Patents

Literature

245results about How to "Good mixing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

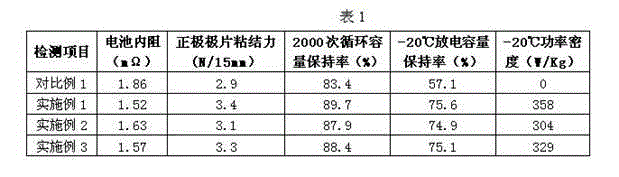

Lithium-ion power battery positive electrode material slurry preparation method

The present invention discloses a lithium-ion power battery positive electrode material slurry preparation method, which comprises mixing various components of a positive electrode material slurry, wherein the mixing specifically comprises: 1, using a three-shaft stirrer to carry out dry mixing on a positive electrode active substance, an electric conduction agent and a binder, 2, adding partial solvent to the three-shaft stirrer, and carrying out primary dispersion, and 3, transferring the dispersed slurry to a planetary stirrer, adding the remaining solvent, and carrying out secondary dispersion. According to the present invention, the dry mixing process is used, the solvent is gradually added to the solid powder, and the high solid content of the system is utilized to improve the dispersion effect; and the three-shaft stirrer and the planetary stirrer are combined so as to achieve the good mixing effect.

Owner:WANXIANG 123 CO LTD

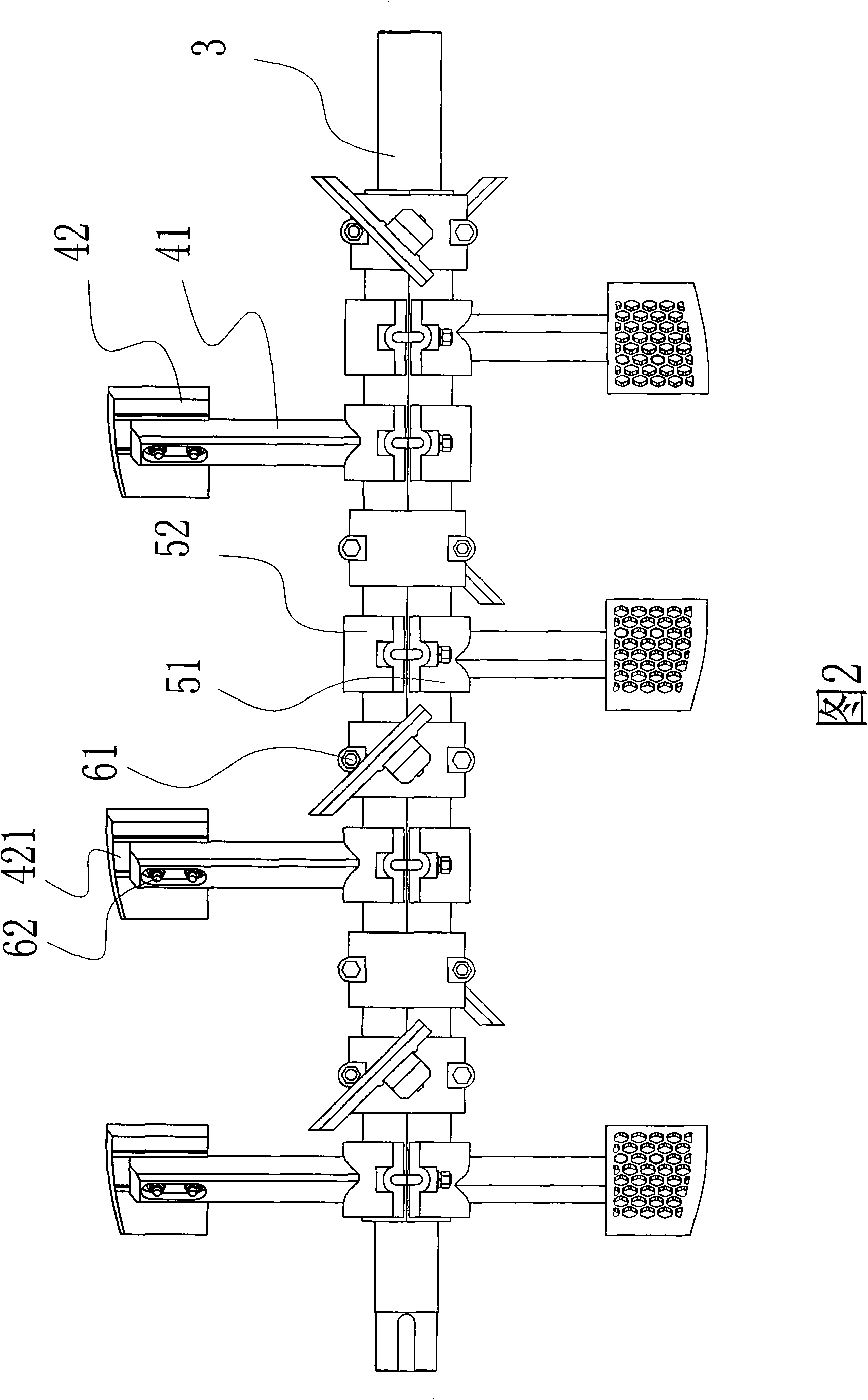

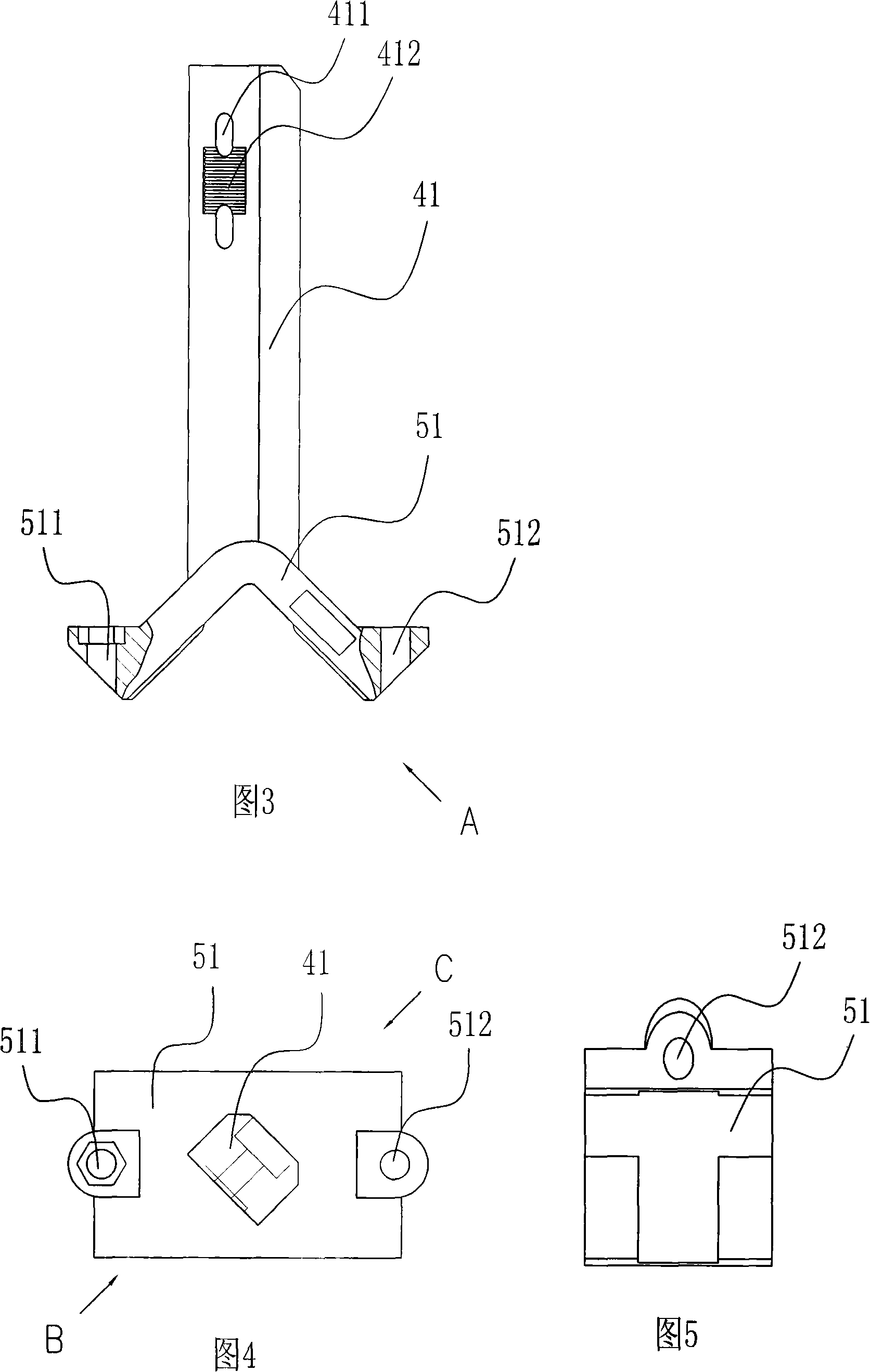

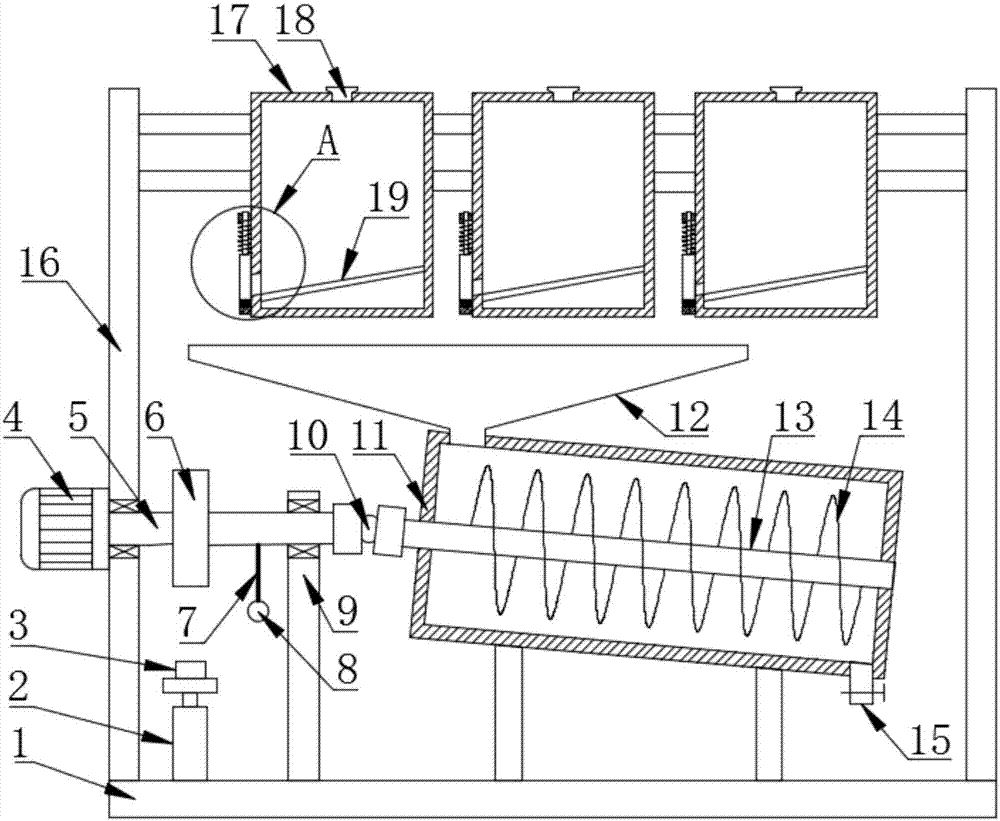

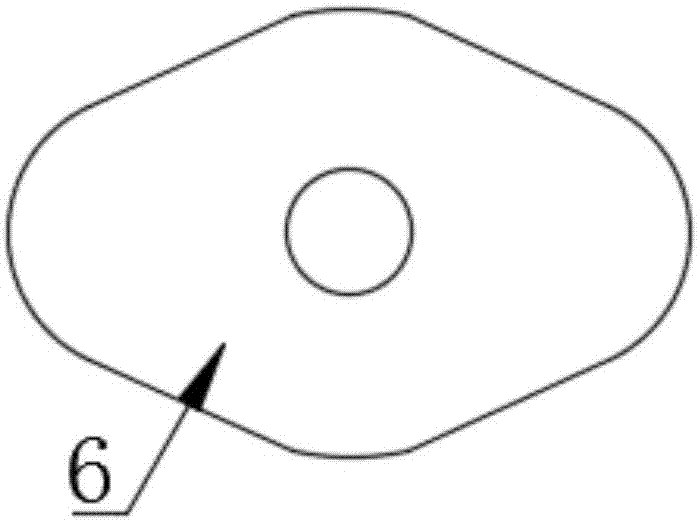

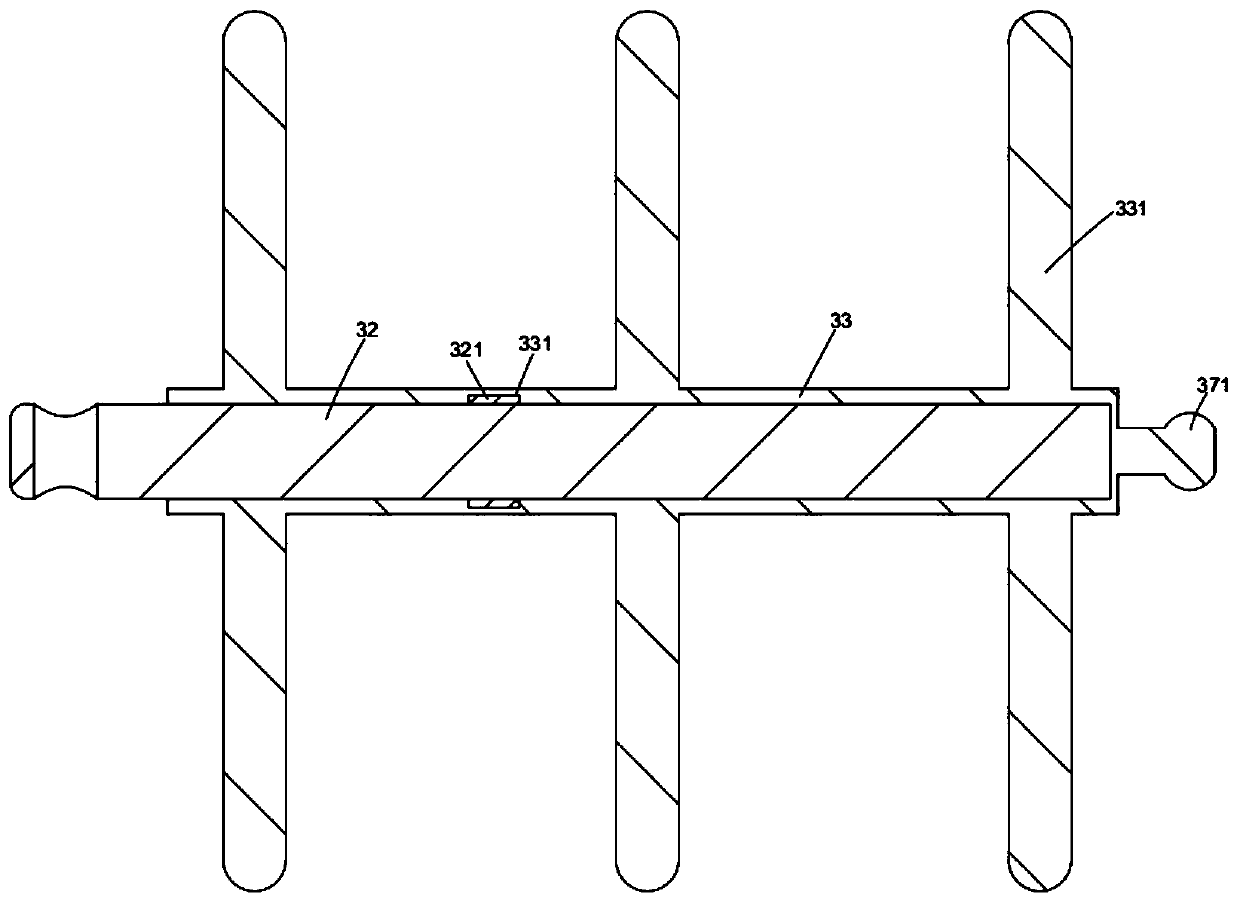

Forced action mixer with adjustable stirring unit

InactiveCN101323149AGood mixing effectImprove stirring efficiencyCement mixing apparatusFastenerBituminous concrete

A compulsory mixer provided with an adjustable mixing unit comprises a horizontal mixing cylinder body, a mixing shaft which can act as support rotationally along the axial direction and a plurality of mixing units which are spaced along the axial direction and arrayed in a screwed manner with deviating from the mixing shaft at different angles in sequence in the circumferential direction. The mixing unit comprises a mixing arm and a mixing blade. A mounting hole extending in the direction of length is arranged on the mixing arm. The mixing arm is connected with the mixing shaft by a dismountable sleeve. The mixing blade is flexibly fixed on the mixing arm by a fastening component that goes through the mounting hole. And a tooth part arranged between the mixing blade and the contact face of the mixing arm is used for locating the mixing blade and the contact face of the mixing arm. The intervals, installation angles and number of the mixing units can be adjusted according to the requirement for mixing. In addition, the mixing unit can be moved in the direction of the length of the mixing arm and the installation position of the mixing blade also can be adjusted, thus meeting the diversified demands placed on mixing asphalt concrete to achieve the best effect of mixing and highest mixing efficiency.

Owner:FUJIAN SOUTHERN HIGHWAY MECHANICAL

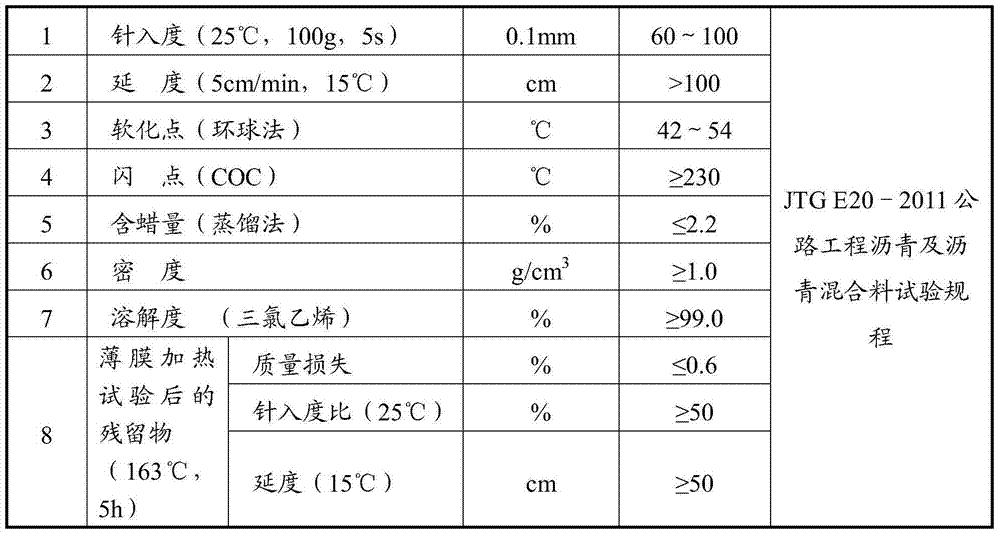

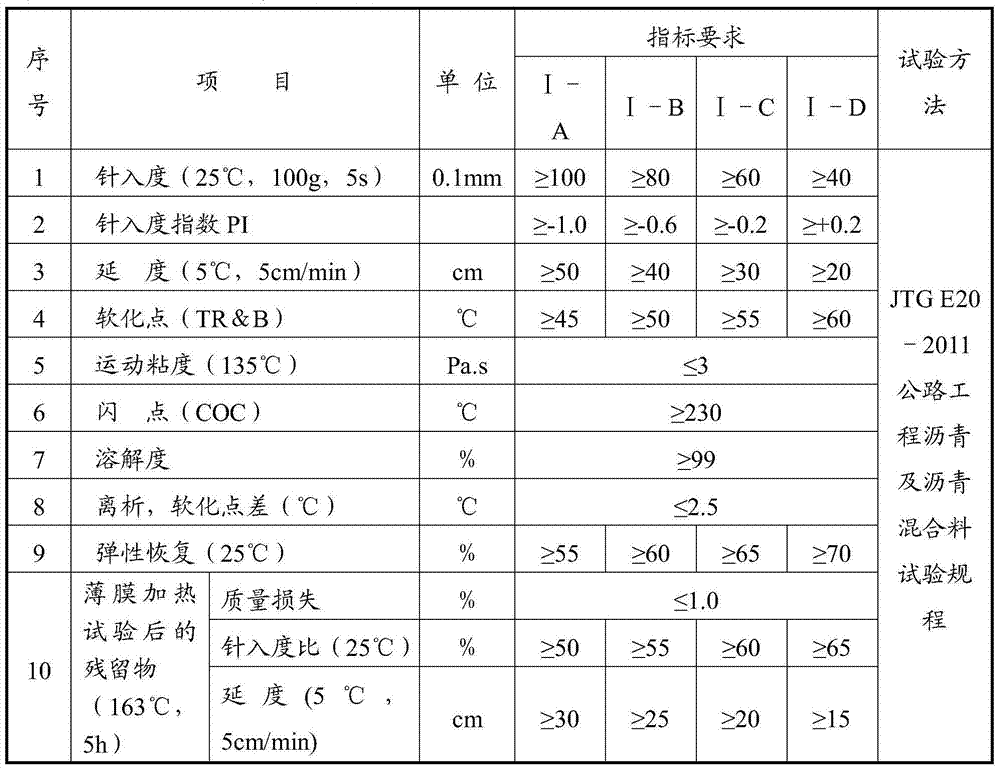

Emulsified asphalt for ballastless track cement emulsified asphalt mortar and preparation method of emulsified asphalt

InactiveCN104277462AGood mixing effectGood compatibilityBuilding insulationsPhenolsInorganic materials

The invention provides emulsified asphalt for ballastless track cement emulsified asphalt mortar and a preparation method of the emulsified asphalt. The emulsified asphalt contains 55-65 parts of matrix asphalt or modified asphalt, 35-45 parts of water, 1.0-3.0 parts of emulsifying agent, 0.05-0.8 part of stabilizer, 0.01-0.1 part of thickening agent, 0.1-2.0 parts of pH regulator and 0.1-1.5 parts of adjuvant. The emulsified asphalt provided by the invention has favorable stability and homogeneity and strong in temperature adaptability when being mixed with inorganic materials such as cement, sand and the like; and the emulsifying agent adopted in the preparation process of the emulsified asphalt provided by the invention does not contain nonyl phenol and derivatives thereof, so that the environment friendliness of the emulsified asphalt and a finished product prepared from the emulsified asphalt is achieved.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

