Fixative device for decorative finial

a fixing device and decorative technology, applied in the field of decorative finials, can solve problems such as loose or displaced finials, and achieve the effects of improving retention, reducing damage, and reducing the number of screws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Numbered labels identify exemplary features in the drawings. The same numbers are used in multiple drawings to show the same or similar features in the drawings.

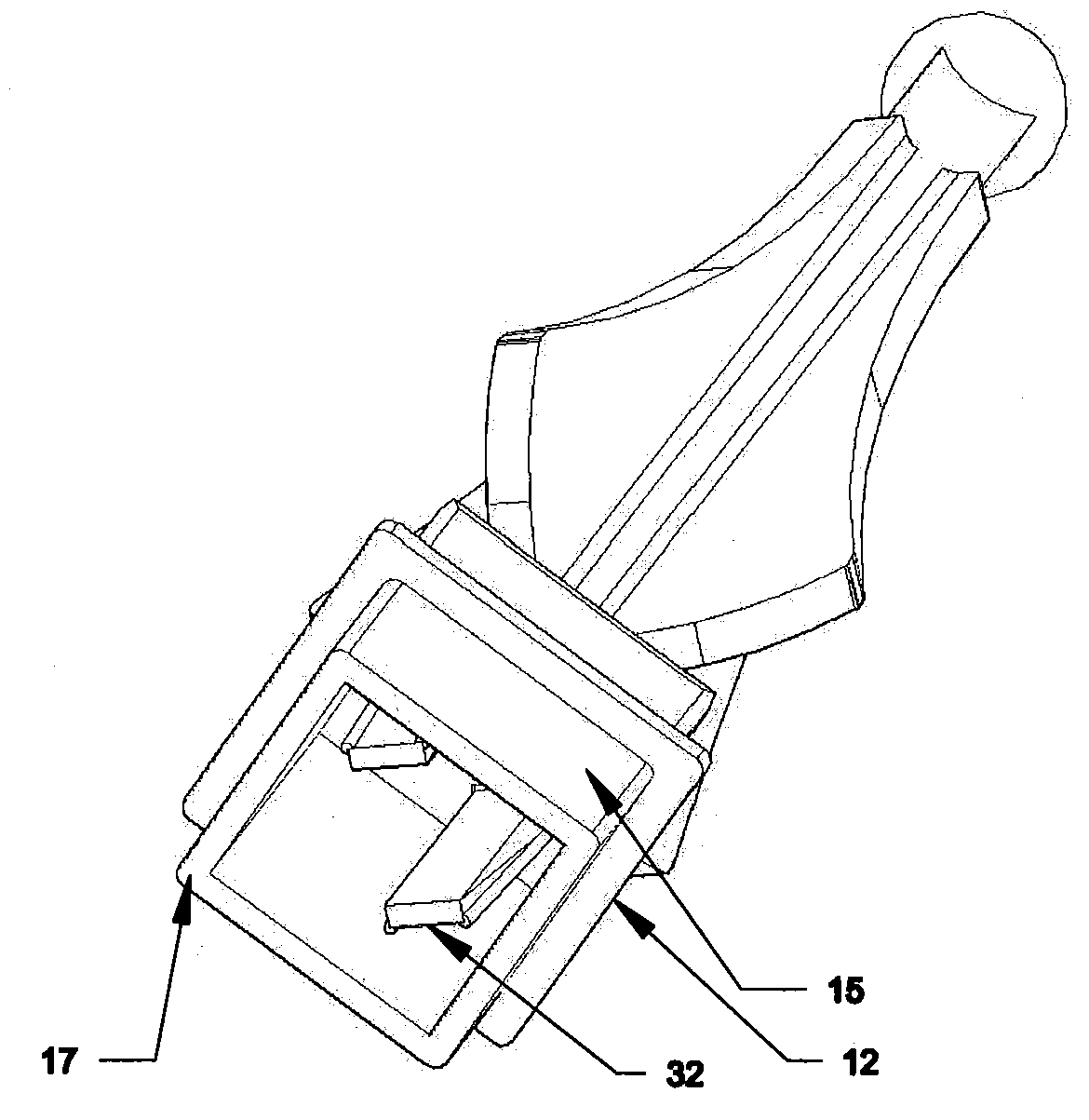

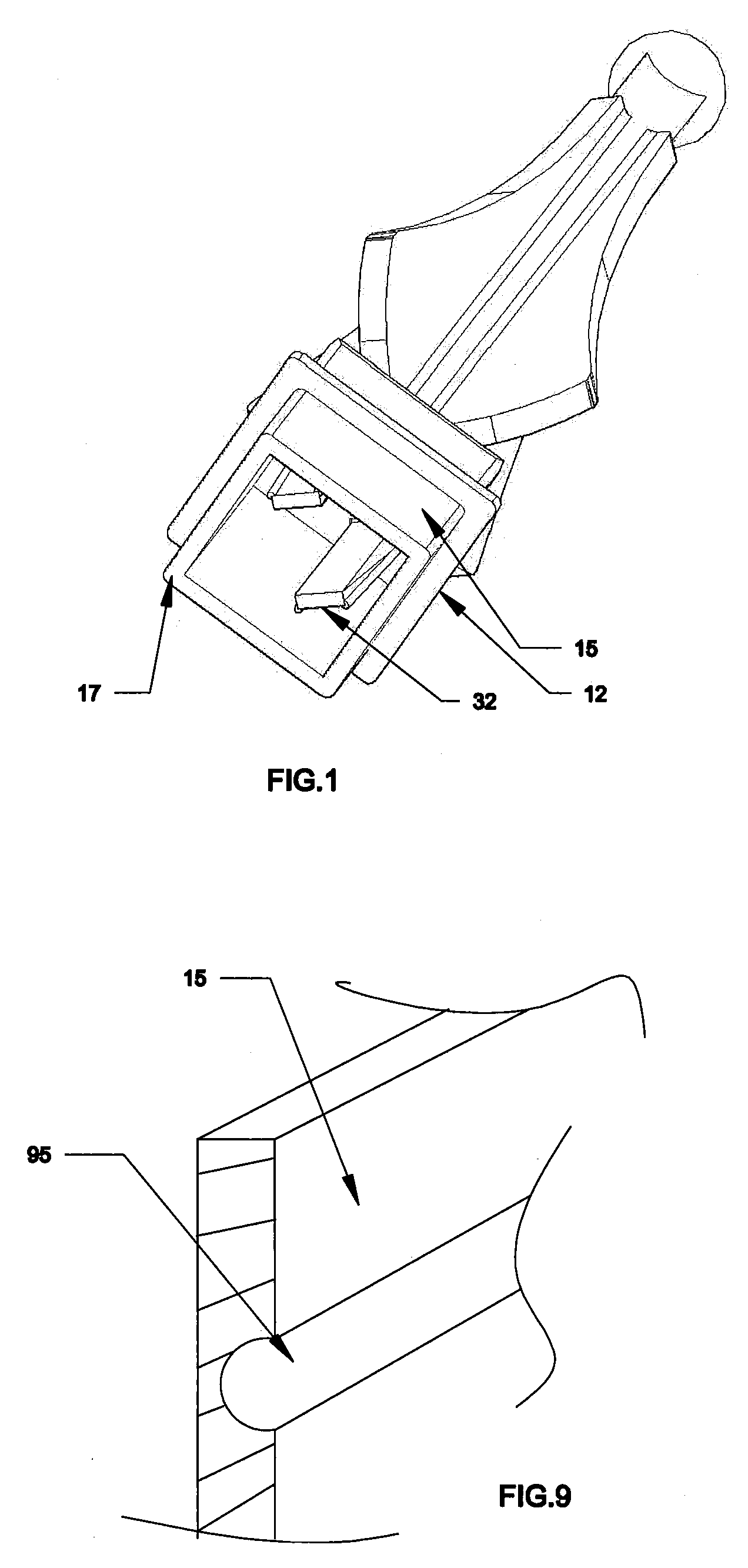

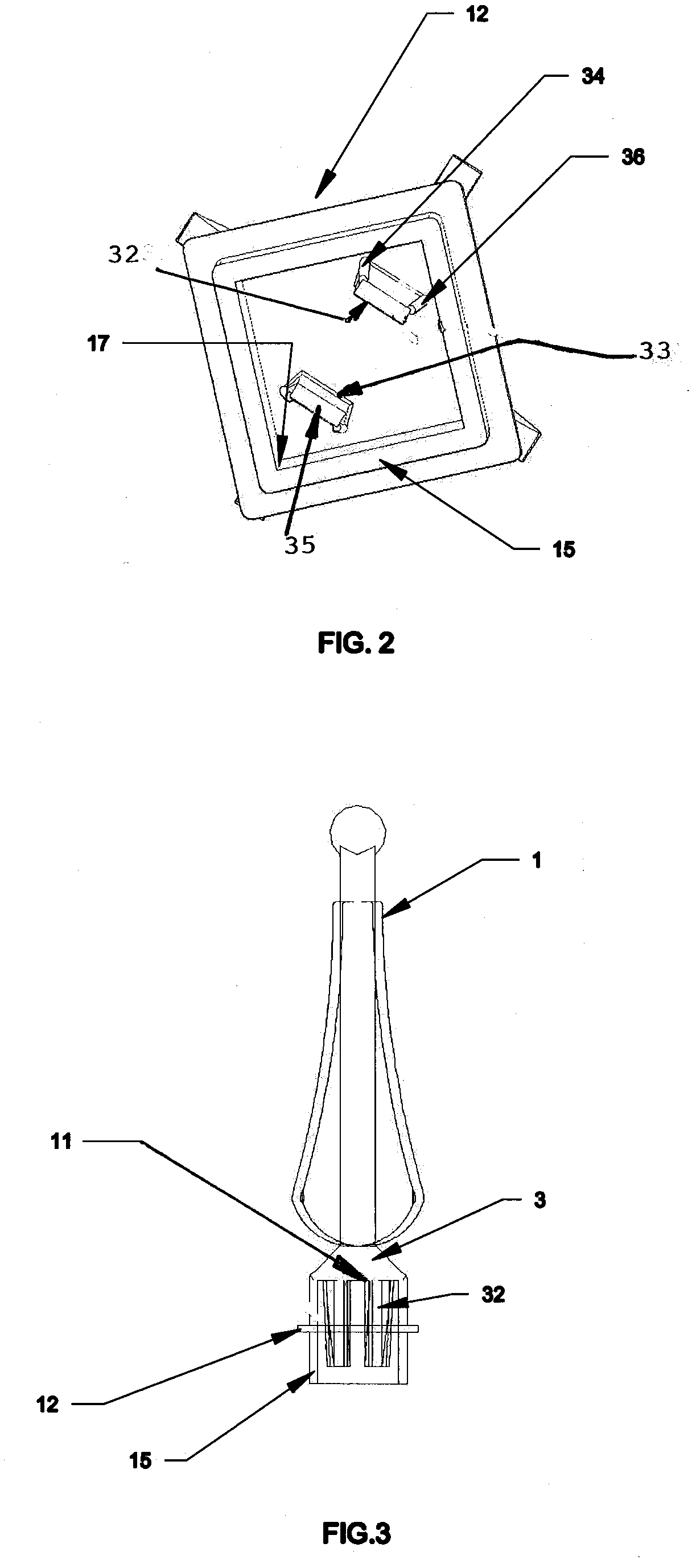

[0026]Now referring to FIG. 1, an example of a decorative finial has a bottom portion with a flange 12. A tubular wall 15 extends outwardly from the bottom of the decorative finial. Tabs 32 extend outwardly from the bottom of the decorative finial and are disposed diagonally across one of the corners 17 of the tubular wall 15. FIG. 2 illustrates a bottom plan view of the arrangement of a plurality of corner tabs 32 integrally formed in a process of molding the decorative finial, such as in a die injection process of a metal or polymer material. For example, aluminum die injection may be used to integrally form the flange 12, tubular wall 15, and four corner tabs 32 in a single die injection process.

[0027]In the example of FIG. 2, each of the tabs 32 has two contact surfaces 34, 36, which extend along opposite sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com