Fixation apparatus for stator blade profile and journal bounce detection

A stator blade and fixing device technology is applied in the field of fixing devices for stator blade profile and journal runout detection. The rate of journal runout detection, the effect of reducing working time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

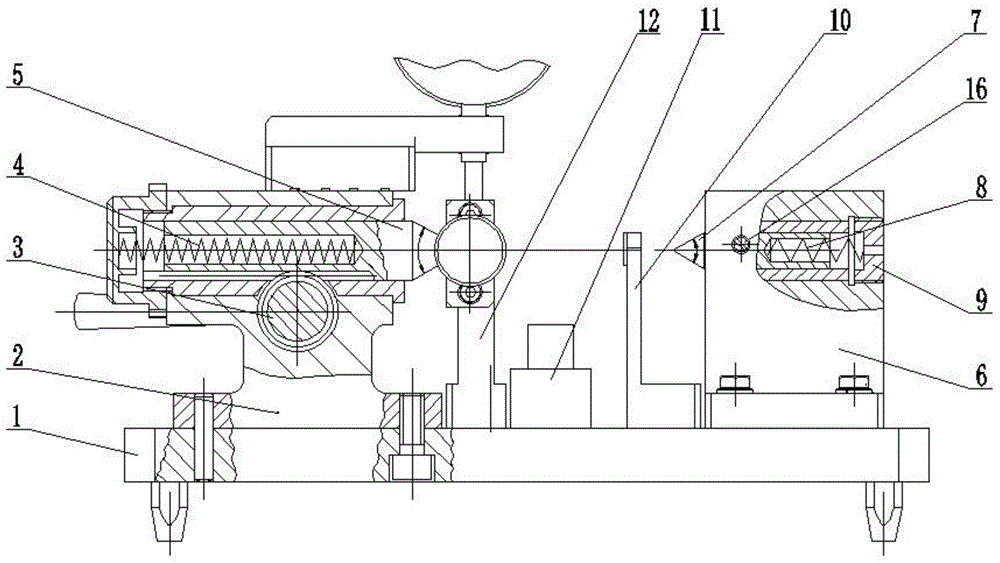

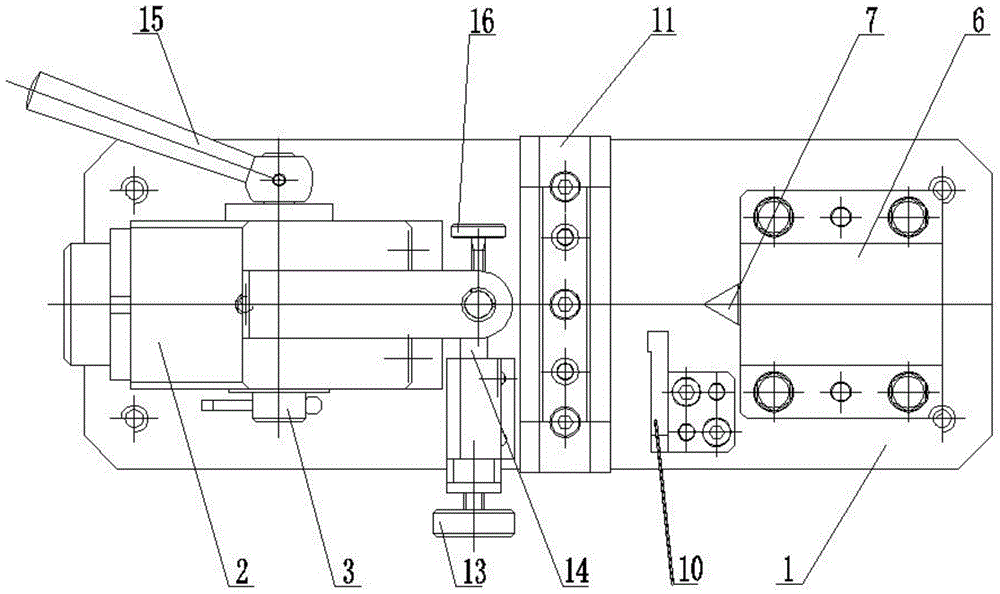

[0014] Example 1, such as figure 1 Shown is a fixing device for stator blade profile and journal runout detection, one side above the base 1 is fixedly connected to the first center seat 2, and the other side is fixedly connected to the second center seat 6, which is arranged on the first center The first apex 5 in the seat 2 is on the same straight line as the second apex 7 arranged on the second apex seat 6, and the action of the handle 15 on the gear 3 is adjusted so that the first spring 4 pushes the first apex 5 along the blade. The axial direction pops up so that the two ends of the blade journal are respectively pressed against the tips of the first center 5 and the second center 7, because the spring force of the first spring 4 is greater than that of the second spring 8 in the second center 7 The relative thrust of the first tip 5 and the second tip 7 fixes both ends of the blade, and the axial positioning surface of the blade is closely attached to the end surface of...

