Patents

Literature

56results about How to "Safety flip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

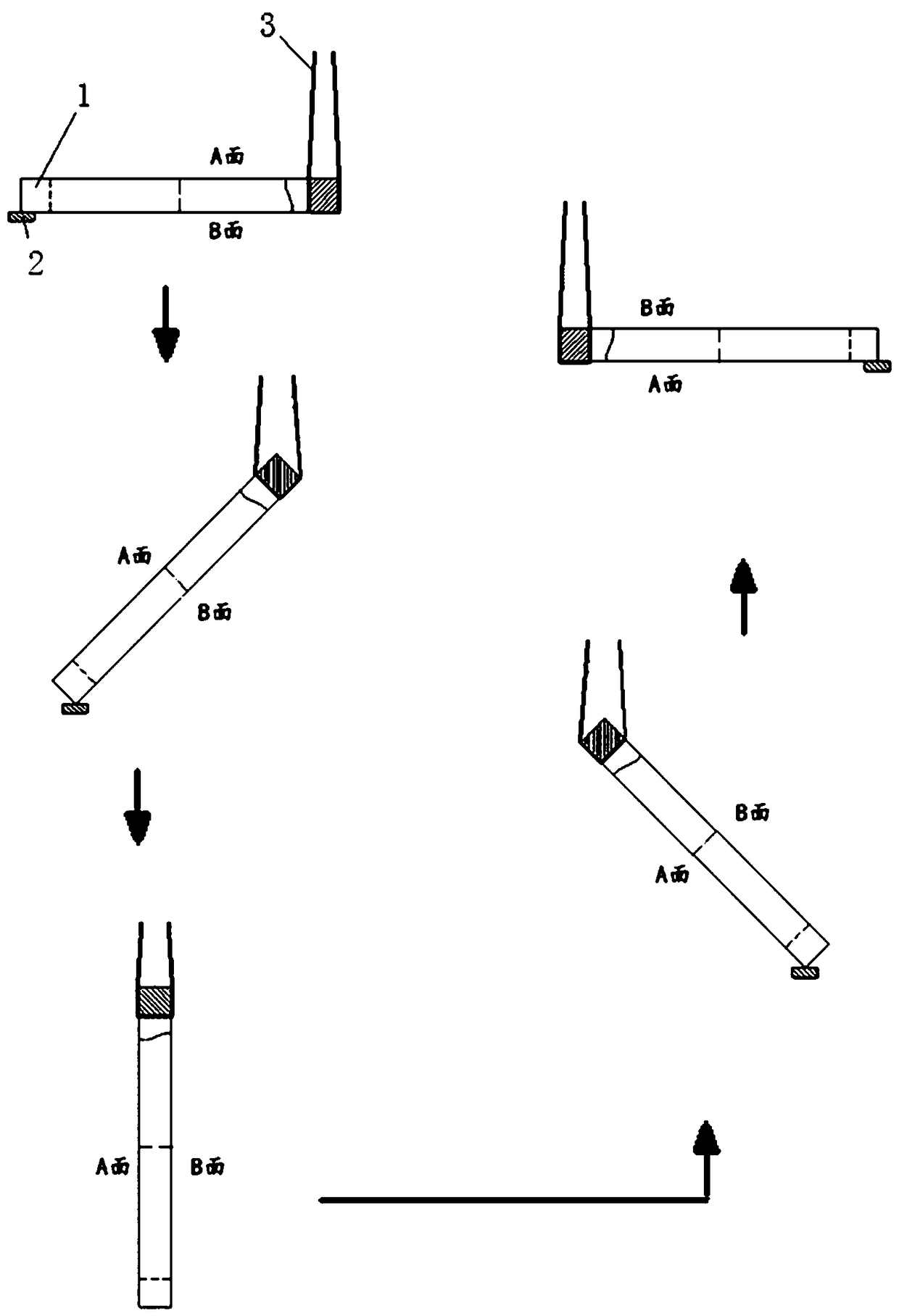

Overturning and lifting method for major-diameter superheavy end socket

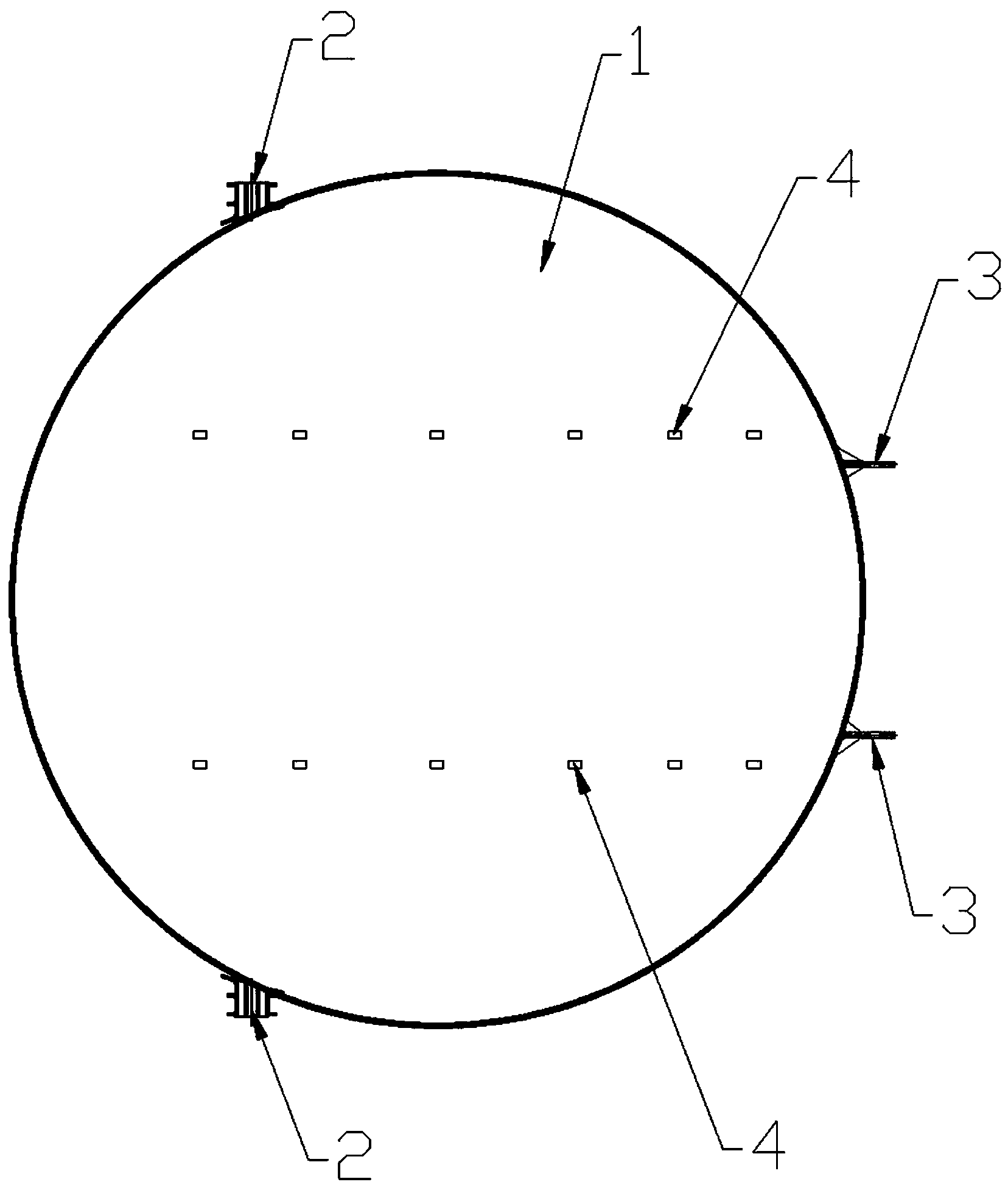

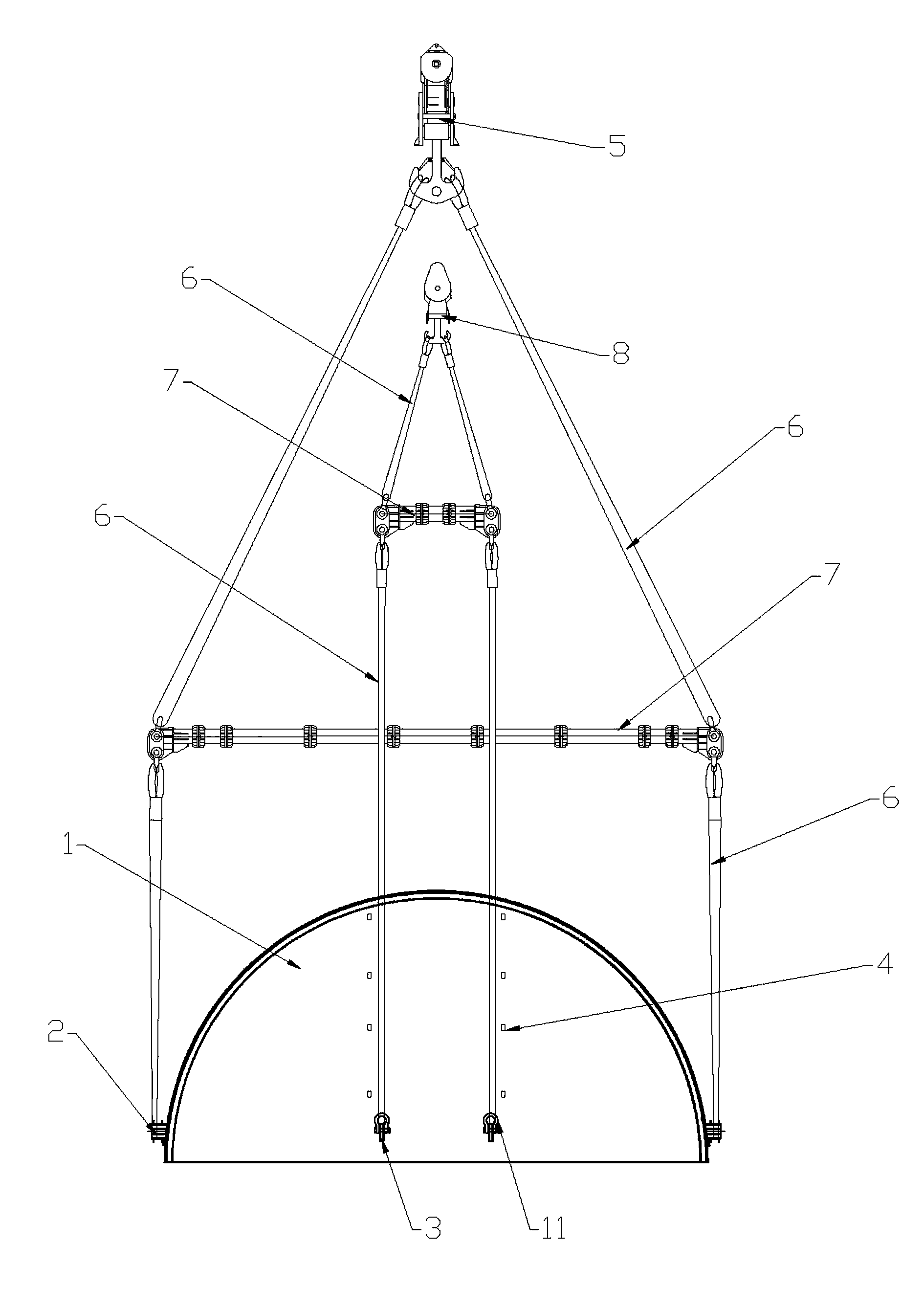

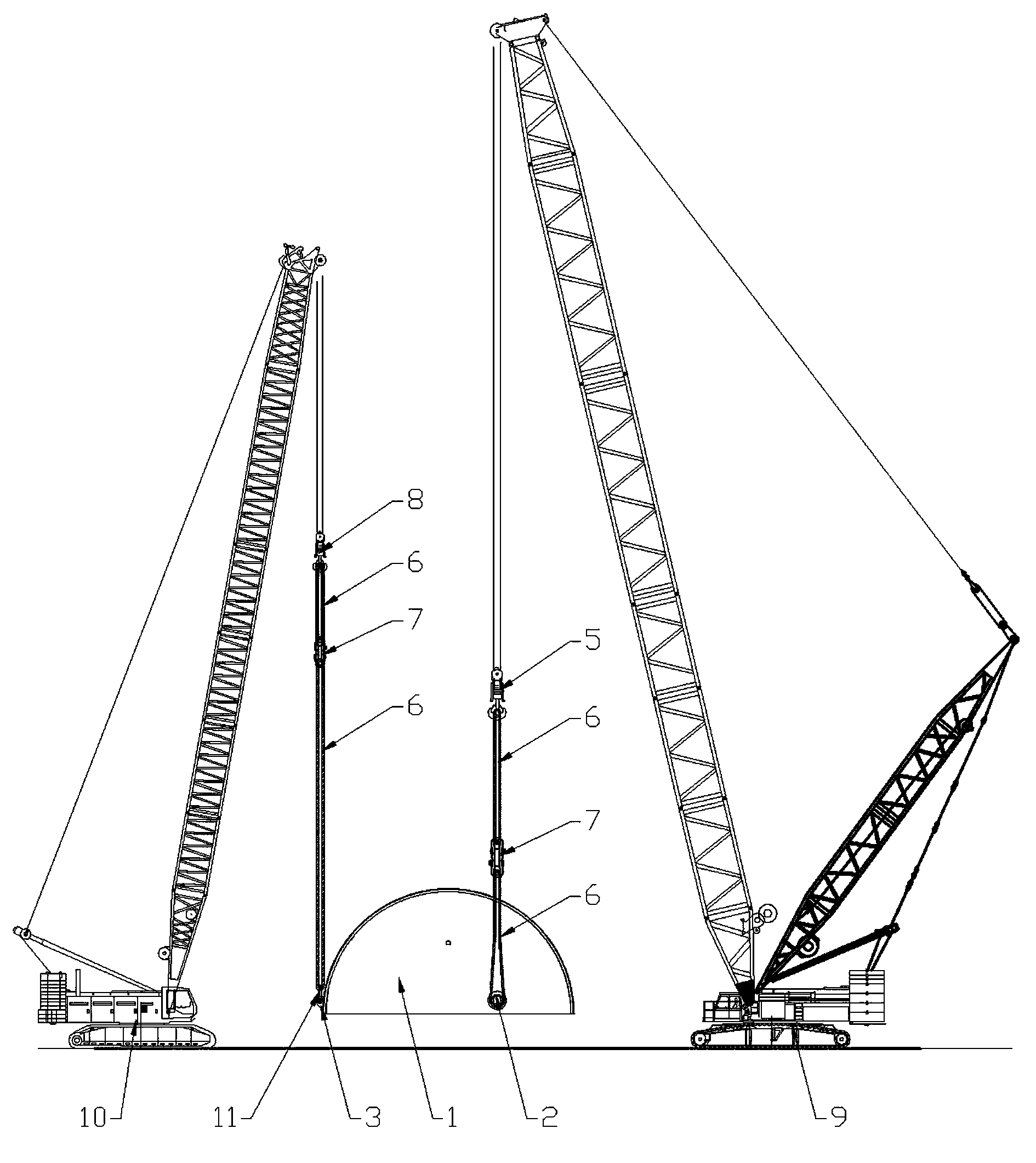

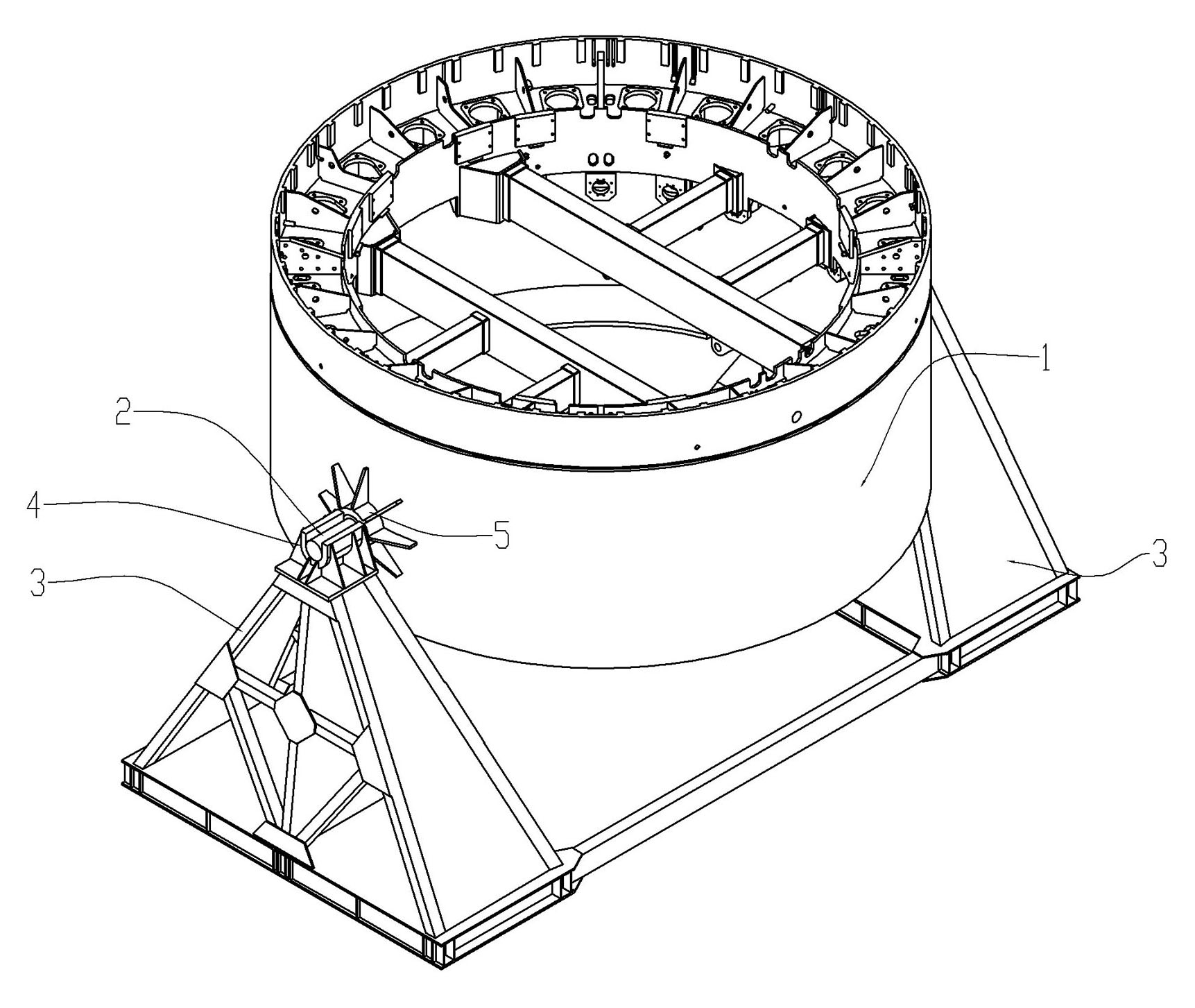

The invention discloses an overturning and lifting method for a major-diameter superheavy end socket. The overturning and lifting method comprises the following steps: first, two main lifting lugs and at least one tail slipping lifting lug are arranged on the outer wall of the end socket correspondingly; a main hoist is connected with the main lifting lugs respectively through a main rigging mechanism, and an auxiliary hoist is connected with the tail slipping lifting lugs respectively through an auxiliary rigging mechanism; the main hoist and the auxiliary