Hydraulic screw nut disengaging device

A nut and hydraulic technology, applied in the field of hydraulic nut breaker, can solve the problems of difficult disassembly and inconvenient use, and achieve the effect of simple operation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

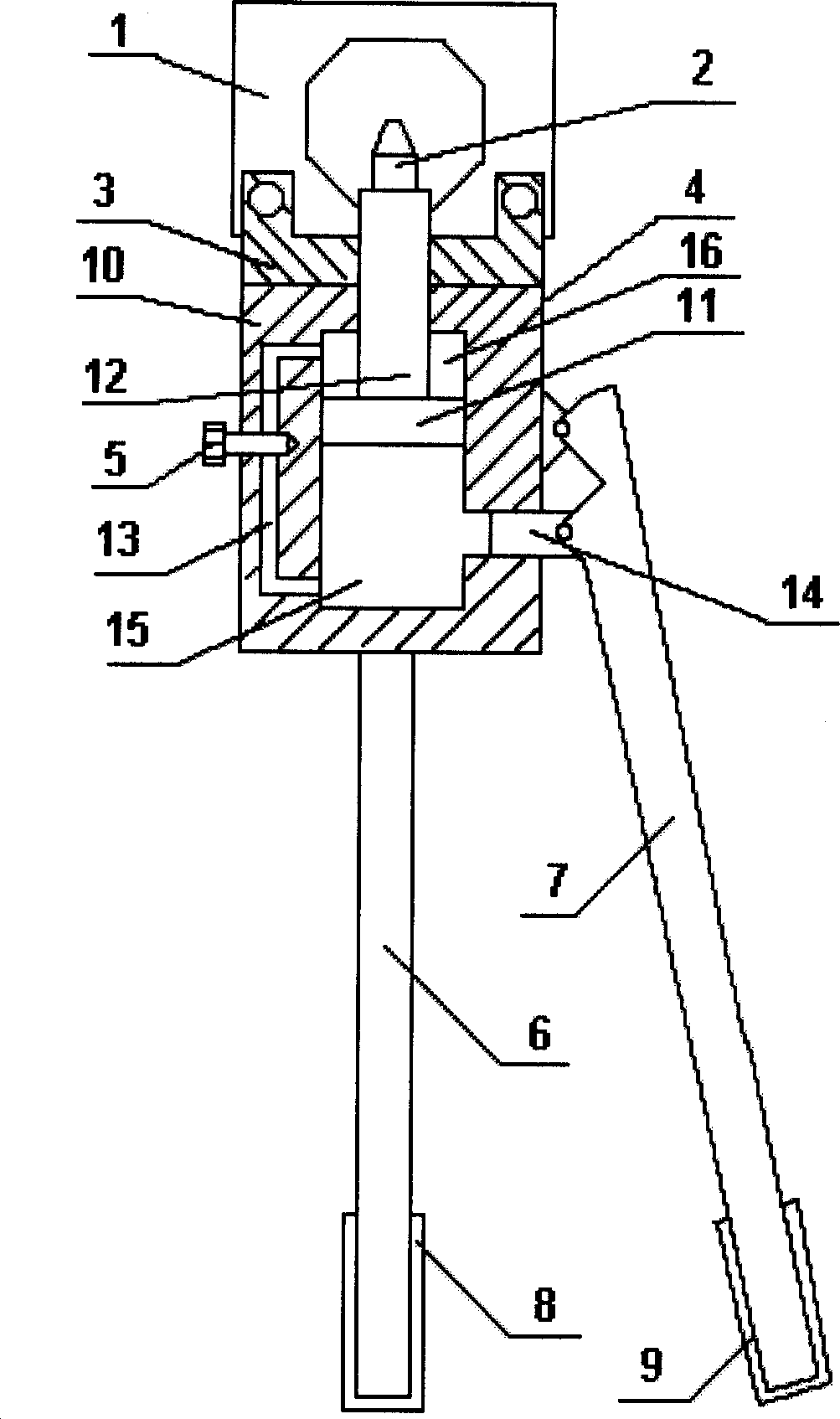

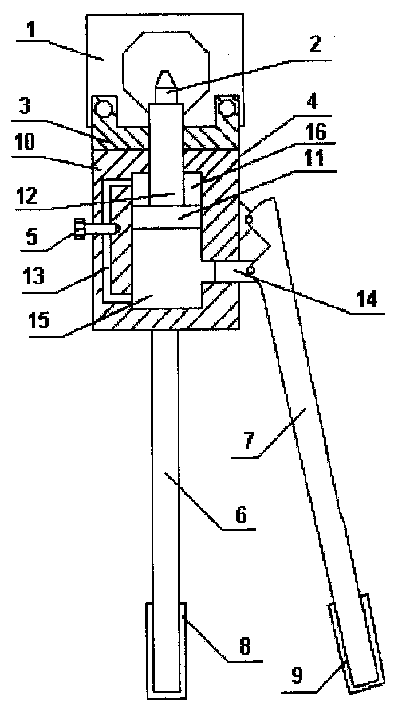

[0007] Such as figure 1 As shown, the hydraulic nut breaker of the present invention consists of a pressure head 1, a top 2, a pliers head 3, a hydraulic pump 4, an oil return nut 5, a fixed handle 6, a movable handle 7, a fixed grip 8 and a movable grip 9 Composition, the described indenter 1 is provided with a central hole, the shape of the described central hole can be a regular hexagon, one end of the described indenter 1 is provided with a slit, and the two sides of the indentation of the described indenter Connect with one end of the pliers head 3, the specific connection method can be a screw connection, a circular through hole is arranged on the axial centerline of the pliers head 3, and the pliers head 3 and the hydraulic pump 4-phase connection, the specific connection method can be welding connection, the hydraulic pump 4 is composed of a pump body 10, a piston 11, a piston rod 12, an oil return line 13, a small piston 14, an oil storage chamber 15 and an oil pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com