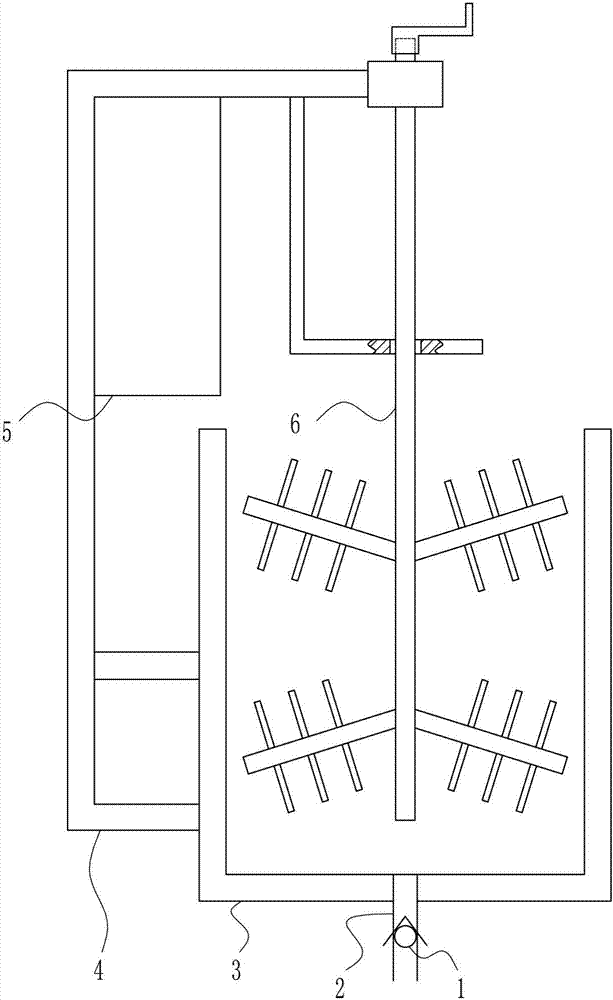

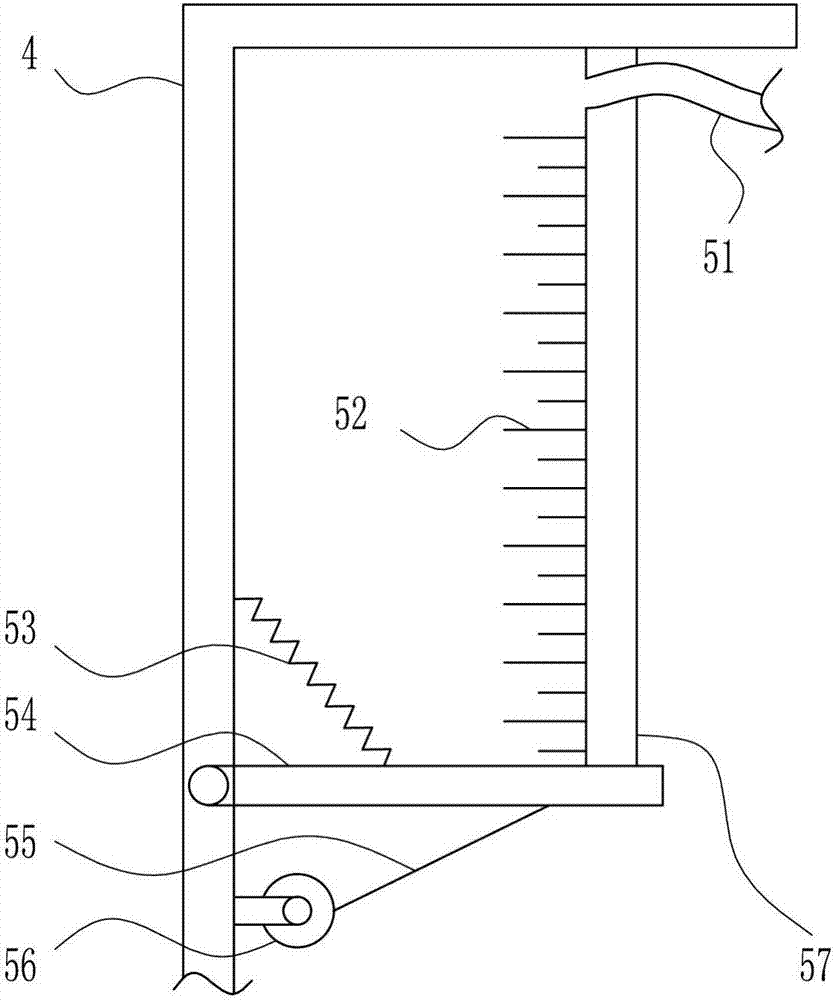

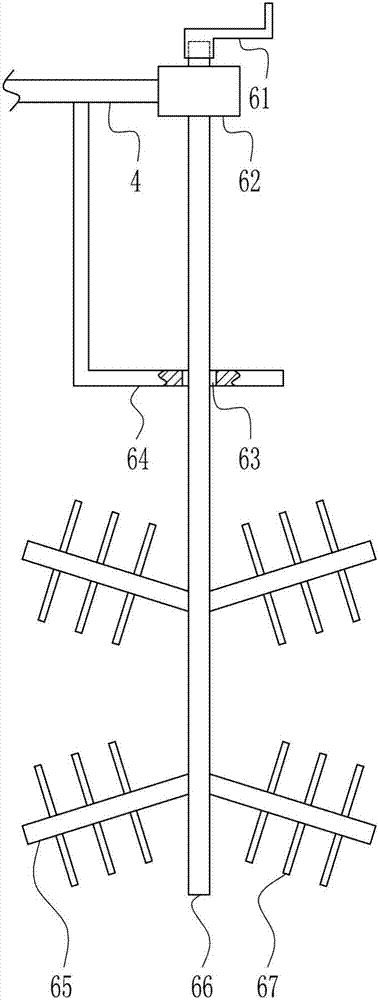

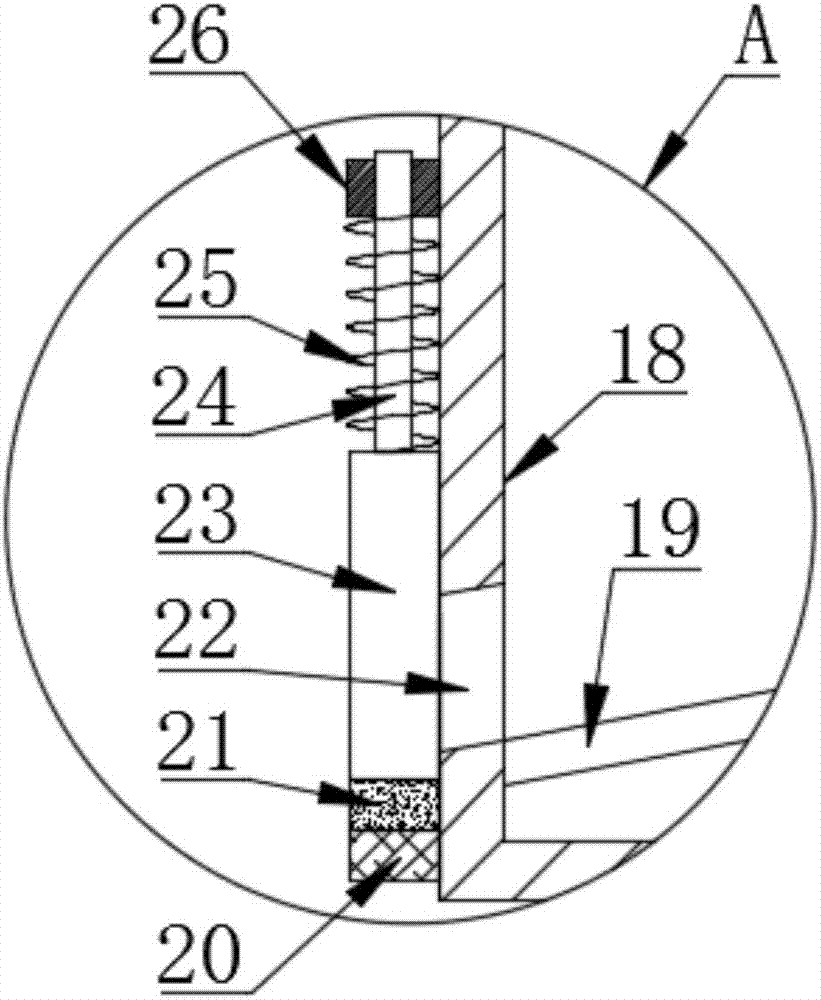

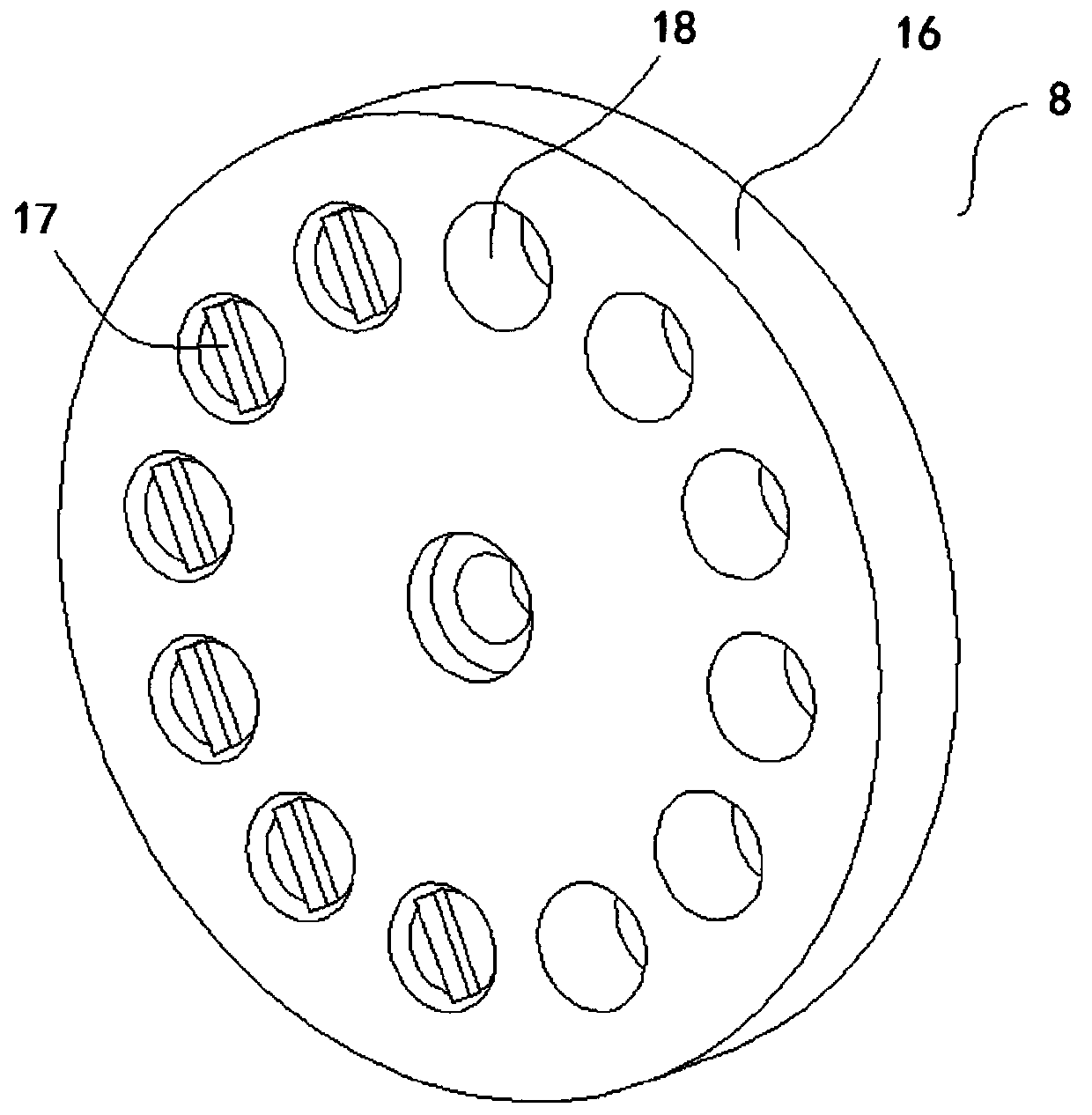

Dye preparing device for leather dyeing

InactiveCN106890597AGood mixing effectEvenly preparedRotary stirring mixersTransportation and packagingSolventDyeing

The invention relates to dye preparing devices, in particular to a dye preparing device for leather dyeing. The dye preparing device comprises a one-way valve, a water discharge pipe, a preparing box, a support, a preparing device, a stirring device and the like, wherein the preparing device and the stirring device are arranged at the top of the support, the preparing device is located on the left of the stirring device, the preparing box is connected to the right end of the lower portion of the support, the water discharge pipe is connected to the middle of the bottom of the preparing box, and the one-way valve is arranged on the water discharge pipe. The dye preparing device has the advantages that a preparing solvent can be measured precisely, a prepared dye solution is even and fine and smooth, the dye solution is high in homogenizing degree and is evenly mixed, and high preparing efficiency and preparing accuracy are achieved.

Owner:翁帆安

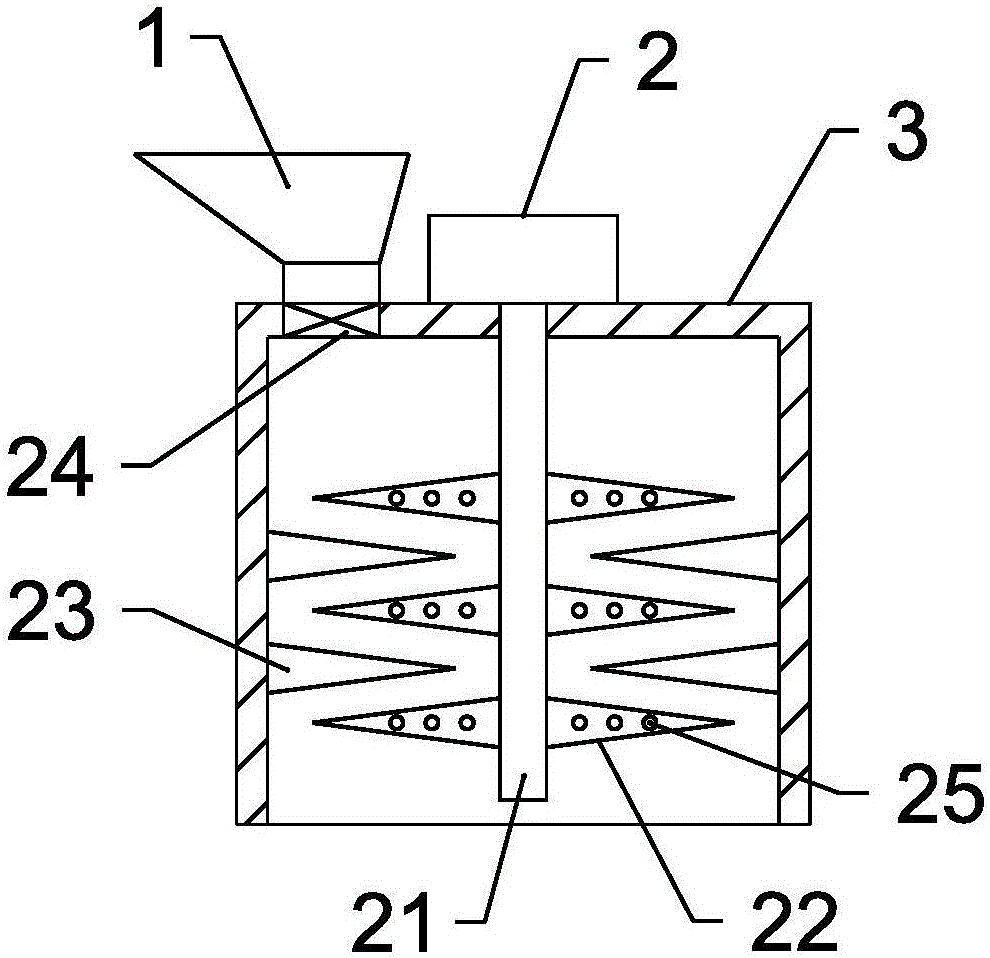

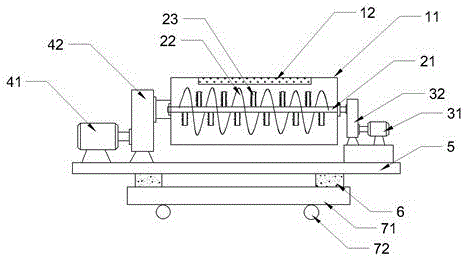

Uniform pellet feed fixed-ratio mixing device

InactiveCN107983195AGood mixing effectWell mixedFeeding-stuffTransportation and packagingMotor shaftEngineering

The invention discloses a uniform pellet feed fixed-ratio mixing device which comprises a base, wherein a mixing box is fixedly arranged on the top of the base by virtue of a bracket; a second rotating shaft in rotational connection with left and right walls of the mixing box is arranged in the mixing box; the left end of the second rotating shaft extends out of the mixing box; screw blades are fixedly connected onto the second rotating shaft and positioned in the mixing box; supporting plates are fixedly arranged on the left and right sides of the top of the base; a gear motor is fixedly arranged on the left side wall of the left supporting plate; a motor shaft at the right end of the gear motor penetrates through the left supporting plate to be connected with a first rotating shaft; andthe right end of the first rotating shaft is connected with the left end of the second rotating shaft by virtue of a universal coupling. According to the device disclosed by the invention, the feed isdriven to move from side to side by virtue of rotation of the screw blades; when the feed is driven to move to the left by virtue of the rotation of the screw blades, the feed is driven to roll, andthe stirring effect; and when the feed is driven to move to the right by virtue of the rotation of the screw blades, the feed can be rapidly discharged out of a discharge pipe, and the processing efficiency is improved.

Owner:季梅

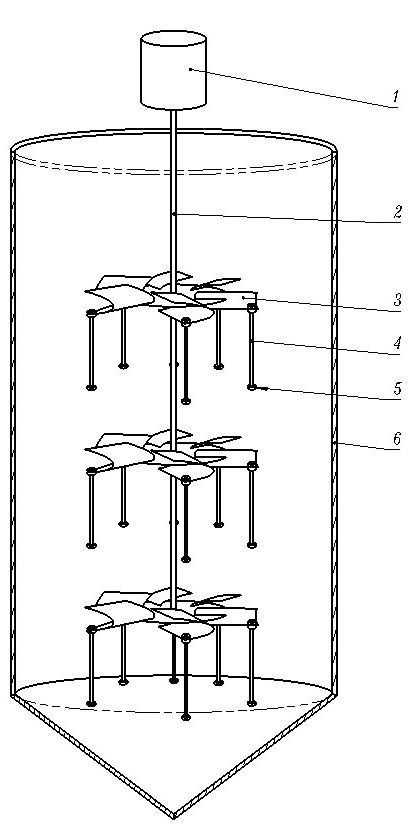

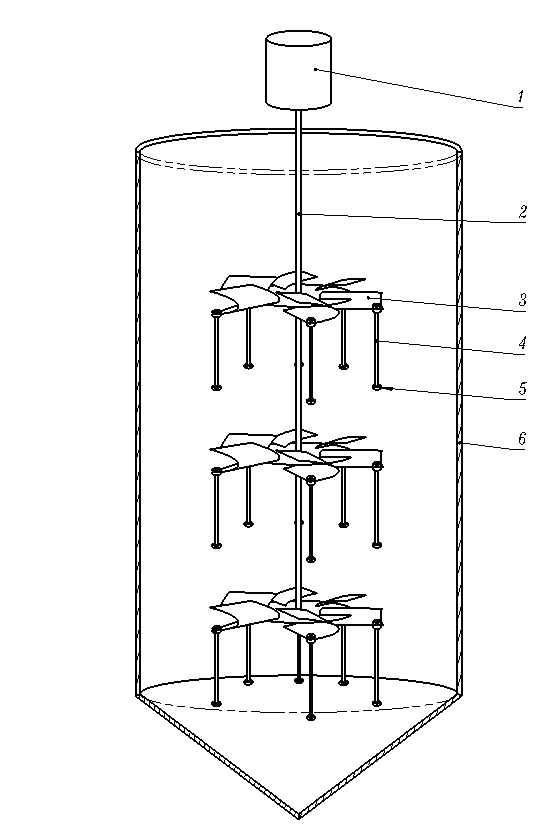

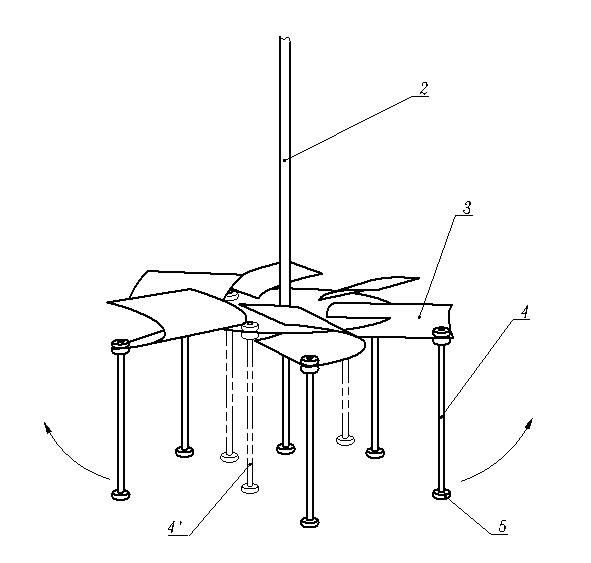

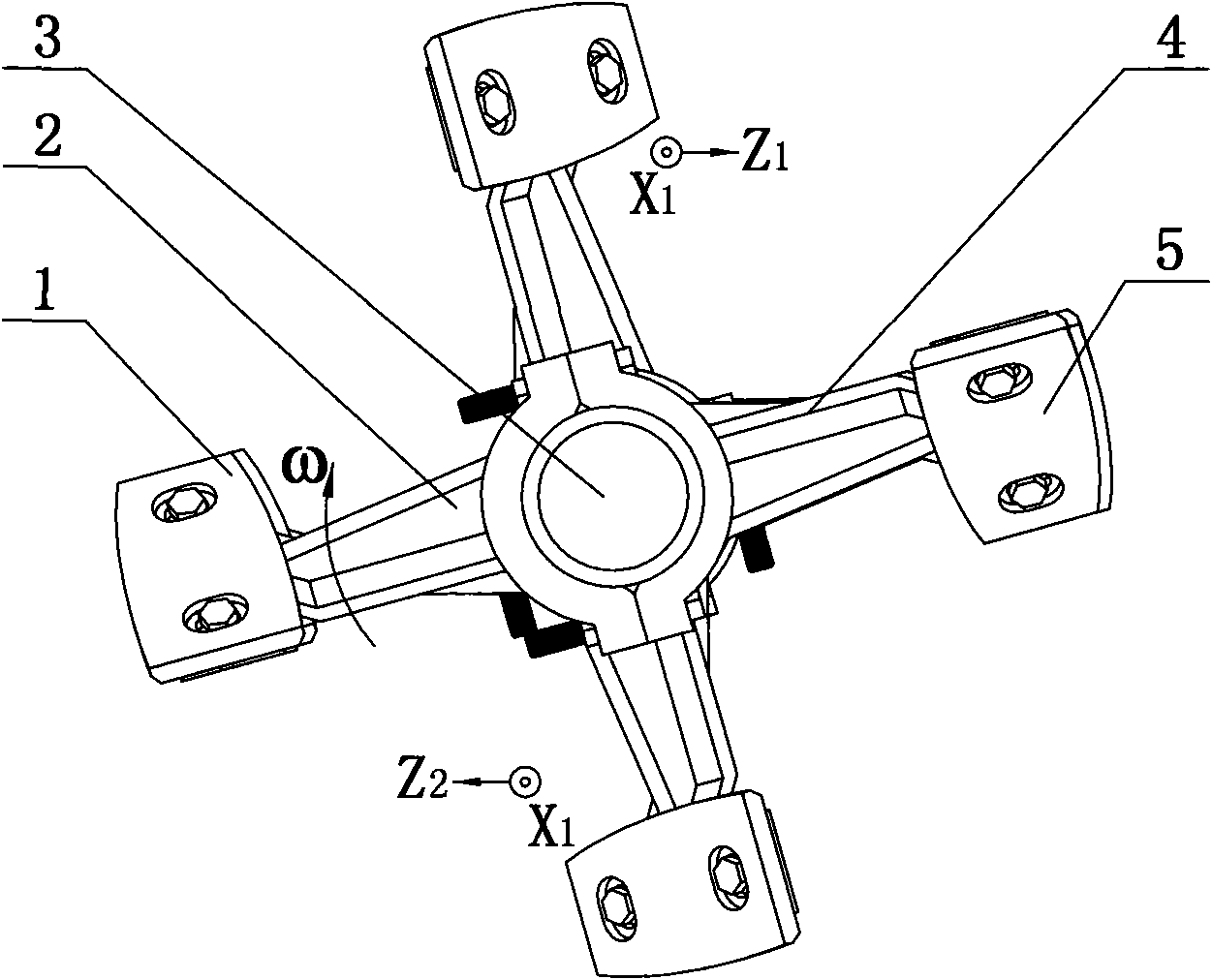

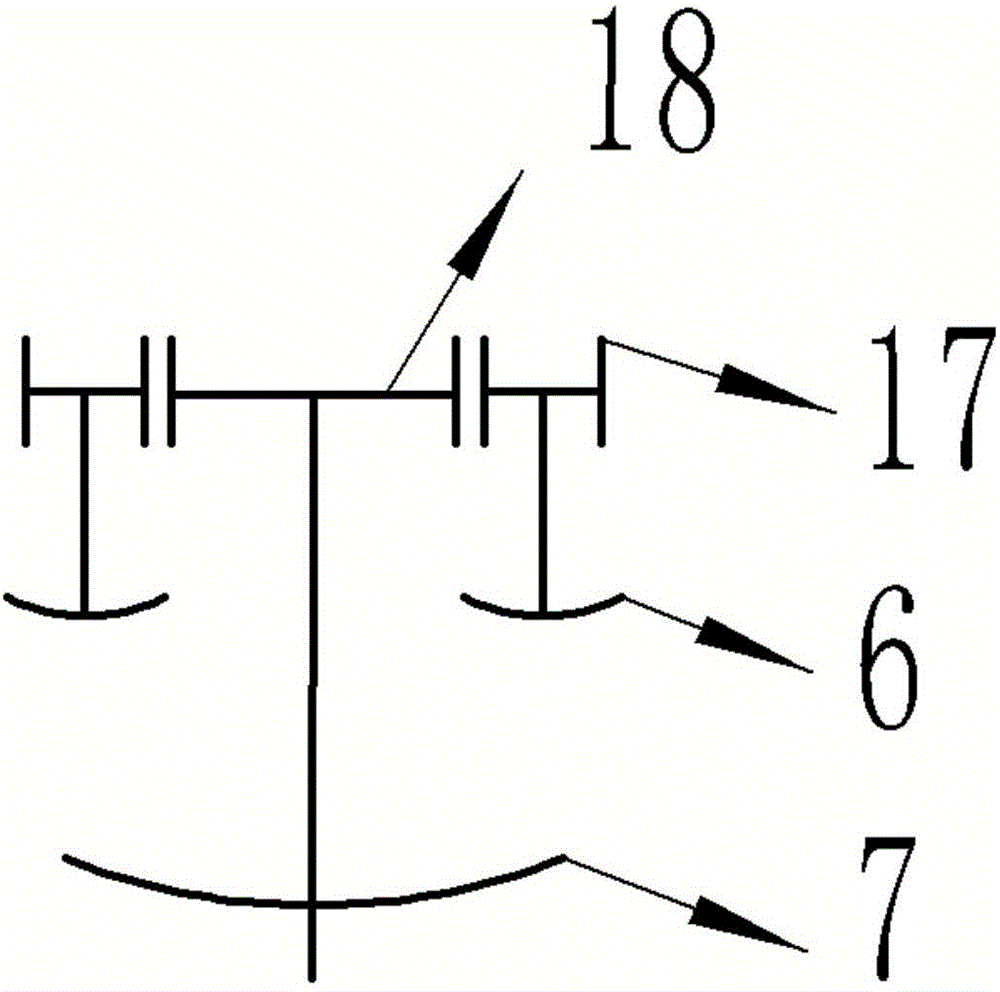

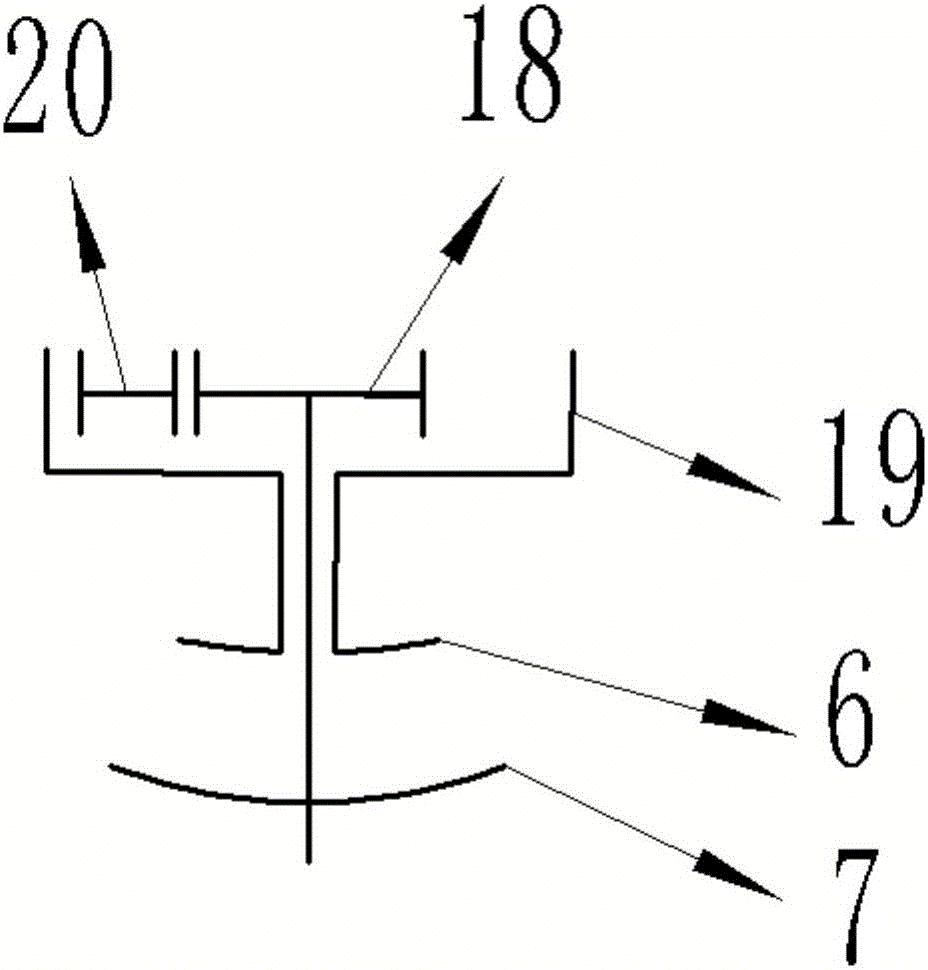

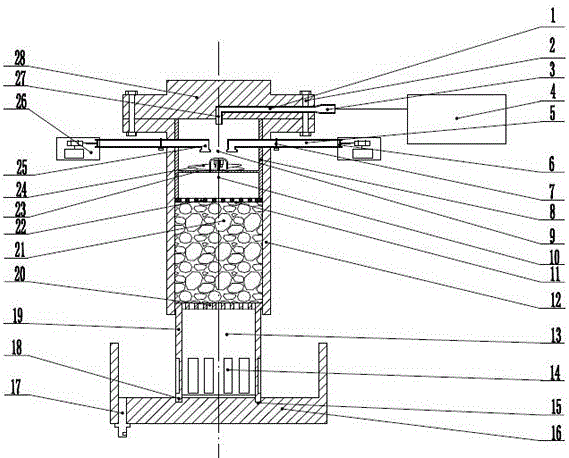

Agitator blade for improving leaching rate of metal manganese electrolyte

InactiveCN102094118AGood mixing effectHigh extraction rateRotary stirring mixersProcess efficiency improvementLeaching rateEngineering

