Fused-salt electrolytic cell for producing rare earth metals and alloys

A technology of molten salt electrolysis and rare earth metals, which is applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve the problems affecting the current efficiency of graphite anode unit consumption, uneven distribution of electrolytic cell power lines, poor product quality stability, etc., to achieve product quality Balanced and stable, small amount of electrolyte for starting the furnace, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

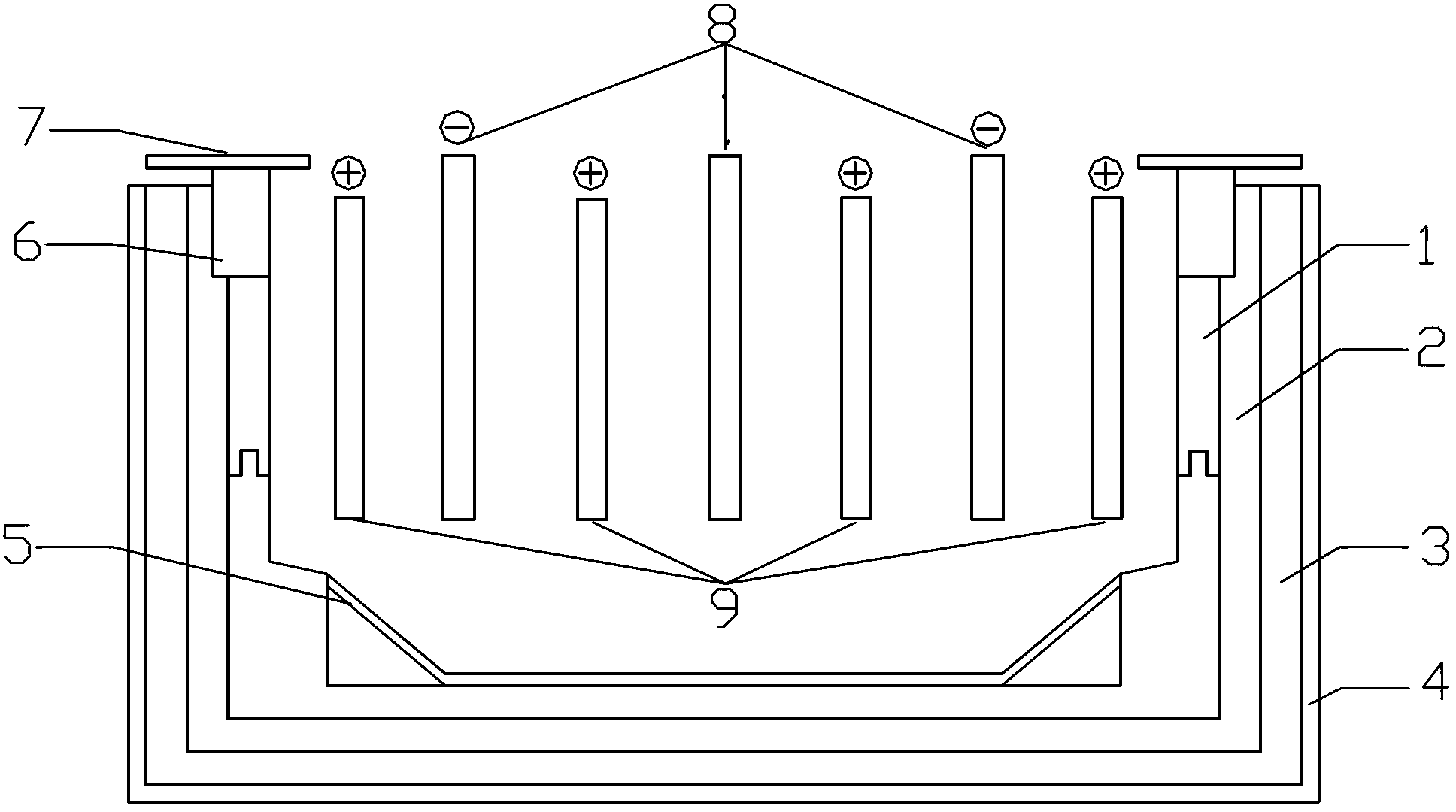

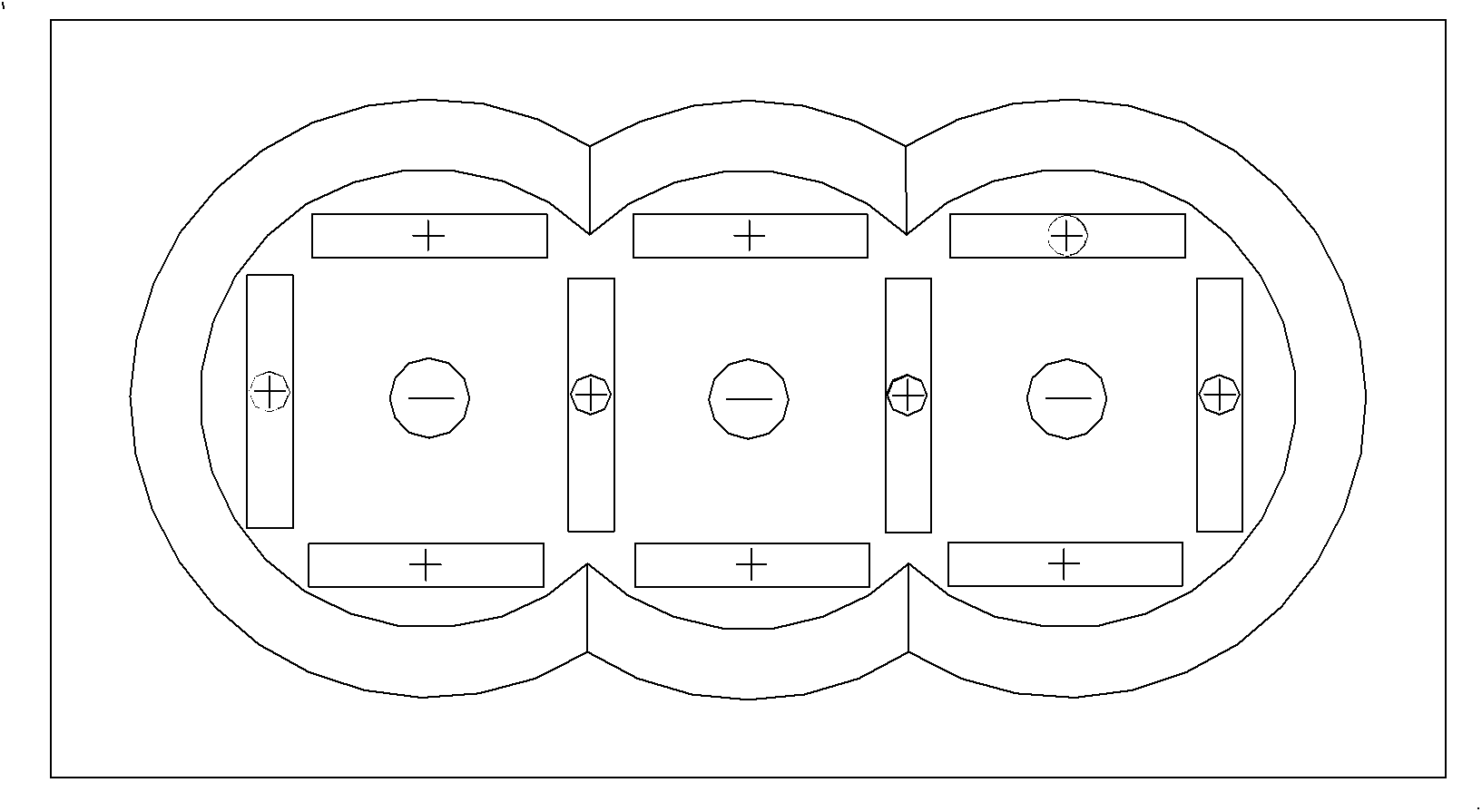

[0014] The invention includes an electrolytic cell body, a cathode 8, an anode 9, a receiver 5, and a cover plate 7. The electrolytic cell body is composed of a graphite lining 1, a carbon knotting layer 2, a refractory insulation layer 3, and a metal jacket 4 from inside to outside Nested, the side wall of the electrolytic cell is formed by connecting two or more arc surfaces to form a closed shape, and the electrolytic cell is non-airtight; the graphite lining is made of graphite with concave and convex grooves. The upper part of the graphite lining is provided with an anti-oxidation layer 6, the cathode and the receiver are made of metal tungsten, the cathode adopts a circular structure, the anode selects a circular and rectangular structure, and is equipped with three tungsten cathodes. The selection range of fluoride molten salt system components is: 75~98% (wt.%) REF 3 , 2~25% (wt.%) LiF. Direct current is applied, the electrolysis temperature is 1050±30°C, and the cath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com