Patents

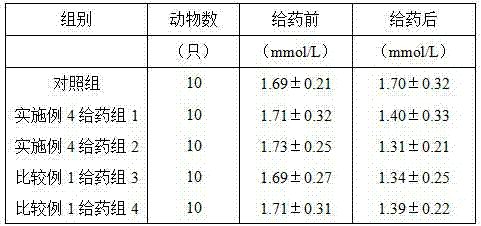

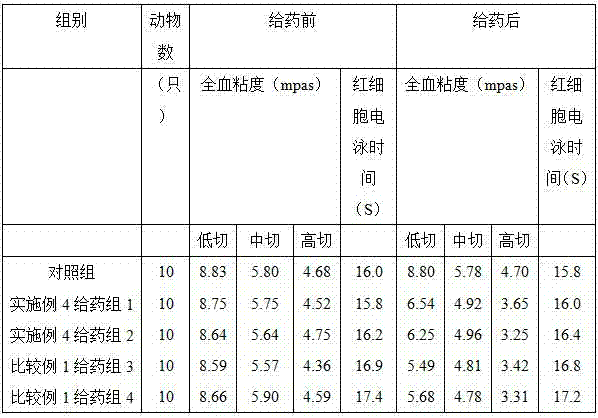

Literature

85results about How to "Uniform and stable product quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores

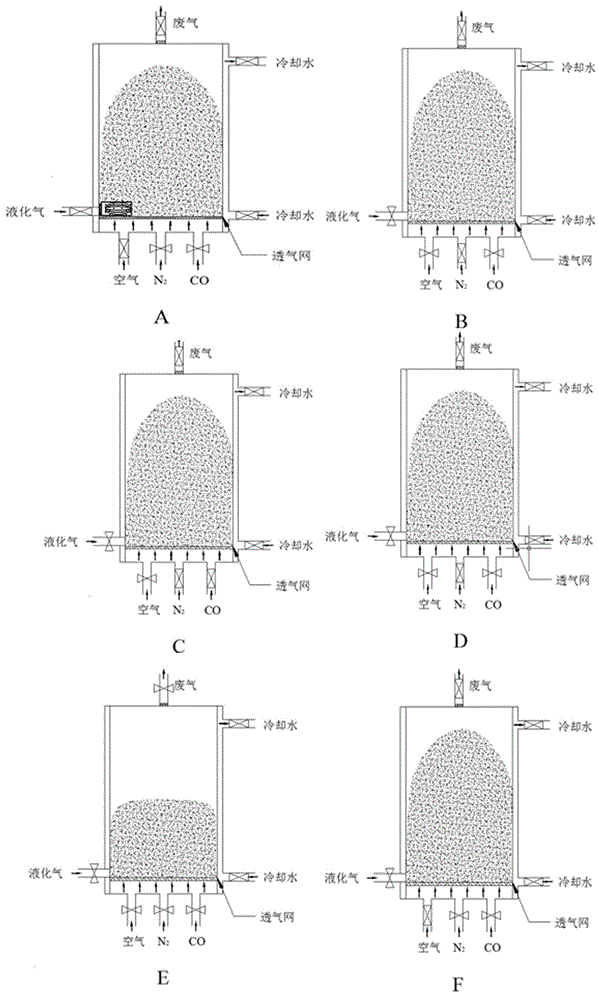

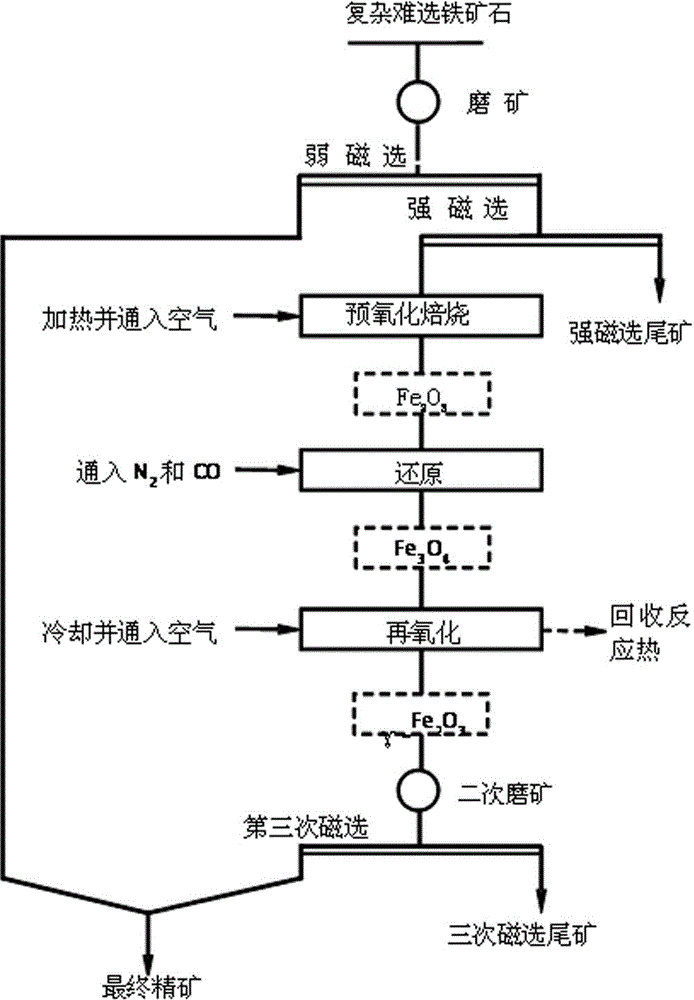

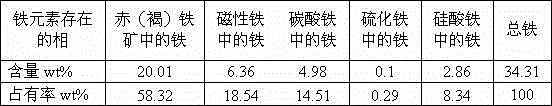

The invention discloses a preenrichment-three segment suspension roasting-magnetic separation treatment method of complex refractory iron ores, and belongs to the technical field of mineral processing. The method comprises the following steps: 1, levigating the complex refractory iron ores, carrying out weak magnetic separation, and carrying out strong magnetic separation on mine tailings; 2, putting concentrate obtained after strong magnetic separation in a suspension roasting furnace, and heating to 450-800DEG C in a suspension state in order to carry out pre-oxidation roasting; 3, introducing nitrogen to displace air, and introducing a reducing gas to carry out reduction in a suspension loose state; 4, introducing air when the temperature decreases to 250-400DEG C in order to oxidize, taking out the obtained material when the temperature decreases to below 100DEG C, and carrying out ore milling; and 5, carrying out third segment magnetic separation, and mixing concentrate obtained after three segment magnetic separation with concrete obtained after the weak magnetic separation to obtain finial concentrate. The method has the advantages of simple process, improvement of the recovery rate of the complex refractory iron ores, strong adaptability, safe and reliable process, uniform and stable product quality, energy saving and consumption reduction.

Owner:上海逢石科技有限公司

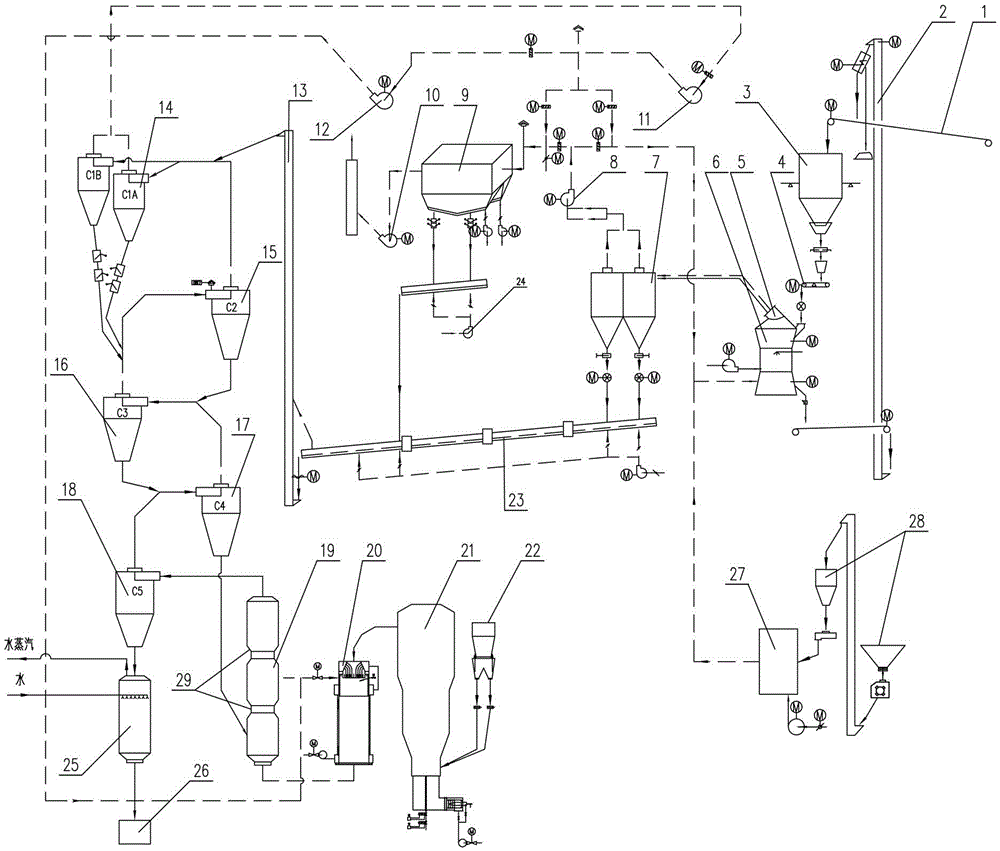

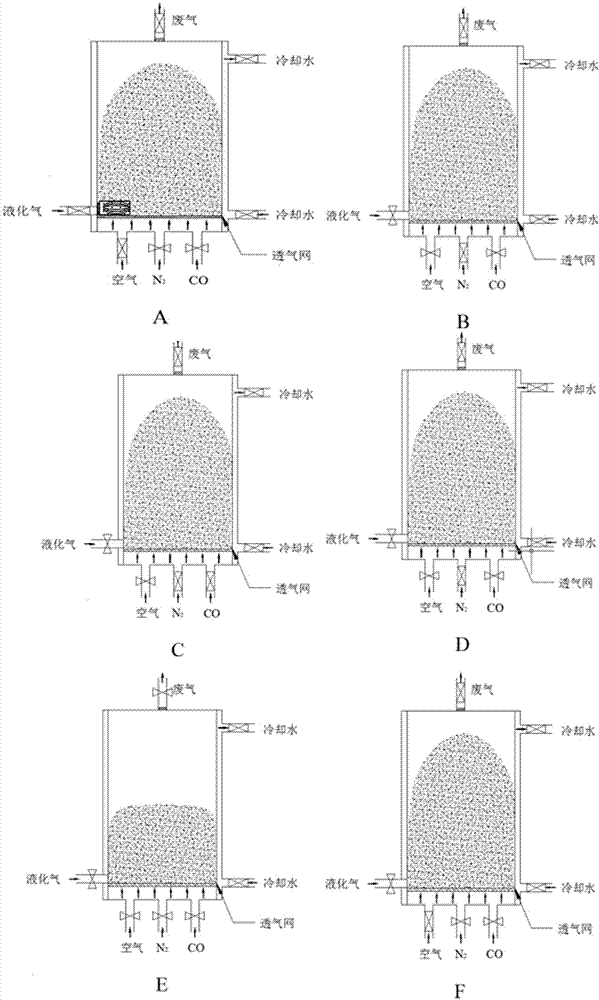

Preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore

The invention relates to the production techniques of iron ore concentrate of refractory ore, in particular to a preparation method for producing strong-magnetism magnetite through refractory weak-magnetism oxidized iron ore. The method comprises the following steps that firstly, the crushed iron ore is ground into fine ore; then the fine ore is subjected to low-temperature roasting, and during the low-temperature roasting, the fine ore is made to be in a roasting system to be preheated and roasted; the roasted ore enters a cooling system to be cooled; and then the cooled roasted ore is subjected to size mixing and sent to a magnetic separation system to be separated, and high-grade iron ore concentrate is obtained through separation. According to the method, the process is simple, the temperature and air flow are distributed uniformly, control is easy, the automation degree is high, the number of operation components of equipment is small, refractory siderite and limonite can be treated, the magnetizing roast efficiency of the refractory iron ore is high, heat is substantially recycled during roasting, the roasted ore is stable in quality and high in magnetic separation efficiency, and the technical indexes that the grade of the iron ore concentrate is larger than 60%, and the iron recycling rate is larger than 85% can be achieved.

Owner:湖北华方装备有限公司

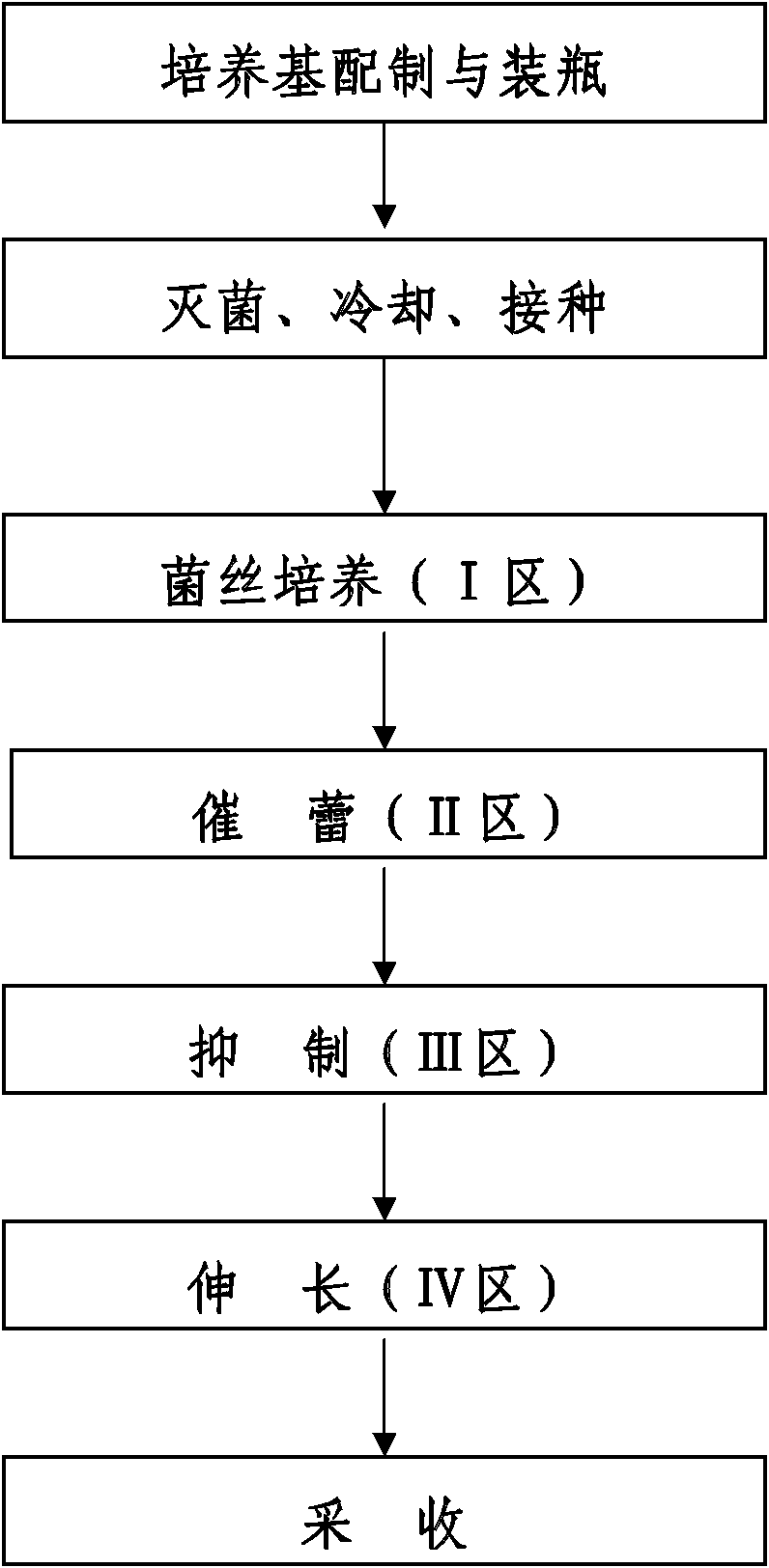

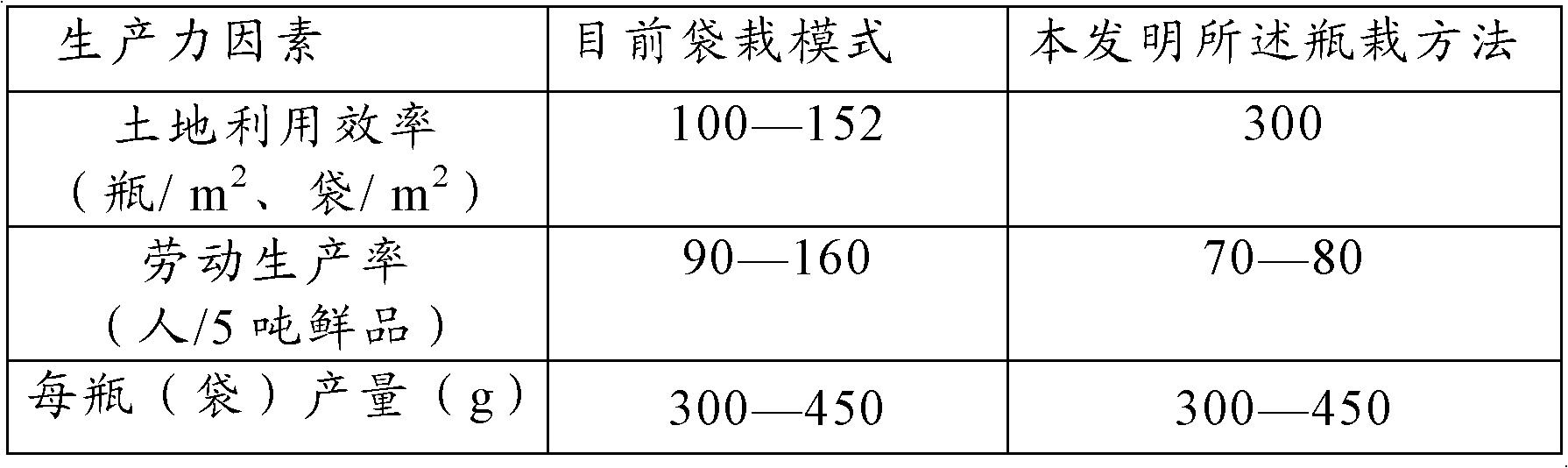

Bottle cultivation method for Hypsizigus marmoreus

The invention discloses a bottle cultivation method for Hypsizigus marmoreus. The bottle cultivation method for the Hypsizigus marmoreus comprises the following steps of: inoculating the Hypsizigus marmoreus on a bottled culture medium, wherein the inoculation ratio is that each bottle of fungal strains are inoculated on 32 to 40 bottles of culture bottles; performing mycelium culture under the conditions of temperature of between 18 and 25 DEG C, humidity of 60 to 80 percent and CO2 concentration of 1,500 to 5,500 ppm; after the Hypsizigus marmoreus are matured, performing mycelium stimulation and supplementing a small amount of water; performing inducement to primordium; after mushroom buds are generated, performing inhibition period culture for 3 to 5 days; when the mushroom buds grow out of the bottleneck, sleeving a plastic sleeve; performing elongating stage culture; and harvesting after the harvesting standard is reached. In the bottle cultivation method, the period is 105 to 125 days and average yield of a single bottle is 300 to 450g. The bottle cultivation method is a factory-like bottle cultivation method using sawdust, cotton seed hulls and corn cobs as main raw materials. By the bottle cultivation method, the mechanization level and the automation degree of the Hypsizigus marmoreus can be increased greatly; production cost is effectively reduced; stable quality isguaranteed; and a popularization prospect is achieved.

