Roll grinder for grinding guide rolls of aluminum foil processing equipment

A technology of processing equipment and roller grinder, which is applied to machine tools, metal processing equipment, grinding/polishing equipment designed for grinding the rotating surface of workpieces, etc. The effect of operating costs, reducing investment costs, and improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

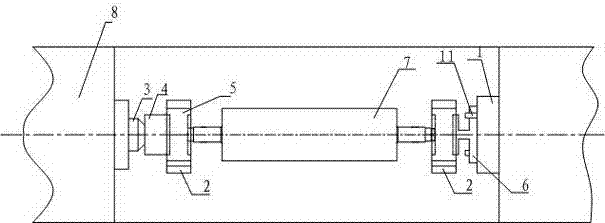

[0030] refer to figure 1 As shown, the guide roller 7 is assembled and supported on the roll grinder 8, and the bearings at both ends of the guide roller 7 are installed with support circles 5, and at the end of the power source on the right, the outside of the support circle 5 is fixedly connected with the connector 6 through screws, and the connection The outer side of the device 6 is clamped with the adjustable claw 11 of the rotary chuck 1. At the non-power source end on the left, the supporting circle 5 is supported and fixed by the top 3 and the nylon block 4, and the nylon block 4 is supported on the concave of the supporting circle 5. Inside the groove 52.

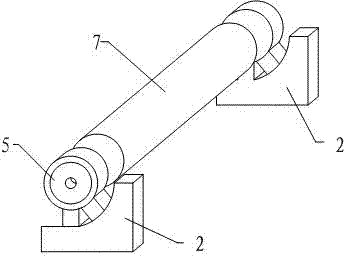

[0031] Such as figure 2 As shown, after the guide roller 7 is assembled, it is placed on the bracket 2, and the supporting circles 5 at both ends are supported on the bracket 2 for grinding;

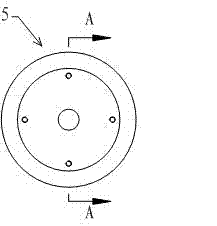

[0032] Such as image 3 and Figure 4 As shown, the support circle 5 is cylindrical as a whole, with a shaft hole 51 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com