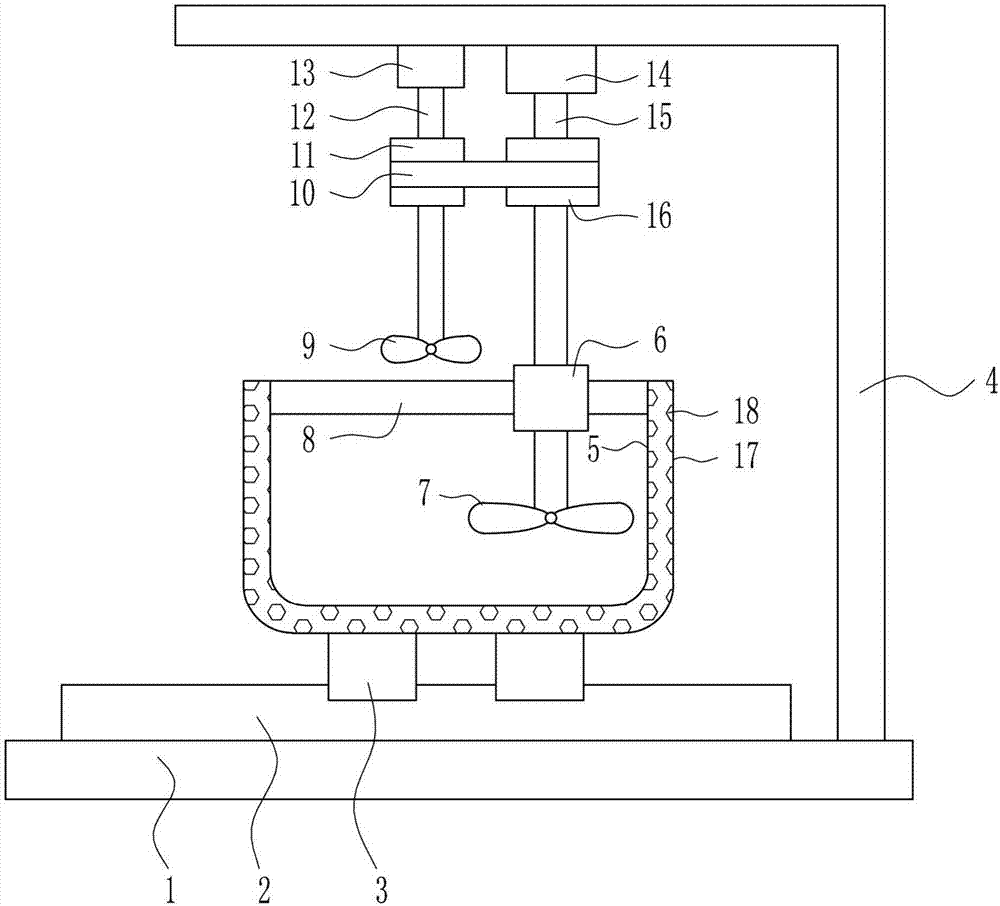

Microbial agent production equipment

InactiveCN108841577AEvenly distributedStir wellBioreactor/fermenter combinationsBiological substance pretreatmentsHydraulic cylinderBiochemical engineering

The invention discloses microbial agent production equipment which comprises a tank body, wherein a transition box is fixedly connected to a top position inside the tank body; a first partition box and a charging through hole are fixedly connected to the bottom positions of the inner walls of the transition box; the charging through hole is formed in one side of the first partition box; a steppingmotor is arranged inside the first partition box; the output end of the stepping motor is movably connected with a stirring rod; the stirring rod is arranged inside the tank body; a rotating disc isarranged below the transition box; the lower surface of the rotating disc is fixedly connected with a second partition box; a hydraulic cylinder is arranged inside the second partition box; the outputend of the hydraulic cylinder is movably connected with a piston rod. The microbial agent production equipment disclosed in the invention has an excellent stirring effect in the middle of the tank body and also has an excellent stirring effect in the bottom of the tank body, microbial agents attached onto the inner side walls and the bottom inner walls can be scraped off, the microbial agent is uniform in distribution, and uniform development of biological bacterium fluid is ensured.

Owner:胡小丽

Filtering and stirring tank

InactiveCN104549009ALarge mixing rangeSimple structureRotary stirring mixersMixer accessoriesElectric machineryFilter effect

The invention discloses a filtering and stirring tank comprising a tank body and a motor arranged at the upper end of the tank body, wherein the lower end of the motor is connected with a stirring shaft; the lower end of the stirring shaft is provided with three angle-changeable stirring rods; and the bottom of the tank body is provided with at least two bases. The filtering and stirring tank is characterized in that the inside of the tank body is divided into a stirring region and a filtering region by a tapered filter screen arranged at the lower end of the tank body; the lowest part of the filter screen is communicated with a drain pipe with a valve; and the upper end of the tank body is provided with a cover for preventing a liquid from being splashed. The filtering and stirring tank has the advantages of simple structure, strong practicability, convenience in operation, favorable filtering effect and the like.

Owner:DALIAN 858 INNOVATION WORKS TECH SERVICE

Stirring device and cooking equipment

The invention relates to a stirring device and cooking equipment. The stirring device is applied to the stirring of materials in a pot body and comprises a stirring shaft assembly, a first stirring assembly and a second stirring assembly. The first stirring assembly is connected to the stirring shaft assembly and comprises a first stirrer, and the first stirrer can be driven by the stirring shaftassembly to rotate; the second stirring assembly is connected to the stirring shaft assembly and comprises a second stirrer, the second stirring assembly is located above the first stirring assembly in a direction from the lower portion of the pot body to the opening of the pot body, and the second stirrer can be driven by the stirring shaft assembly to rotate and can rotate relative to the stirring shaft assembly. The stirring device can adapt to stirring of materials at different positions in a pot through the stirring action of the first stirrer and the second stirrer, and uniform mixing ofthe materials is achieved. The second stirrer stirs materials in a vertical direction through rotation of the second stirrer, the stirring strength is large, the stirring range is wide, and the materials can be fully mixed.