hoist are started to lift the end socket at the same time, the auxiliary hoist stops operating after the end socket leaves the ground by a certain distance, and the main hoist continues to lift the end socket; the end socket rotates autonomously around the main lifting lugs under the action of the self weight, the auxiliary hoist decreases a load gradually, and the main hoist stops operating and enables the auxiliary rigging mechanism to be operated from the tail slipping lifting lugs when the load of the auxiliary hoist is zero; the end socket is rotated 180 degrees and then connected with the tail slipping lifting lugs again, and the auxiliary hoist operates to enable the end socket to be overturned to a horizontal state, namely overturning operation is completed. The overturning and lifting method enables the major-diameter superheavy end socket to overturn in a self-balancing mode with unequal moments under the action of the gravity of the major-diameter superheavy end socket, the overturning process is smooth and safe, and the quality perfectness ratio is 100% after the overturning process.

Owner:SINOPEC NANJING ENG & CONSTR +2

Turning-over method, structure and device for large-scale equipment

Owner:广州广船国际股份有限公司

Mould cleaning device of pipe pile production line

PendingCN107971254AFall off quicklyFully cleanedCleaning using toolsCleaning using liquidsProduction lineSteel frame

The invention belongs to the technical field of cleaning devices, in particular to a mould cleaning device of a pipe pile production line. The mould cleaning device comprises a frame-shaped bracket, wherein a pipe mould turnover mechanism, a pipe mould cleaning mechanism and a pipe mould lifting mechanism are arranged on the frame-shaped bracket; the pipe mould cleaning mechanism comprises a sliderail, a water storage slot, a water-resisting rib plate, a movable bracket, a translation drive mechanism, a rolling brush, a tool, a high-pressure spray gun bracket, a high-pressure spray gun, a mould release agent storage box, a high-pressure water pump, a turbofan and a water pump electrical appliance box; the pipe mould turnover mechanism comprises a second slide rail, a travelling bracket, atravelling drive mechanism, a belt wheel drive motor, a belt wheel box, a belt wheel, a scissors type bracket, a supporting arm and a ring-shaped lifting belt; and the pipe mould lifting mechanism comprises a third slide rail, an air cylinder fixing frame, a lifting air cylinder, a tube mould support plate, a n-shaped bracket, a guide post slide sleeve, a guide post and a second air cylinder. According to the mould cleaning device disclosed by the invention, a steel frame structure is matched with the precise rail travelling tool, the rolling brush and the high-pressure spray gun, so that high-speed effective mould cleaning is realized.