Owner:郑雪平

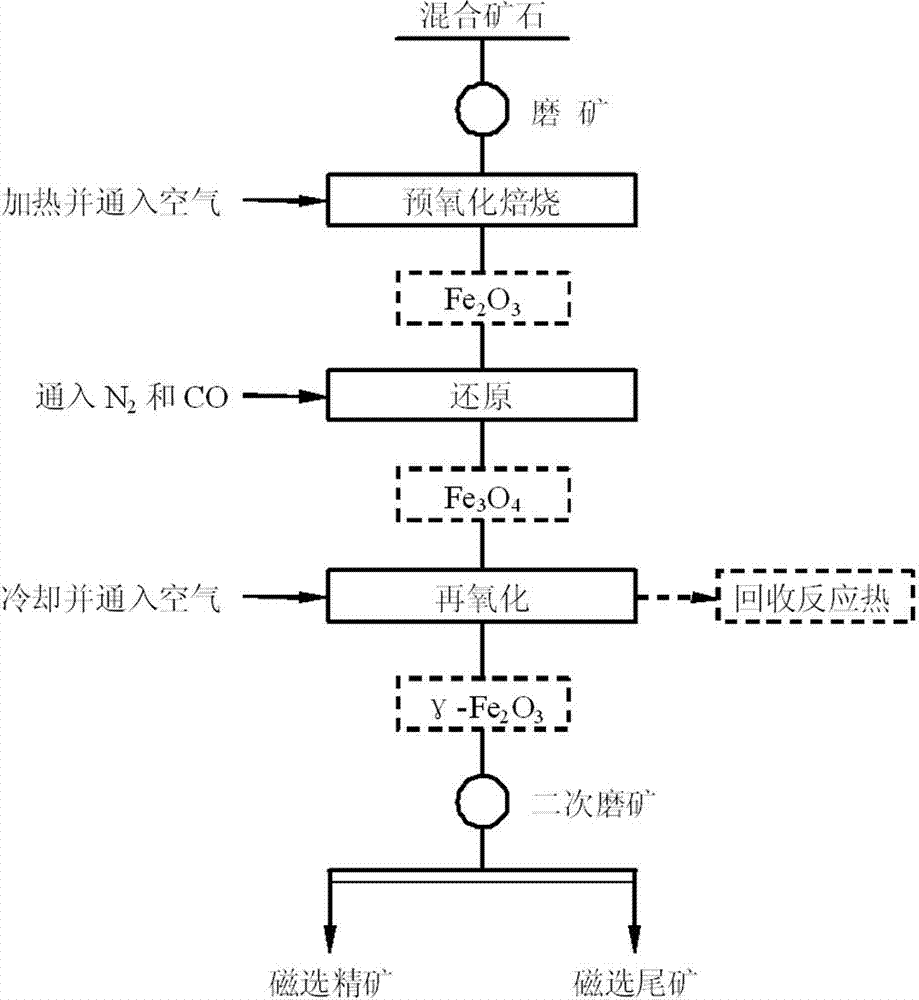

Three-stage suspension roasting-magnetic separation method for hematite-limonite mixed iron ores

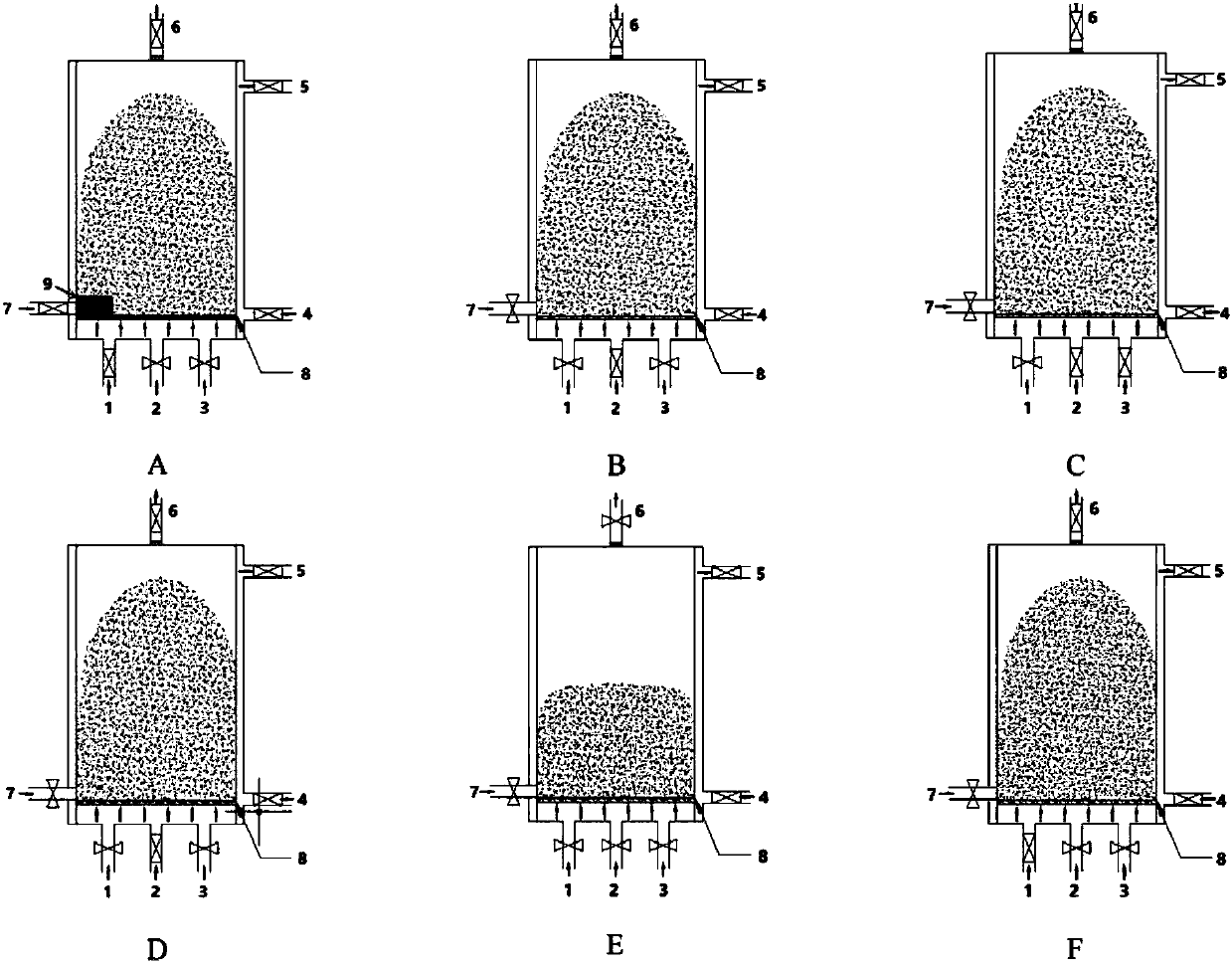

The invention relates to a three-stage suspension roasting-magnetic separation method for hematite-limonite mixed iron ores and belongs to the technical field of mineral processing. The method comprises the following steps: (1) milling the hematite-limonite mixed iron ores, then, putting the milled material into a suspension reacting furnace, and enabling the material to be in a suspended state; heating to the temperature of 450-800 DEG C, so as to carry out preoxidation roasting; (2) stopping heating, and introducing nitrogen gas to displace air; introducing reductive gas, and enabling the material to be in a suspended loose state, so as to carry out reduction; (3) displacing unreacted residual reductive gas, introducing air to carry out reoxidation when the temperature is lowered to 250-400 DEG C, and then, taking out and carrying out secondary milling; (4) carrying out magnetic separation under the condition that the intensity of a magnetic field is 60-100kA / m. According to the method disclosed by the invention, the process is simple, the recovery ratio of highly-difficultly-separated ores is increased, the adaptability of the method is strong, the process is safe and reliable, and the product quality is uniform and stable; the method has the advantages of energy saving and consumption reducing.