Owner:深圳鸿博智成科技有限公司

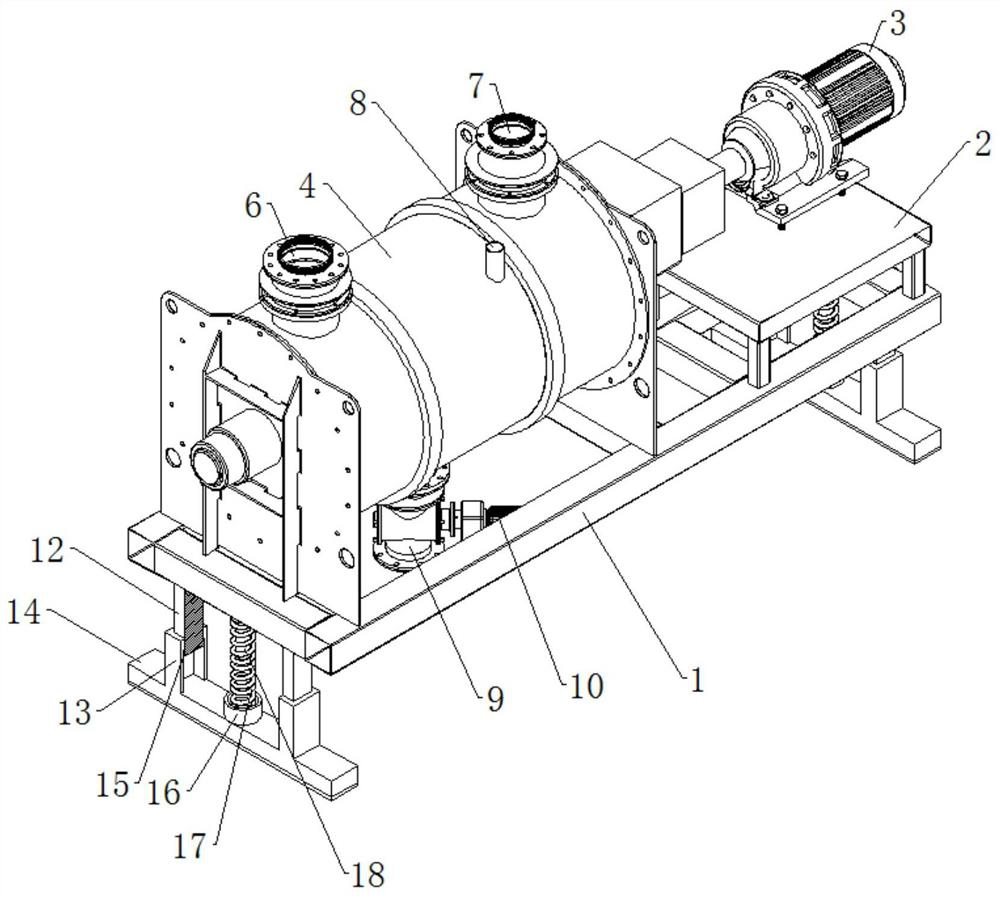

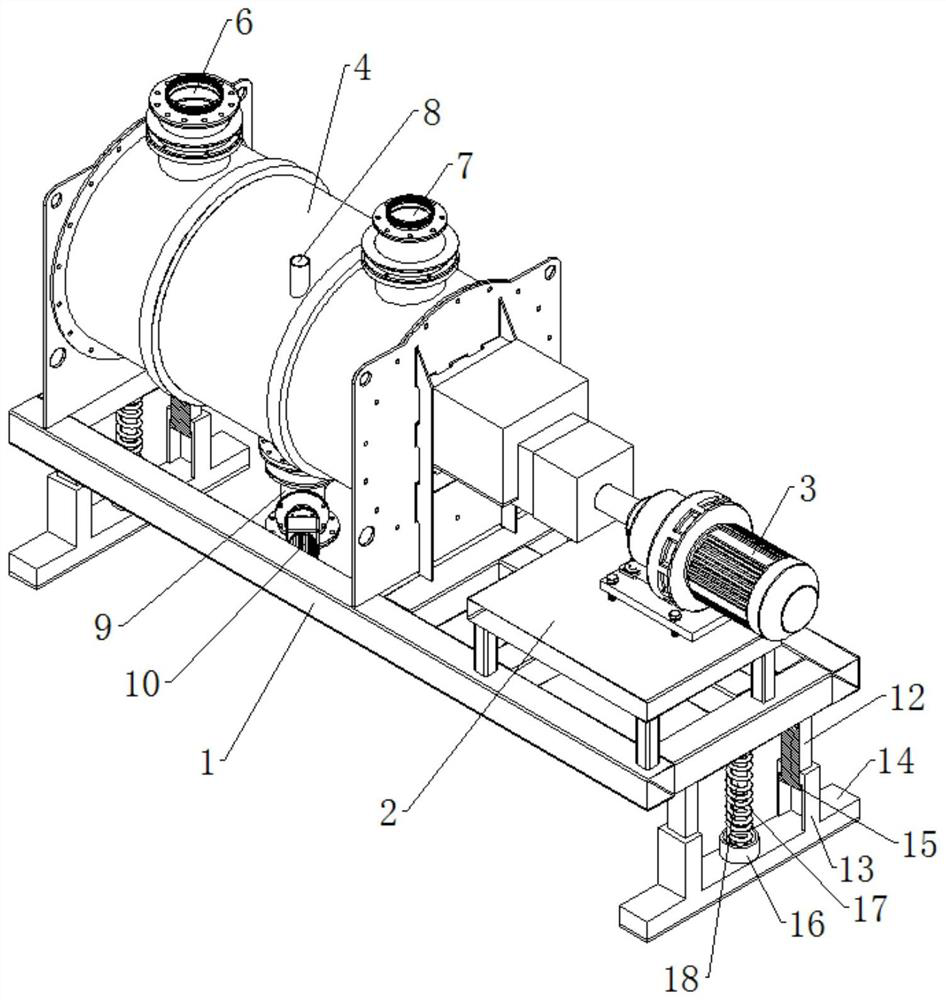

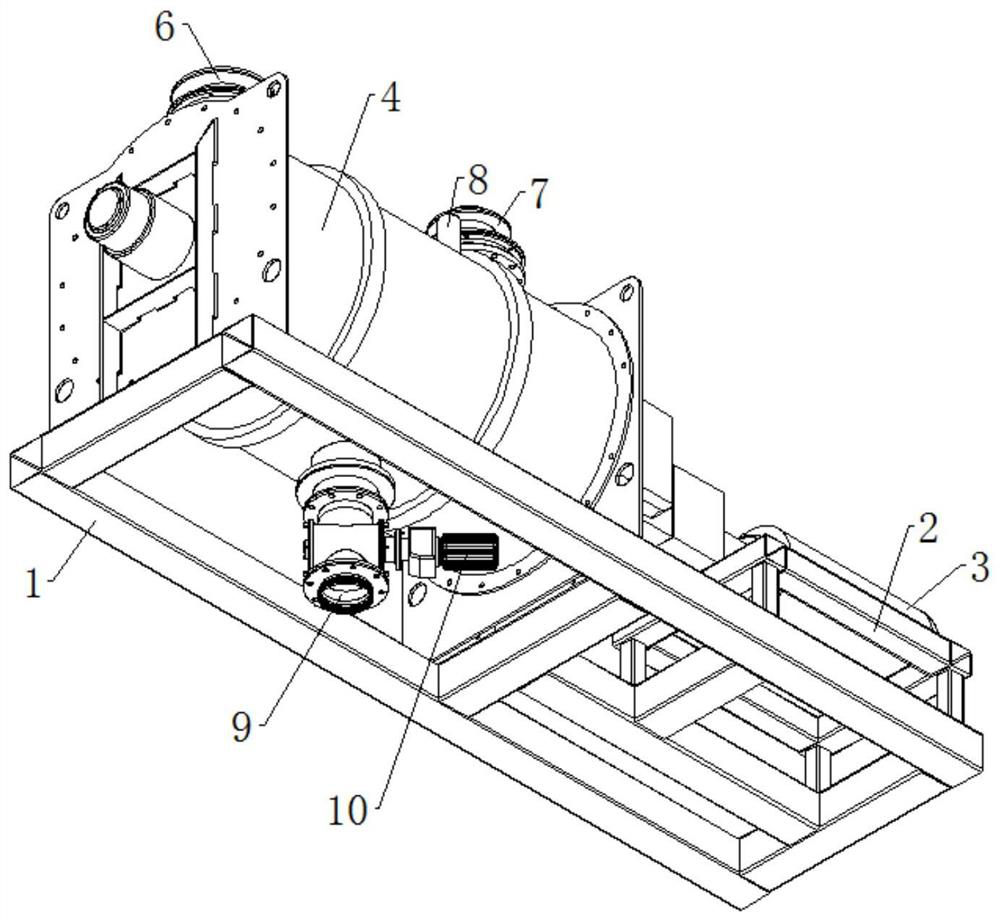

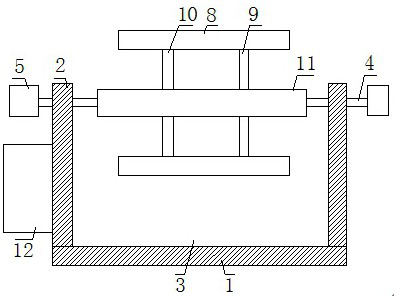

Mixing device for high polymer material processing

InactiveCN113457521ALarge mixing rangeGood mixing effectRotating receptacle mixersTransportation and packagingPhysicsElectric machinery

The invention discloses a mixing device for high polymer material processing. The mixing device comprises a mounting seat, a mounting groove is formed in the mounting seat, a rotating box is rotatably mounted in the mounting groove, a fixed seat fixedly mounted on the ground is arranged beside the mounting seat, a mounting block is fixedly mounted on the fixed seat, and a groove is formed in the mounting block. According to the device, a high polymer material is poured into the rotating box, a second driving motor is started to rotate, the rotating box is driven to rotate, a first driving motor is started to rotate, a first gear is driven to rotate, a second gear is driven to rotate according to the meshing transmission principle of clamping teeth, a first connecting rod, a connecting rod and a second connecting rod drive a moving block to reciprocate in a groove, and further a stirring rod is driven to move in the rotating box; and the moving stirring rod can stir raw materials in different areas in the rotating box, so that the stirring range is wide, and the material mixing effect is good.

Owner:安徽绿能技术研究院有限公司

Efficient textile dye mixing device for textile machinery

InactiveCN112403336AIncrease freedomStir wellRotary stirring mixersTransportation and packagingButterfly valveIndustrial engineering

The invention relates to the technical field of textile process raw material processing, and particularly discloses an efficient textile dye mixing device for textile machinery, which comprises a first base, a support column is arranged above the first base, a second base is arranged above the support column, and a damping bearing device is arranged above the first base. The damping bearing devicecomprises a first box body, a second box body is arranged in the first box body, a feeding port is formed in the front side of the second box body, a discharging port is formed in the bottom of the second box body, and a butterfly valve is arranged at an opening of the discharging port; and a stirring device is arranged in the second box body, and a power device is arranged above the second base.The power device drives the stirring device to uniformly stir dye, the stirring range is wide, and the stirring process is stable. The damping bearing device has a protective effect, so that the device is smart in structure, high in degree of freedom of the stirring device, diverse in stirring direction, large in stirring range, uniform in dye stirring effect and convenient to use.

Owner:SUZHOU MEILU TEXTILE MASCH ELECTRONICS CO LTD

Building solid waste recycled concrete admixture treatment device

PendingCN112873540AInternal mixing is more thoroughGood mixing efficiencyCement mixing apparatusVibration suppression adjustmentsElectric machineArchitectural engineering