Owner:ZHEJIANG JINGDIAN CNC EQUIP CO LTD

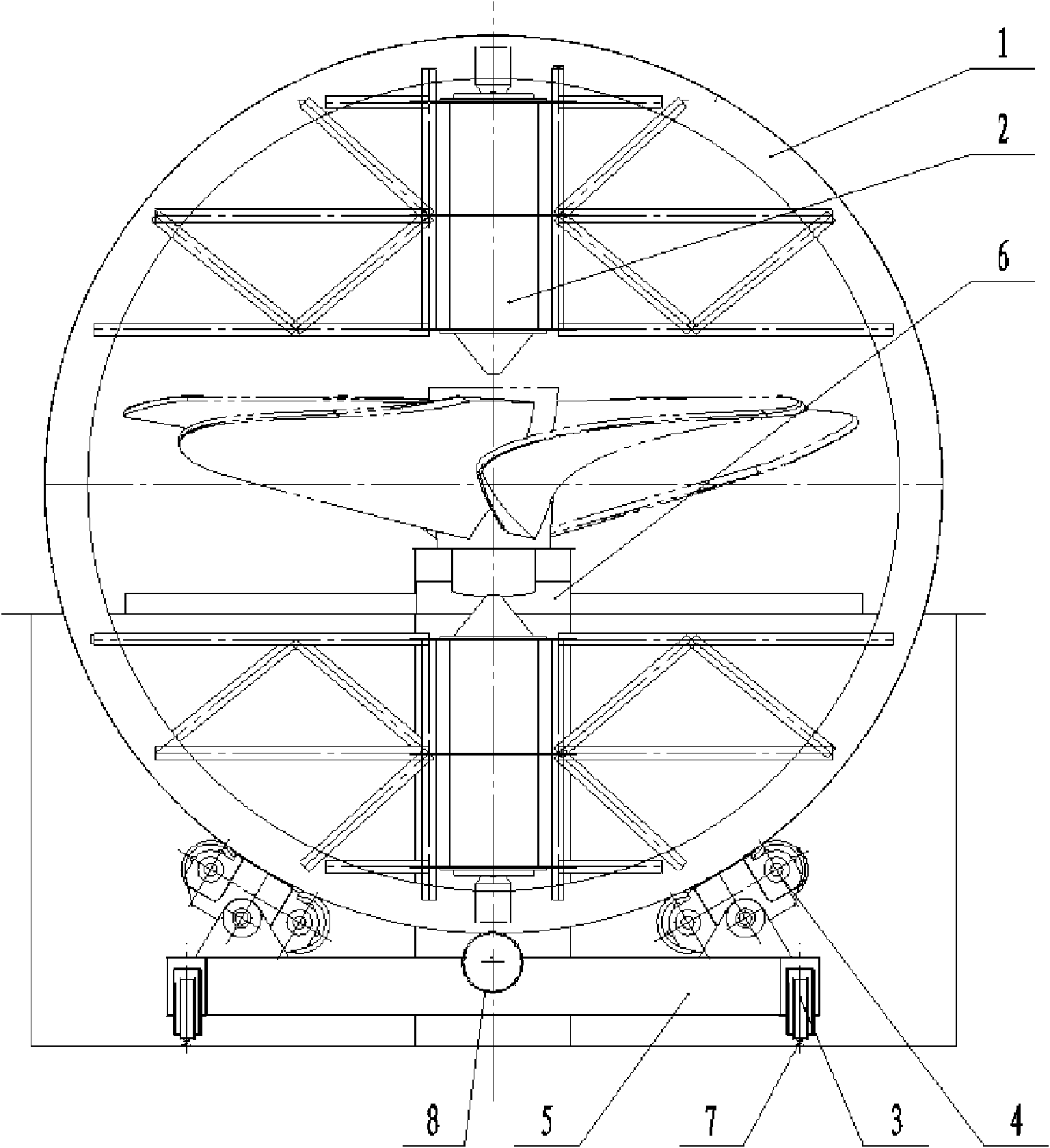

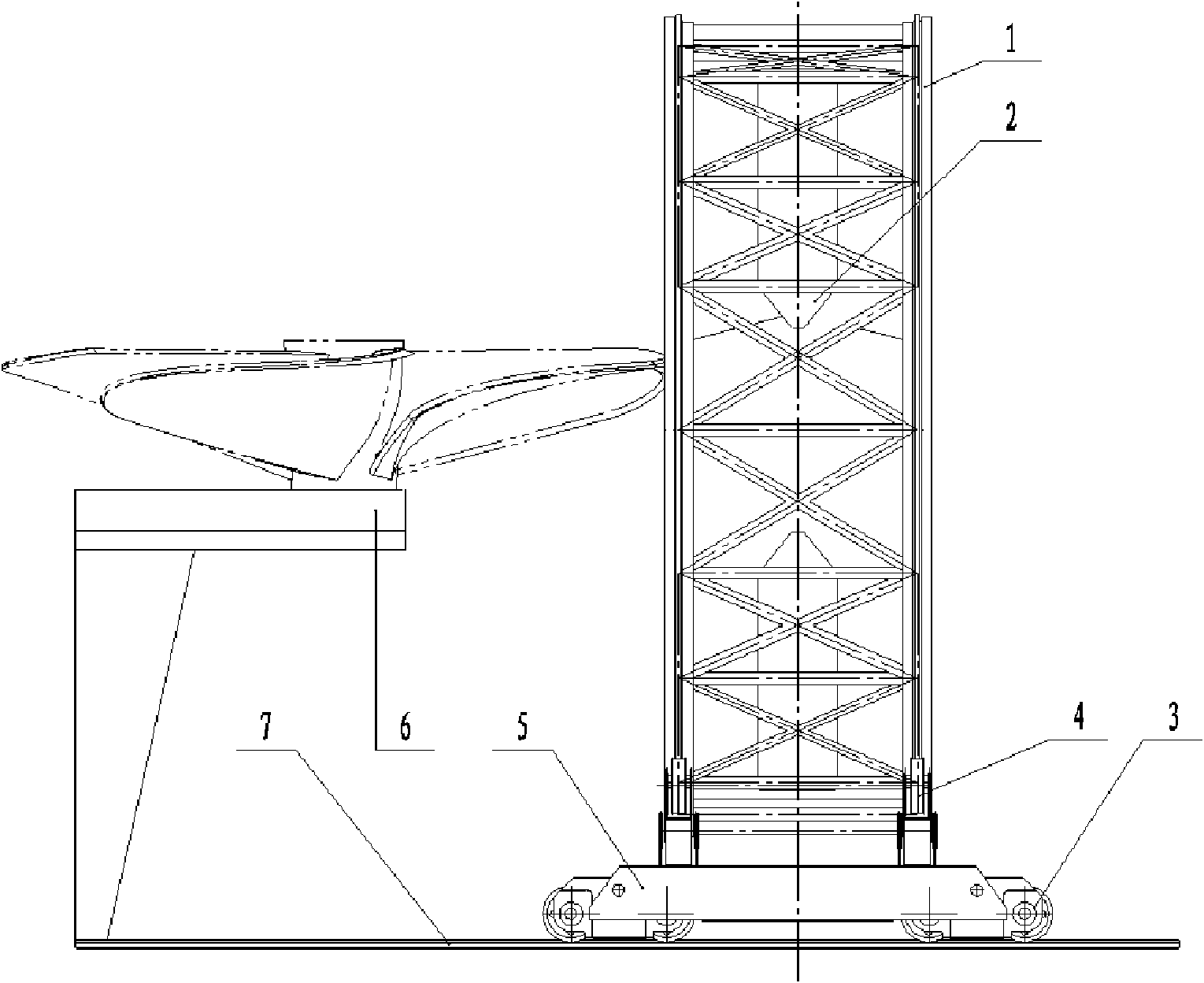

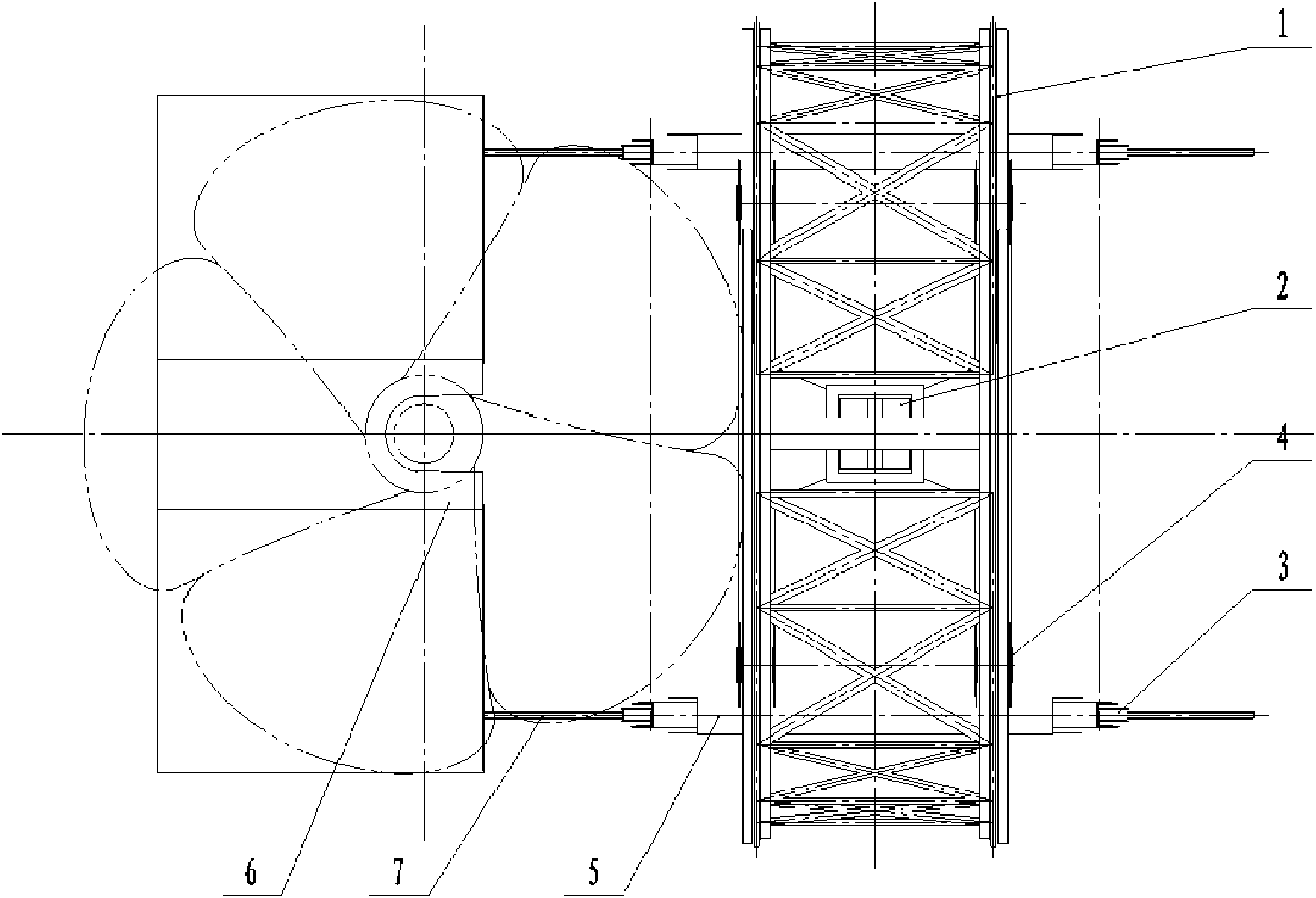

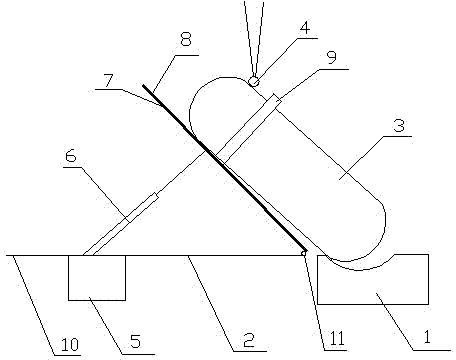

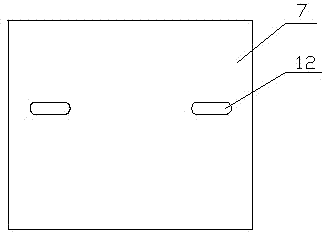

Sideway roller type propeller tipper

The invention discloses a sideway roller type propeller tipper and belongs to the technical field of mechanical manufacturing. The whole tipper consists of a turning wheel, adjustable finials, wheel sets, turning wheel sets, a sideway trolley, a U-shaped supporting rack, a track and a turning drive mechanism. The shaftless turning wheel is used as a core part of a turning device; the turning wheel is provided with a horizontal opening; and the upper part and the lower part of the opening are symmetrically distributed with two sets of the adjustable finials. The sideway trolley