The invention discloses an agitator blade for improving the leaching rate of metal manganese electrolyte. A plurality of layers of agitator blades are arranged, and are fixedly arranged on an agitating shaft coaxial with a leaching groove for the metal manganese electrolyte. The outer end of each agitator blade in each layer of agitator blades is fixedly suspended with a flexible belt; the length of the flexible belt of the agitator blade positioned on the upper layer meets the conditions that: the flexible belt in the vertical state cannot be scratched by the agitator blade on the lower layer, and when the flexible belt is unfolded due to centrifugal force and rotates in ore pulp, the flexible belt cannot be scratched by the side wall of the leaching groove; and the length of the flexible belt of the agitator blade positioned at the lowest layer meets the conditions that: the flexible belt in the vertical state cannot be scratched by a corresponding part at the bottom of the leaching groove, and when the flexible belt is unfolded due to centrifugal force and rotates in the ore pulp, the flexible belt cannot be scratched by the side wall of the leaching groove. The agitator blade can eliminate stirring dead zones under the condition of not increasing energy consumption basically, so the leaching rate of the metal manganese electrolyte can be improved. The agitator blade has the advantages of simple structure and low equipment cost.

Owner:CHONGQING UNIV

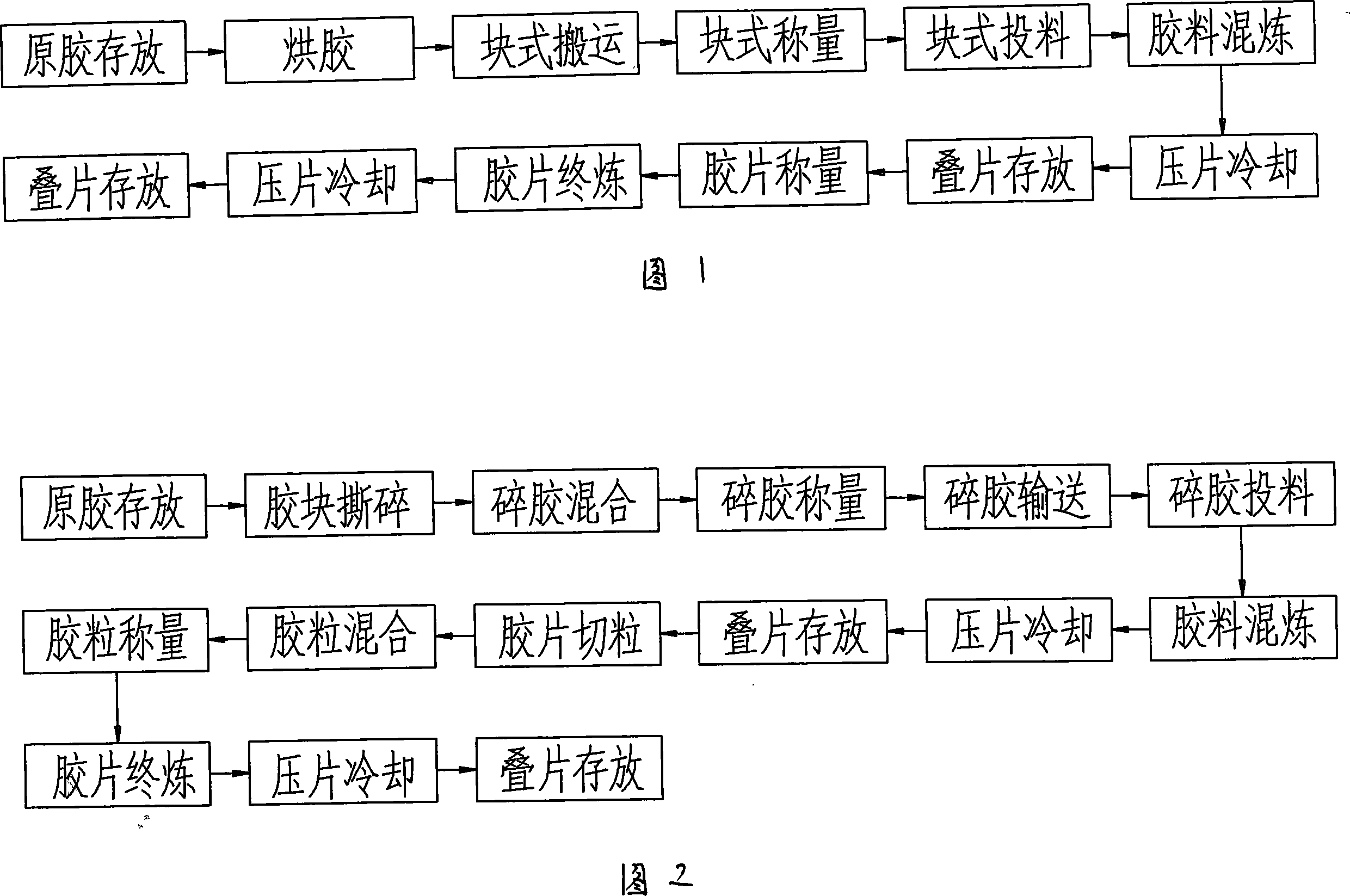

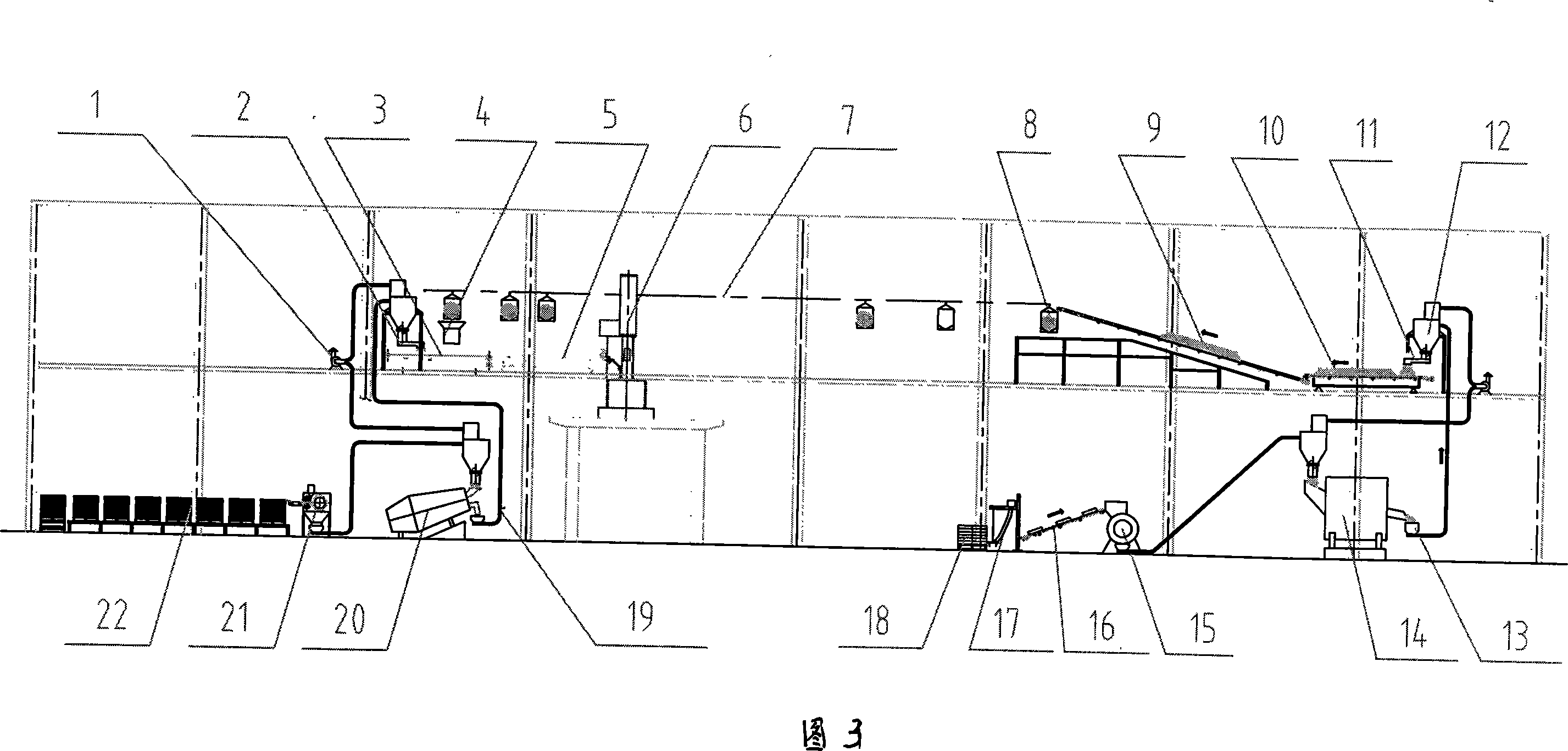

Broken glue feeding rubber mixing technique

ActiveCN101214705AStable and uniform qualityIncrease the level of automationRubber materialEngineering

The present invention relates to a cuttings-feeding rubber mixing technique, which belongs to the field of rubber-processing machines. The technique includes the following steps: (1) the storage of raw rubber, (2) the ripping of rubber blocks, (3) the weighing of cuttings, (4) the conveying of the cuttings, (5) the charging of the cuttings, (6) the mixing of the rubber material, (7) sheeting and cooling, (8) the stacking and storing of rubber sheets, (9) the granulating of the rubber sheets, (10) the mixing of rubber particles, (11) the weighing of the rubber particles, (12) the final mixing of rubber sheets, (13) sheeting and cooling, and (14) the stacking and storing of the rubber sheets. By the ripping of the rubber blocks, the granulating of the mother rubber sheets and two times of uniform mixings, the present invention realizes the uniform mixings of multiple batches of materials, so that the quality of the rubber material is more uniform and stable, and therefore the banburying effect is more ideal, and the following effects are achieved: The uniformity and stability of rubber mixing is improved, the efficiency of rubber mixing is increased, the impact damage of equipement is abated, and the automatization degree of material flowing is increased.

Owner:TRIANGLE TIRE

Comprehensive processing device for coal ash recycling

The invention discloses a comprehensive processing device for coal ash recycling. The comprehensive processing device for coal ash recycling comprises a smashing box, a comprehensive processing box, an impurity box and a stirring box. The smashing box is arranged on the left side of the top of the comprehensive processing box in a communication manner. The stirring box is arranged in the middle of the bottom of the comprehensive processing box in a communication manner. The internal right end of the comprehensive processing box inclined downwards to be provided with a vibrating sieve. The upper side of the right end of the vibrating sieve is provided with an impurity pipe in a communication manner on the side wall of the comprehensive processing box, and the right end of the impurity pipe is connected with the impurity box. A plurality of air inlet branch pipes are arranged on the right side of the top of the comprehensive processing box in a communication manner and communicate with an air inlet header pipe. Water inlet pipes are arranged on the bottom of the left side and the bottom of the right side of the comprehensive processing box. A guide plate is arranged on the lower portion of the interior of the comprehensive processing box, and a plurality of supporting springs are arranged on the outer circle of the comprehensive processing box. The comprehensive processing device is used for comprehensively processing the coal ash, is good in smashing and stirring effect and capable of sieving, filtering and removing impurities, carrying out drying and pulping operation, has multiple purposes and is beneficial to popularization.

Owner:HEFEI ZHIHUI LONGTUTENG INTPROP CO LTD

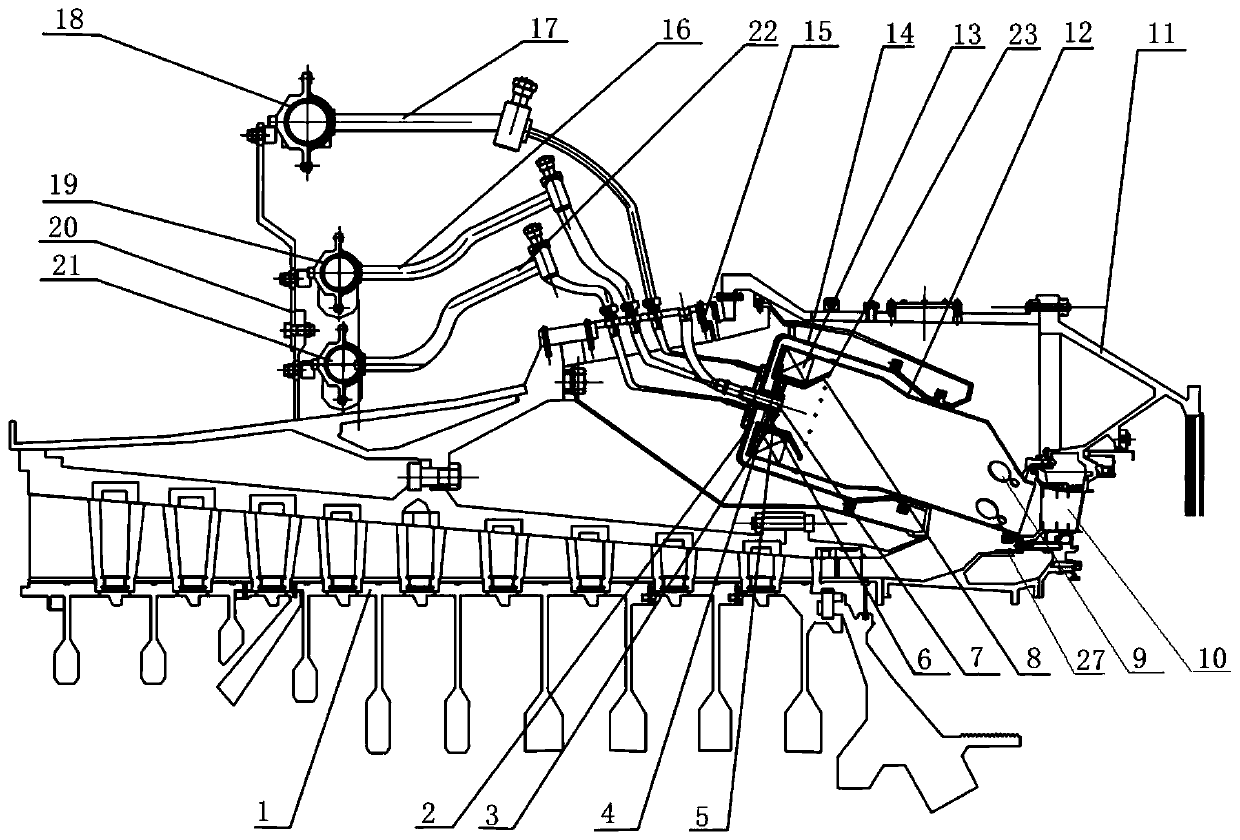

Gas turbine low-emission combustion chamber using gas fuels

InactiveCN110131750AReduced flow areaGood mixing effectContinuous combustion chamberAutomotive engineeringCombustion chamber

The invention discloses a gas turbine low-emission combustion chamber using gas fuels, and belongs to the technical field of gas turbines. The combustion chamber comprises an on-duty grade, a main combustion grade, a high-pressure igniter, a mixing hole, an exhaust outlet, a bearing machine box, a flame cylinder, the flame cylinder outer machine box, a flange, a first on-duty grade gas fuel pipeline, a main combustion grade gas fuel pipeline, a main combustion grade fuel main pipe, a first on-duty grade fuel main pipe, a pipeline bracket, a second on-duty grade fuel main pipe, a second on-dutygrade gas fuel pipeline, an air conditioning device, a first on-duty grade fuel tank, a second on-duty grade fuel tank and a main combustion grade fuel tank; when a gas turbine is started in low-loadstates, only the on-duty grade works; when the gas turbine is started in high-load states, the on-duty grade and the main combustion grade work together; and through diffusion combustion of on-duty grade fuels, a stable ignition source is provided to a main combustion area, so that the low emission requirement is guaranteed, the combustion stability and the combustion efficiency are fully considered, and the performance requirements of the combustion chamber are comprehensively met.

Owner:SHENYANG AEROSPACE UNIVERSITY

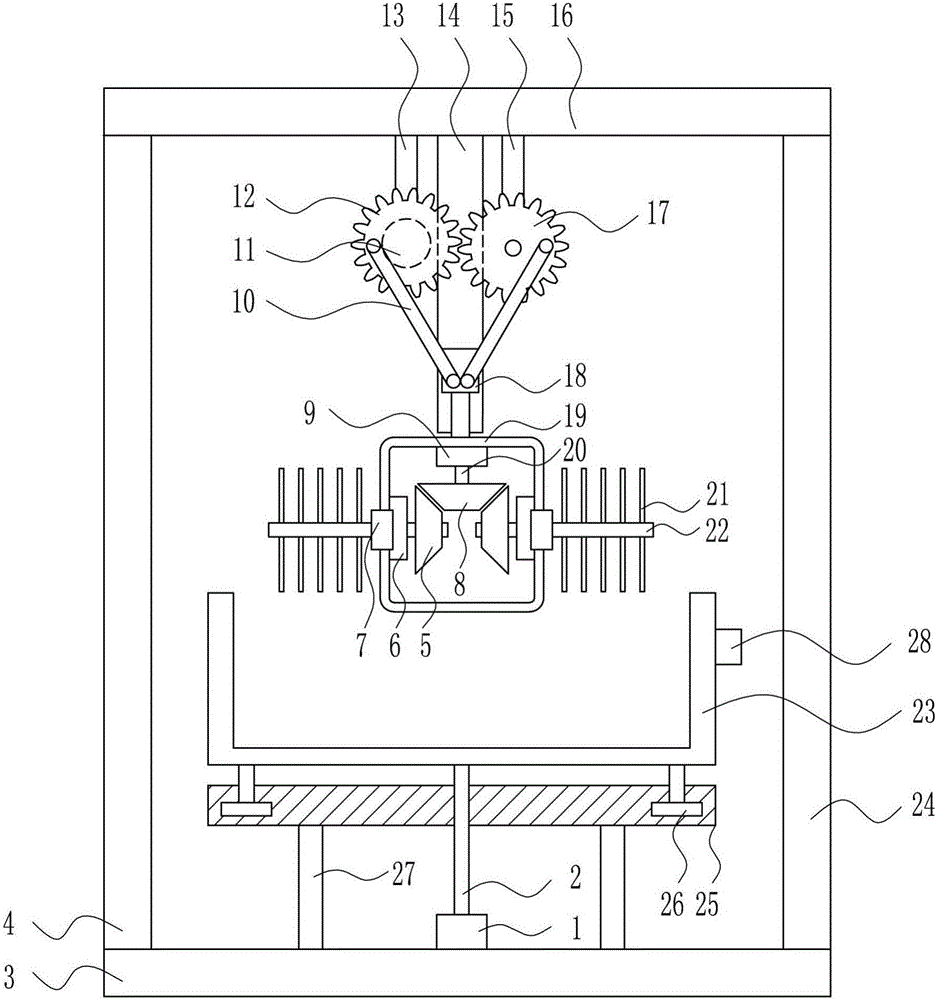

Raw material quantitative mixing equipment for refractory brick production

InactiveCN110721618AGood mixing effectWell mixedShaking/oscillating/vibrating mixersTransportation and packagingPistonEngineering

The invention provides raw material quantitative mixing equipment for refractory brick production. The raw material quantitative mixing equipment comprises a base and a material mixing barrel, whereina stirring assembly, a power assembly and a material falling assembly are arranged on the material mixing barrel, the stirring assembly comprises a rotating shaft, a stirring rod and a guide groove,the power assembly comprises a transmission member and a driving member, the material falling assembly comprises a sliding member, a material storage member and a material control member, the transmission member is in transmission connection with the driving member and a stirrer, the driving member drives the sliding member to perform reciprocating motion, and the material control member controlsa material discharging member arranged on the sliding member to fall a material. According to the invention, the material falling assembly is driven by the power mechanism assembly to do reciprocatingmotion, the piston is matched with the material blocking plate to extrude the raw material in the quantitative material cylinder into the material mixing barrel, the power assembly drives the rotating shaft in the material mixing barrel to rotate, and the gear and the gear rack a are matched to drive the stirring rod to do circumferential motion along with the up-down fluctuation of the rotatingshaft and can rotate, so that the technical problems that automatic quantitative feeding cannot be achieved and raw materials are mixed unevenly in the prior art are solved.