Embodiment 2

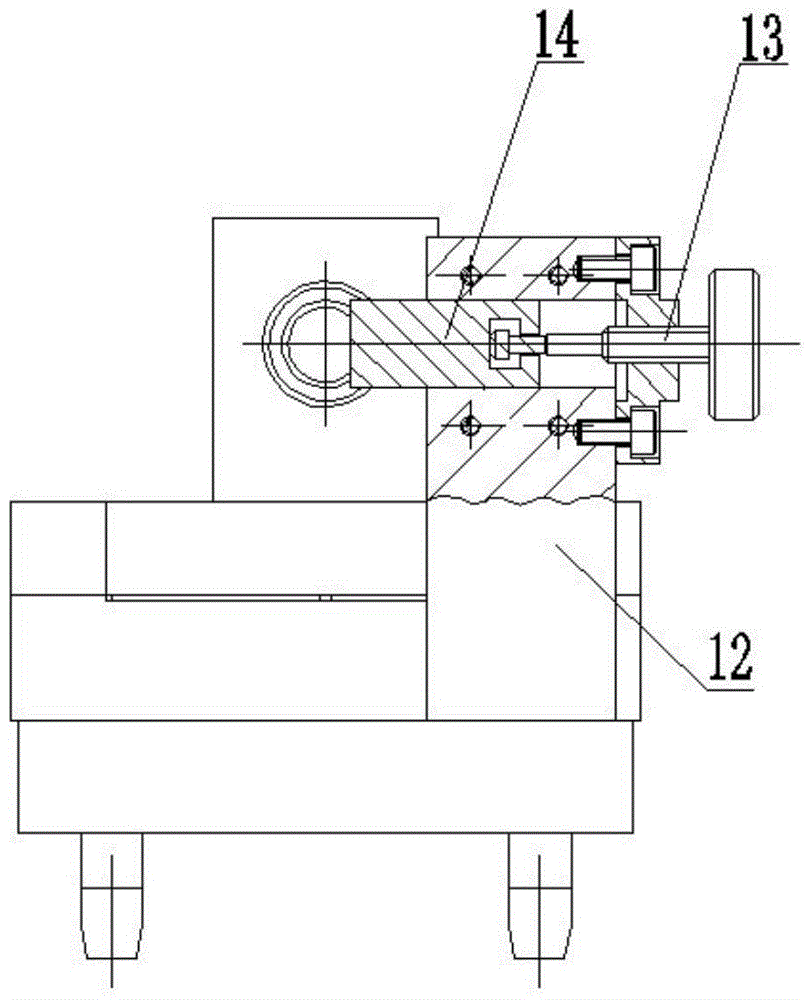

[0015] Example 2, such as figure 1 The shown is a fixing device for stator blade profile and journal runout detection. The premise of detecting the blade journal runout is that the blade can rotate freely between the first center 5 and the second center 7. In order to achieve the above purpose , after detecting the size parameters of the blade profile and the intake side and exhaust side, use the screw 13 to pull the angular positioning plate 14 back into the body 12, and then push the screw plug 9 towards the direction of the blade, so that the second top 7 The axial direction of the blade moves so that the angular positioning plate 14 leaves the end surface of the blade edge plate, and the blade rotates freely around the two tops. A platform surface is made on the first top seat 2 and the second top seat 6, and the table seat is placed On the platform surface, screw 16 fixes the measuring instrument on the table seat, and detects the runout of the blade journal through the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com