Owner:NORTHEASTERN UNIV

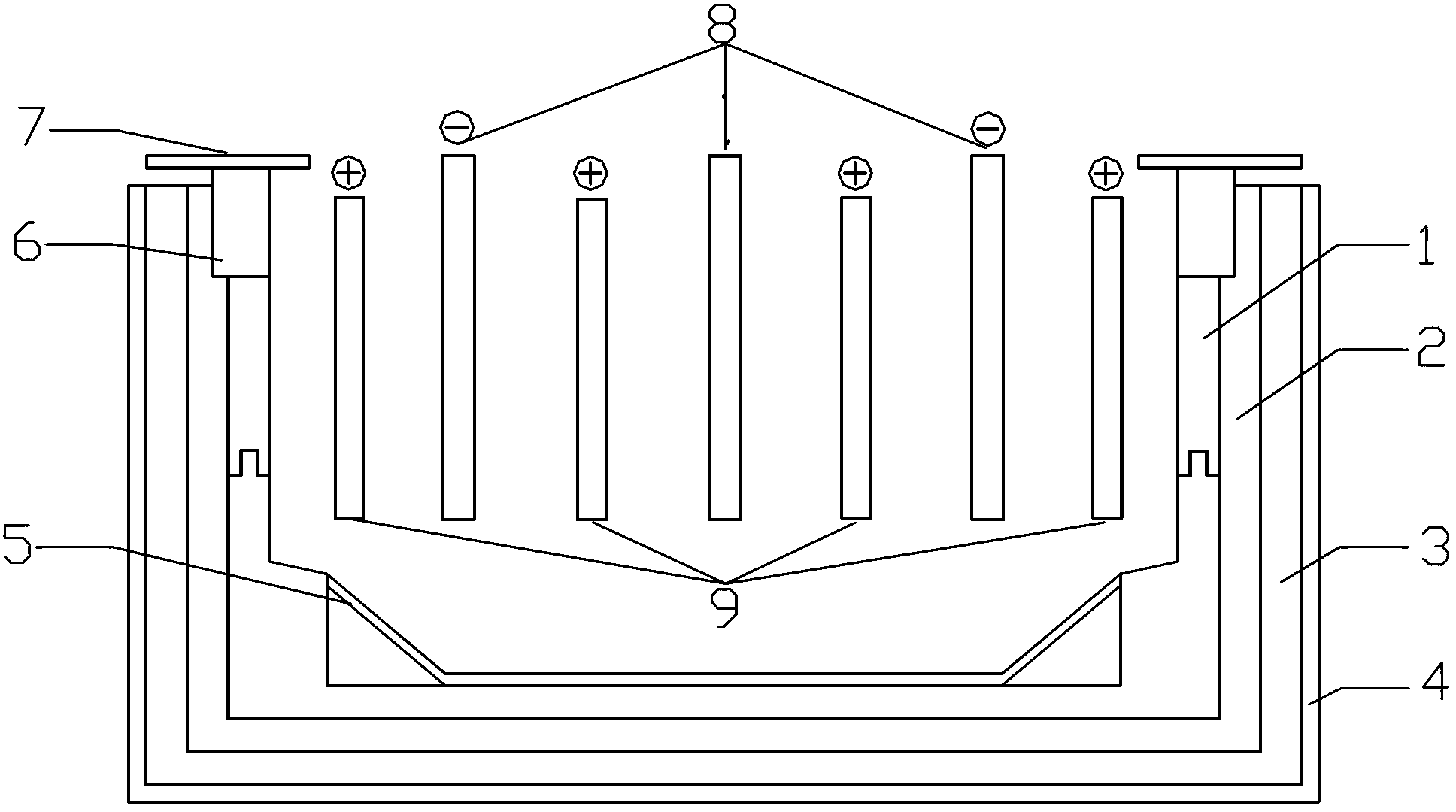

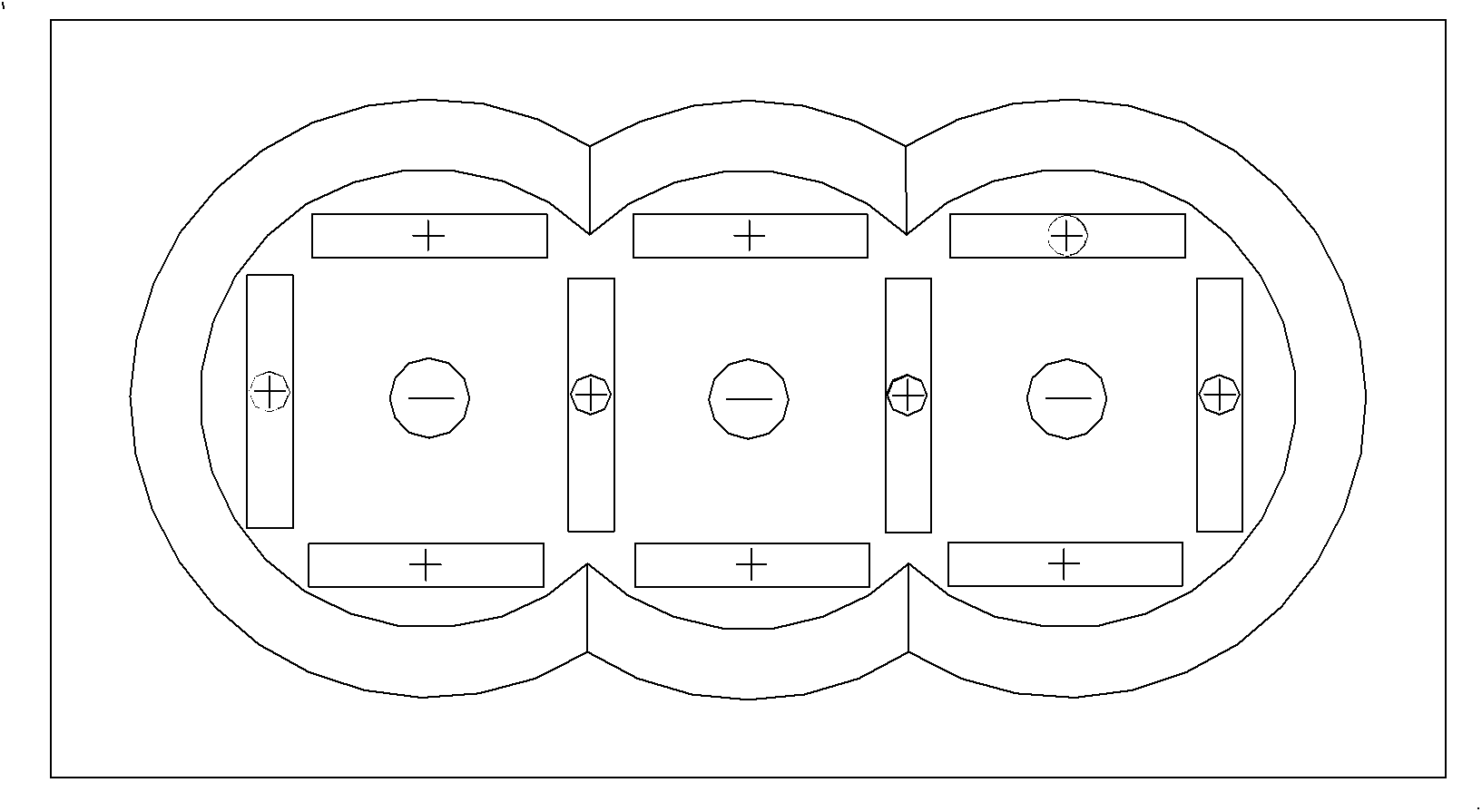

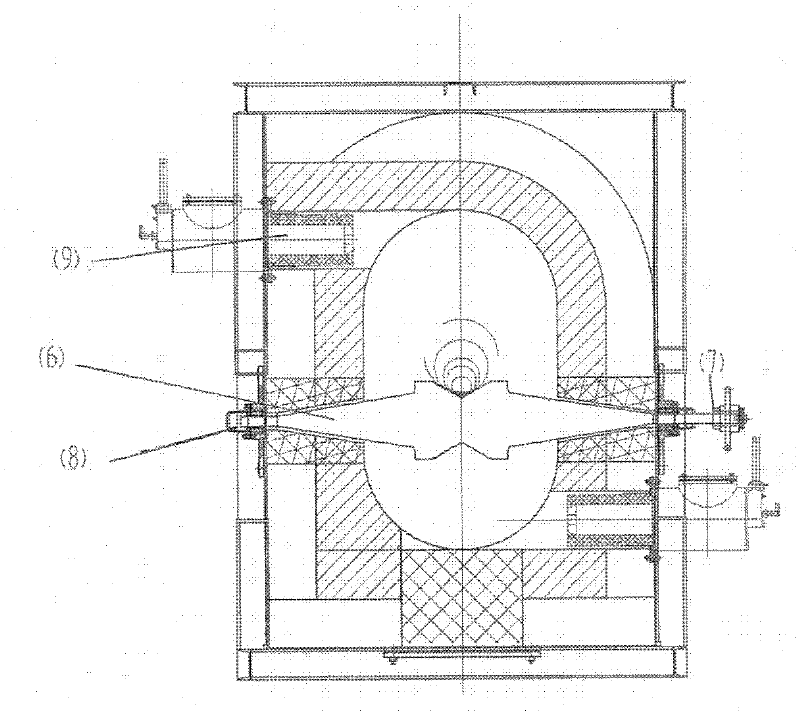

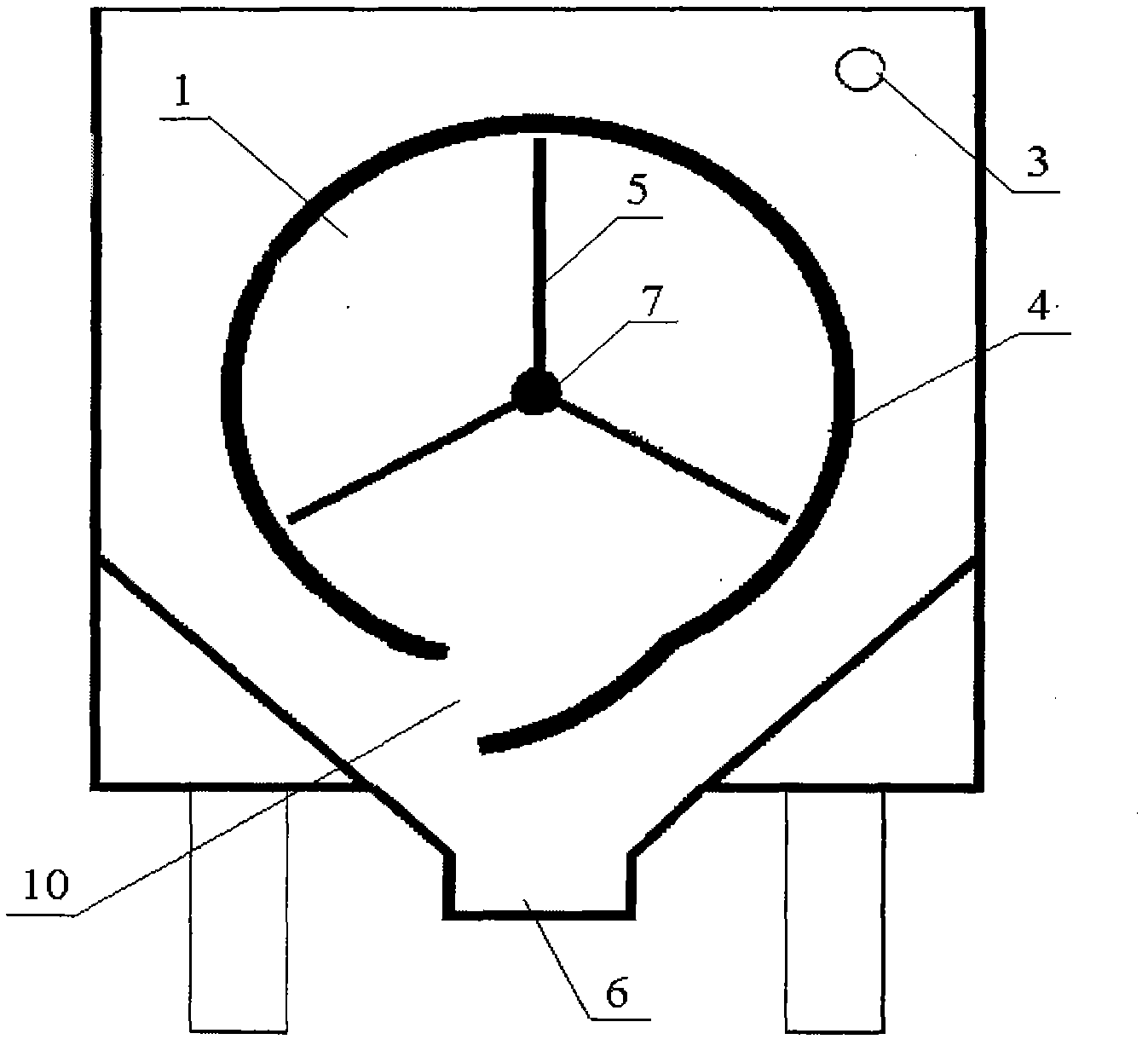

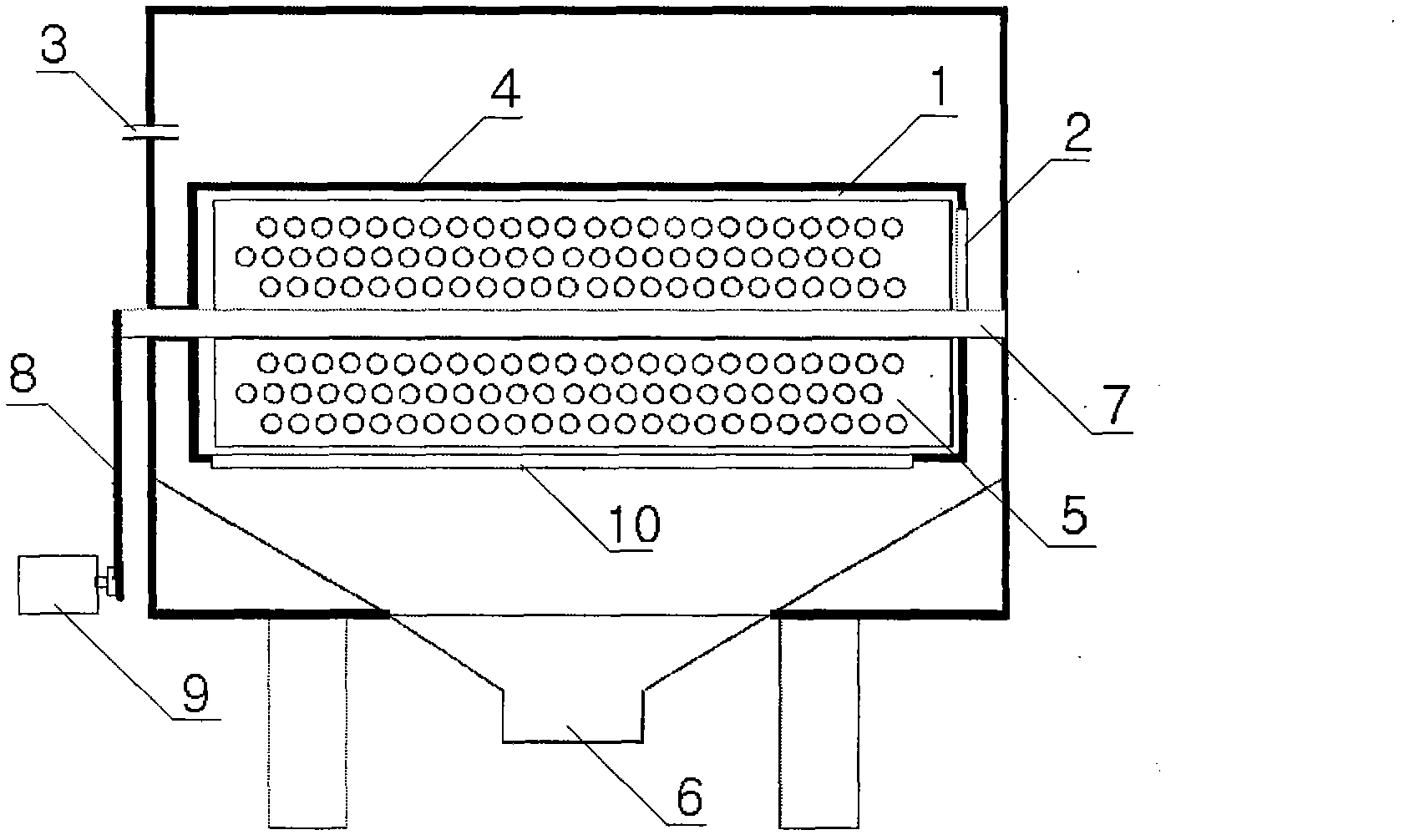

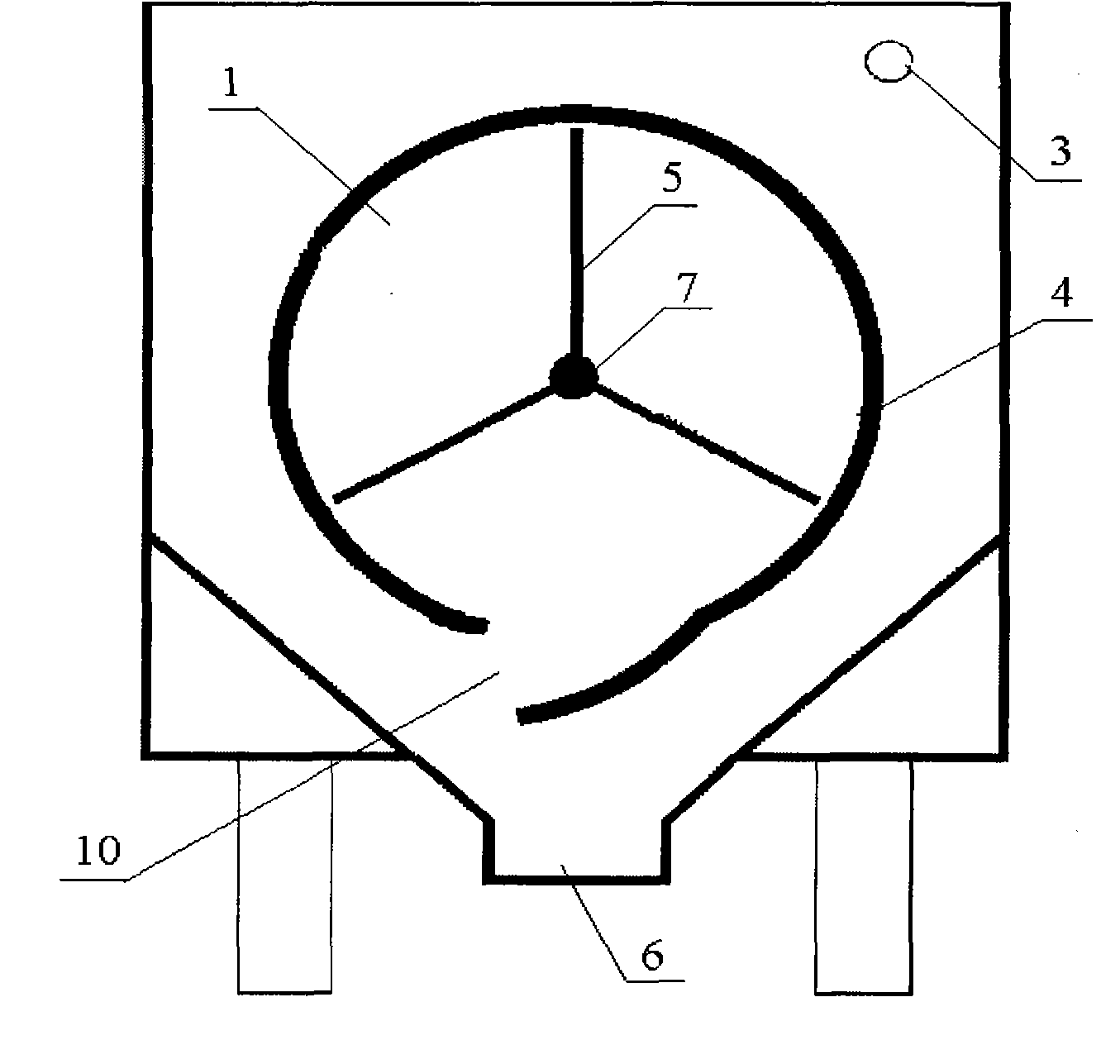

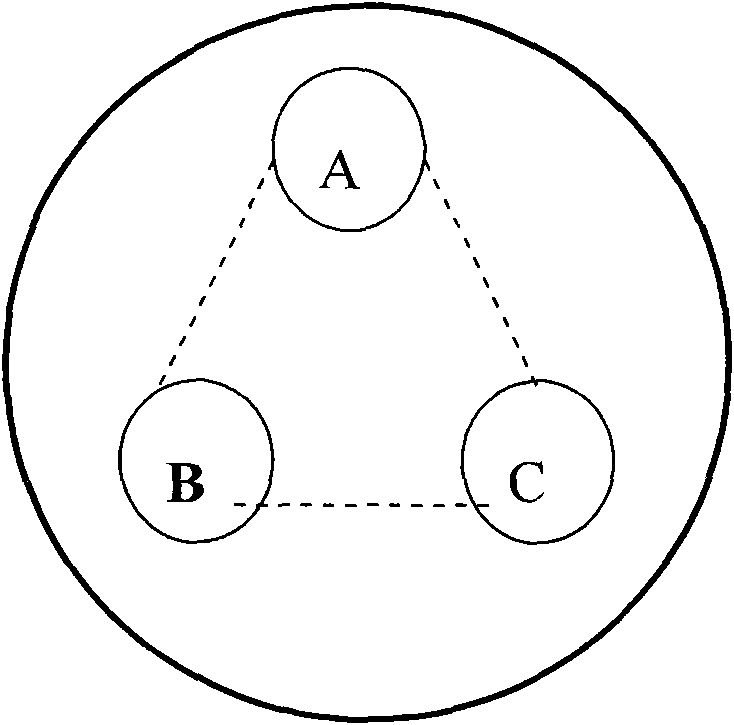

Fused-salt electrolytic cell for producing rare earth metals and alloys

InactiveCN103290434AReasonable configurationImprove current efficiencyCellsInsulation layerRare earth

The invention relates to a fused-salt electrolytic cell for producing rare earth metals and alloys, and the electrolytic cell comprises an electrolytic cell body, a cathode, an anode, a receiver, and a cover plate; and the electrolytic cell body is formed by nesting of a graphite inner liner, a carbon knotting layer, a fireproof heat-insulation layer, and a metal coat from inside to outside. The electrolytic cell is characterized in that, the sidewall of the electrolytic cell body is formed by two stages or more stages of arc surfaces which are connected with each other to form a closed state, and the electrolytic cell body is a non-enclosed type cell. The electrolytic cell has advantages of high current efficiency, a little amount of electrolytes for running a furnace, low unit consumption of graphite, long service life, balanced and steady quality of products, and low price; and the electrolytic cell is applicable to any scale productions greater than 1000 A, wherein the productions of rare earth metals and alloys are prepared by an electrolytic method of fluoride molten salt system oxide.

Owner:BAOTOU REWIN RARE EARTH METAL MATERIALS

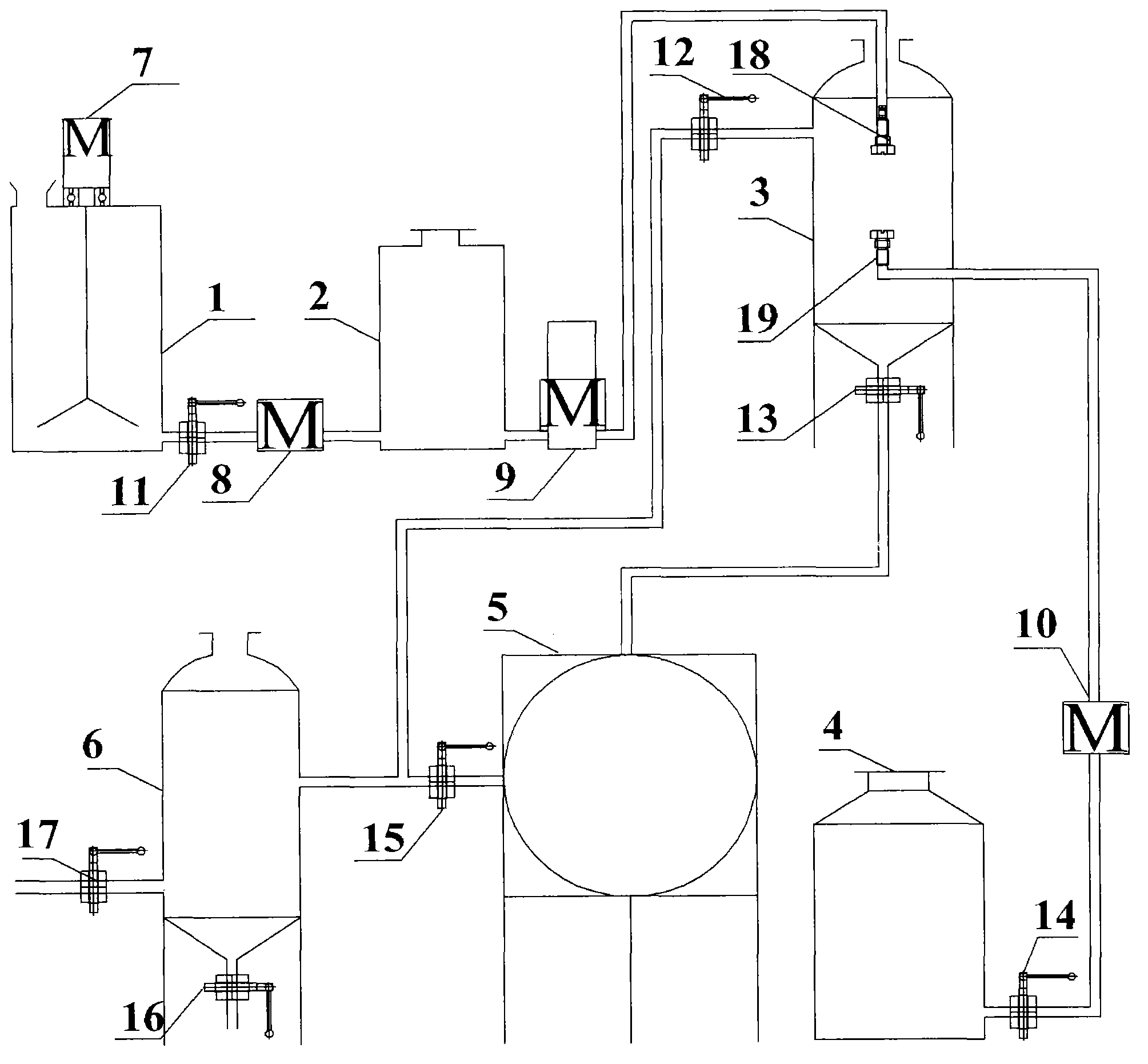

Alcohol precipitation device with combination of high pressure atomization and countercurrent and method

ActiveCN103070919AFully alcoholizedUniform and stable product qualitySolvent extractionSettling tanks feed/dischargeSolventHigh pressure

The invention provides an alcohol precipitation device with the combination of high pressure atomization and countercurrent and a method. A stirring tank is communicated with a transit tank connected with an alcohol precipitation tank, and the alcohol precipitation tank is communicated with a standing tank; and the lower part of the alcohol precipitation tank is connected with a solvent storage tank, and a centrifugal machine is connected with the alcohol precipitation tank and communicated with the standing tank. The method comprises the steps that after a salviae miltiorrhizae aqueous extract is stirred, a feed liquid is sprayed into an ethanol solvent which is prepared in advance by a plunger pump through high pressure atomization, simultaneously ethanol is sprayed in a countercurrent manner, so that the feed liquid is fully contacted with a new solvent, and an excellent separation effect can be realized; and an supernatant liquor overflows to enter the standing tank for standing, alcohol precipitation sediments are centrifuged by the centrifugal machine, and then all liquors enter the standing tank to stand for 24 hours. The alcohol precipitation device combing high pressure atomization with countercurrent and the method are suitable for the alcohol precipitation of products such as Chinese medical extracts and the like and have the advantages of stable product quality, high effective component recovery rate, possibility in automation and continuous production, low equipment investment and operation cost, and the like.

