Continuous Quenching Line for Large Diameter Tube and Bar

A large-diameter tube and bar technology, applied in the field of industrial heat treatment production line equipment, can solve problems such as inability to achieve mechanical properties, and achieve the effects of uniform and stable product quality, high quality performance, and low comprehensive investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

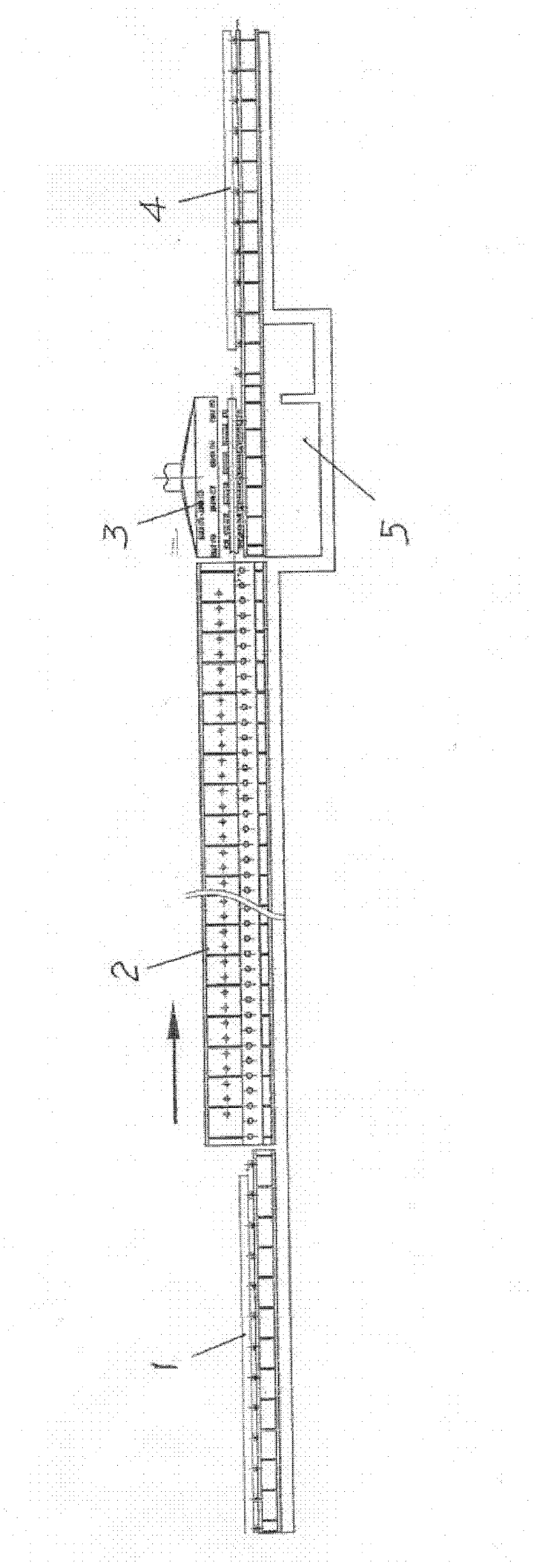

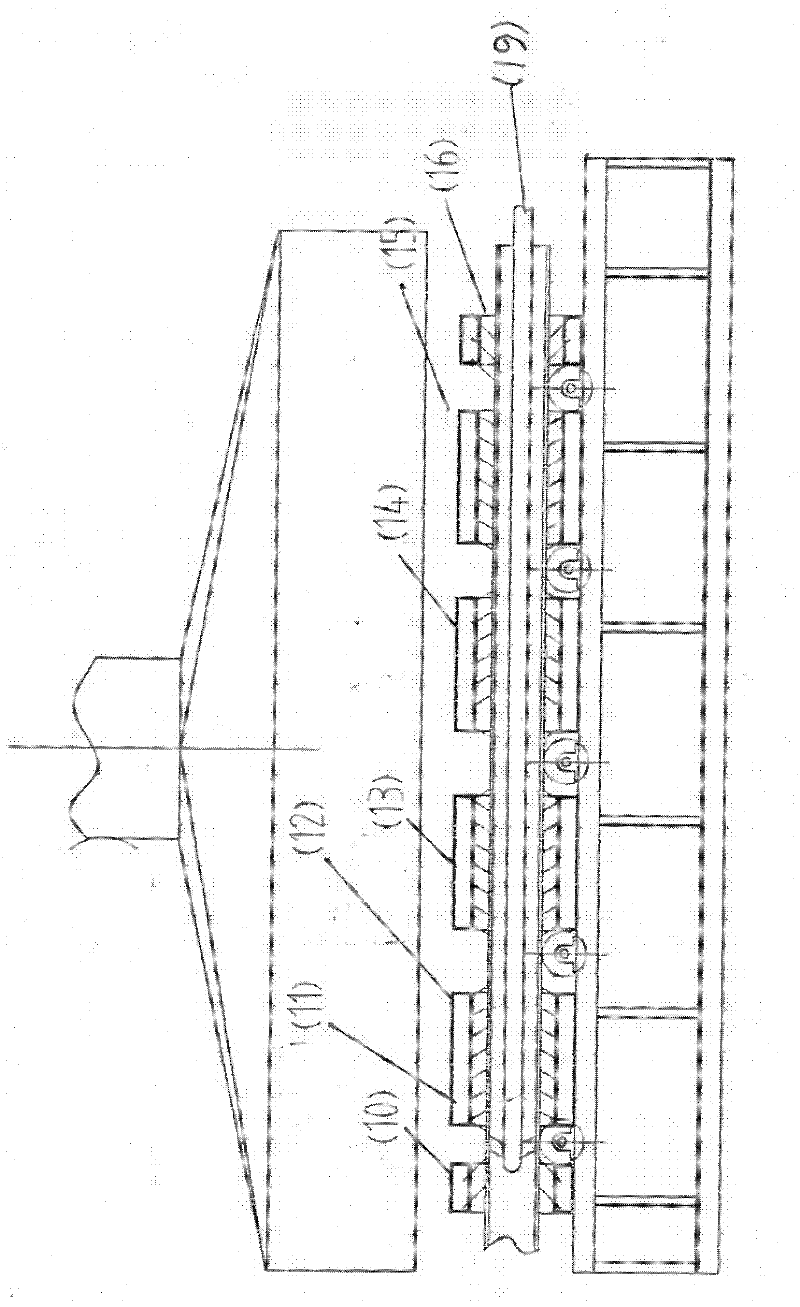

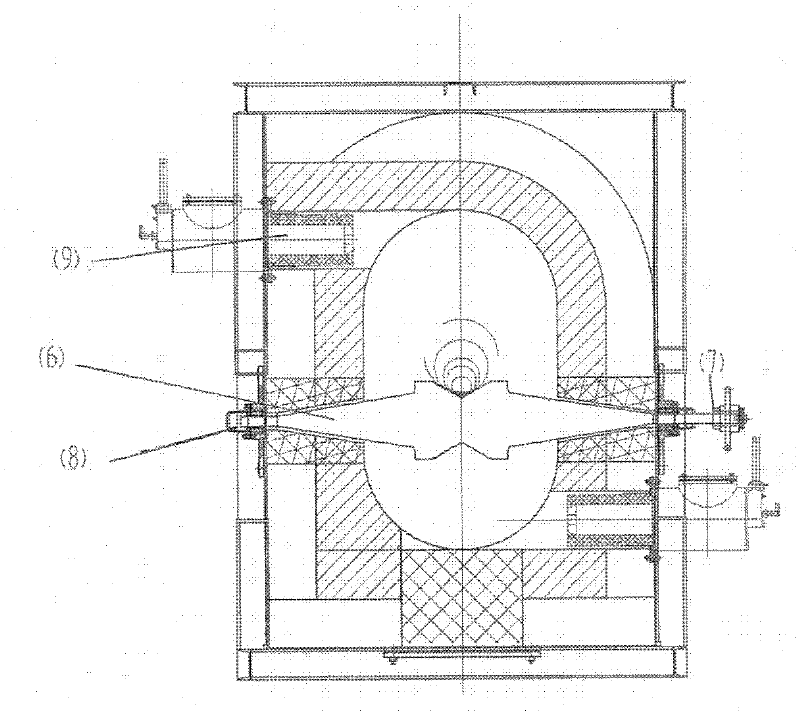

[0031] Such as figure 1 The continuous quenching line for large-diameter tubes and bars is characterized in that it consists of an automatic feeding machine, a V-shaped inclined roller transmission continuous heating furnace, a multi-functional quenching machine, an automatic unloading machine, and an automatic control system. Along the running direction of the tube and bar, the end of the automatic feeding machine (1) is connected to the V-shaped inclined-roller transmission continuous heating furnace (2), and the end of the V-shaped inclined-roller transmission continuous heating furnace (2) is connected to the multi-functional quenching machine (3) , the multifunctional quenching machine (3) is connected with the automatic blanking machine (4), and the bottom of the multifunctional quenching machine is provided with a sump (5), which is automatically controlled from the automatic feeding machine to the automatic blanking machine.

[0032] The automatic feeding machine has a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com