Owner:长兴县威尔特耐火材料有限公司

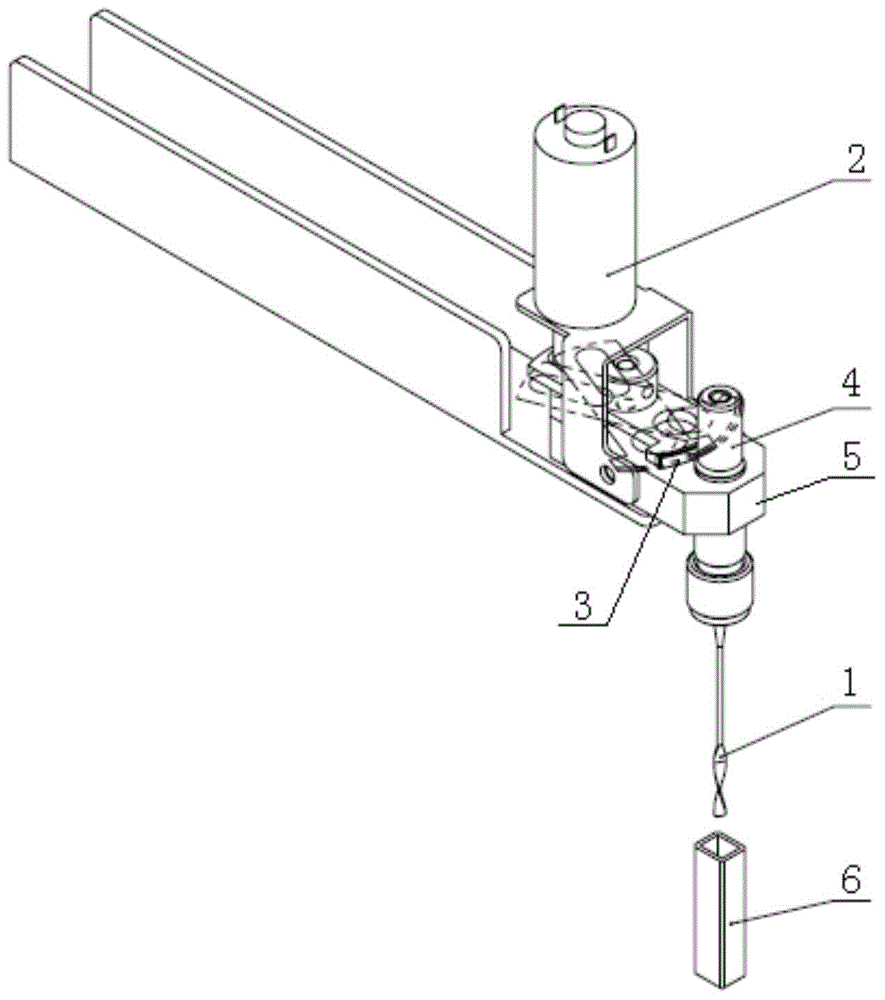

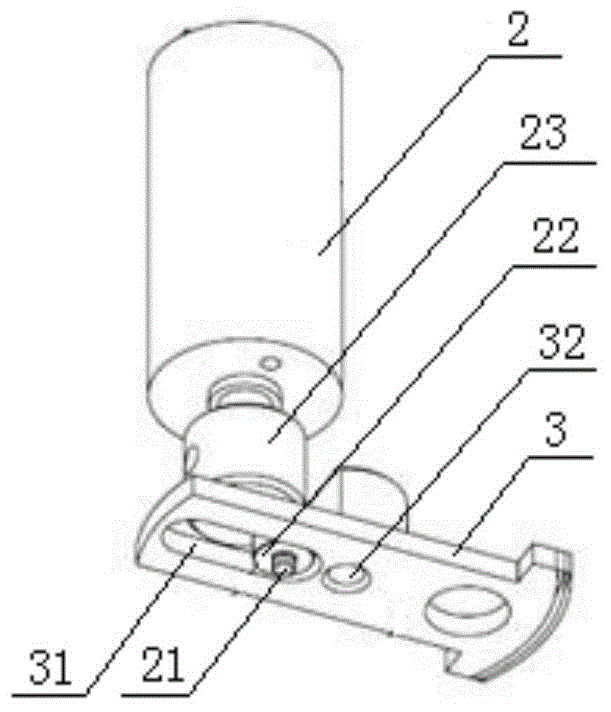

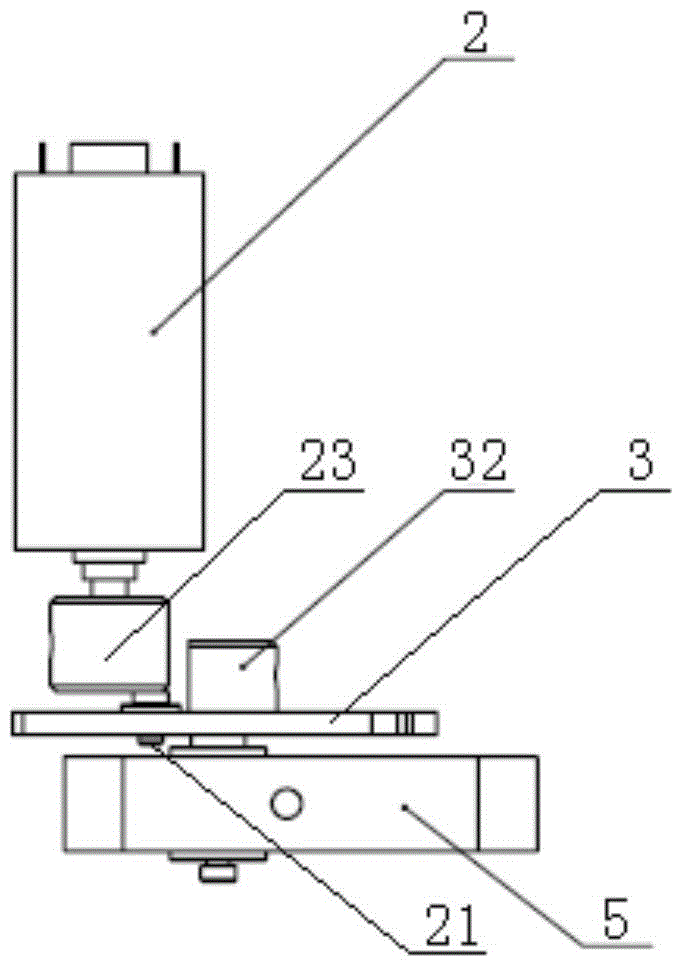

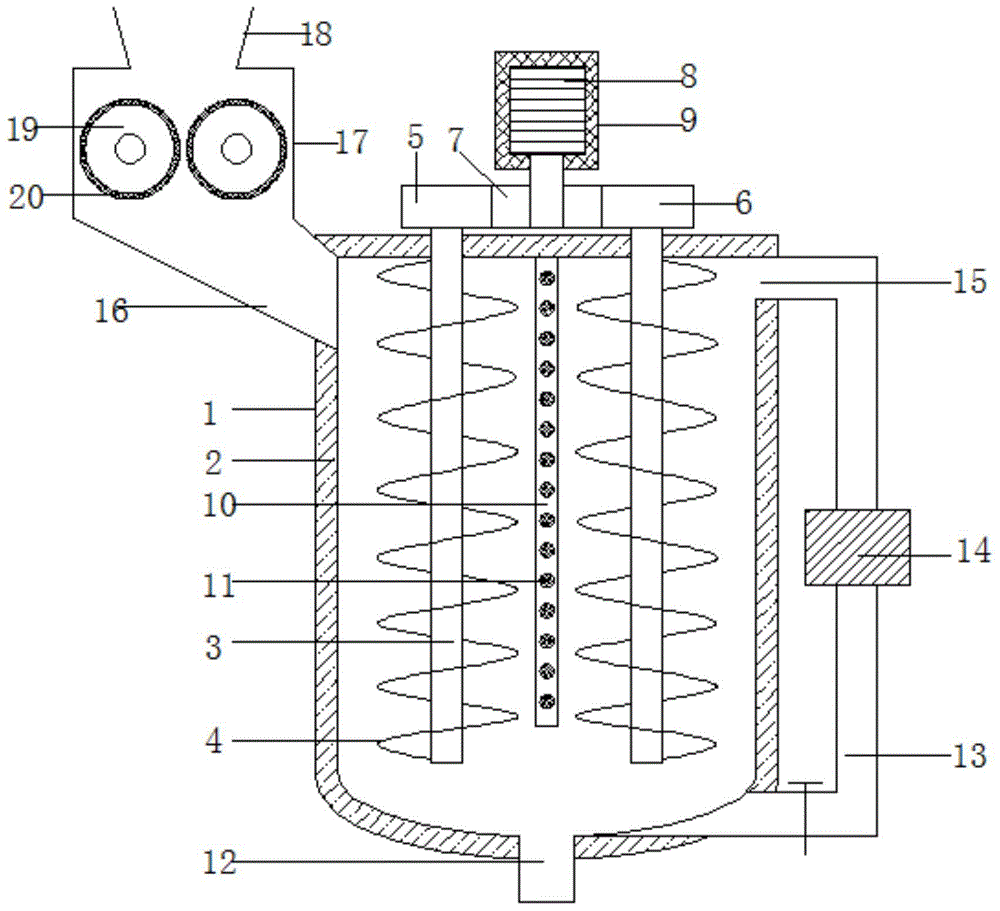

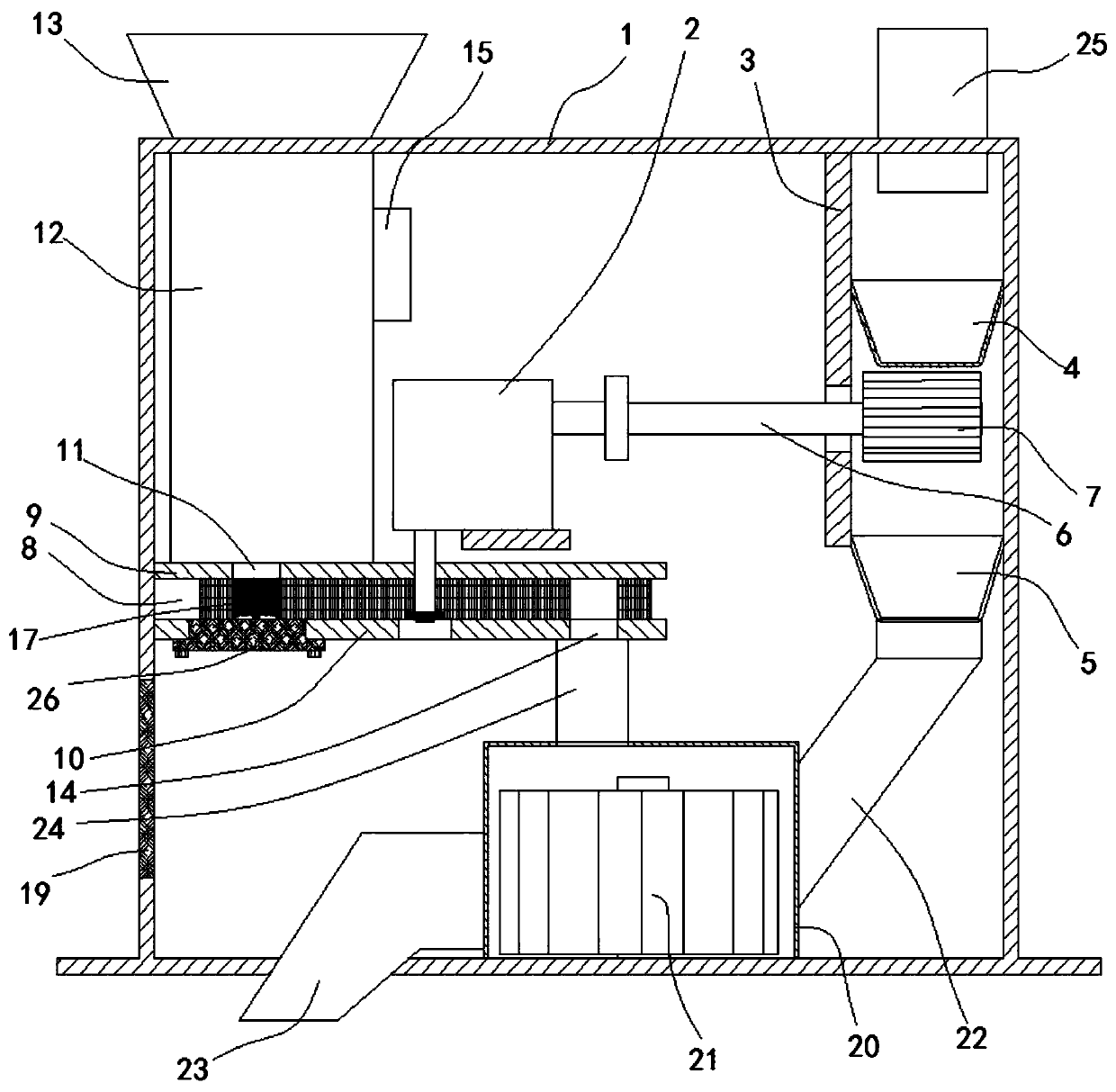

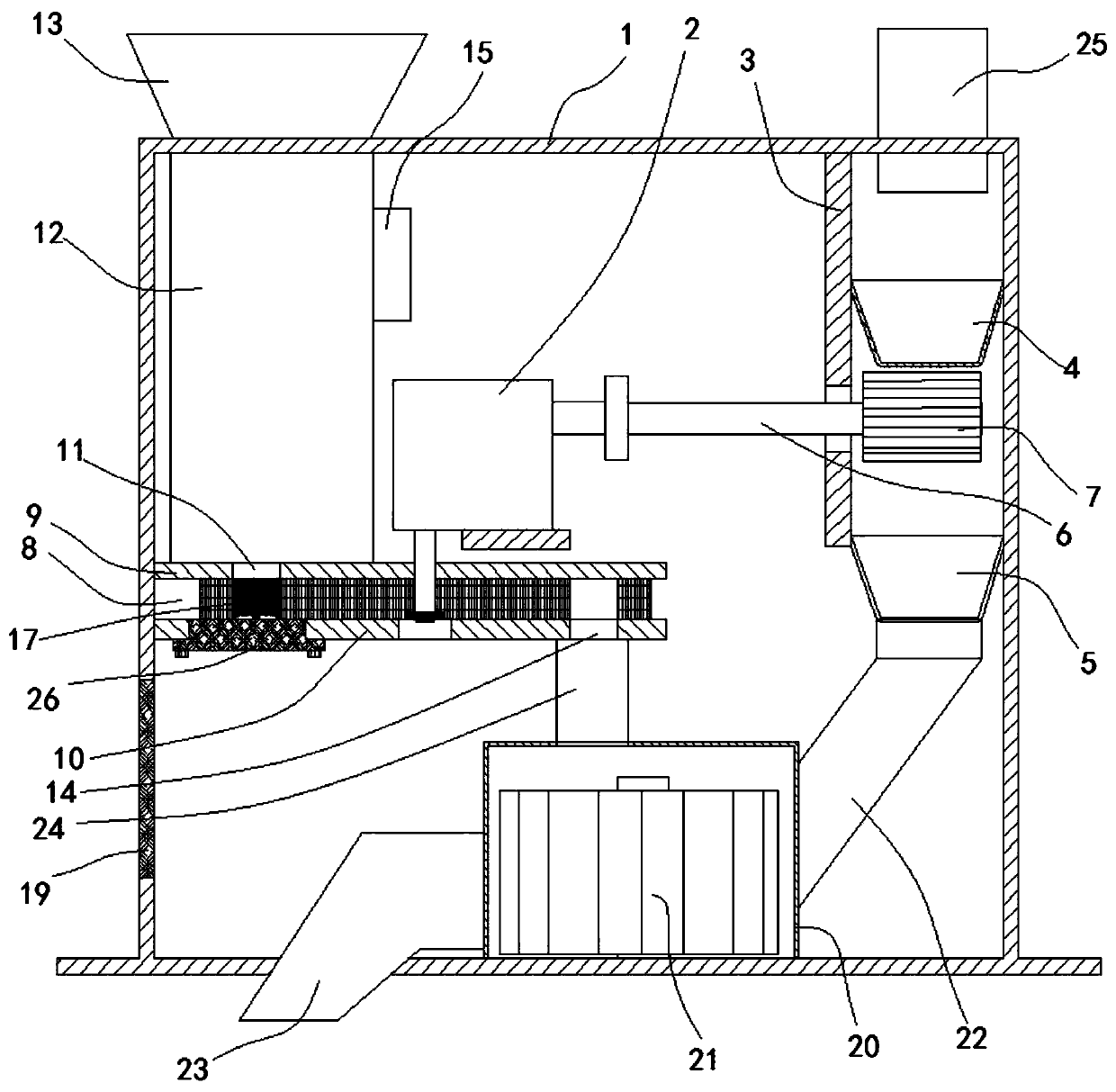

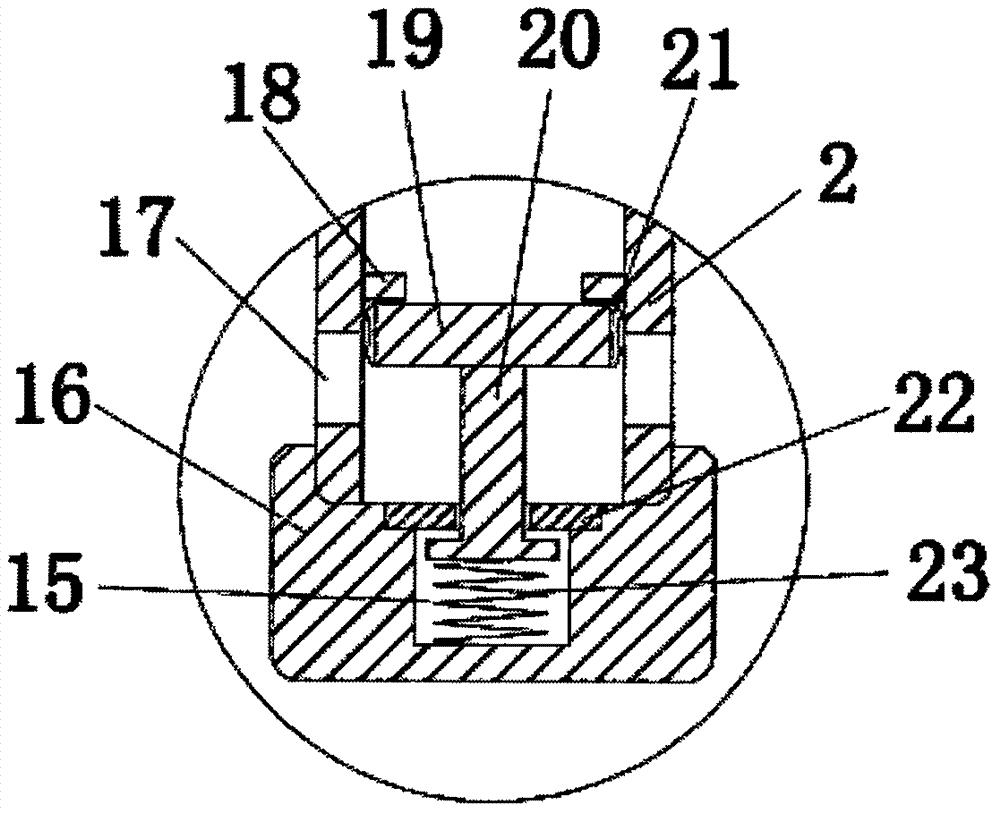

Full-automatic biochemical analyzer and stirring device thereof

ActiveCN103913584AImprove stirring efficiencyGood mixing effectRotary stirring mixersMixer accessoriesEngineering

The invention provides a full-automatic biochemical analyzer and a stirring device thereof. The stirring device has a good stirring effect and relatively high stirring efficiency. The stirring device provided by the invention comprises a stirring paddle and a stirring motor. The stirring motor is connected with a swing member swinging reciprocatingly with the rotation of the stirring motor. The stirring paddle is provided with a drive member for driving the rotation of the stirring paddle. The swing member is connected to the drive member. The reciprocating swing of the swing member drives the drive member to make forward and backward bi-directional rotation. In the stirring device provided by the invention, the stirring motor is connected to the drive member of the stirring paddle through the swing member, so that the stirring motor can drive the swing member to swing reciprocatingly without changing the rotation direction of the stirring motor, so as to change the rotation direction of the drive member, realize bi-directional driving of the drive member and further drive the stirring paddle to bi-directionally rotate and stir, thereby increasing stirring efficiency and achieving a better stirring effect.

