Mixing and high-efficient cooling device for chemical raw materials

A technology for cooling devices and chemical raw materials, applied in household refrigeration devices, mixers, shaking/oscillating/vibrating mixers, etc., can solve problems such as lack of cooling effect, rising raw material temperature, affecting raw material quality, etc., to achieve lower temperature , prolong the service life, and have the effect of wide stirring range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

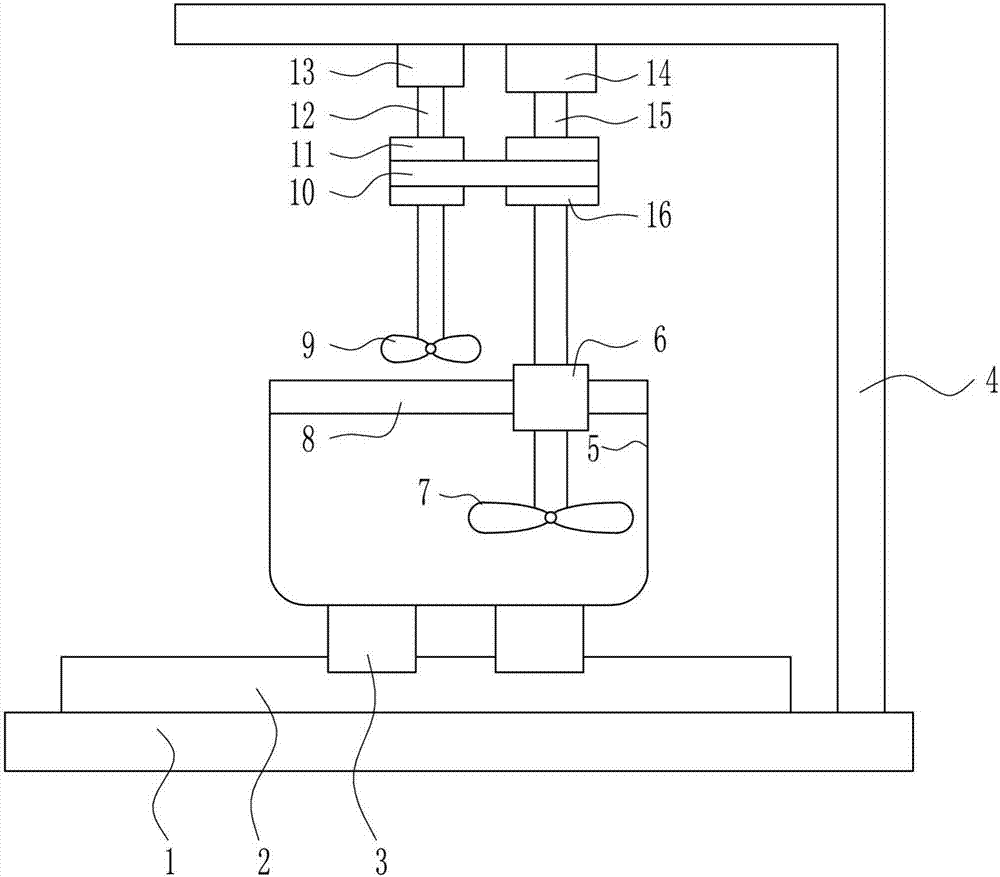

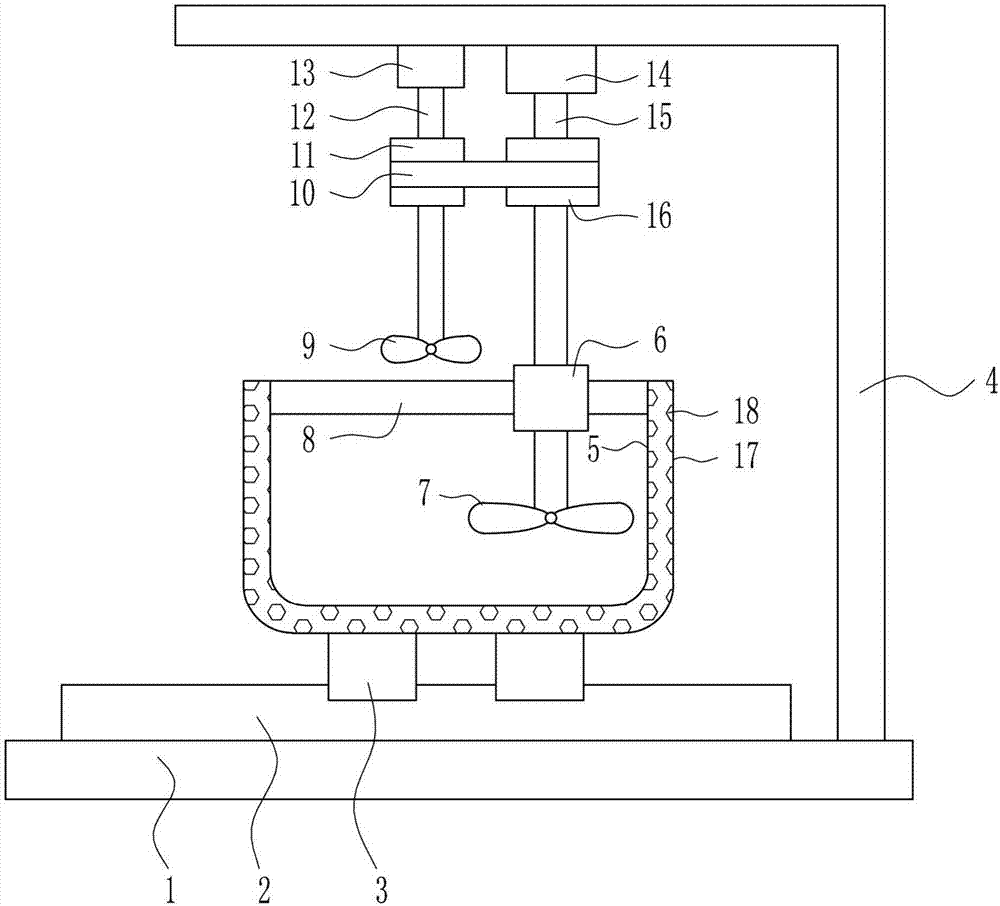

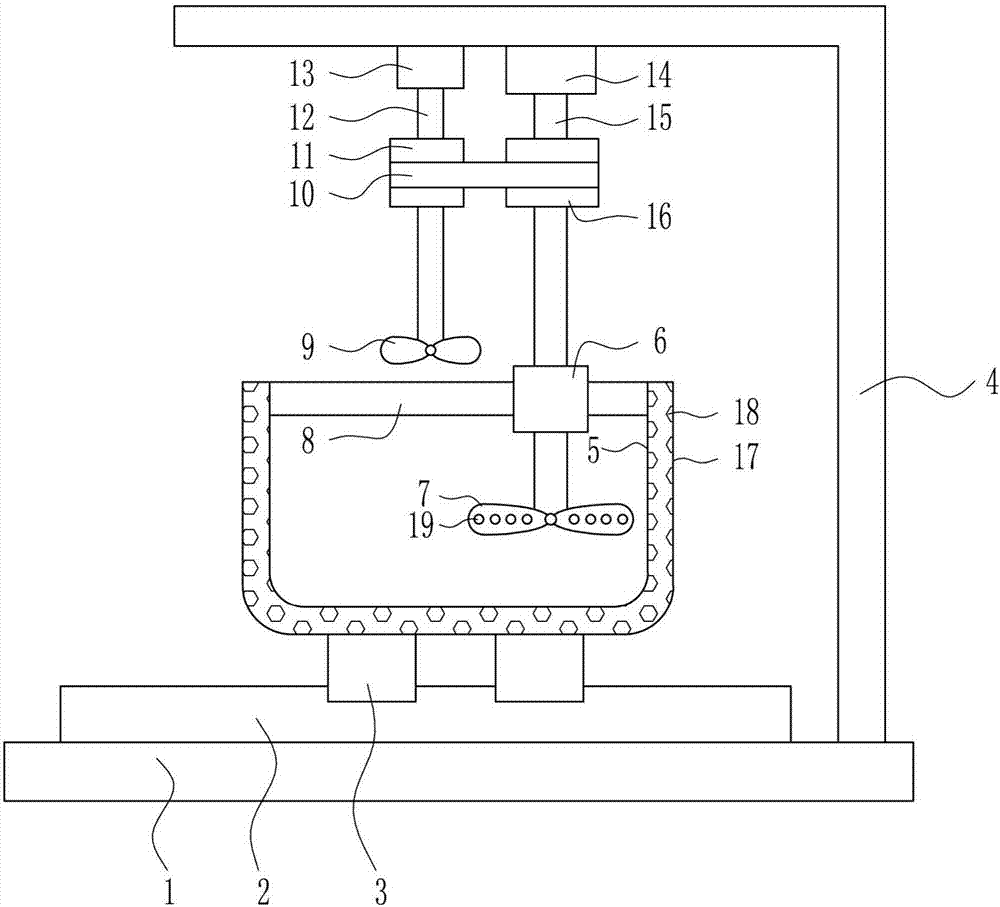

[0026] A chemical raw material mixing high-efficiency cooling device, such as Figure 1-3 As shown, it includes a base 1, a slide rail 2, a slider 3, a bracket 4, a processing tank 5, a gear 6, a stirring blade 7, a rack 8, a fan blade 9, a flat belt 10, a second pulley 11, and a second rotating shaft 12. Bearing housing 13, motor 14, first rotating shaft 15 and first pulley 16, the top of base 1 is connected with slide rail 2 by means of bolt connection, slide rail 2 is slidably connected with slide block 3, slide rail 2 and slide The block 3 cooperates, the top of the slider 3 is welded with a processing tank 5, the left and right sides of the inner wall of the processing tank 5 are connected with a rack 8 through bolt connection, the right side of the top of the base 1 is welded with a bracket 4, and the inner top of the bracket 4 passes through The bearing seat 13 and the motor 14 are connected by bolt connection, and the bearing seat 13 is located on the left side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com