Opposite mixing mechanism for compulsory type asphalt mixing machine

A mixing mechanism and opposed technology, which is applied in the direction of cement mixing equipment, clay preparation equipment, chemical instruments and methods, etc., can solve the problems of poor mixing quality, limited number of mixing blades, low mixing efficiency, etc., and achieve good mixing quality and high mixing efficiency. Good effect and high stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

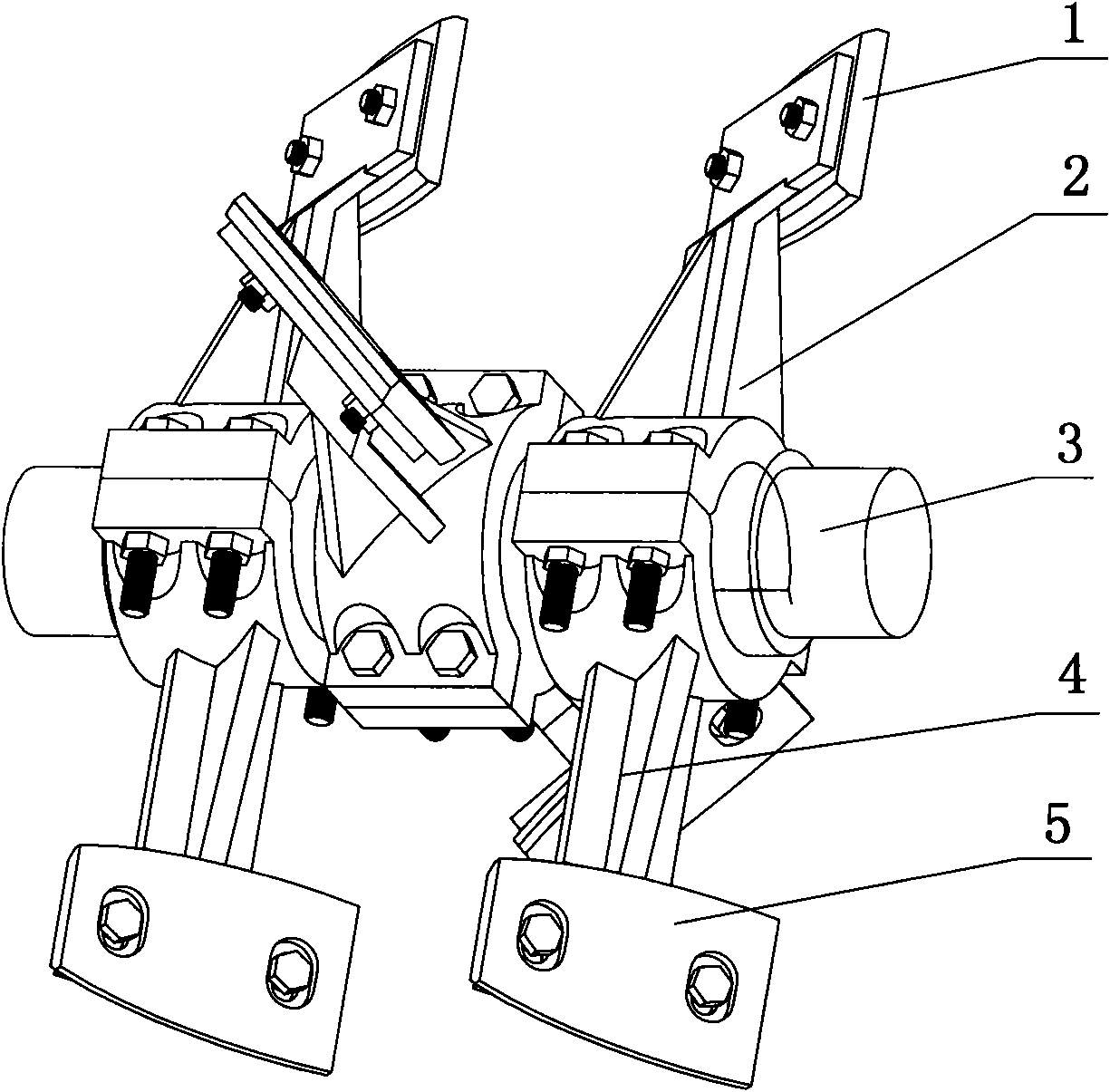