Owner:XIAN HONSON BIOTECH

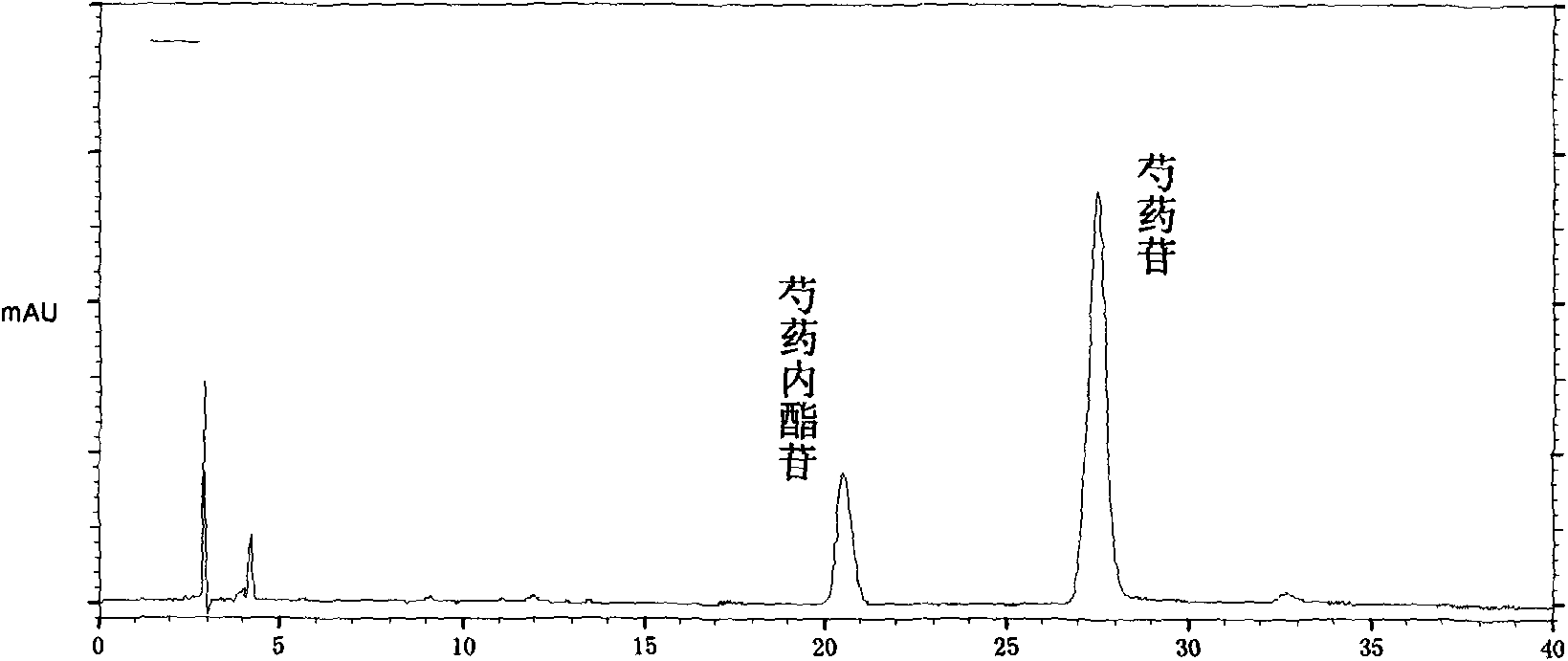

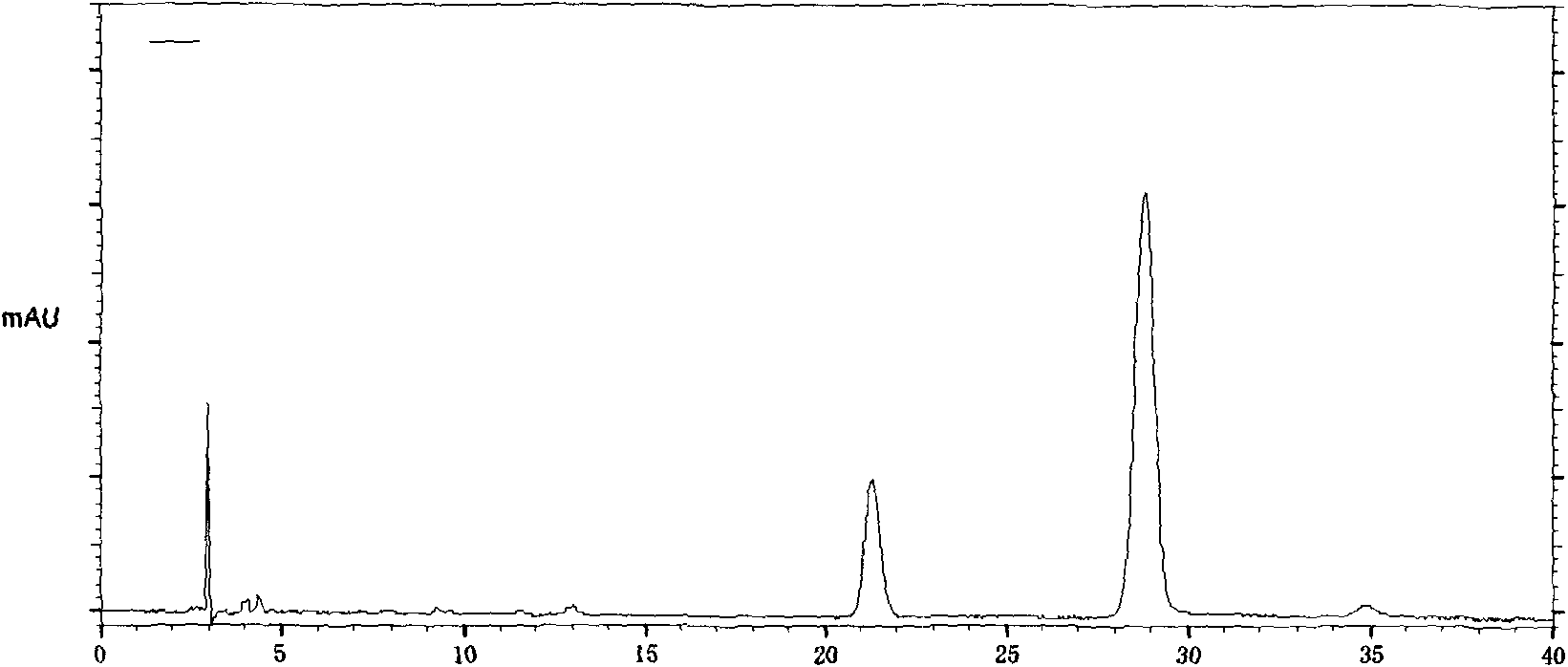

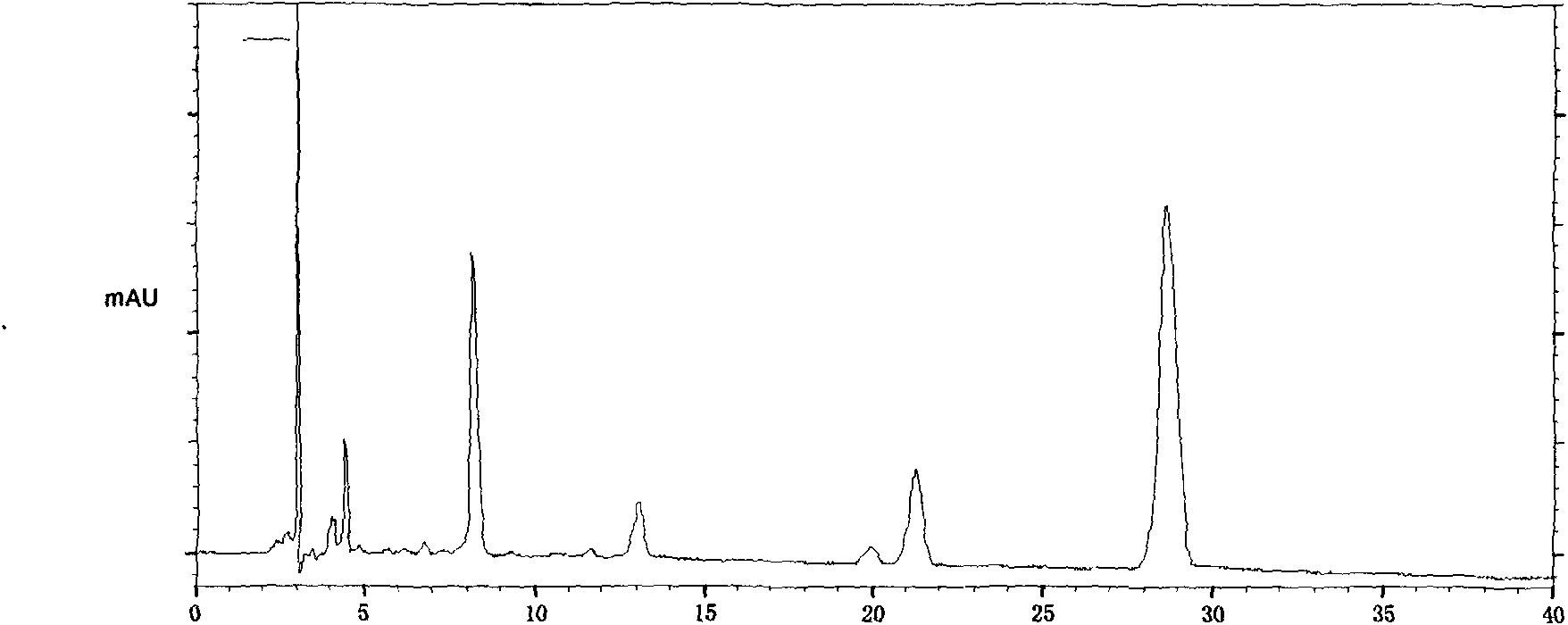

Quality control method of total glycosides single preparation of white paeony roots

ActiveCN102138985AQuality assuranceGuaranteed curative effectComponent separationPlant ingredientsClinical efficacyCurative effect

The invention provides a quality control method of a preparation of white paeony roots. The method comprises the following steps of: establishing a synchronous content measuring method of white paeony root herbs, white paeony root total glycosides and paeoniflorin and albiflorin in the white paeony root preparation by adopting the same liquid-phase chromatography condition; and accurately measuring the contents of the paeoniflorin and the albiflorin. The method is simple to preprocess a sample, keeps complete characteristic components and provides a stable sample solution and has higher accuracy, favorable reproduction and a certain specificity; characteristic peaks in the obtained fingerprint map have favorable separation effect, the fingerprint maps of the white paeony root herbs, the white paeony root total glycosides and the preparation have favorable relativity; the standard fingerprint map of the white paeony root herbs is established at a new angle by utilizing the relativity research of the fingerprint maps, can be used for identifying the qualities of the white paeony root herbs and improving the controllability of the production process of the white paeony root preparation and is favorable to ensuring the quality stability and the clinical curative effect of the white paeony root preparation.

Owner:NINGBO LIWAH PHARM CO LTD

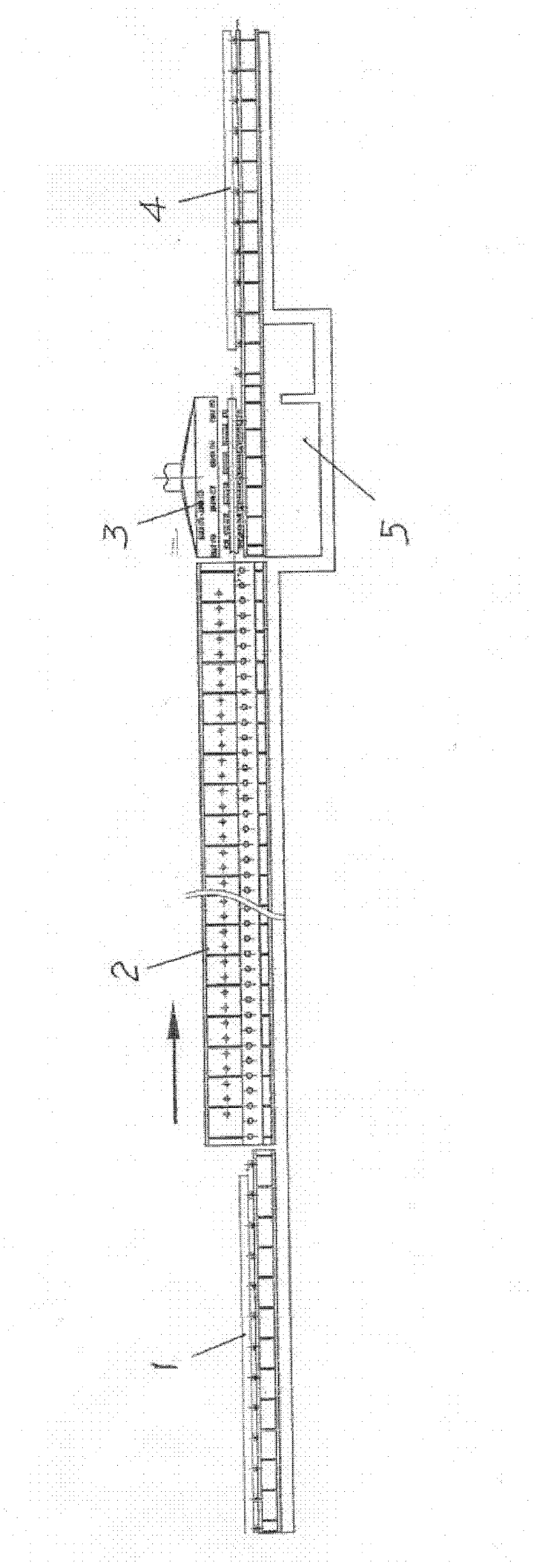

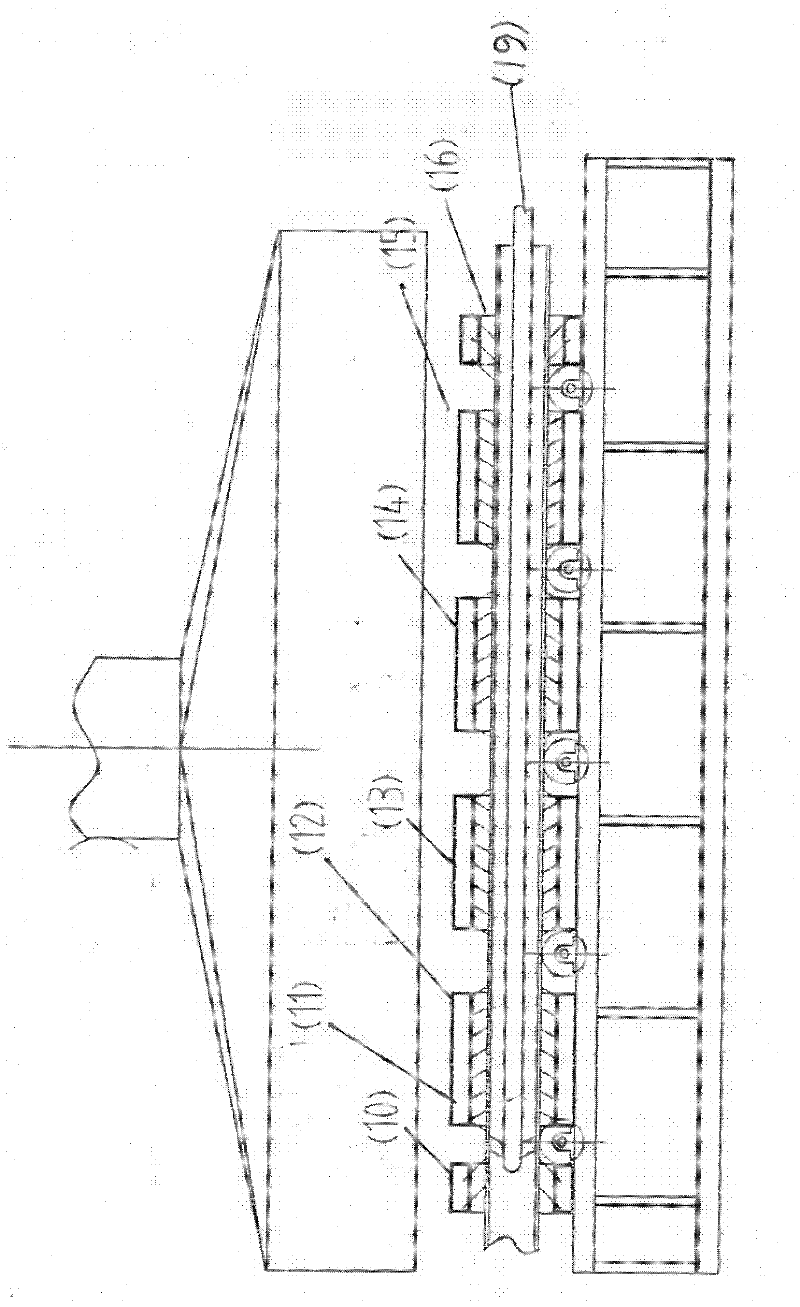

Continuous Quenching Line for Large Diameter Tube and Bar

ActiveCN102268523ALow costImprove product quality performanceFurnace typesHeat treatment furnacesAutomatic controlAutomated control system

A continuous quenching line for large-diameter tube and bar materials is provided. Along the moving direction of tube and bar materials, a V-shaped inclined roll transmission continuous heating furnace is connected to an end of an automatic material charging machine; a multifunctional quenching machine is connected to an end of the V-shaped inclined roll transmission continuous heating furnace; the multifunctional quenching machine is connected to an automatic material discharging machine; a water collecting pool is disposed at the lower part of the multifunctional quenching machine; an automatic control system controls the devices from the automatic material charging machine to the automatic material discharging machine; continuous horizontal heat processing of alloy steel, stainless steel, light alloy bar and tube materials with a diameter of 100-800 mm and a length of above 2000 mm (a wall thickness of below 100 mm) can be performed. During the heating and quenching processes, the material both moves forward and performs self-rotation, does not bend or deform, is heated and quenched uniformly, and has a deep quenched layer, and the invention has the functions of performing quenching, solid solution treatment, normalization processing, annealing processing and the like of alloy tool steel tube and bar materials, alloy structure steel tube and bar materials, heat resistant steel tube and bar materials, various stainless steel tube and bar materials, aluminium alloy tube and bar materials, and the like.

Owner:ARES IND FURNACE TIANJIN

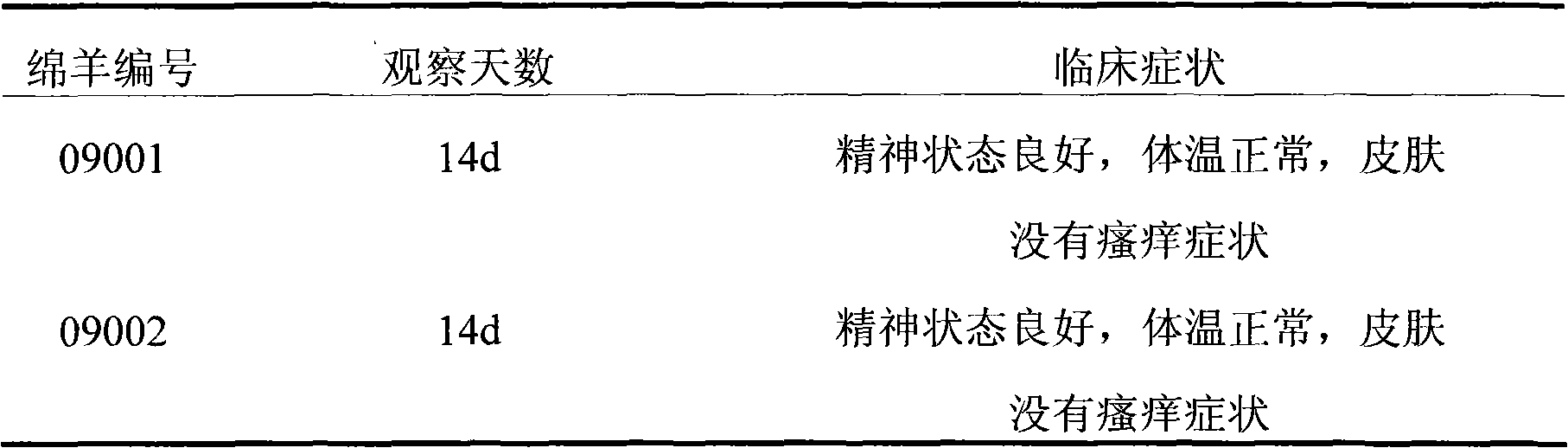

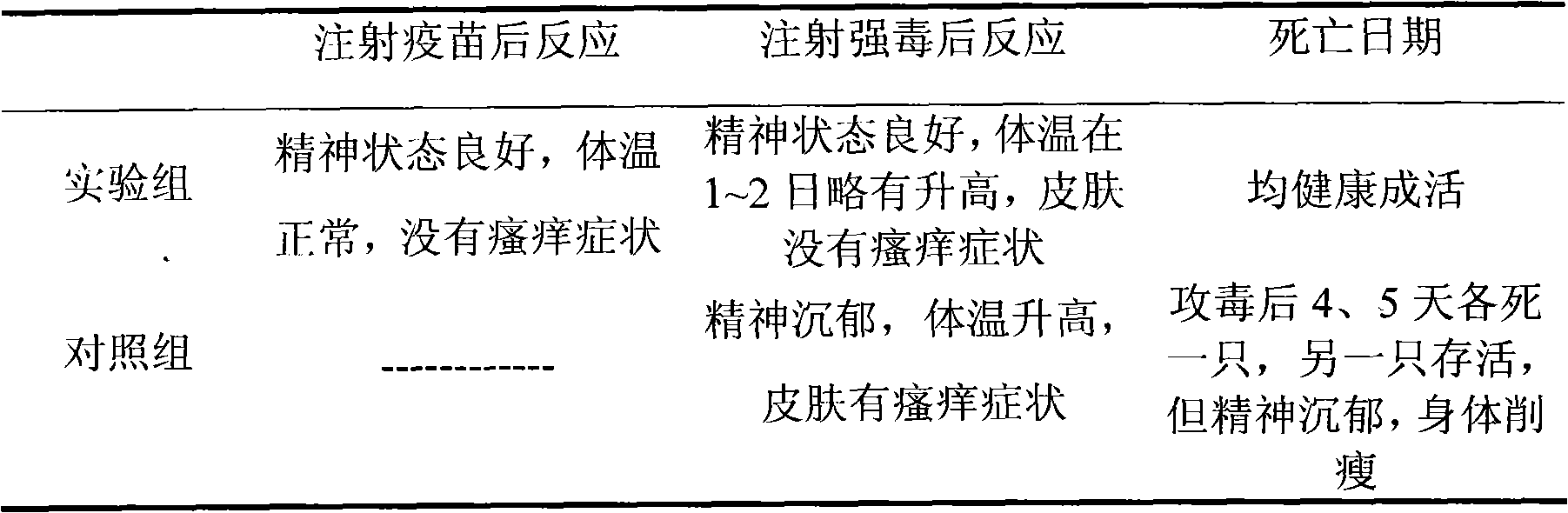

Method for producing pseudorabies attenuated vaccine by using bioreactor and pseudorabies attenuated vaccine product

ActiveCN101695572AImprove immune efficiencyIncrease growth densityMicroorganism based processesAntiviralsVaccine ProductionAntibiotic Y

The invention provides a method for producing a pseudorabies attenuated vaccine by using a bioreactor and a pseudorabies attenuated vaccine product. After being sterilized, the bioreactor and a micro carrier are inoculated with cells for producing the vaccine, and a cell growth medium is added for culture. A maintenance medium containing attenuated strains of pseudorabies viruses are inoculated into the bioreactor to continue culturing the cells. 2 to 3 days after virus inoculation, cell culture virus liquid is obtained and added with a stabilizer and antibiotics, and the cell culture virus liquid is refrigerated and dried under vacuum to obtain the pseudorabies attenuated vaccine. In the method, the cell density and virus concentration are improved greatly, the titer of the vaccine is improved, the side reactions, labor intensity and product cost are reduced, the monitoring performance of vaccine production is improved and uniform and stable product quality is guaranteed. The pseudorabies attenuated vaccine produced by the method has high safety, immune efficacy and good immune and protective effect against the attack by the virulent pseudorabies viruses.