Owner:东软威特曼生物科技(沈阳)有限公司

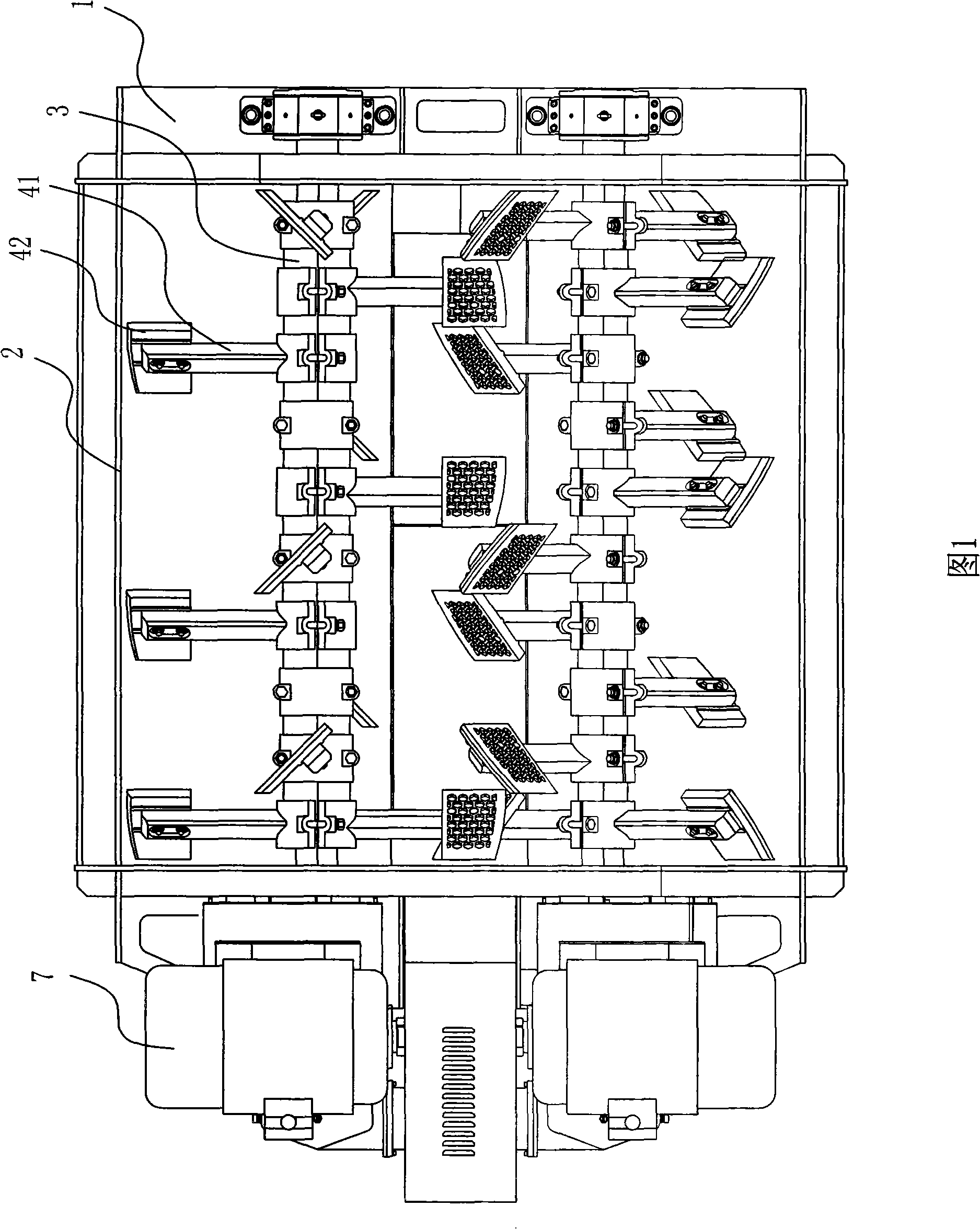

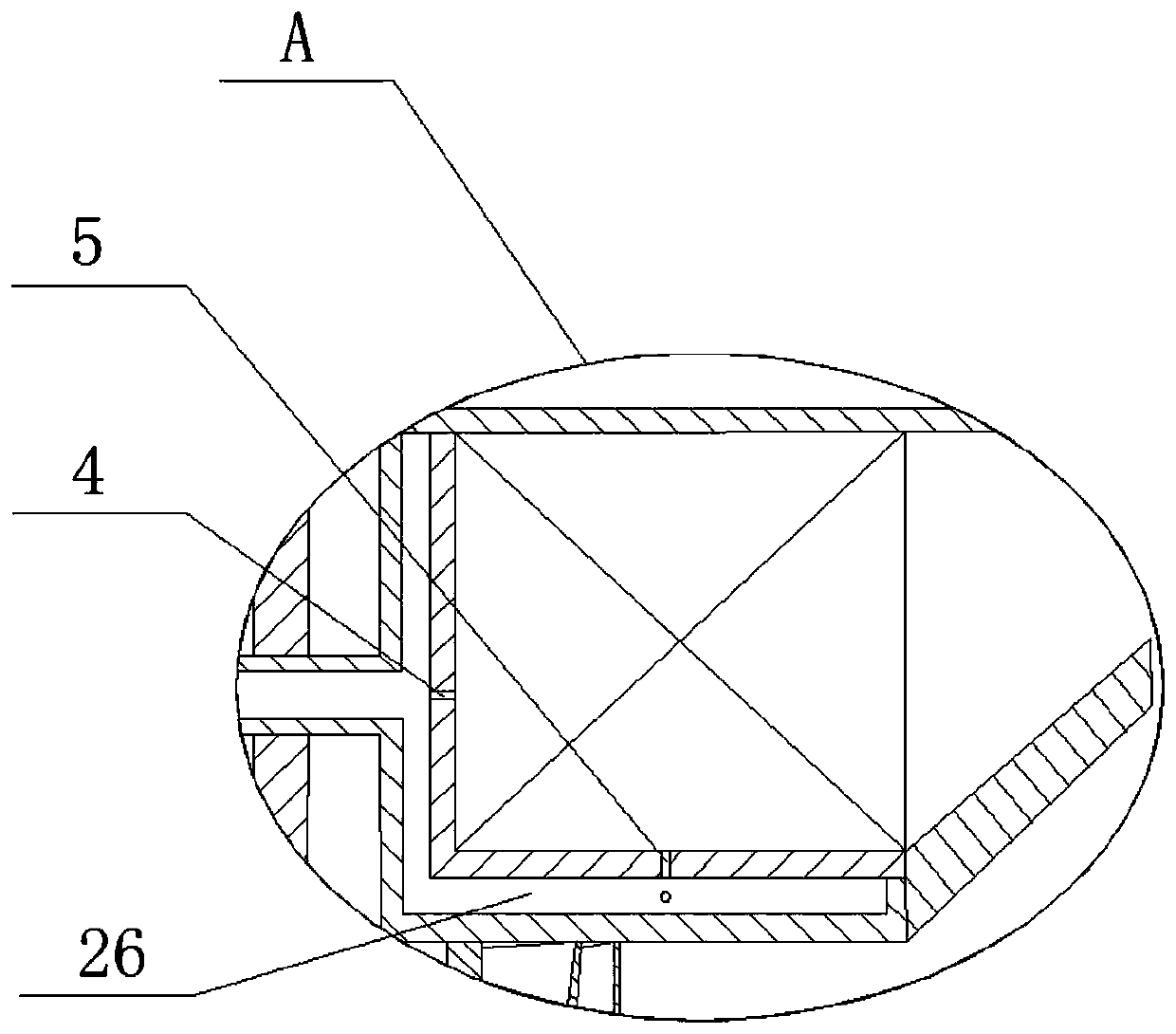

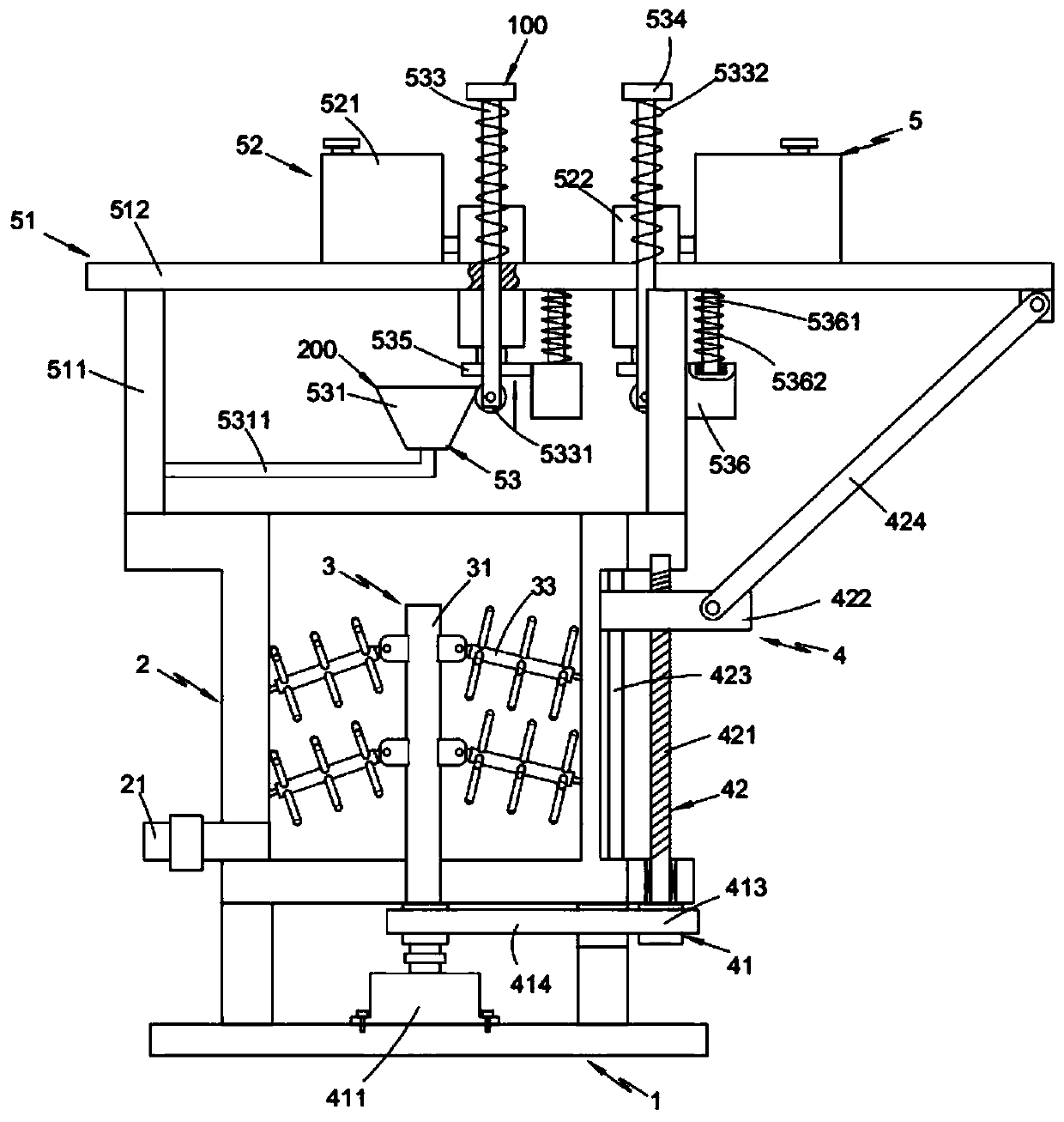

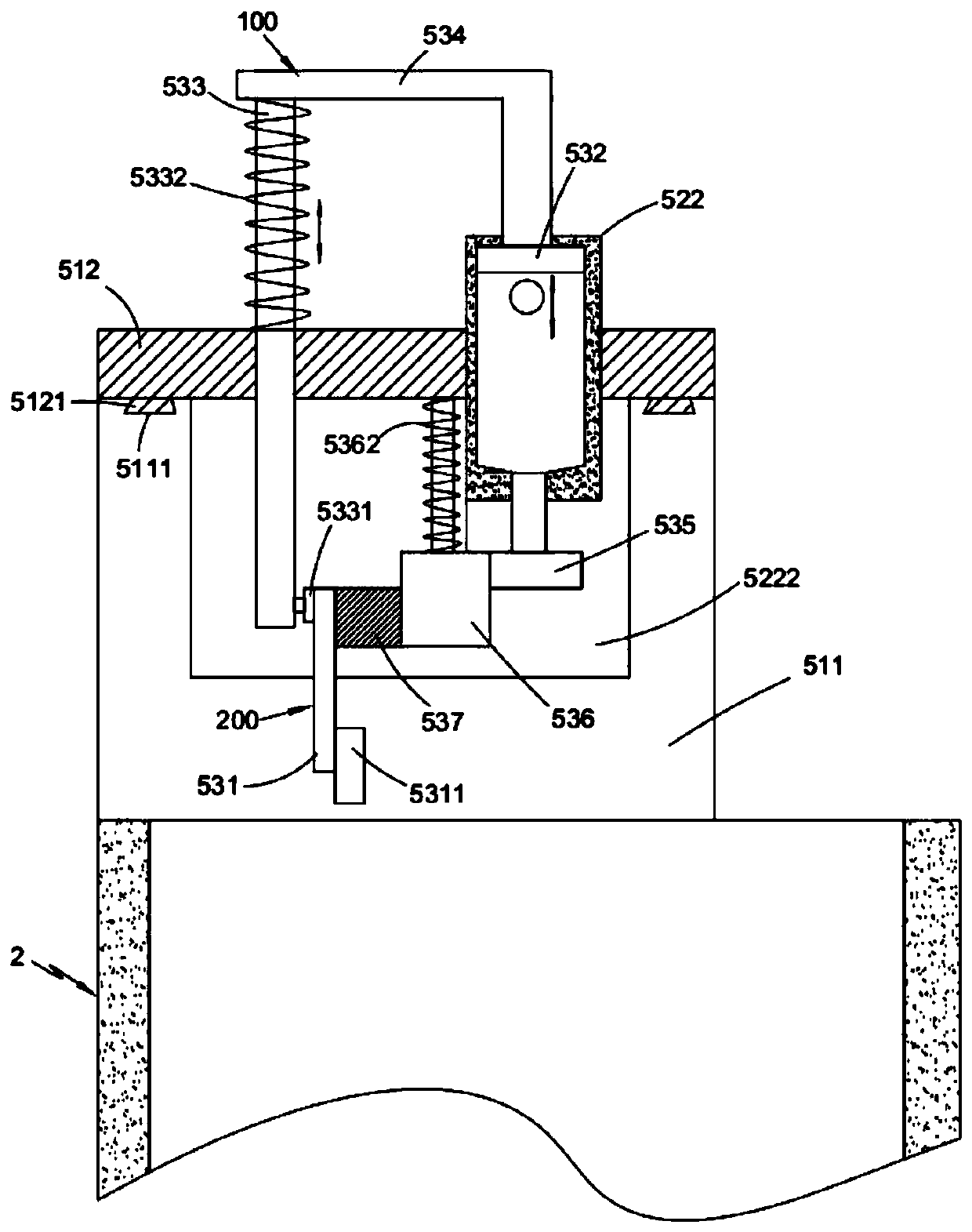

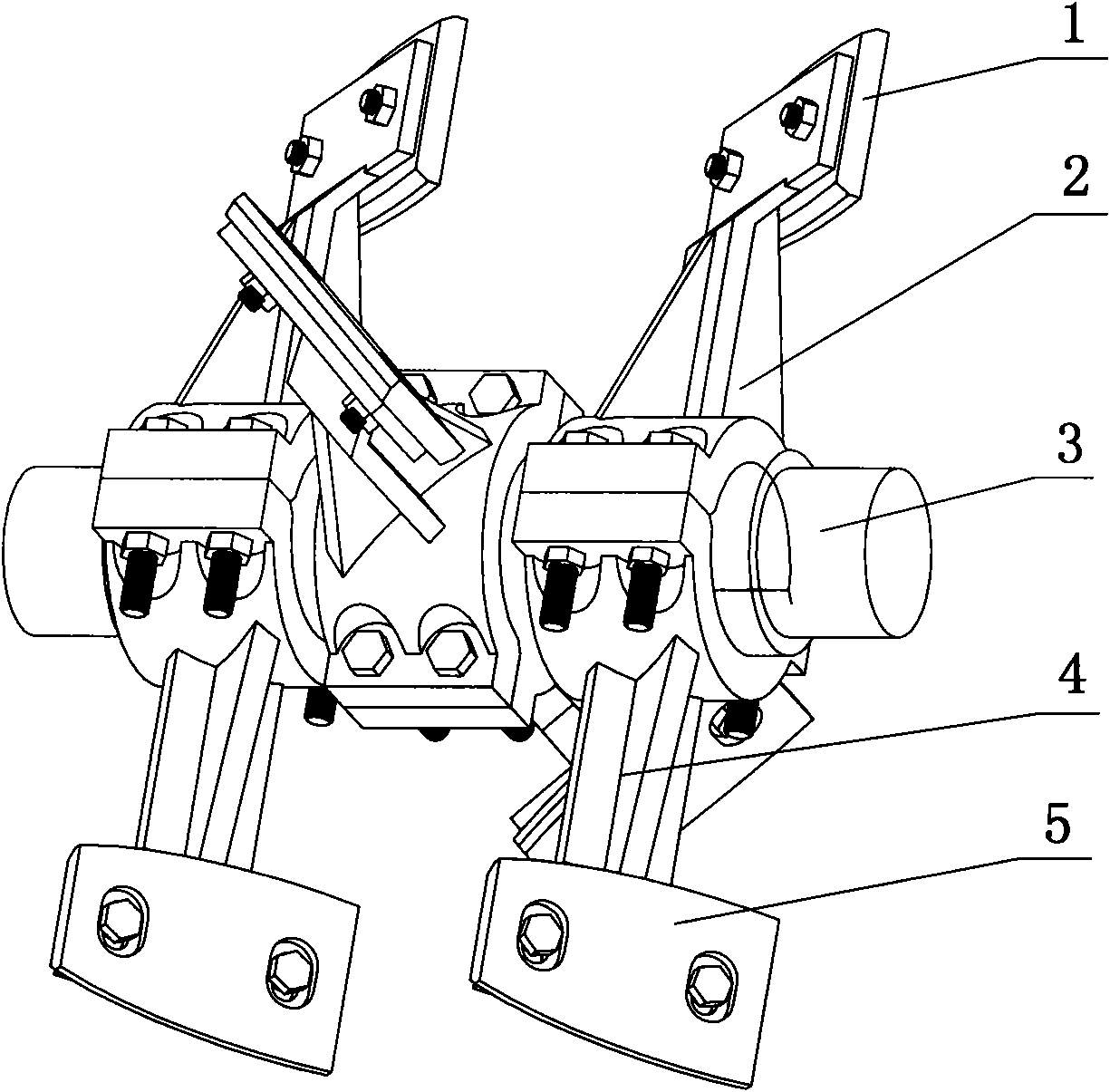

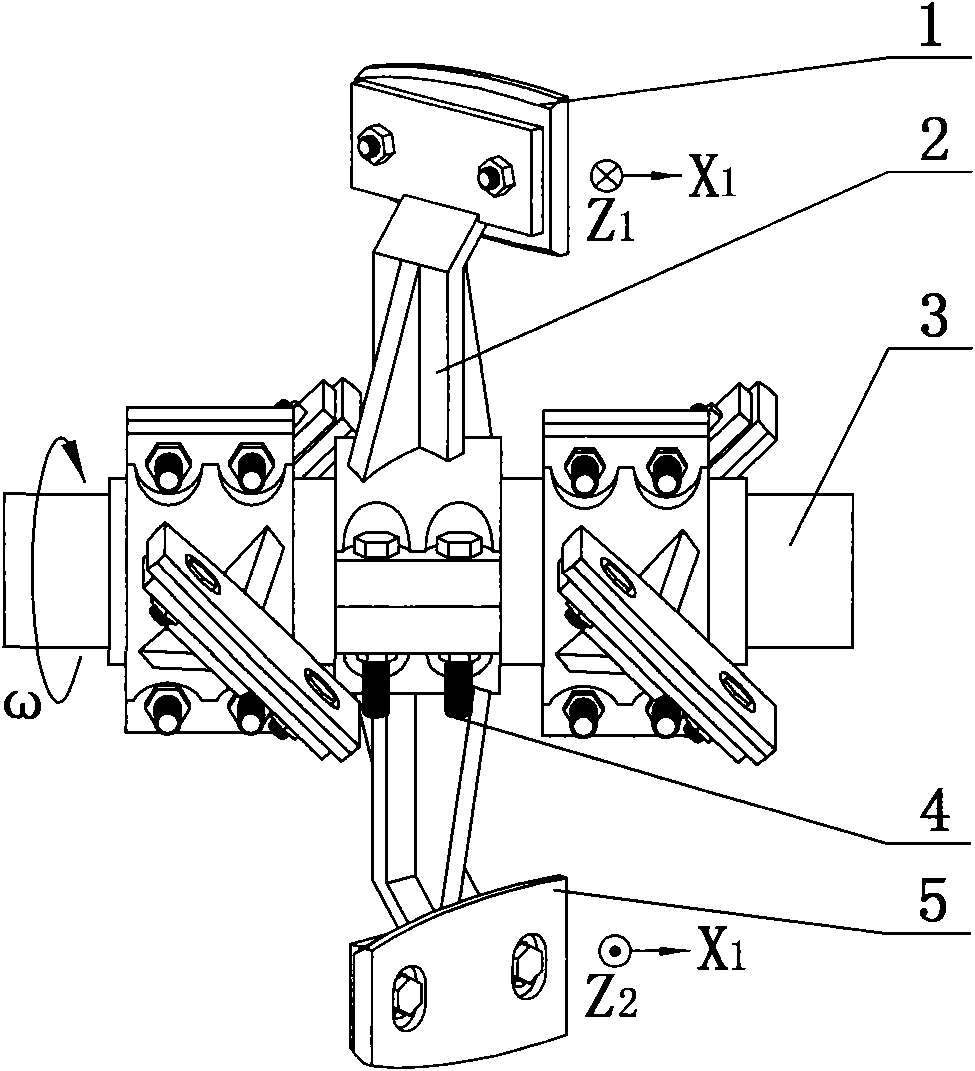

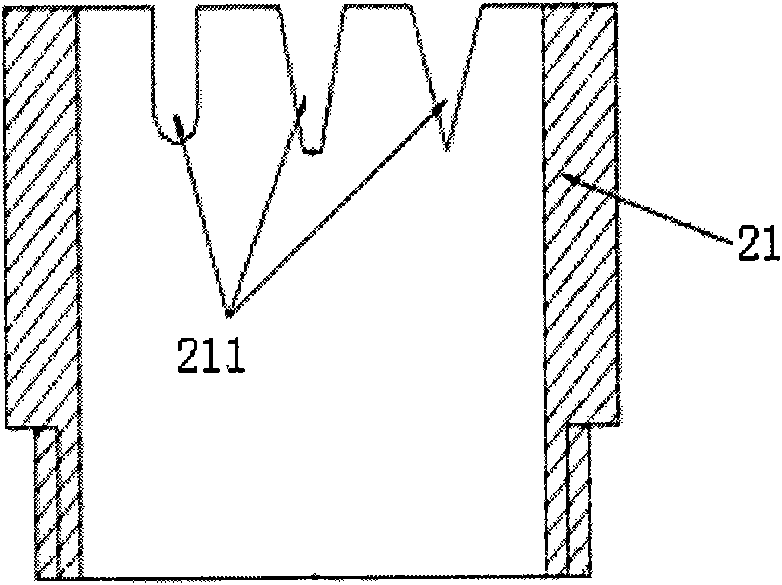

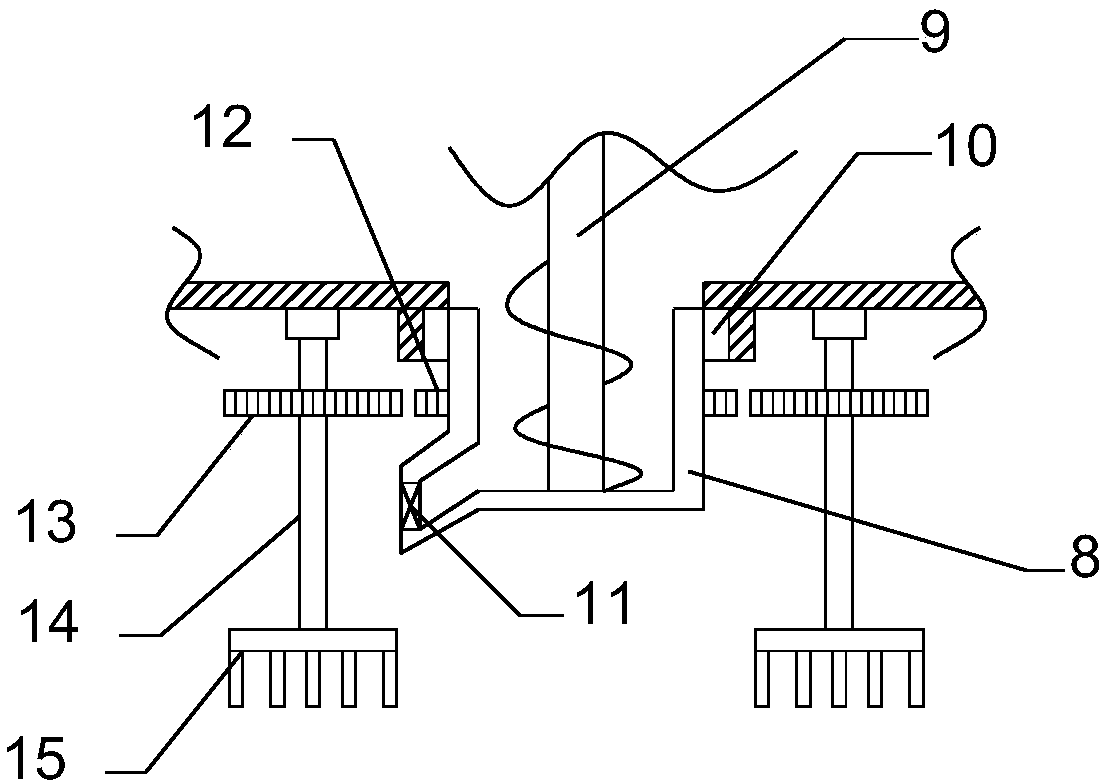

Opposite mixing mechanism for compulsory type asphalt mixing machine

The invention discloses an opposite mixing mechanism for a compulsory type asphalt mixing machine, comprising a mixing shaft and a plurality of groups of opposite mixing units sequentially arranged onthe mixing shaft. The mixing shaft and the opposite mixing units arranged on the mixing shaft form the opposite mixing mechanism which can continuously push and mix materials. Each opposite mixing unit comprises two linear mixing arms and two mixing blades, wherein the linear mixing arms are symmetrically arranged at both sides of the mixing shaft with the same structure and size; the mixing blades are respectively arranged at the tail ends of the two mixing arms with the same structure and size; and the directions for the two mixing blades to push the materials to move in the axial directionare the same. The invention has reasonable design, high mixing efficiency and good mixing quality, and can effectively solve the practical problems of limited number of mixing blades in work, low mixing efficiency, poor mixing quality, and the like of the prior compulsory type mixing machines.

Owner:CHANGAN UNIV

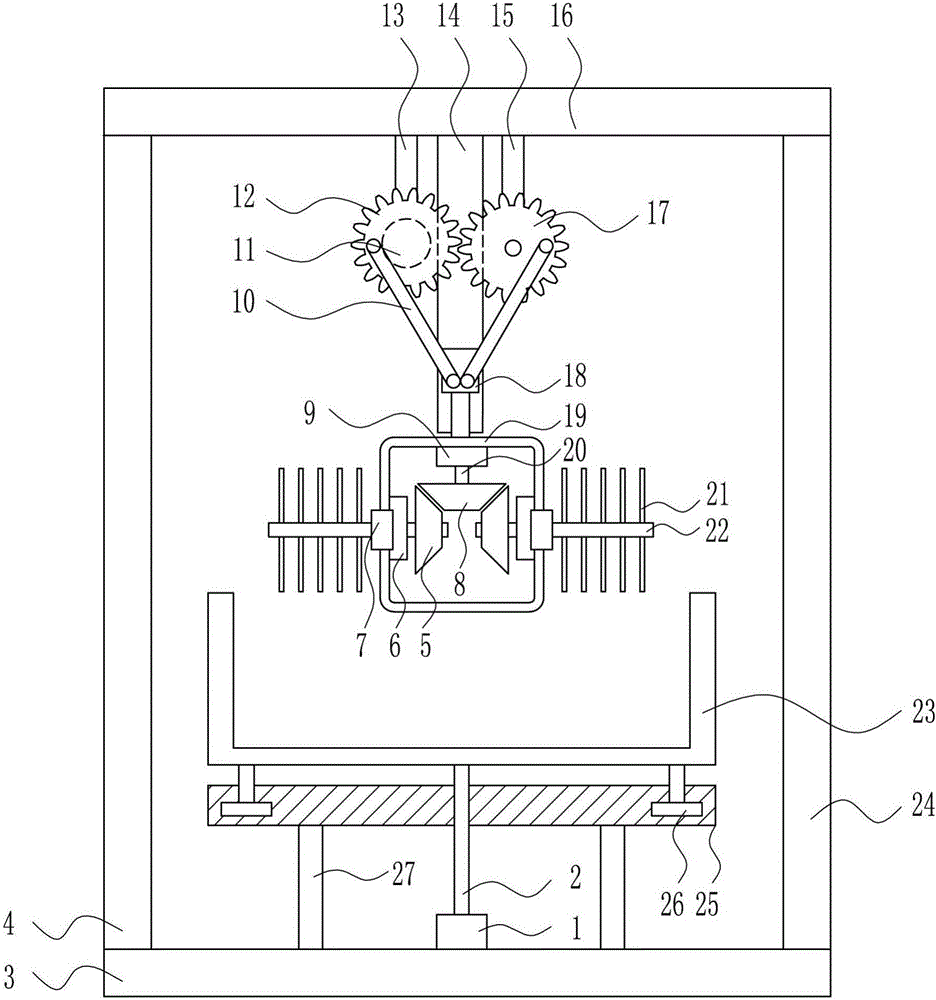

Mixer provided with grinding device for ceramic production

InactiveCN105032231AGood mixing effectImprove mixing effect and efficiencyRotary stirring mixersMixer accessoriesEngineeringSpiral blade

The invention discloses a mixer provided with a grinding device for ceramic production. The mixer comprises a mixer body, a circulating delivery pump and a grinding cavity, wherein an inclined discharging pipe is connected with the left end of the upper side of the mixer body; the grinding cavity is connected with the top end of the discharging pipe; a feeding hopper is arranged on the upper side of the grinding cavity. According to the mixer provided with the grinding device for ceramic production, the operating noise is low; two spiral blades rotating in the reverse direction are adopted to stir and mix materials, so that the mixing effect and the work is good, and the efficiency is high; materials are heated and dried during stirring and mixing, and dried materials can be mixed conveniently, so that the material mixing effect and working efficiency are improved; materials at the bottom of the mixer can be pumped into the top of the mixer in a circulating manner to be mixed, so that the phenomenon that materials at the bottom cannot be stirred to cause insufficient mixing is avoided; in addition, materials can be fully ground before material mixing, so that the phenomenon that materials with bigger particles cannot be effectively mixed is avoided, and the quality of processed finished products is guaranteed.