is provided with four wheel sets, four turning wheel sets and the turning drive mechanism, wherein the wheel set is used as a sideway walking device; and the turning wheel set is used as a supporting and turning drive device of the turning wheel. The U-shaped supporting rack has a fixed supporting structure for putting a propeller before and after the turning. The U-shaped opening allows the turning wheel and the U-shaped supporting rack to complete the butt joint of the propeller. The sideway roller type propeller tipper has the advantages of compact structure, light weight, reasonable stress, simple auxiliary process, safe and high-efficient turning operation and small turning drive power.

Owner:DALIAN UNIV OF TECH

Large glass-lined pot overturning technology

The invention discloses a large glass-lined pot overturning technology. The technology comprises the steps of horizontal overturning and vertical turning, wherein horizontal overturning is achieved through horizontal turning and horizontal rotation, a supporting plate is attached to a glass-lined pot through vertical turning, the two sides of the glass-lined pot are clamped by a protective frame, and a 5-10 mm thick protective cushion is laid on the surface of the supporting plate. The technology is characterized in that the supporting plate and the glass-lined pot move synchronously, impact force generated during hoisting of the glass-lined pot is reduced greatly, the protective frame can guarantee that the glass-lined pot does not swing leftwards and rightwards, overturning is safe and quick without collision caused, glass-lined pot overturning stability is effectively improved, the glass-lined pot can not be damaged, and production efficiency is improved.