Owner:广东永顺生物制药股份有限公司

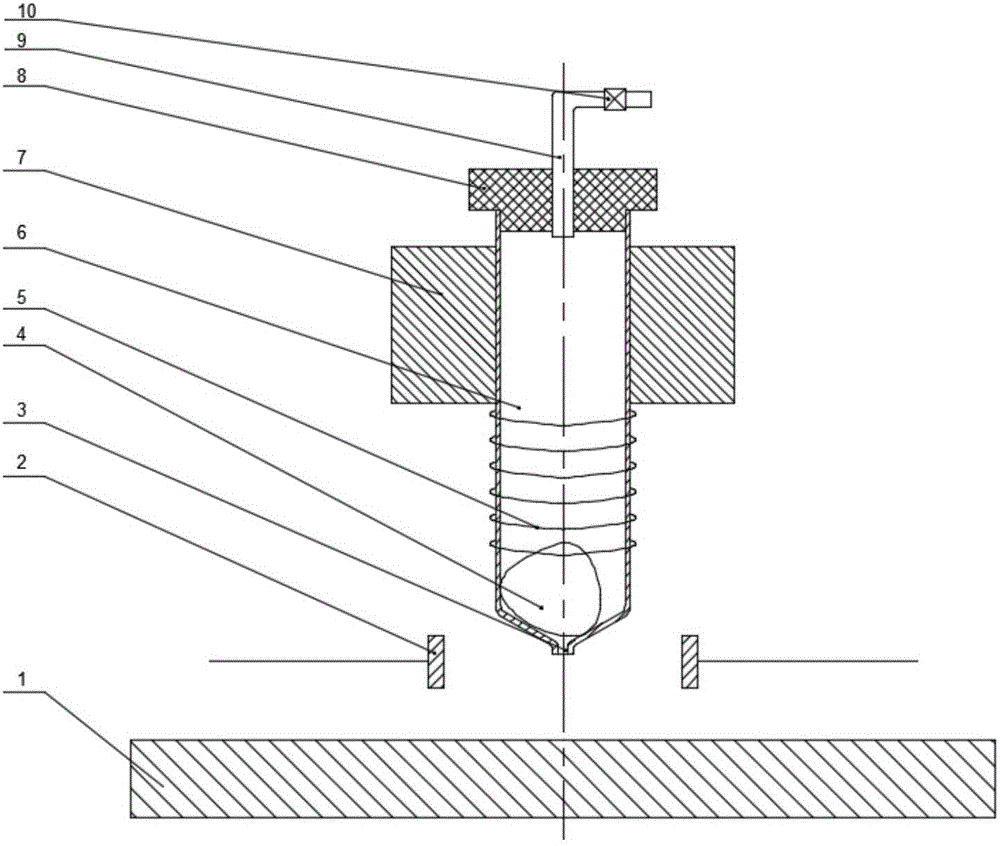

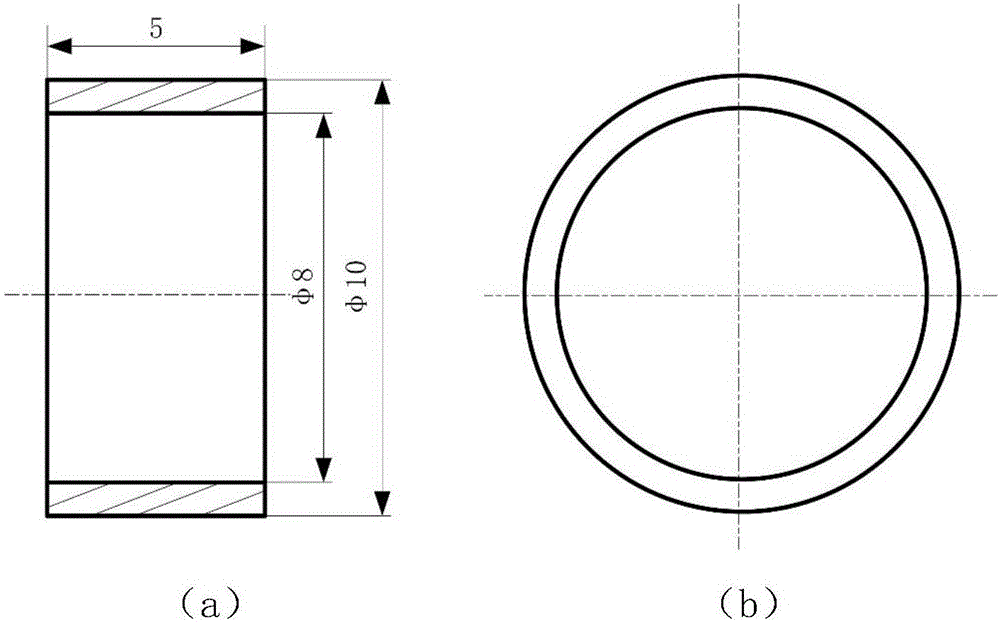

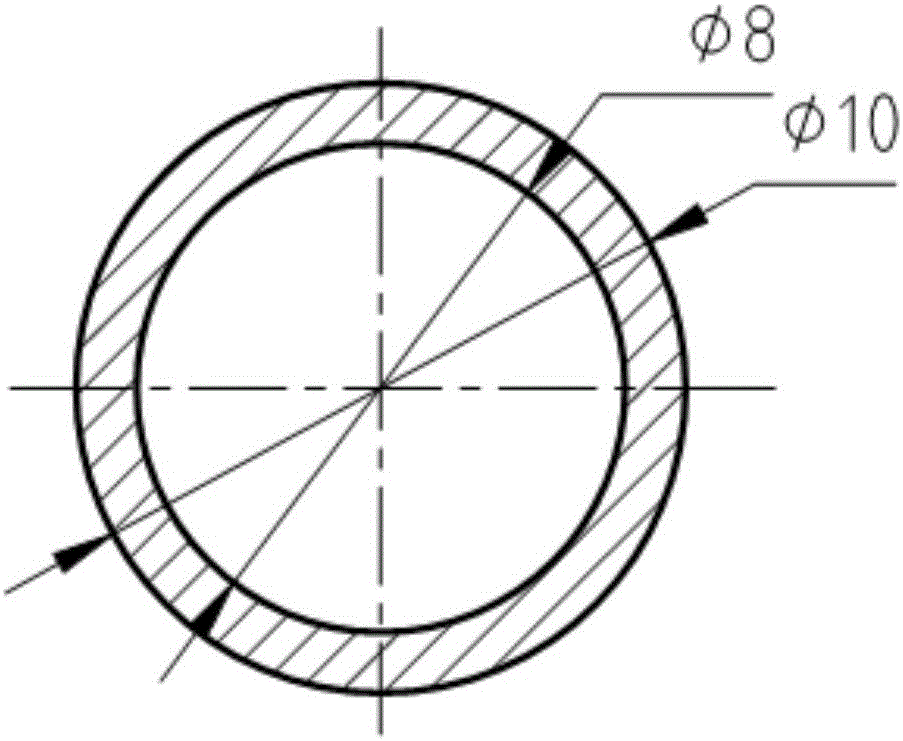

Device and method for rapidly forming metal part through induction heating

InactiveCN105903970AHeating evenlyEven and stable heatingAdditive manufacturing apparatusCrucibleMachining

The invention discloses a device and method for rapidly forming a metal part through induction heating. The device comprises a base plate, a front heating unit and an induction smelting unit. The base plate is located below the induction smelting unit and used as a platform for metal part forming. The front heating unit is located between the base plate and the induction smelting unit and used for forming a uniform temperature field. The induction smelting unit comprises a support and a smelting crucible arranged on the support. An induction coil is arranged on the smelting crucible. The outlet end of the smelting crucible is provided with a smelting crucible nozzle opposite to the base plate. The inlet end of the smelting crucible is connected with an air inlet through a rubber plug and used for providing inert gas for the smelting crucible. The method is used for achieving induction heating and rapid forming of the metal part through the device. The device and method have the advantages of being high in machining flexibility, small in subsequent machining amount and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

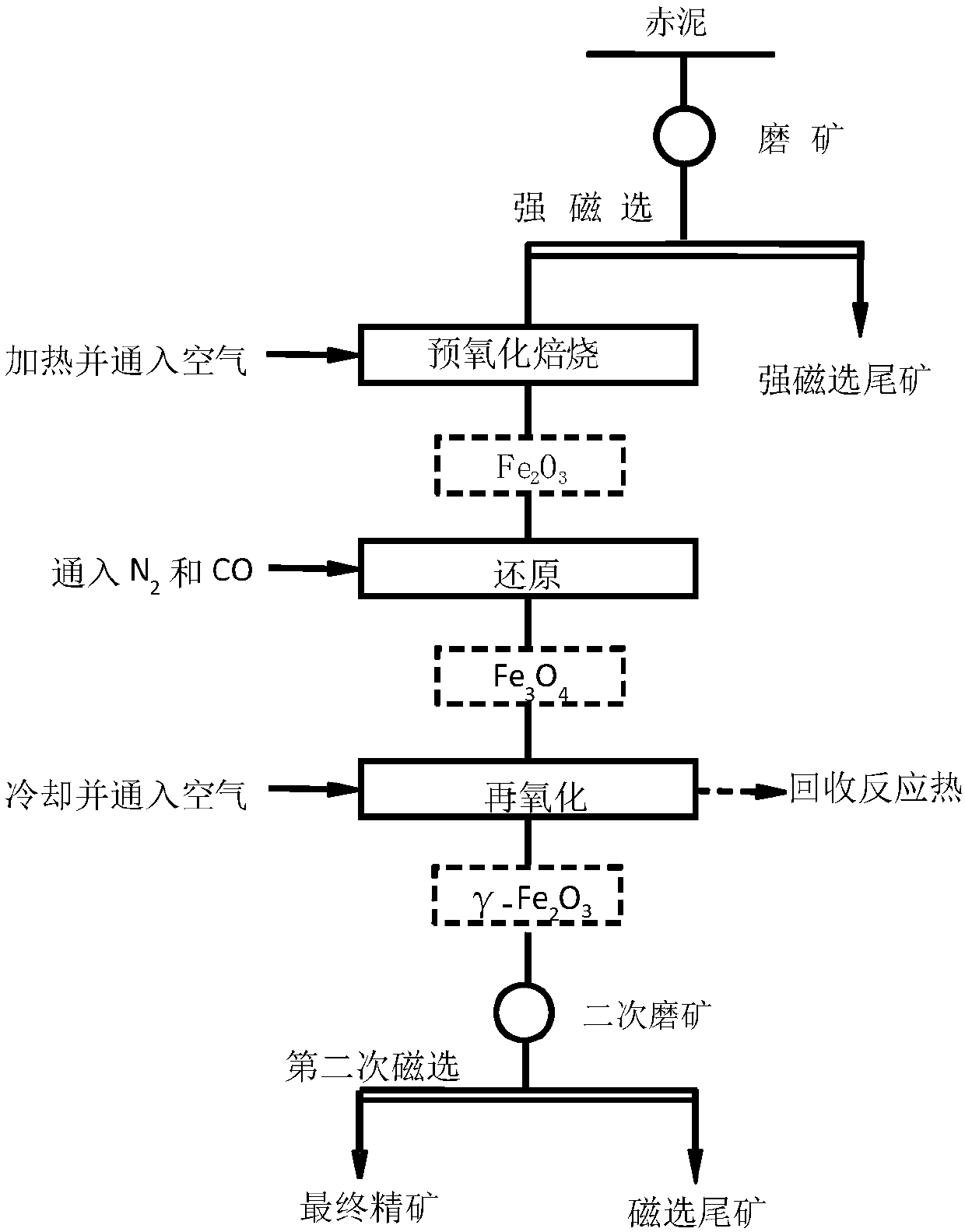

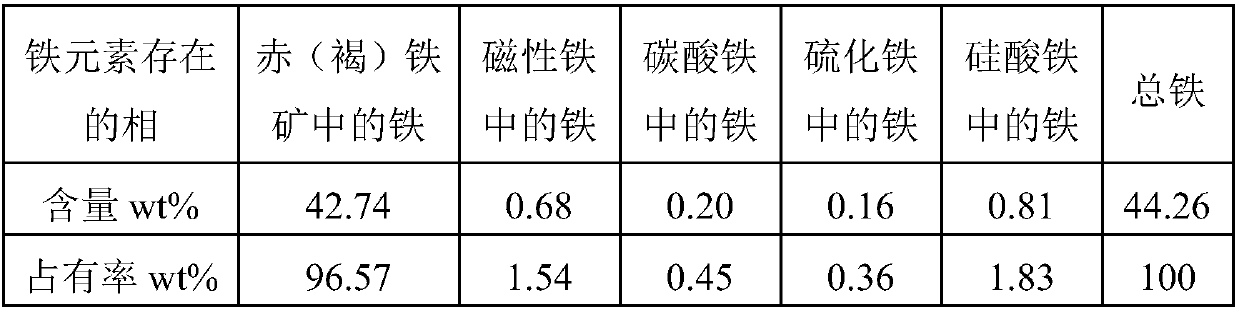

Method for recovering iron from red mud

InactiveCN107760862AStrong magnetismStrong sorting methodMagnetic separationAir atmosphereHigh energy

The invention relates to a method for recovering iron from red mud. The method for recovering the iron from the red mud belongs to the technical field of mineral processing, and comprises the steps ofin a suspension roaster, pre-oxidizing a magnetic-separated red mud material in an air atmosphere, and completely transforming spathic iron and brown iron ore in the red mud material into hematite; utilizing self-stored heat of a material obtained through pre-oxidization treatment for reducing the material in a reducing gas atmosphere so as to completely reduce hematite in the material into Fe3O4; re-oxidizing the obtained material in an air atmosphere, and transforming at least part of Fe3O4 in the material into gamma-Fe2O3; and carrying out magnetic separation on the material obtained through the treatment in the steps. The method provided by the invention solves the problems of long calcination time, high temperature, higher reducing gas CO content, loss of valuable elements, high energy consumption and the like in an existing process method for treating the red mud so as to recover fine iron powder.

Owner:NORTHEASTERN UNIV

Synthetic rubber wet mixing technology

The invention discloses a synthetic rubber wet mixing technology. The synthetic rubber wet mixing technology comprises the following steps of (1) liquid preparation, wherein synthetic rubber is placedin a container, white carbon black emulsion is added into the synthetic rubber dropwise at a stirring speed of 600 r / min, after dropping is completed, stirring is conducted at 1,000 r / min for 30 minto enable the emulsion to be mixed evenly, the stirring speed is reduced to 800 r / min, sulfamic acid, an accelerant NS, stearic acid and an anti-aging agent are added into the emulsion in sequence during stirring, and after adding is completed, stirring is conducted continuously for 45-48 min to obtain latex mixed liquid; (2) coagulation; (3) collection; (4) stirring, wherein a rubber mixture is stirred in a rubber wet mixer; (5) drying, wherein the stirred mixture is subjected to flocculation, rubber washing and solvent removal to obtain synthetic rubber. According to the synthetic rubber wetmixing technology, by combining two modes of surface modification and mechanical dispersion, the interfacial compatibility among the rubber and filler molecules is enhanced, so that the mixed emulsion is stabler and evener, and the comprehensive performance of the synthetic rubber is improved.

Owner:益凯新材料有限公司

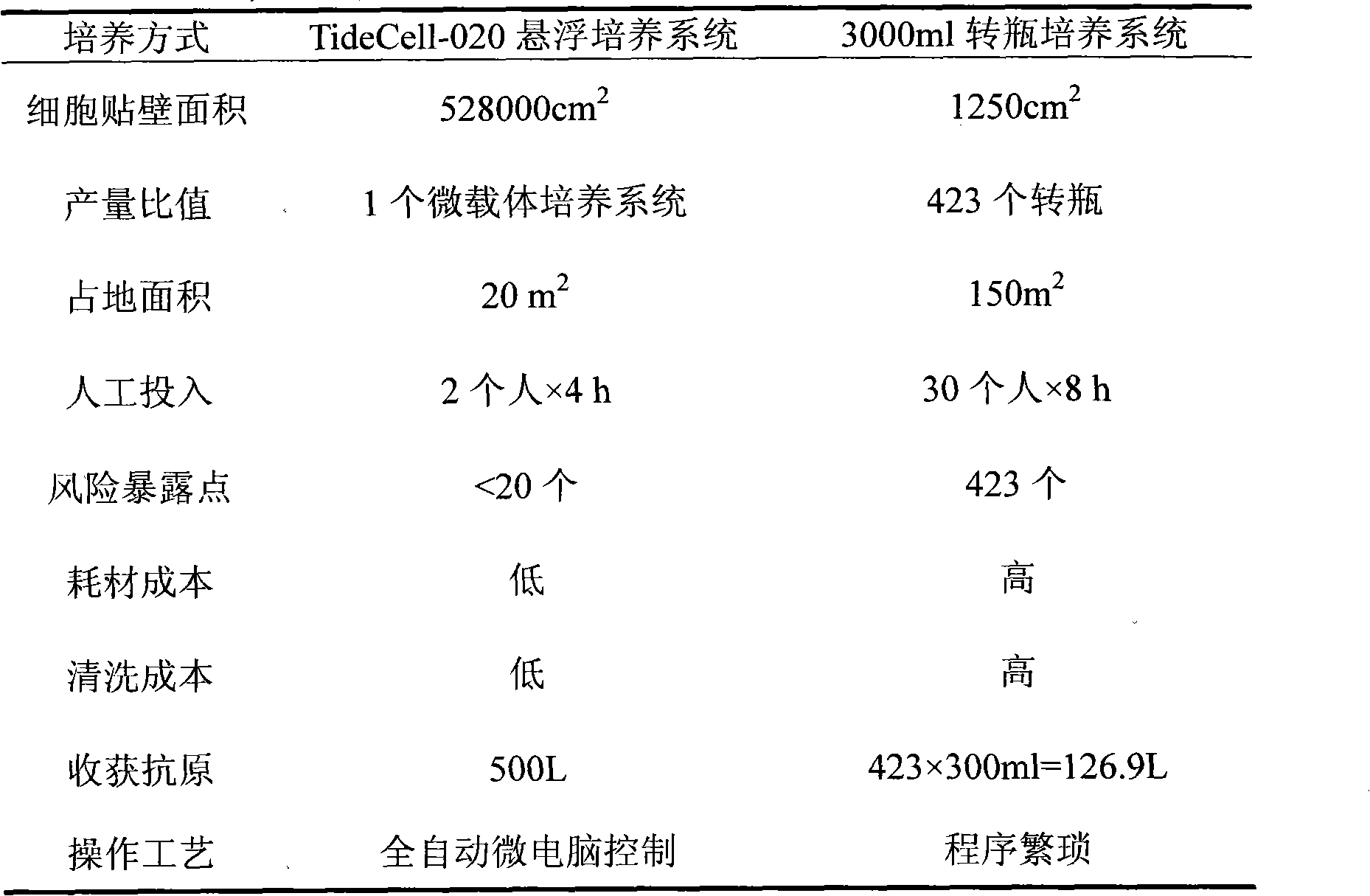

Method for mass production of pseudorabies virus vaccine

InactiveCN101804203ASolve the problems of low production output, high labor intensity and high costExpand production scaleAntiviralsTissue/virus culture apparatusFiberPolyester

The invention discloses a method for mass production of pseudorabies virus vaccine, comprising the following steps: (a) adding netty polyester fiber which serves as a carrier into a bioreactor provided with a tide type micro-carrier suspension culture system and inoculating cells for producing vaccine; (b) inoculating pseudorabies virus vaccine when the culture cell grows to a certain intensity, so that the cells are infected by the pseudorabies virus vaccine; (c) reproducing the virus in great numbers under appropriate conditions; (d) harvesting the virus when cytopathic rate reaches above 70%; (e) carrying out freeze thawing on the harvested virus for once or twice to lead the cells to completely come off and disperse and then adding freeze-drying protective agent, evenly mixing the mixture, packaging the mixture in fixed volume and freeze-drying.The method of the invention has the advantages of good stability, explicit process control indicators, good controllability, easy operation, large process scale and the like.

