Patents

Literature

54 results about "Finial" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A finial or hip-knob is an element marking the top or end of some object, often formed to be a decorative feature. In architecture it is a decorative device, typically carved in stone, employed to emphasize the apex of a dome, spire, tower, roof, or gable or any of various distinctive ornaments at the top, end, or corner of a building or structure. Where there are several such elements they may be called pinnacles. Smaller finials in materials such as metal or wood are used as a decorative ornament on the tops or ends of poles or rods such as tent-poles or curtain rods or any object such as a piece of furniture. These are frequently seen on top of bed posts or clocks. Decorative finials are also commonly used to fasten lampshades, and as an ornamental element at the end of the handles of souvenir spoons. The charm at the end of a pull chain (such as for a ceiling fan or a lamp) is also known as a finial.

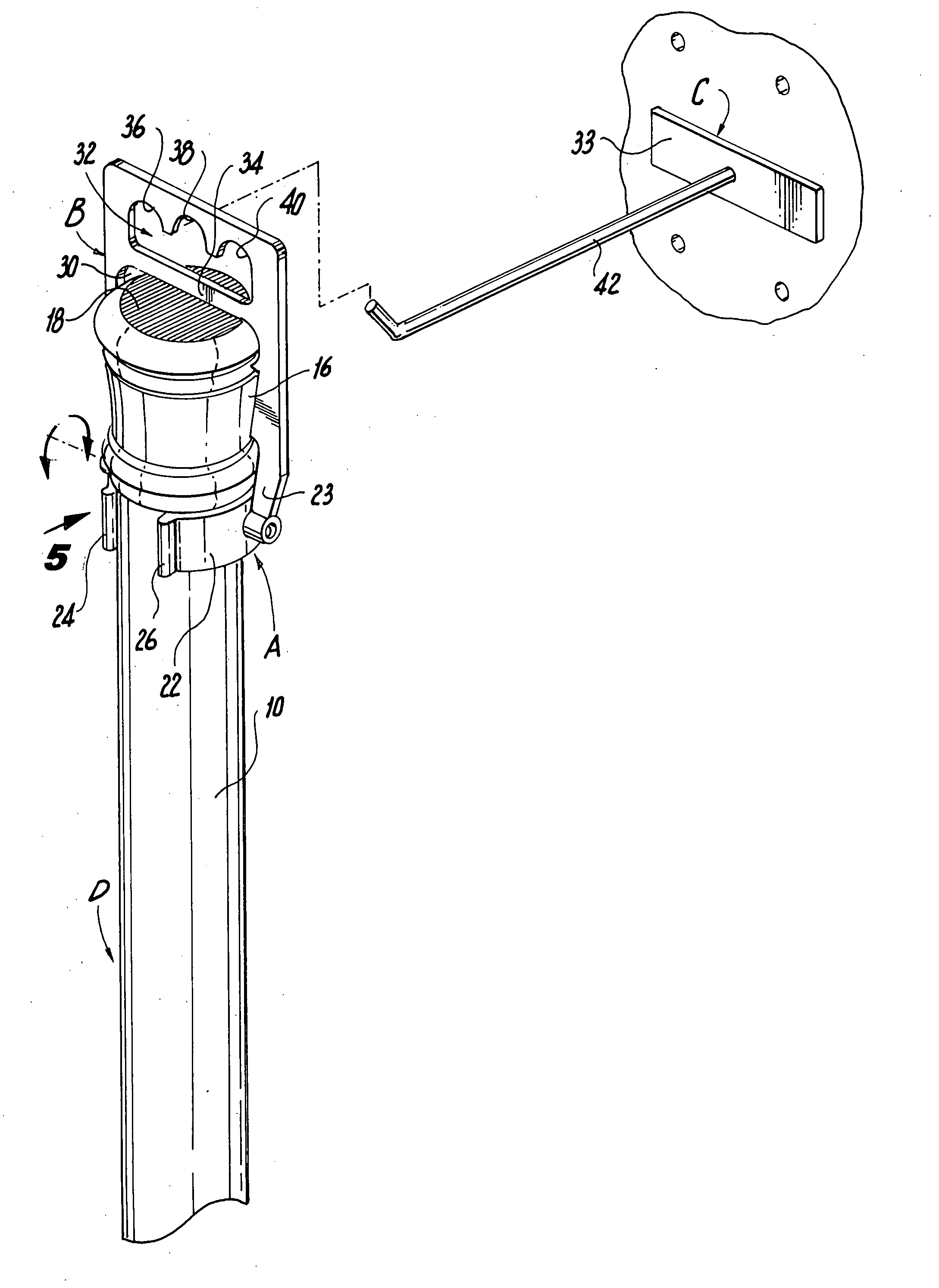

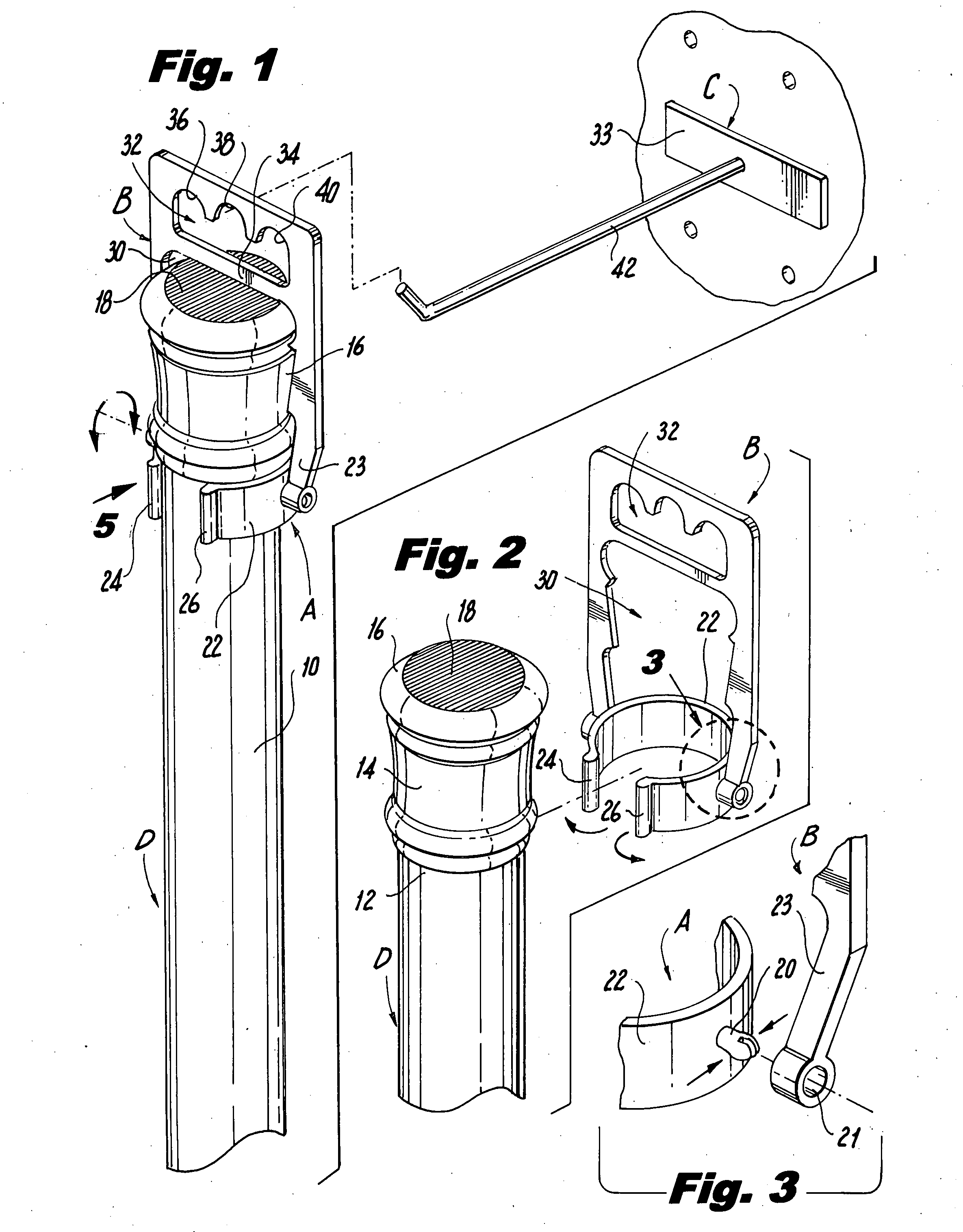

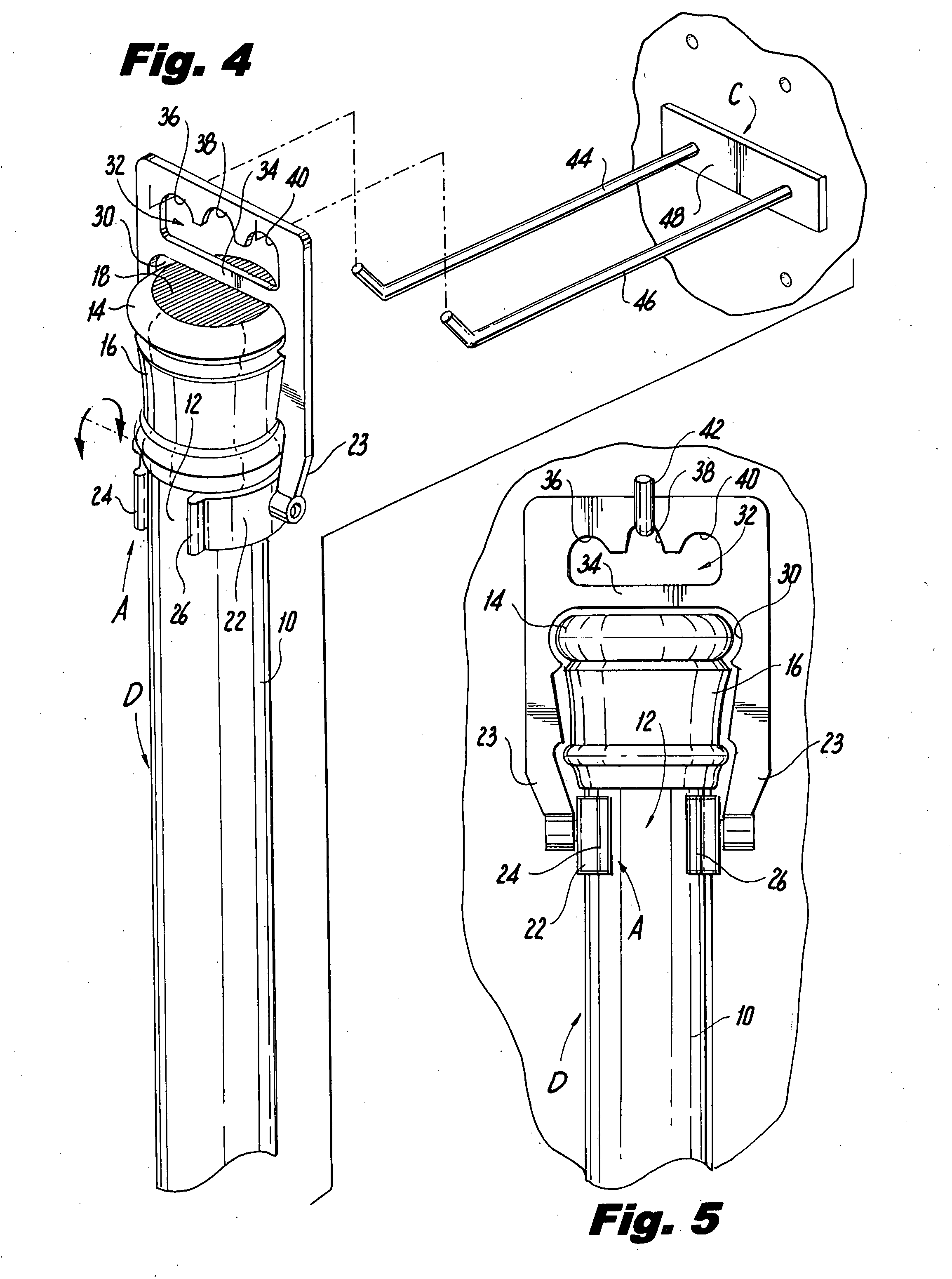

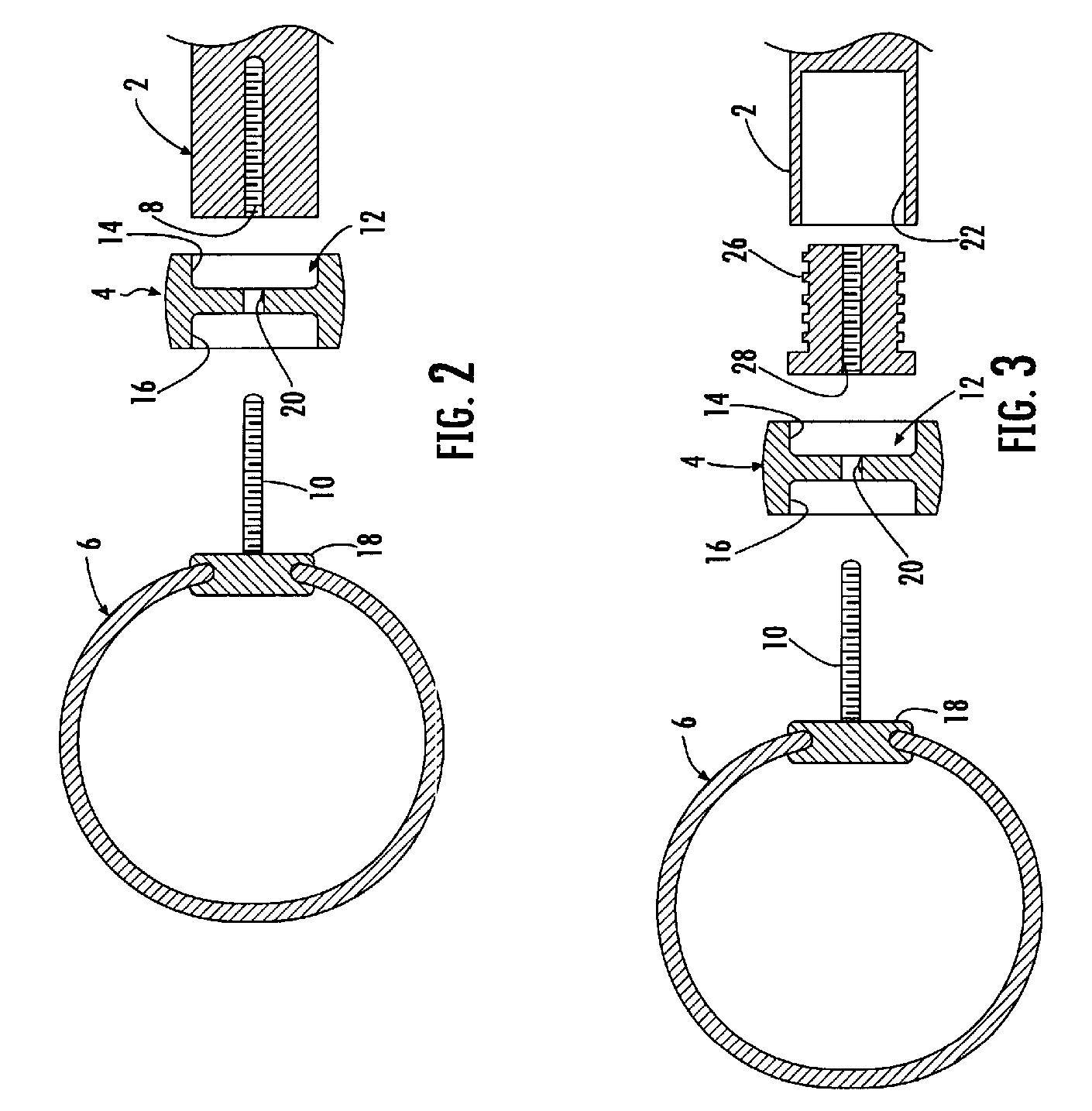

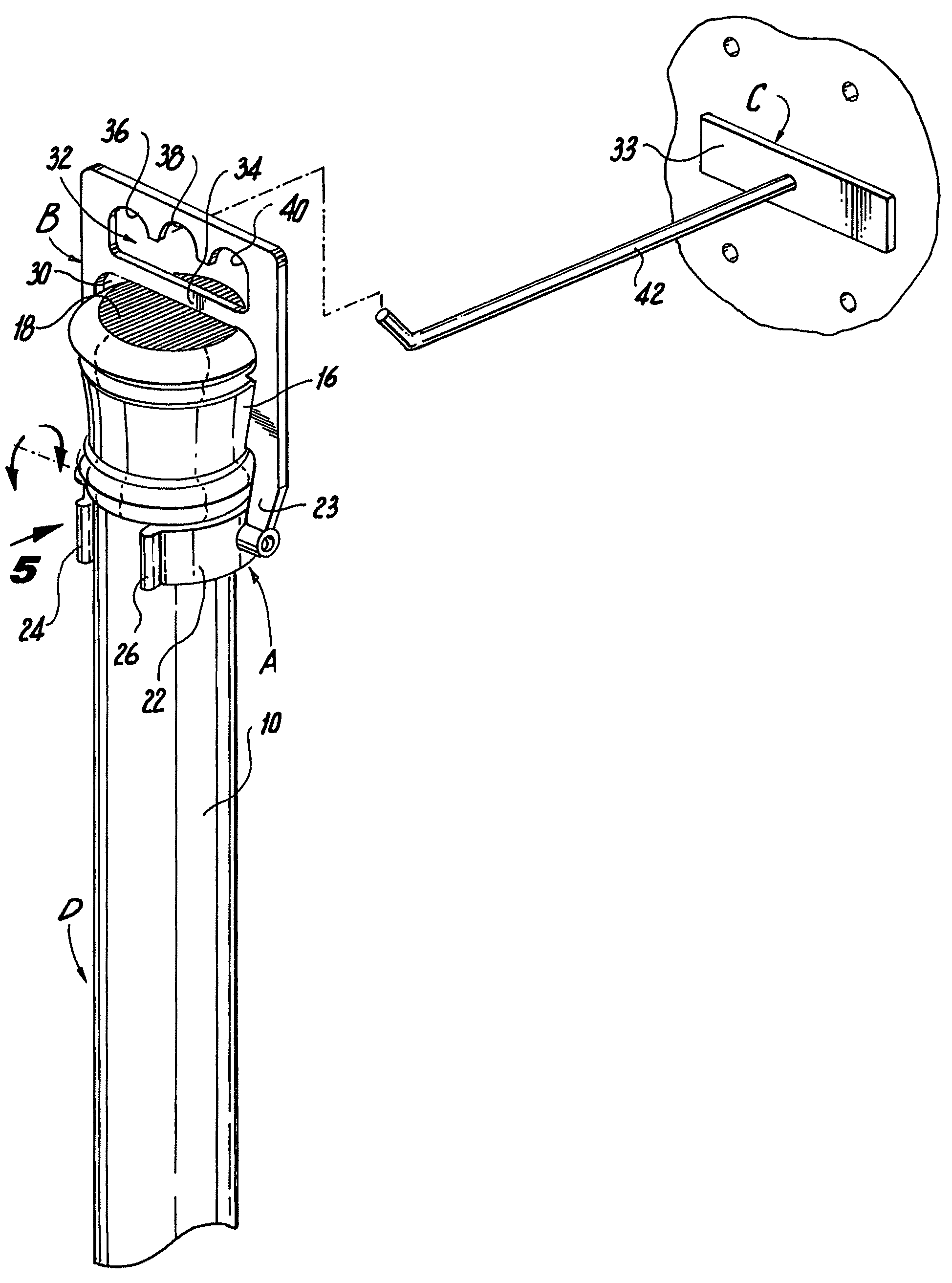

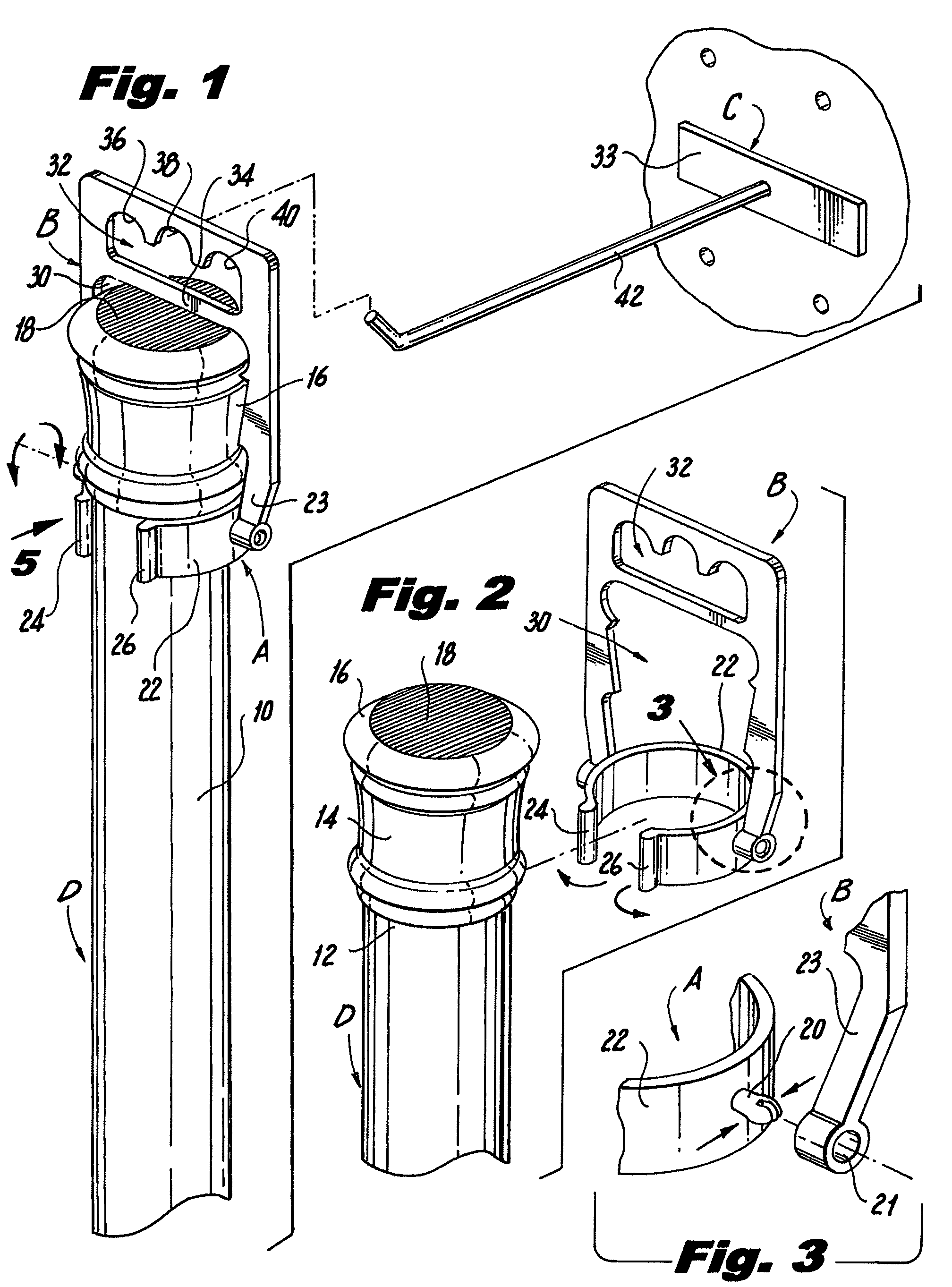

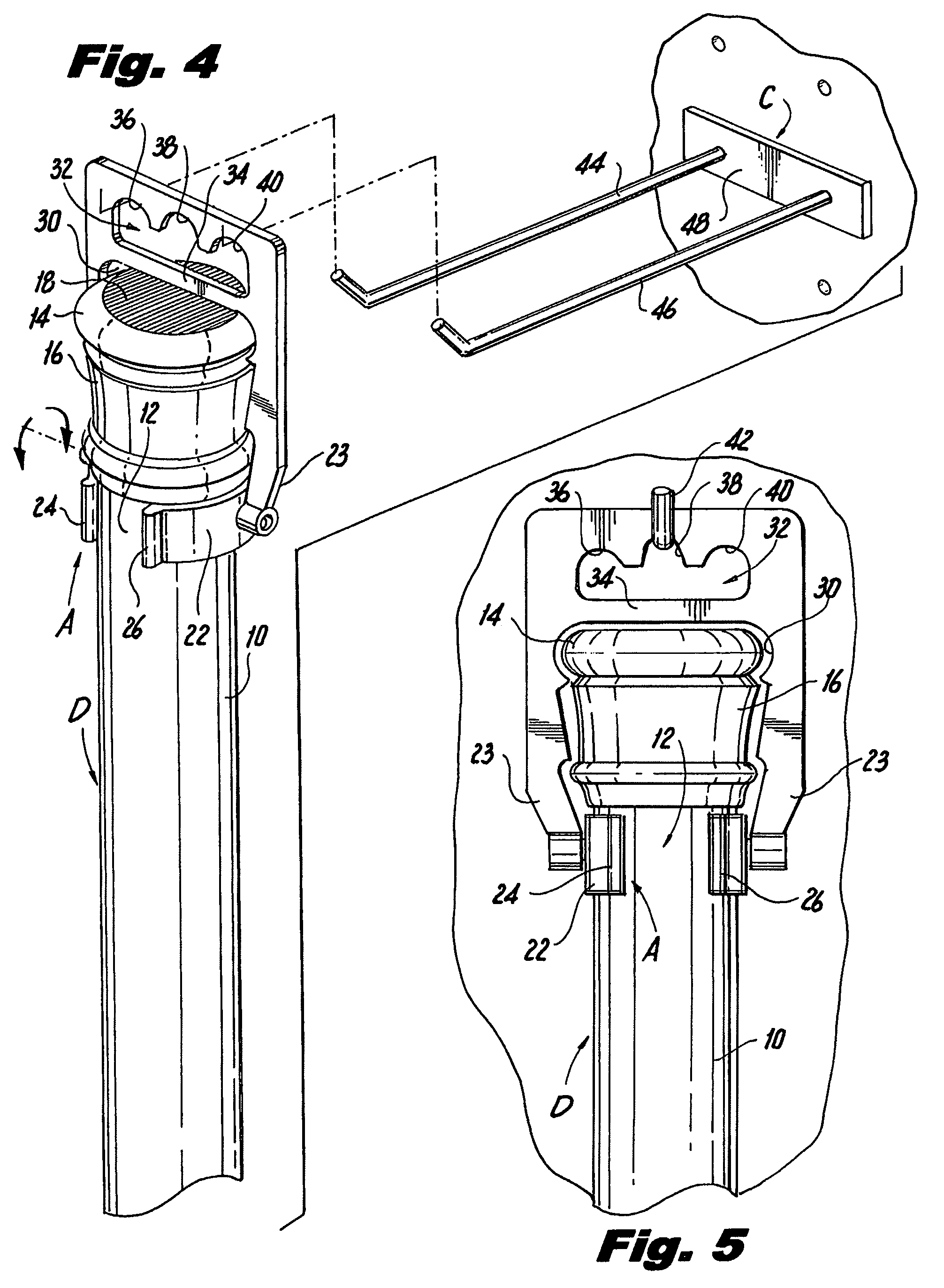

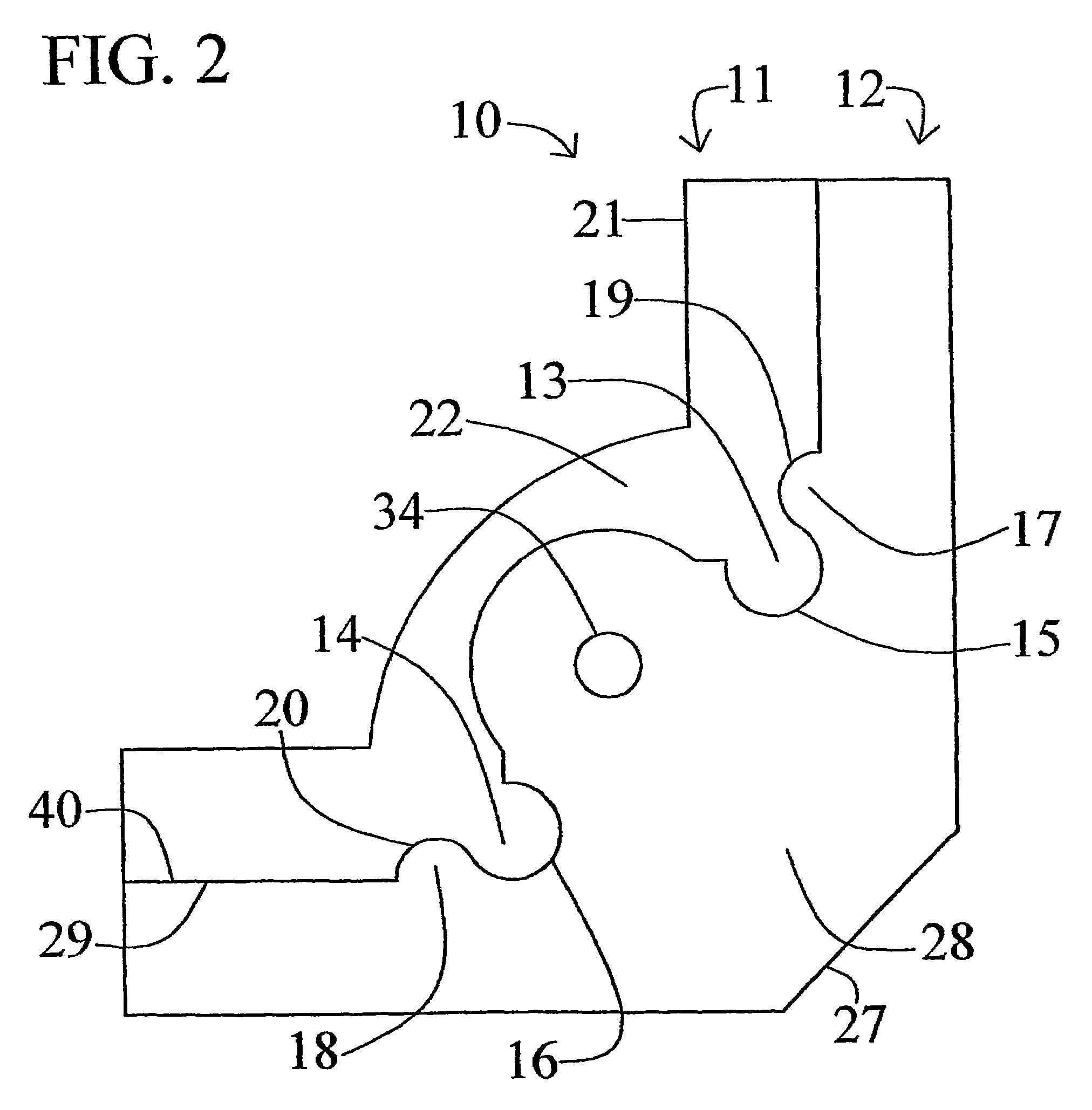

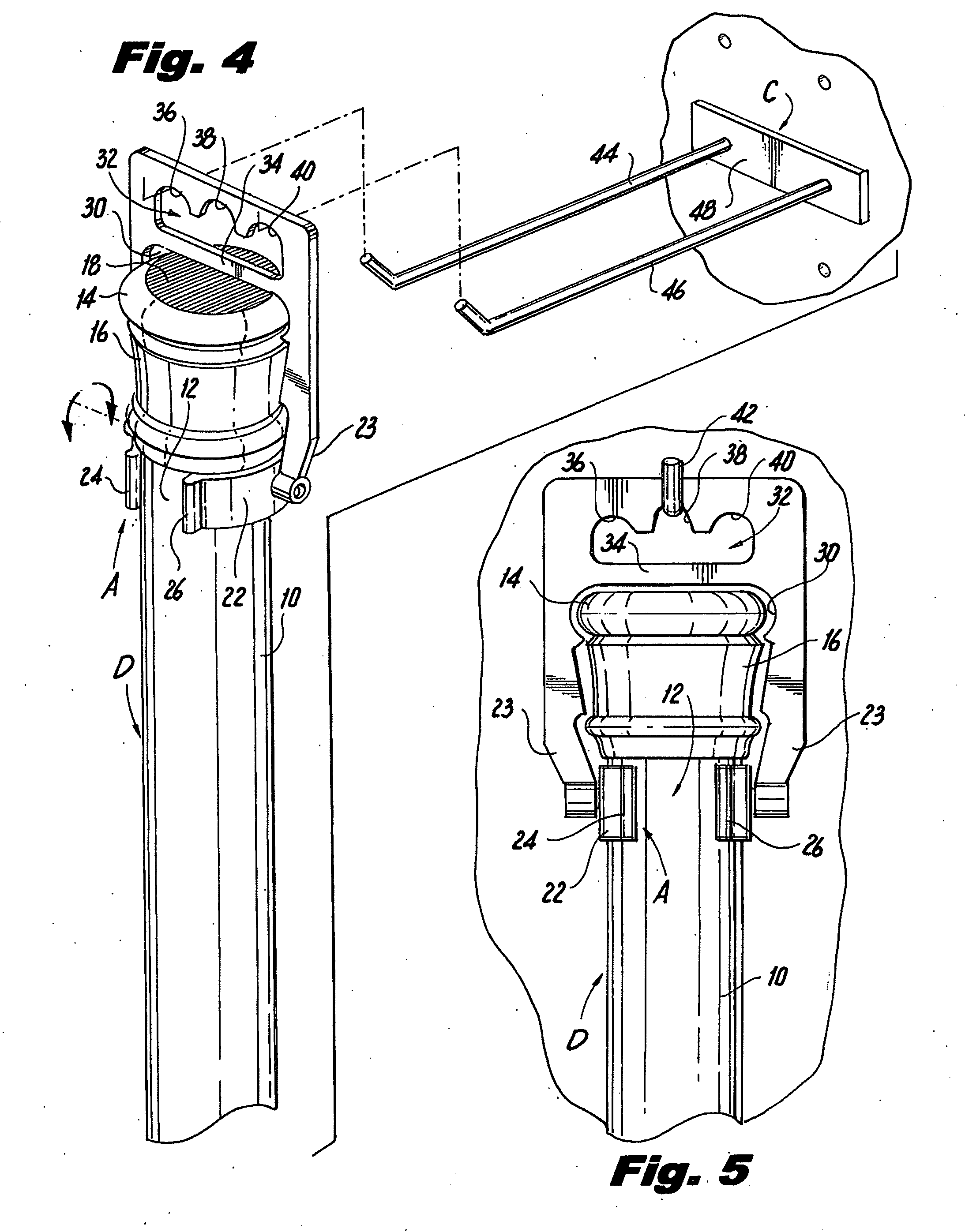

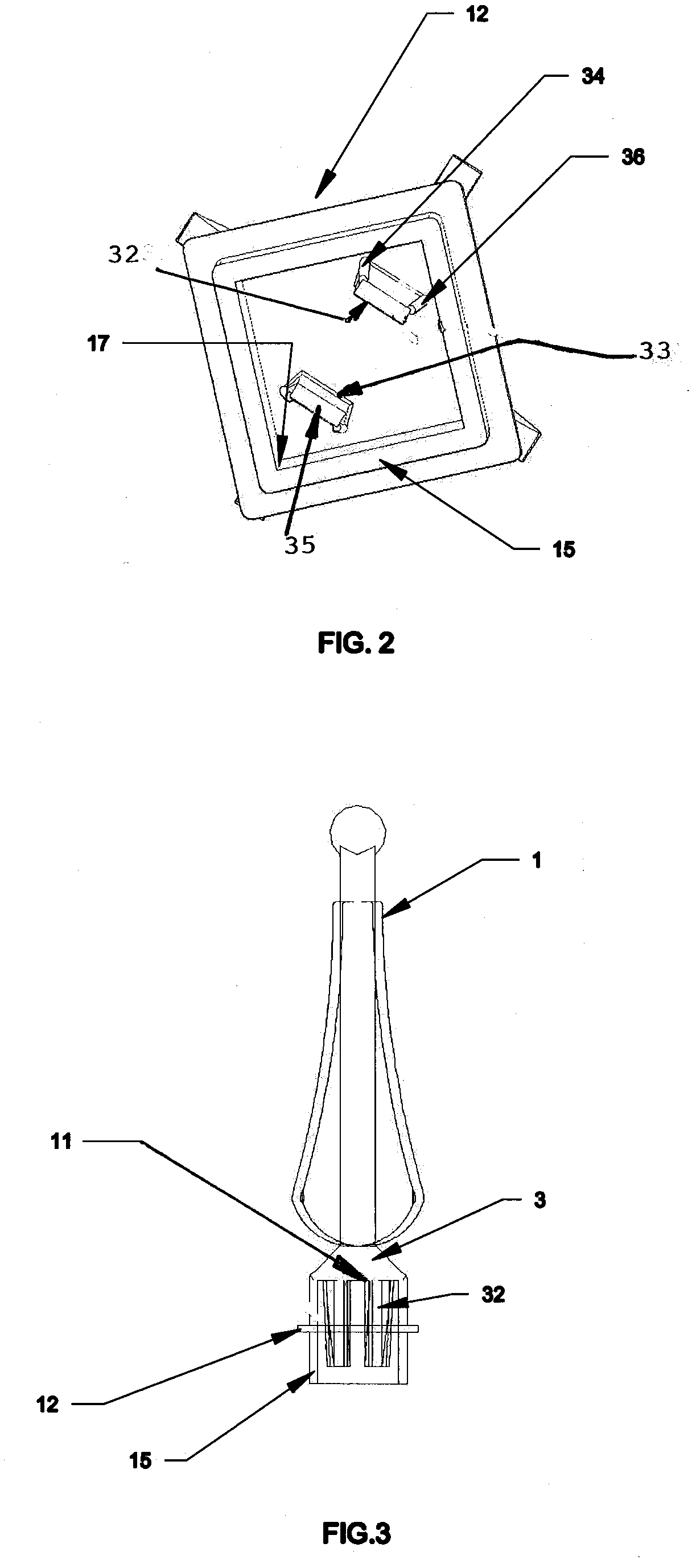

Display hanger for curtain rod

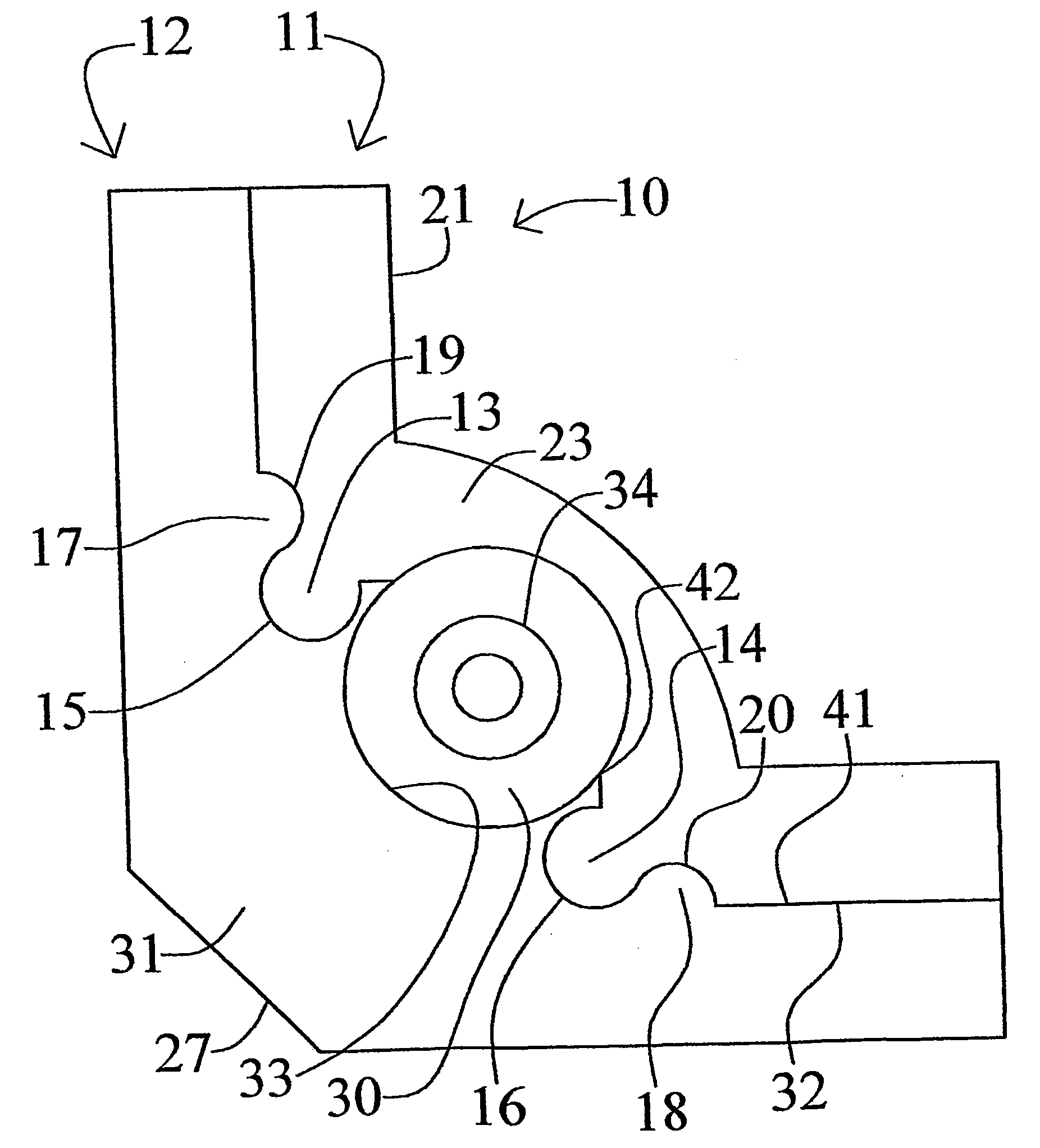

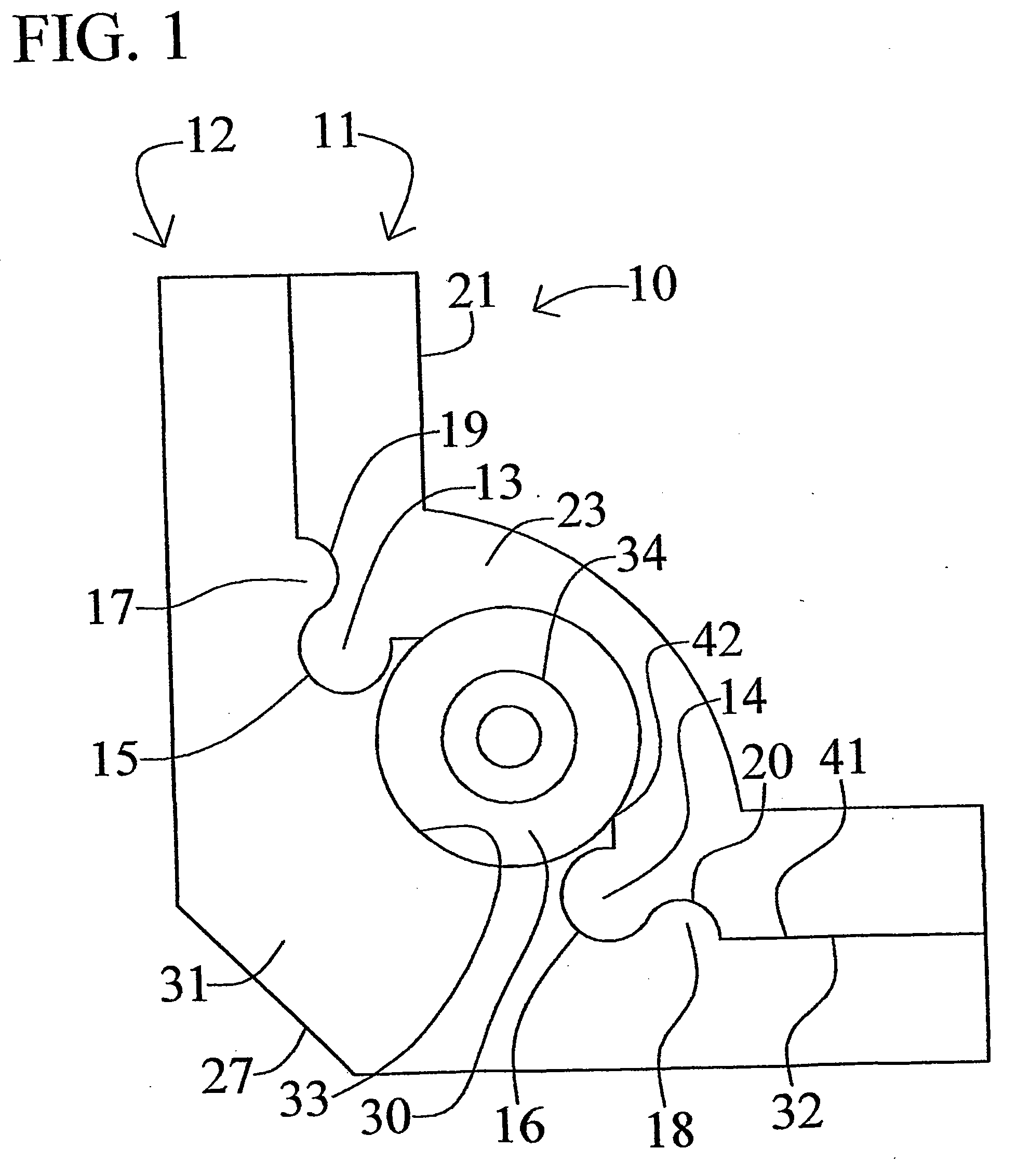

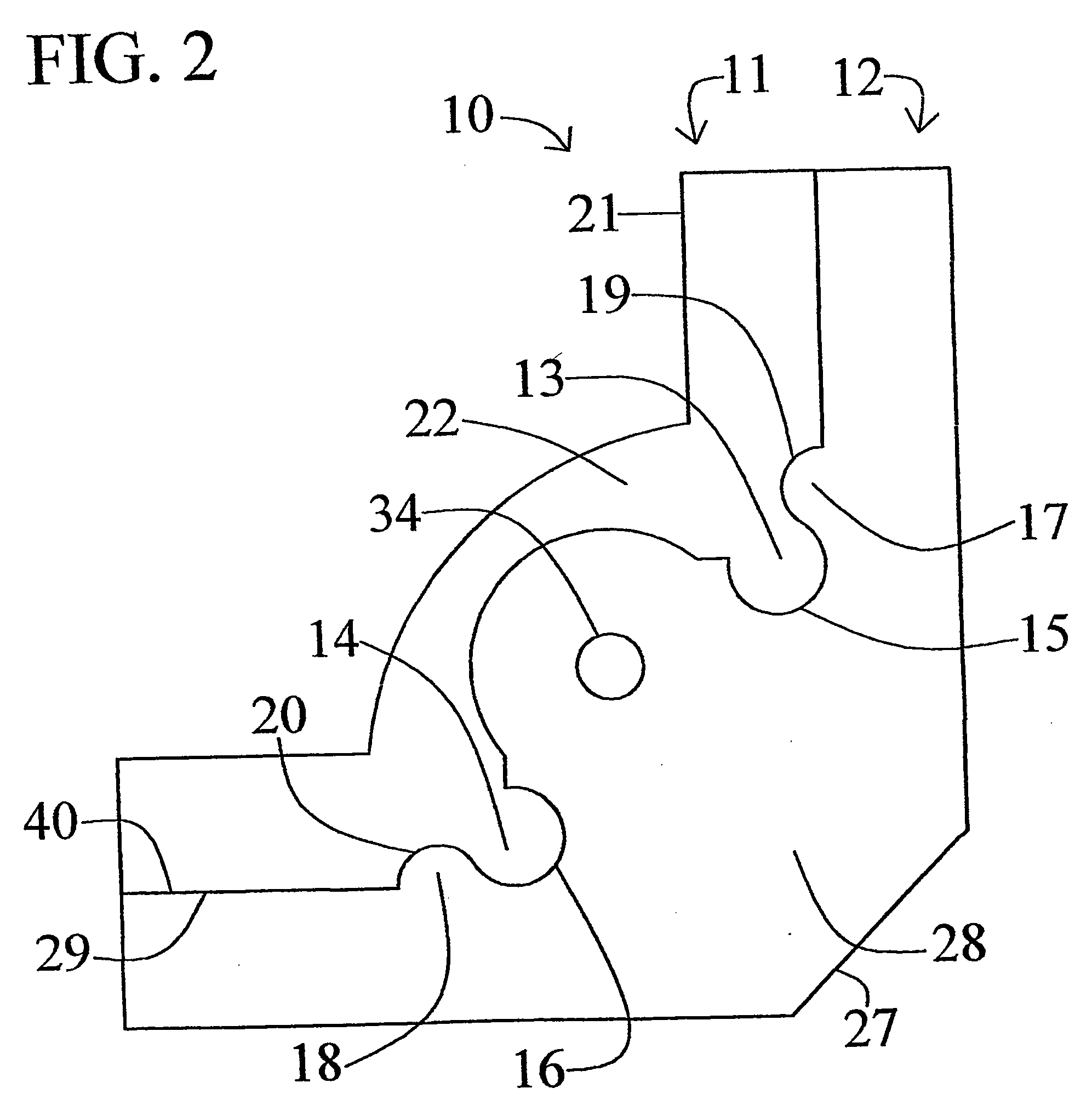

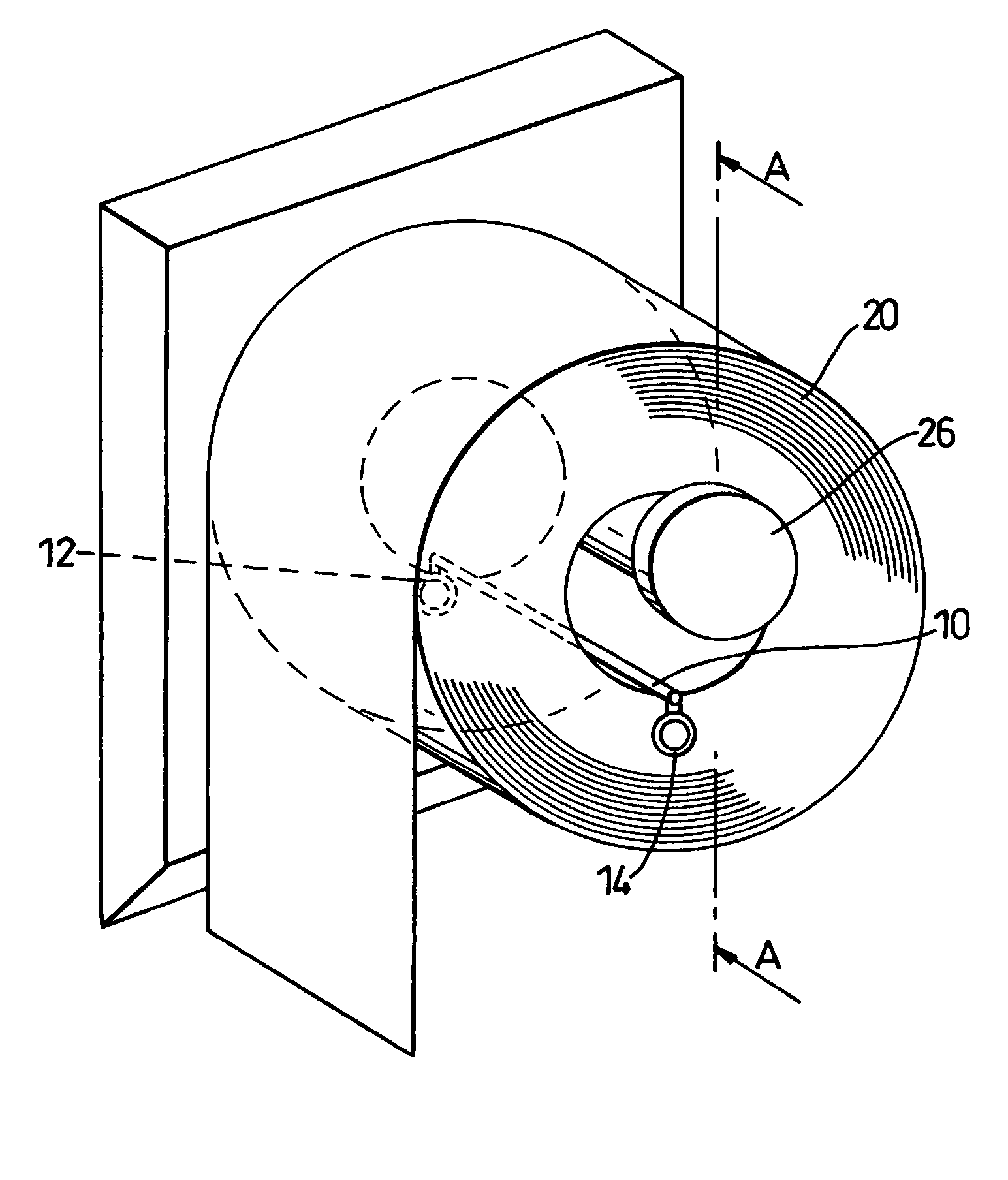

InactiveUS20080210827A1Cheap manufacturingInexpensive to assemblePipe supportsPipesFinialDisplay device

A hanger is provided for mounting a curtain rod, such as a shower curtain tension rod, on a display. The hanger includes a body and a resilient collar, pivotally connected to the body, for engaging the rod in a “snap-fit” fashion. The body has a first opening adapted to receive the curtain rod end and a second opening adapted to be engaged by a prong of the display, to mount the curtain rod on the display. The curtain rod end may include a part, such as a finial, with an exterior surface having a contour. The first opening has a shape substantially corresponding to that contour. The second opening preferably includes three recesses such that conventional single prong and double prong displays can be accommodated.

