High-efficiency rimer tool sharpening apparatus

A cutting edge and high-efficiency technology, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of affecting the clamping accuracy, difficulty in guaranteeing the runout of the blade, and low work efficiency, so as to ensure the sharpening accuracy and simplify the cutting edge. Grinding operation, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

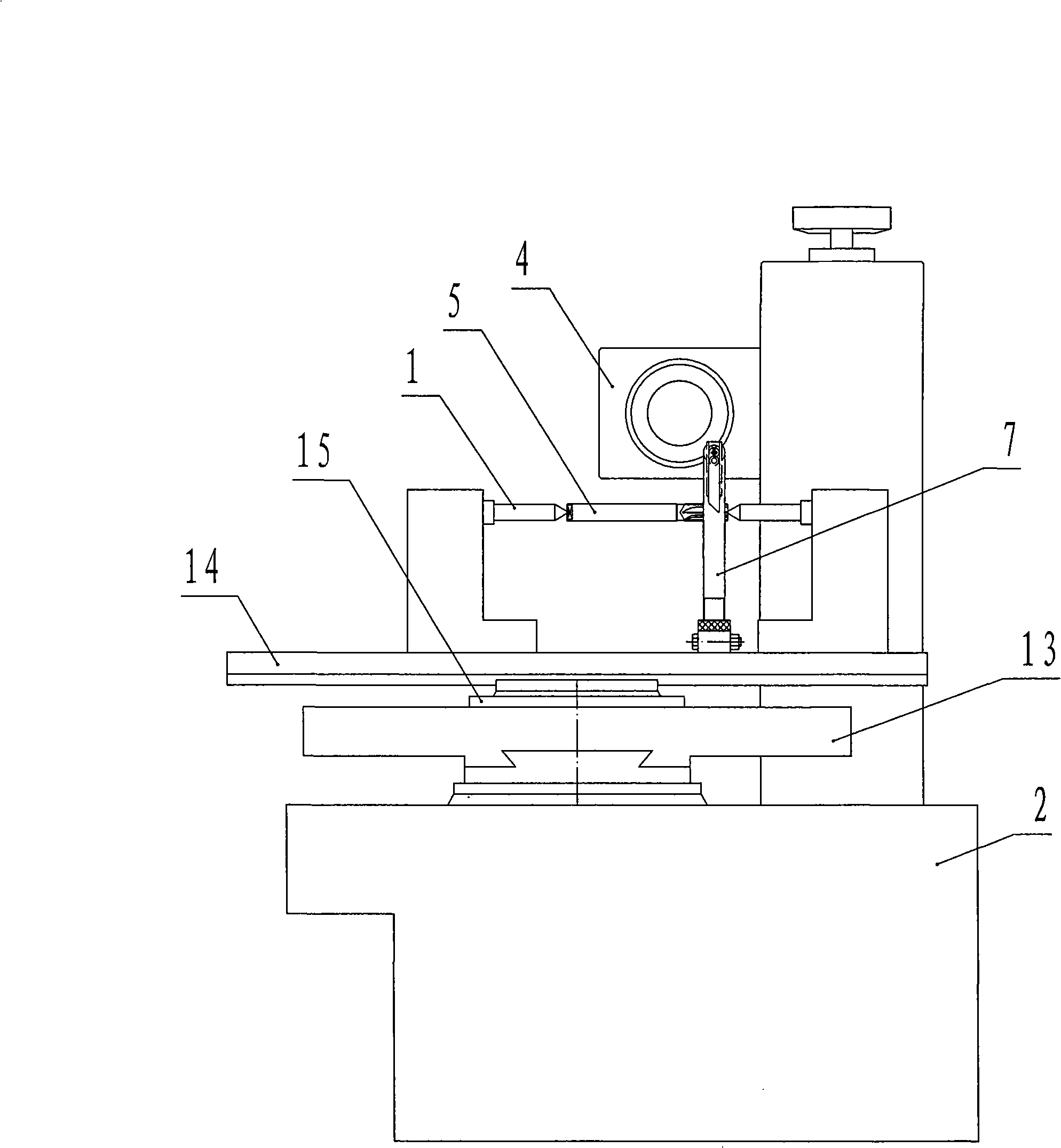

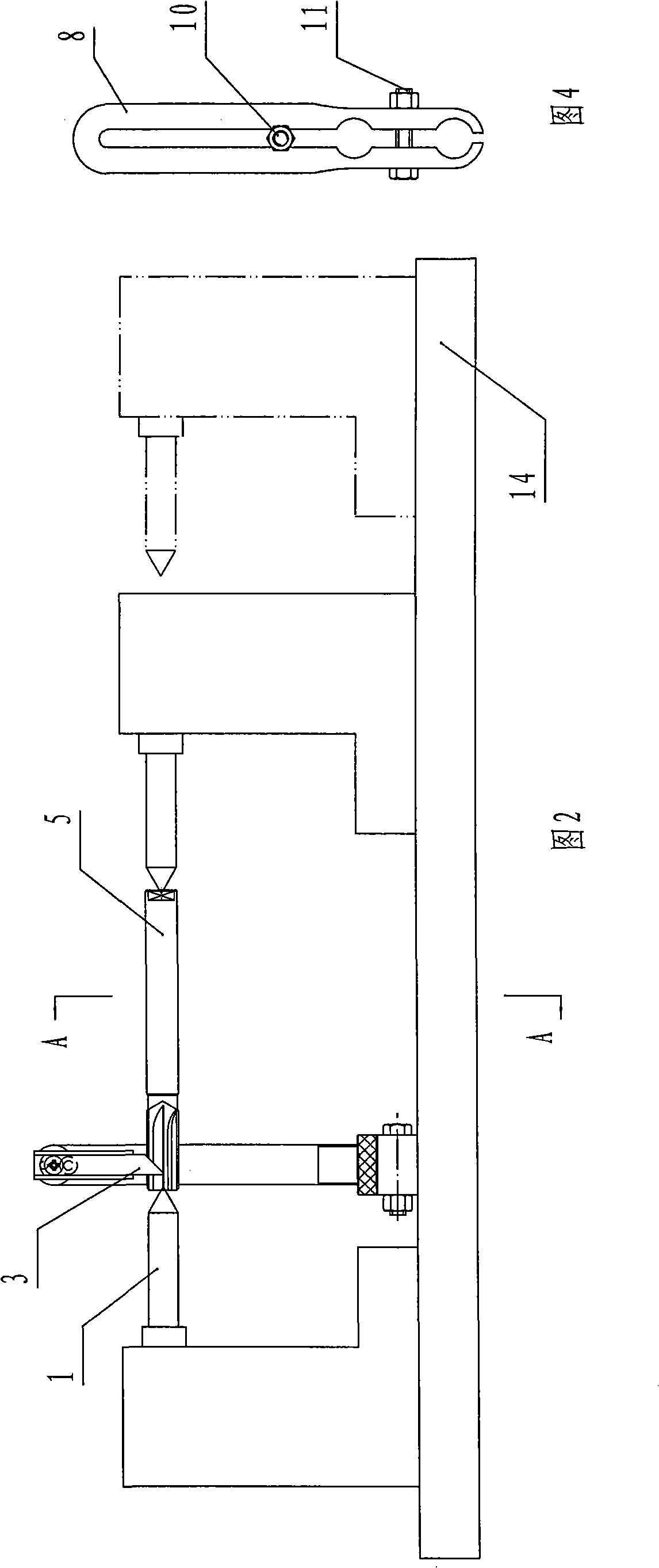

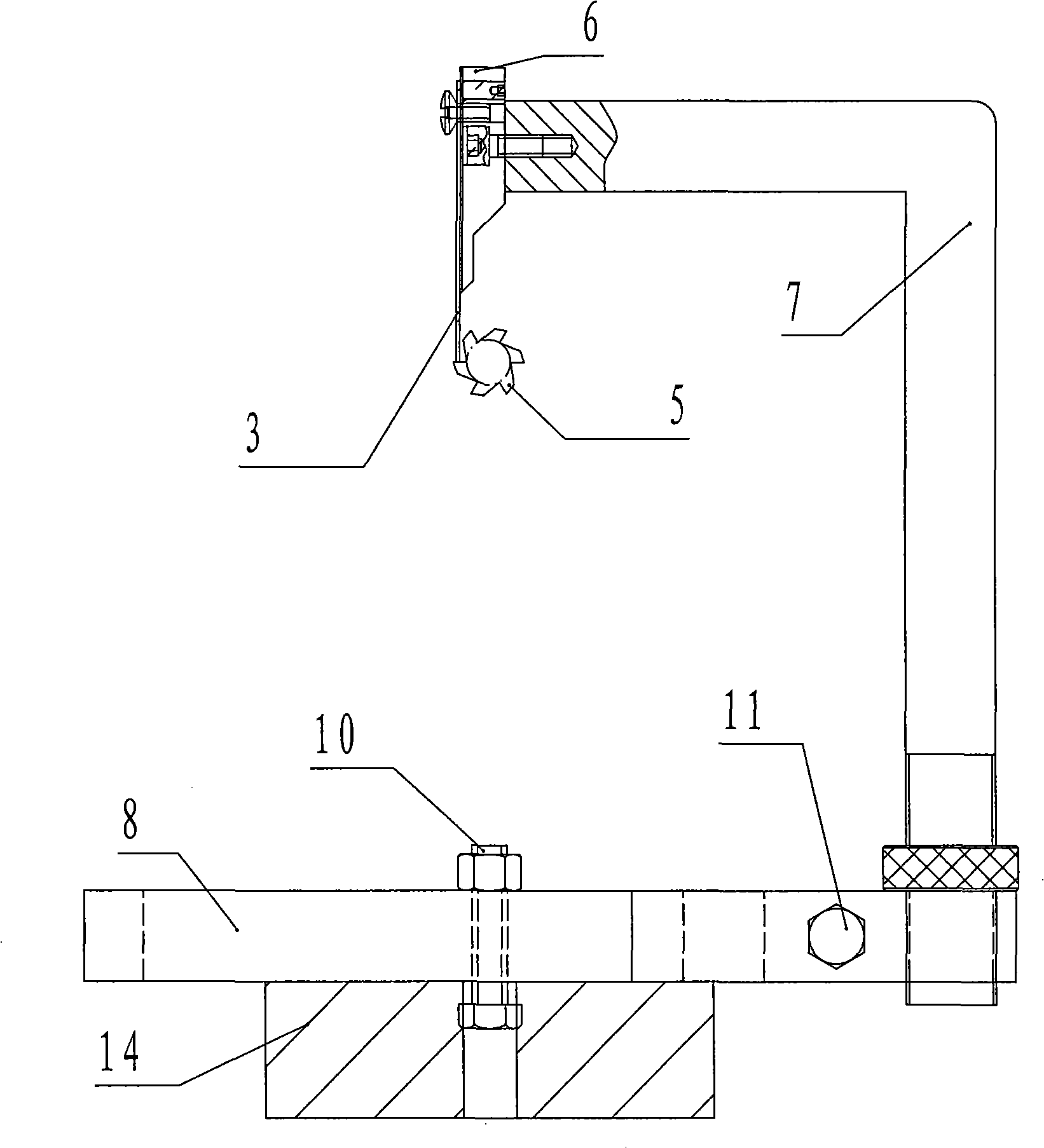

[0018] See figure 1 Figure 2, Figure 3, Figure 4, the present invention is a device that uses an elastic support plate 3 and a reamer clamping center 1 to sharpen the reamer after positioning. The elastic support plate 3 is fixed to the support plate by the support plate fixing bolts 12 On the base 6, the top of the elastic support plate 3 should exceed the adjustment screw 9. The elastic support plate 3 can be adjusted by adjusting the adjustment screw 9. The support plate base 6 is bolted to the upper end of the base support 7, and the base support 7 The lower end of the reamer is connected and fixed by the base support fixing bolt 11 and the connecting frame 8. The connecting frame 8 is connected by the connecting frame fixing bolt 10 to the upper surface of the upper slide plate 14 of the sliding table, and the entire reamer unidirectional rotation control mechanism is therefore fixed On the upper surface of the upper slide 14 of the sliding table.

[0019] Referring to Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com