Owner:PU LIKE BIO ENG

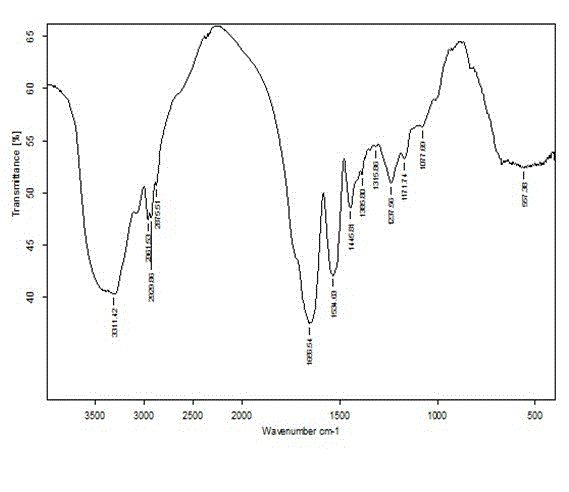

Method for preparing cellulose polysaccharide degradable high water absorbing agent from crop straw

The invention relates to a method for preparing cellulose polysaccharide degradable high water-absorbing agent from farm crop straws, belonging to the technical field of farm and side line products comprehensive utilization and agricultural chemicals. The invention relates to a method for using farm crop straws as main material to prepare high water-absorbing agent of cellulose polysaccharide, which comprises that refines cellulose substrate from farm crops straws and synthesizes water-absorbing agent. Taking corn straw as example, the invention refines cellulose and modifies functions, to obtain high water-absorbing agent functional material. The inventive high water-absorbing agent keeps original absorbing property of water-absorbing material, with simple production process, belonging to biological degradable product. The high water-absorbing agent has better water adsorption and retention properties, with wide application in drought resistance, desert greening, afforestation, food processing, and medical sanitation or the like, which can effectively develop cheap resources.

Owner:JIANGNAN UNIV

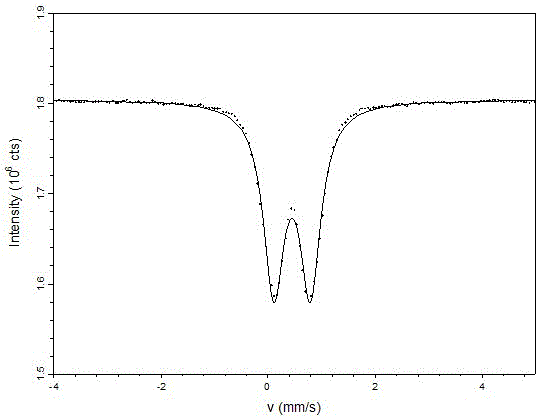

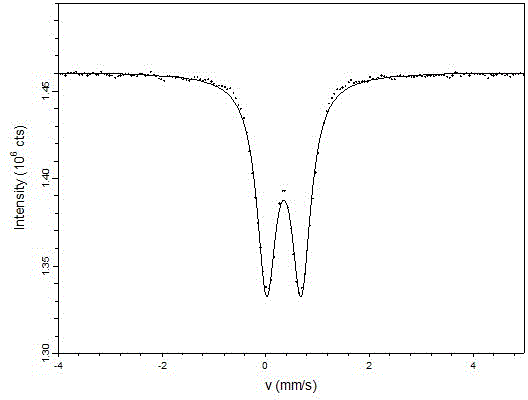

Preparation method of iron-protein succinylate with high iron content

ActiveCN104402984AThe synthesis method is simpleLow costPeptide preparation methodsAnimals/human peptidesSolubilitySodium bicarbonate

The invention belongs to the technical field of medicine, and relates to a preparation method of iron-protein succinylate with a high iron content. The preparation method comprises the following steps: (1) acylation: adding succinic anhydride into a casein solution to carry out reactions, continuously adding a sodium hydroxide solution into the reaction system to keep the pH value in a range of 6 to 9, after the reaction, adding acid into the reaction liquid to adjust the pH value to a range of 1 to 4, and filtering to obtain precipitate; (2) iron loading: dispersing the obtained precipitate into water, adding a proper amount of sodium hydroxide solution, stirring to dissolve the precipitate, then adding a ferric trichloride solution containing sodium bicarbonate into the obtained protein succinylate solution, adding a sodium hydroxide solution simultaneously to maintain the pH value of the reaction liquid in a range of 6 to 9, after the reaction filtering to remove the insoluble substances so as to obtain a iron-protein succinylate solution; refining the solution to remove the insoluble substance, adding acid to generate precipitate, filtering to obtain the precipitate, washing the precipitate by water, and finally drying the precipitate. In the recent literature, the reported iron content of iron-protein succinylate is in a range of 4.5 to 10%, while the iron content of iron-protein succinylate prepared by the provided method is as high as 15%. Moreover, the provided preparation method has the advantages of simple technology, good product solubility, and stable product quality.

Owner:WUHAN CONFORM PHARMA CO LTD

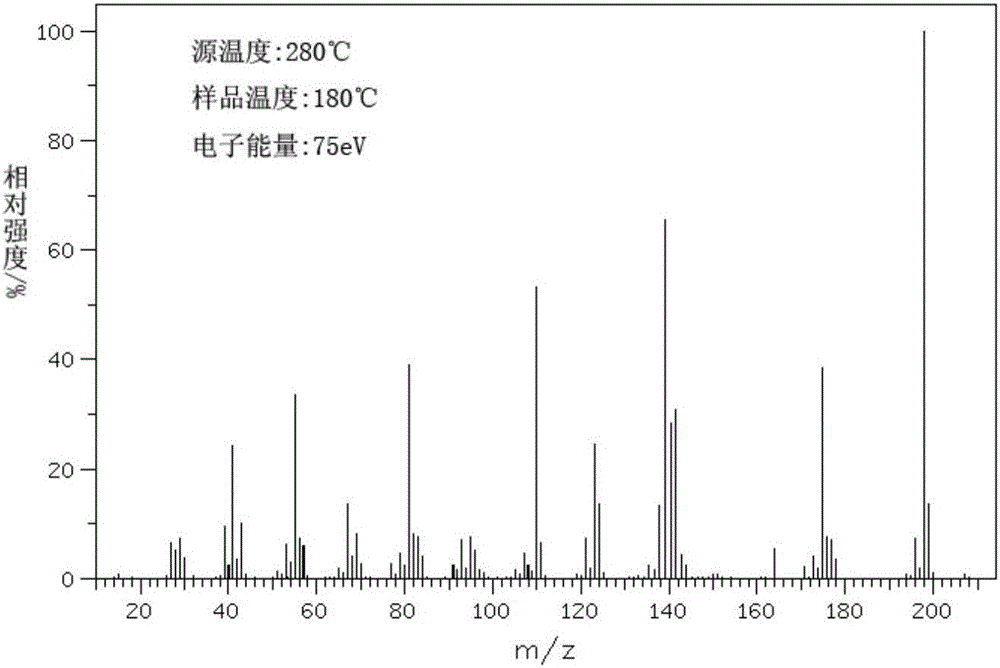

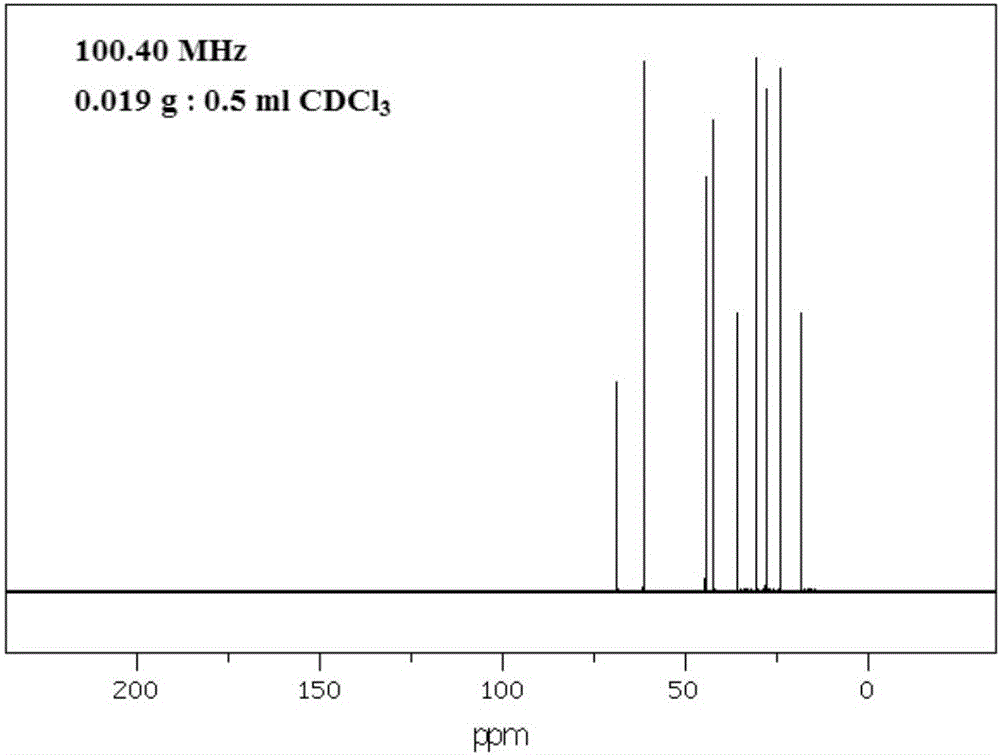

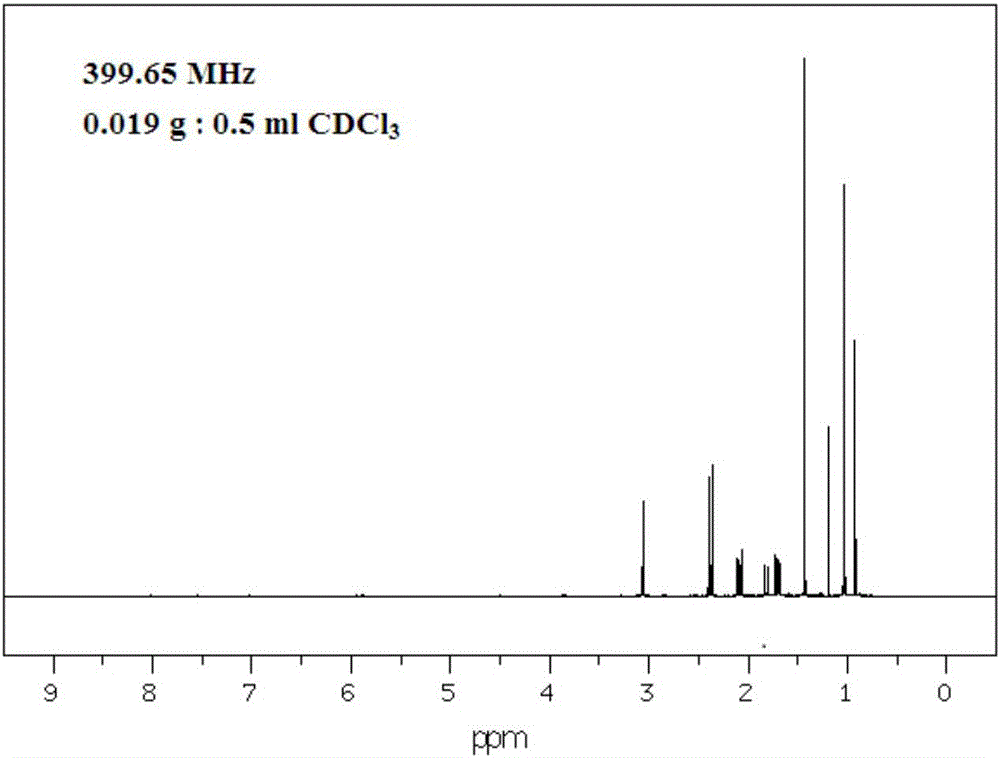

Preparation method and application of 3-dimethylaminomethyl-3, 5, 5-trimethylcyclohexanol

ActiveCN105001099AHigh catalytic activityLow costOrganic compound preparationAmino-hyroxy compound preparationHydrogenOil phase

The invention relates to a preparation method and application of 3-dimethylaminomethyl-3, 5, 5-trimethylcyclohexanol, and polyurethane foam prepared therefrom. The preparation method comprises: in the presence of a catalyst and acidic substance and under certain temperature and pressure, subjecting 3-aminomethyl-3, 5, 5-trimethylcyclohexanol, formaldehyde and hydrogen to aminomethylation reaction to obtain a reaction mixture containing an aqueous phase and an oil phase, separating the aqueous phase from the oil phase, wherein the oil phase mainly contains 3-dimethylaminomethyl-3, 5, 5-trimethylcyclohexanol, and the aqueous phase mainly contains formaldehyde; and optionally, purifying the oil phase so as to obtain 3-dimethylaminomethyl-3, 5, 5-trimethylcyclohexanol. The method provided by the invention realizes effective utilization of IPDA byproduct, and the polyurethane foam material prepared therefrom has the advantages of low smell, excellent physical performance and the like.

Owner:WANHUA CHEM GRP CO LTD

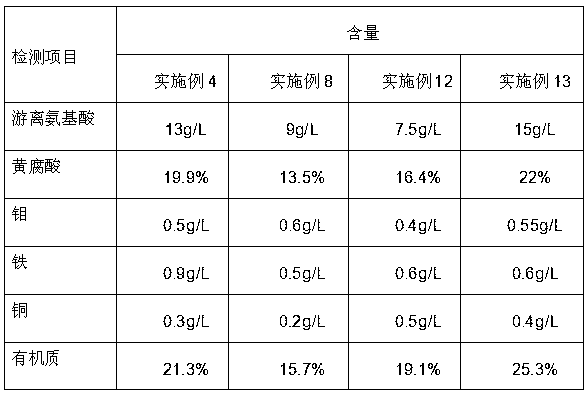

Organic fertilizer derived from fermented cordyceps sinensis

InactiveCN110342991AComposition is stableBatch product uniformityFungiMagnesium fertilisersCordyceps ophioglossoidesShake-Flask Culture

The invention discloses organic fertilizer derived from fermented cordyceps sinensis. The organic fertilizer is obtained according to the following preparation steps that (1) strains of a cordyceps sinensis bacterial genus or / and a cordyceps sinensis auxiliary bacterial genus are joined into a shake flask culture medium in a sterile mode to be cultivated; (2) a shake flask strain is joined into afirst-grade seed tank to be cultivated; (3) all strain materials in the first-grade seed tank are transferred to a second-grade seed tank to be cultivated, and the number of strains in the seed tank is amplified; (4) the strains are joined into a terminal fermentation tank in a sterile mode, and material supplementing is conducted; and (5) fermentation broth is subjected to solid-liquid separation. The problem of treatment of a large amount of the fermentation broth in the fermentation process of cordyceps sinensis type fermented mycelia is solved, the problem that the fermentation broth generated by related fermentation of conventional cordyceps sinensis cannot be directly applied to the organic fertilizer is solved, and the good organic fertilizer or organic fertilizer raw materials areobtained by direct production.

Owner:宁夏西麒麟生物科技有限公司

Classical swine fever virus vaccine and production method thereof

InactiveCN101926991AHigh poison priceExpand production scaleInactivation/attenuationMicroorganism based processesCulture fluidFreeze-drying

The invention discloses a method for preparing a classical swine fever (CSF) vaccine by using a cell microcarrier suspension culture system, which comprises the following steps of: (1) inoculating cells for preparing the vaccine to a carrier tank containing culture solution and a microcarrier, and uniformly mixing the cells and the microcarrier to make the cells attached to the microcarrier; (2) when the concentration after cell proliferation is 5 to 40 times of the initial inoculation concentration, inoculating CSF virus (lapinized virus) to the cells according to multiplicity of infection (M.O.I.) of the virus of 0.01-1 and reproducing the virus; and (3) mixing prepared virus liquid, adding an appropriate freeze-drying protective agent, fully and uniformly mixing, quantitatively packaging, and freeze-drying to obtain the CSF vaccine. The CSF vaccine produced by the method has the advantages of high density of cultured cells, continuous culture, high yield of the virus, high immune effect, high safety, complete immune protection on attack of violent CSF, and the like.

Owner:PU LIKE BIO ENG

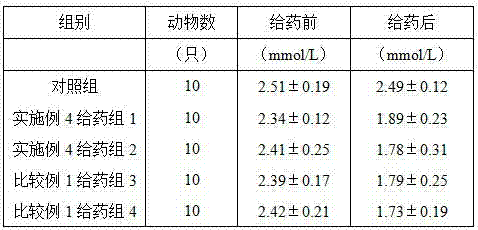

Medicinal composition for treating hypertension and application thereof

ActiveCN103893571AAvoid dependencyAvoid damageMetabolism disorderOil/fats/waxes non-active ingredientsGastrodiaAdjuvant

The invention relates to the technical field of traditional Chinese medicines, and particularly discloses a medicinal composition for treating hypertension and an application thereof. The medicinal composition comprises the following components by weight: 80-200g of red-rooted salvia root extract, 50-120g of tall gastrodia tuber extract, 40-200g of eucommia ulmoides leaf extract, 100-500g of natural dispersing agent and 10-50g of natural suspending agent. Through synergistic effect among various Chinese medicinal extracts, the medicinal value of each extract is increased, the dose of each Chinese medicinal extract for achieving the same medicinal effect is reduced, and the defects of a large number of taking forms, large dosage, slow response, gastrointestinal tract discomfort and the like in the conventional oral antihypertensive Chinese medicinal composition are overcome. Meanwhile, a special production process is adopted, and pure natural extracts such as the dispersing agent are taken as medicinal adjuvants, so that the mouthfeel of the medicine is improved. Compared with other products of the same type, the medicinal composition has the advantages of no bitterness and convenience in taking, and the compliance of patients is improved.

Owner:XIZANG HANSES PHARMA DEV

Lycopene food and preparation method thereof

InactiveCN107411076AImprove performanceRetain stabilityFood ingredient as antioxidantFood ingredient as emulsifierPropolisAntioxidant

The invention discloses a lycopene food and a preparation method thereof. The lycopene food comprises the following raw materials in parts by weight: 60-80 parts of lycopene, 10-20 parts of propolis, 5-8 parts of gelatin, 1-5 parts of foo-grade glycerine, 5-12 parts of olive oil, 1-3 parts of vitamin E, 0.1-0.8 part of an antioxidant, 2-8 parts of an emulsifying agent, 0.6-1.5 parts of a stabilizing agent and 40-50 parts of water. According to the preparation method disclosed by the invention, a high-shear mixing and emulsifying technique, a homogenizing technique and a degassing and ageing technique are adopted, uniform and stable product quality is guaranteed, and the coloring power and the stability of lycopene are reserved to the maximum extent. After the lycopene food disclosed by the invention is eaten, the immunity of human bodies can be enhanced, and the effects of beautifying faces, nourishing faces and delaying senescence can be achieved.

Owner:ANHUI HUAYU FOOD

Virus and vaccine of porcine reproductive and respiratory syndrome and preparation method of same

ActiveCN101979514AHigh viral titerHigh poison priceViral antigen ingredientsAntiviralsFreeze-dryingCells/microL

The invention discloses a method for preparing virus of porcine reproductive and respiratory syndrome on a large scale. In the method, the virus of the porcine reproductive and respiratory syndrome is prepared in a cell microcarrier suspension culture system by a bioreactor. The method comprises the following steps of: inoculating host cells for preparing the virus to a carrier tank containing culture solution and a microcarrier, and mixing the cells and the microcarrier uniformly to ensure that the cells are attached to the microcarrier; providing sufficient nutrients and appropriate gas environment for the cells under the appropriate culture environment to ensure that the cells are grown until the cells are in an amount which are 10 to 20 times of the inoculation concentration on the microcarrier; preparing virus suspension from the virus of the porcine reproductive and respiratory syndrome by using cell maintenance culture solution to ensure that the suspension is adsorbed to the cells; culturing the virus under the appropriate culture environment; culturing continuously for 2 to 3 days to obtain virus solution; and after the virus solution passes inspection, performing freeze thawing on the virus solution twice at the temperature of -20 DEG C, and inactivating and purifying to prepare an inactivated vaccine of the porcine reproductive and respiratory syndrome or adding a freeze-drying protective agent for freeze drying to prepare a live vaccine of the porcine reproductive and respiratory syndrome. The method has large production scale, high yield of single batch and low production cost.

