Geometric precision testing method for vertical machine tool with external bracket

A technology of geometric accuracy and detection method, applied in computer control, instruments, simulators, etc., can solve problems such as ineffective detection and achieve the effect of precise correction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

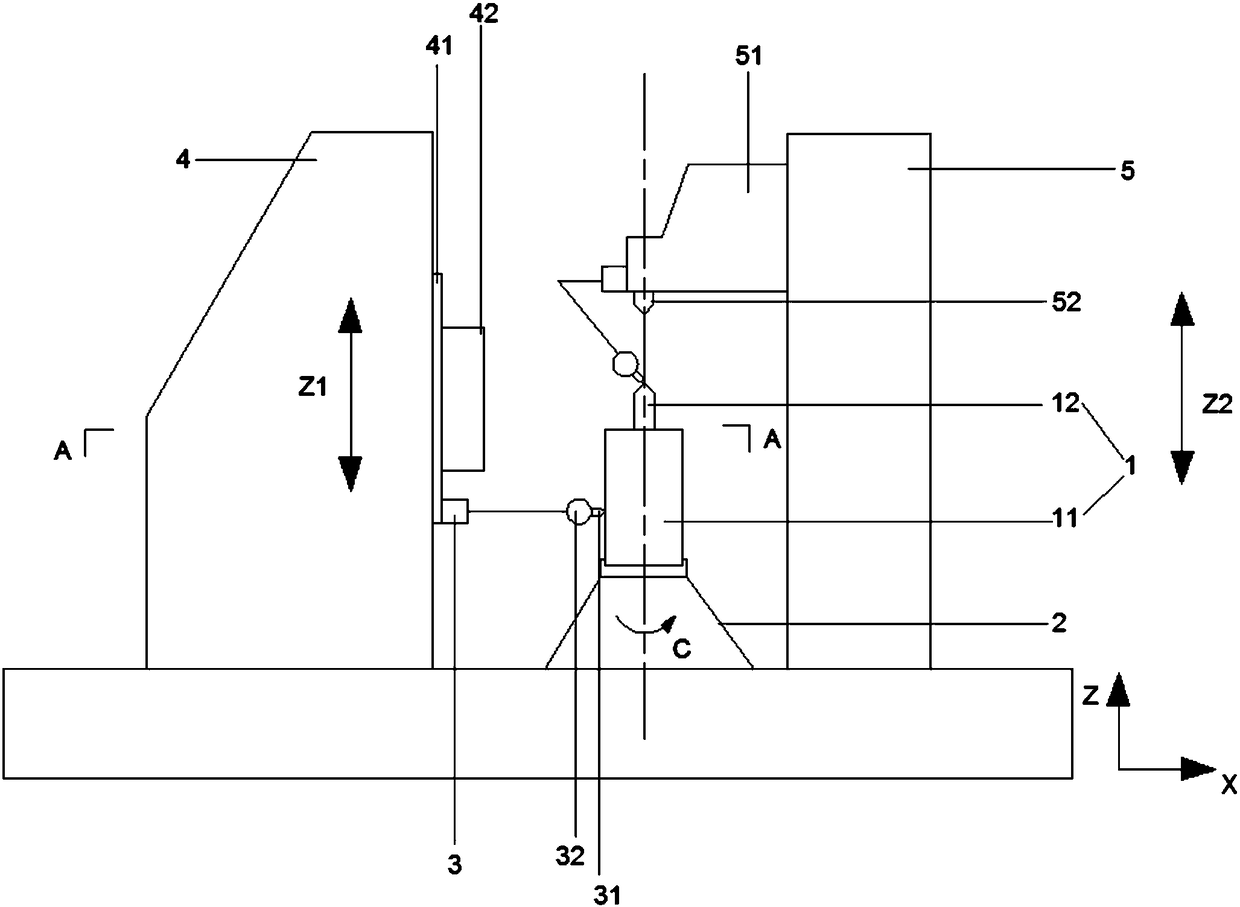

[0023] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0024] A method for detecting the geometric accuracy of a vertical machine tool with an external support, comprising the following steps:

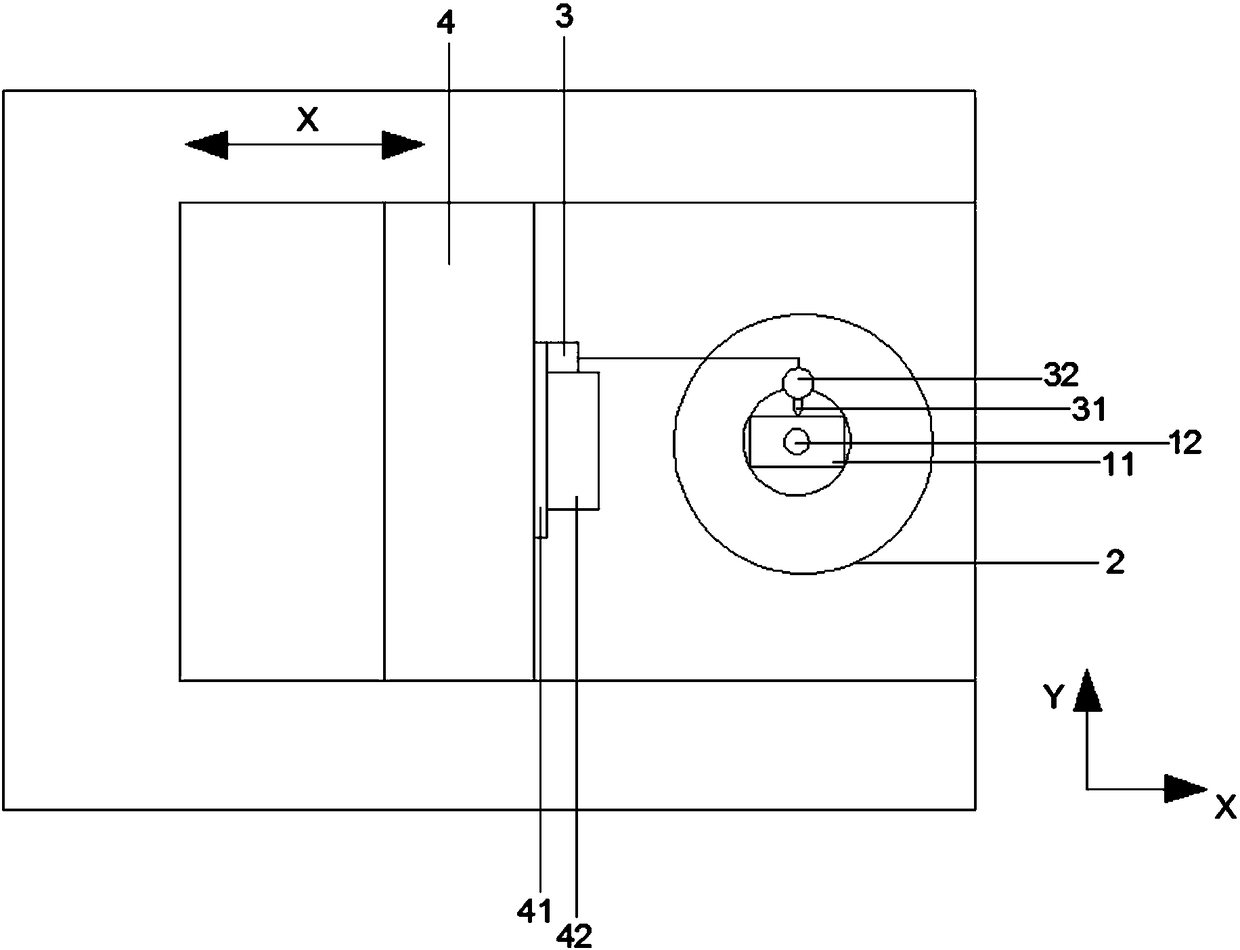

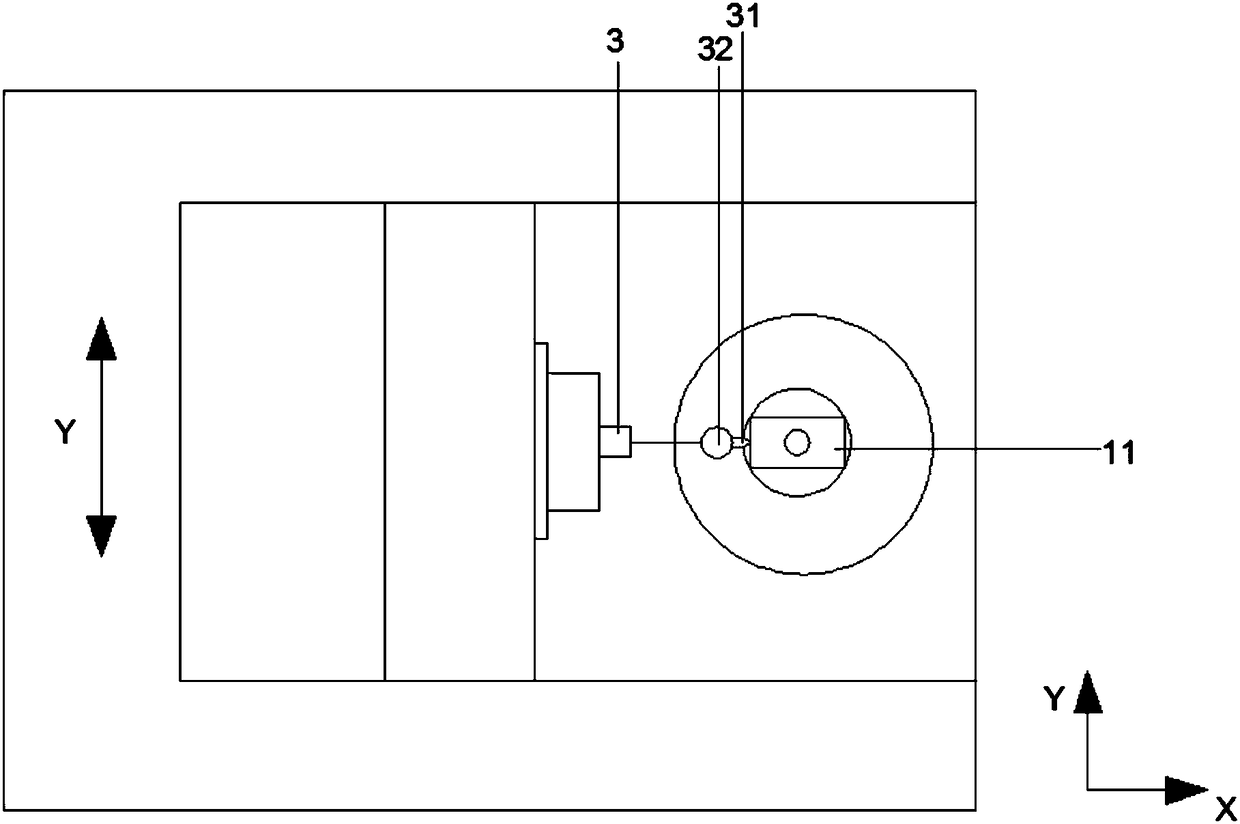

[0025] Step (1), installing the composite inspection tool 1 on the rotary table 2; the composite inspection tool 1 includes a square 11 in the shape of a cuboid, and a top 12 arranged on the top of the square 11 in the direction of its central axis;

[0026] Step (2), correcting the coaxiality of the central axis of the compound inspection tool relative to the central axis C of the rotary table, specifically fixing the magnetic base 3, pointing the needle 31 to the outer cone of the top 12, and starting the rotary table 2 to rotate at a constant speed , adjust the coaxiality according to the deviation value on the dial 32 until the deviation value is zero;

[0027] The purpose of this step is to adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com