Graphene paste material and preparation method thereof

A graphene and slurry technology, applied in the field of obtained graphene slurry materials, can solve the problems of reduced graphene performance, low graphene yield, usage restrictions, etc., and achieves uniform and stable quality, high yield, and damage prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

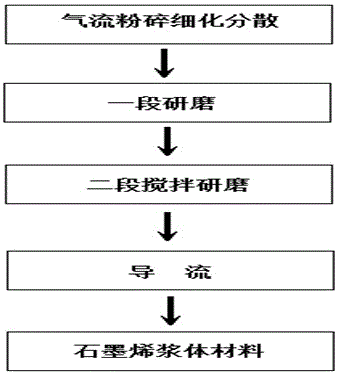

Image

Examples

Embodiment 1

[0034] (1) Mix the dense crystalline graphite powder passed through a 100-mesh sieve with the dispersant sodium pyrophosphate and the chelating agent ethylenediaminetetraacetic acid at a mass ratio of 100:1:2, and then process the material into micron-sized particles through a jet mill , and disperse the graphite powder during the crushing process;

[0035] (2) Take the material obtained in step (1), add solvent water and reducing agent sodium sulfite and mix evenly. The amount of solvent added is to ensure that the viscosity of the mixed slurry is between 100-200 mPa·s, and the amount of reducing agent added is graphite 0.5% of the mass, and then the slurry is sent to a first-stage grinder disc mill, and the grinding time is controlled at 30min;

[0036] (3) Send the slurry ground in step (2) into the second-stage grinder. The second-stage grinder is a uniform-speed stirring grinder and a high-speed shear emulsifier. During the uniform-speed stirring process, a stable liquid ...

Embodiment 2

[0039] (1) Mix flake graphite powder passed through a 100-mesh sieve with dispersant sodium lauryl sulfate and chelating agent triethylenetetramine hexamethylenephosphonic acid at a mass ratio of 100:3:2, and then pass the material through a jet mill Processed into micron-sized particles, and disperse graphite powder during the crushing process;

[0040](2) Take the material obtained in step (1), add solvent ethanol and reducing agent thiourea dioxide and mix evenly. The amount of solvent added is to ensure that the viscosity of the mixed slurry is between 100-200 mPa·s. The amount of reducing agent added is 1% of the mass of graphite, and then the slurry is sent to a grinding machine star-type ball mill, and the grinding time is controlled at 45min;

[0041] (3) Send the slurry ground in step (2) into the second-stage grinder. The second-stage grinder is a constant-speed stirring grinder, that is, a vertical stirring mill. During the uniform-speed stirring process, a stable l...

Embodiment 3

[0044] (1) Mix the expanded graphite powder passed through a 100 mesh sieve with the dispersant polyvinylpyrrolidone and the chelating agent citric acid at a mass ratio of 100:3:5, and then process the material into micron-sized particles through a jet mill, and in the pulverization process disperse the graphite powder;

[0045] (2) Take the material obtained in step (1), add the solvent N-methylpyrrolidone, and the reducing agent hydrazine hydrate and mix evenly. The amount of solvent added is to ensure that the viscosity of the mixed slurry is between 100-200 mPa·s. The addition amount of graphite is 2% of graphite mass, then the slurry is sent into a colloid mill of a grinder, and the grinding time is controlled at 60min;

[0046] (3) Send the slurry ground in step (2) into the second-stage grinder. The second-stage grinder is a constant-speed stirring grinder. During the uniform-speed stirring process, a stable liquid surface is formed, and the flow line of the stirring is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com