The invention relates to the technical field of recycled concrete production, in particular to a building solid waste recycled concrete admixture treatment device. The device comprises a base, wherein a mounting seat is arranged on the right side of the upper surface of the base, a first driving motor is arranged on the upper surface of the mounting seat, a mixing tank is arranged on the left side of the upper surface of the base, the driving end of the first driving motor penetrates through the right side wall of the mixing tank and extends into the mixing tank to be provided with a first stirrer, a first adding opening is correspondingly formed in the left side of the upper surface of the mixing tank, a second adding opening is correspondingly formed in the right side of the upper surface of the mixing tank, a water adding opening is formed in the position, located between the first adding opening and the second adding opening, of the upper surface of the mixing tank, a discharging opening is correspondingly formed in the center of the bottom of the mixing tank, and a second driving motor is correspondingly arranged on the outer side of the discharging opening. Through the design, overall convenience, efficiency and practicability of the building solid waste recycled concrete admixture treatment device can be improved.

Owner:江苏瓦楷新材料科技有限公司

Stirring machining rapid cooling and lubricating device

InactiveCN112090329AImprove the mixing effectImprove work efficiencyShaking/oscillating/vibrating mixersTransportation and packagingWhole bodyElectric machinery

The invention discloses a stirring machining rapid cooling and lubricating device which comprises a base, a supporting plate, a stirring tank, a rotating device, a cooling device, a lubricating device, a sliding device, stirring blades, a first supporting column, a second supporting column and a fixed base, the supporting plate is connected to the upper portion of the base, and a motor is connected to the side edge of the supporting plate; the stirring tank is arranged in the supporting plate; the upper part of the stirring tank is connected with the stirring blades; the first supporting column and the second supporting column are arranged above the stirring blades; the first supporting column is arranged on the side of the second supporting column. The stirring machining rapid cooling andlubricating device is convenient to use, the stirring effect is improved and fine; working efficiency is improved, a whole body penetrates through the two sides of the supporting plate, stability isimproved, cooling liquid is conveyed into the rotating device through through holes, the rotating device can be rapidly cooled, the lubricating effect is also improved, appliance abrasion caused by the high temperature is avoided, and safety is also improved.

Owner:朕诺机械设备江苏有限公司

Automatic pigment color mixing equipment for art painting teaching

PendingCN114435017AEasy to fall intoAdjustable positionOther artistic work equipmentsHydraulic cylinderPhotopigment

The invention discloses an automatic pigment color mixing device for art painting teaching, which comprises a base table, a pushing assembly, a moving assembly, a lifting assembly, three discharging assemblies, an adjusting assembly, a stirring assembly, a clamping assembly and a tray, two fixing frames are welded at the top of the base table, and the pushing assembly is arranged between the two fixing frames; the moving assembly is arranged at the top of one fixing frame, a third hydraulic cylinder drives a third hydraulic rod to move up and down, the third hydraulic rod drives a stirring rod to move up and down, the height of the stirring rod can be adjusted, pigments are stirred through the stirring rod, and different pigments can be fully mixed. And the left-right position of the stirring assembly is adjusted through the adjusting assembly, it is guaranteed that the pigment stirring range of the stirring assembly is wider, the color mixing efficiency of the equipment is further improved, and the high efficiency of the equipment during use is improved.