Owner:PU LIKE BIO ENG

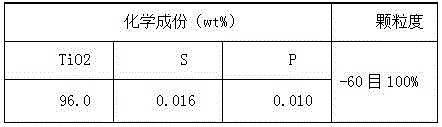

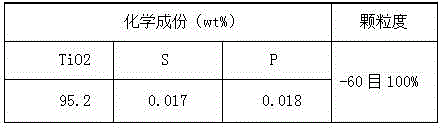

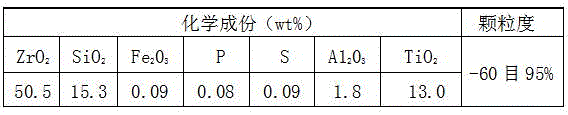

Natural rutile or zircon sand dry separation production method

ActiveCN106733175ASimple production processIncrease productivityMagnetic separationElectricityHigh pressure

The invention discloses a natural rutile or zircon sand dry separation production method which sequentially comprises a first-stage electric separation, a second-stage electric separation, a third-stage electric separation, high-voltage arc plate electric separation and strong magnetic separation to obtain zircon sand concentrate or natural rutile concentrate. According to the invention, the production technology is simplified, the production efficiency is greatly improved, the labor strength is lowered, and uniform and stable product quality can be ensured.

Owner:MAOMING UBRIDGE GROUP MINERAL IND

Low-temperature expansion process for ginseng and red ginseng

The invention relates to a low-temperature expansion equipment and process for ginseng and red ginseng, which can be mainly used for deeply processing ginseng and red ginseng and can be also used for processing Chinese medicinal plants or foods of which the active ingredients and organization structures are similar to those of the ginseng and red ginseng. A constant-temperature electric heating layer is coated on the periphery of a container of the low-temperature expansion equipment used in the invention, and a swivel bearing with a stirrer is installed at the middle part of the low-temperature expansion equipment, thus, ginseng or red ginseng can be effectively expanded. The process provided by the invention comprises the following steps: raw material selecting, smashing, screening, low-temperature expanding, screening and packaging. By using the low-temperature expansion equipment and process for ginseng and red ginseng, the production rate is increased, the raw material loss caused by coking and high temperature is reduced, the energy consumption is reduced, and the active ingredients of red ginseng are more sufficiently utilized.

Owner:YANBIAN TANJUN BIOTECH

Method for preparing MAX phase material

The invention provides a method for preparing a layered ceramic material MAX phase material. A transition metal source, a main group element source, a carbon source and / or a nitrogen source are mixedto form a solid raw material, the solid raw material itself in a reaction furnace is directly electrified to generate heat and gradually rises to above 900 DEG C, and carbonization and / or nitridation are conducted to form the MAX phase material. The method has the advantages of high thermal efficiency, low power consumption, good product consistency, stable process and large-scale production ofthe MAX phase material.

Owner:冯良荣

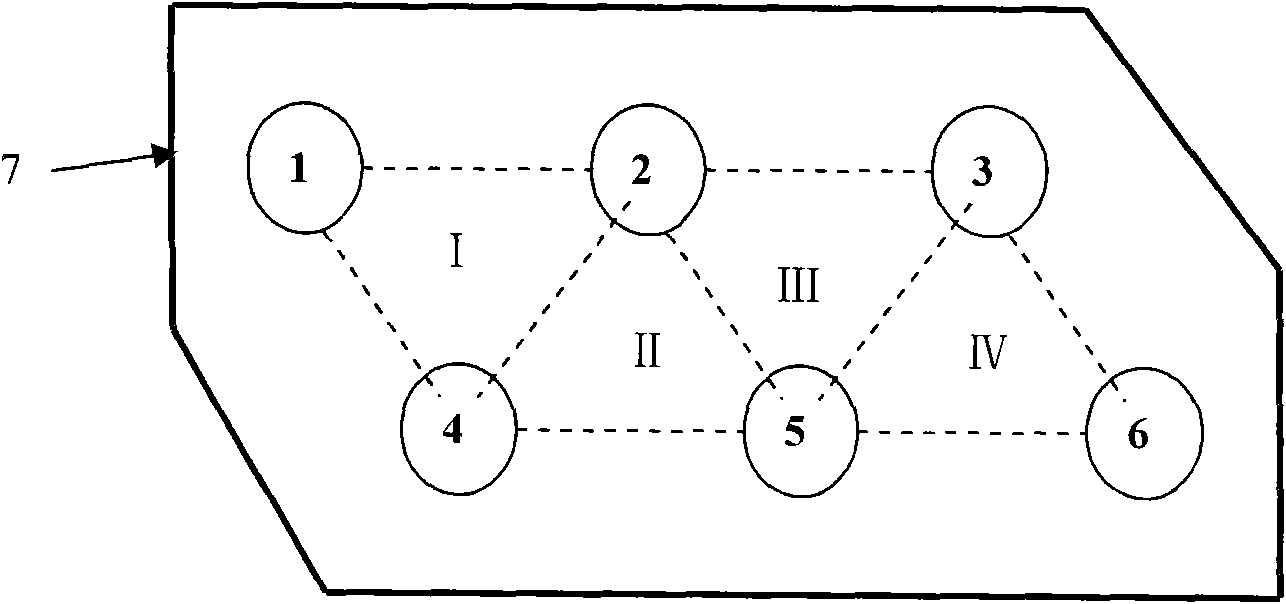

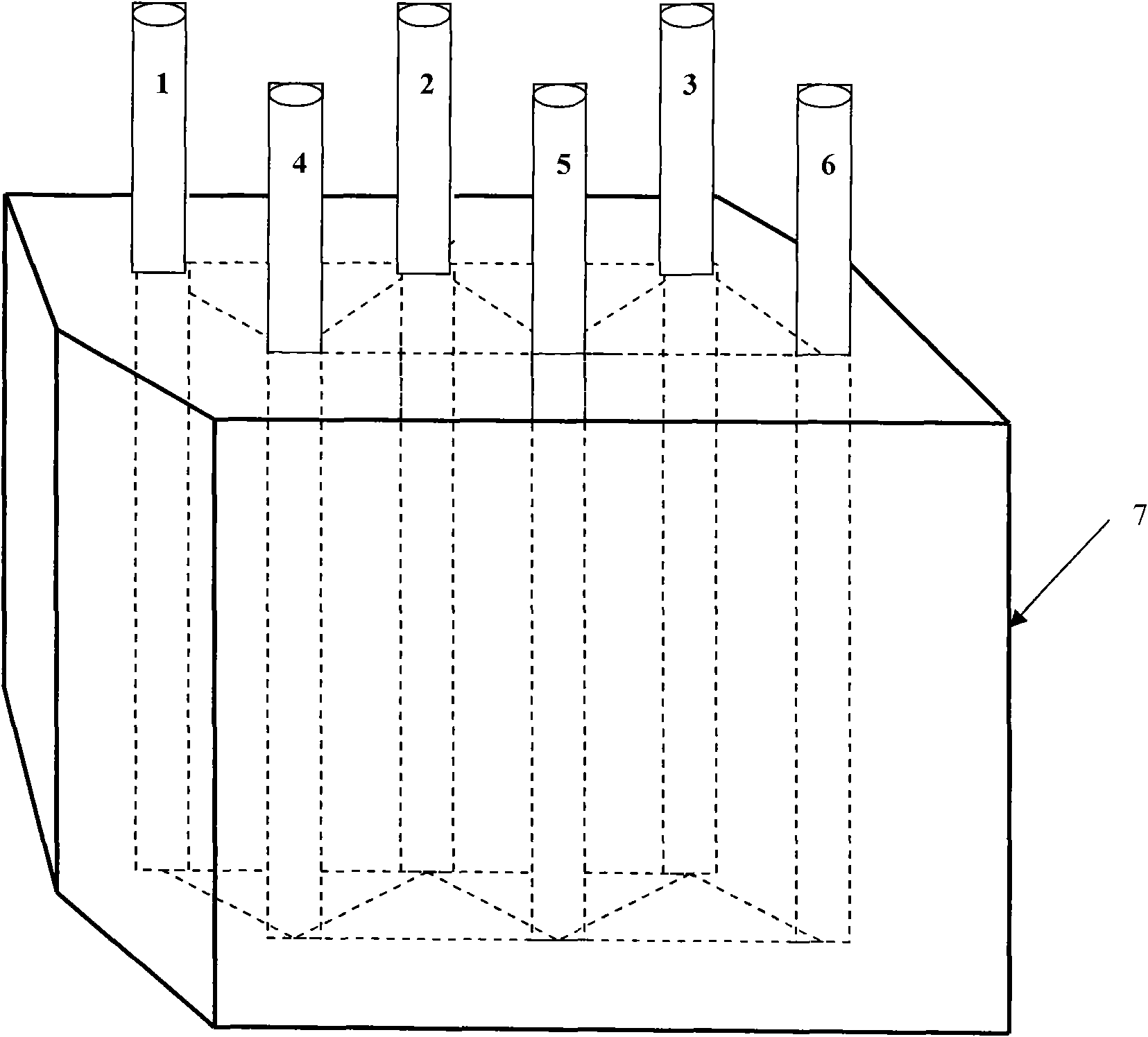

Six phase electrode electric melting furnace

InactiveCN101619928AImproved arc stabilityReduce burning lossCrucible furnacesElectric heating for furnacesFurnace temperatureIsoetes triquetra

The invention provides a six phase electrode electric melting furnace, relating to an electric melting magnesium smelting device, solving the problems of slow temperature rise of furnace temperature, high energy consumption and low yield which exist in current three phase electrode electric melting furnace. In the six phase electrode electric melting furnace, the furnace body is a six-prism body; the six phase electrode is inserted and arranged in the furnace body; the first electrode, the second electrode and the third electrode are arranged in a row with uniform spacing; the fourth electrode, the fifth electrode and the sixth electrode are arranged in a row with uniform spacing; the two rows of electrodes as a whole form a parallelogram; four equilateral triangle hot zones are respectively formed by the first, second, fourth electrodes, the second, fourth, fifth electrodes, the second, third, fifth electrodes, and the third, fifth, sixth electrodes. In the smelting process, the six phase electrode electric melting furnace forms four triangle hot zones, thus achieving concentrated heat, rapid heating of magnesium stones, steady reaction, dramatic lowering of electricity consumption, high speed of temperature rise of furnace temperature which can reach 3500 DEG C, uniform and stable product quality, energy saving and consumption lowering, high yield and good benefit.

Owner:大石桥市金益特种镁质材料厂

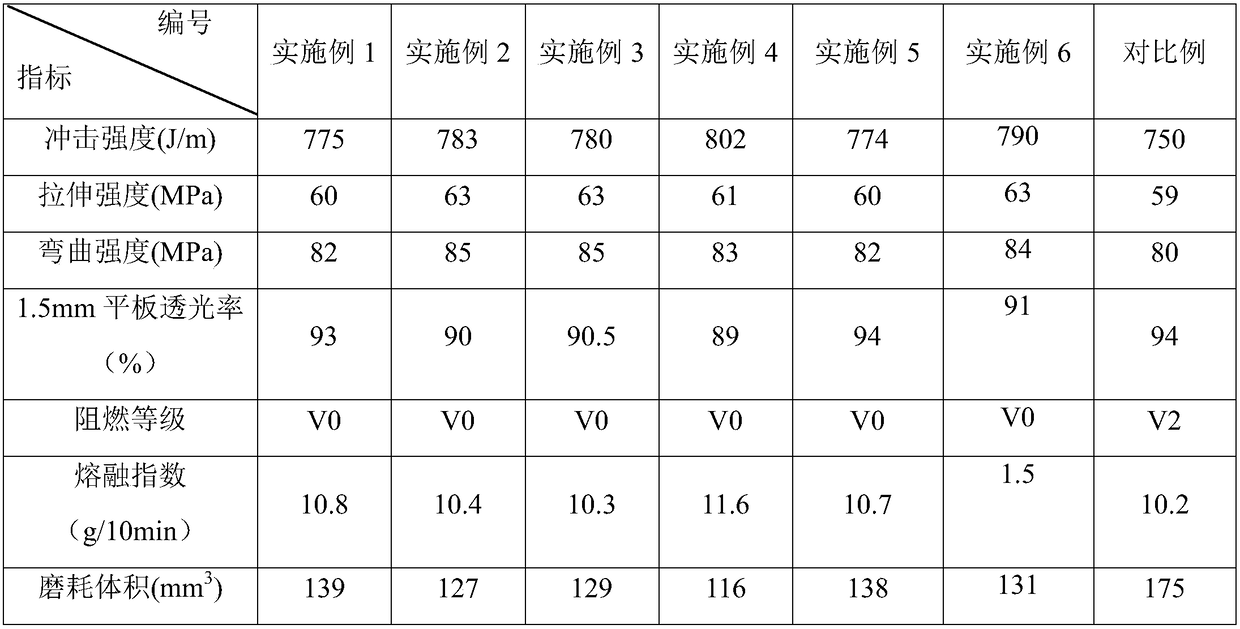

Wear-resistant transparent flame-retardant polycarbonate material and preparation method thereof

ActiveCN109082093AImprove flame retardant performanceHigh light transmittancePolycarbonateWear resistance

The invention relates to a wear-resistant transparent flame-retardant polycarbonate material and a preparation method thereof. The wear-resistant transparent flame-retardant polycarbonate material comprises the following raw materials in parts by weight: 90-95 parts of polycarbonate, 5-10 parts of transparent flame-retardant masterbatches, 0.5-1 part of ZnO / SiO2 nano composite and 0.1-1 part of anantioxidant. The prepared polycarbonate material has high flame retardancy, high light transmitting rate and good wear resistance, and the other original mechanical properties of the material can beimproved. The flame-retardant masterbatches serve as the raw material components, the consistency is good, and the quality of the product is uniform and stable; and a double-screw extruder serves as processing equipment, and the technological process is simple and continuous.

Owner:PUYANG SHENGTONGJUYUAN ADVANCED MATERIALS CO LTD

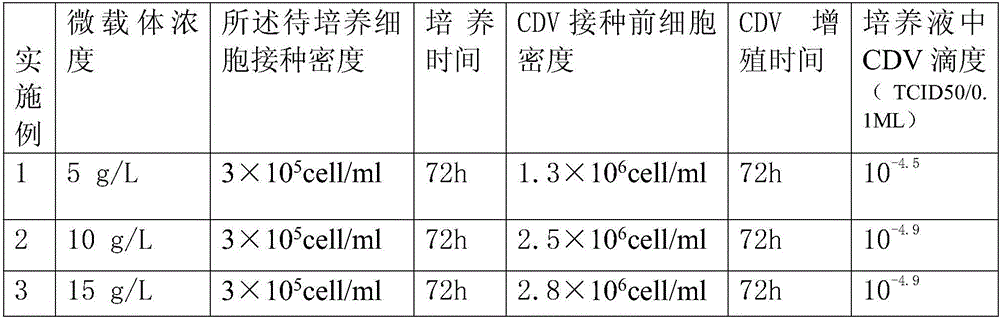

Method for proliferation of mink canine distemper virus by applying novel cell microcarrier

InactiveCN105838683AHigh densityIncrease productivitySsRNA viruses negative-senseAnimal cellsAntigenCanine distemper virus CDV

The invention discloses a method for proliferation of a mink canine distemper virus by applying a novel cell microcarrier. The method realizes efficient proliferation of the mink canine distemper virus by applying the novel cell microcarrier and a large-scale high-density cell suspension culture technology, has advantages of large cell density, high virus titer, high production efficiency, strong process controllability, uniform and stable product quality and the like, and overcomes a plurality of defects of batch-batch difference, long antigen content, low production efficiency and the like in products produced according to the traditional spinner bottle production technology.