Owner:EX CELL HOME FASHIONS

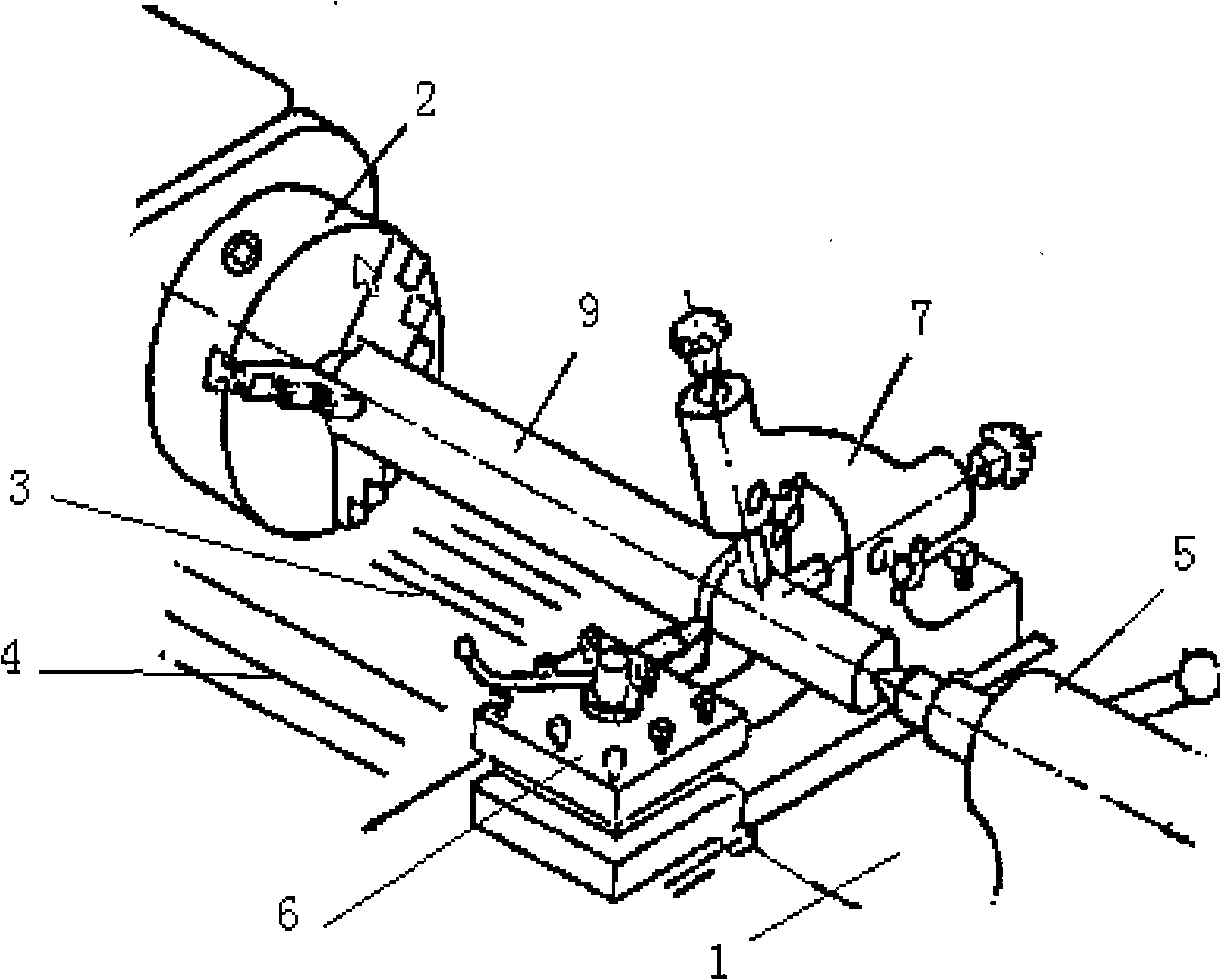

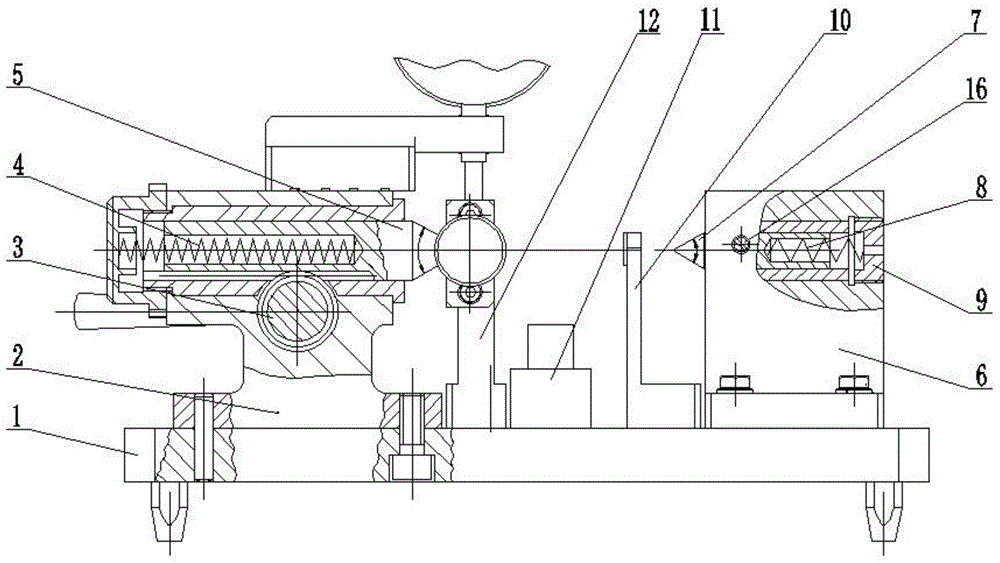

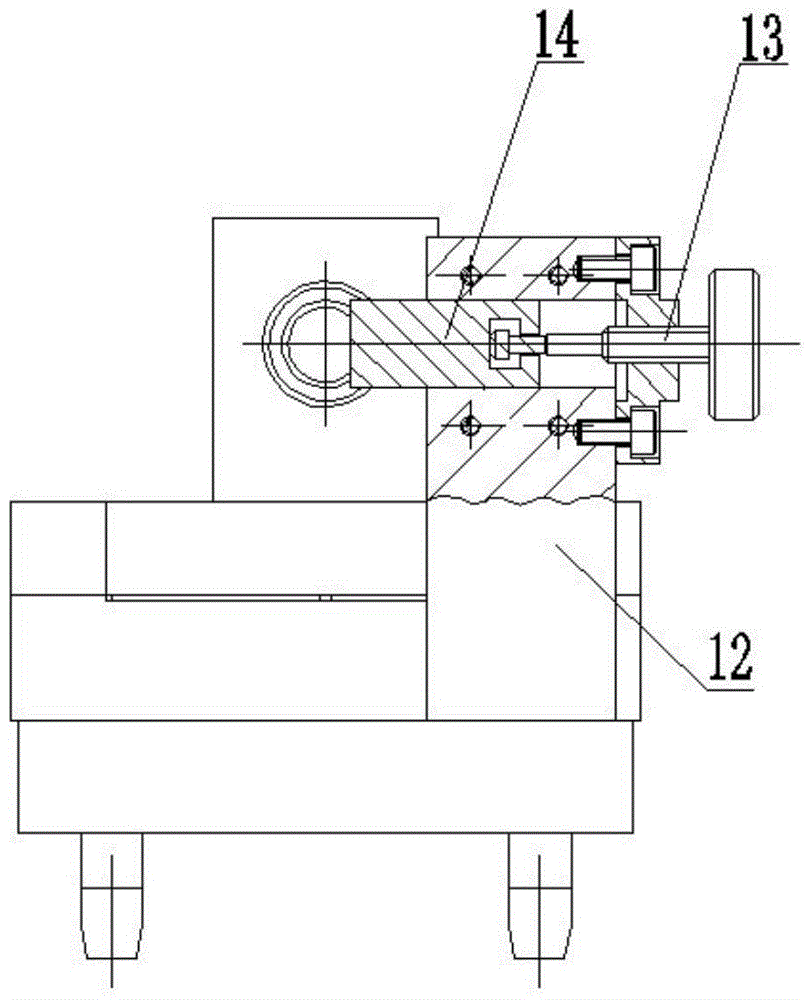

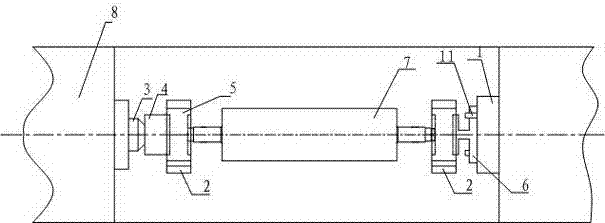

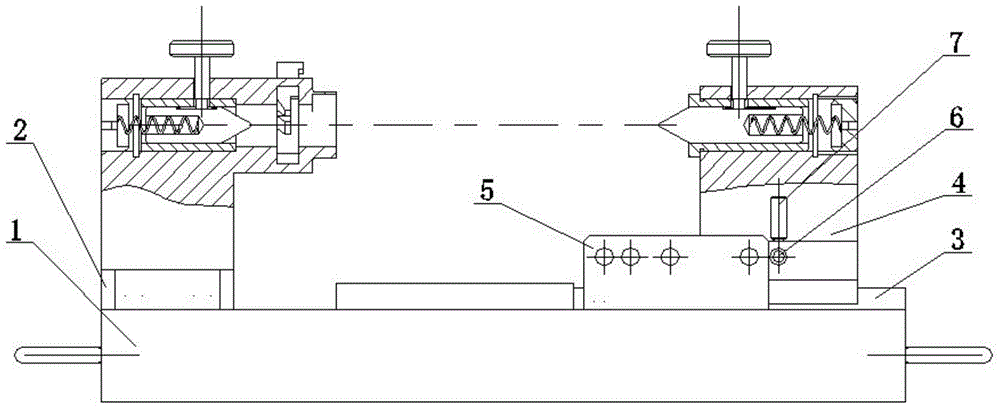

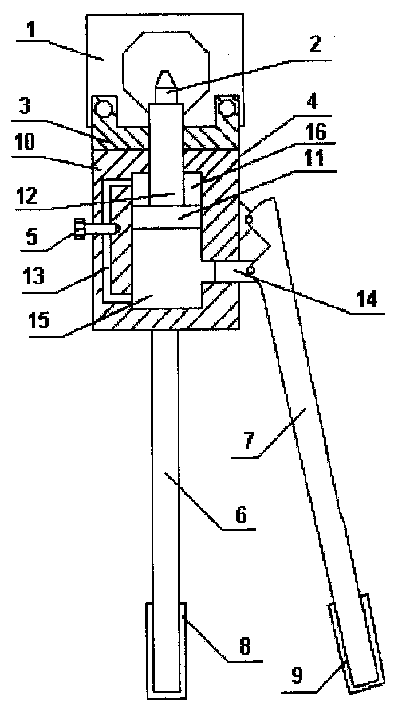

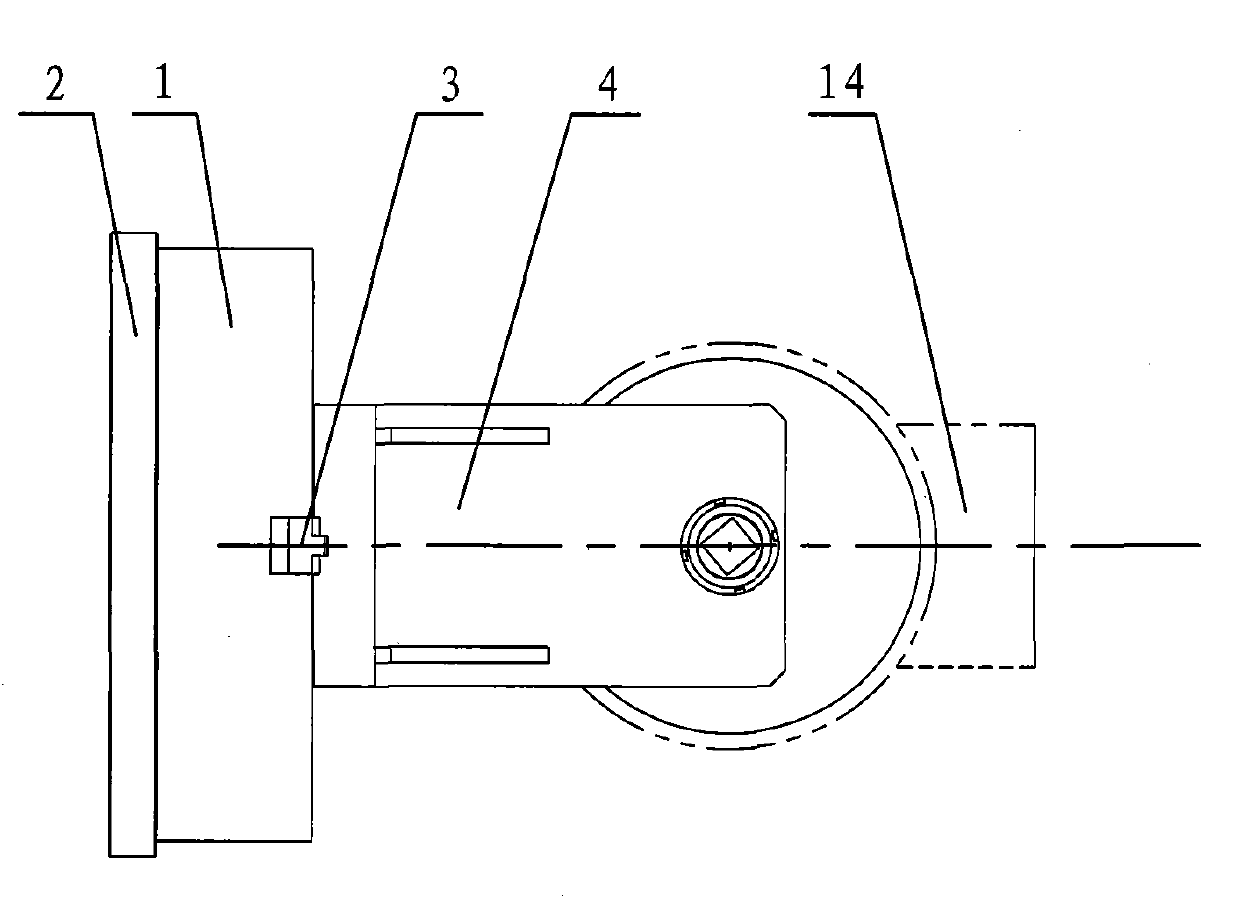

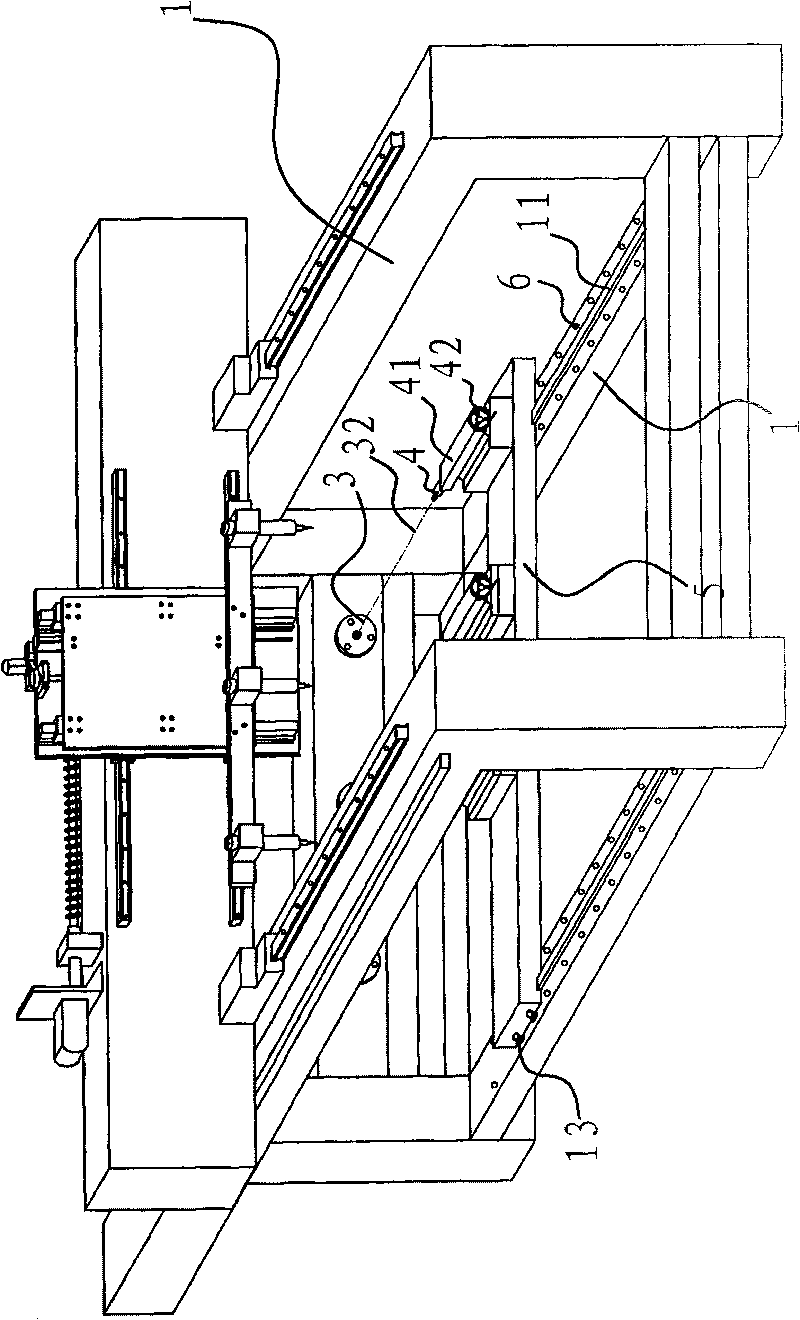

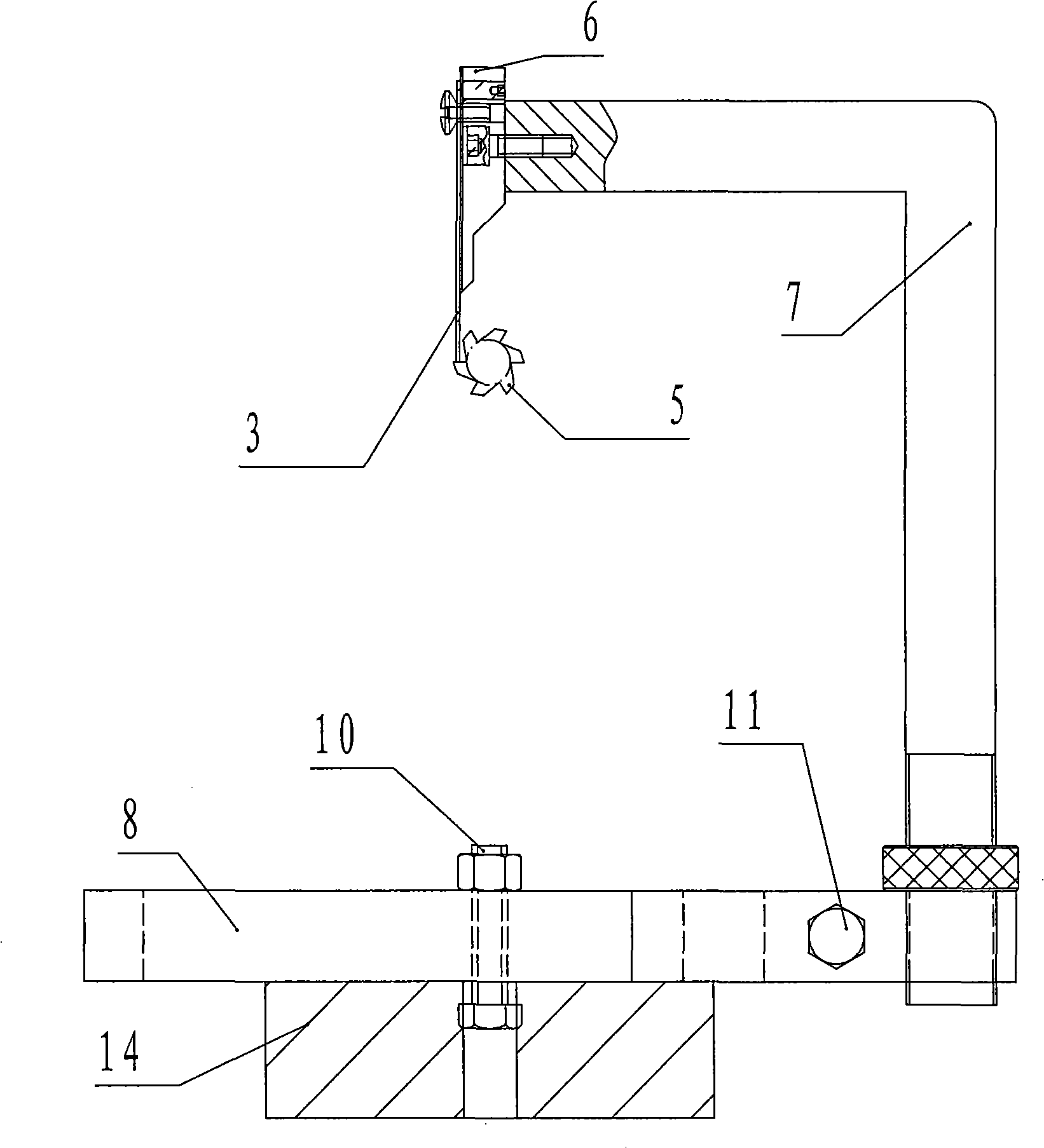

Machine tool and method for machining over-long diameter ratio shaft exceeding machine tool standard

InactiveCN101574743AIncrease profitIncrease travelLarge fixed membersTurning machinesFinialLongest Diameter

The invention discloses a machine tool and a method for machining an over-long diameter ratio shaft exceeding the machine tool standard. The method comprises the following steps: firstly, leaving a section of chuck dock with an effective length respectively at two ends of a workpiece in advance, and drilling central holes on two end surfaces of the workpiece; secondly clamping one end of the workpiece on a chuck of a headstock, and supporting the other end by a finial on a tailstock; thirdly, coarsely turning the excircle of each section of the workpiece, and reversing the workpiece for turning when a knife rest feeds to the tail end of a knife rest lead rail; fourthly, finely turning the excircle of each section of the workpiece, and reversing and clamping the workpiece for turning when the knife rest feeds to the tail end of the knife rest lead rail; and finally, milling the chuck docks at the two ends and the chamfer angle on a boring lathe, a milling machine or other machine tools. The machine tool and the method for machining an over-long diameter ratio shaft exceeding the machine tool standard achieve the purpose of machining long-shaft parts over 15 m on a common machine tool for machining long shaft parts, thereby reducing the production cost.