Owner:易茹

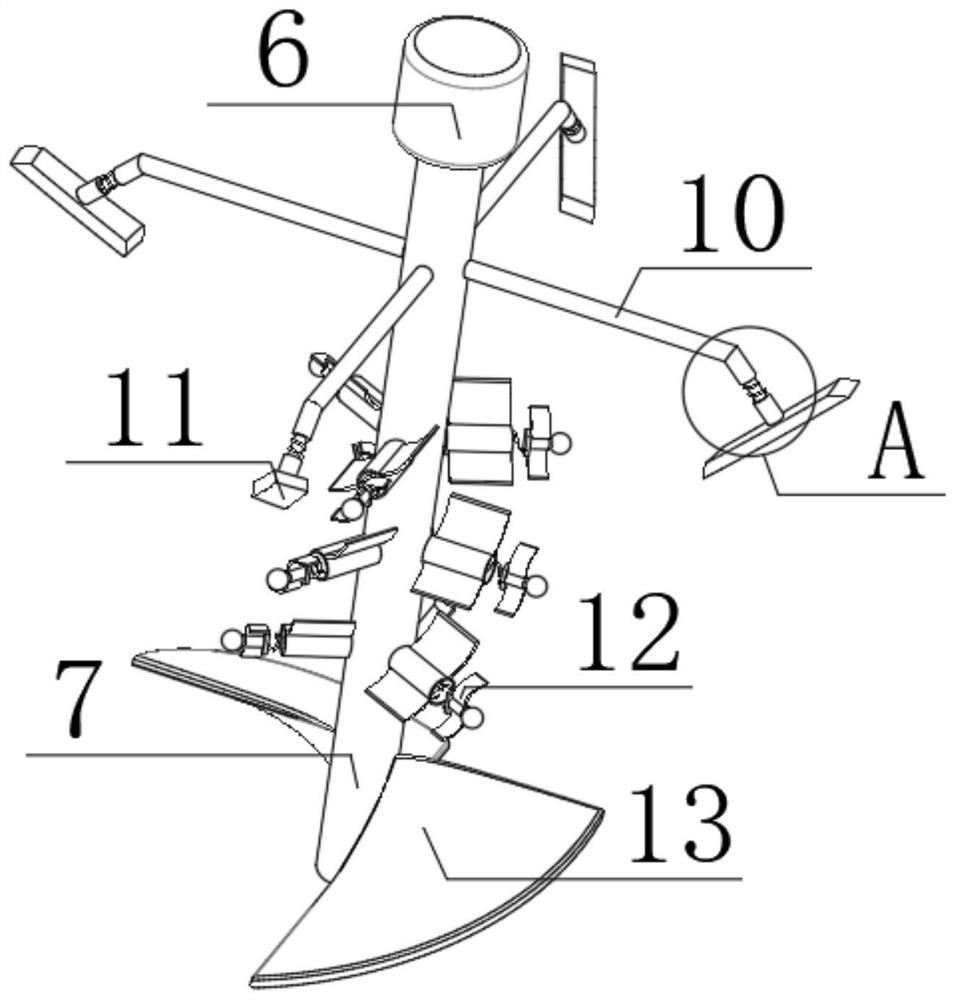

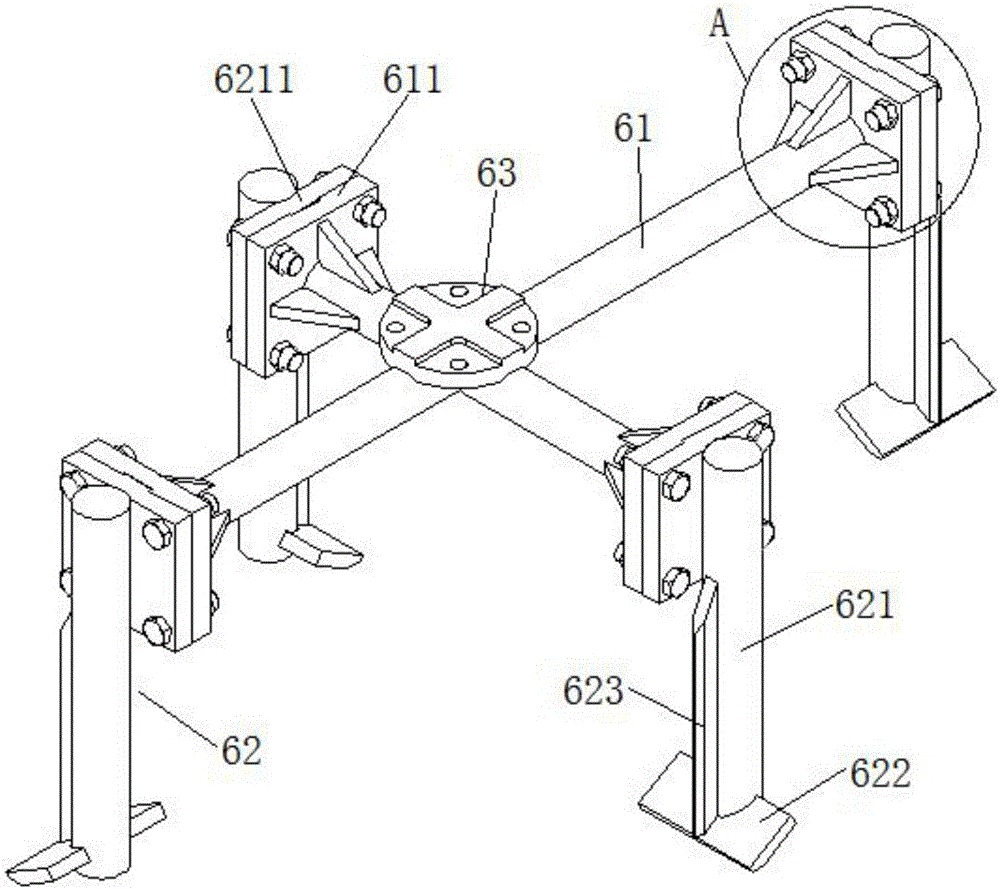

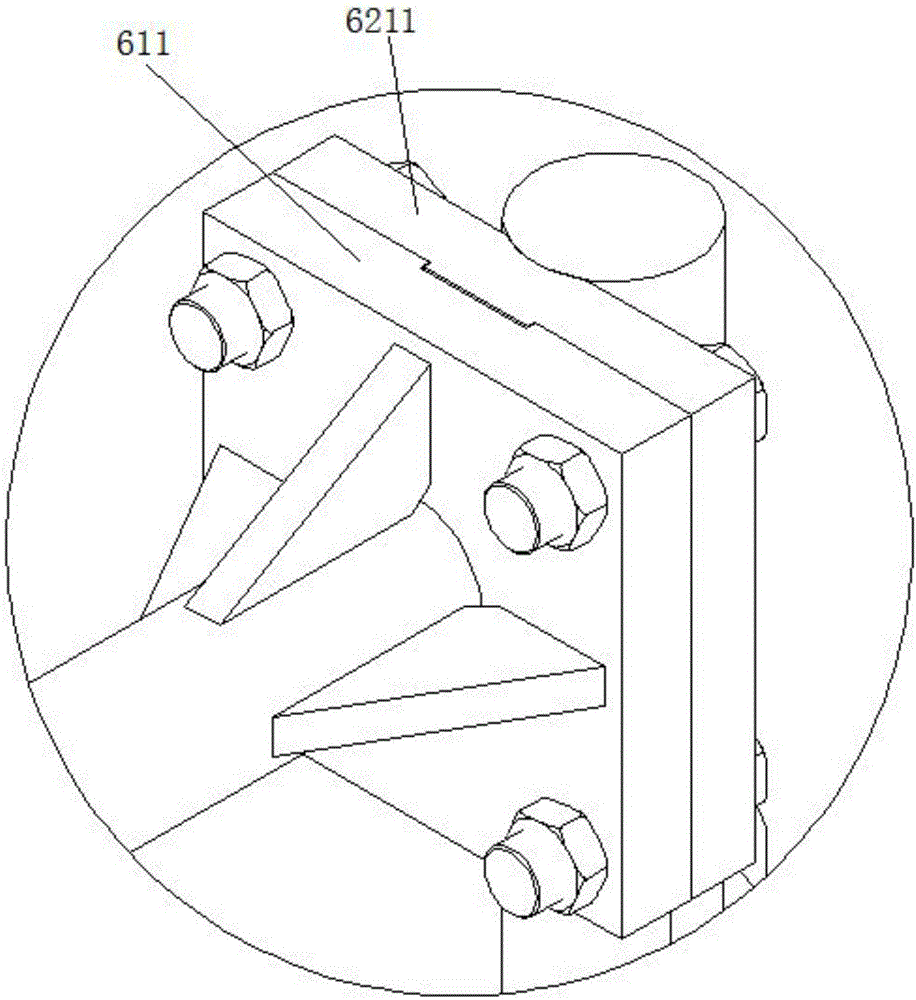

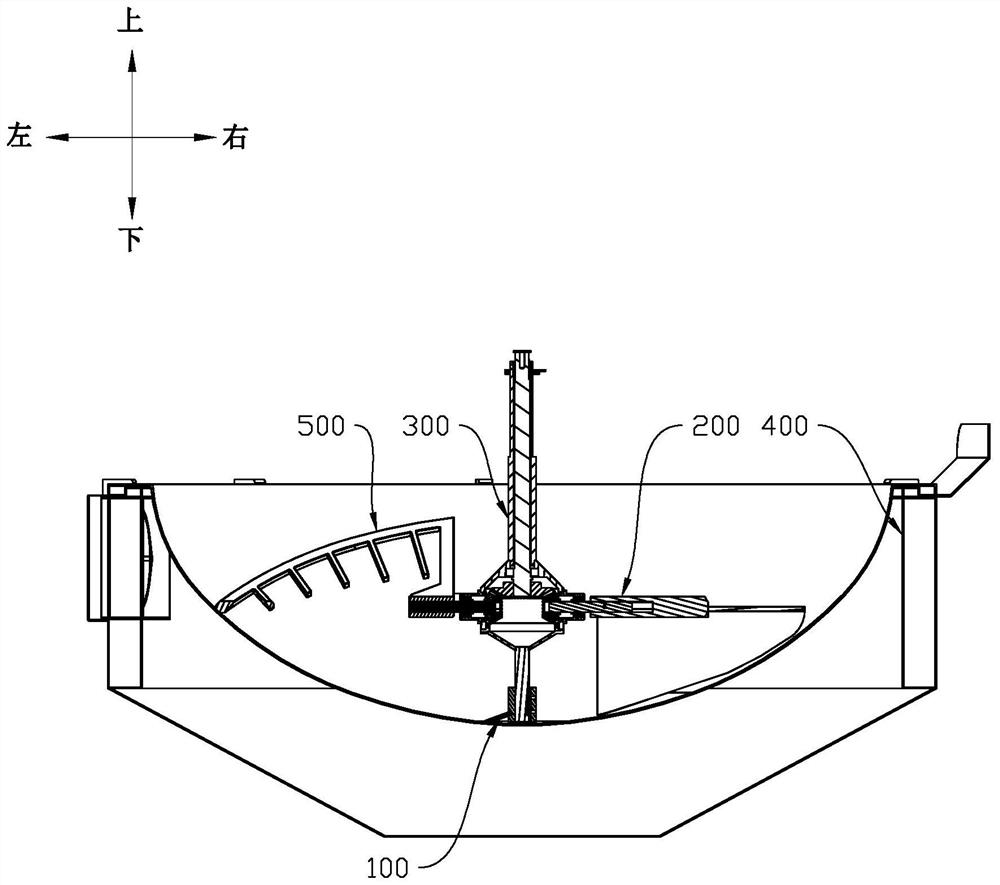

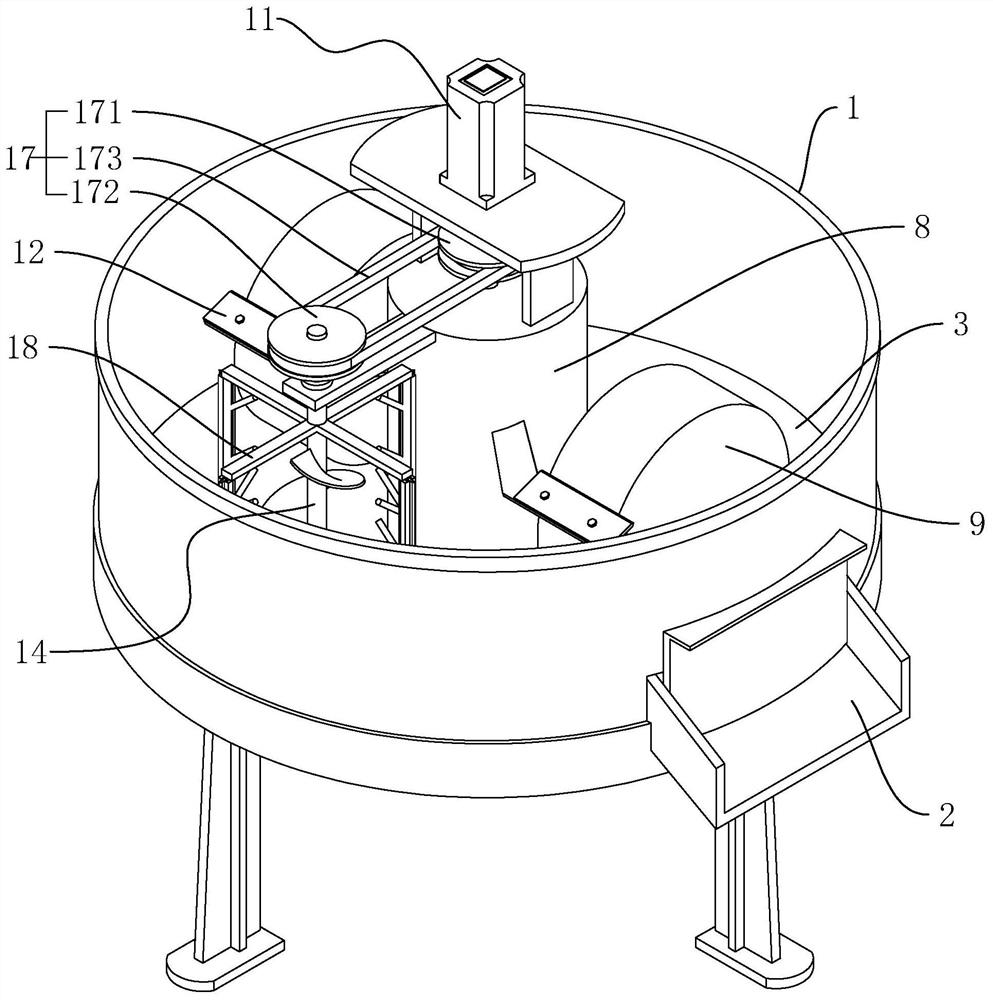

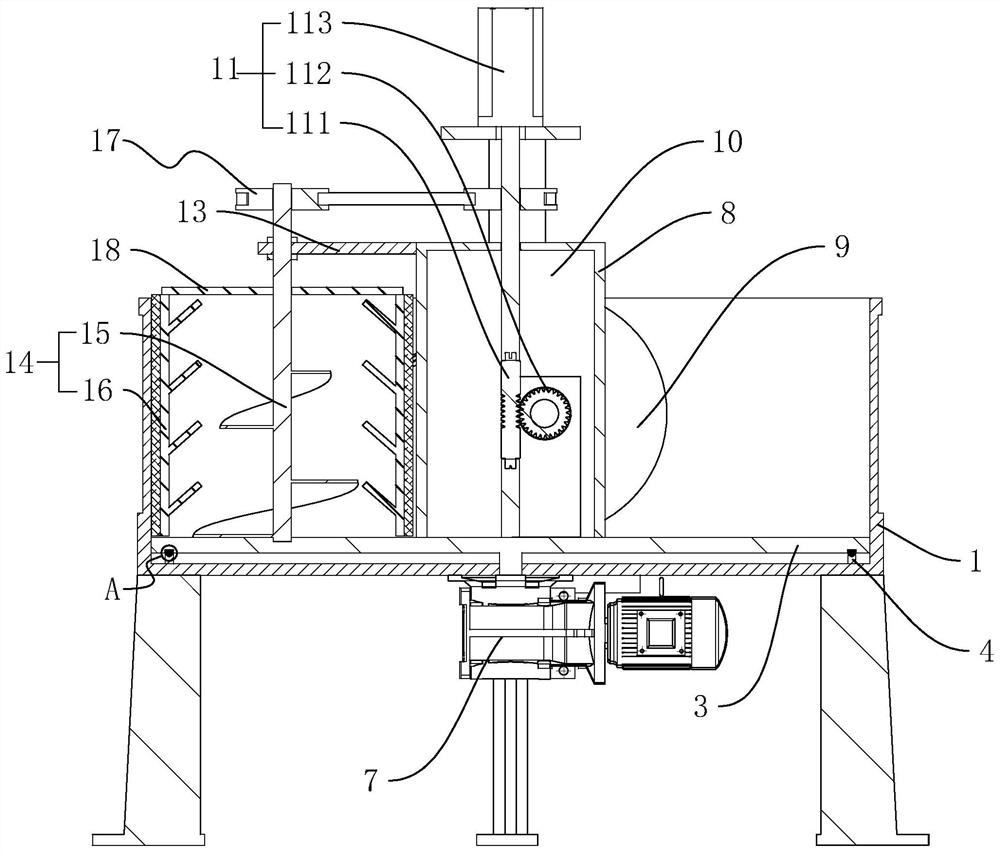

Vertical mixing and heating device for mixing and stirring materials

ActiveCN111549630ALarge mixing rangeImprove stirring efficiencyRoads maintainenceVertical mixingEngineering

The invention discloses a vertical mixing and heating device for mixing and stirring materials. The invention relates to the technical field of asphalt recycling. The stirring device comprises a stirring shaft, a connecting block and a stirring rod; the lower end of the stirring shaft is fixedly connected with the connecting block; the stirring rod is fixed on the side end surface of the connecting block; a stirring block is fixed at the front end of the stirring rod; a circulating heat pipe is arranged in the stirring shaft, the connecting block and the stirring rod; an exhaust pipe is arranged on an upper cover, two groups of ventilation holes are formed