Owner:顾马飞

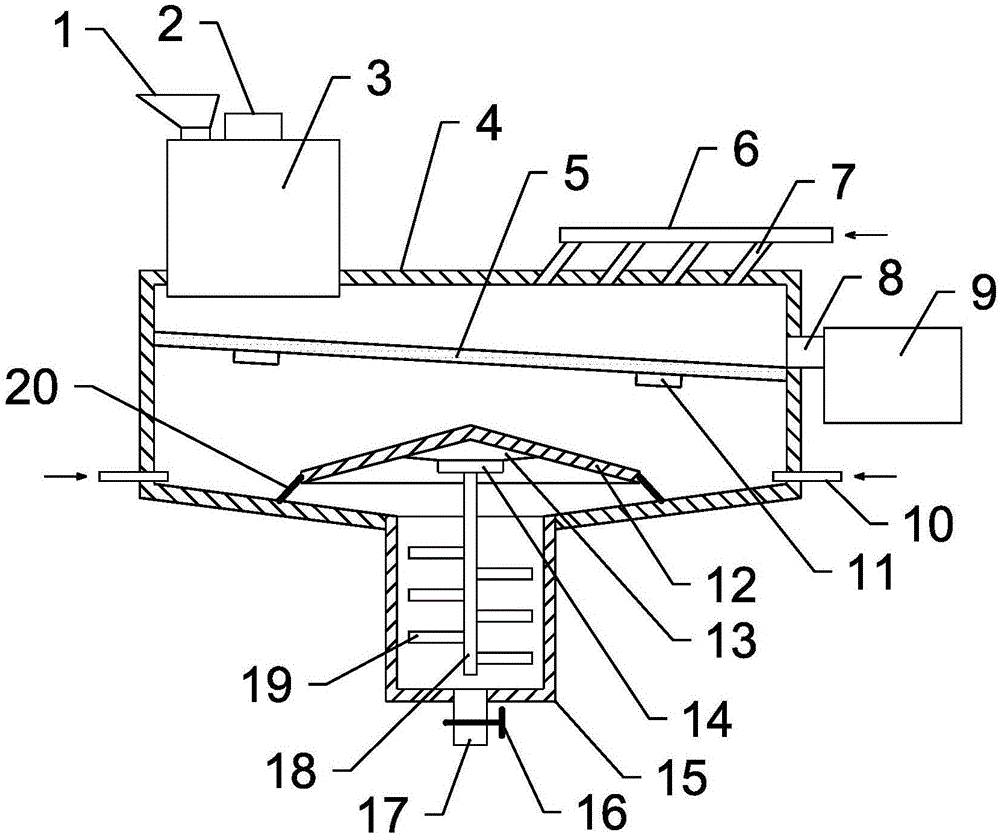

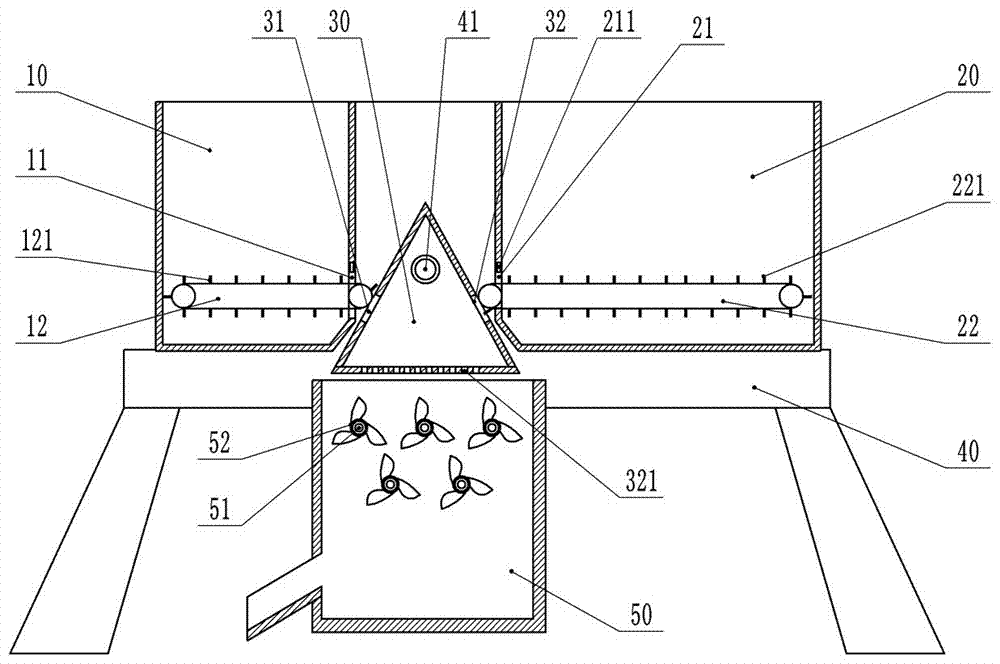

Sand mixer with enhanced preliminary mixing function

ActiveCN106799459AImprove the mixing effectImprove efficiencyMould handling/dressing devicesTemperature controlWork period

The invention relates to a sand mixer with an enhanced preliminary mixing function. The sand mixer is provided with an intelligent composite material inlet, wherein a multi-stage preliminary mixing disk for preliminarily mixing supplied materials is mounted on a main mixing bin; by the adoption of an optimized curved surface material throwing structure with a rotating speed and a rotating direction which are different from the rotating speed and the rotating direction of a main mixing mechanism, a load can be scientifically distributed according to an actual requirement; by the independent design of the mechanical loads and power of a preliminary mixing mechanism and the main mixing mechanism, the mechanical effect is effectively enhanced; a special material conveying opening for supplying an adhesive and / or a curing agent is formed in the middle part or the lower part of the main mixing bin of the sand mixer, so that the workload and the working time of the main mixing mechanism can be reduced to an extremely large extent, and the workload of the preliminary mixing mechanism is also reduced; furthermore, the sand mixer realizes controllability of production from quantitative material feeding and precise temperature control, and equipment works safely and reliably.

Owner:青岛科润机电设备有限公司

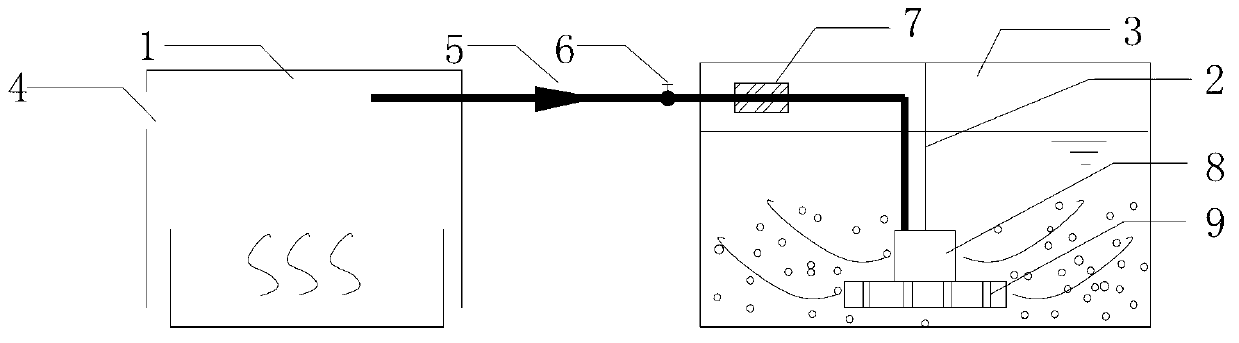

Fractured rock mass water inrush and sand inrush simulation experiment device capable of continuously supplying water and sand

InactiveCN106442209AGood mixing effectGuaranteed continuityWeighing by removing componentPermeability/surface area analysisPistonPetrology

The invention relates to a fractured rock mass water inrush and sand inrush simulation experiment device capable of continuously supplying water and sand. The device is characterized in that water is quantitatively added from a top base by virtue of a water flow supplying and measuring device, sand is continuously supplied by virtue of two sand injection pipes at the side part above a permeation main cylinder, the water and the sand are mixed, then enter fractured rock mass via a porous water permeable plate, then enter a piston and then are discharged, collected and measured, the porous water permeable plate, a pressure bearing circular ring and the top base are arranged above the fractured rock mass, the piston is arranged below the fractured rock mass, equipment is mounted on a press, under the action of the press, the piston moves, and the fractured rock mass can be compressed to designated porosity (described in the specification) or a specified axial force can be applied to the fractured rock mass. The device provided by the invention can continuously supply sand during a test, can simulate the condition of seepage of a water-sand mixed fluid formed by a large number of sand grains under the action of water flow in the fractured rock mass and can improve test accuracy and test effect.

Owner:CHINA UNIV OF MINING & TECH

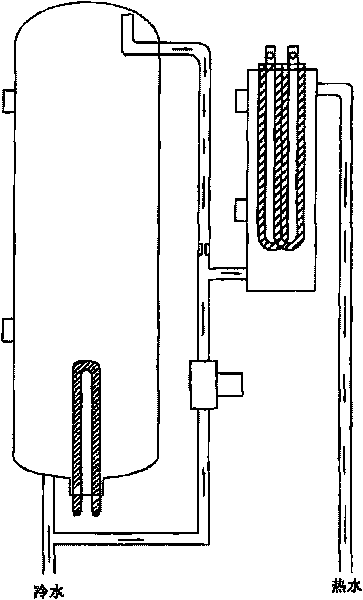

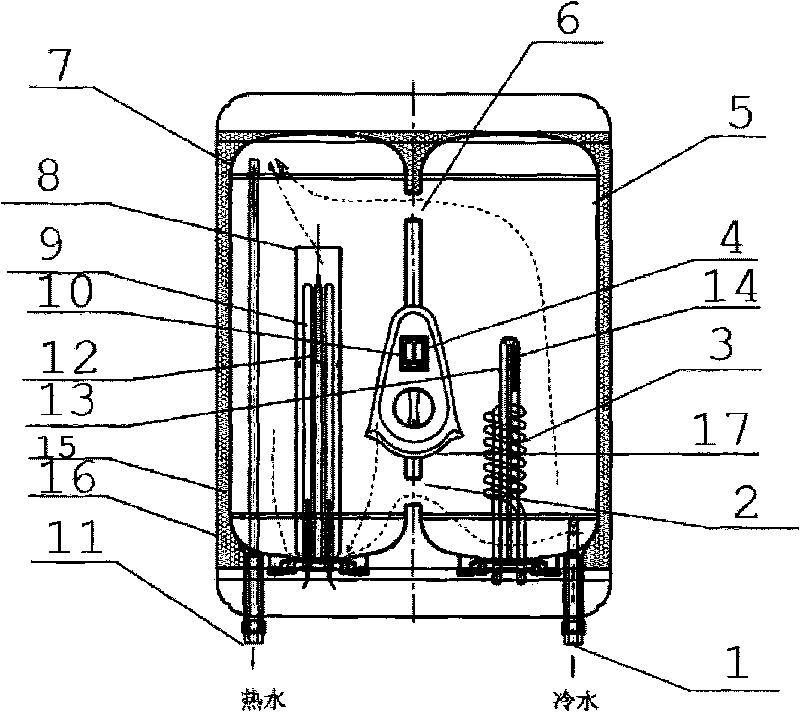

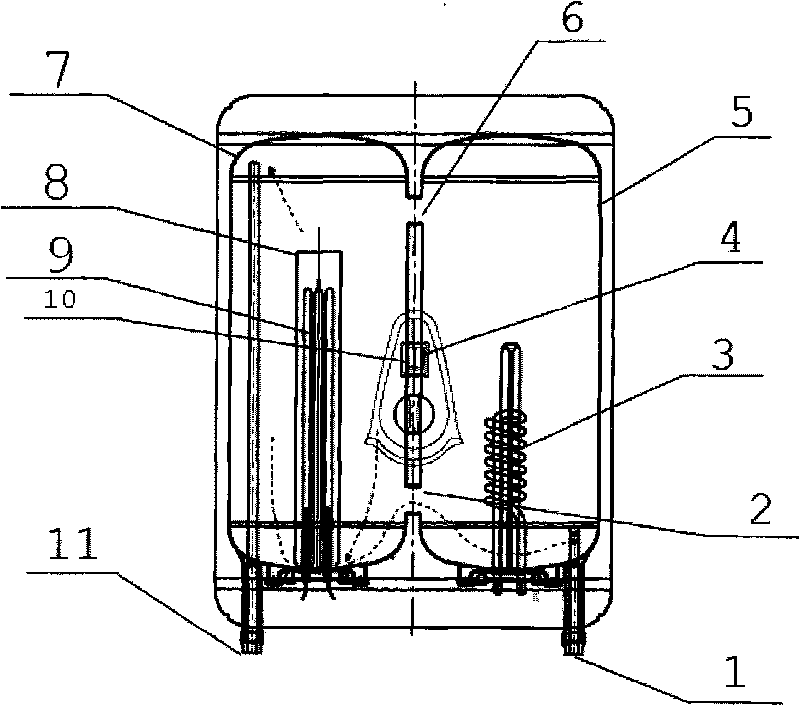

Instantaneous preheating dicaryon electric water heater

The invention discloses an instantaneous preheating dicaryon electric water heater which comprises a preheating bladder, a preheating pipe, an instantaneous heating bladder and an instantaneous heating pipe, wherein the preheating bladder is connected with a water inlet, the preheating pipe is positioned in the preheating bladder, the instantaneous heating bladder is connected with a water outlet, and the instantaneous heating pipe is positioned in the instantaneous heating bladder; and the preheating bladder and the instantaneous heating bladder are communicated with each other through an upper communicating pipe and a lower communicating pipe. In addition, a sleeve is arranged outside the instantaneous heating pipe, the upper end of the sleeve is open, and the periphery of the lower end is provided with a gap. The invention combines the characteristics of the instantaneous heating electric water heater and the preheating electric water heater, and can realize three different heating modes. The user can select power according to needs to switch the heating modes. The required hot water can be produced in an electric water heater with a small size, thereby meeting the requirements for beautiful appearance, convenience, safety and energy saving.

Owner:余玉旭

Method for using bulk sintered neodymium iron boron (NdFeB) machining waste to prepare high-performance regenerated NdFeB magnet

InactiveCN104036949AEvenly distributedGood mixing effectInductances/transformers/magnets manufactureMagnetic materialsScrapHydride

The invention relates to a method for using bulk sintered neodymium iron boron (NdFeB) machining waste to prepare a high-coercivity regenerated NdFeB magnet and belongs to the technical field of magnetic materials. The rare earth neodymium hydride nano powder doping technology is used to regenerate the sintered NdFeB machining waste so as to prepare the high-performance regenerated sintered NdFeB permanent magnet. The method includes: using hydrogen explosion and air flow milling to prepare NdFeB powder; using the physical gas phase deposition technology to prepare neodymium hydride nano powder; mixing the two kinds of powder, and performing magnetic field orientation and compression moulding; performing dehydrogenation, sintering and thermal treatment on the compressed base at different temperatures to obtain the sintered magnet. The method has the advantages that various magnetic performances of the regenerated magnet prepared by the method can restore to the level an original magnet, and the method is short in process flow, low in cost and energy consumption and resource saving.

Owner:BEIJING UNIV OF TECH

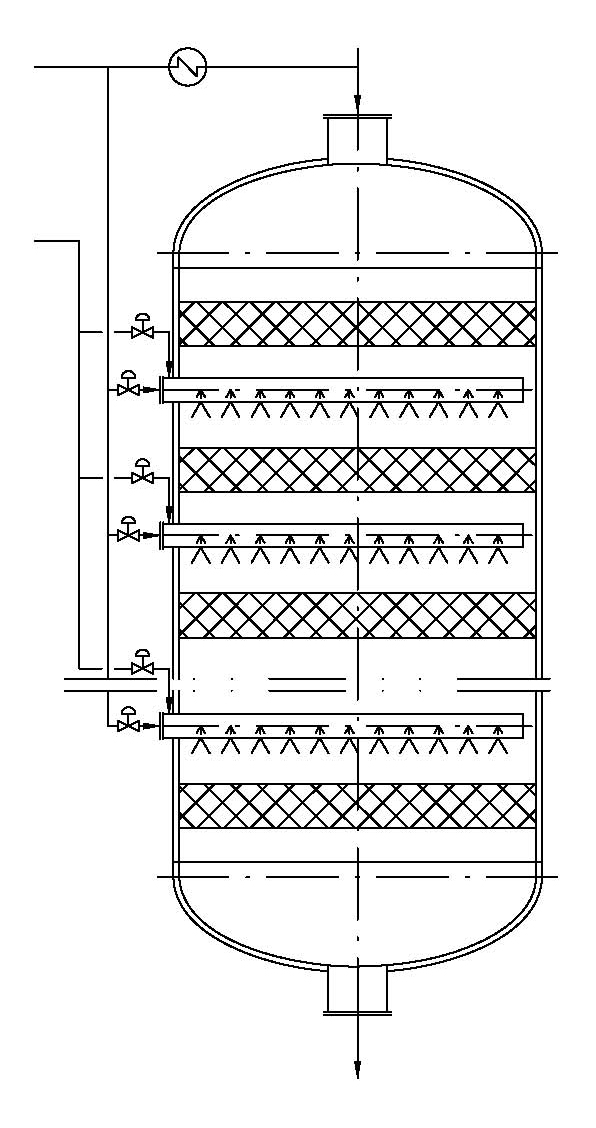

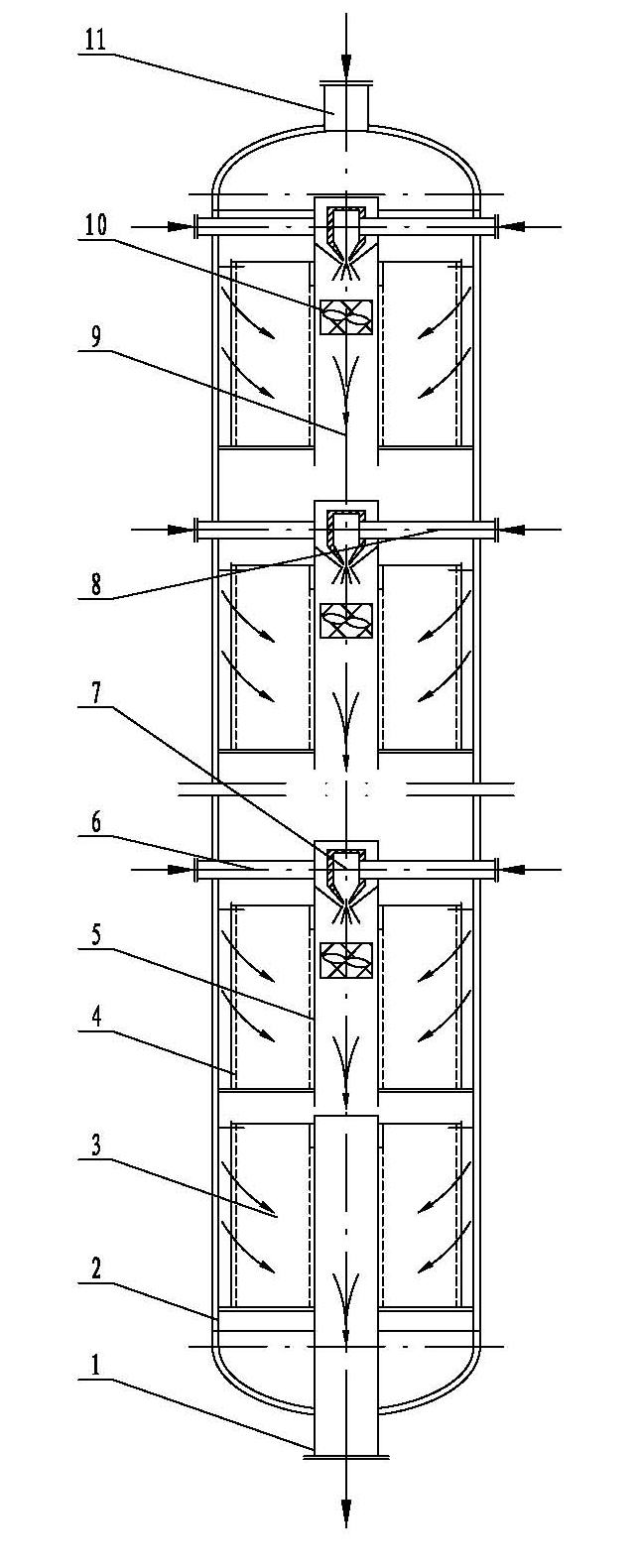

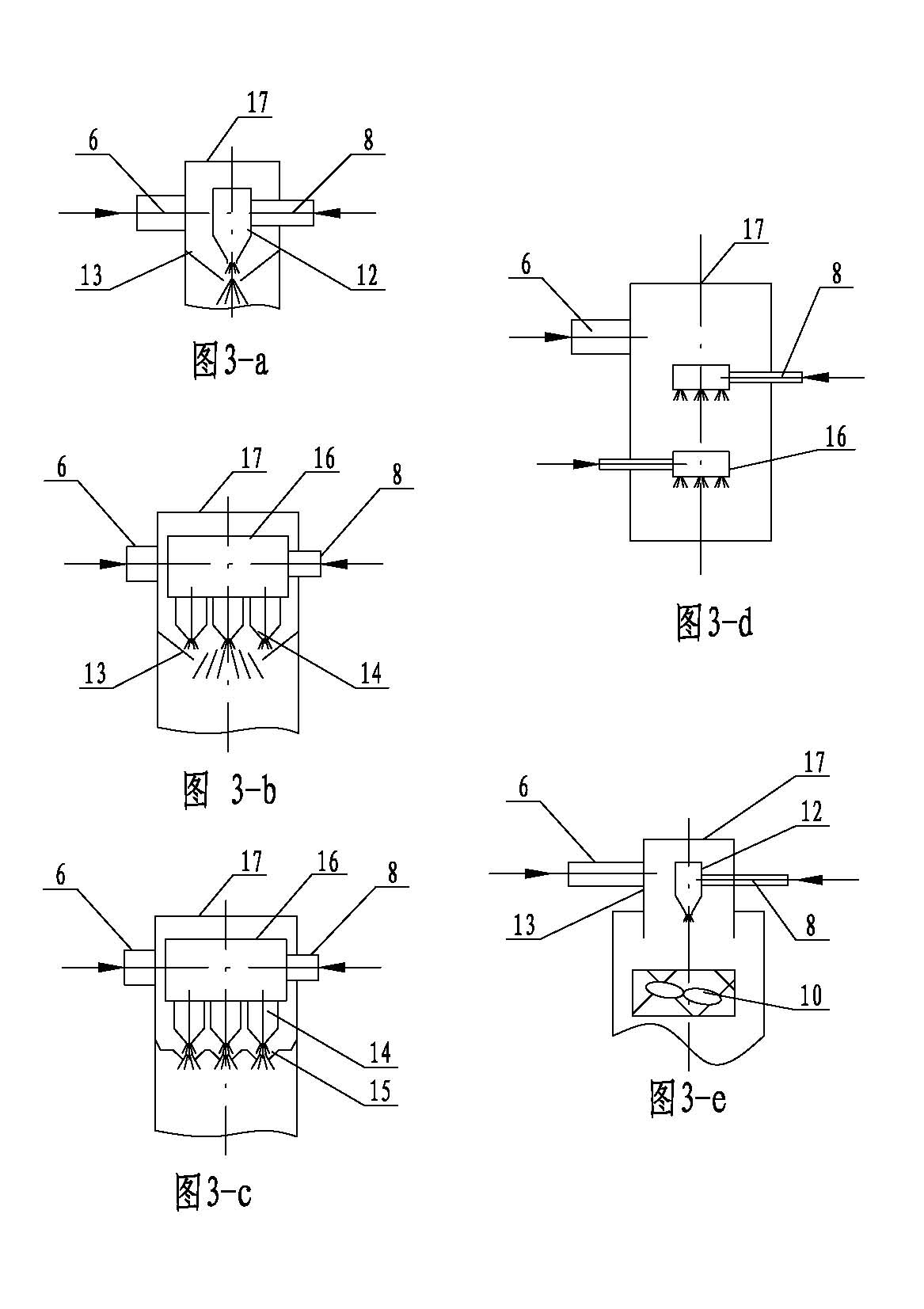

Multi-fluid jet quench radial flow reactor

ActiveCN102151522AImprove space utilizationGood mixing effectChemical/physical processesSpray nozzleProcess engineering

The invention discloses a multi-fluid jet quench radial flow reactor, which comprises a radial reactor shell (2), and is characterized in that: a plurality of radial catalyst beds (3) are arranged in the shell (2); each radial catalyst bed (3) is provided with a radial flow external distribution cylinders (4) and a central radial flow internal gas collection cylinder (5); central mixing pipes (9)are arranged in the radial flow internal gas collection cylinders (5); multi-fluid jet quenchers (7) are arranged on the internal upper ends of the central mixing pipes (9); internal spray nozzles (12) and external spray nozzles (13) are arranged in the quenchers (7); the internal spray nozzles (12) are communicated with second quench fluid inlet pipes (8); the external spray nozzles (13) are communicated with first quench fluid inlet pipes (6); and gas mixing chambers for supplying quench gas for the radial catalyst beds (3) on a lower layer are arranged between adjacent radial catalyst beds(3), and the gas mixing chambers are communicated with the radial flow internal gas collection cylinders (5) and the central mixing pipes (9) at the same time. The reactor has the advantages of noveland simple structure, good temperature regulation performance, high operation quality and low manufacturing cost.