Owner:SHANGHAI HEAVY MACHINERY PLANT

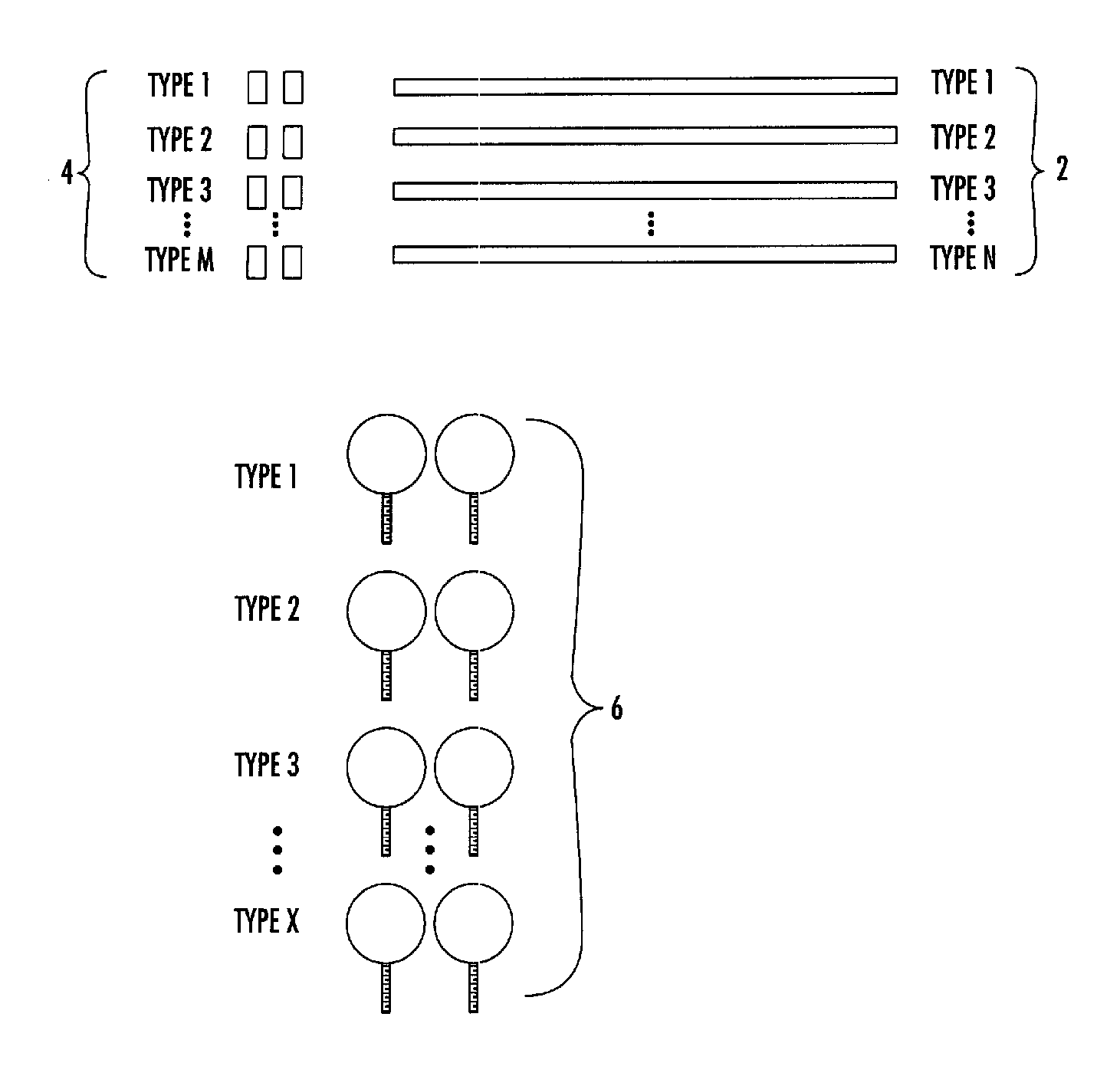

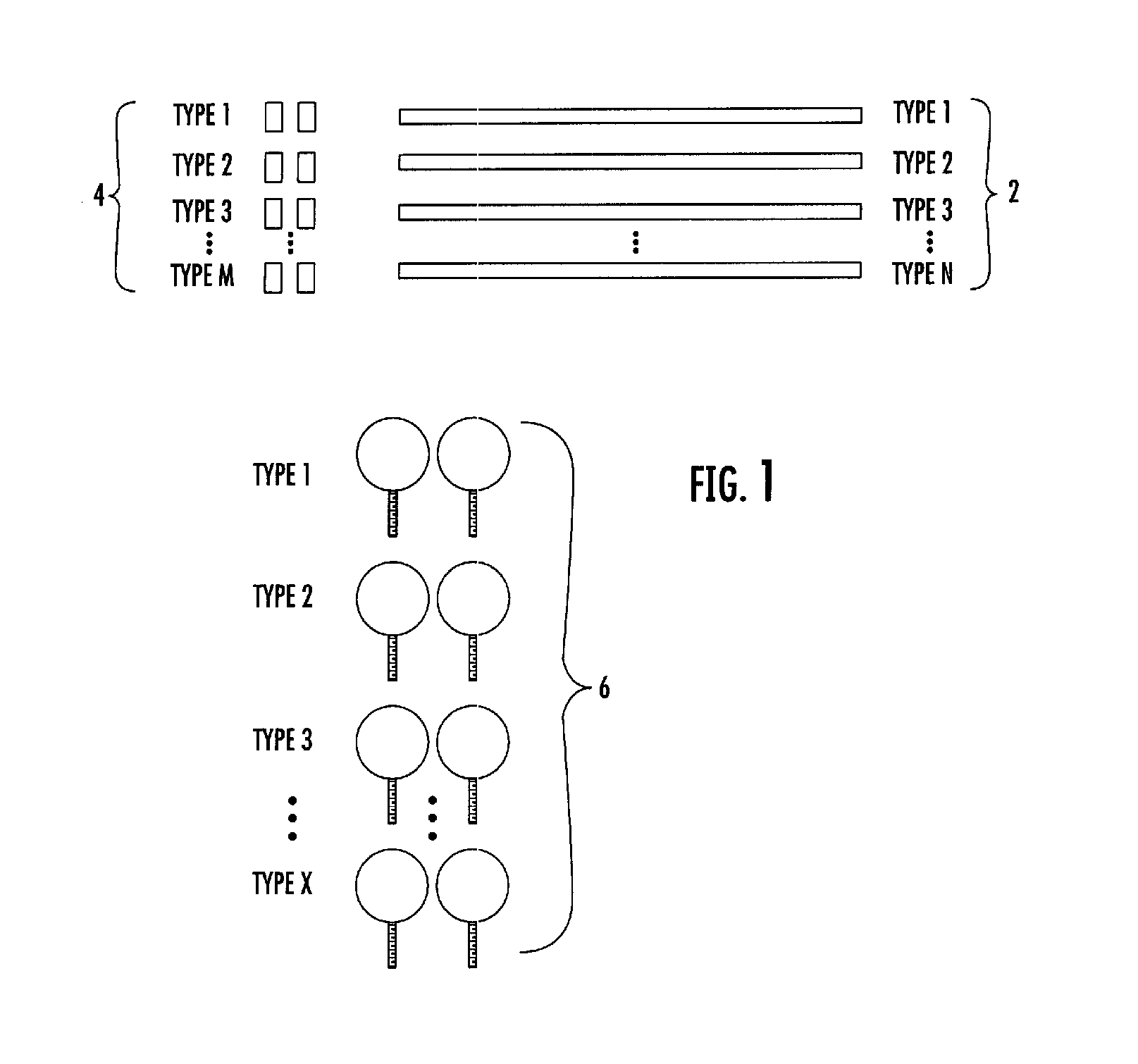

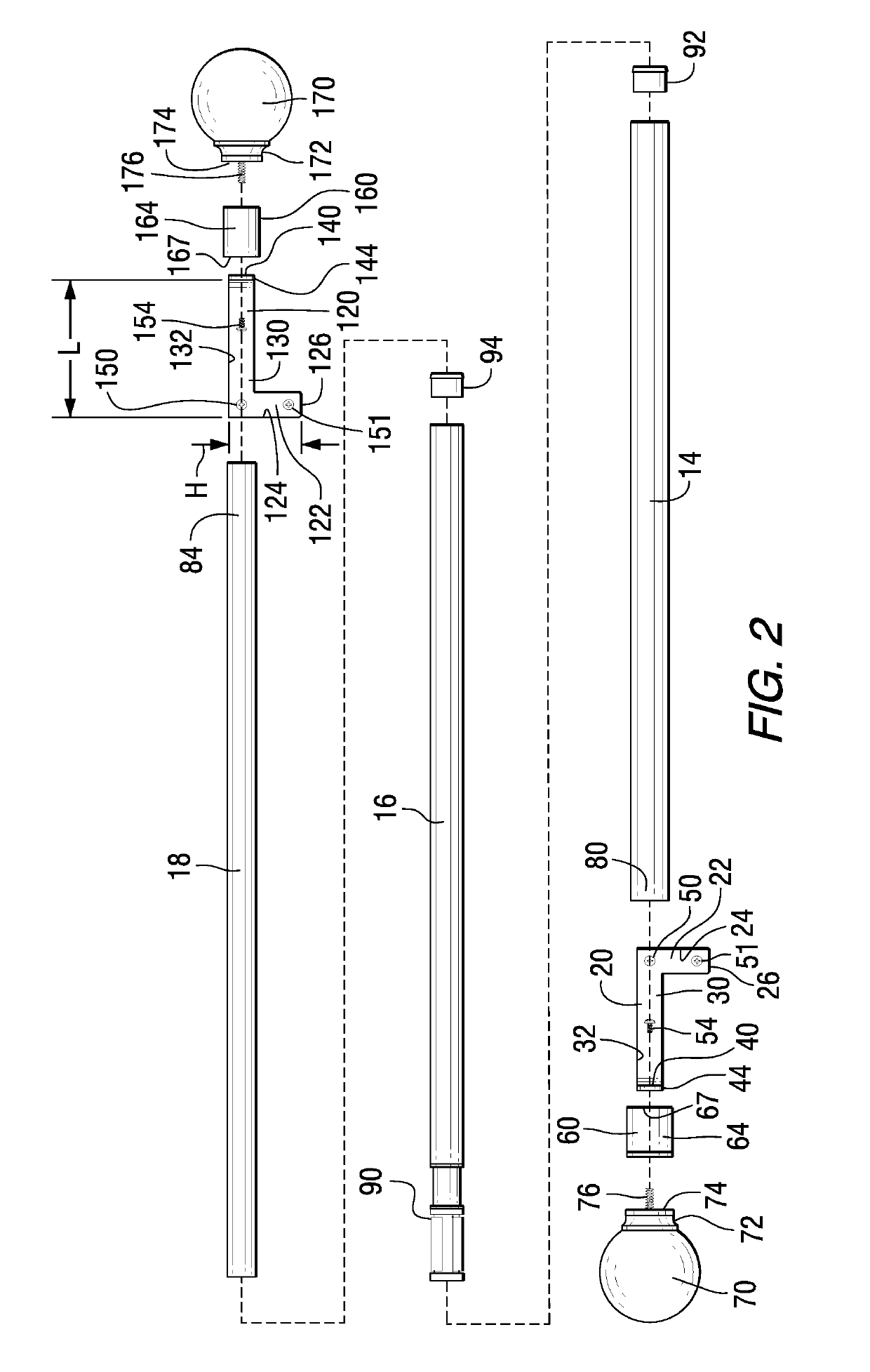

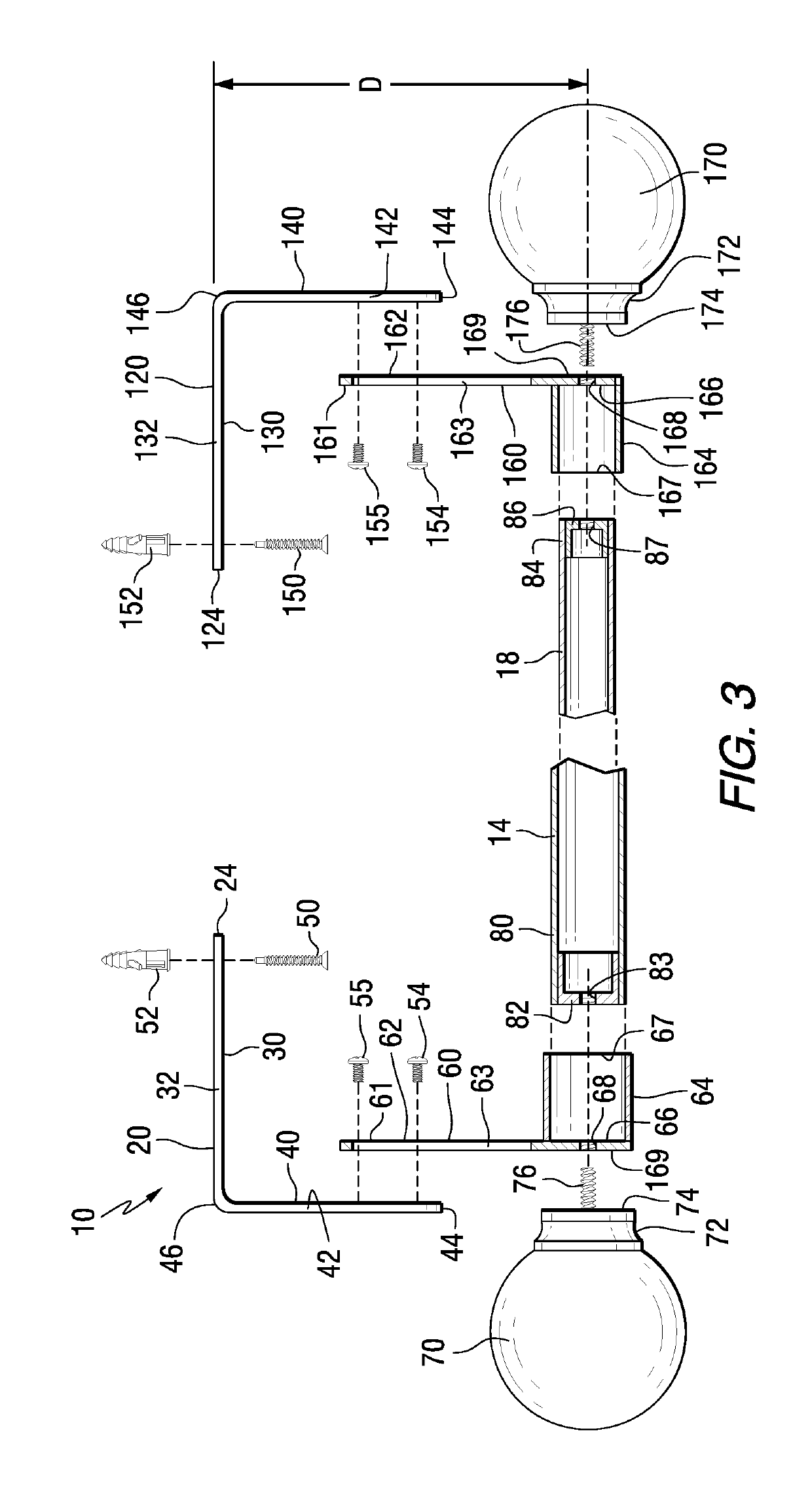

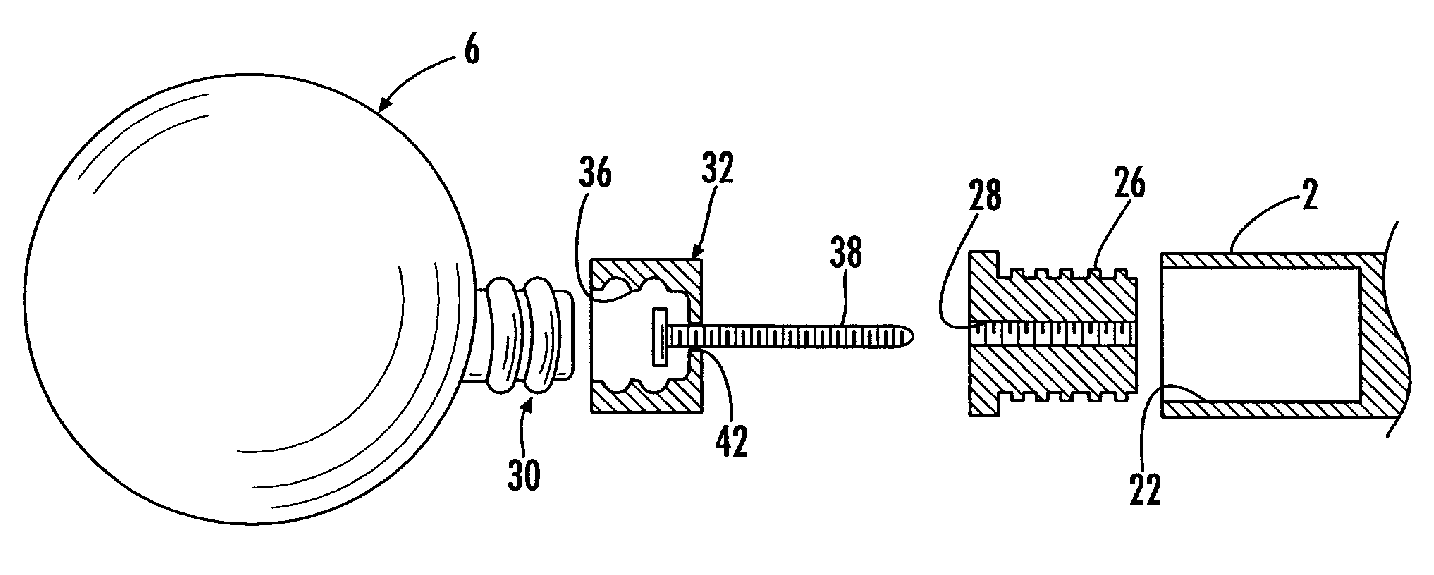

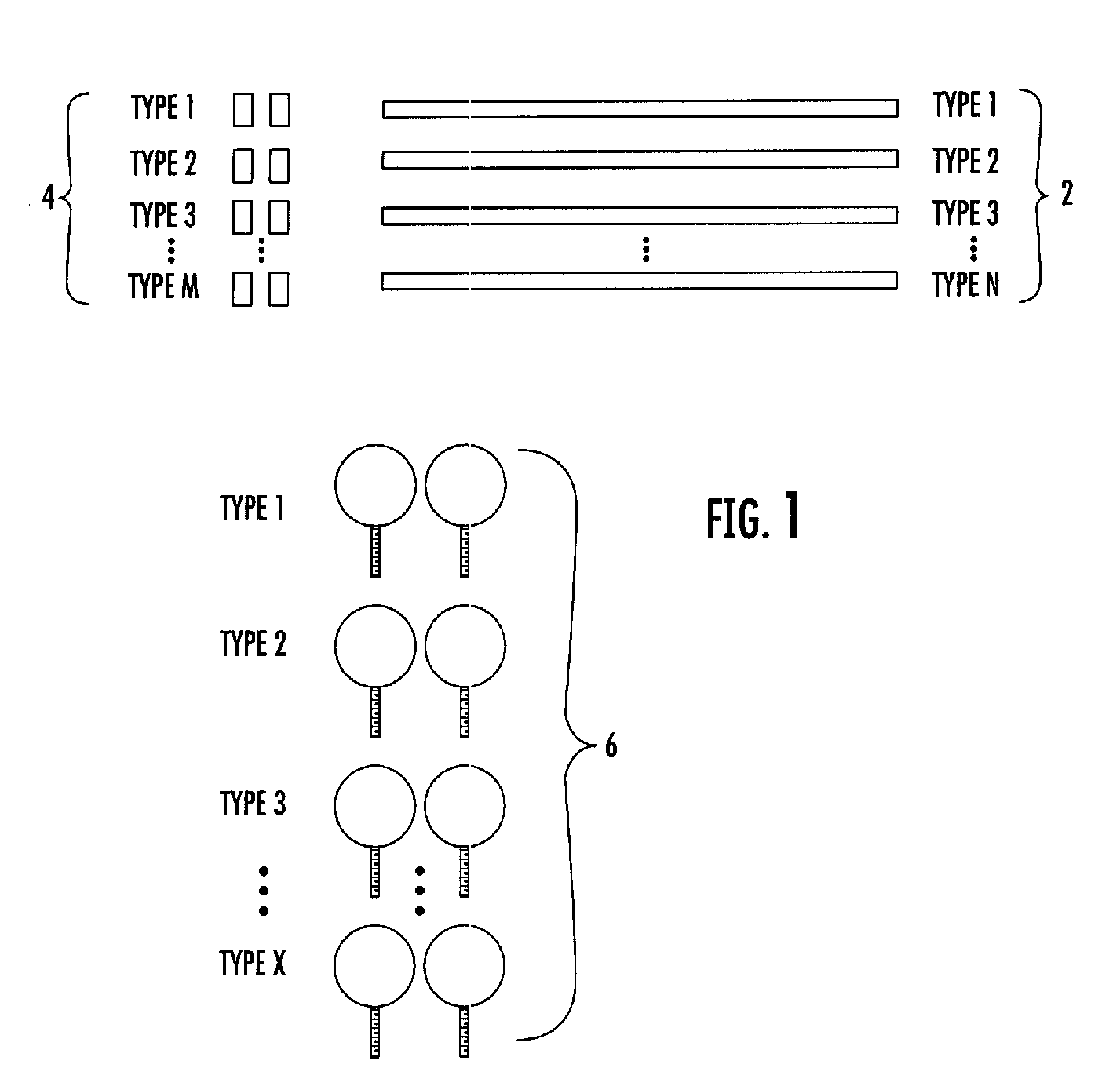

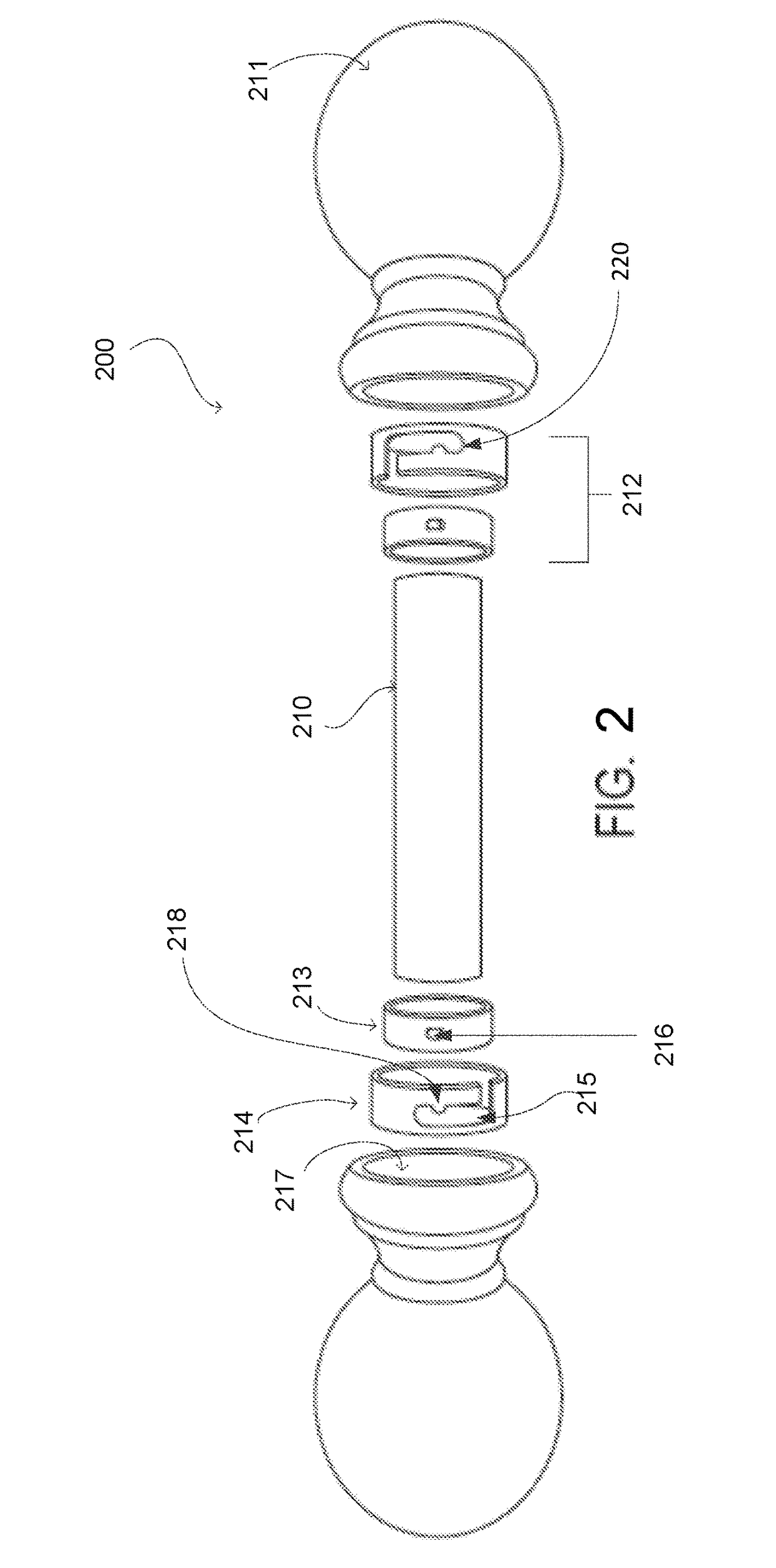

Modular, customizable window covering hardware system

The window hardware system of the invention comprises a variety of different types of poles in different finishes, colors and styles. A variety of different types of finials are also provided in different colors, materials, styles and shapes. A variety of different types of separate collars are also provided where certain types of collars may match the color, style and finish of the poles. A connection mechanism is provided to connect the finial, collar and pole to one another such that any combination of finial, collar and pole can be assembled. The body of the finial can have a modular construction such that the finial can be assembled from a variety of components to create a custom look.

Owner:KENNEY MFG

Room darkening curtain rods including removable finials

Room darkening window curtain rod assemblies that include a curtain rod and two bracket assemblies, each including a removable magnetic finial are disclosed. Each bracket assembly includes a wraparound leg that extends perpendicularly from an axis of the curtain rod toward a wall or window frame upon which the assembly is installed. The removable finials allow a curtain to be drawn onto the wraparound leg of each bracket assembly from the curtain rod to provide curtain wraparound regions. The curtain wraparound regions reduce or prevent light from entering into a room, and allow the bracket assemblies to be hidden. Once the curtain is extended into the wraparound regions, the magnetic finials are magnetically attached to the bracket assemblies with portions of the curtain located therebetween.