in the stirring shaft along the axial direction; a ventilation sleeve is arranged in the periphery of each group of ventilation holes;the ventilation sleeve is mounted on the stirring shaft through a bearing; the exhaust pipe is communicated with one of the ventilation sleeves, the stirring block comprises a connecting plate, the connecting plate is fixedly connected with the stirring rod, the lower end of the connecting plate is fixedly connected with a cutter, stirring fins are fixed to the lower end of the cutter, and the sumof the lengths of all the stirring fins on the stirring device is not smaller than the difference between the radius of a stirring kettle and the radius of a protruding box.

Owner:DONGYUE SPECIAL PURPOSE AUTOMOBILE SHANDONG MFG

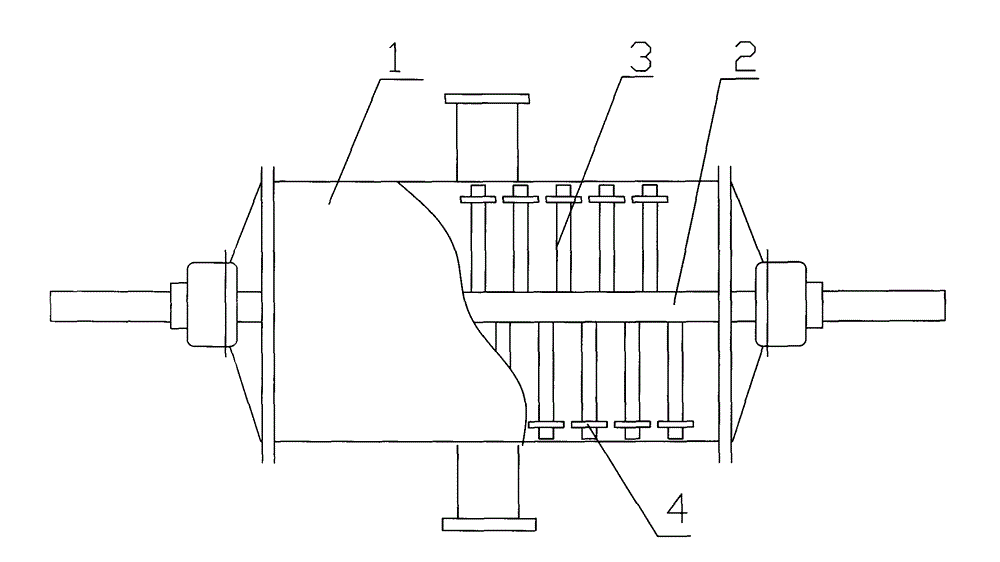

Double stirring device

ActiveCN105148768BLarge mixing rangeStir wellRotary stirring mixersLow speedAgricultural engineering

The invention relates to a double-stirring device. The double-stirring device comprises an upper speed reducer, a lower speed reducer, an upper motor, a lower motor, a shell, an outer stirring shaft, an upper internal stirring shaft, a frame type stirrer, an inner stirrer and a transition shaft, wherein a lower auxiliary plate is installed in the middle of the lower end of the frame type stirrer, a shaft sleeve is installed in the middle of the lower auxiliary plate, a transition shaft is installed inside the shaft sleeve, the upper end of the transition shaft is installed inside a cylinder hole in the lower end of the inner stirring shaft, the two sides of the lower end of the outer stirring shaft are connected with two upper auxiliary plates which are obliquely installed at the two sides of the outer stirring shaft in a splayed shape and are connected to the middle of the upper end of the frame type stirrer by bolts and screw nuts. The double-stirring device has the advantages that the design is simple, the use is convenient, the structure is reasonable and compact, a sanitation type stirring device comprises a paddle type stirrer and the frame type stirrer, so that the stirring operation requirements of different viscosities of materials can be met.