Owner:NANJING GOODCHINA CHEM TECH +1

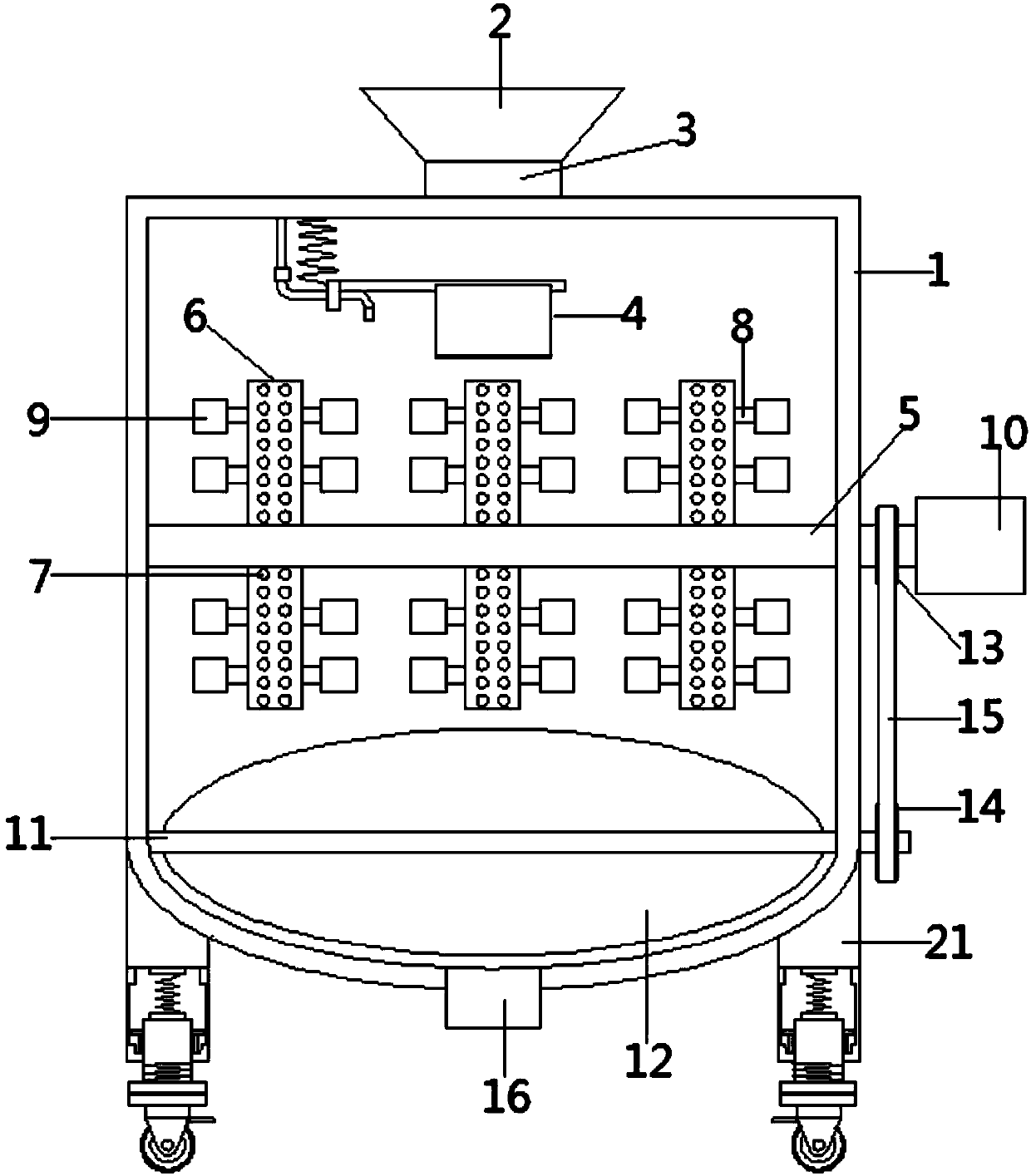

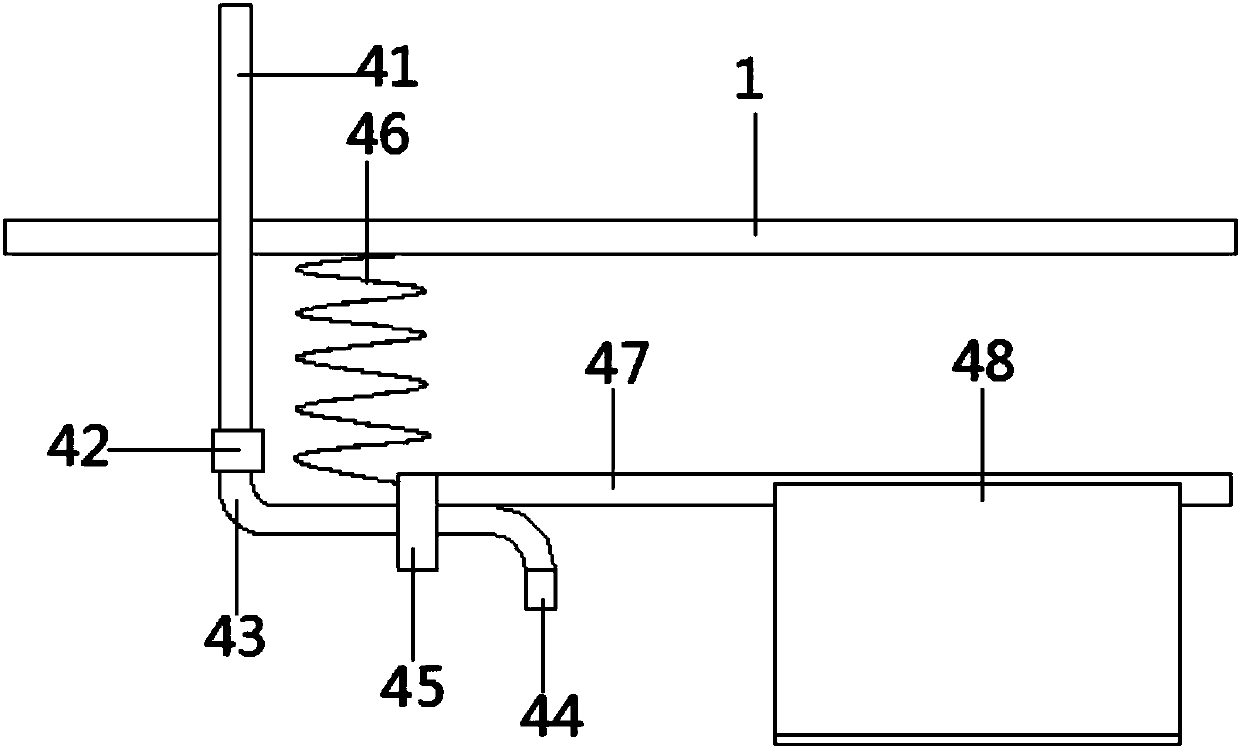

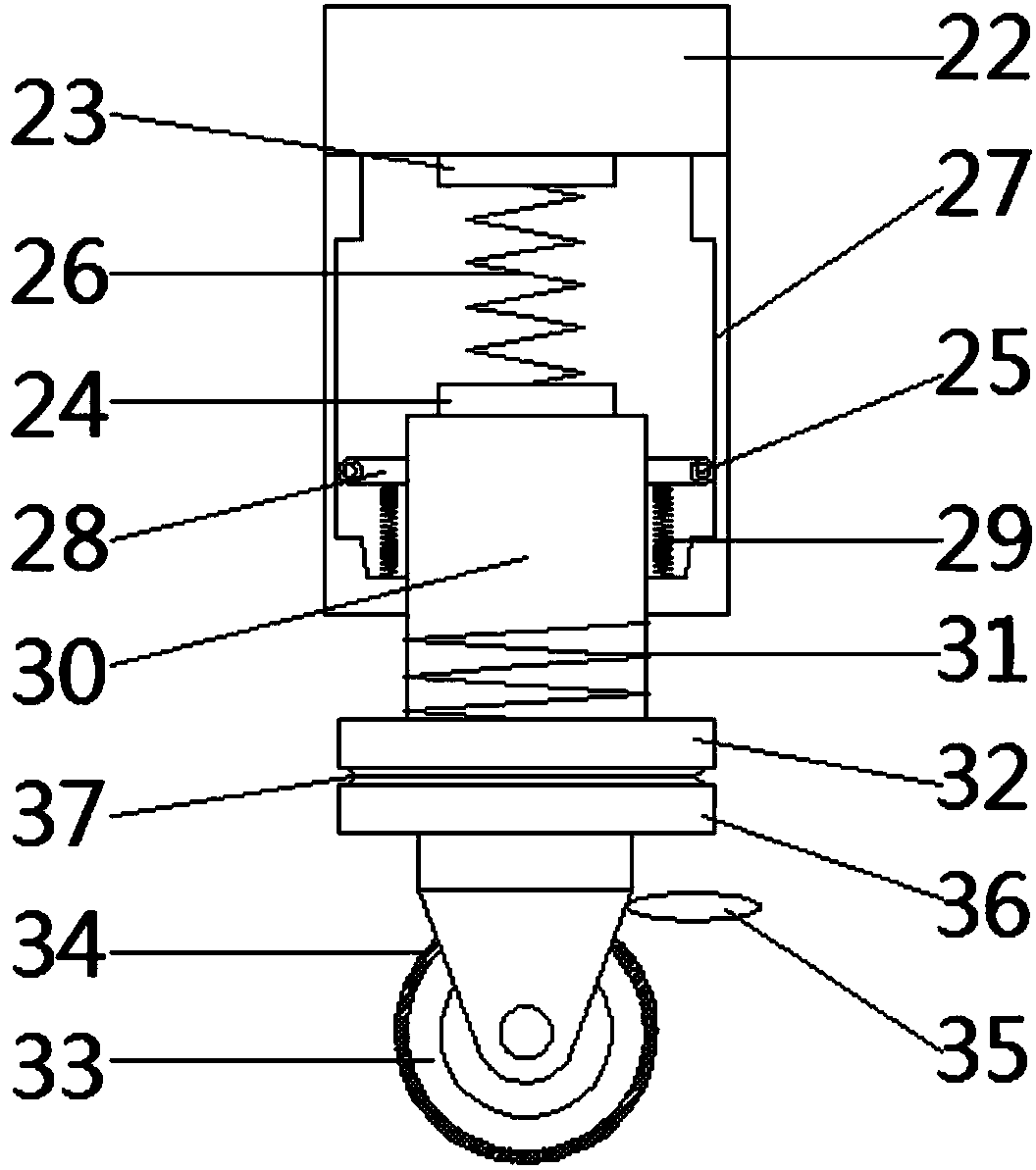

Stirring and mixing device for chemical fertilizer production

InactiveCN107583548AGood mixing effectImprove efficiencyShaking/oscillating/vibrating mixersMixer accessoriesFertilizerSieve

The invention discloses a stirring and mixing device for chemical fertilizer production. The device comprises a machine body, wherein a feeding hopper is arranged in the middle of the upper side of the machine body, the bottom end of the feeding hopper is connected with a feeding port in the upper side of the machine body through a vibrating sieve, a fertilizer additive scattering device is arranged on the upper side in the machine body and comprises a fixed pipe, an elastic pipe, a nozzle, an elastomer and a swing mechanism, and one end of the fixed pipe is connected with the elastic pipe. The stirring and mixing device for chemical fertilizer production can sufficiently stir and mix fertilizer and a fertilizer additive, and the fertilizer mixing efficiency is effectively improved; a stirring mechanism and a turning mechanism are used for stirring and mixing the fertilizer, sufficient and uniform mixing is guaranteed, the stirring mechanism and the turning mechanism are driven by onemotor, and accordingly, energy consumption is effectively reduced. Besides, the stirring and mixing device can be conveniently moved and fixed, effective damping can be realized, and the work stability of the device is improved.

Owner:TIANJIN KECHUANG FUXIN TECH CONSULTING CO LTD

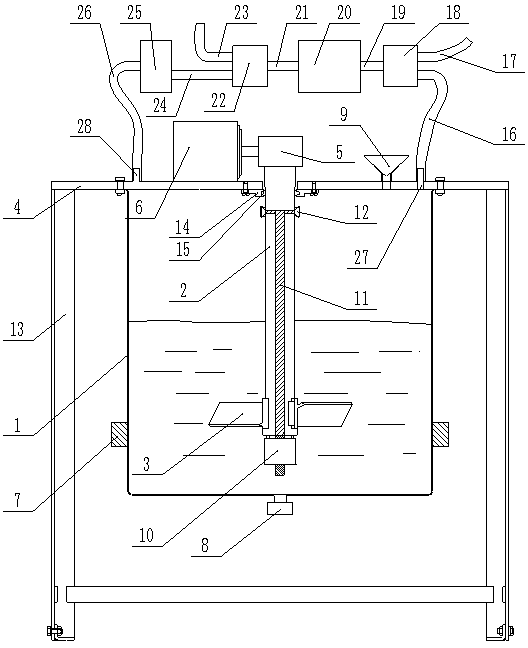

Sealed mixing tank wall washing device

The invention provides a sealed mixing tank wall washing device, comprising a mixing system, a nozzle system and a ventilation system, wherein the mixing system is connected with the nozzle system, and the mixing system is connected with the ventilation system. According to the present invention, a lower end of a shaft is provided with a through hole, materials just below the shaft is pumped by a pump mounted on the bottom of the shaft and is sprayed to a tank wall through a nozzle on the top, solids coagulated on the tank wall is rinsed off, the tank wall is kept clean and the mixing effect of the materials is improved. The nozzle of the device is a direct flow nozzle which sprays liquid linearly, and is rotated with the shaft to rinse off the tank wall in all directions, thus the problem of some dead angles cannot be sprayed is prevented. The ventilation system is used for generating positive pressure, negative pressure and drying steam, and exhausting toxic gases for the apparatus.

Owner:嘉兴笼列电子商务有限公司

Automatic dosing device in feed water treatment process

InactiveCN110697813AGood mixing effectThe overall structure is compact, reasonable and simpleTransportation and packagingMixer accessoriesWater treatmentDISC assembly

The invention discloses an automatic dosing device in a feed water treatment process, and relates to the technical field of water treatment. The device comprises a rectangular dosing box body and a speed reducer, the speed reducer is installed in the dosing box body through a supporting plate, and a partition plate is fixed to one opposite side wall of the dosing box body and a top surface; a first liquid gathering funnel is fixed between one side of the partition plate and the inner wall of the dosing box body; a water inlet pipe is fixedly arranged on the upper surface of the dosing box bodyand located just above the first liquid gathering funnel in a penetrating mode; a second liquid gathering funnel is fixed between the lower end of the partition plate and the inner wall of the dosingbox body; the side wall of the partition plate is rotationally connected with a first spindle through a bearing; and a water wheel is fixed to one end of the first spindle and located below the firstliquid gathering funnel. The designed dosing box body pushes a feeding disc assembly to rotate through water flow for dosing, mixing is conducted in a mixing box body, the mixing effect is good, automatic dosing is conducted with the entered water flow as power, and the problem that existing fixed dosing equipment is high in cost is solved.

Owner:FOSHAN UNIVERSITY

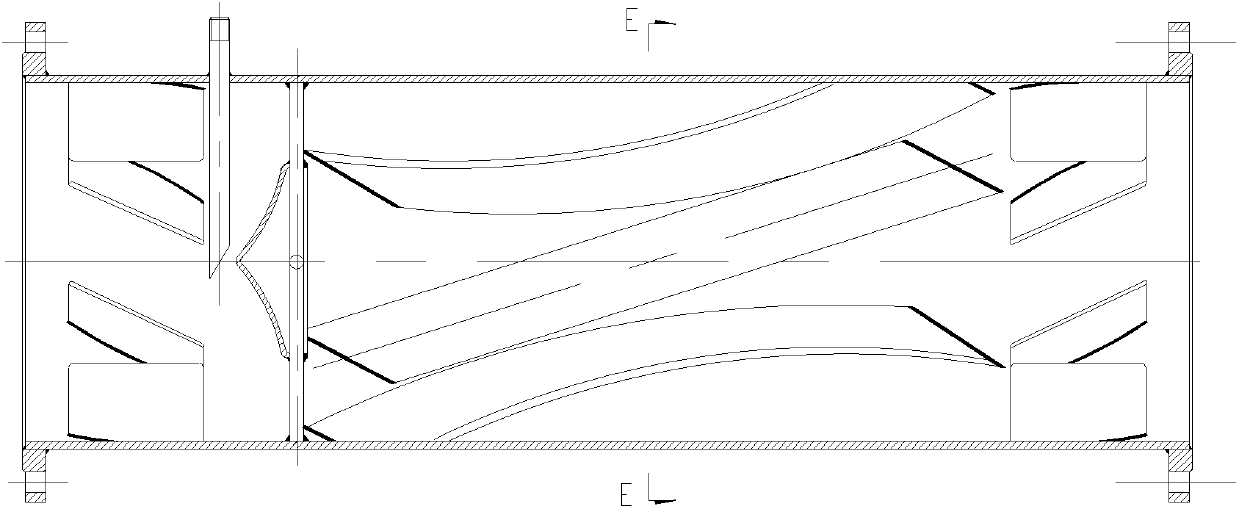

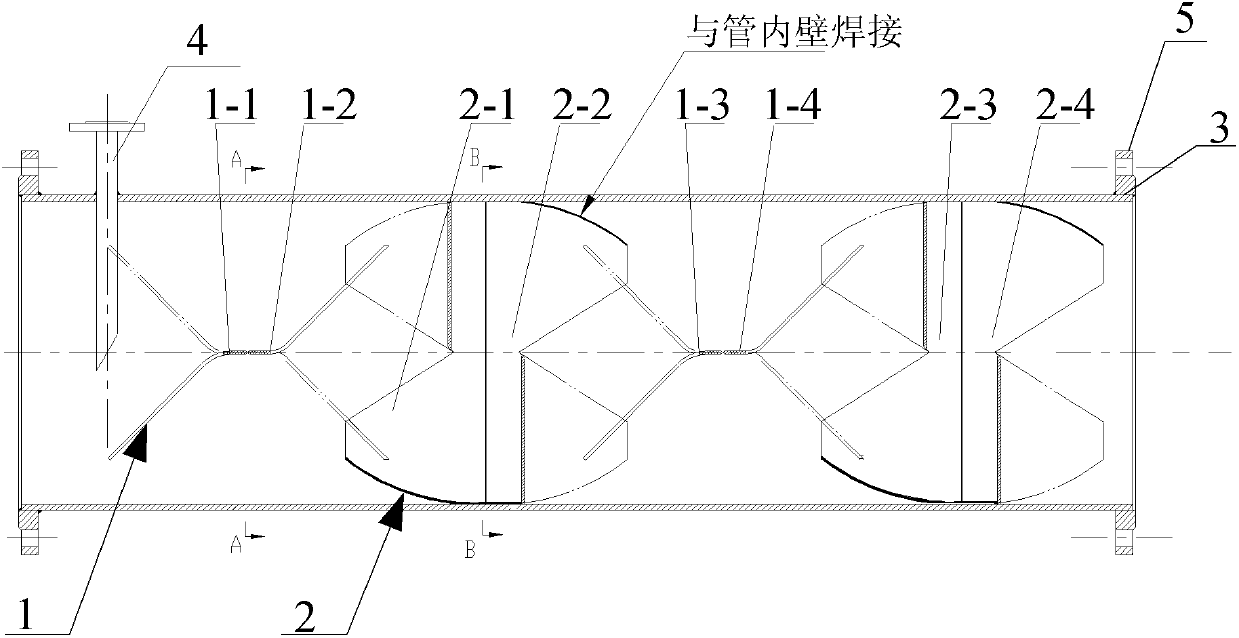

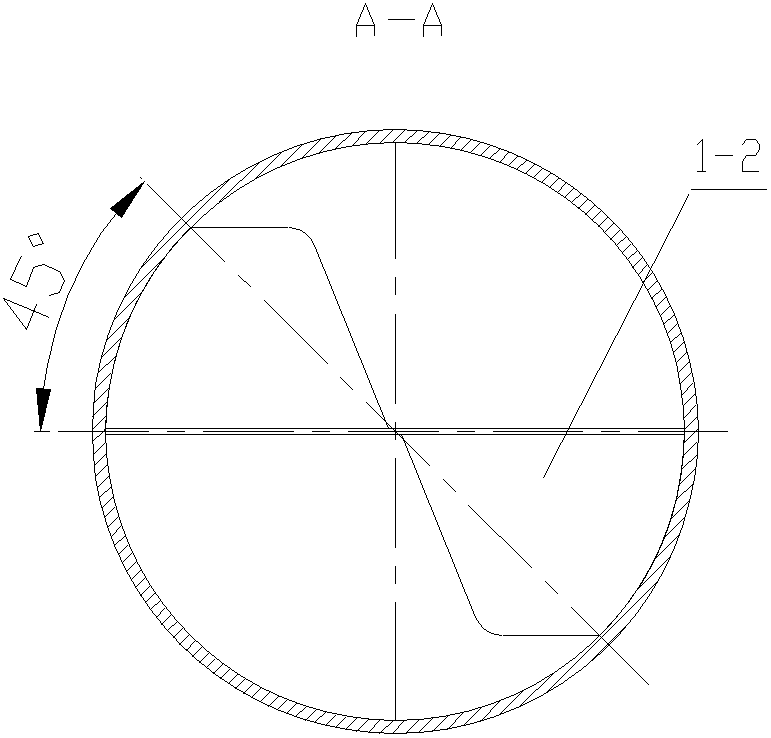

Static pipeline mixer

The invention relates to a static pipeline mixer which is a mixing device in a water treatment process. The static pipeline mixer comprises a pipeline, and a liquid adding pipe is arranged at an inlet end of the pipeline. The main characteristics of the static pipeline mixer are that: a plurality of groups of mixing blades are fixedly connected inside the pipeline; each group of mixing blades are composed of identical spiral blades; beams of two left-rotating unit blades oppositely form a left-rotating combination, or beams of two right-rotating unit blades oppositely form a right-rotating combination; the position difference between the mixing blades of the left-rotating combination and the mixing blades of the right-rotating combination in the pipeline is 90 degrees. The pipeline mixer is a novel efficient mixing device, and has the advantages of being good in mixing effect, simple in structure, convenient in production, small in pipeline loss and the like.