Owner:MAYTEX MILLS

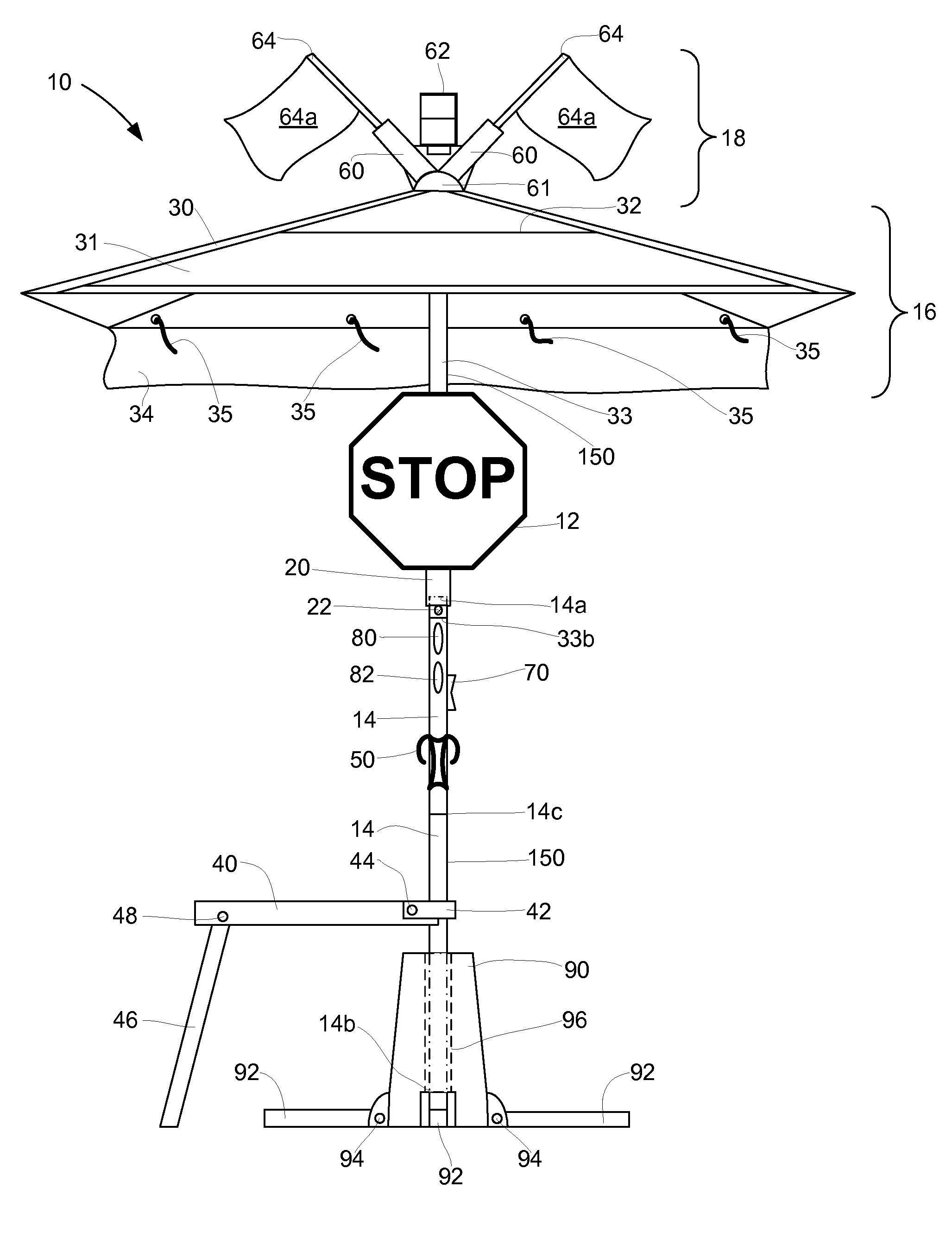

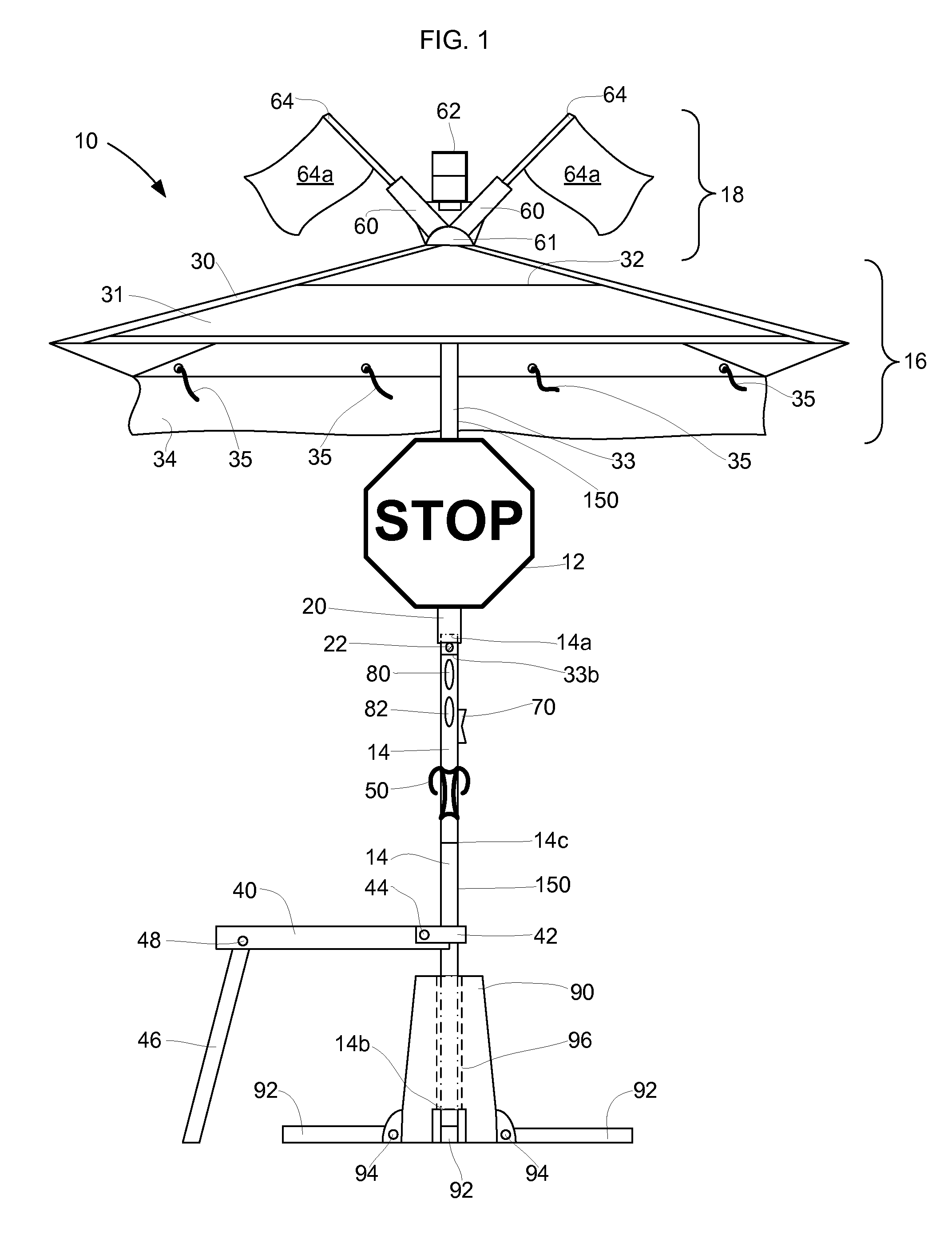

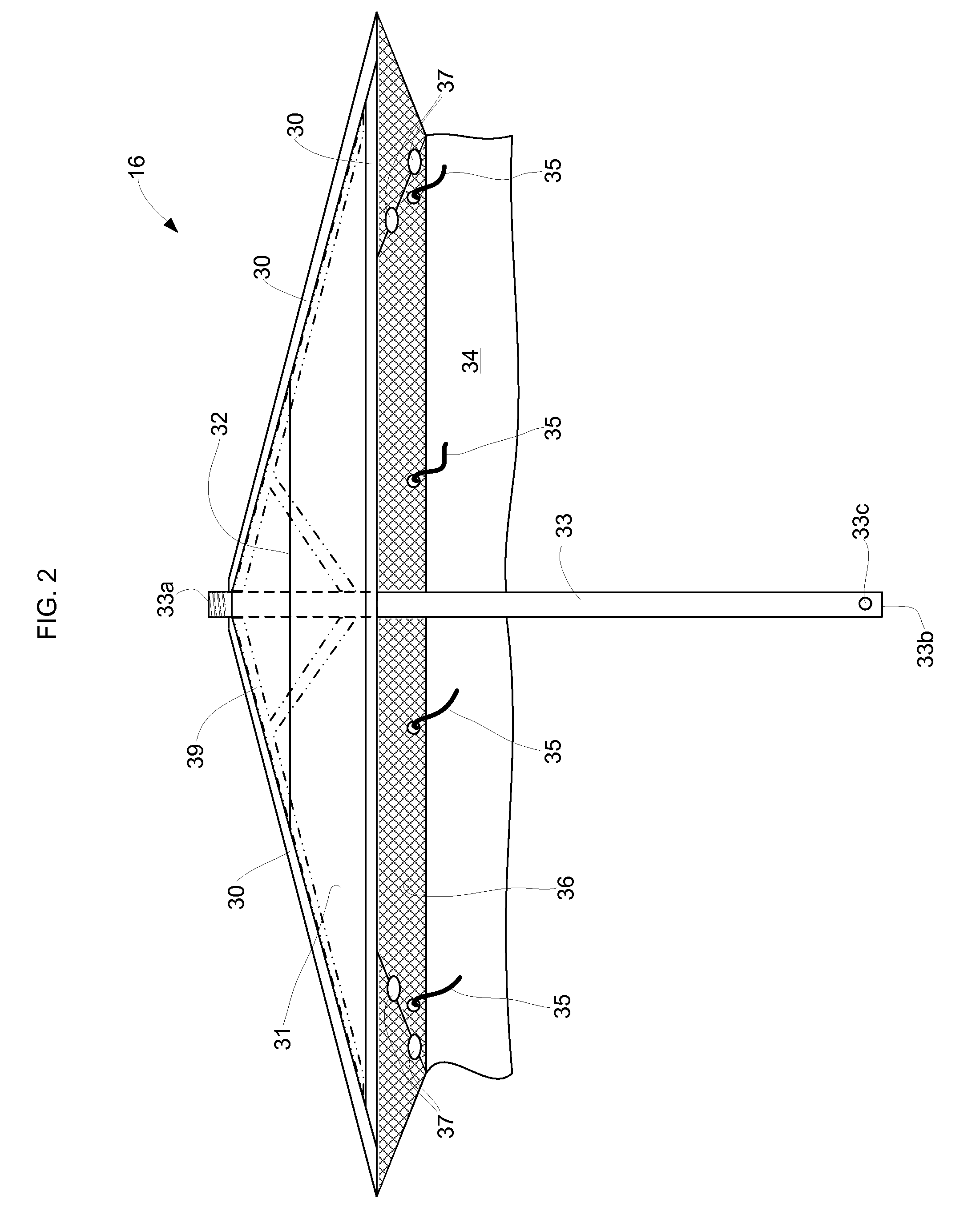

Safety Sign System

A safety sign system comprises one or more traffic or informational signs, an expandable pole, a detachable umbrella canopy assembly, and a safety finial assembly. The signs are removably attached to a sleeve that surrounds a portion of a pole and rests upon a sign support. The sleeve with the signs attached swivels about the pole. The umbrella canopy assembly is attached to an upper end of the pole and may include additional features including reflective tape, vents, drop-down flaps, reflective coating, and lights. The safety finial assembly is removably attached to the top of the umbrella canopy assembly and may include flag supports, removable flags, and a safety light assembly. The safety sign system optionally further comprises a collapsible seat, a beverage holder, a satellite tracking device, a communication device, a base, and a control panel for operating the safety light and other features.

Owner:CREATIVE TENT SOLUTIONS USA INC

Room darkening curtain rods including removable finials

Room darkening window curtain rod assemblies that include a curtain rod and two bracket assemblies, each including a removable magnetic finial are disclosed. Each bracket assembly includes a wraparound leg that extends perpendicularly from an axis of the curtain rod toward a wall or window frame upon which the assembly is installed. The removable finials allow a curtain to be drawn onto the wraparound leg of each bracket assembly from the curtain rod to provide curtain wraparound regions. The curtain wraparound regions reduce or prevent light from entering into a room, and allow the bracket assemblies to be hidden. Once the curtain is extended into the wraparound regions, the magnetic finials are magnetically attached to the bracket assemblies with portions of the curtain located therebetween.

Owner:MAYTEX MILLS

Modular, customizable window covering hardware system

Owner:KENNEY MFG

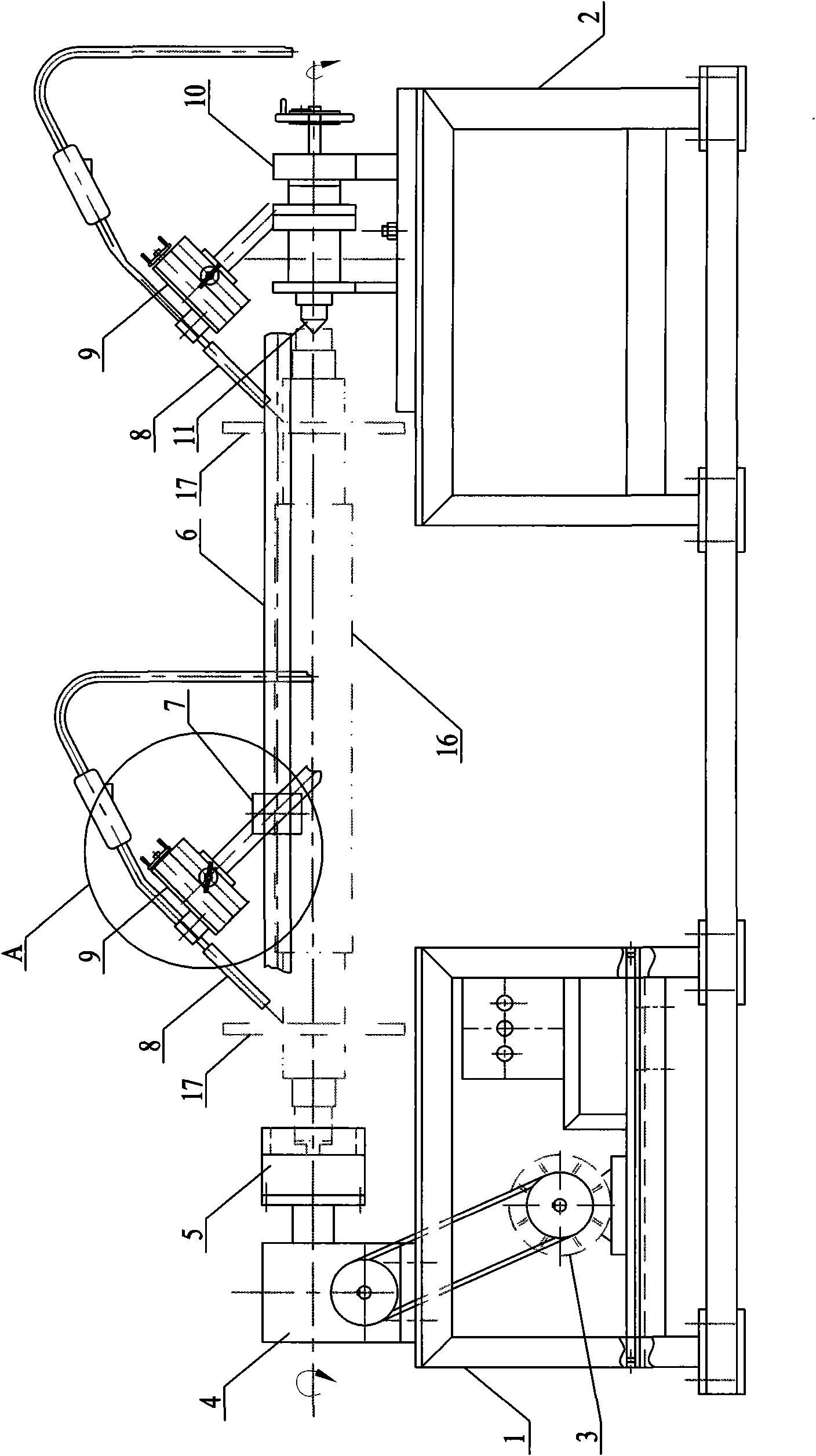

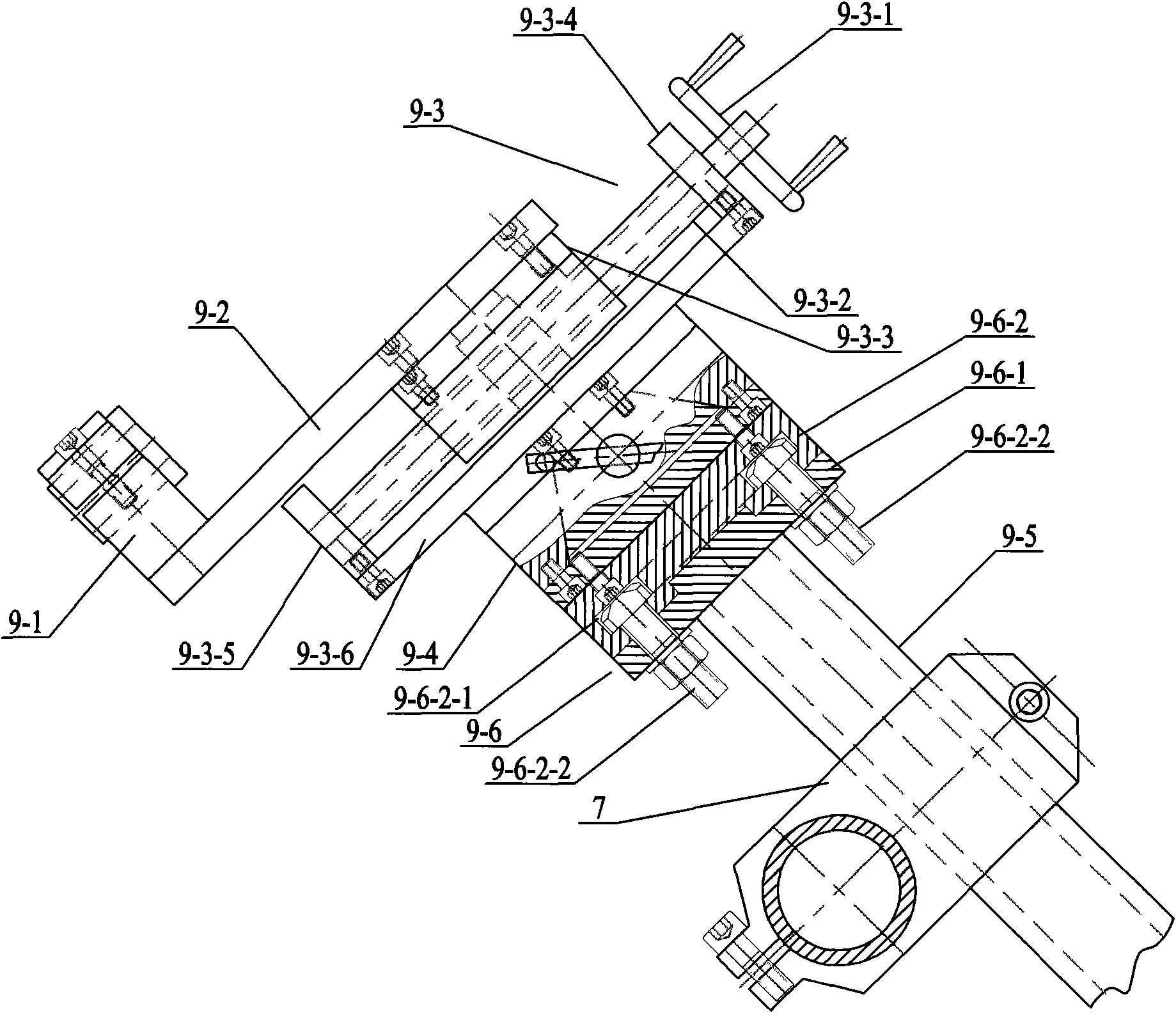

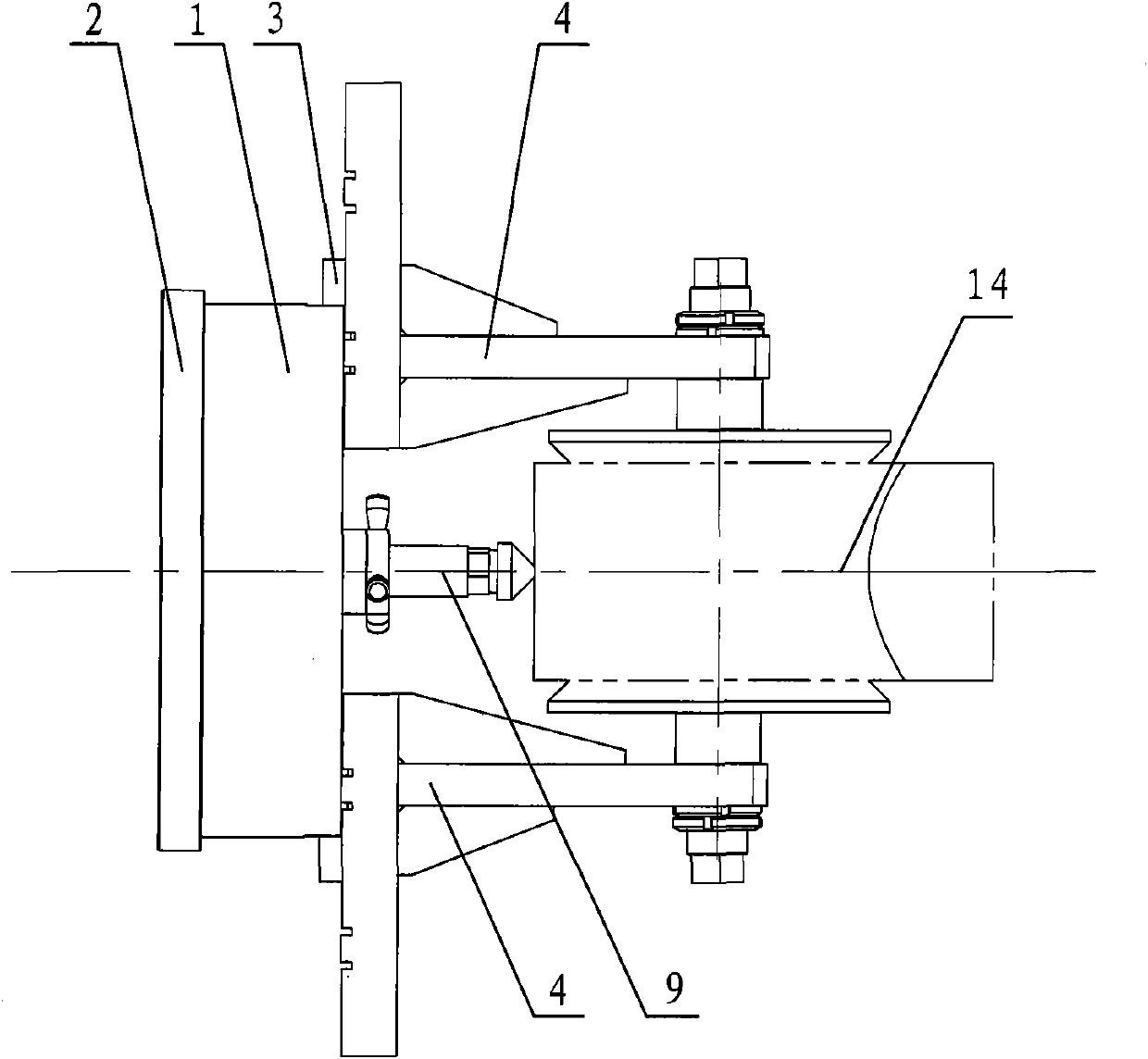

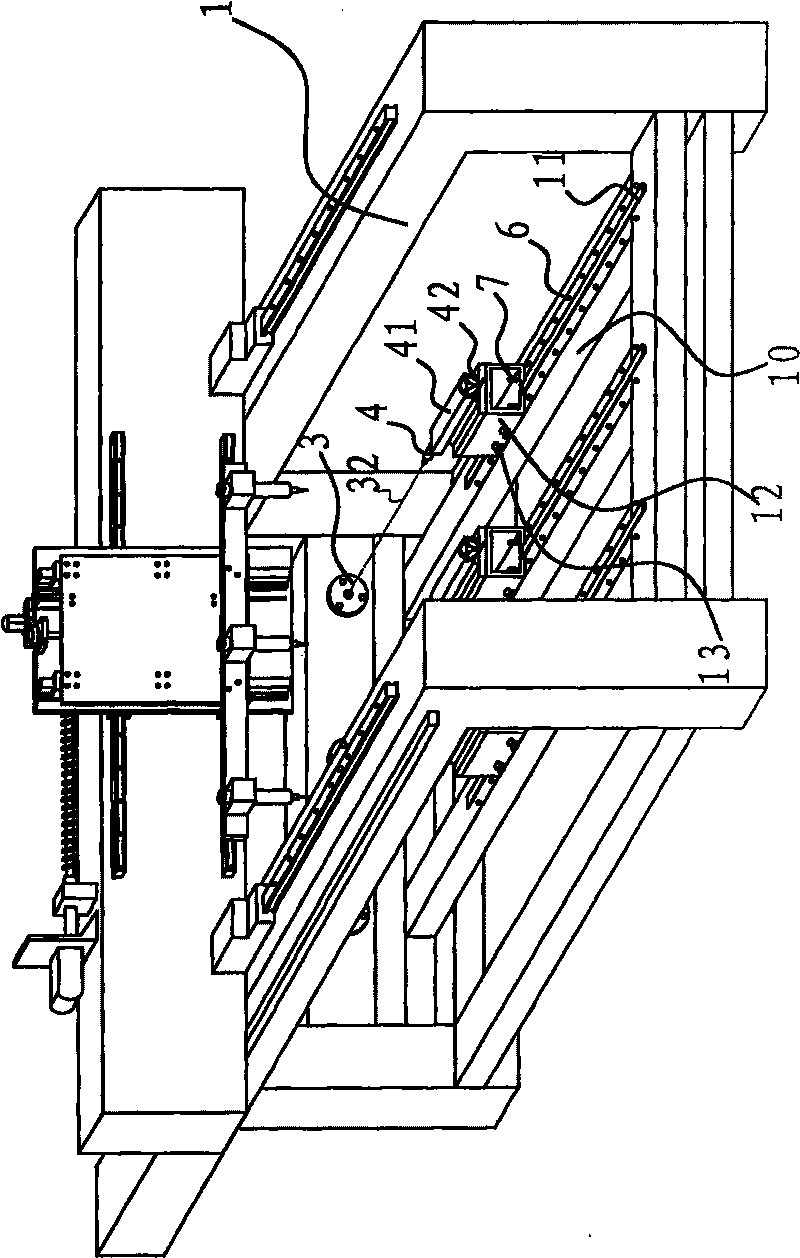

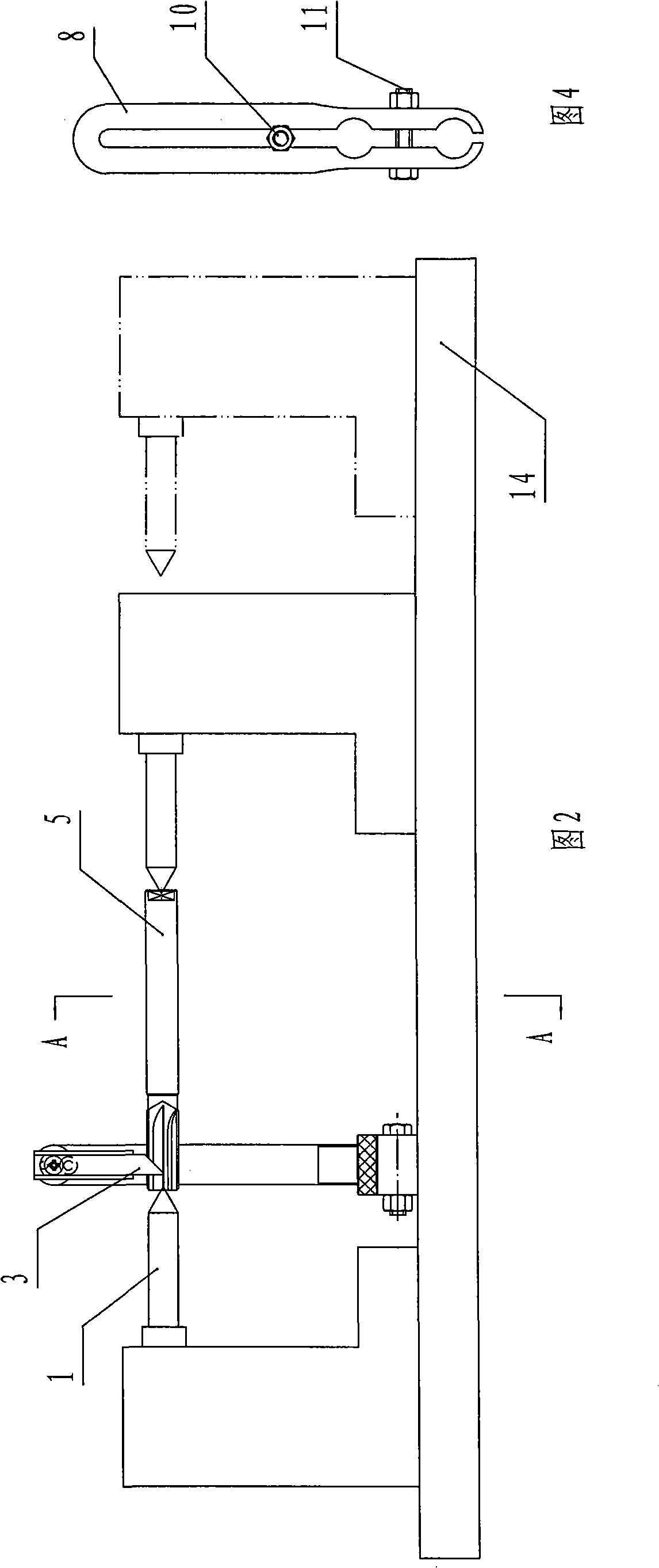

Automatic welding machine

ActiveCN101537541AImprove product qualityIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesFinialEngineering

The invention discloses an automatic welding machine which belongs to the technical field of welding equipment, realizes the effective combination of mechanical transmission and welding, replaces a way of the manual welding for shaft similar parts, enhances the production quality, also greatly enhances the production efficiency and lowers the labor intensity. The automatic welding machine comprises a first stand and a second stand which are oppositely arranged, wherein the first stand is connected with a variable speed motor and a reduction box; the output end of the variable speed motor is connected with the input end of the reduction box, and the output end of the reduction box is connected with a clamping disc; a transverse support pipe spans the first stand and the second stand, a clamping hoop positioned on the transverse support pipe is connected with one or more clamping hoop joints, and each clamping hoop joint is connected with a welding torch; the second stand is connected with a tailstock which is connected with a loose finial, and the loose finial is opposite to the clamping disc.

Owner:SUZHOU XINDA ESCALATOR ACCESSORIES

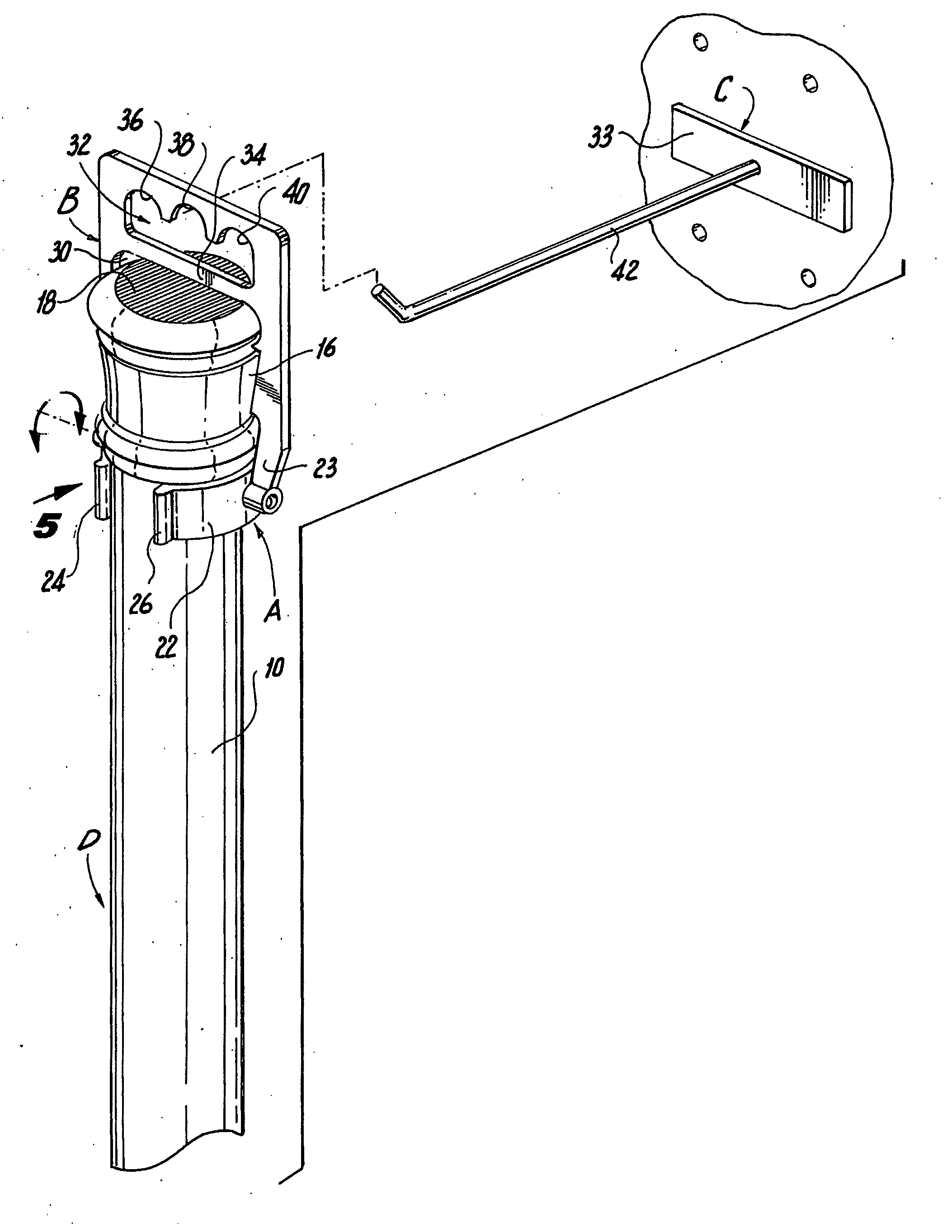

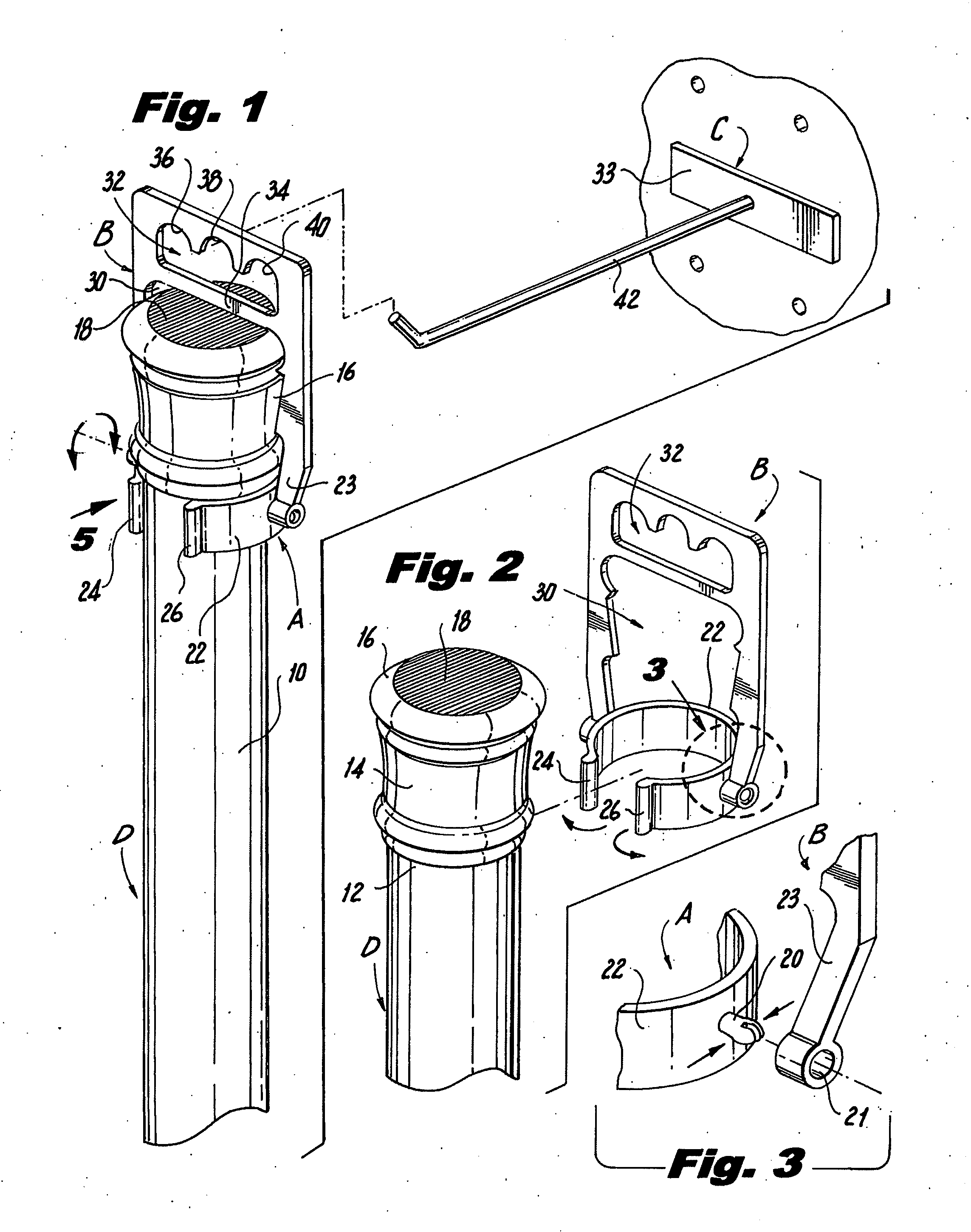

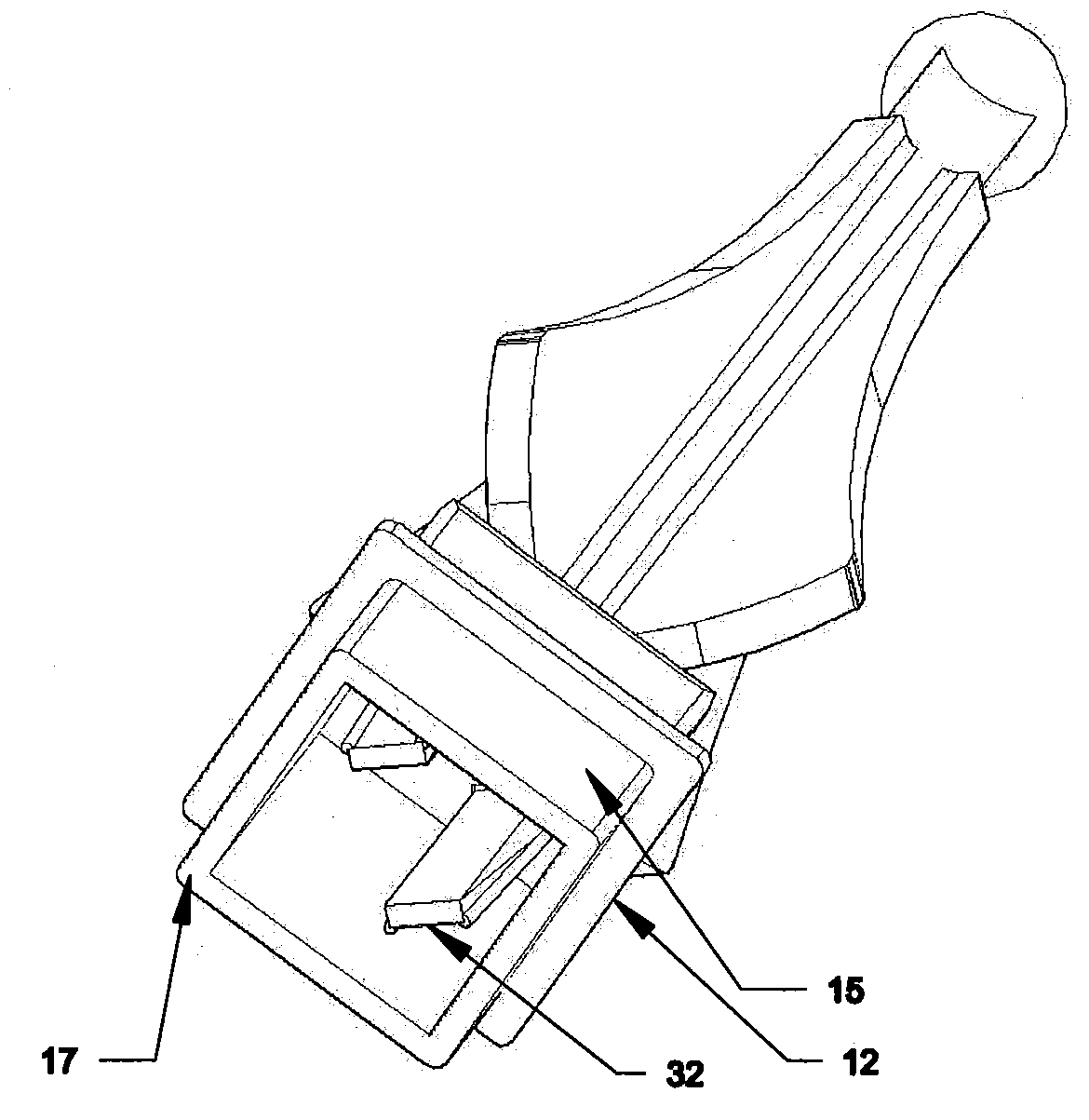

Display hanger for curtain rod

InactiveUS8186509B2Cheap manufacturingInexpensive to assembleCandle holdersLighting support devicesFinialDisplay device

A hanger is provided for mounting a curtain rod, such as a shower curtain tension rod, on a display. The hanger includes a body and a resilient collar, pivotally connected to the body, for engaging the rod in a “snap-fit” fashion. The body has a first opening adapted to receive the curtain rod end and a second opening adapted to be engaged by a prong of the display, to mount the curtain rod on the display. The curtain rod end may include a part, such as a finial, with an exterior surface having a contour. The first opening has a shape substantially corresponding to that contour. The second opening preferably includes three recesses such that conventional single prong and double prong displays can be accommodated.