Owner:SHANGHAI SANQIANG VESSEL NANTONG CO LTD

A vertical mixing and heating device for mixing and stirring material

ActiveCN111549630BLarge mixing rangeImprove stirring efficiencyRoads maintainenceVertical mixingMechanical engineering

Owner:DONGYUE SPECIAL PURPOSE AUTOMOBILE SHANDONG MFG

sand mixer for foundry

ActiveCN110508746BRolled bigLarge mixing rangeMould handling/dressing devicesFoundryElectric machinery

The invention discloses a sand mixing machine for casting, and relates to the technical field of casting. According to the technical scheme, the sand mixing machine comprises a barrel body and a runner wheel. The interior of the barrel body is coaxially connected with an installation plate. A driving piece is further arranged at the bottom of the barrel body. An installation part is arranged on the upper end face of the installation plate. The runner wheel is correspondingly and rotationally connected to the installation part. A driving assembly is further arranged on the installation part andcomprises a worm rotationally connected with the interior of the installation part, a worm wheel fixedly connected to the runner wheel and a driving motor. An extending plate is fixed to the installation part in the radial direction of the barrel body. A stirring assembly is further arranged in the barrel body and correspondingly connected with the extending plate. The stirring assembly comprisesa main stirring piece and an auxiliary stirring piece. The worm is provided with a transmission assembly capable of driving a main stirring shaft to rotate. By means of rotation of the installation plate, the runner wheel on the installation plate and the stirring assembly can rotate along the axis of the barrel body in the grinding and stirring process, thus, the grinding and stirring range is larger, and therefore, the overall grinding and mixing effect is better.

Owner:杭州兴海铸造有限公司

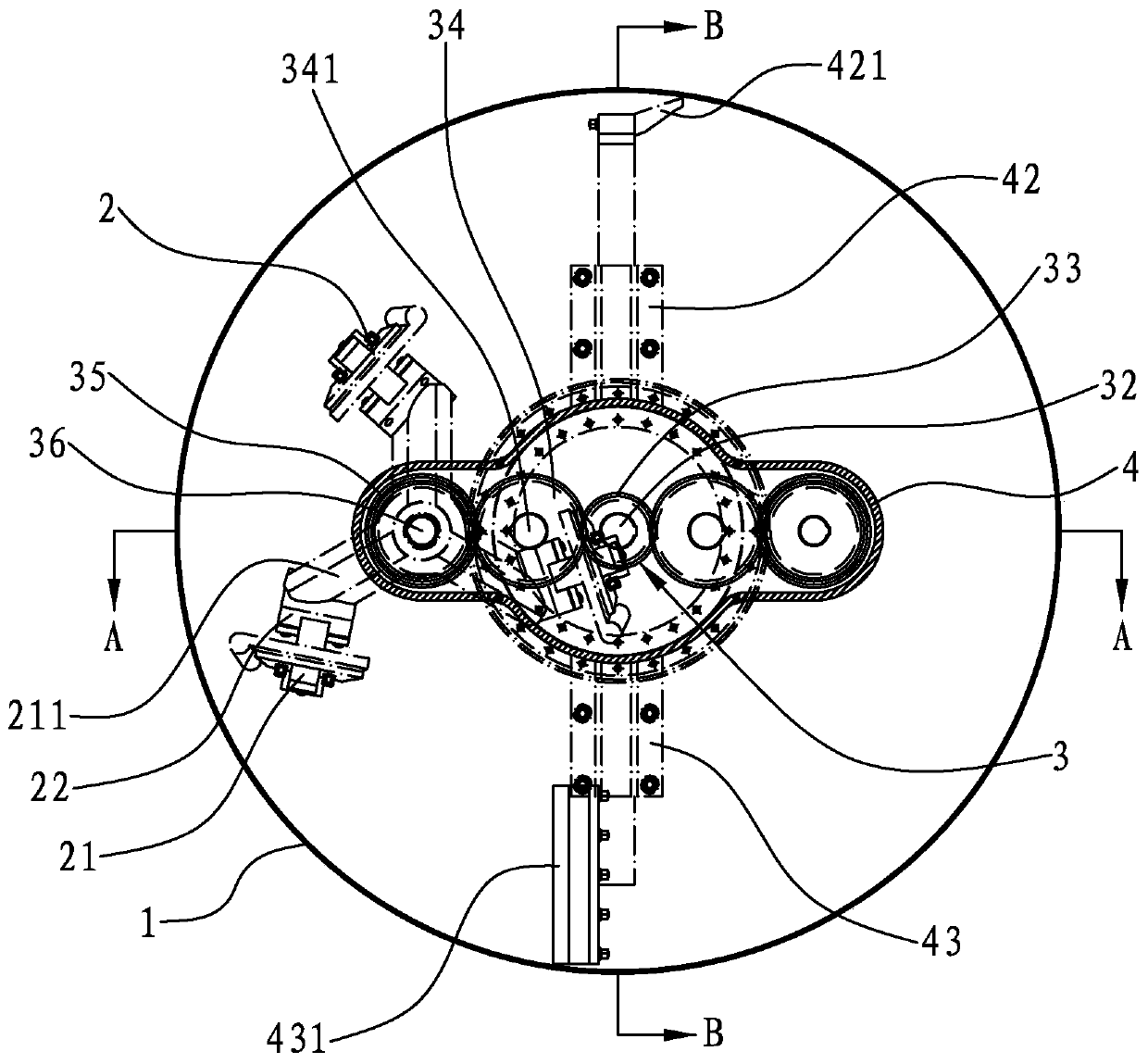

A mixer for sewage treatment

ActiveCN105381747BHigh speedHigh strengthRotary stirring mixersTransportation and packagingSewageEngineering

The invention proposes a mixer for sewage treatment, which includes a working bridge, a first driving mechanism, a walking mechanism, a slide rail, a second driving mechanism, a stirring device and a third driving mechanism; the working bridge spans the sewage pool, The first driving mechanism drives the working bridge to rotate along the central axis of the sewage pool. There is a slide rail on the working bridge. The slide rail extends along the extension direction of the working bridge. Travel switches are installed at both ends of the slide rail. The second driving mechanism drives the running mechanism to move, the stirring device is connected to the running mechanism in rotation, and is driven by the third driving mechanism; the stirring device includes a rotating shaft, and the first lifting assembly and the first stirring assembly are arranged on the rotating shaft in sequence from top to bottom , the second lifting assembly, the second stirring assembly. The invention has wide stirring range, sufficient stirring, high stirring intensity and high efficiency.