Owner:GANSU GOLDEN BRIDGE GRP CO LTD

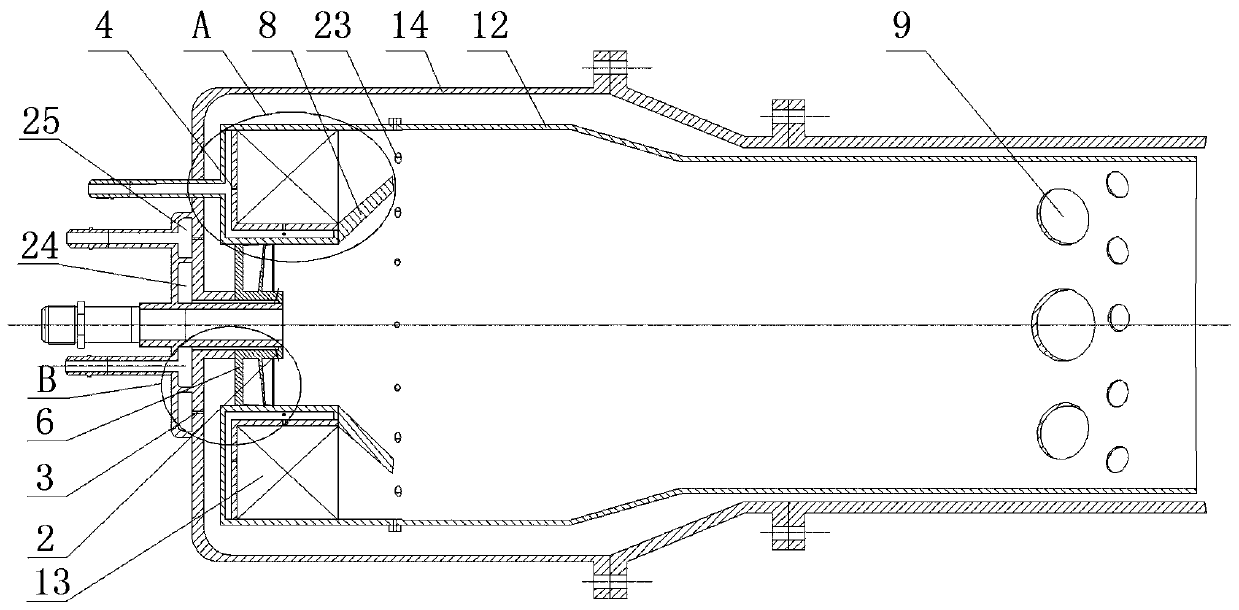

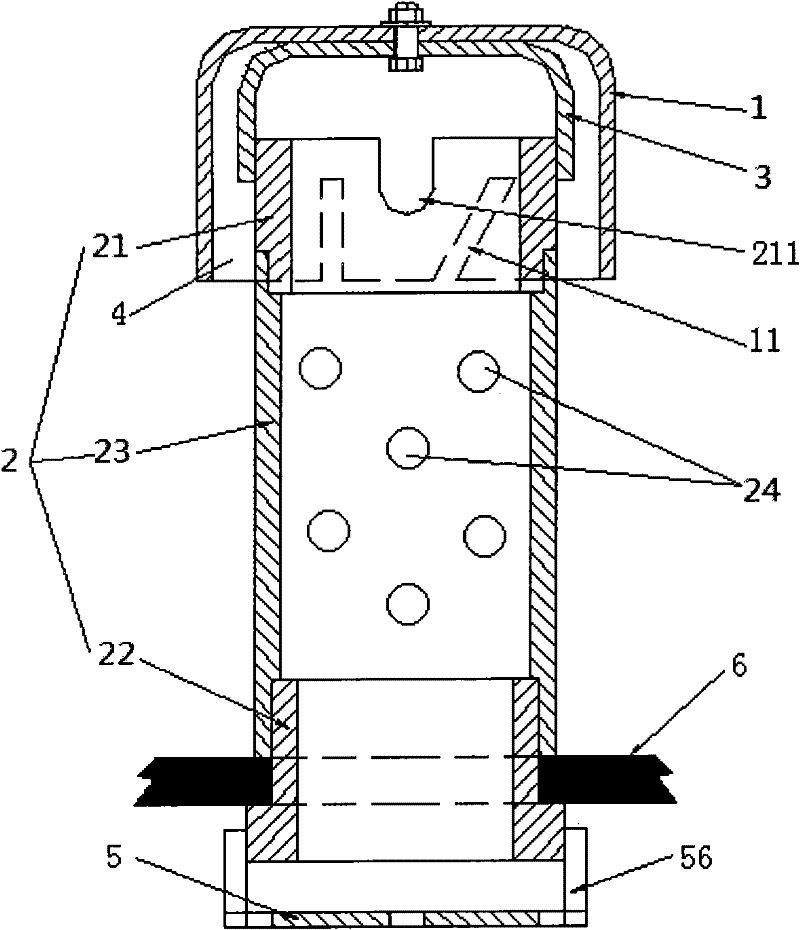

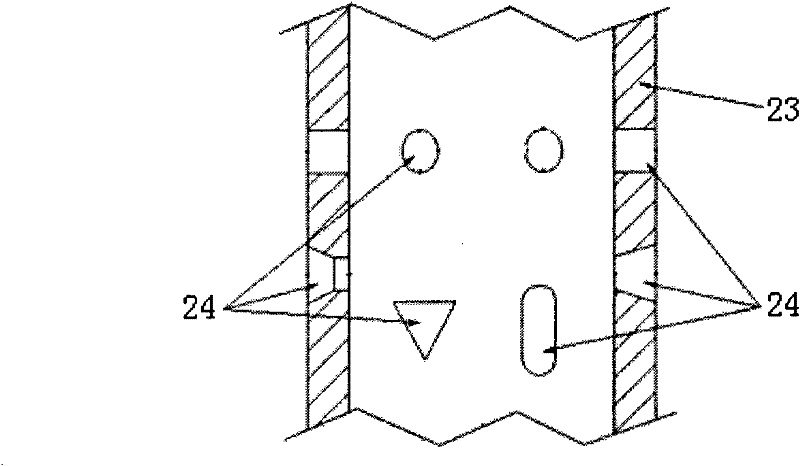

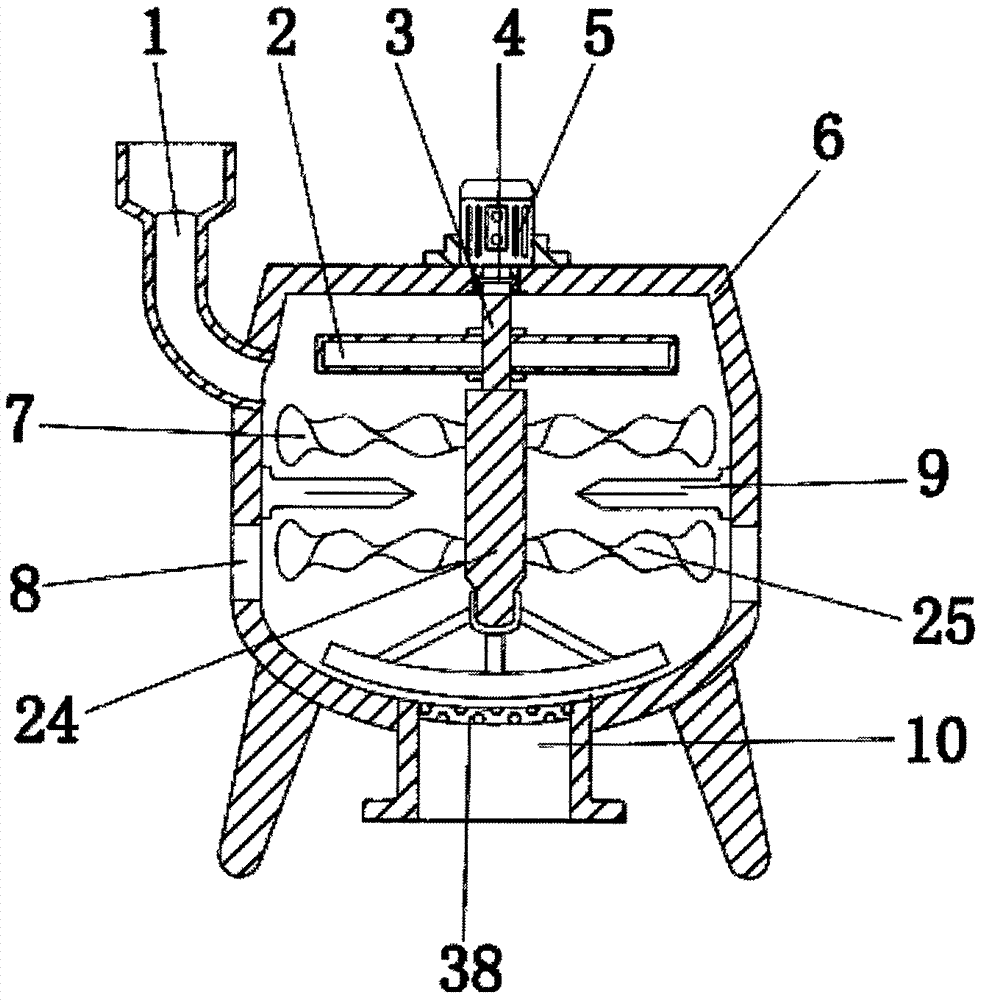

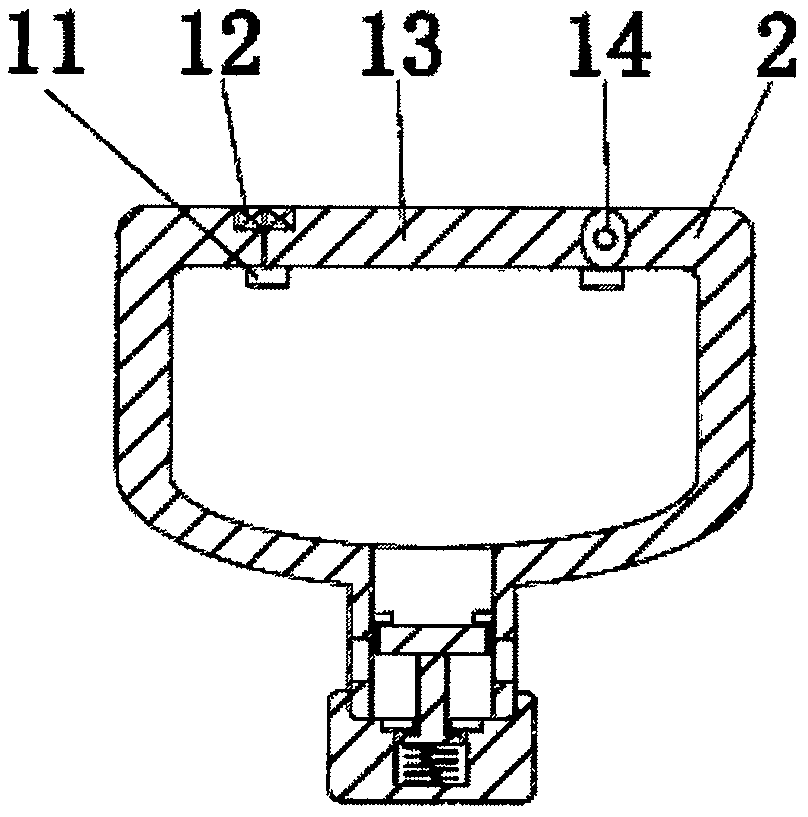

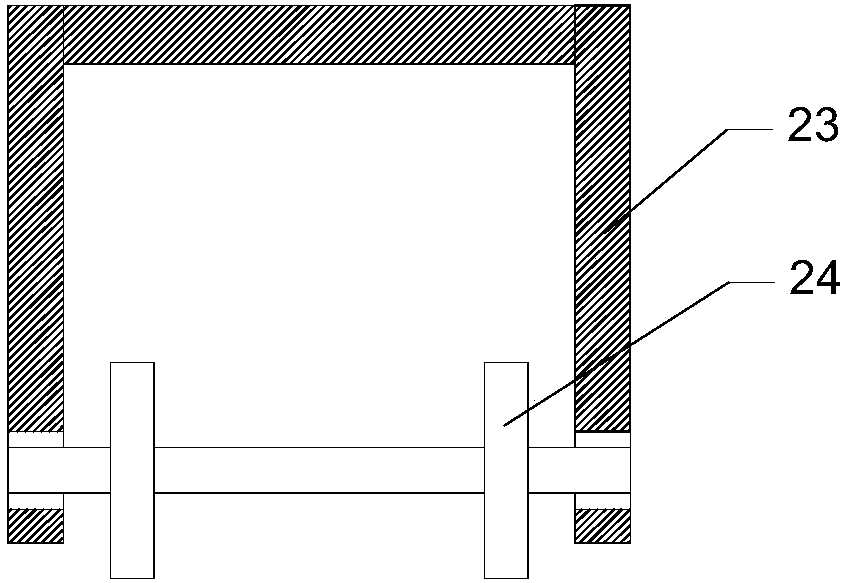

Gas liquid distributor

ActiveCN102451648AGood mixing effectEvenly distributedChemical/physical/physico-chemical processesTraffic volumeEngineering

The invention discloses a gas liquid distributor, which comprises a top cover (1), a center pipe (2), and a connection board (3); the center pipe (2) comprises an inlet part (21), an outlet part (22), and a liquid-falling part (23) located between the inlet part and the outlet part; the top cover is fixed above the inlet part of the center pipe through the connection board; an annular space (4) is formed between the inner wall of the top cover and the outer wall of the inlet part; wherein a plurality of through holes (24) are formed on the liquid-falling part of the center pipe and are distributed along an axis direction of the center pipe. In the gas liquid distributor, the flow directions of the gas phase and the liquid phase is basically perpendicular, and thus better mixing effect is achieved. In addition, when a plurality of distributors with different mounting heights are mounted on a distribution disc, or the distribution disc is inclined or liquid level fluctuation occurs, the plurality of through holes which are distributed on cross sections with different heights along the axis direction of the center pipe can balance the flow distribution among the plurality of distributors, and thus the whole distribution uniformity of the plurality of distributors is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Novel electric stirring machine

InactiveCN107096468AAdd evenlyGood mixing effectTransportation and packagingRotary stirring mixersEngineeringMaterial storage

The invention discloses a novel electric stirring machine, which includes a machine shell. A material feeding hopper and a material discharging hopper are respectively arranged on the top end of the left side and the center of the bottom end of the machine shell. A material storage box is installed on the outer side of a rotary rod. A cover plate is disposed on the top end of the material storage box. A through hole is formed in the outer side of the bottom of the material storage box. A plugging plate is mounted on the top of an inner rod and is matched with an inner annular plate. Through combination of the material storage box, the plugging plate and stirring blades, the novel electric stirring machine stirs materials when a stirring roller rotates and drives the stirring blades to rotate, and when the rotary rod rotates, the material storage box is rotated, so that centrifugal force is generated by the material storage box, and the plugging plate, under effects of the centrifugal force, drives the inner rod to move outwardly to compress a compressive spring in a chamber, so that the materials are thrown into the machine shell through the through hole. The machine can uniformly spray an additive into the machine shell when the materials are stirred, so that the machine achieves auto-addition of the additive and has ideal mixing and stirring effects on the additive and the raw materials.

Owner:张志通

Drum-type stirring device for edible fungi culture media

InactiveCN105080402AGood mixing effectStir wellRotating receptacle mixersTransportation and packagingCulture mediumsFungi culture

The invention relates to the field of mixing machines of rotary stirring devices, and discloses a drum-type stirring device for edible fungi culture media. The drum-type stirring device comprises a frame, a rotary drum and a stirring shaft. The rotary drum is connected with a first motor, and a first speed reducer is connected between the rotary drum and the first motor. The stirring shaft is connected with a second motor, and a second speed reducer is connected between the stirring shaft and the second motor. The first motor, the first speed reducer, the second motor and the second speed reducer are arranged on the frame. The stirring shaft is arranged in the rotary drum and is in coaxially rotary connection with the rotary drum. A helical blade is arranged on the stirring shaft, and a feed port is formed in the rotary drum. The drum-type stirring device has the advantages that the culture media at the bottom can be brought up by the rotary drum, fall off and be stirred by the helical blade, so that each portion of the culture media can be fully stirred, dead angles are avoided and good stirring effect is achieved.

Owner:重庆五间食用菌种植股份合作社

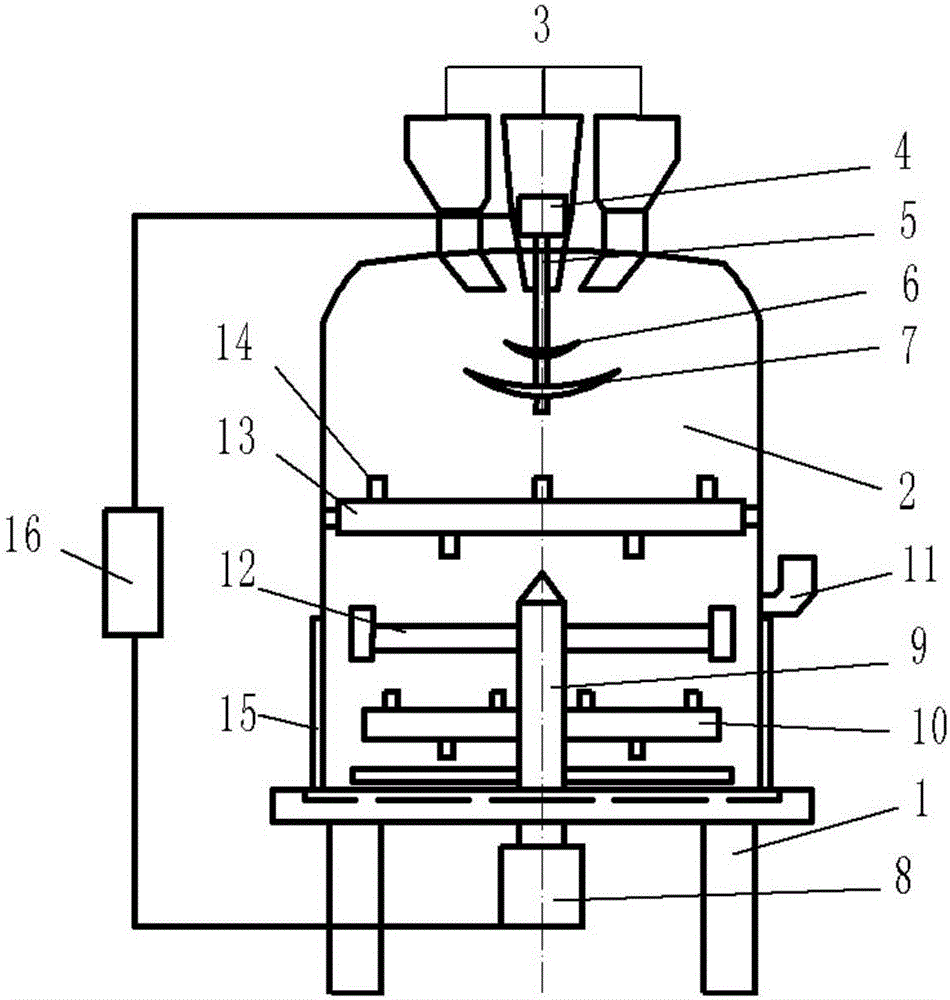

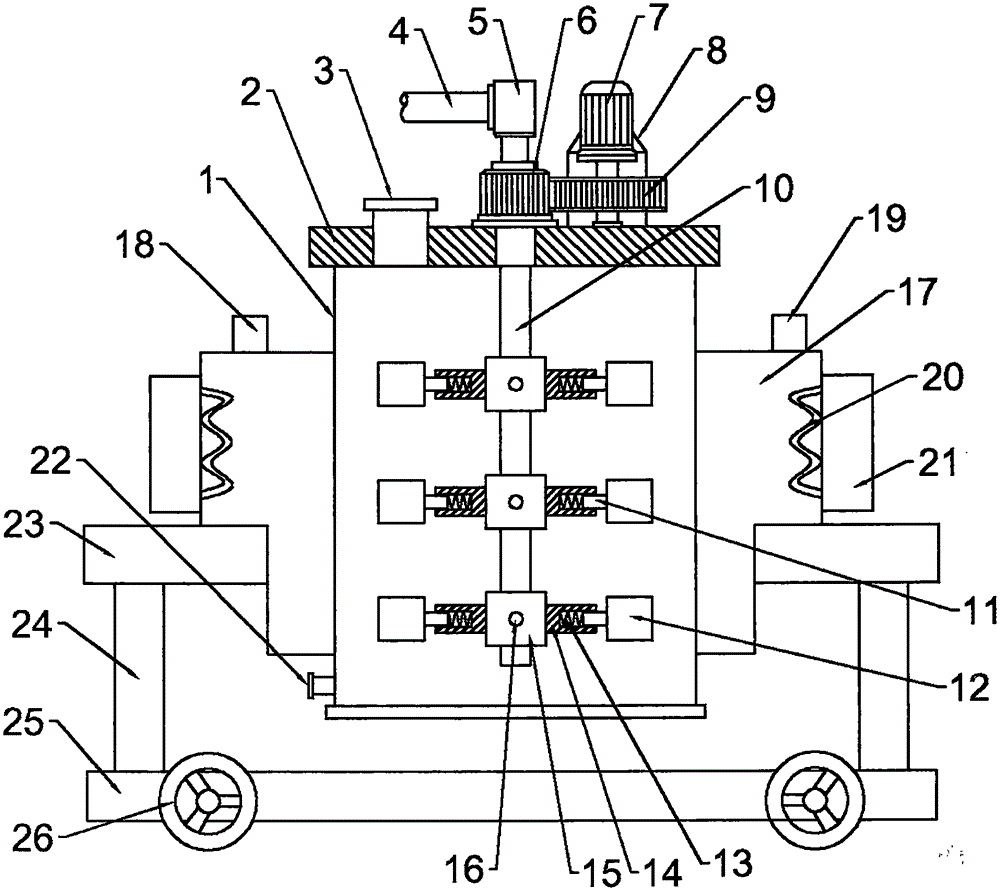

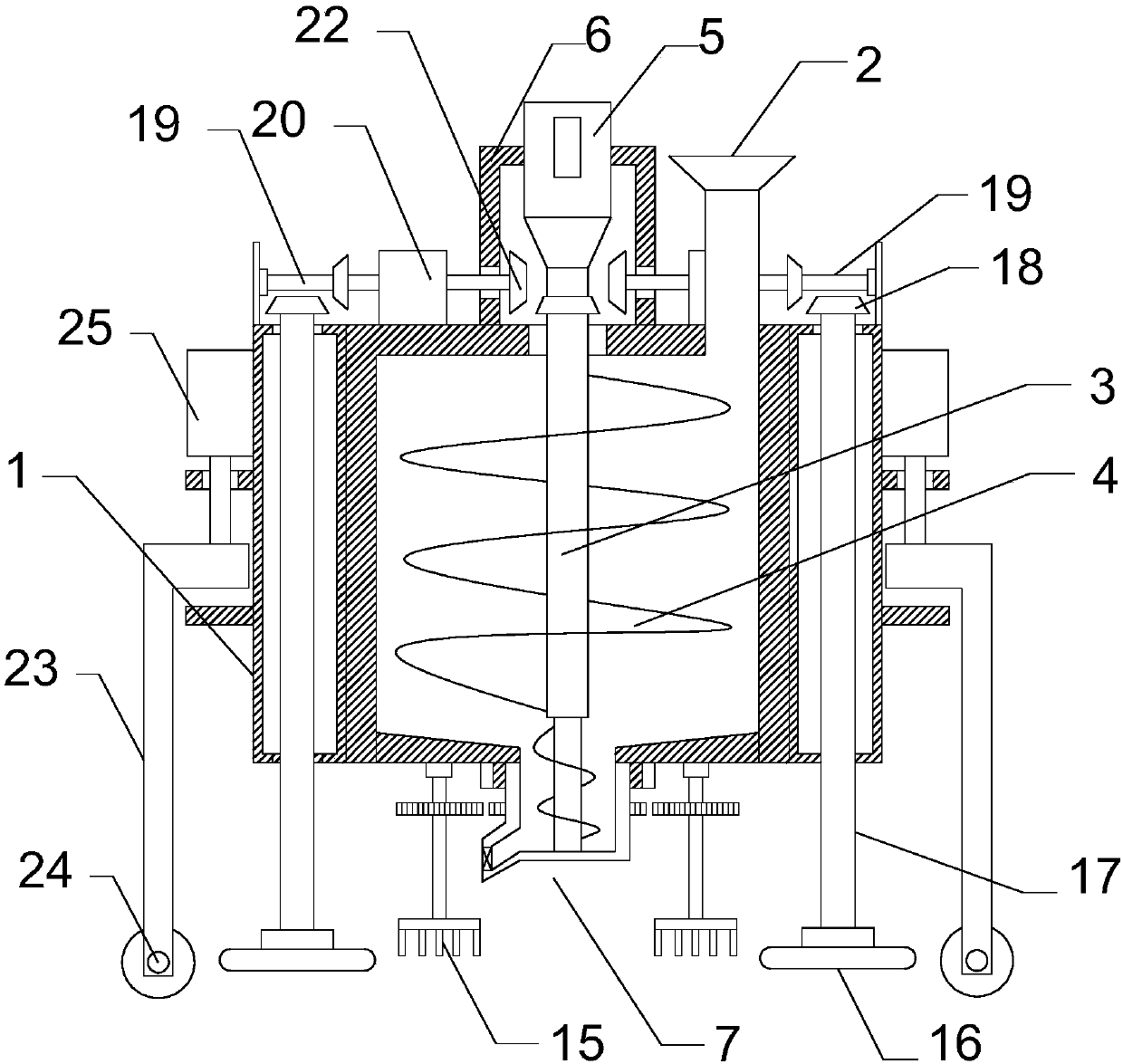

Movable adjustable-stirring-radius reaction kettle

InactiveCN105642216AGood mixing effectImprove mixing efficiency and mixing effectChemical/physical/physico-chemical stationary reactorsWater tanksInlet valve

The invention discloses a movable adjustable-stirring-radius reaction kettle. The movable adjustable-stirring-radius reaction kettle comprises a kettle body, a motor is mounted on a seal cover which is connected above the kettle body, an output end of the motor is connected with a transmission gear through a driving gear, the transmission gear is fixed to a stirring shaft, and the top of the stirring shaft is connected with a liquid adding pipe through a right-angled liquid inlet valve. Positioning sleeves are arranged, in the kettle body, on the stirring shaft and provided with first connection columns. Each first connection column is internally provided with a hollow cylindrical groove, a reset spring is arranged in each cylindrical groove and connected with one end of the corresponding cylindrical groove, and the other end of each reset spring is connected with a second connection column which is connected with a stirring blade. A water tank is arranged on the outer side of the lower end of the kettle body, left and right ends of the water tank are provided with a water outlet and a water inlet respectively, and heating tubes are arranged on heating devices which are arranged on two sides of the water tank respectively. The movable adjustable-stirring-radius reaction kettle has the advantages of excellent stirring effects and improvement of mixing efficiency, mixing effects and heat radiation effects.

Owner:姚莲琴

Efficient mixing device for fertilizer

InactiveCN106166463AGood mixing effectTo achieve the effect of high-efficiency mixingShaking/oscillating/vibrating mixersTransportation and packagingEngineeringMixing effect

The invention relates to mixing devices and particularly relates to an efficient mixing device for a fertilizer. The efficient mixing device for the fertilizer, provided by the invention, is good in mixing effect and simple in operation and is timesaving and laborsaving. The efficient mixing device for the fertilizer, provided by the invention, comprises a first motor, a first rotating shaft, a bottom board, a left frame, a first bevel gear, a bearing block, a sealing ring, a second bevel gear, a second motor, a connecting rod, a third motor and the like; and the left frame is arranged at the left side of the top of the bottom board, two third supporting rods are symmetrically arranged at the middle of the top of the bottom board, an annular slide rail is arranged at the top ends of the third supporting rods, a second sliding block is connected onto the annular slide rail in a sliding manner, a mixing box is arranged at the top of the second sliding block, the first motor is arranged at the top of the bottom board between the two third supporting rods, and the first rotating shaft is arranged on the first motor. The efficient mixing device for the fertilizer achieves the effects of being good in mixing effect and simple in operation and being timesaving and laborsaving.

Owner:丁芹

Stirring device used for wine brewing

PendingCN106906102AGood mixing effectReduce consumptionAlcoholic beverage preparationProcess engineeringBran

The application discloses a stirring device used for wine brewing. The stirring device includes a left feed chamber, a right feed chamber, a mixing chamber, a first conveyor belt, a second conveyor belt and a support. The support is provided with a shaft rod, and the mixing chamber is in rotation connection to the shaft rod; the left side of the mixing chamber is provided with a left feed port, and the right side of the mixing chamber is provided with a right feed port; the first conveyor belt is arranged in the left feed chamber, and the second conveyor belt is arranged in the right feed chamber; the first conveyor belt is provided with a plurality of first projections, and the second conveyor belt is provided with a plurality of second projections; the bottom of the mixing chamber is provided with a plurality of through holes; a stirring chamber is arranged below the mixing chamber, a plurality of the stirring shafts are fixed in the stirring chamber and are in rotation connection with a stirrer, and a plurality of stirring blades are arranged on the stirrer in an inclined manner. Compared with the prior art, the stirring device can fully mix fermented grains and bran husk, is good in mixing consistency, and makes Chinese liquor excellent in quality. The device can effectively save energy.

Owner:贵州省仁怀市茅台镇永泰酒业股份有限公司

Method and device for integral deodorization and sewage treatment of municipal sewage plants

InactiveCN103127820AGood mixing effectImprove mass transfer efficiencyDispersed particle separationSustainable biological treatmentOdor sourceMunicipal sewage

The invention discloses a method for integral deodorization and sewage treatment of municipal sewage plants. The method comprises the following steps of: erecting a half-sealed gas collection area around or above an odor source, or using a former half-sealed building, and collecting generated odor; and conveying the odor into a submersible jet type aerator through a conveying pipeline, uniformly enabling the mixed odor and sewage to enter an aeration basin through the submersible jet type aerator, and removing fusty matters through adsorption, dissolving and biological degradation. With the adoption of the manner, the method for the integral deodorization and sewage treatment of the municipal sewage plants can be used for simplifying the design, the operation and the management of a deodorization facility, reducing the investment cost and the operation cost, and effectively treating various fusty matters. Furthermore, the method for the integral deodorization and sewage treatment of the municipal sewage plants has a good treatment effect and is very applicable to deodorization updating improvement of the built sewage plants and construction of an integrated deodorization facility of newly built sewage plants.

Owner:SUZHOU TONGDE ENVIRONMENTAL PROTECTION TECHCO

Multifunctional ground leveling device for decoration

InactiveCN107654053AImprove stirring efficiencyGood mixing effectBuilding constructionsFloor levelDrive motor

The invention discloses a multifunctional ground leveling device for decoration, which comprises a casing and a driving motor; a stirring shaft is arranged inside the casing; the stirring shaft extends to the top of the casing and is connected with a driving motor; the bottom of the casing A discharge device is provided, and the discharge device is provided with a rotating tube. The present invention integrates a stirring device to efficiently stir and mix the coagulation map. Compared with manual labor, the stirring efficiency is high and the stirring effect is good; The leveling speed is fast and manpower is saved; the invention is equipped with an electromagnetic clutch and a leveling wheel, and uses a set of power devices to stir and smooth the concrete, reduces the volume of the device, improves the leveling efficiency, has various functions, and saves investment.

Owner:徐志华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com