Owner:EX CELL HOME FASHIONS INC

Fixation apparatus for stator blade profile and journal bounce detection

The invention relates to a fixation apparatus for stator blade profile and journal bounce detection. The fixation apparatus comprises a first foot block and a second foot block which are fixed at the two sides of a base; the axial positioning of a blade is finished by clamping a baled axle center by use of two opposite finials in the two foot blocks and attaching an axial positioning plate to a blade axial positioning surface; by use of the attachment of an angle positioning plate in a body seat and a blade profile, the angle positioning of the blade is realized, and the blade profile is further detected; by use of the push effects of the plug screw arranged at the second foot block, the blade is enabled to disengage from the axial positioning plate and rotate on the two finials; and then journal bounce detection is performed on the blade. The fixation apparatus solves the problem of performing blade profile detection and journal bounce detection at the same measuring tool, facilitates one-time multiple dimension clamping and processing on numerical control equipment in terms of process to finish needed detection means, and reduces the labor intensity of repeated positioning.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

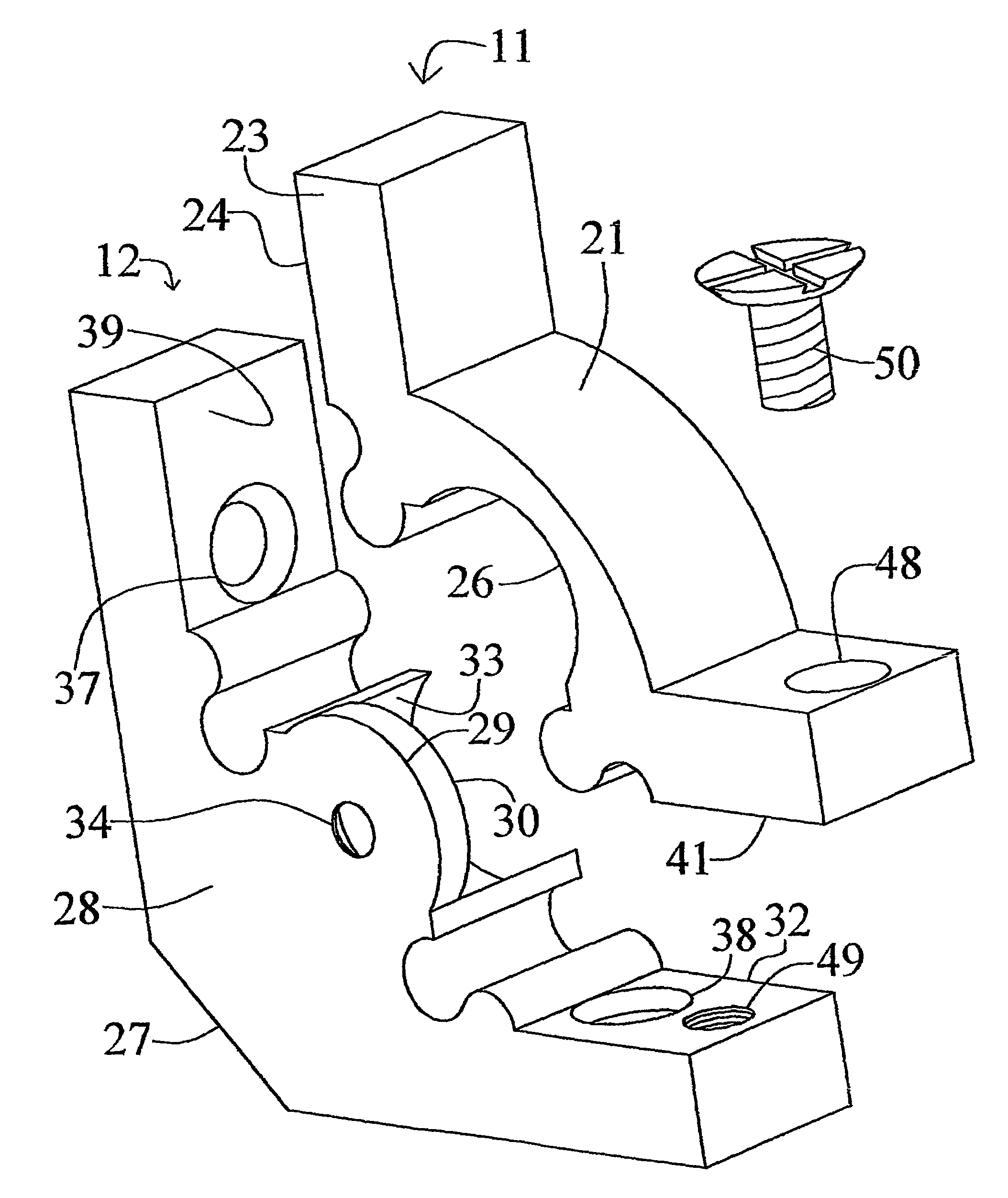

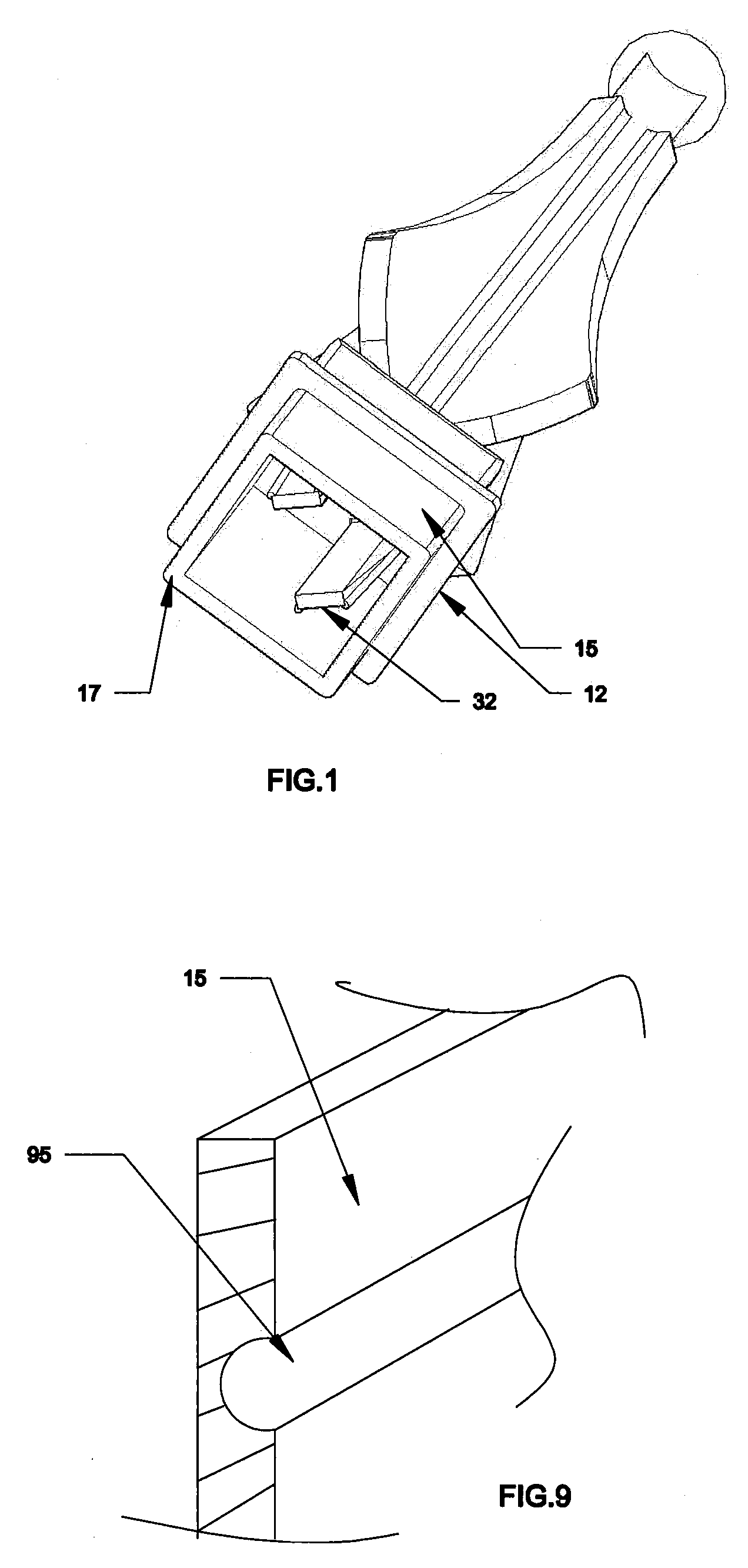

Stair rod bracket

The present invention provides a transversely interconnecting slidable stair rod bracket. The bracket may also be provided for use in a stair rod set, the set also including a stair carpet retaining rod and a finial. The bracket has a top portion and a bottom portion. The top portion having a plurality of projections and complementary shaped channels for receiving projections from the bottom portion; the bottom portion contains a rod-receiving portion, an outside end wall with an aperture therein for accepting either a threaded finial fastener which engages with a “female” finial, or the fastening portion of a “male” finial, and a plurality of projections and complementary shaped channels for receiving projections from the top portion.

Owner:STAIR HOLD

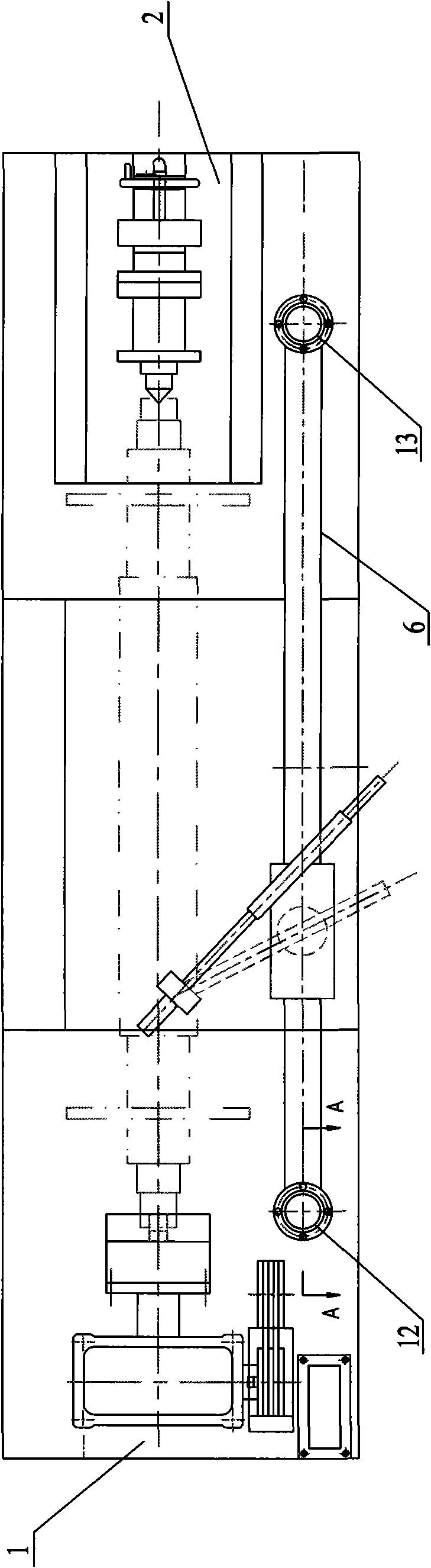

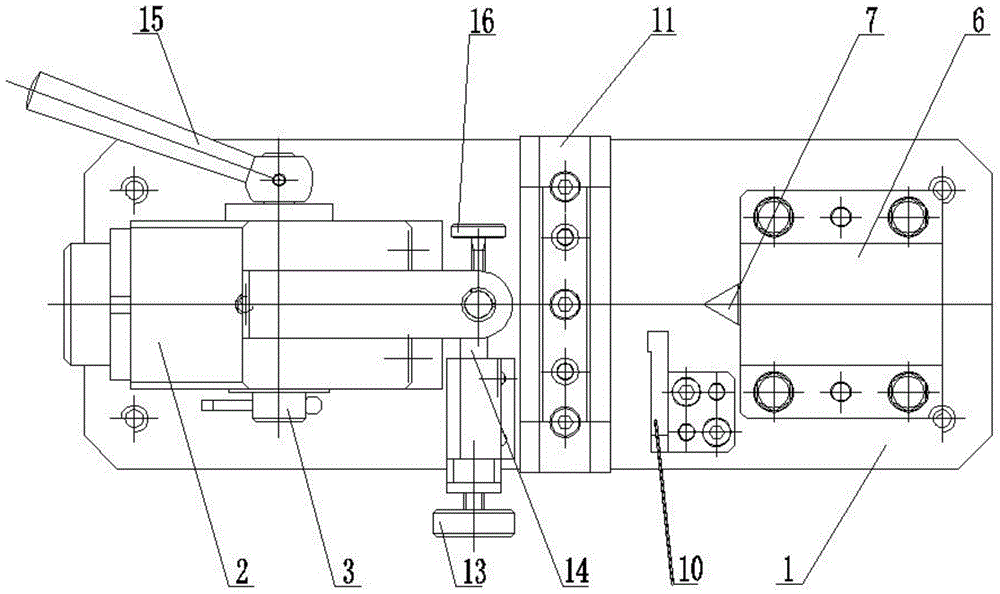

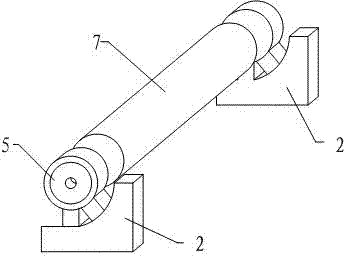

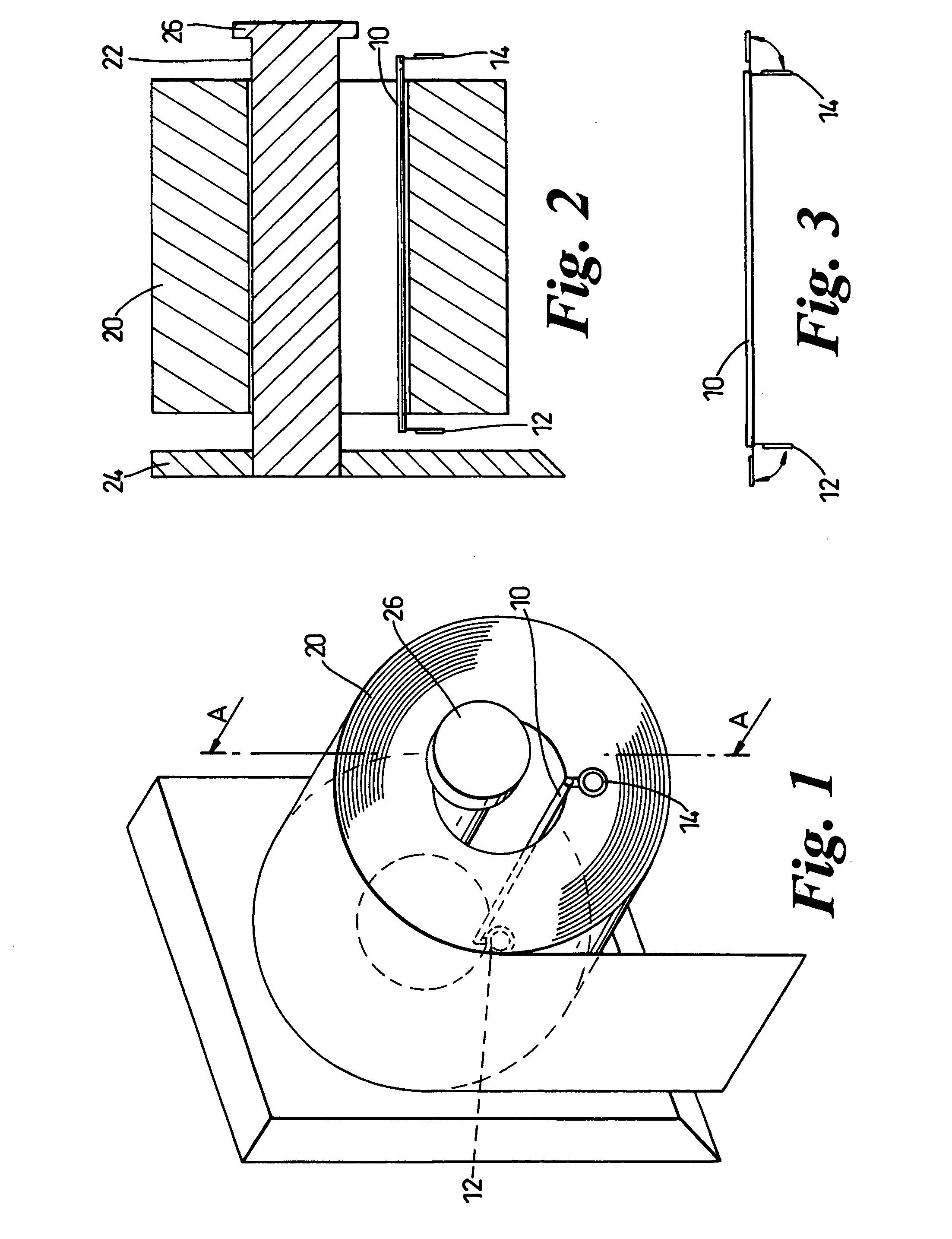

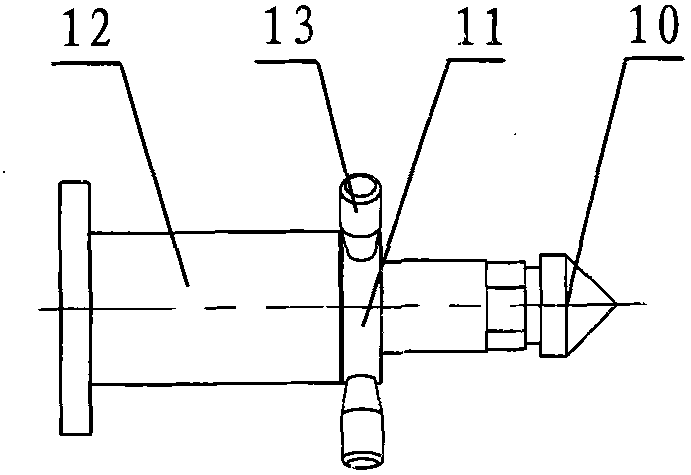

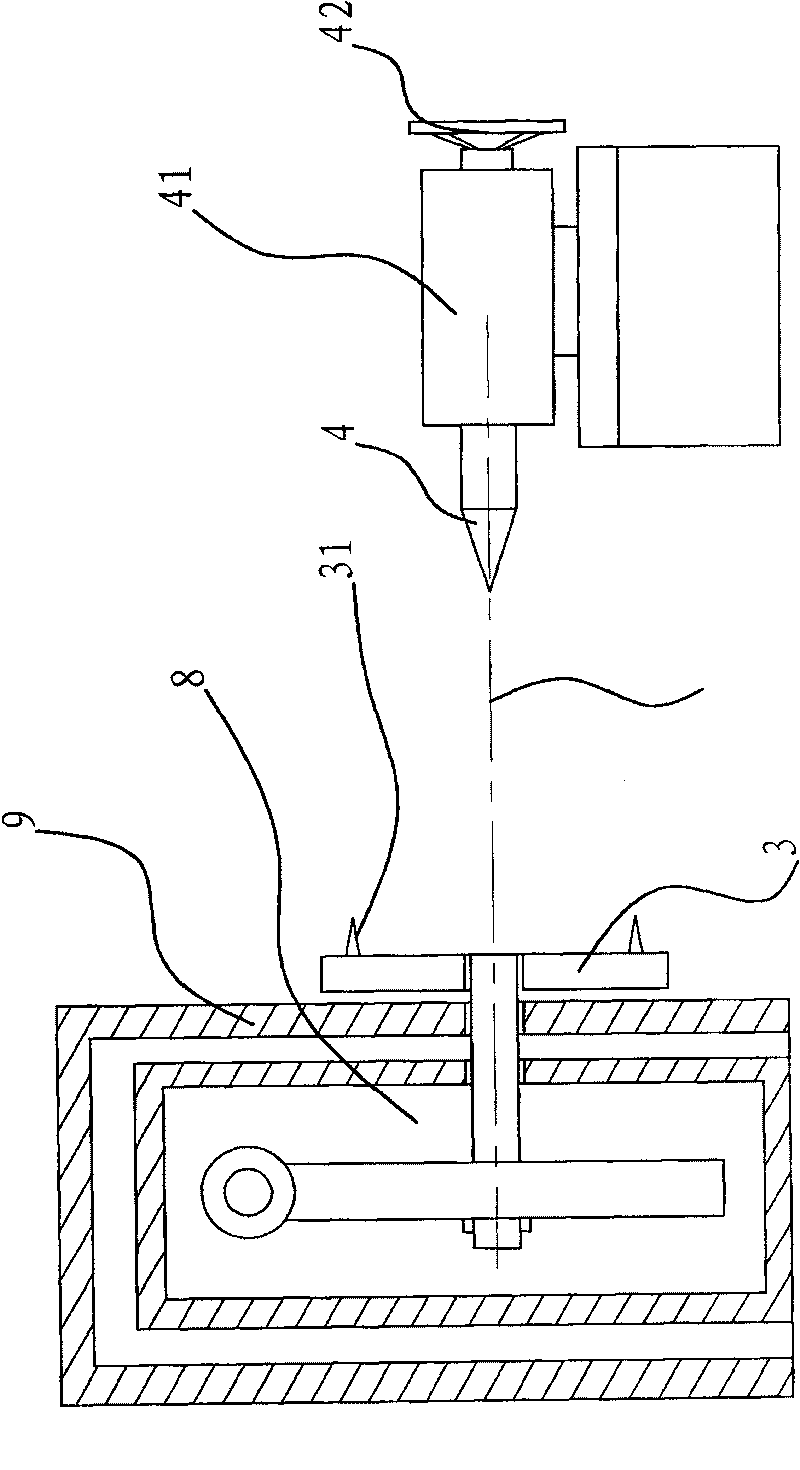

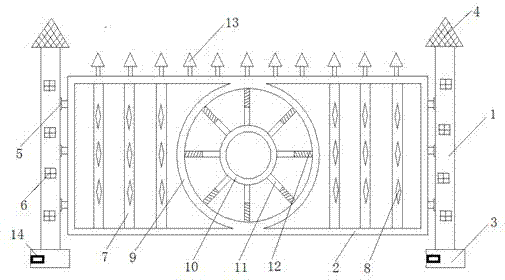

Roll grinder for grinding guide rolls of aluminum foil processing equipment

InactiveCN102922382ALow investment costIncrease profitRevolution surface grinding machinesSupporting systemFinial

The invention provides a roll grinder for grinding guide rolls of aluminum foil processing equipment, and can solve the problem that the conventional roll grinder cannot be used for grinding the guide rolls of the aluminum foil processing equipment. The invention adopts the technical scheme that the roll grinder comprises a support system for a guide roll; the support system comprises a finial, a nylon block, a rotary chuck and two brackets; the rotary chuck is provided with an adjustable pusher dog; support circles are arranged at two ends of the guide roll and are supported by the brackets; a connector is arranged on the outer side of the support circle at one end of the guide roll; one side of the connector is connected with the support circle; the other side of the connector is connected to the pusher dog of the rotary chuck in a clamping manner; the support circle at the other end of the guide roll is propped against the nylon block; and the nylon block is propped against the finial. The roll grinder can be used for grinding not only working rolls but also guide rolls, so as to ensure that an aluminum foil processing enterprise is not required to purchase a cylindrical grinder to grind the guide rolls specially any more, which reduces the investment cost and the operation cost of fixed capital and improves the utilization ratio of the fixed capital.

Owner:QINGDAO RUNFENG ALUMINUM FOIL

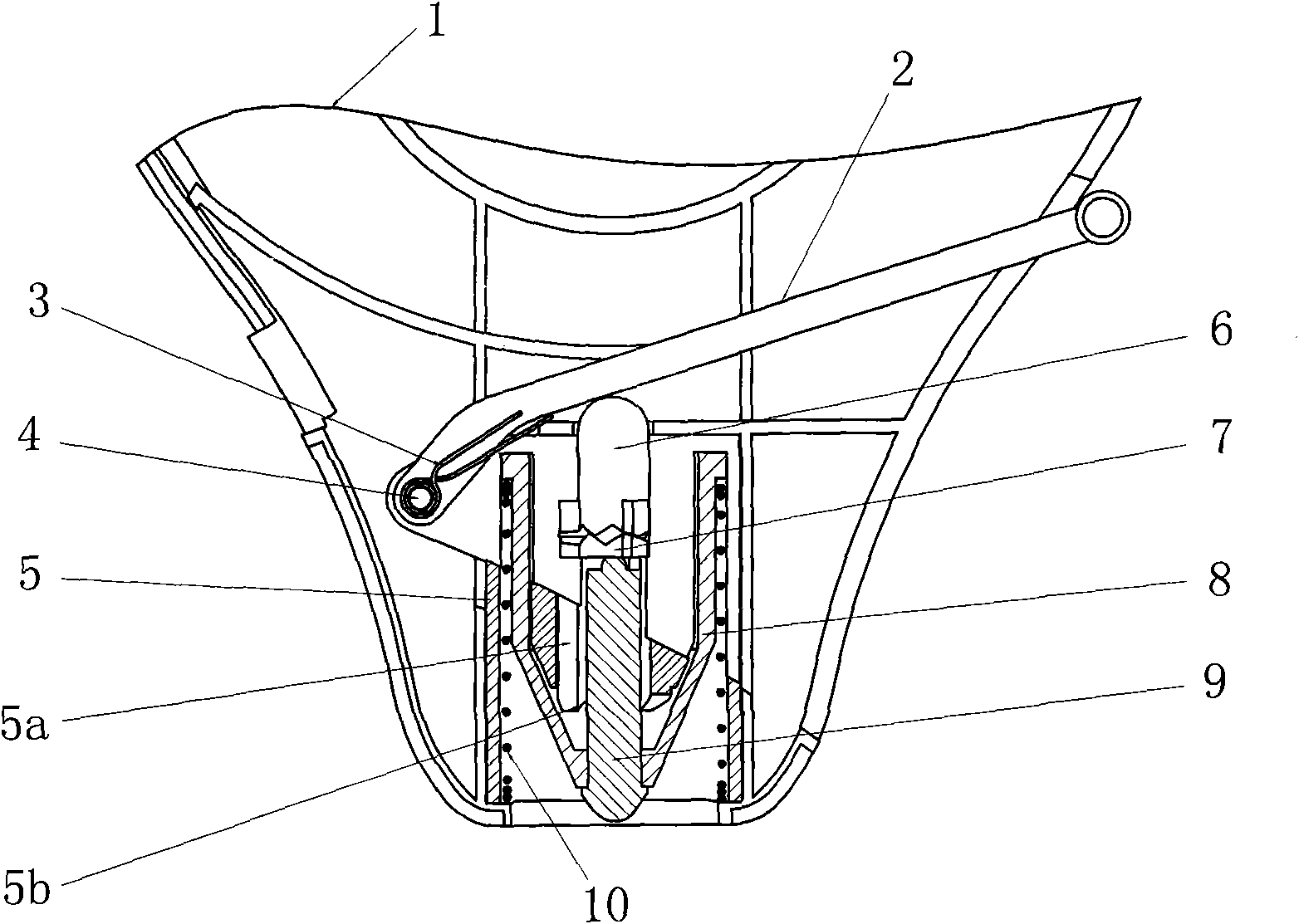

Measuring tape finial mechanism and measuring tape thereof

The invention relates to a measuring tape finial mechanism. The finial mechanism comprises a finial and is characterized by also comprising t a central convex column of a sheath, an upper push piece,a lower push piece, a finial seat and a restoration piece, wherein the column has a through hole penetrating the sheath, and the inside of the through hole has an axial slide rail; first skew gears are formed and distributed on the lower end of the column and around the through hole; the upper push piece is slidably arranged inside the through hole, and first ring gears are formed and distributedon the lower end of the upper push piece in circumferential direction; the first ring gears are radially provided with an outward first flange which is matched with the slide rail; the lower end of the lower push piece is propped on the finial, and the upper end is detachably connected with the upper push piece; moreover, second ring gears in division rotary fit with the first ring gears of the upper push piece are convexly formed and distributed on the lower end of the lower push piece in circumferential direction, and the outer circumferential wall of the lower end has second skew gears which are matched with the first skew gears of the lower end of the column; the second skew gears protrude outwards in radial direction to form a second flange in back-and-forth sliding fit with the sliderail inside the through hole to drive the mechanism; the finial seat is telescopically limited on the lower end of the sheath; the restoration piece extends outside the finial to fix the measuring tape when used, and retracts the finial into a measuring tape shell when not used to avoid causing injuries to people; and moreover, the total volume of the measuring tape is reduced, which is favorablefor packaging, transportation and storage.

