Organic fertilizer derived from fermented cordyceps sinensis

A technology for fermenting Cordyceps sinensis and Cordyceps sinensis, which is applied in the direction of organic fertilizers, inorganic fertilizers, and methods based on microorganisms. It can solve the problems that the supernatant liquid does not meet the conditions of organic fertilizers, cannot be directly applied, and has low resource utilization, so as to eliminate human interference. , Convenient and convenient production, controllable and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

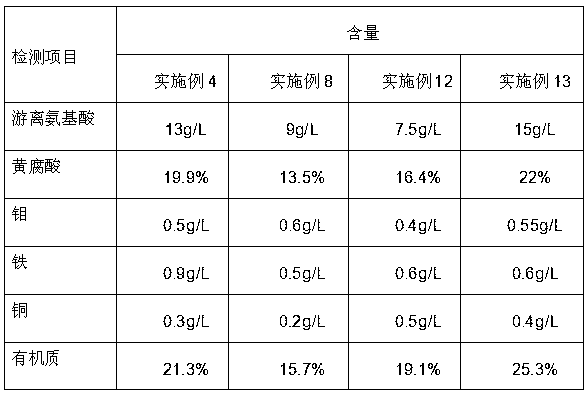

Examples

Embodiment 1

[0038] The production process of the organic fertilizer derived from fermented Cordyceps sinensis of the present invention is as follows:

[0039] 1. Weigh the material according to the process requirements, and the medium formula: silkworm chrysalis powder 5.5 / L, glucose 14 / L, corn flour 6 / L, peptone 6.5 / L, broad bean powder 1g / L, corn steep liquor 1.5g / L, bran 12g / L, magnesium sulfate 0.01g / L, dipotassium hydrogen phosphate 0.01g / L, and the rest is water. The prepared liquid medium was filled into shake flasks and sterilized for use. Mortierella China species ( Hirsutella sinensis ) were aseptically inserted into the shake flask medium, and cultured at 15°C for 10 days according to the requirements of the process characteristics of the strain.

[0040] 2. Weigh the material according to the process requirements of the seed tank, and the medium formula: silkworm chrysalis powder 5.5g / L, glucose 14g / L, corn flour 6g / L, peptone 6.5g / L, yeast extract powder 2.5g / L, broad bean ...

Embodiment 2

[0045] The production process of the organic fertilizer derived from fermented Cordyceps sinensis of the present invention is as follows:

[0046] 1. Weigh the materials according to the process requirements, and the medium formula: silkworm chrysalis powder 10g / L, glucose 21g / L, corn flour 11g / L, peptone 10.5g / L, broad bean powder 10g / L, corn steep liquor 12g / L, bran 21g / L, magnesium sulfate 0.05g / L, dipotassium hydrogen phosphate 0.05g / L, and the rest is water. The prepared liquid medium was filled into shake flasks and sterilized for use. Mortierella China species ( Hirsutella sinensis ) were aseptically inserted into the shake flask medium, and cultured at 17°C for 10 days according to the process characteristics of different strains.

[0047] 2. Weigh the material according to the process requirements of the seed tank. The medium formula: silkworm chrysalis powder 10g / L, glucose 21g / L, corn flour 11g / L, peptone 10.5g / L, yeast extract powder 5.5g / L, broad bean powder ...

Embodiment 3

[0052] The production process of the organic fertilizer derived from fermented Cordyceps sinensis of the present invention is as follows:

[0053] 1. Weigh the material according to the process requirements, and the medium formula: silkworm chrysalis powder 24g / L, glucose 28g / L, corn flour 18g / L, peptone 17g / L, broad bean powder 22g / L, corn steep liquor 23g / L, bran 27.5 g / L, magnesium sulfate 2.4g / L, dipotassium hydrogen phosphate 2.4g / L, and the rest is water. The prepared liquid medium was filled into shake flasks and sterilized for use. Mortierella China species ( Hirsutella sinensis ) were aseptically inserted into the shake flask culture medium, and cultured at 20°C for 8 days according to the requirements of the process characteristics of the strain.

[0054]2. Weigh the material according to the process requirements of the seed tank. The medium formula: silkworm chrysalis powder 24g / L, glucose 28g / L, corn flour 18g / L, peptone 17g / L, yeast extract powder 9g / L, broad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com