Owner:ASIA PACIFIC WATER TREATMENT TIANCHANG

Gynecological cleaning fluid disinfecting and homogenizing device

PendingCN113908741ASolve the problem of small mixing range and slow homogenization speedLarge mixing rangeShaking/oscillating/vibrating mixersTransportation and packagingEngineeringGynecology department

The invention discloses a gynecological cleaning fluid disinfecting and homogenizing device, and relates to the technical field of medical equipment. The gynecological cleaning fluid disinfecting and homogenizing device comprises a base and a box body, and the box body is provided with a feeding opening and a discharging opening. The gynecological cleaning fluid disinfecting and homogenizing device further comprises a stirring mechanism and a power assembly. The stirring mechanism is arranged in the box body and used for stirring and homogenizing cleaning fluid, and the stirring mechanism at least comprises a swinging assembly and a pumping assembly which are connected with each other. The power assembly is connected with the outer wall of the box body and is used for providing power for the box body and the stirring mechanism. Cleaning liquid raw materials are poured into the box body through the feeding opening, the power mechanism is started to drive the box body to rotate and the stirring mechanism to reciprocate, and the stirring device is matched with rotation of the box body, so that the stirring range is larger, the homogenizing speed is high, the homogenizing effect is better, and the problem that an existing homogenizing device is small in stirring range and low in homogenizing speed is solved.

Owner:江西金思康药业有限公司

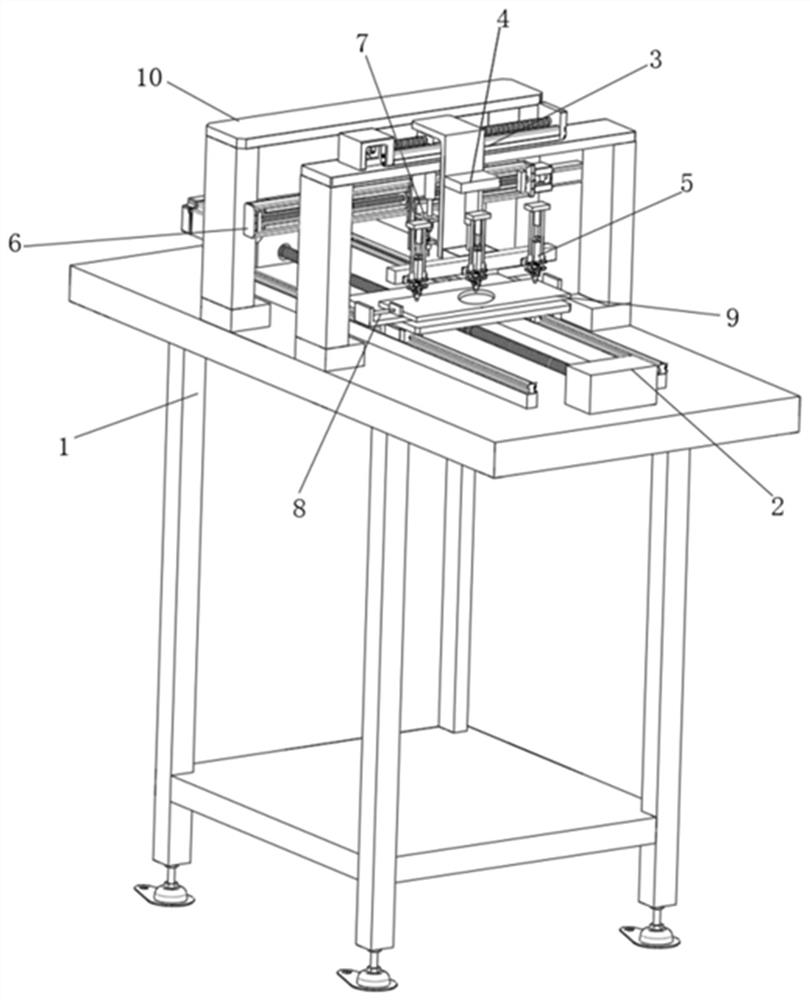

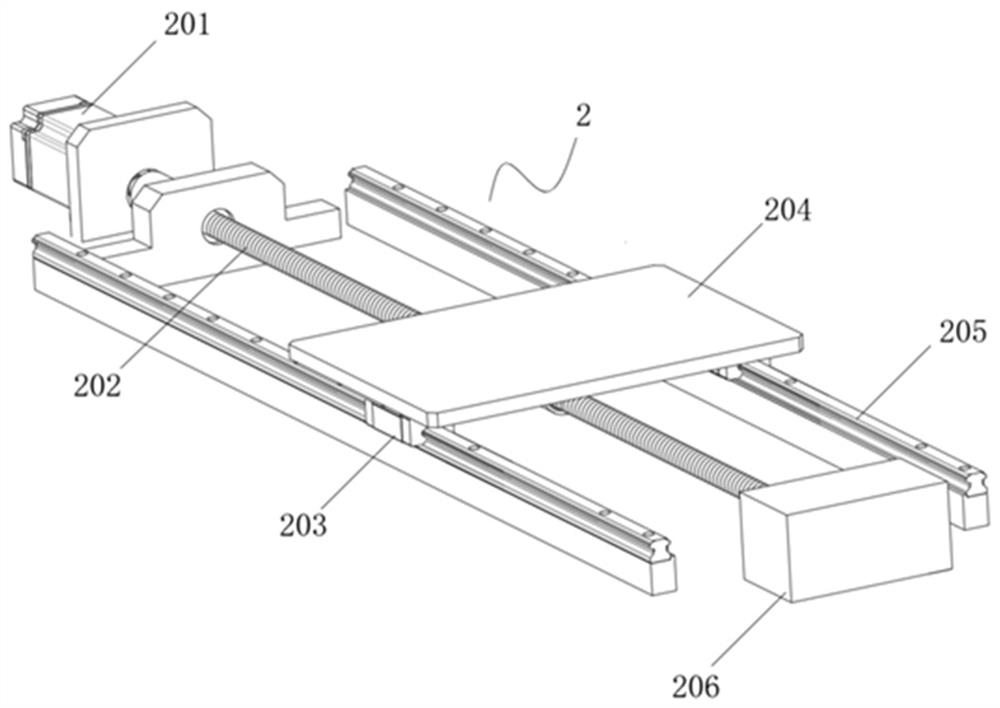

Feed mixer realizing uniform discharge

InactiveCN108816135AUniform dischargeStir wellFeeding-stuffTransportation and packagingEngineeringMixing effect

The invention relates to the technical field of mixing and discloses a feed mixer realizing uniform discharge. The feed mixer comprises a mixing box, wherein a feed port is formed in the left side ofthe top of the mixing box; a first discharge port is formed in the left side of the bottom of the mixing box; a second discharge port is formed in the bottom end of the right side of the mixing box; afirst rotating shaft and a second rotating shaft are inserted into centers of the cross sections of the two ends of the mixing box respectively; motors are fixedly mounted at the left end and the right end of the mixing box; output shafts of the two motors are fixedly connected with first pulleys; the two first pulleys are rotationally connected with two second pulleys through a belt; the two second pulleys are in sleeve joint with one ends, away from the mixing box, of the first rotating shaft and the second rotating shaft respectively; a partition board is fixedly mounted at the upper end of the inner wall of the mixing box. According to the feed mixer realizing uniform discharge, the mixing range can cover the whole mixing box better, the mixing effect is better, the discharge is moreuniform, and the feed mixer is convenient for a user to use.

Owner:肇庆市天地人科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com