Owner:NINGBO GREAT WALL PRECISION INDAL

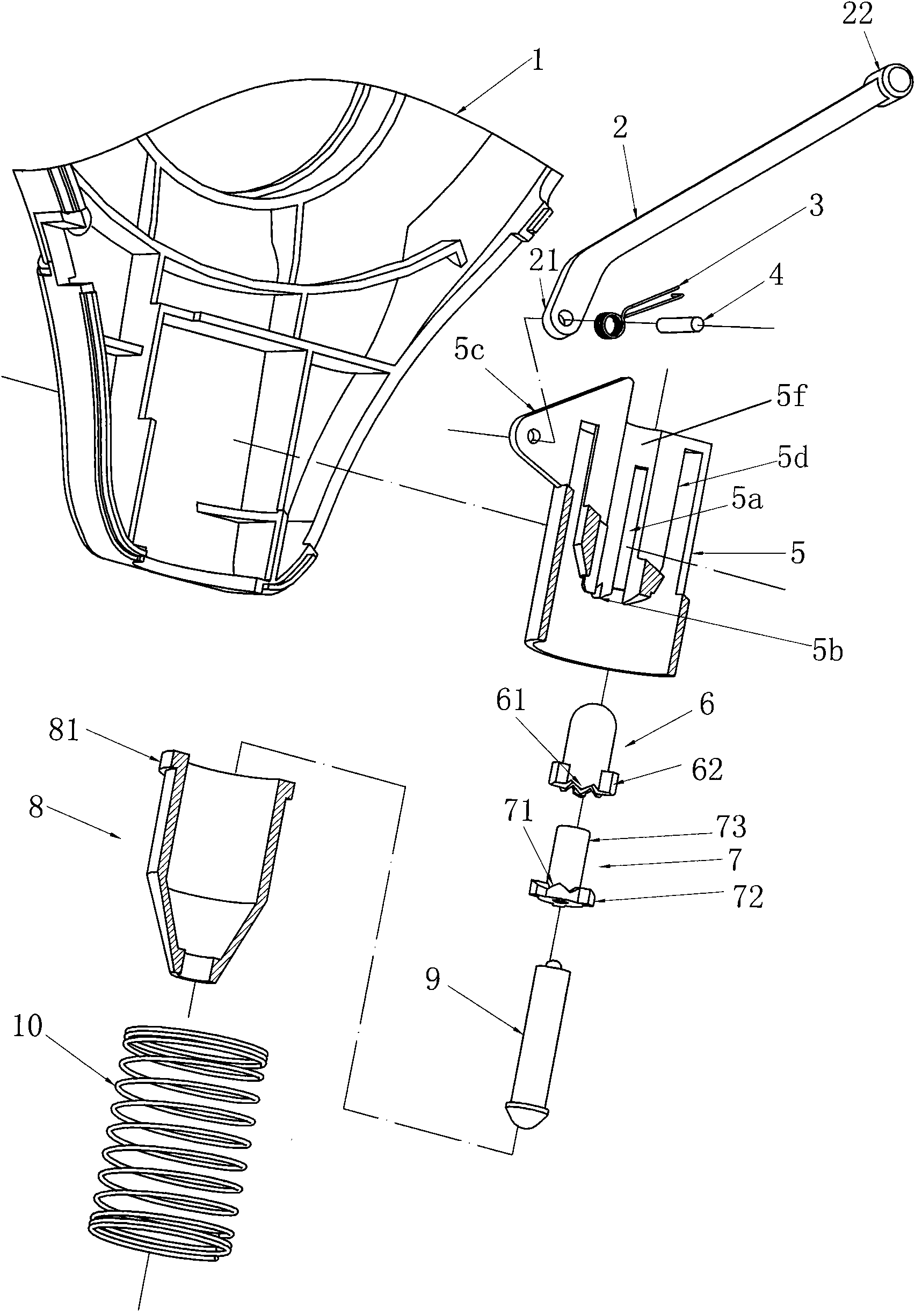

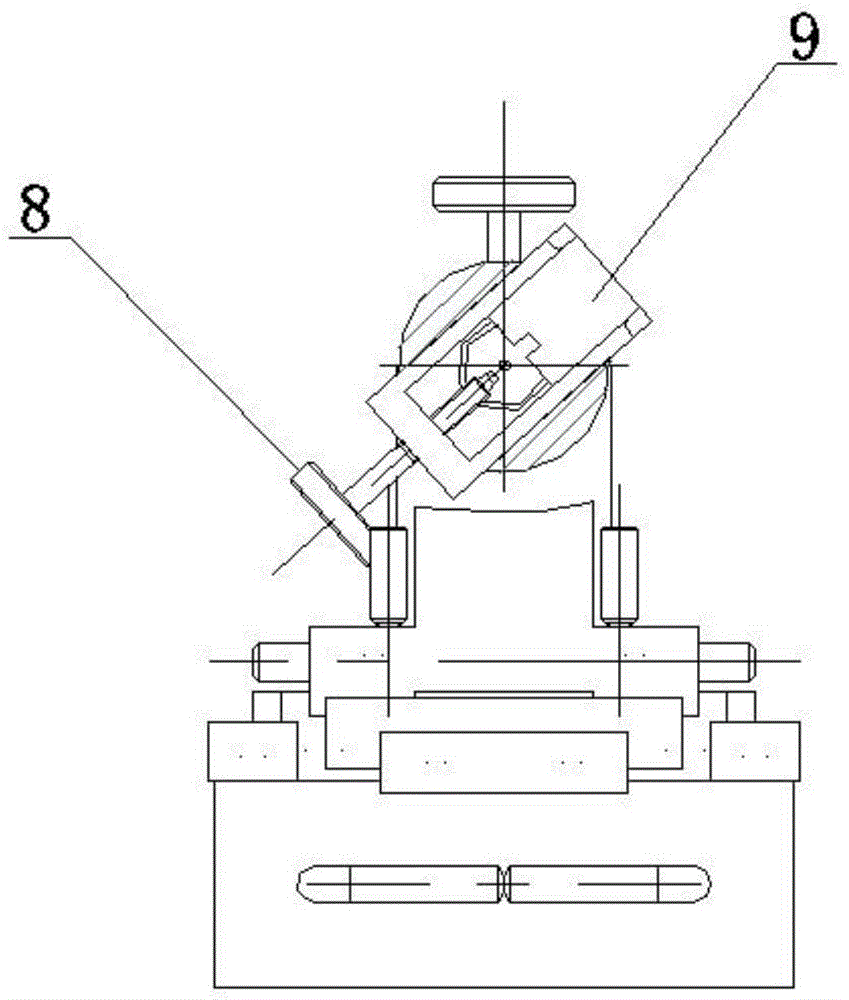

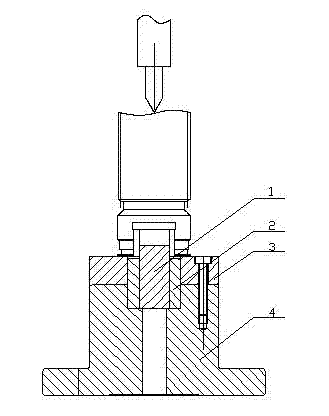

Multistage general angle self-adaptive blade three-coordinate measuring holder

ActiveCN103604397APrevent top deflectionPrevent damageMeasurement devicesWork holdersFinialCoordinate-measuring machine

The invention relates to a multistage general angle self-adaptive blade three-coordinate measuring holder. Height concentric finial structures at the two sides of the holder are ejected into the finial holes at the two ends of a blade for realizing precision positioning of the center line of the blade; a finial at one side is installed on a linear guide rail, the precision slide performance of the linear guide rail is utilized, and a spring pin structure is designed on the slide guide rail to cooperate with the limiting hole in a base for realizing center positioning of blades with different lengths; and a fixed finial mechanism at the other side is provided with a chute and draw frame structure, the design structure utilizes the precision cooperation between a chute and a draw frame in theoretical angles, the upper portion of the draw frame is provided with a screwing screw, when the screw is screwed tight, the two sides of the draw frame are close to an inner side, and when the angle positioning surface portion of the blade is placed at the draw frame position and the screw is screwed, the draw frame is automatically attached to the blade angle positioning surface so that the blade angle self-adaptive positioning is realized, and thus the blade three-coordinate measuring precision and efficiency are improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Display hanger for curtain rod

InactiveUS20110240814A1Cheap manufacturingInexpensive to assembleCandle holdersLighting support devicesFinialDisplay device

A hanger is provided for mounting a curtain rod, such as a shower curtain tension rod, on a display. The hanger includes a body and a resilient collar, pivotally connected to the body, for engaging the rod in a “snap-fit” fashion. The body has a first opening adapted to receive the curtain rod end and a second opening adapted to be engaged by a prong of the display, to mount the curtain rod on the display. The curtain rod end may include a part, such as a finial, with an exterior surface having a contour. The first opening has a shape substantially corresponding to that contour. The second opening preferably includes three recesses such that conventional single prong and double prong displays can be accommodated.

Owner:EX CELL HOME FASHIONS INC

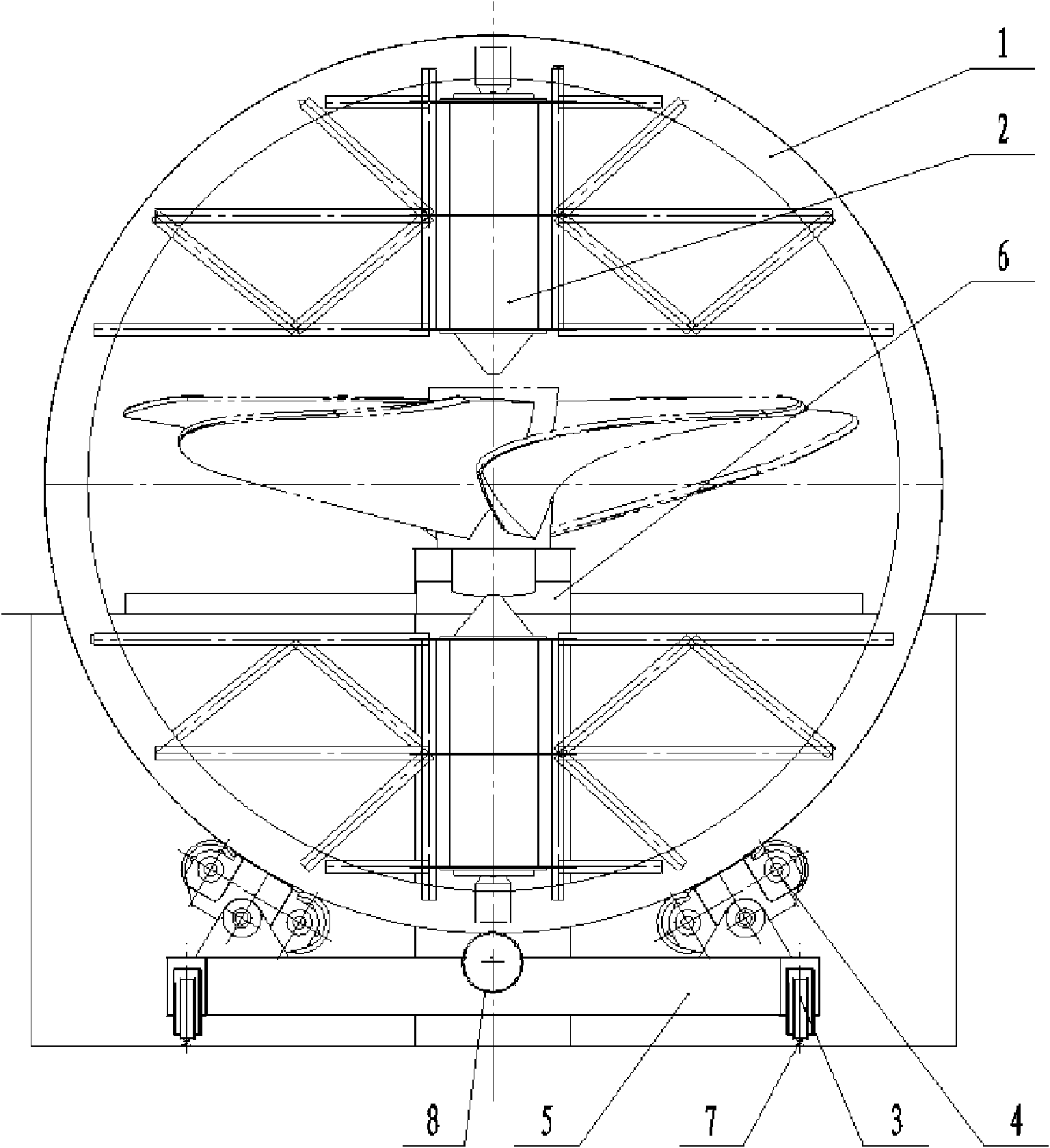

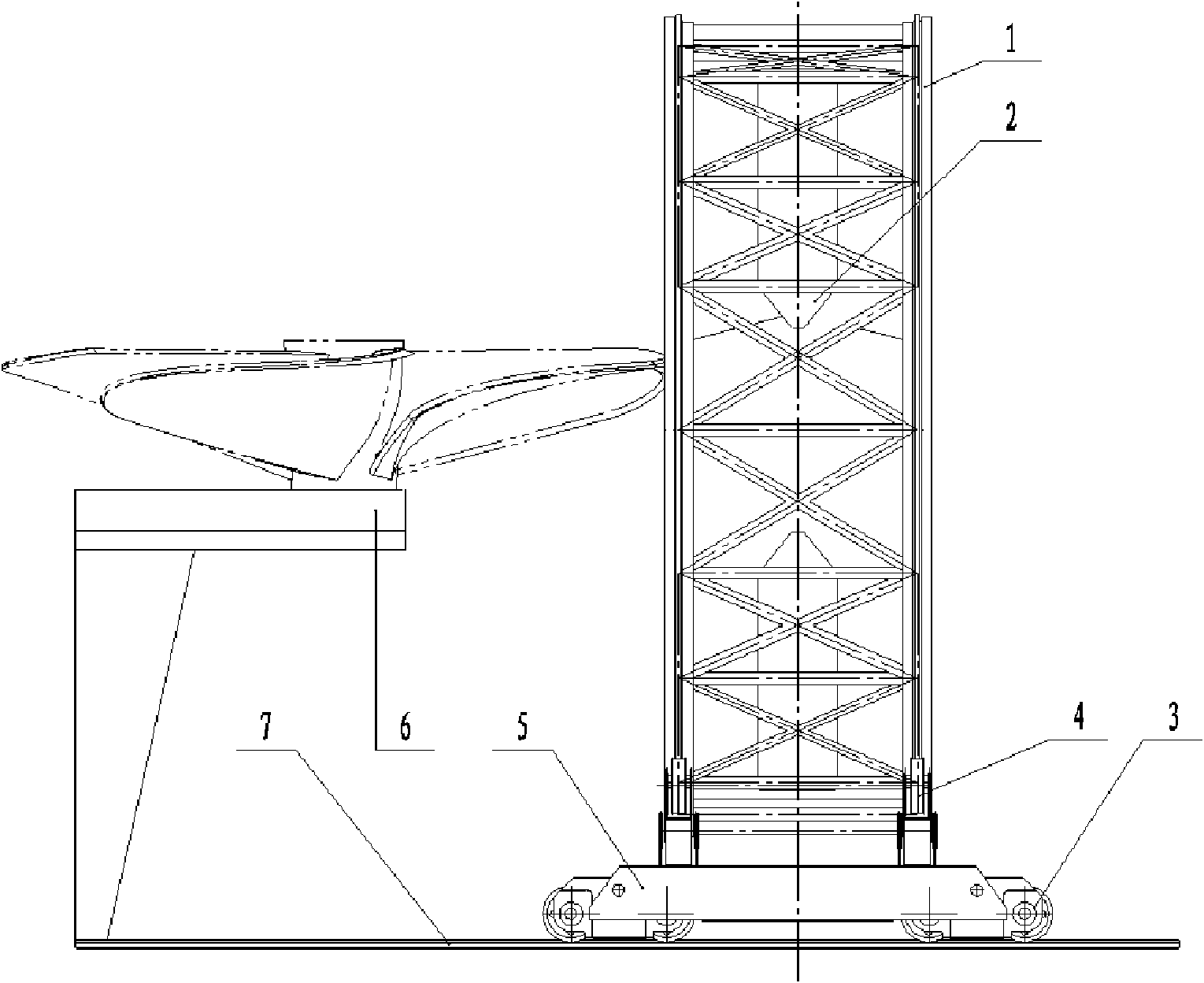

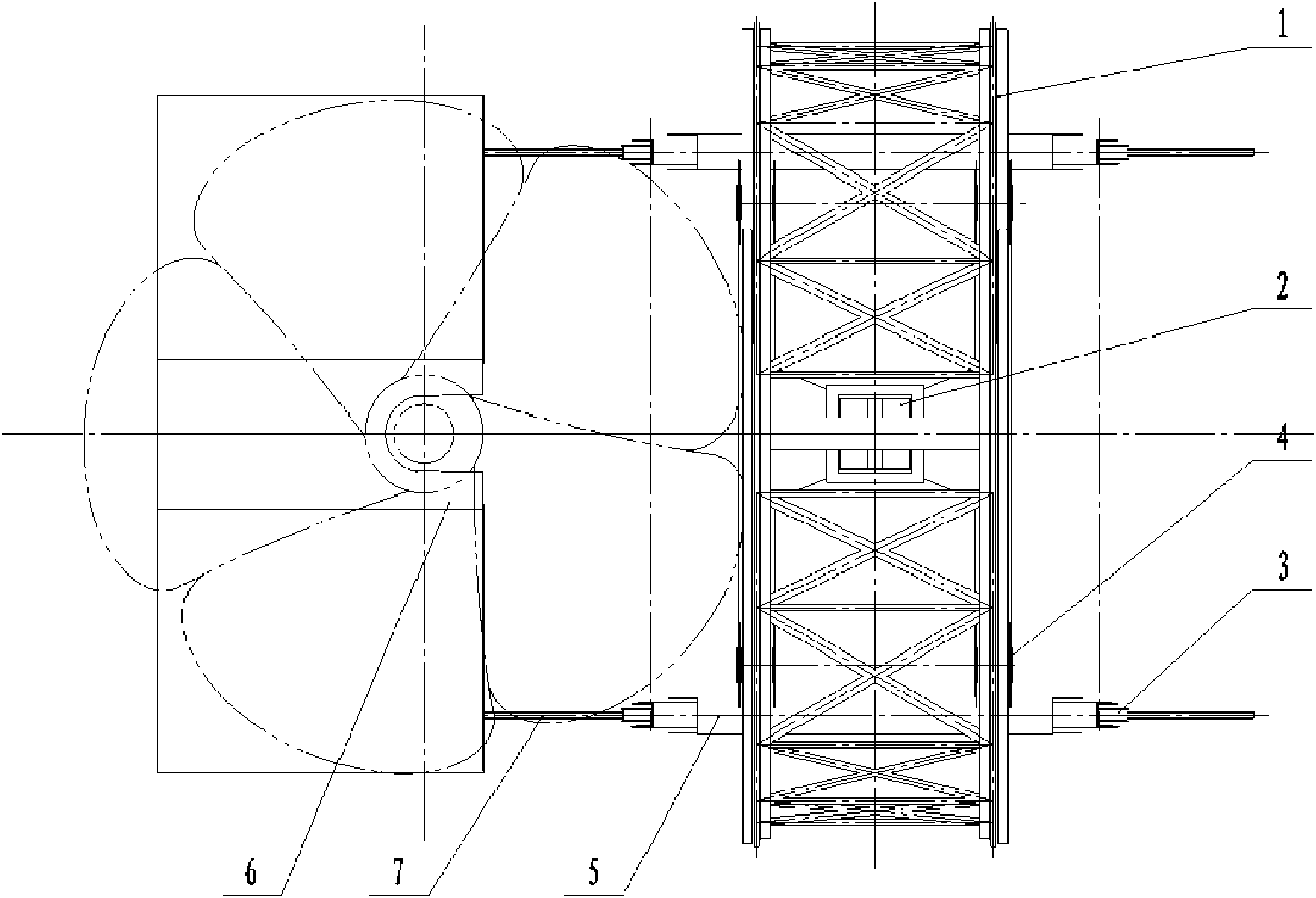

Sideway roller type propeller tipper

The invention discloses a sideway roller type propeller tipper and belongs to the technical field of mechanical manufacturing. The whole tipper consists of a turning wheel, adjustable finials, wheel sets, turning wheel sets, a sideway trolley, a U-shaped supporting rack, a track and a turning drive mechanism. The shaftless turning wheel is used as a core part of a turning device; the turning wheel is provided with a horizontal opening; and the upper part and the lower part of the opening are symmetrically distributed with two sets of the adjustable finials. The sideway trolley is provided with four wheel sets, four turning wheel sets and the turning drive mechanism, wherein the wheel set is used as a sideway walking device; and the turning wheel set is used as a supporting and turning drive device of the turning wheel. The U-shaped supporting rack has a fixed supporting structure for putting a propeller before and after the turning. The U-shaped opening allows the turning wheel and the U-shaped supporting rack to complete the butt joint of the propeller. The sideway roller type propeller tipper has the advantages of compact structure, light weight, reasonable stress, simple auxiliary process, safe and high-efficient turning operation and small turning drive power.

Owner:DALIAN UNIV OF TECH

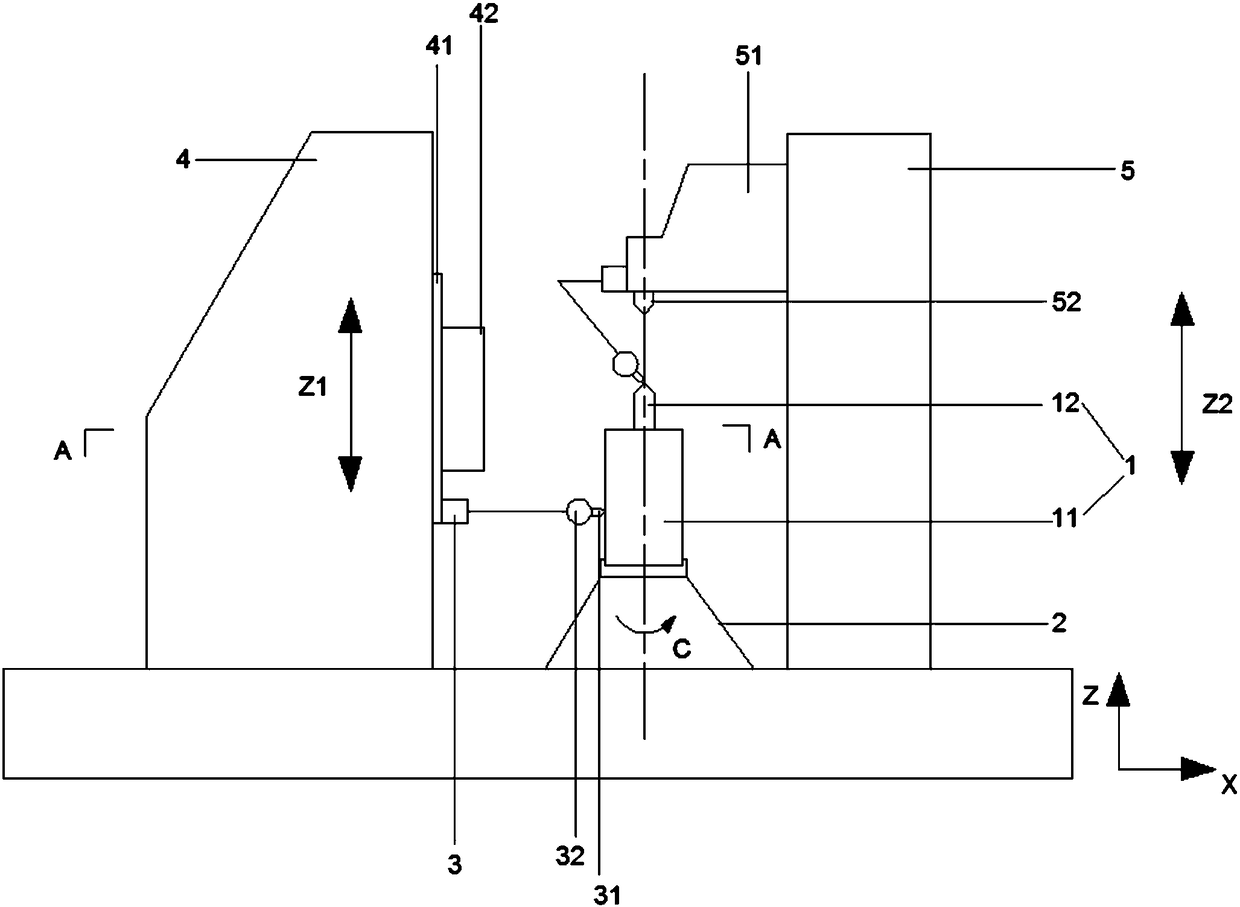

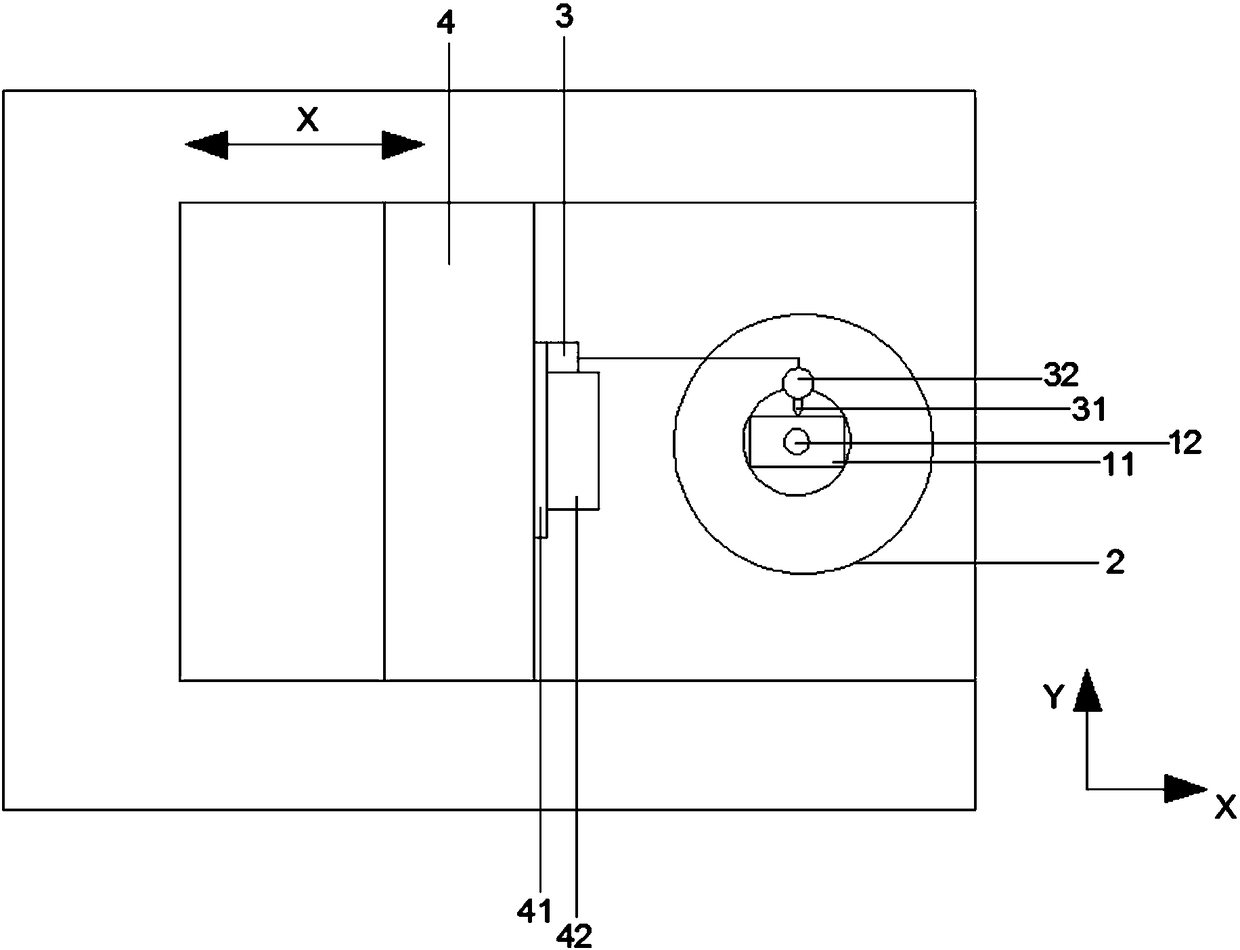

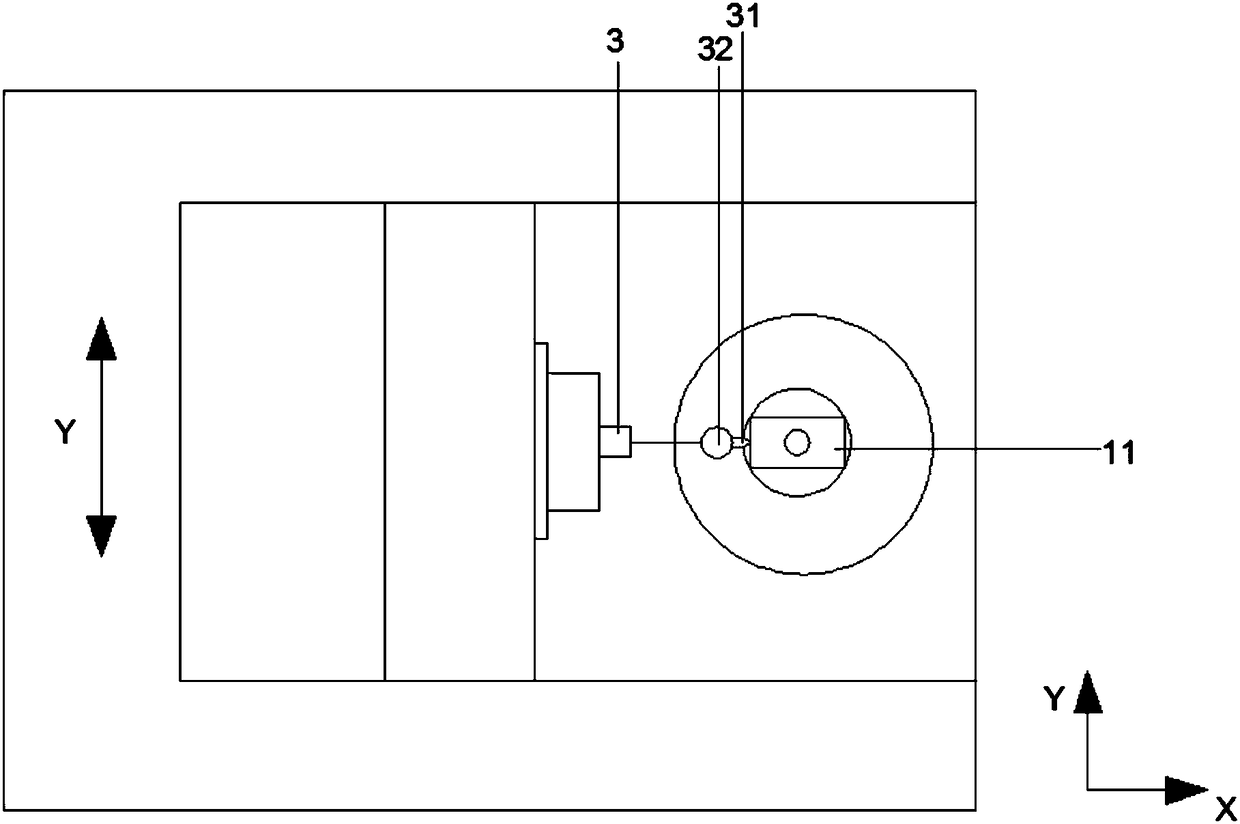

Geometric precision testing method for vertical machine tool with external bracket

The invention discloses a geometric precision testing method for a vertical machine tool with an external bracket, wherein the method is applied to the field of machine tool precision testing. The method comprises the following steps of (1), mounting a composite testing fixture on a rotating worktable, wherein the composite testing fixture comprises a cuboid angle square, and a finial which is arranged at top of the angle square and is in the direction of the central axis; (2), correcting coaxiality of the central axis of the composite testing fixture relative to the C axis of the central axisof the rotating worktable; and (3)-(6), respectively measuring the parallelism among the X-direction, the Y-direction and the Z-direction of a large vertical column and a small vertical column, and the verticality between the X-direction and the Y-direction. A testing fixture which is adopted in the current testing method is a cylindrical testing fixture. The cylindrical testing fixture can onlytest the large vertical column which operates with a cutter rest, and the small vertical column which operates with an external bracket. The parallelism relative to a main axis, the parallelism relative to a horizontal direction (XY direction) and the verticality of the XY direction are not effectively tested. The geometric precision testing method can effectively settle the problem.

Owner:CHONGQING MACHINE TOOL GROUP

Hydraulic screw nut disengaging device

The invention relates to a hydraulic screw cap opener which comprises a pressure head, a finial, a binding clip, a hydraulic pump, an oil return screw nut, a fixed handgrip, a movable handgrip, a fixed lever and a movable lever. Compared with the prior art, by using the hydraulic screw cap opener, the invention can be used for dismounting various types of screw caps with easiness in use and simple operation.

