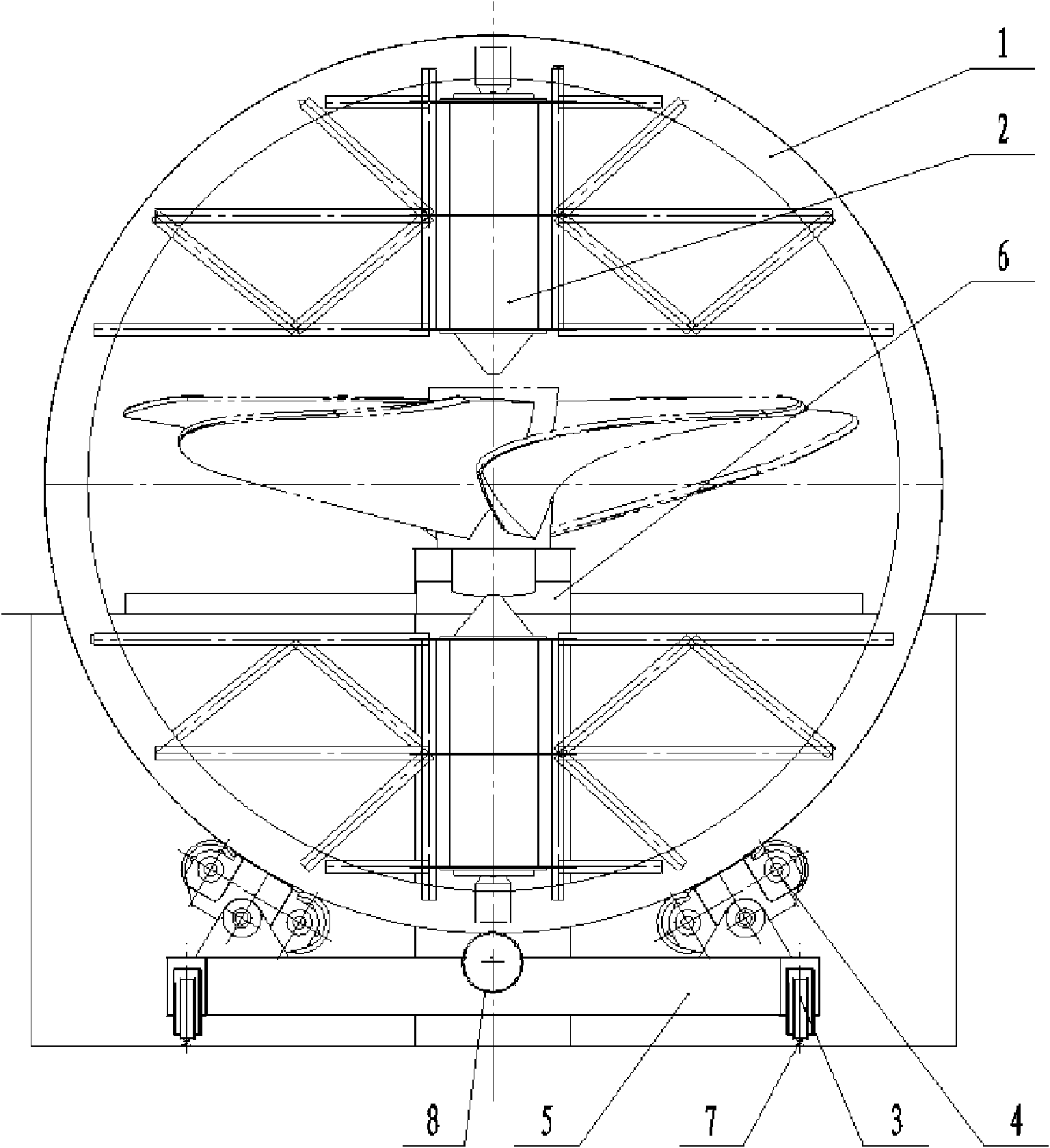

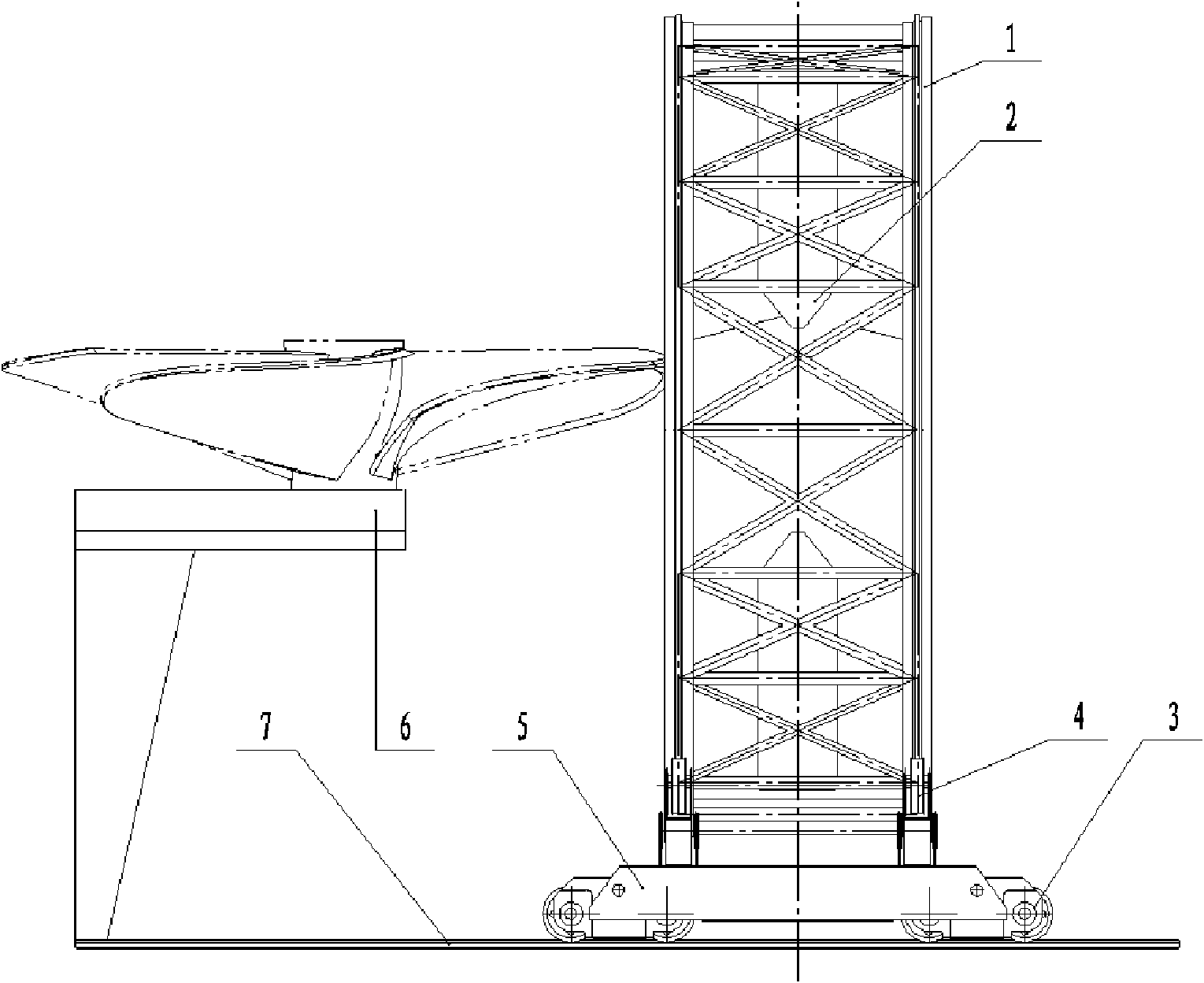

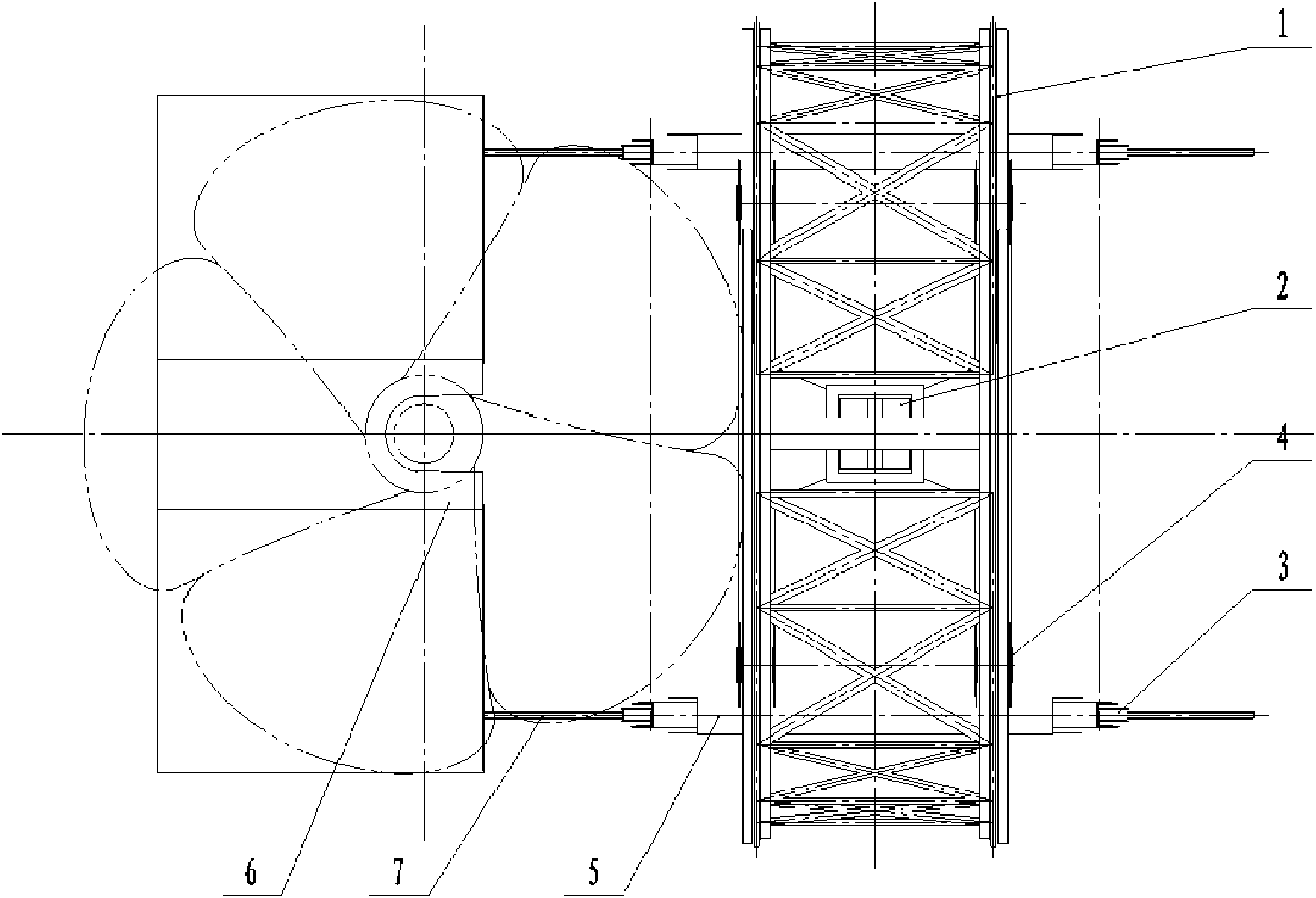

Sideway roller type propeller tipper

A propeller and turning machine technology, applied in metal processing, etc., can solve the problems of unsafe operation, easy damage to the propeller, high operating intensity, etc., and achieve the effect of safe and efficient turning operation, reasonable force, and safe turning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0012] The traversing trolley 5 is at its right limit position, and the inverted propeller is placed on the U-shaped support frame 6; the adjustable top 2 on the runner 1 is in a retracted state, the opening is horizontal, and the traversing trolley is driven to the left 5. Make the tip align with the center hole of the propeller; extend the upper and lower tips in order to make the propeller leave the U-shaped support frame 6 and clamp it; drive the traverse trolley 5 to the flip position to the right, and adjust the upper and lower tips according to the weight data of the turned propeller Make the overall center of gravity of the propeller and the runner 1 near the center of rotation of the runner; start the turning wheel set 4 to make the runner 1 turn over 180 degrees; drive the traversing trolley 5 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com