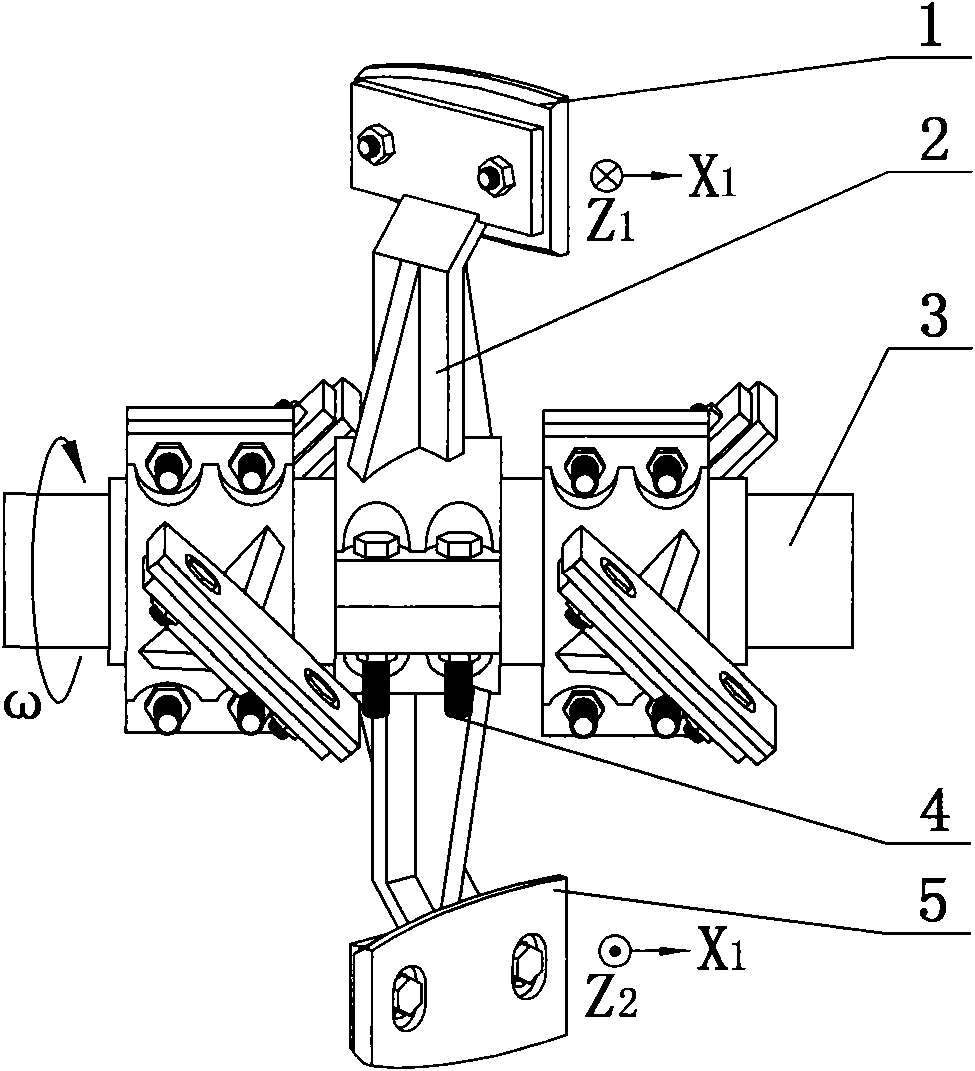

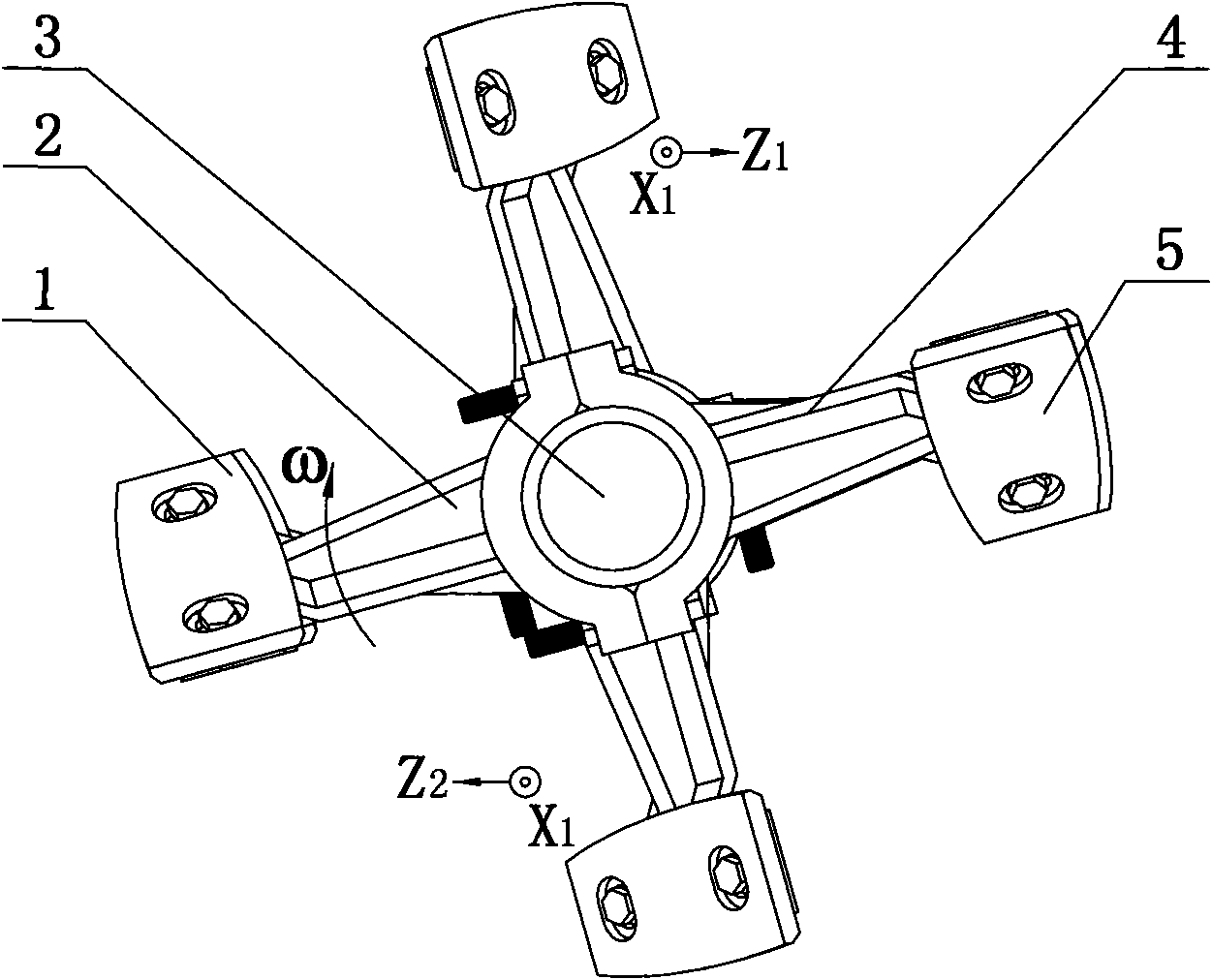

[0024] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a stirring shaft 3 and multiple sets of opposed stirring units installed on the stirring shaft 3 from left to right in turn, and the stirring shaft 3 and the opposed stirring units installed thereon form a continuous pushing and stirring of materials. Opposed stirring structure. The opposed stirring unit includes two linear stirring arms with the same structure and size and symmetrically installed on the top, bottom, front and rear sides of the stirring shaft 3 and two stirring arms with the same structure and size and installed at the ends of the two stirring arms respectively. blades, the stirring surfaces of the stirring blades are plane, and the direction in which the two stirring blades push the material to move axially is the same. The included angle between two adjacent stirring arms is 90°, and the included angle between the stirring surface of the stirring blade and the axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com