Owner:上海神模电气有限公司

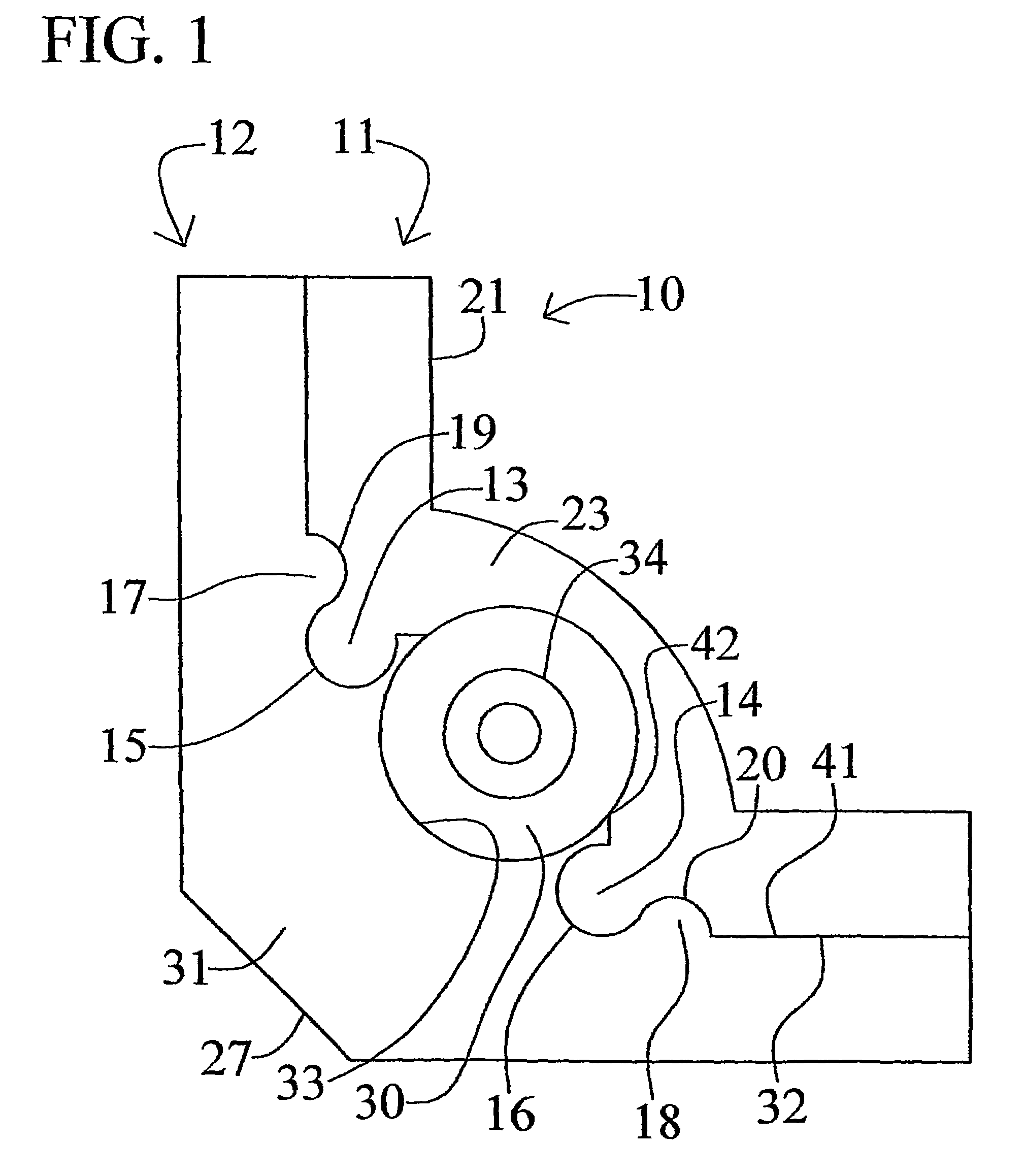

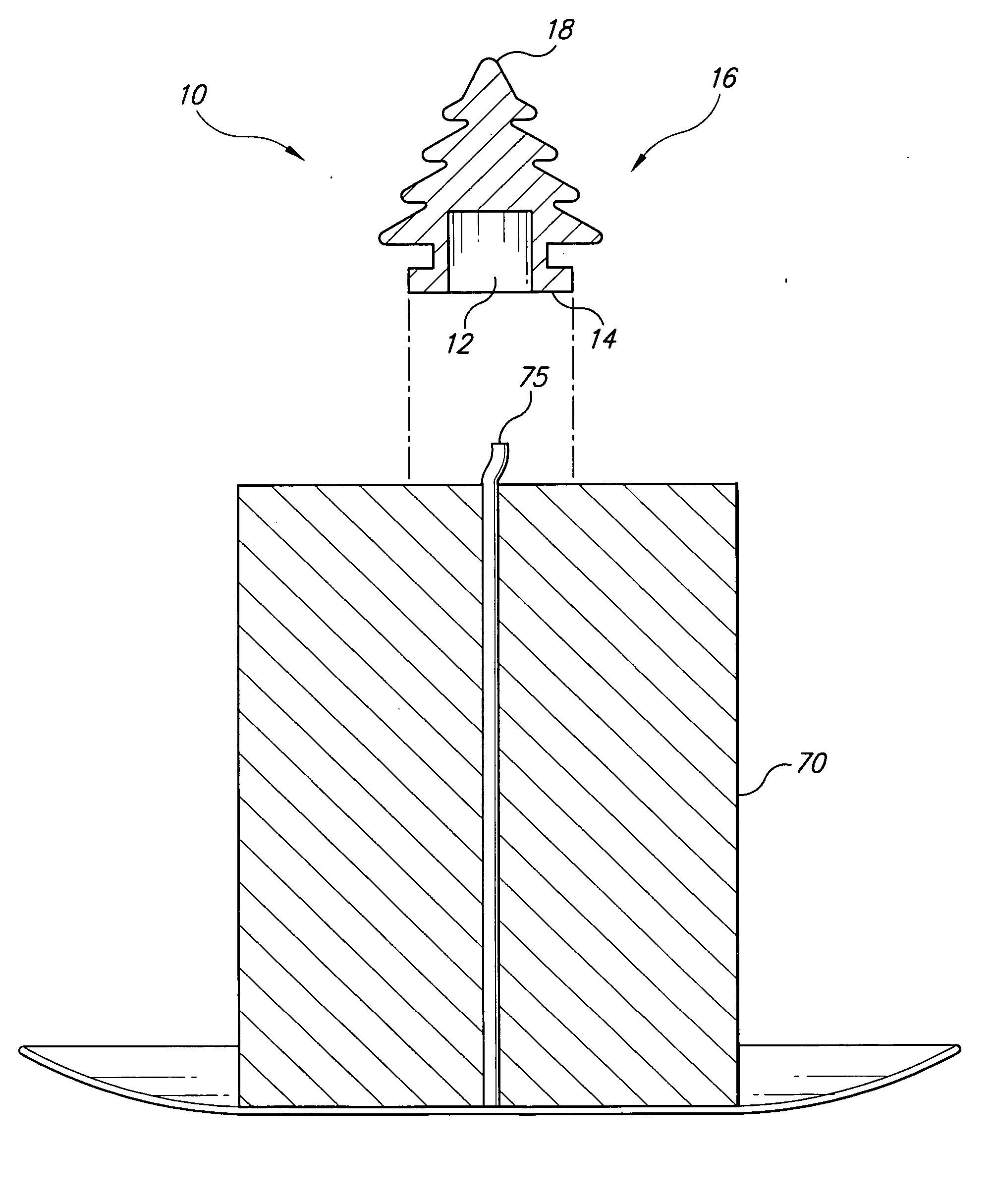

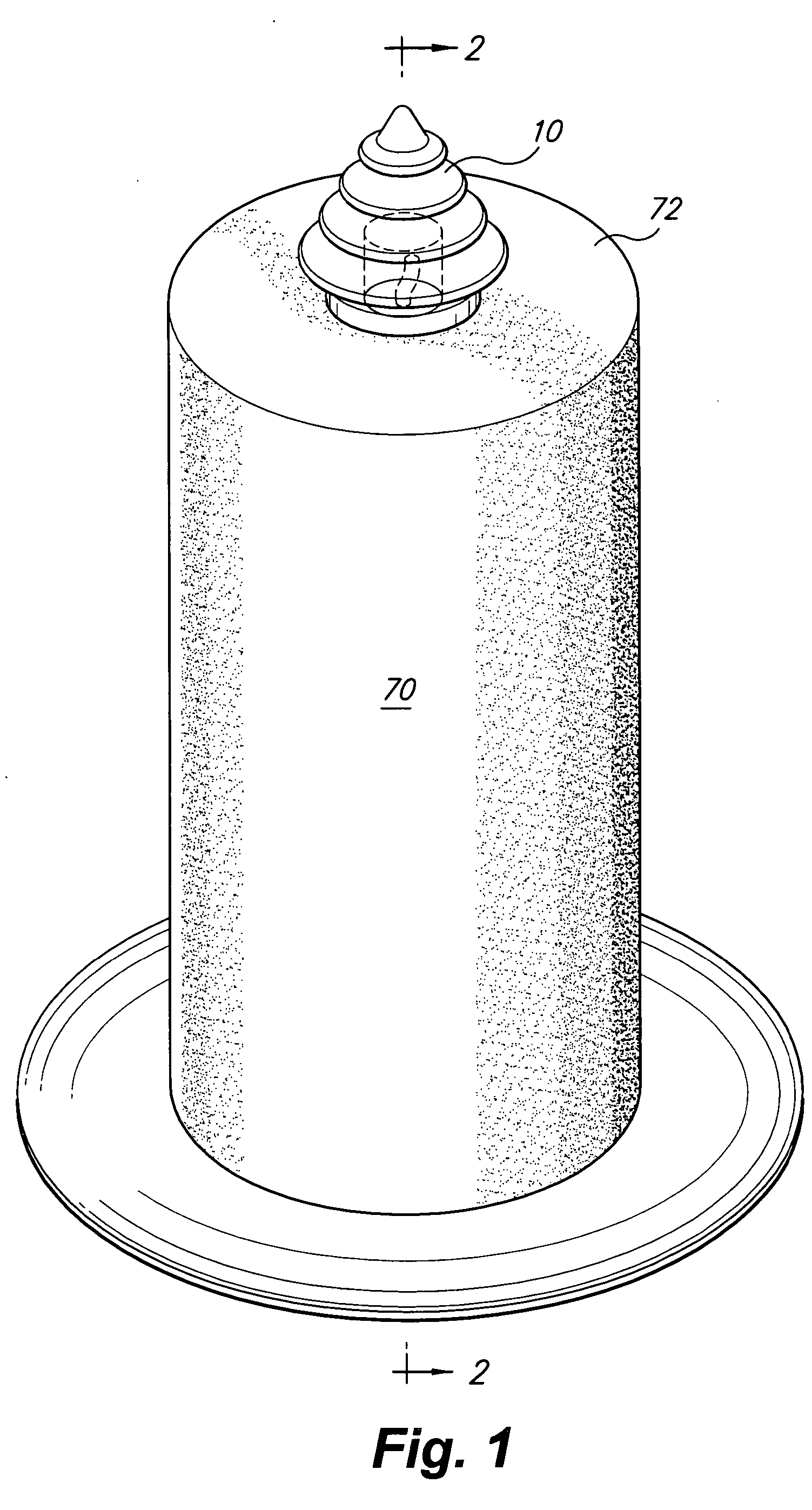

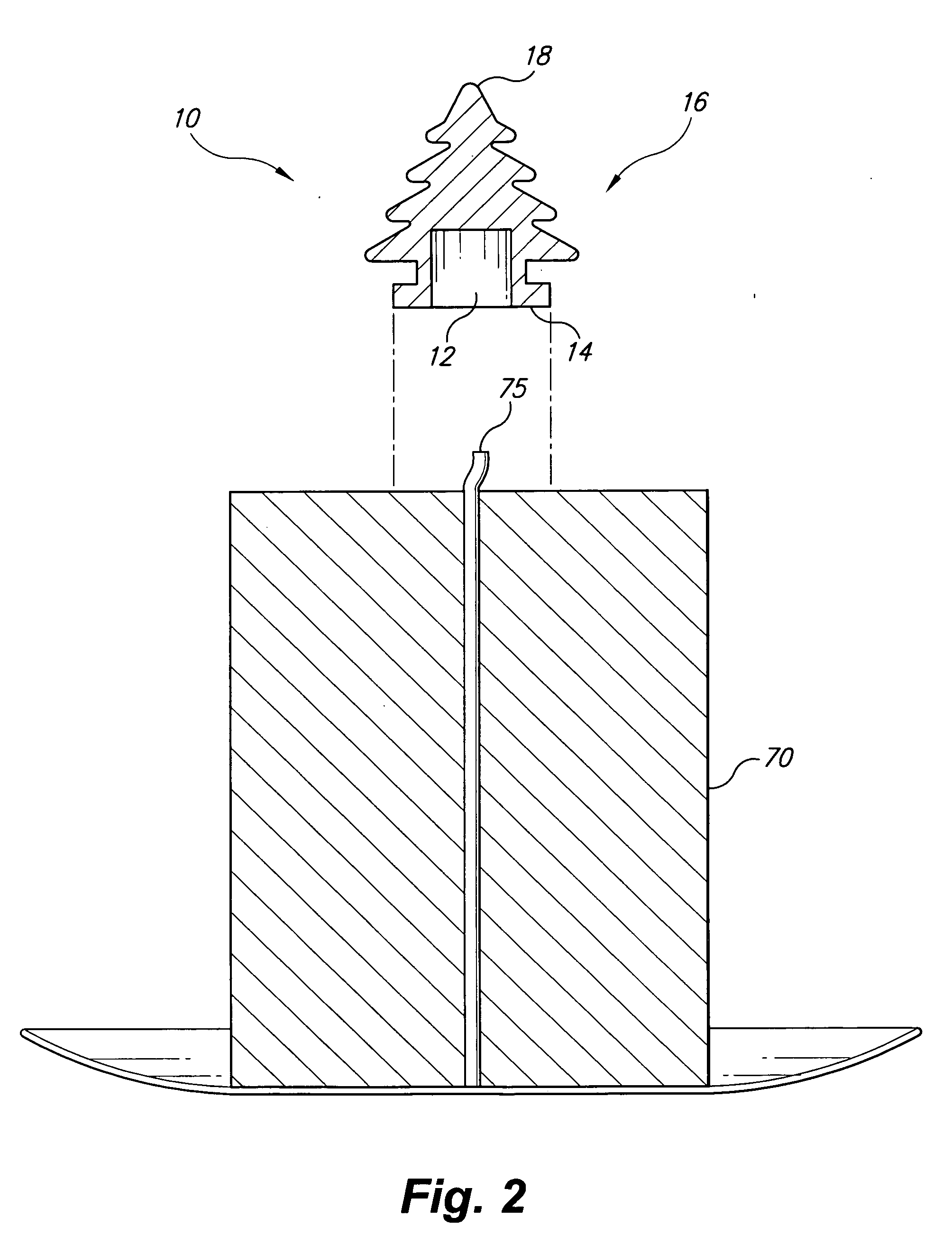

Candle finial

The candle finial is a decorative, ornamental body having a base end, a top end, a central section, and a cavity extending from the base end into the central section. The cavity is an inverted opening defined within the body and is dimensioned and configured to receive a candlewick. The finial may have the shape of a heart, a figurine, a holiday ornament or any other desired shape or design. The finial may be made of any material, such as plastic, wood, metal, etc. In use, the finial is placed on a cooled, unlit candle. The finial is disposed on the top surface of the cooled candle after a lighted candlewick has been extinguished to cover up the unsightly blackened candlewick.

Owner:HANES CHANDRA E

Stair rod bracket

The present invention provides a transversely interconnecting slidable stair rod bracket. The bracket may also be provided for use in a stair rod set, the set also including a stair carpet retaining rod and a finial. The bracket has a top portion and a bottom portion. The top portion having a plurality of projections and complementary shaped channels for receiving projections from the bottom portion; the bottom portion contains a rod-receiving portion, an outside end wall with an aperture therein for accepting either a threaded finial fastener which engages with a “female” finial, or the fastening portion of a “male” finial, and a plurality of projections and complementary shaped channels for receiving projections from the top portion.

Owner:STAIR HOLD

Toilet roll holders

InactiveUS20050116082A1Increase friction forceIncrease braking powerFilament handlingDomestic applicationsFinialEngineering

A stabilising bar assembly, to prevent inadvertent unwinding of a toilet roll mounted in a roll holder is disclosed. The bar assembly is intended for insertion into the core of the toilet roll. The bar assembly includes an elongate bar portion, there being finials at each of the opposite ends of the bar portion, the finials being articulate with respect to the bar portion, to allow the stabilising bar to be inserted into the core of the roll and resist the bar from rotating or slipping from the roll. The axes of articulation are parallel, such that they can both hang down at opposite sides of a roll.

Owner:MOLLOY DAVID

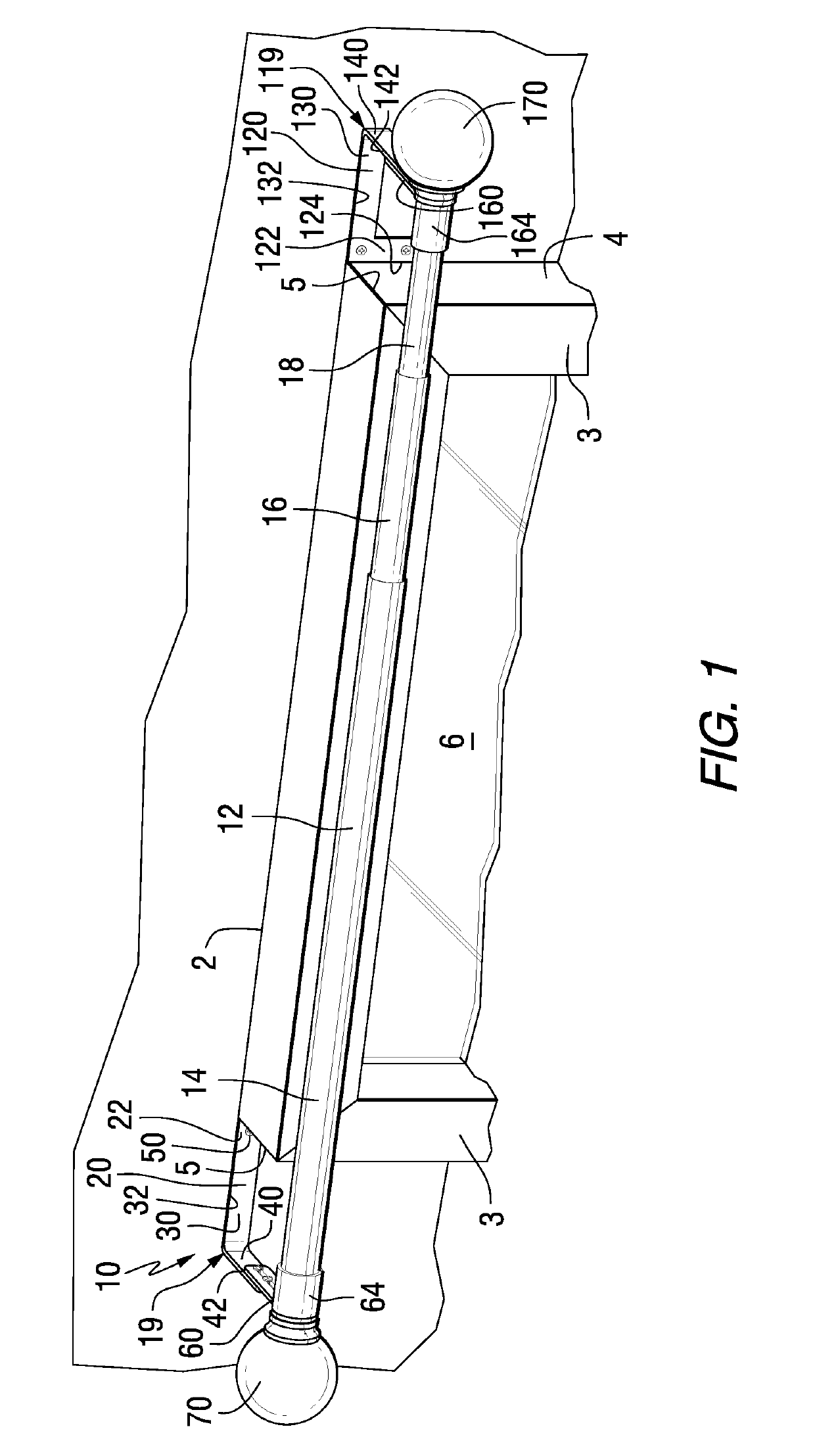

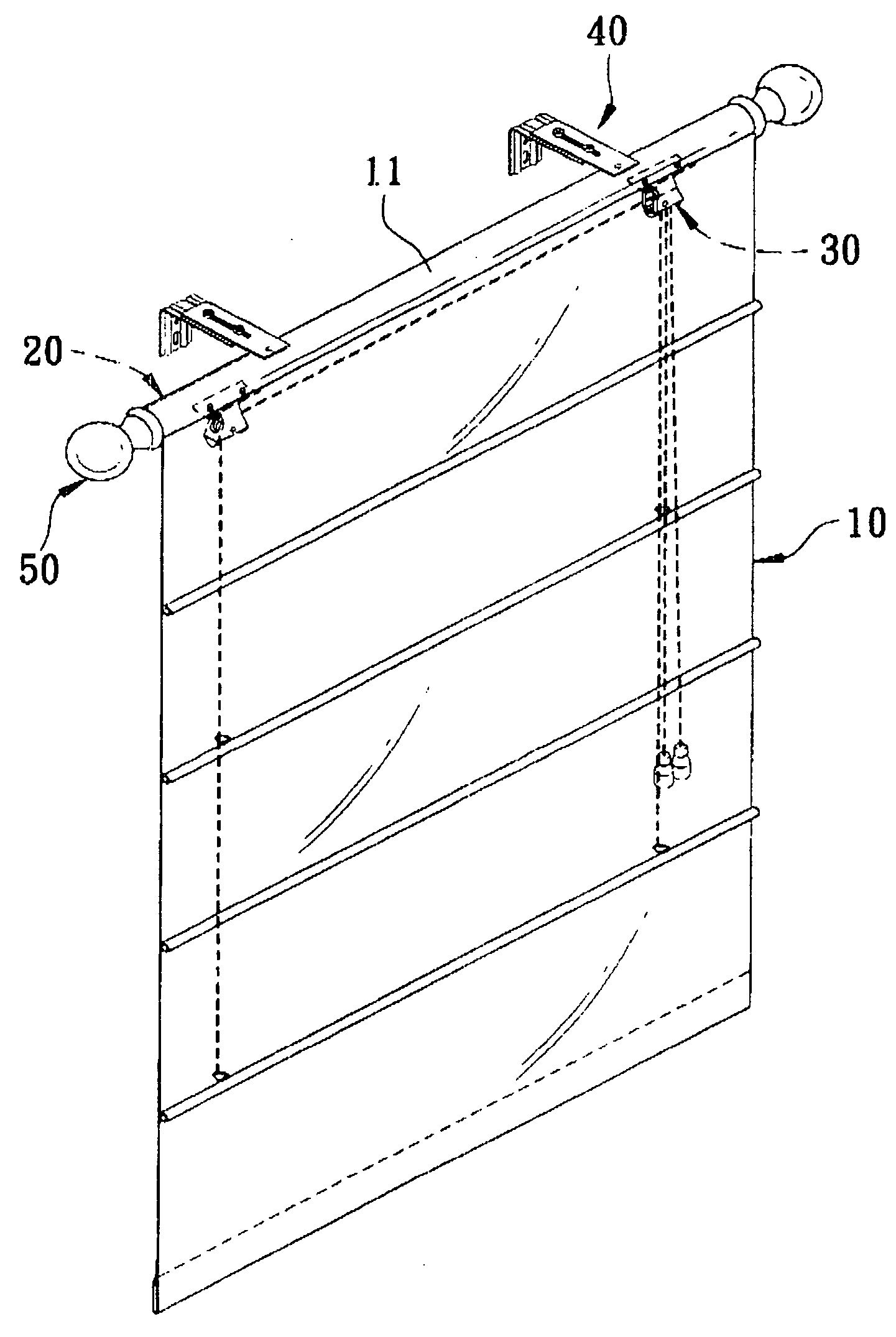

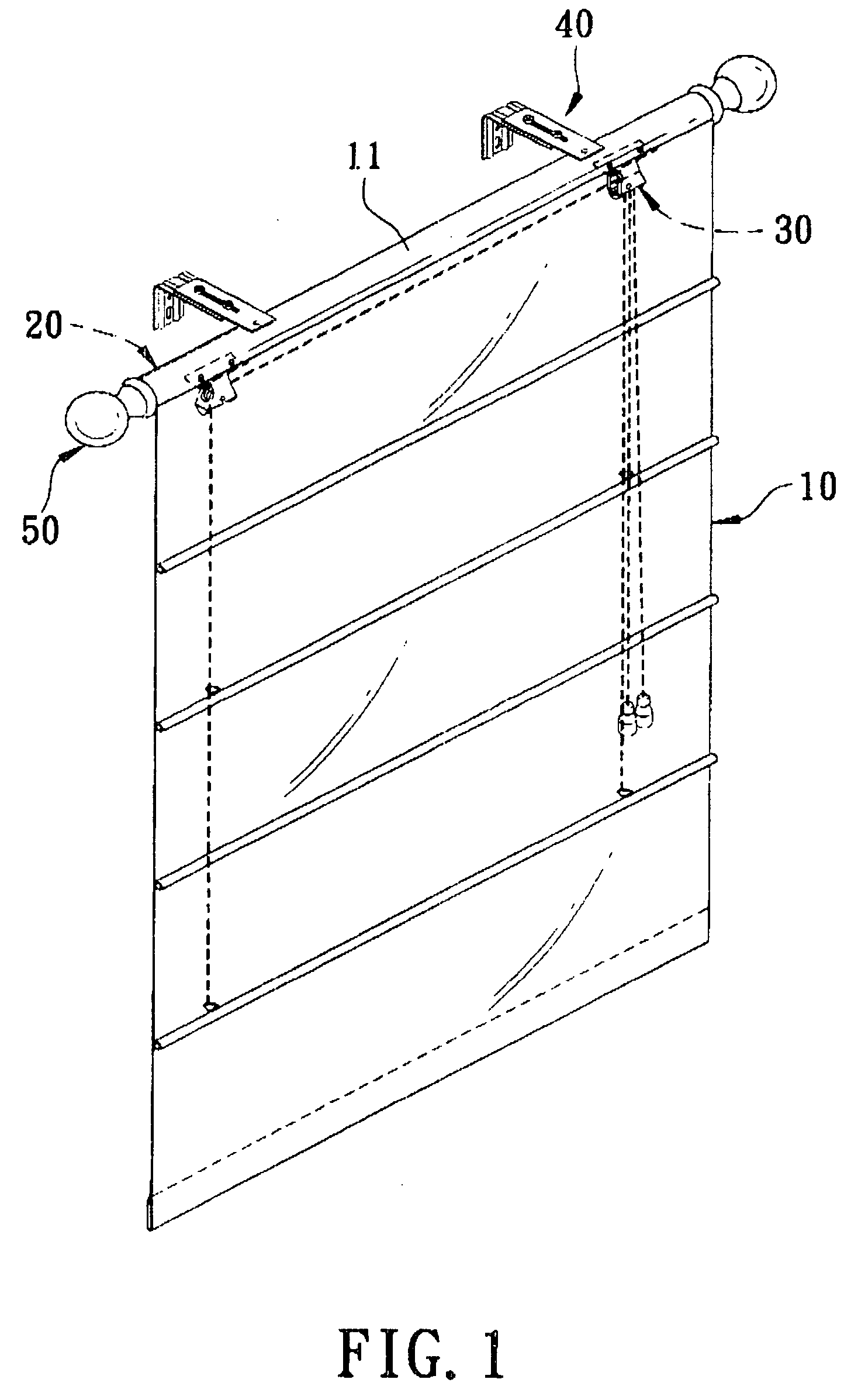

Hanging device for a Roman shade

A hanging device for a Roman shade includes a shade cloth with a cloth tube formed in its upper end, an upper tubular rod and two brackets. The cloth tube has two opposite holes, and the upper tubular rod has two opposite vertical holes corresponding to the location of the two holes of said cloth tube, and the upper tubular rod extends in the cloth tube so vertical bolts of the two brackets may pass through those two holes of the upper tubular rod and the cloth tube and then screwed tightly with a nut for supporting the upper tubular rod together with the cloth shade. Then the two brackets are fixed on a wall available for fixing the Roman shade. Further, a finial can be attached with two ends of the upper tubular rod for decoration. Then the Roman shade is optionally applicable to an inside mounted one, an outside mounted one, or an outside one with finials.

Owner:NIEN MADE ENTERPRISE CO LTD

Two-jaw self-centering adjustable chuck

The invention relates to a two-jaw self-centering adjustable chuck which comprises a chuck body and an adapter plate connected with the chuck body and a machine tool, wherein a jaw connecting plate and jaws connected on the chuck body through the jaw connecting plate are arranged on the chuck body, an adjustable finial is connected on the adapter plate by a bolt, the adjustable finial comprises a finial, a lock nut which is arranged on the bolt and matched therewith and a nut base connected with the finial and the adapter plate, the adjustable finial extends from a hole at the center of the chuck body to the outside, and the adjustable finial is positioned at the center of the chuck body; and the jaws comprise a pair of adjustable jaws which are positioned on one diameter on the chuck, each adjustable jaw comprises a thimble, a connecting rod which is vertically connected on the thimble, a jaw support which is matched with the jaw connecting plate and a nut for fixing the connecting rod on the jaw support, and the jaw supports are fixed on the jaw connecting plate. As the two-jaw self-centering adjustable chuck is provided with the adjustable finial and the pair of the adjustable jaws, the two-jaw self-centering adjustable chuck can be used for positioning and clamping cylinder type parts; furthermore, the two-jaw self-centering adjustable chuck has simple structure and convenient use.

Owner:XUZHOU HUAHENG ROBOT SYST

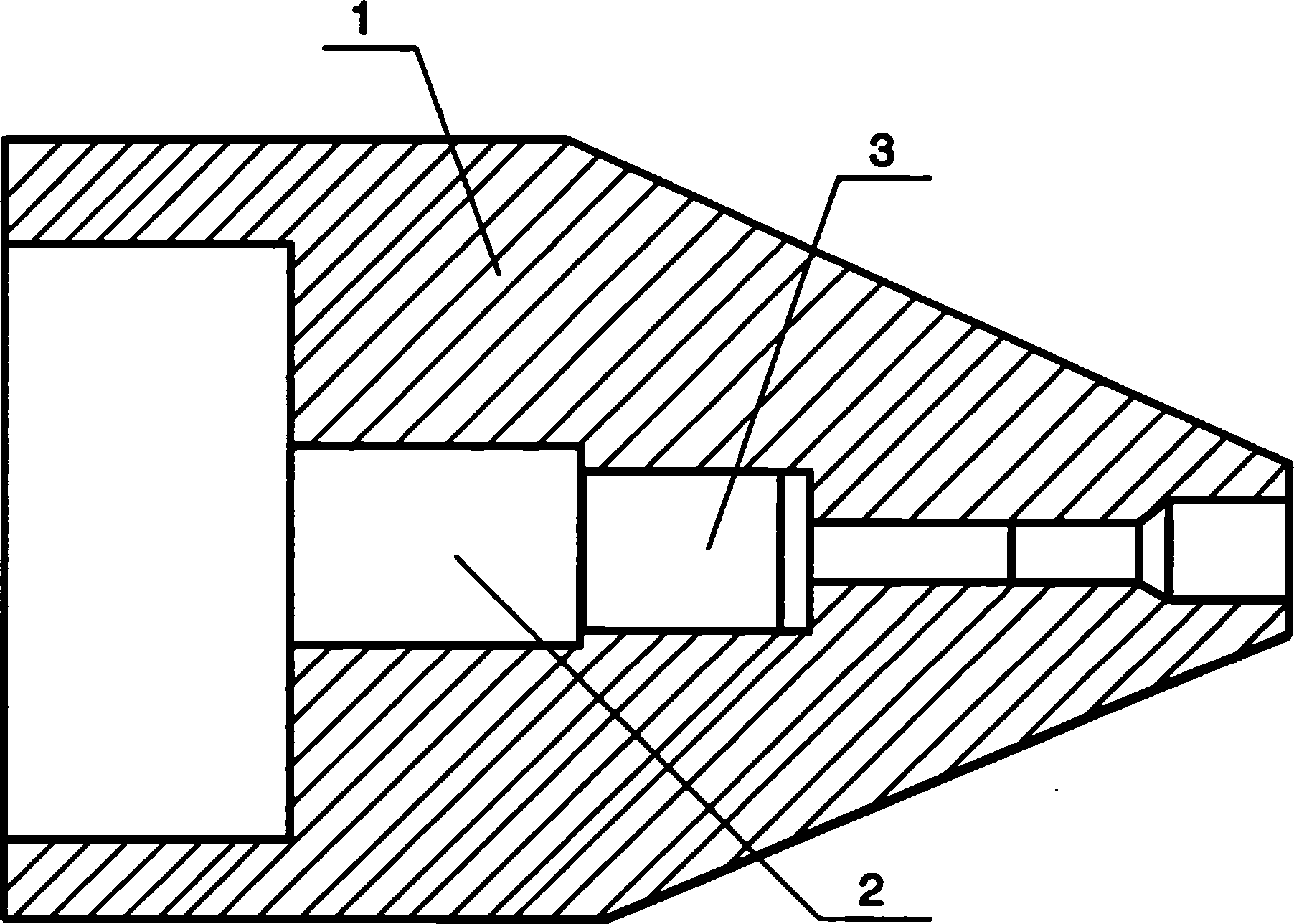

Process of grinding nozzle for impacting generator set

InactiveCN1887523ASmall concentricity deviationReduce roughnessEdge grinding machinesFinialEngineering

The process of grinding nozzle needle for impacting generator set includes matched grinding the external circle of the spindle and the nozzle needle, grinding the 60 deg conic surface of inner hole and central hole of the spindle with oil stone finial, grinding the external circle, precisely trimming grinding wheel and other steps. The present invention has the advantages of simple technological process, convenient operation, less error in the axiality of the nozzle needle and low roughness of the nozzle needle.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

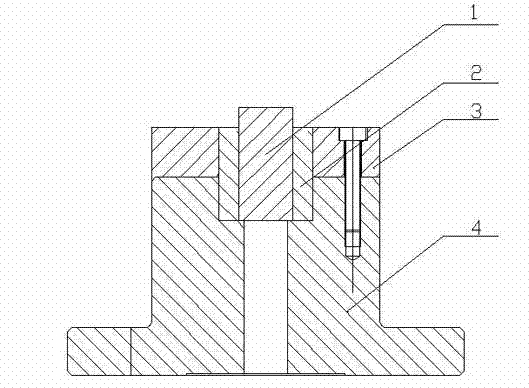

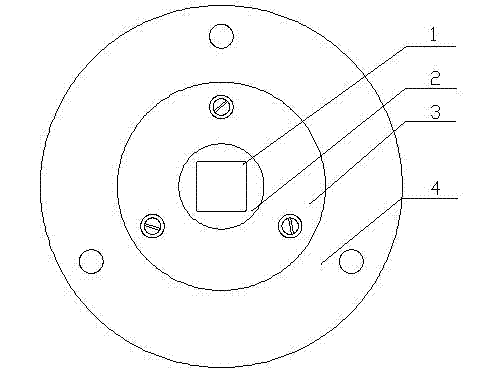

Tooth alignment and hobbing clamp for octagonal blind hole

The invention relates to a tooth alignment and hobbing clamp for an octagonal blind hole. An inner quadrilateral core is arranged at the center of the clamp, a sheath is sheathed on the periphery of the inner quadrilateral core, a gasket is further sheathed outside the sheath, a connecting seat is arranged below the gasket, a screw hole is formed on the gasket, a boss of the connecting seat is connected through a countersunk head screw, and a bolt through hole for fixing with a machine tool is arranged on the connecting seat. The top end surface of the inner quadrilateral core protrudes from the top end surface of the sheath and the gasket. The diameter of the outer circle of the gasket is the same with that of a bulge of the connecting seat. The inner quadrilateral core, the sheath, the gasket and the connecting seat are coaxial. According to the tooth alignment and hobbing clamp disclosed by the invention, a workpiece is centered by an inner octagonal core, an inner hole of a base is used for positioning, the position of a cutter can be adjusted conveniently for realizing alignment between the octagonal blind hole and tooth shape, the inner octagonal core and an upper finial are used for driving the workpiece to rotate, the clamping is convenient, and a mechanism is simple but very practical.

Owner:常州德劢精密传动有限公司

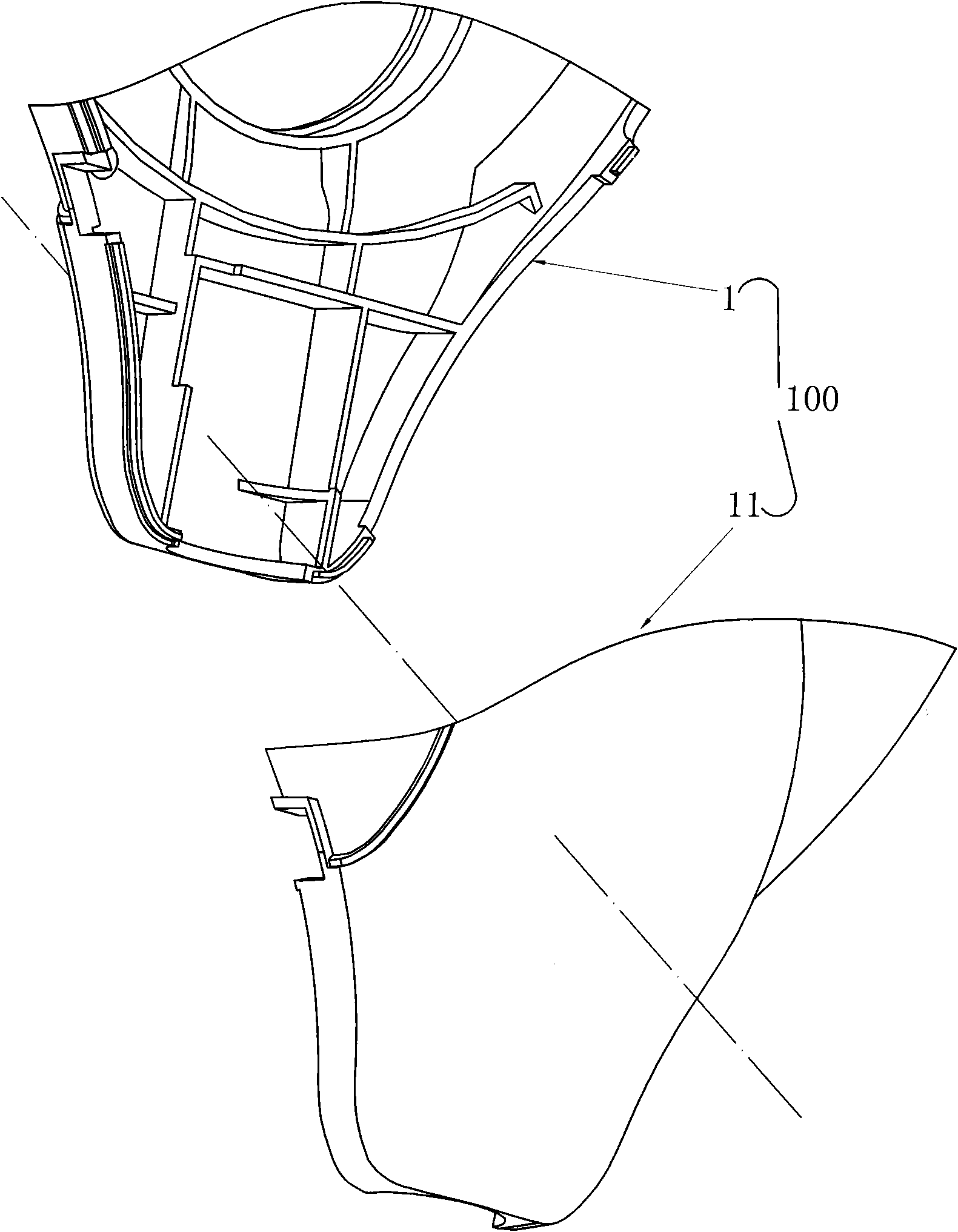

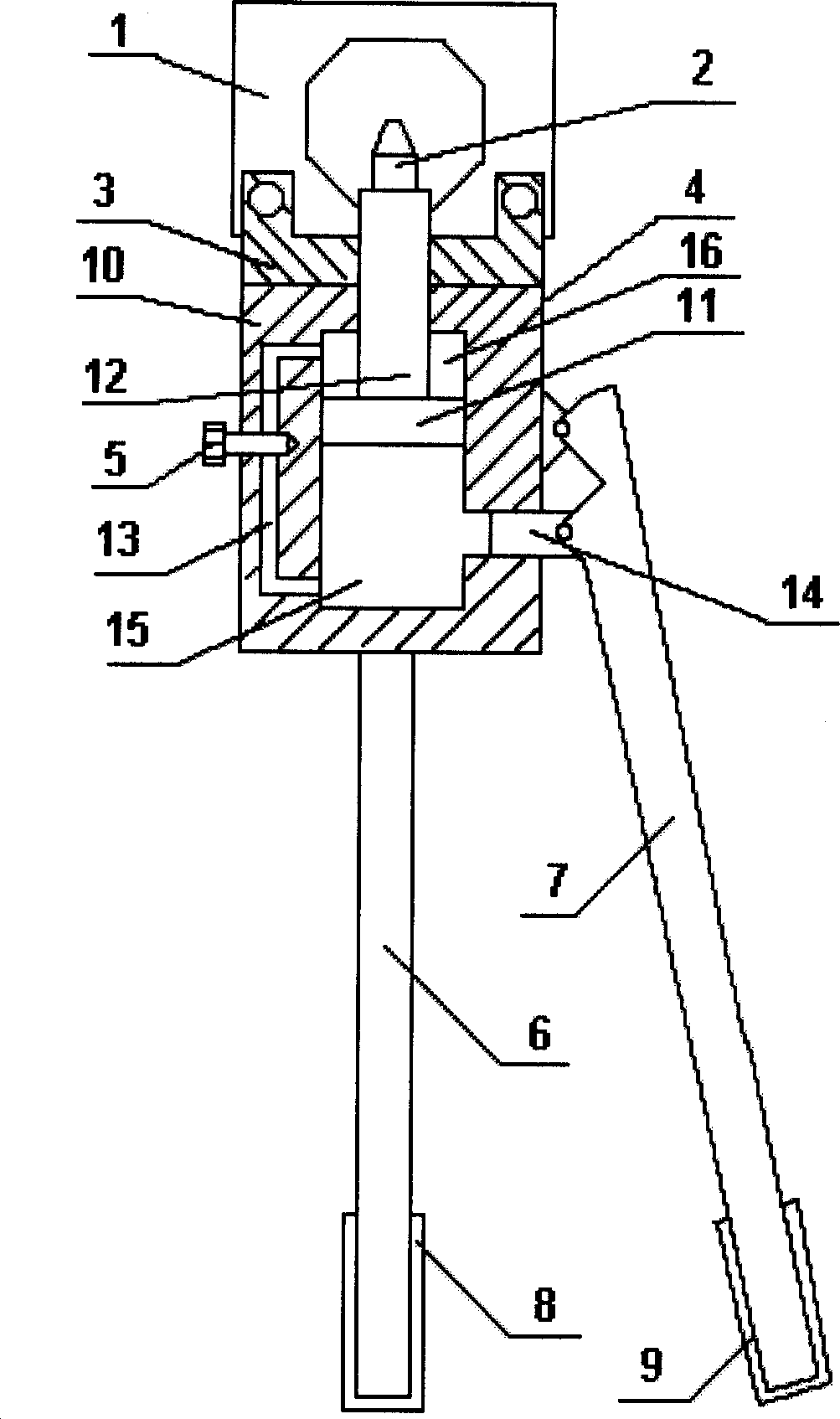

Workpiece clamping device of the numerical controlled solid carving machine

The present invention provides one kind of workpiece holder for numerically controlled stereo carving machine, and belongs to the field of carving machine technology. The workpiece holder includes oneframe, one motor, one turntable on the frame, one finial for holding the workpiece together with the turntable and capable of telescoping in the axial direction of the turntable, one sliding mechanism capable of shifting in the axial direction of the turntable, and one rotation mechanism for rotating the turntable with the motor. The workpiece holder for numerically controlled stereo carving machine has simple structure, capacity of step rotating the workpiece and adaptability of carving both large and small artworks.

