Broken glue feeding rubber mixing technique

A crushing and mixing technology, applied in the field of rubber processing, which can solve the problems of large impact damage of internal mixer, poor mixing uniformity, large impact load of internal mixer, etc., to achieve the improvement of rubber mixing uniformity and stability, logistics The effect of increasing the level of automation and reducing the impact damage of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

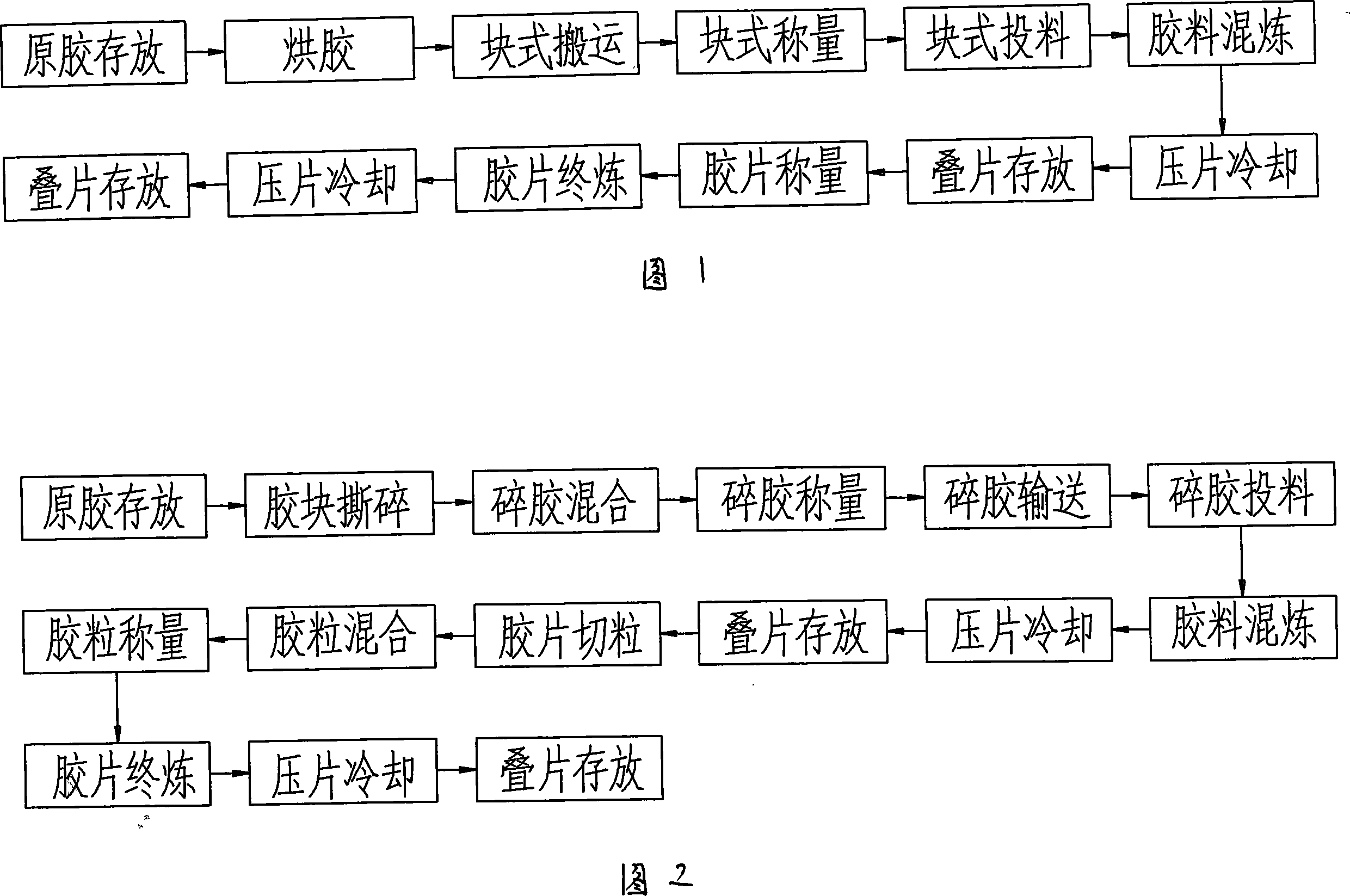

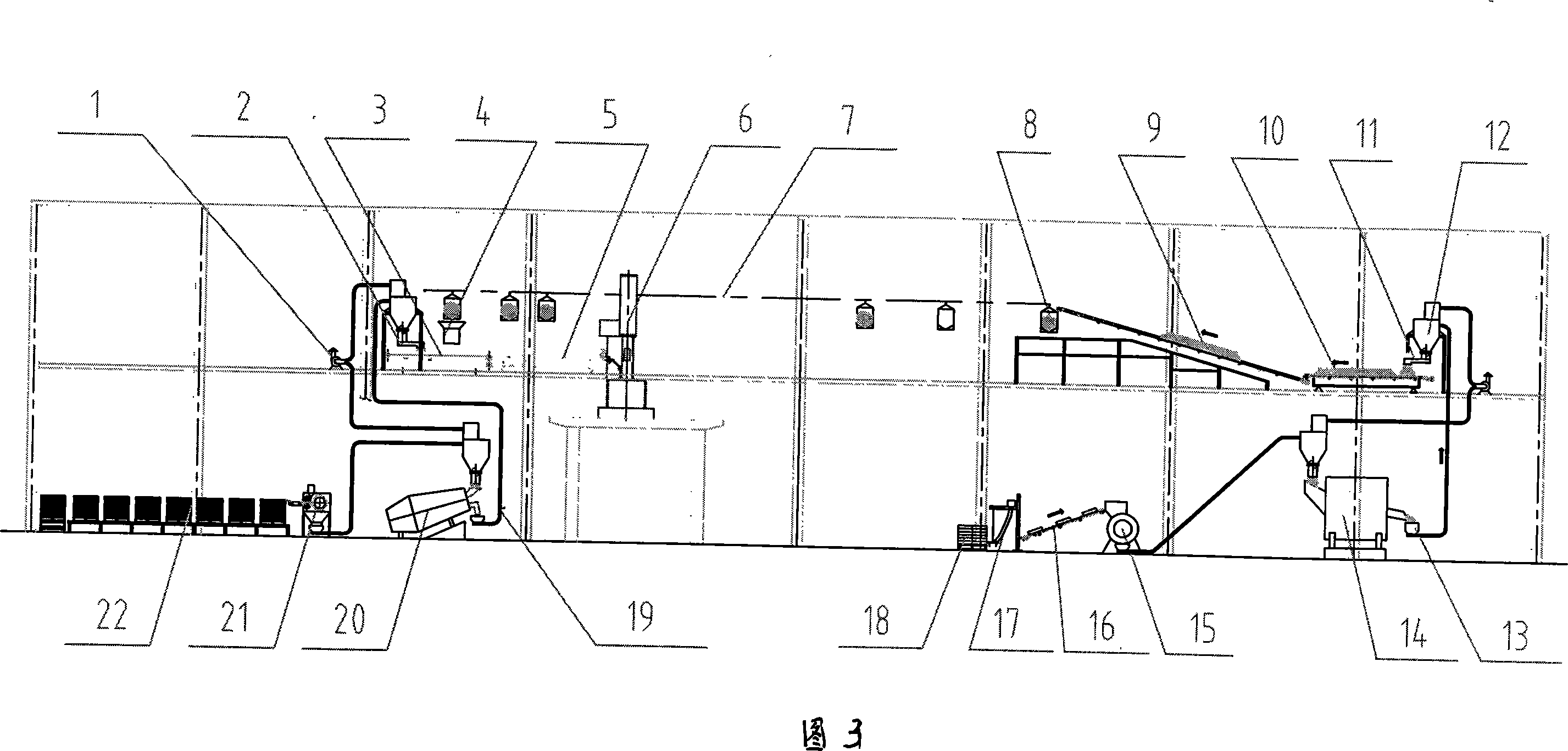

[0026] In Figure 2, the process steps are: storage of raw rubber, shredding of rubber blocks, weighing of crushed rubber, conveying of crushed rubber, feeding of crushed rubber, mixing of rubber materials, cooling of compressed sheets, storage of stacked sheets, cutting of films, gluing Particle mixing, rubber particle weighing, film final refining, tablet cooling and stack storage. The specific process is described in detail as follows:

[0027] The first step is to crush the rubber block: put the rubber block into the raw rubber crusher for crushing, and then discharge;

[0028] The second step, mixing the crushed glue: transfer the crushed glue into the mixer for mixing;

[0029] The third step, weighing crushed rubber: weigh the mixed crushed rubber on a belt scale according to the required weight;

[0030] The fourth step, crushed rubber batching: Multiple mixers placed side by side store different batches and sources of raw rubber crushed, weighed according to the set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com