Owner:SHANDONG BINZHOU ANIMAL SCI & VETERINARY MEDICINE ACADEMY

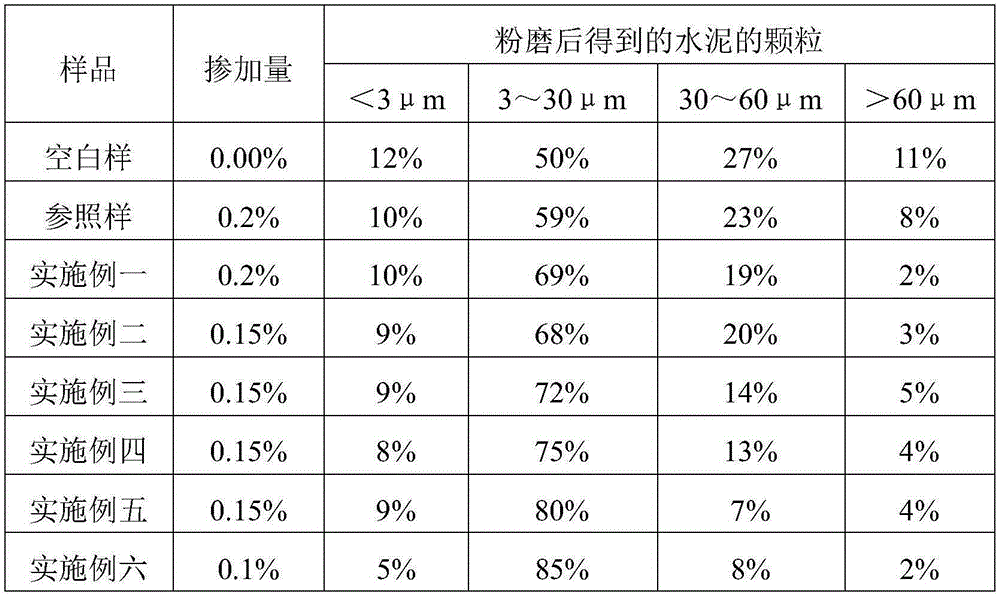

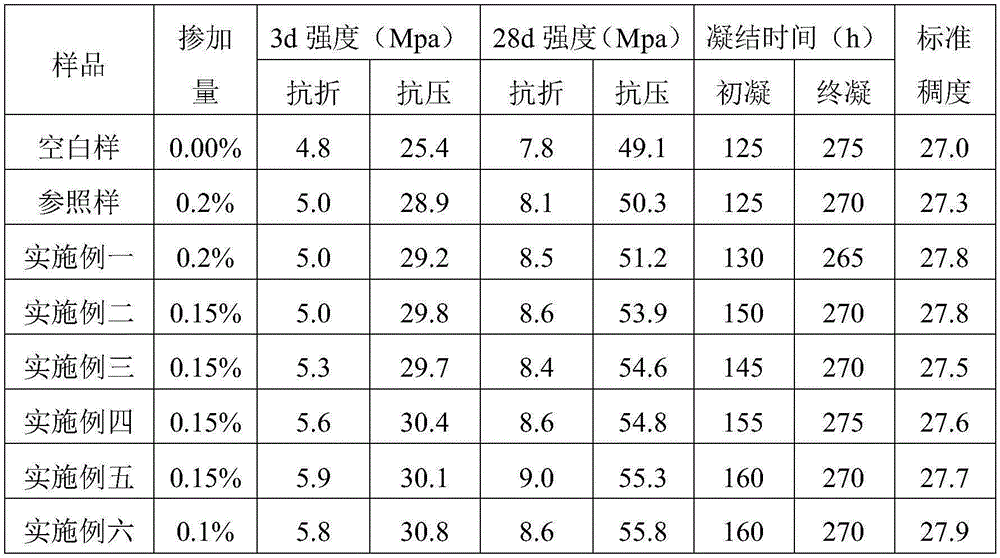

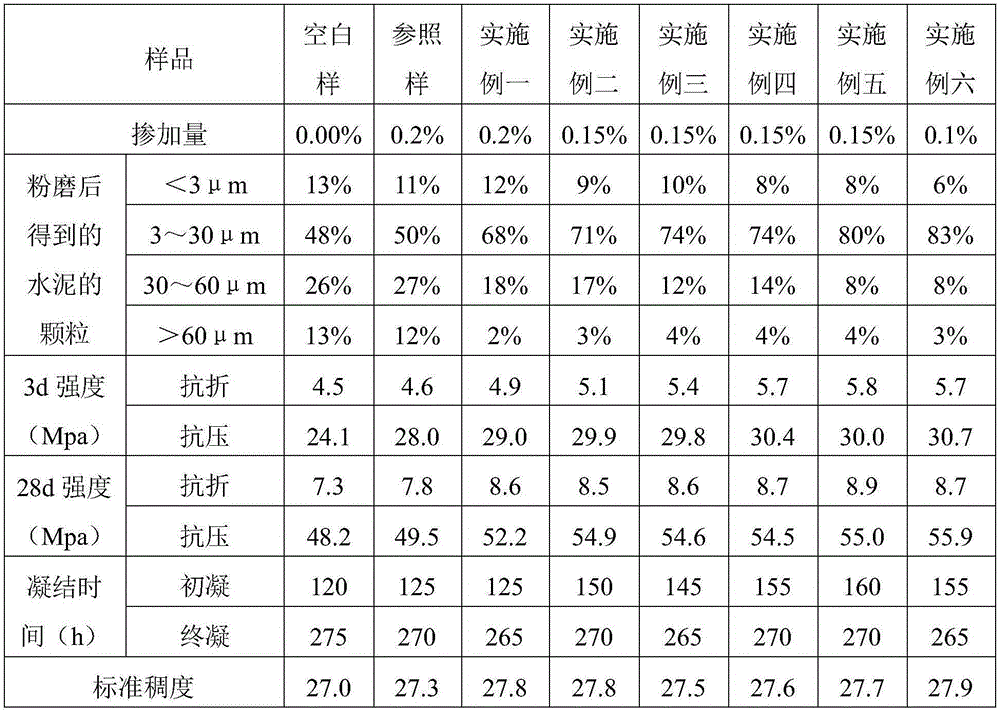

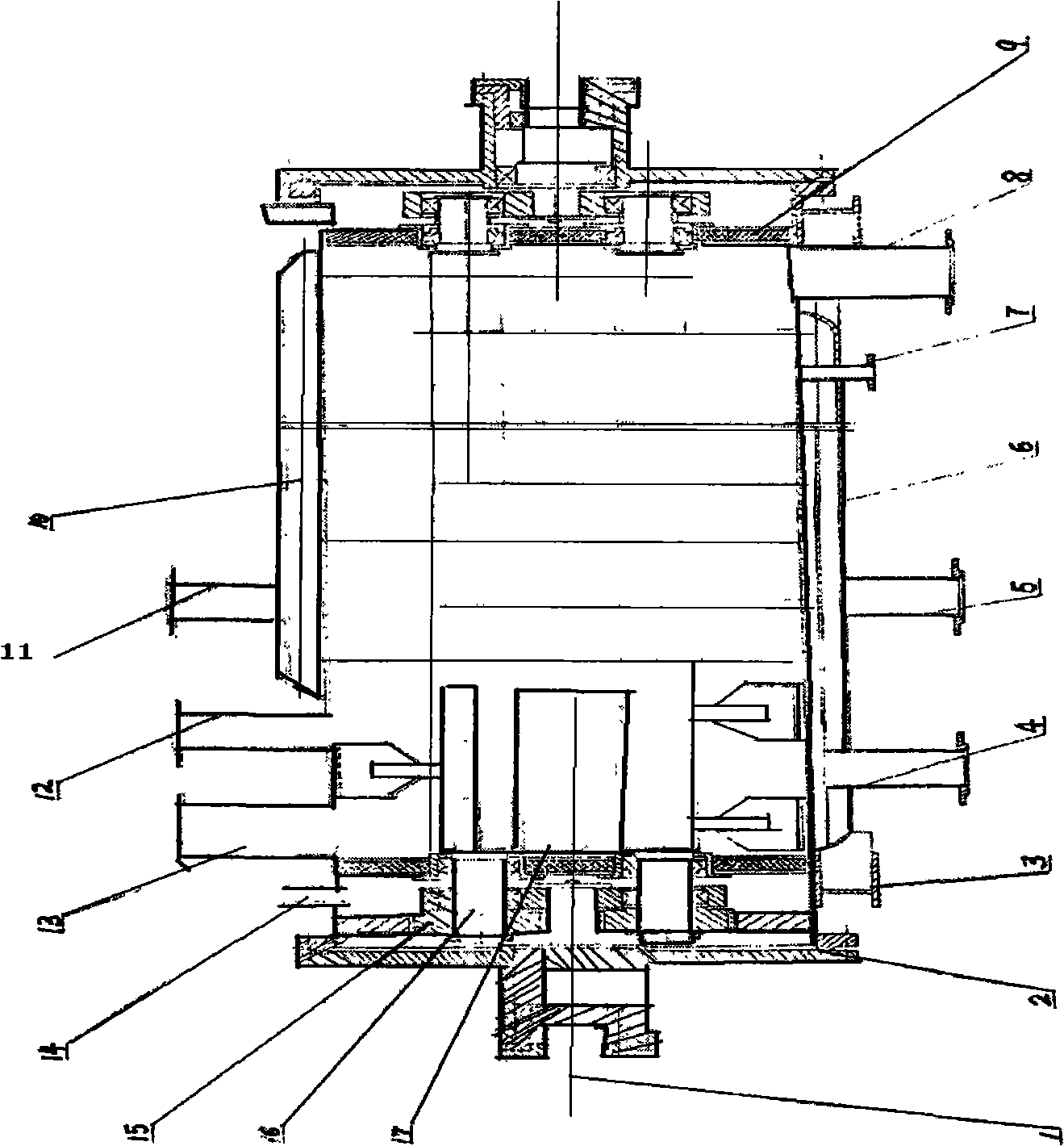

Cement grinding aid as well as preparation method and application method thereof

The invention discloses a cement grinding aid as well as a preparation method and an application method thereof. The cement grinding aid comprises the following raw materials in parts by weight: 5-15 parts of triethanolamine, 5-20 parts of honey, 1-5 parts of sodium gluconate, 1-5 parts of N-sulfo-glucosamine potassium salt, 5-10 parts of C1-C3 alcohol and 40-100 parts of water. The invention aims to provide the cement grinding aid that the grain composition of cement added with the cement grinding aid is reasonable after powdering, the fineness of cement is appropriately reduced, the strength of grinded cement can be improved, and the comprehensive effect is relatively good.

Owner:HANGZHOU LIPING IND & TRADE CO LTD

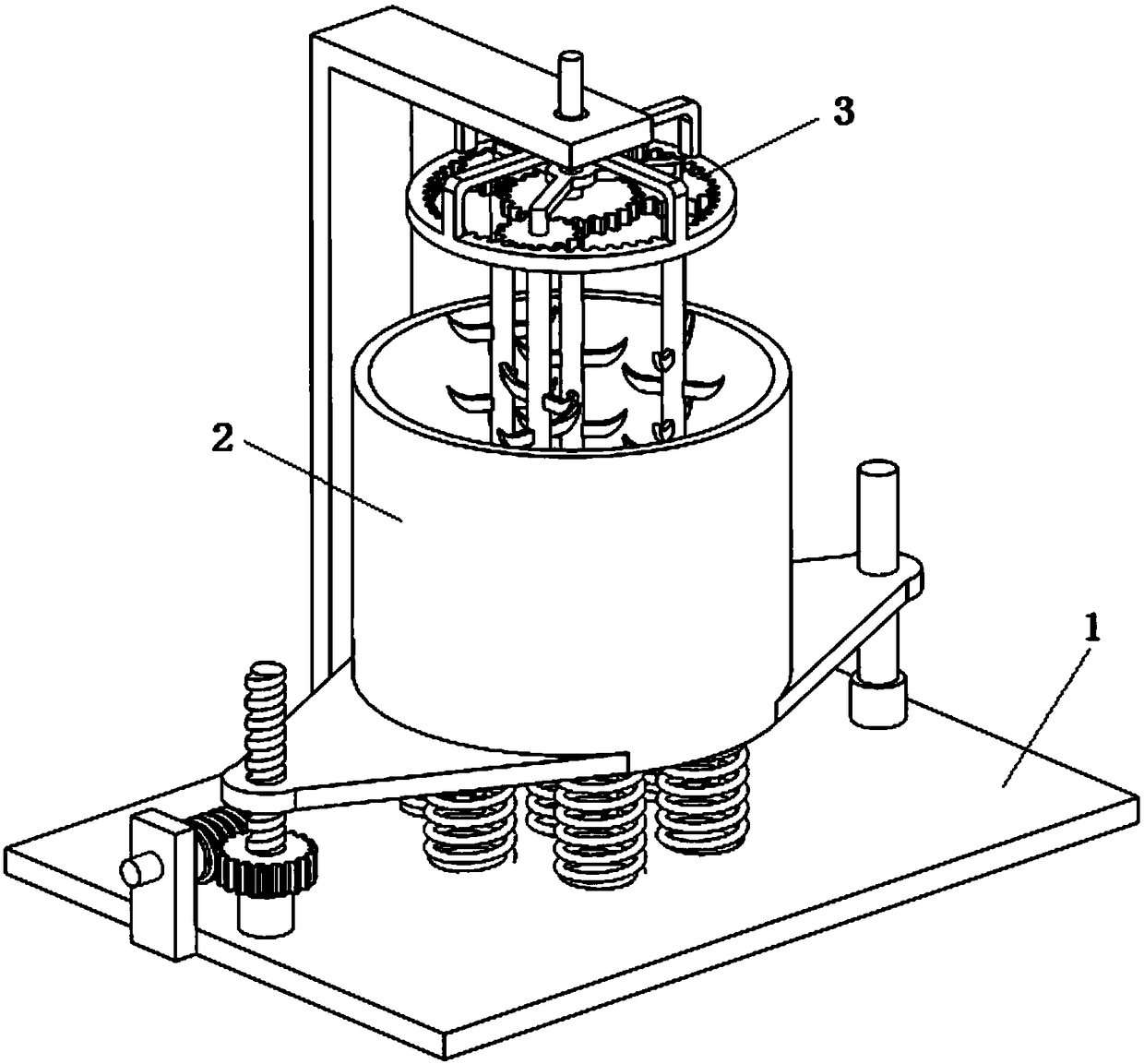

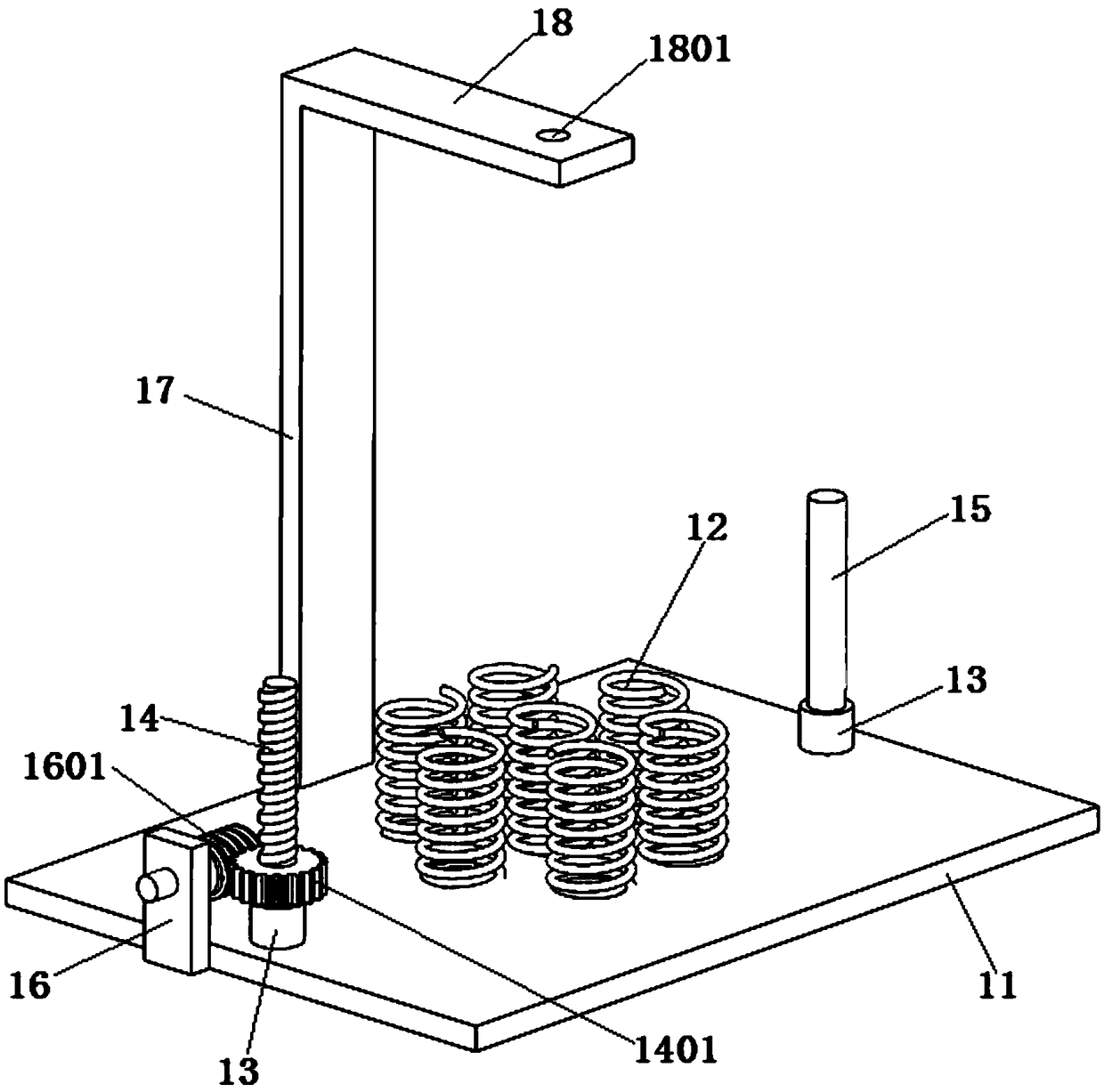

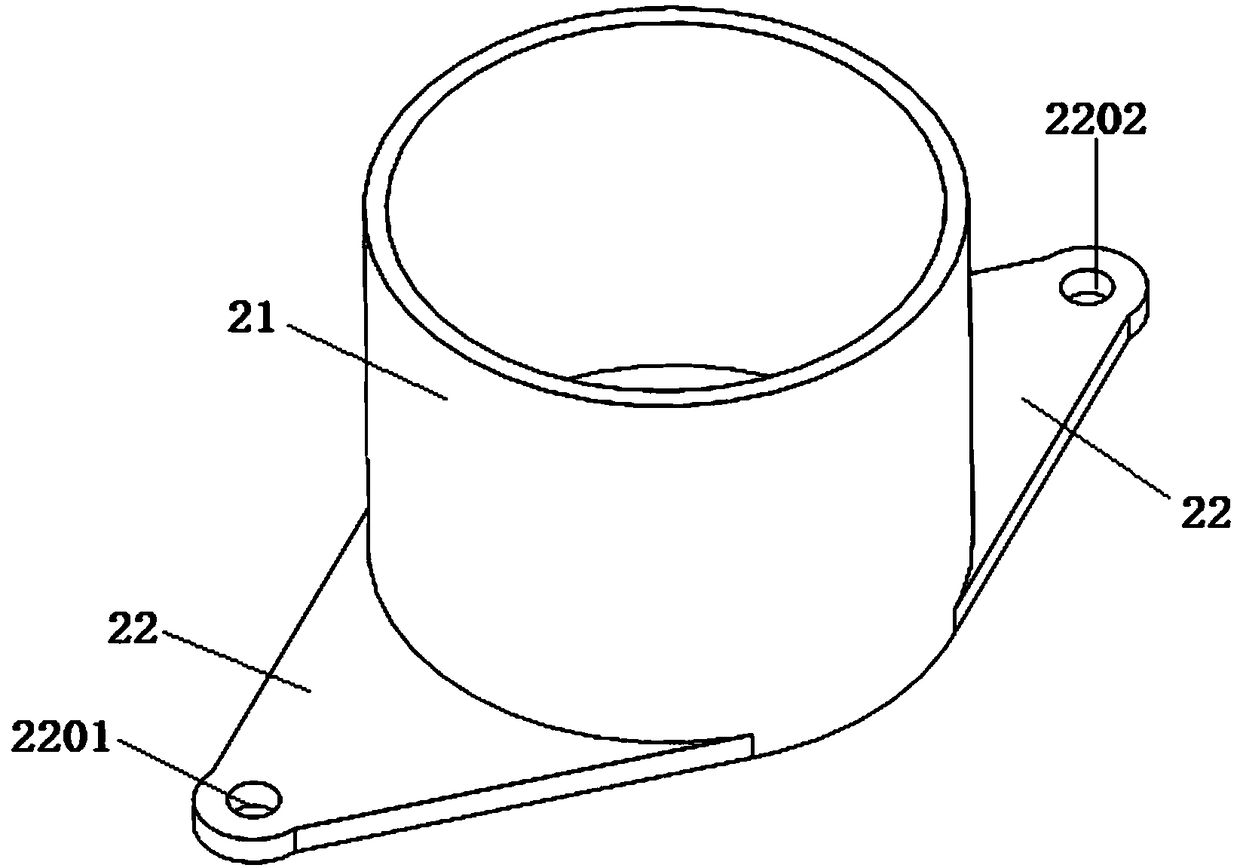

Small solid-phase tack producing device suitable for experimental laboratory and use method thereof

InactiveCN101274981ACompact structureLow costMonocomponent polyesters artificial filamentPolyesterGear drive

The invention provides a mini solid state polycondensation device and a using method thereof applicable to labs. The device is characterized by comprising a tank body, a feeding-discharge port and a heating jacket on the tank body, two mixer shafts and mixing arms thereof, a planetary gear drive system, and a vacuumed opening, a nitrogen inlet, a biphenyl inlet and a biphenyl outlet connected with the tank body and the jacket. Before the operation of equipment, biphenyl enters into the jacket of the equipment and is heated to a certain temperature; then polyester chips enter the equipment through a charging opening and the equipment begins to operate. The device of the invention has compact structure and low construction cost, has an equipment feeding coefficient over 65 percent and is applicable to the technological development of factories or the scientific research of scientific research institutions.

Owner:张家港保税区万盛机械工业有限公司

Method for preparing hydroxypropul starch under ultrasound and microwave synergistic effect

The invention relates to a method for preparing hydroxypropul starch under ultrasound and microwave synergistic effect, belonging to the grain processing field; cereal grains or yam starch are used as raw material, epoxypropane is taken as etherifying agent, sodium hydroxide is taken as catalyst, and anhydrous sodium sulfate is used as swelling restraining agent, and the hydroxypropul starch is prepared under the ultrasound and microwave synergistic effect; the starch raw material is prepared into starch milk with 10-50 percent of concentration by mass ratio, and then the starch milk is placed in an ultrasonic wave reactor with 200W-800W of supersonic wave electric power and 20kHz-500kHz of frequency, ultrasound action is carried out for 10-60min, and then the starch milk is taken out, filtered and dried, and then the starch milk is mixed with 0.2-0.4 percent of sodium hydroxide, 1.0-3.0 percent of the anhydrous sodium sulfate and 2.0-7.2 percent of epoxypropane, the mixture is fully stirred and mixed uniformly, and then the mixture is placed in a microwave reactor for reaction, the microwave power is 60-300W, and the microwave action time is 2-20min; after the reaction is carriedout, the reaction product is taken out and is neutralized by HCL with 1mol / L until the pH value is 5.5-6.0, and then the drying is carried out, so as to obtain the hydroxypropul starch with 0.01-2.00of molecule substitution degree; in the method, the reaction time is short, the efficiency is high, the product quality is good, the molecule substitution degree can be adjusted in a large range, andthe application range is wide.

Owner:ZHEJIANG GLOBALVILLAGE TECH INNOVATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com