Owner:玉环圣弘法数控雕刻设备有限公司

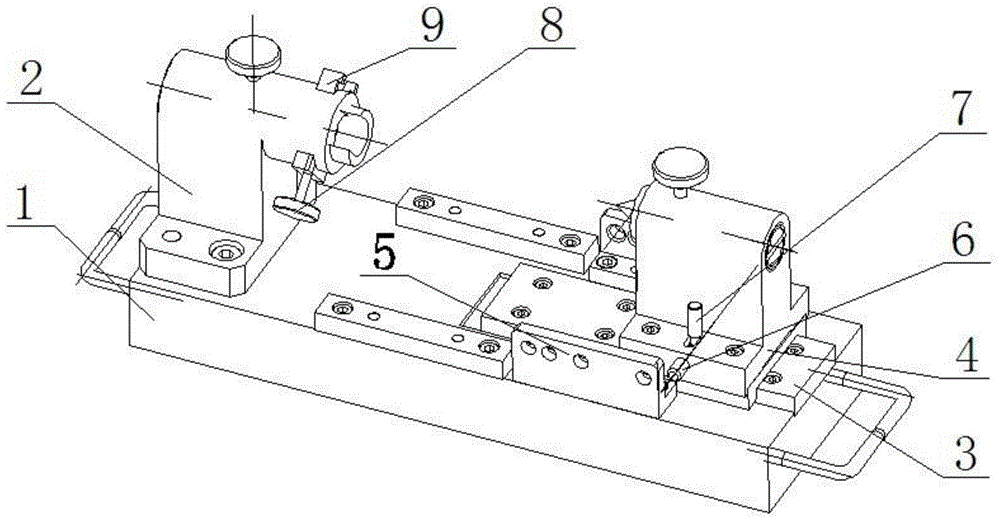

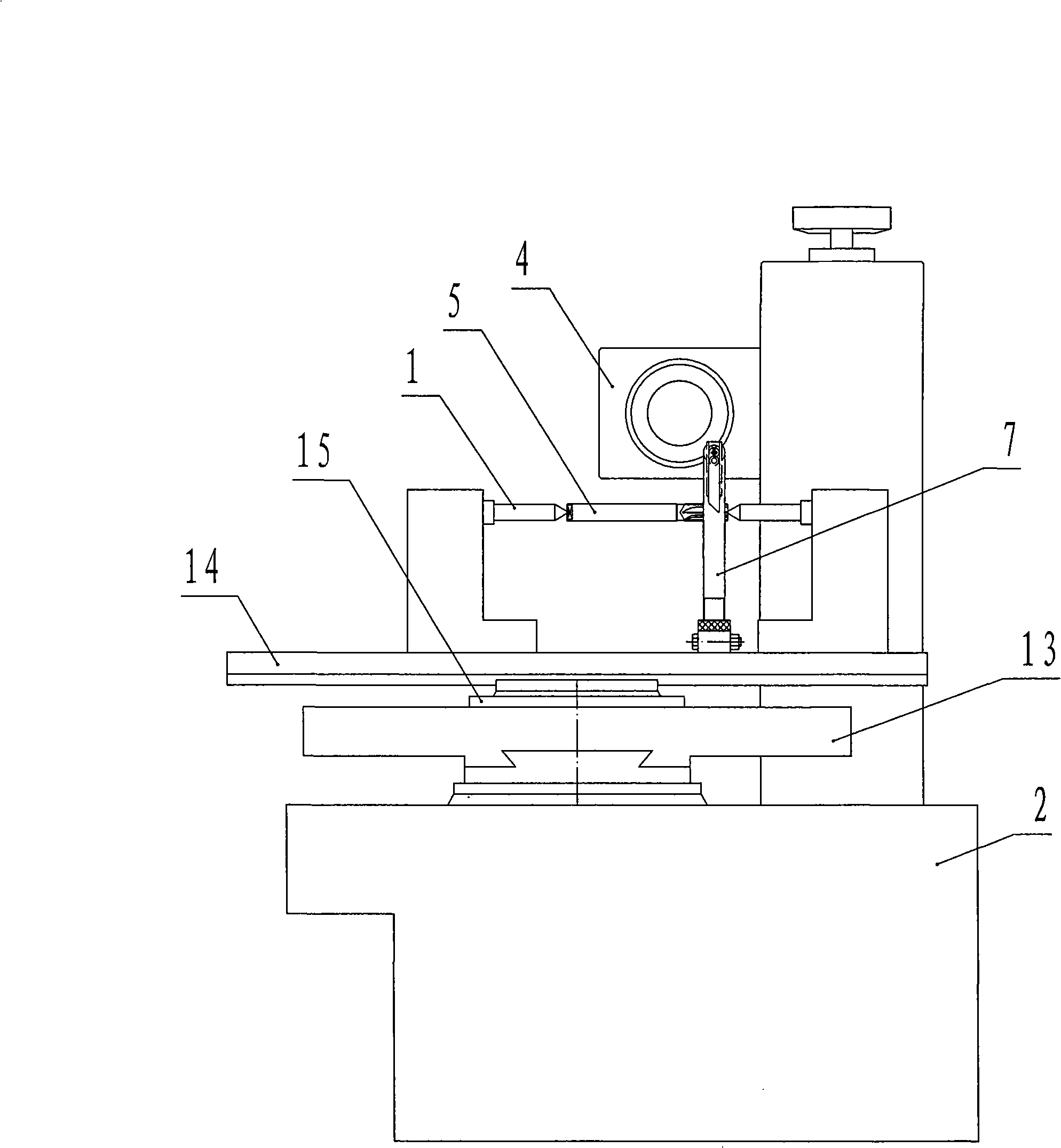

High-efficiency rimer tool sharpening apparatus

InactiveCN101402176APrevent rotationEasy to operateOther manufacturing equipments/toolsFinialEngineering

The invention relates to a high-efficient reamer blade grinding device for solving the problem of grinding a reamer blade. The device adopts the technical proposal that the device consists of a sliding platform, two reamer clamping finials arranged on a slide board of the sliding platform, and a grinding wheel fixedly connected with a sliding platform base; a unidirectional rotating control mechanism for a reamer is arranged between the two reamer clamping finials; the unidirectional rotating control mechanism for the reamer consists of a strip elastic supporting plate vertically arranged and a bracket thereof; the upper middle part of the elastic supporting plate is fixedly connected with the slide board of the sliding platform through the bracket; and the lower end of the elastic supporting plate is supported on one active face of the grinded reamer. With the device, the reamer can rotate without deviating from the blade grinding device, thereby simplifying the blade grinding operation, improving working efficiency and ensuring the precision of blade grinding.

Owner:GREAT WALL MOTOR CO LTD

Macromolecular guardrail

InactiveCN103498593AImprove securityEasy to installLighting applicationsPoint-like light sourceFinialEngineering

The invention discloses a macromolecular guardrail. The macromolecular guardrail mainly comprises columns and a guardrail board frame. The macromolecular guardrail is characterized in that the columns are provided with solar panels, grooves, LED lamps and bases, the columns are connected with the guardrail board frame through the grooves, connection rods and a guardrail ring are arranged in the guardrail board frame, and finials are arranged at the top of the guardrail board frame; the connection rods are provided with first light reflecting strips, the guardrail ring is composed of an outer ring body, an inner ring body and supporting rods, and the supporting rods are provided with second light reflecting strips. The solar panels and the LED lamps are arranged at the top ends of the columns of the macromolecular guardrail, so that the macromolecular guardrail can flicker at night, have the warning function and improve safety of a scenic region at night; the grooves are formed in the columns to facilitate installation of the columns and the guardrail board frame, and installation work efficiency is improved; the guardrail board frame and the connection rods are made of H-shaped macromolecular sectional materials, so that raw materials and production cost are saved, and the macromolecular guardrail does not rust and is long in service life. The macromolecular guardrail is simple in structure, beautiful, durable and convenient to implement.

Owner:芜湖迅丰园林交通科技有限公司

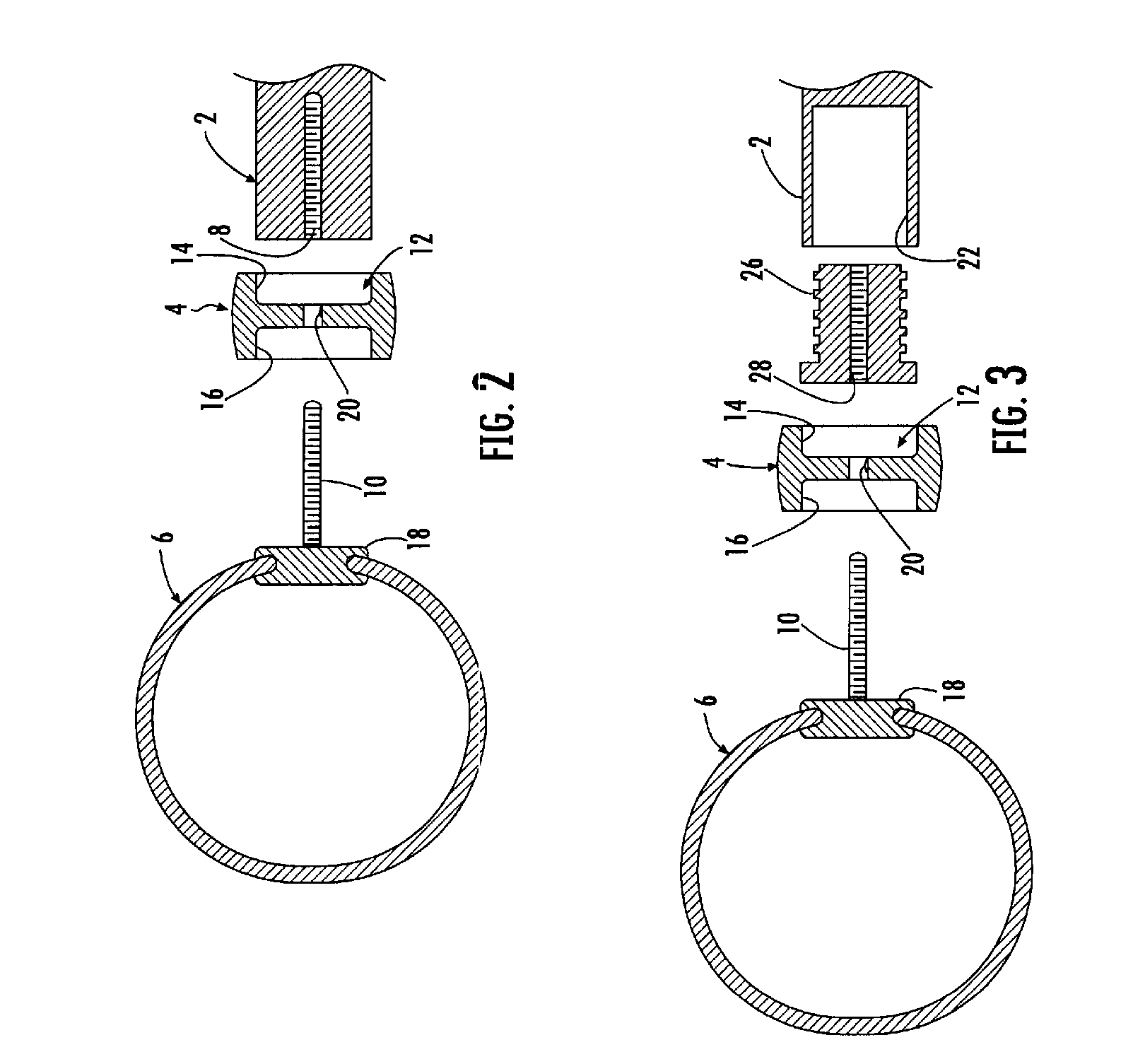

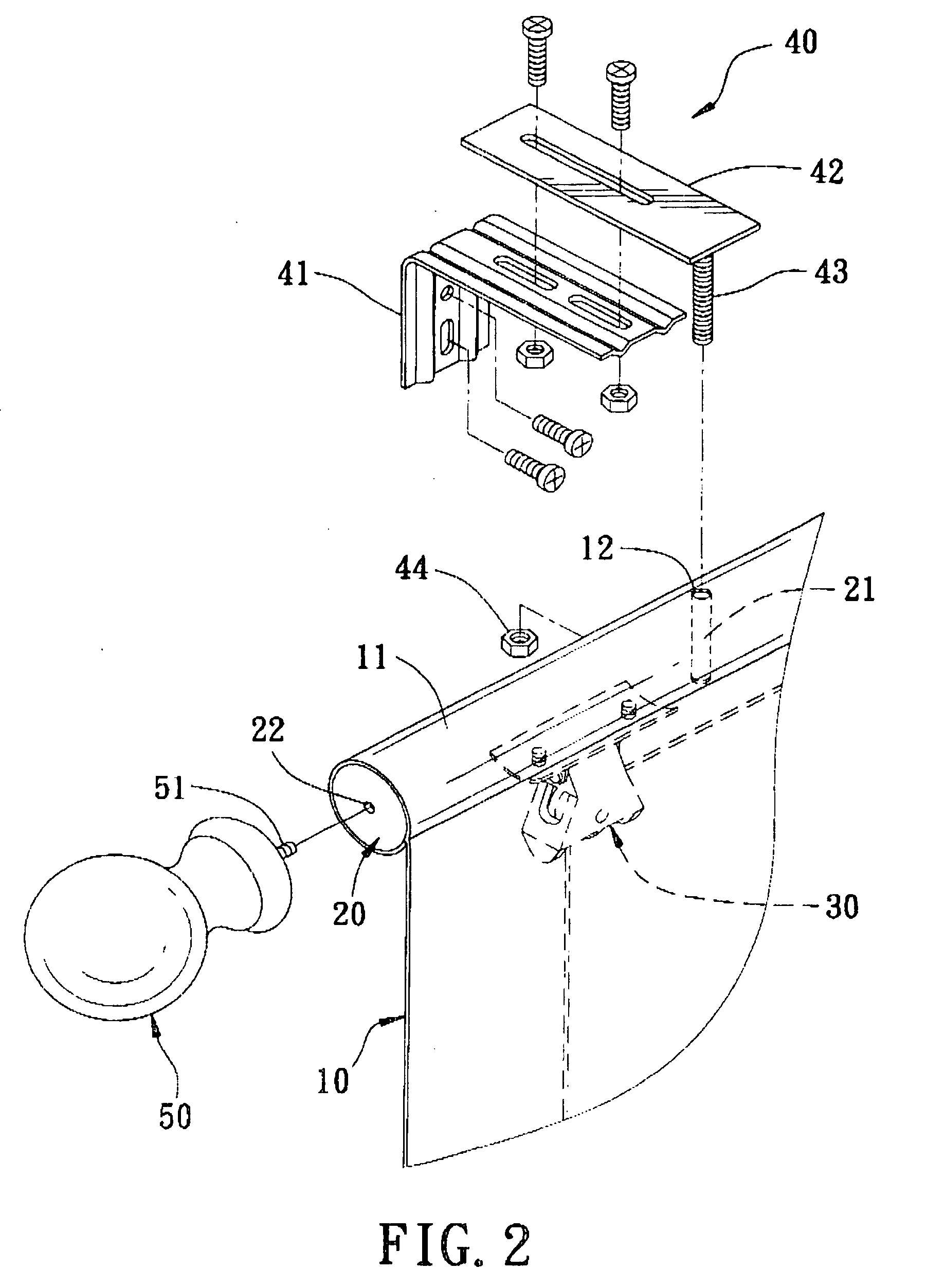

Fixative device for decorative finial

InactiveUS20080250749A1High retention rateProvide damage toleranceFencingBuilding componentsFinialEngineering

A fixative device for a decorative finial capable of being press fit onto a picket or post includes a pair of contact tabs arranged to bridge across a bend or corner formed by the inner surface of the free end of a tubular picket or post. A fit may be provided by a channel and protrusion or o-ring.A plurality of contact tabs, each having two contact surfaces may accommodate manufacturing defects and variations in the wall thickness of tubular, extruded posts.

Owner:WELDON INDS

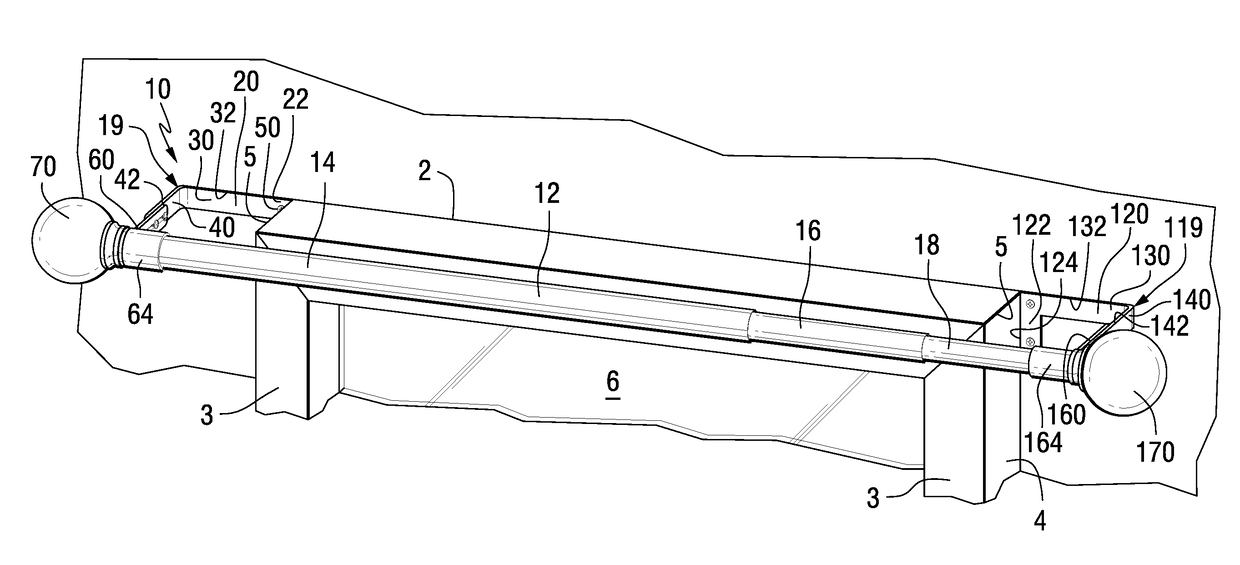

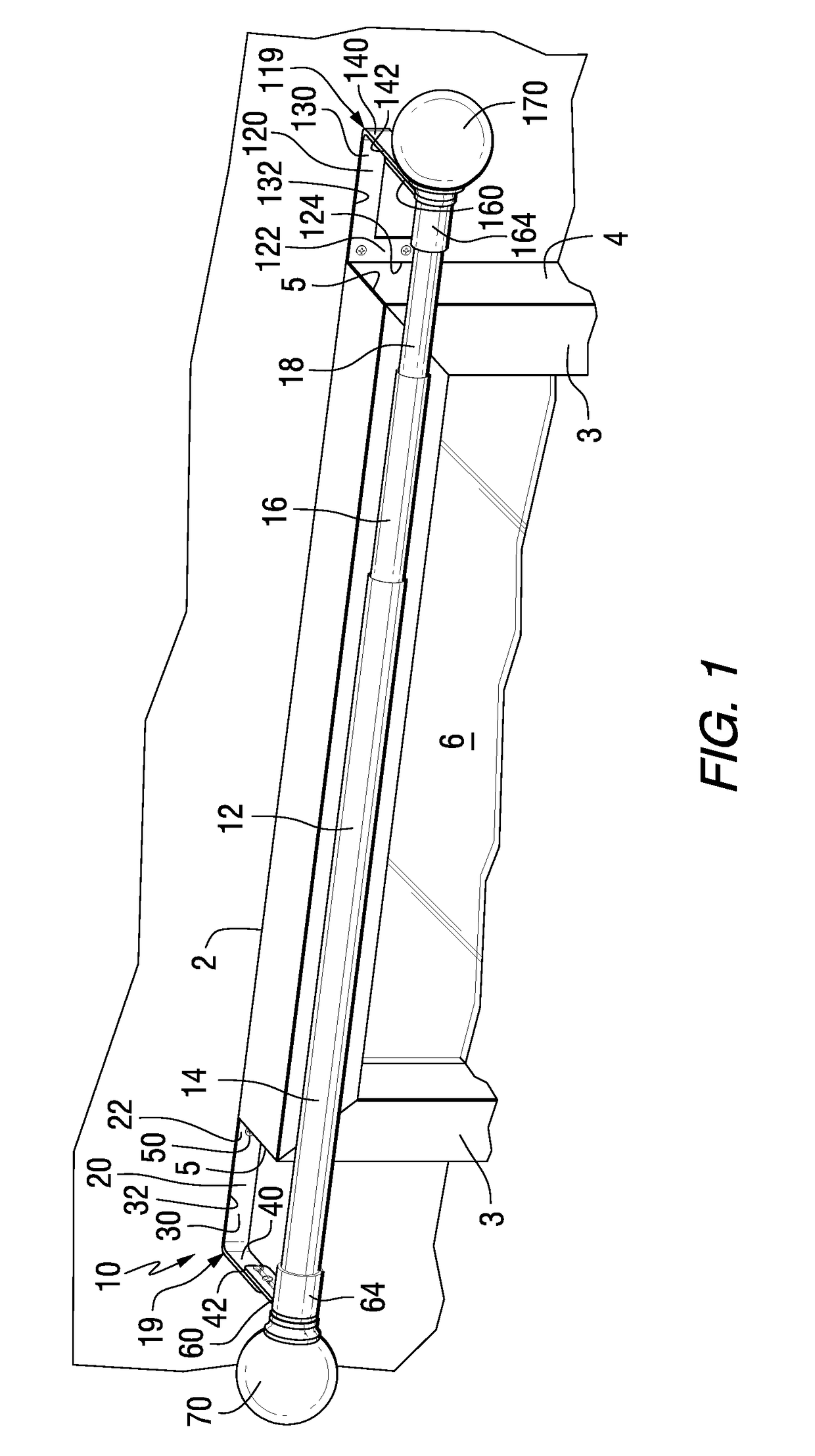

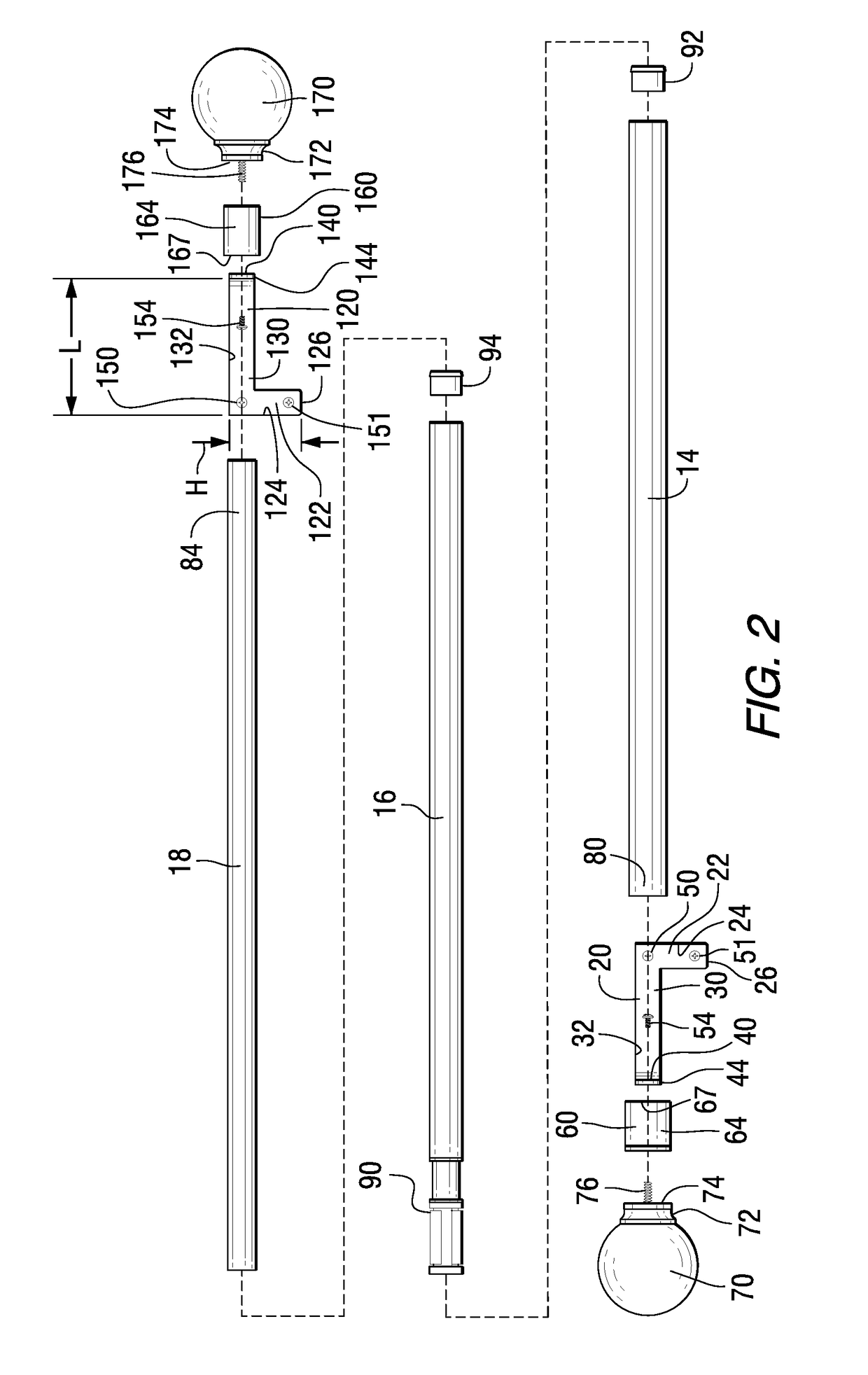

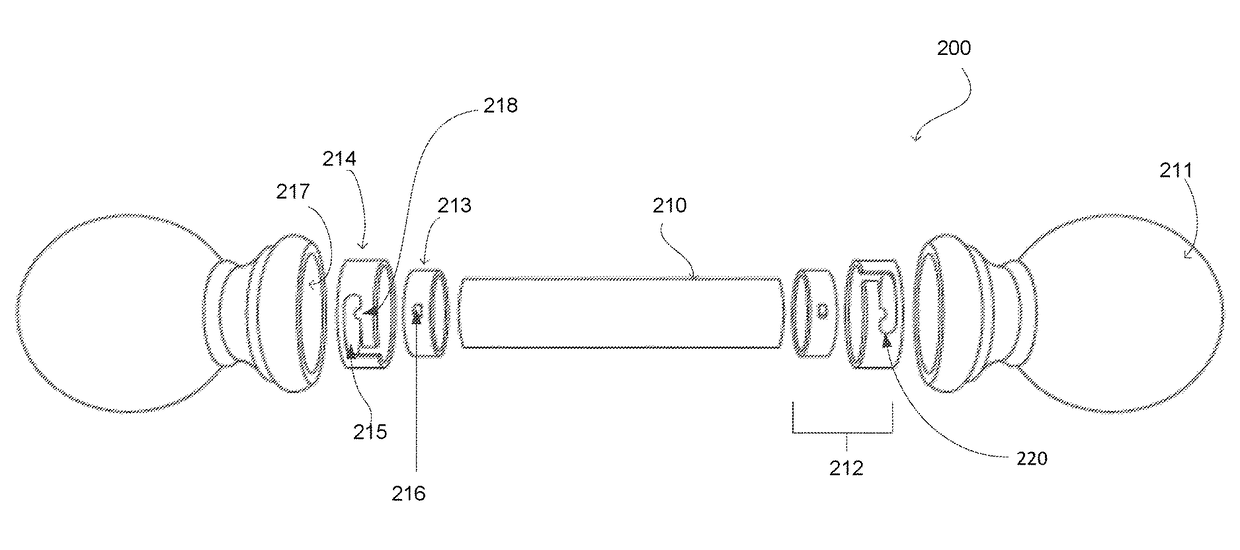

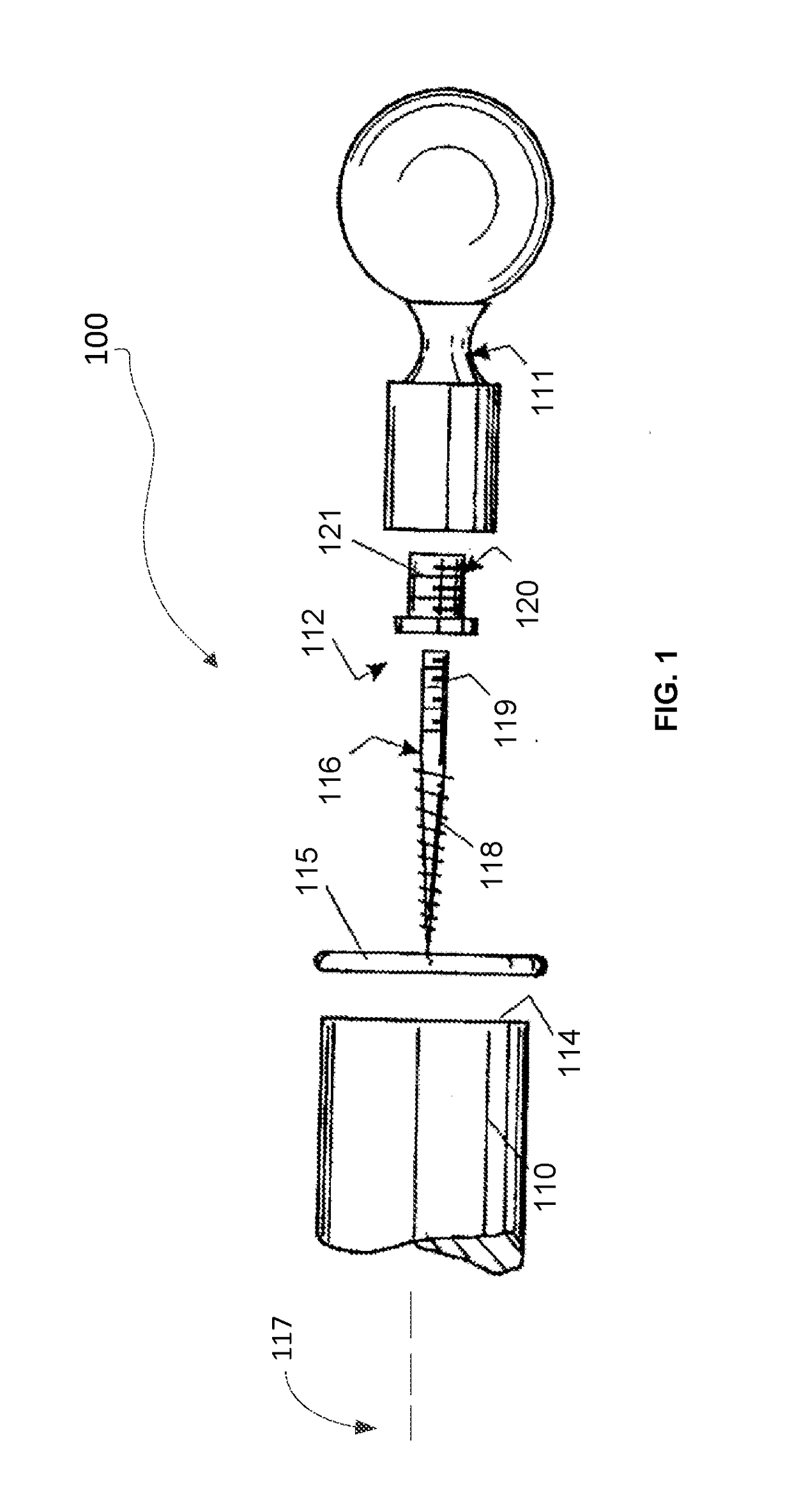

Curtain rod assembly

An improved curtain rod assembly is provided that obviates limitations and problems with conventional assemblies. In particular, the improved curtain rod assembly utilizes complementary locking and key components which allow for a secure, robust, and reversible connection between a curtain rod and an associated finial. As such, assembling the curtain rod assembly does not require the use of screws, nails, or other items which may permanently damage the curtain rod assembly, limit the longevity or usefulness of the curtain rod assembly, or present a danger to the user.

Owner:FRETT JEREMIAH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com