Multi-fluid jet quench radial flow reactor

A flow reactor and multi-fluid technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as difficult to meet process requirements, difficult adjustment and operation, complex structure, etc., to achieve simple design, increased manufacturing difficulty, good mix effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

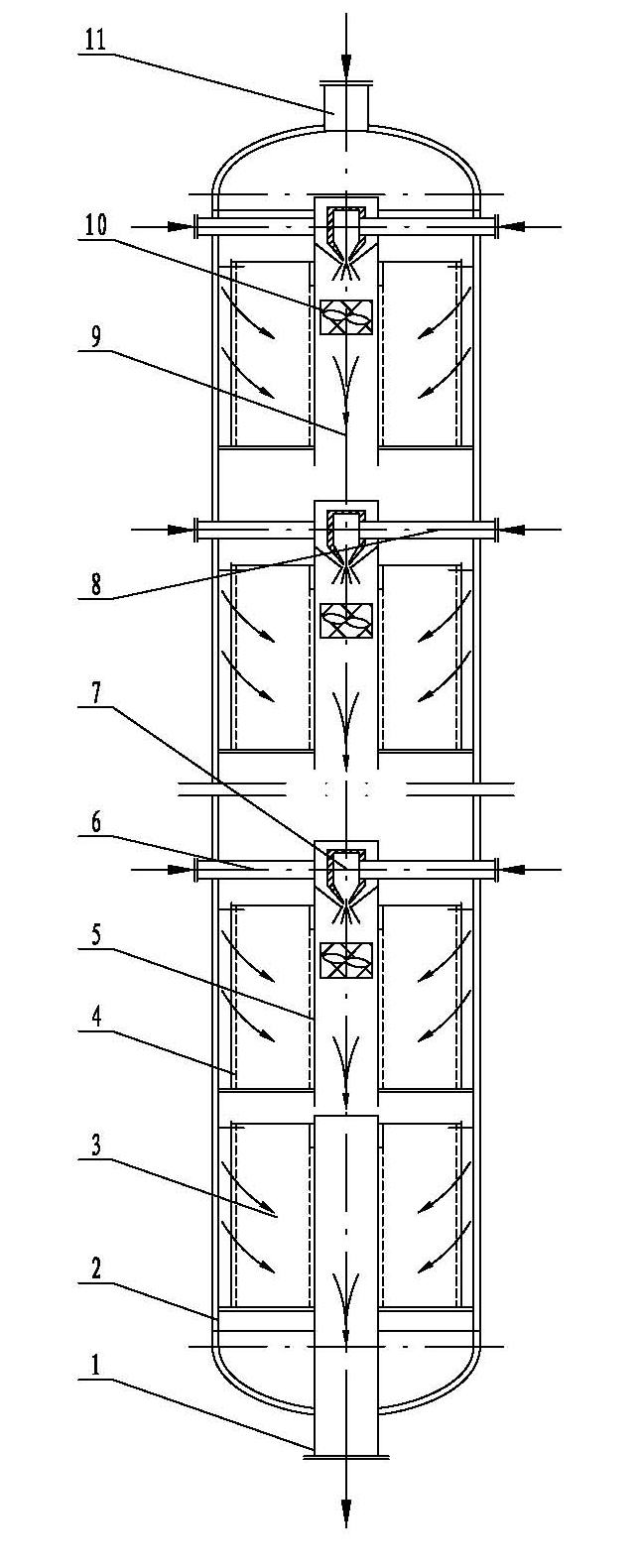

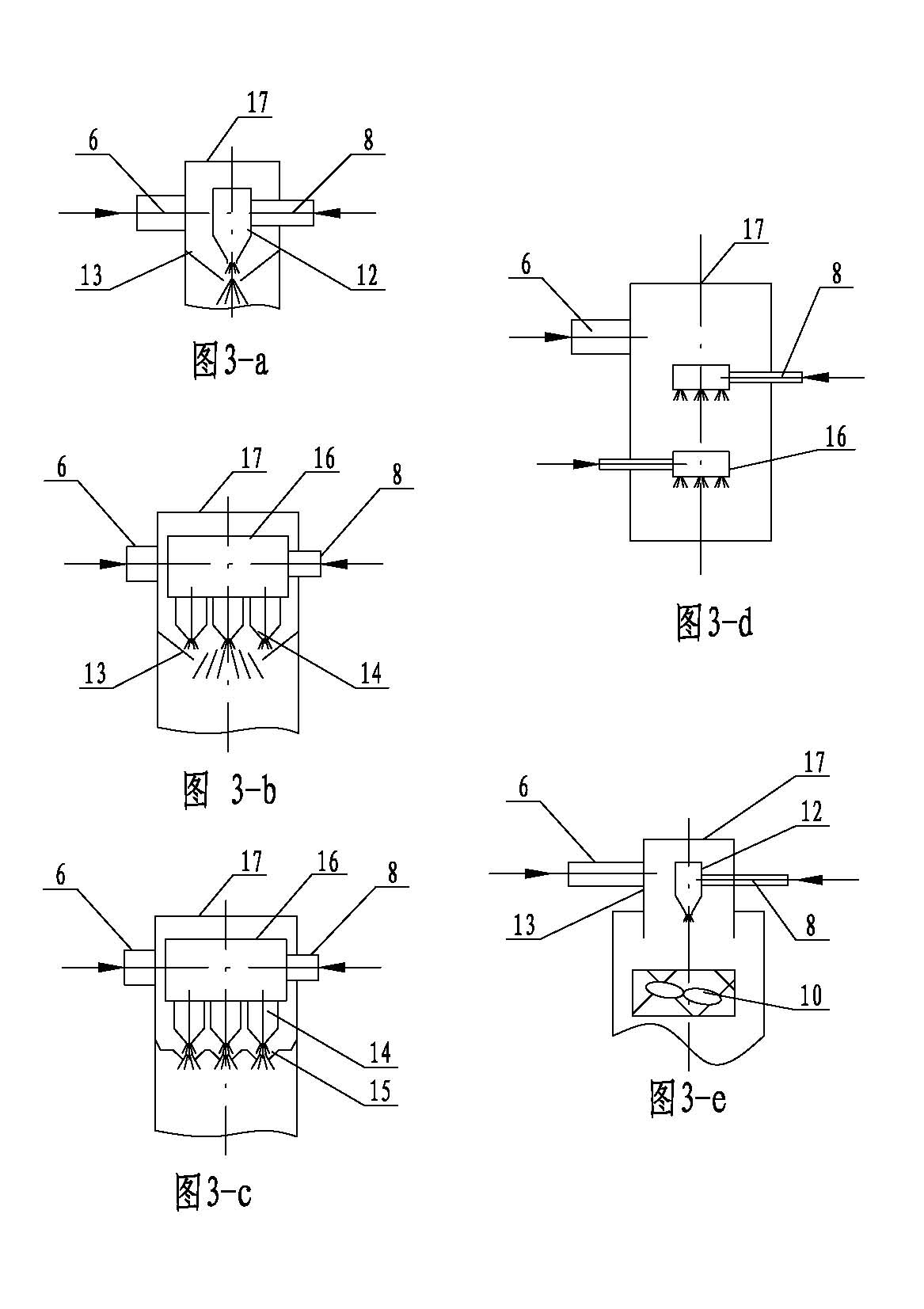

[0040] Such as figure 2 , 3 , 4, and 5.

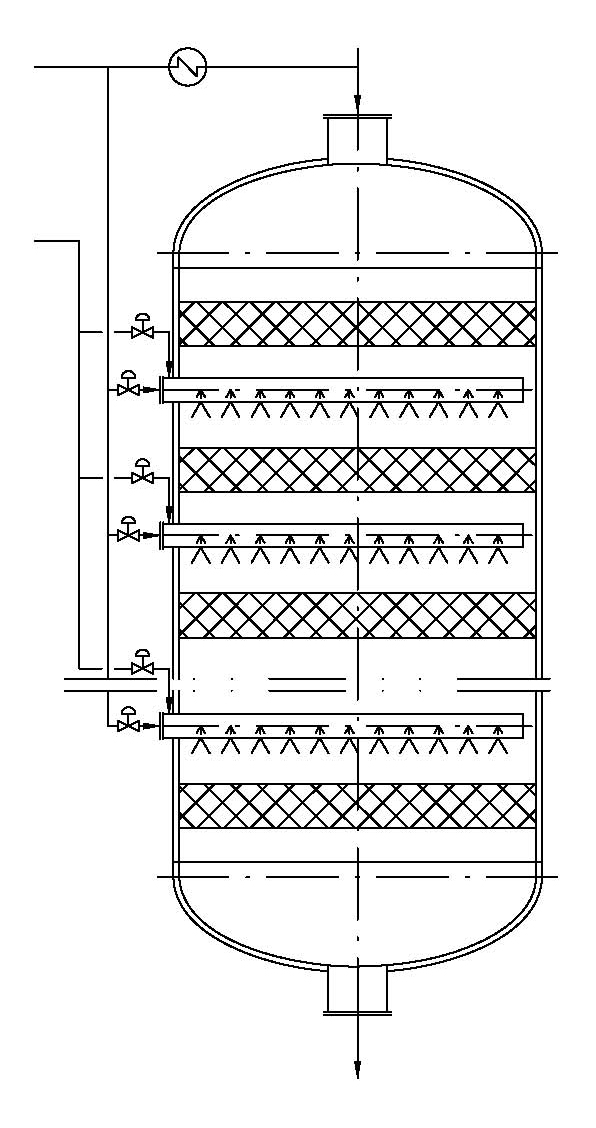

[0041]This example is a multi-fluid injection chilled radial flow reactor, which includes a radial reactor shell 2, the upper end of the shell 2 is provided with a gas inlet pipe 11 communicating with the inside, and the lower end of the shell 2 A gas outlet pipe 1 communicating with the inside is provided, and several radial catalytic beds 3 are provided in the housing 2, and each radial catalytic bed 3 is provided with a radial flow outer distribution cylinder 4, and the radial flow outer The center of the distribution cylinder 4 is provided with a radial flow inner gas collector 5, and a central mixing tube 9 is installed in the radial flow inner gas collector 5. Heat exchange can be performed between the radial flow inner gas collector 5 and the central mixing tube 9. The hot fluid in the gas collector 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com