Owner:JIANGSU YANGYANG CHEM EQUPIMENTS MFR

Blowout preventer turning system

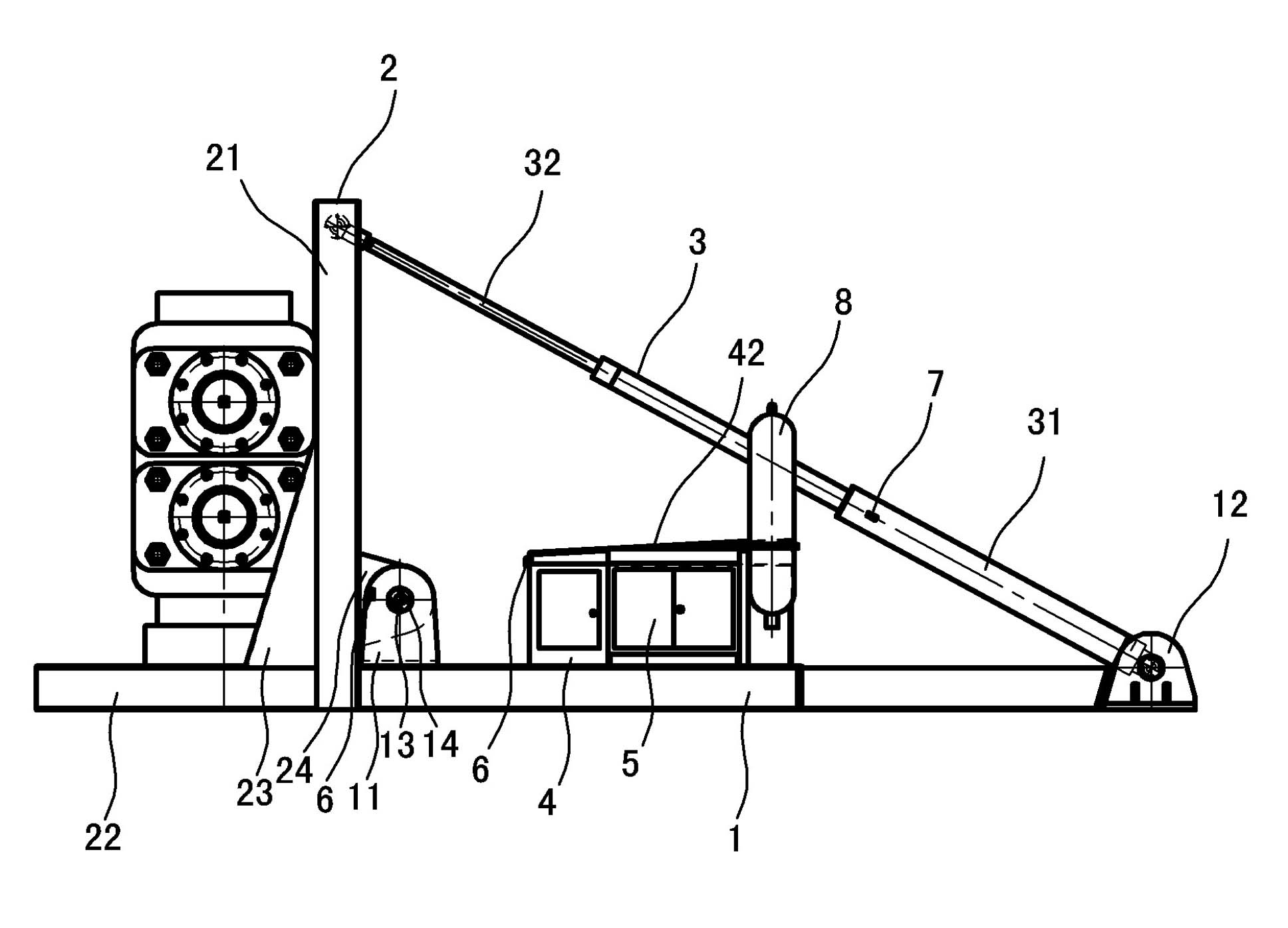

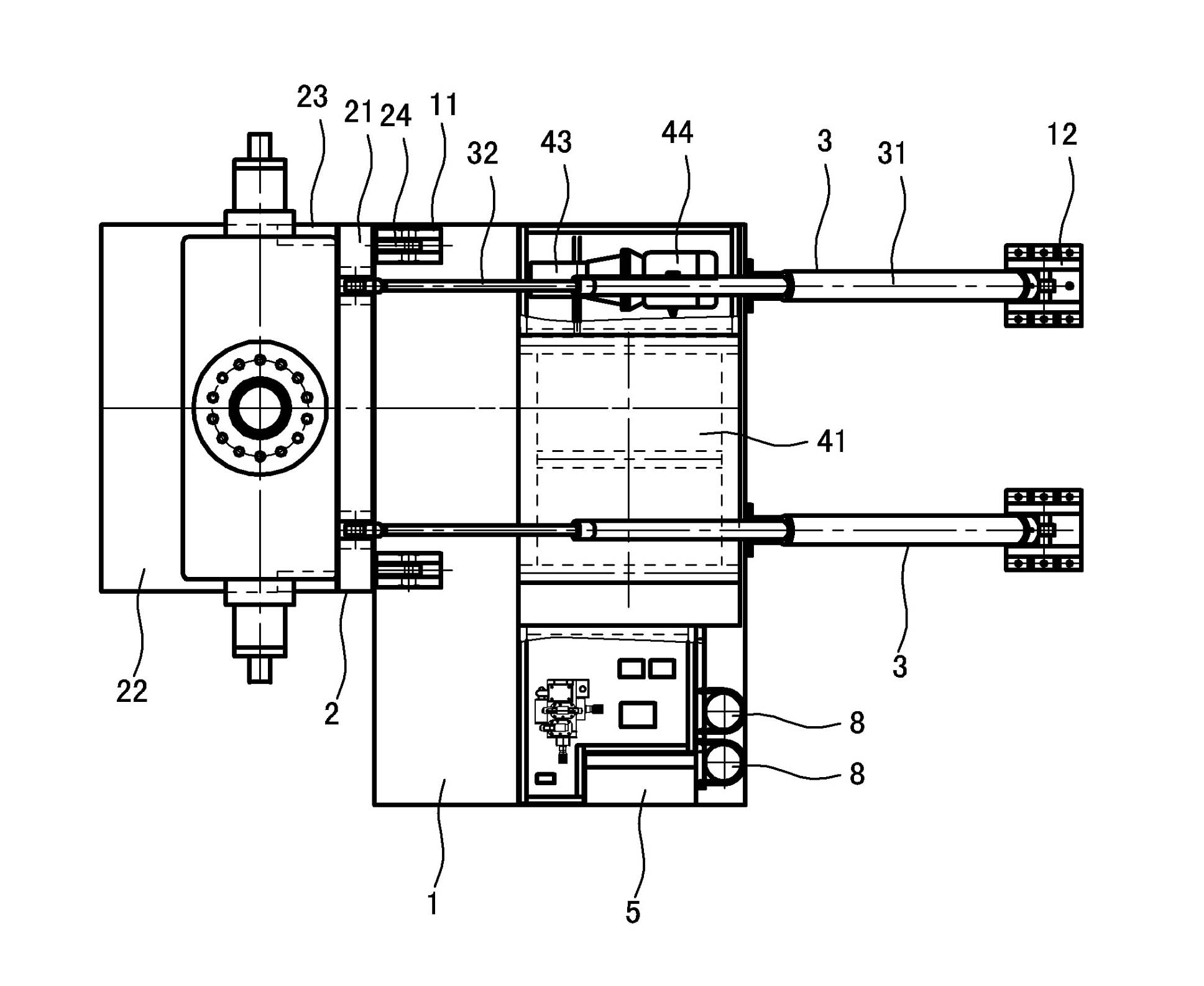

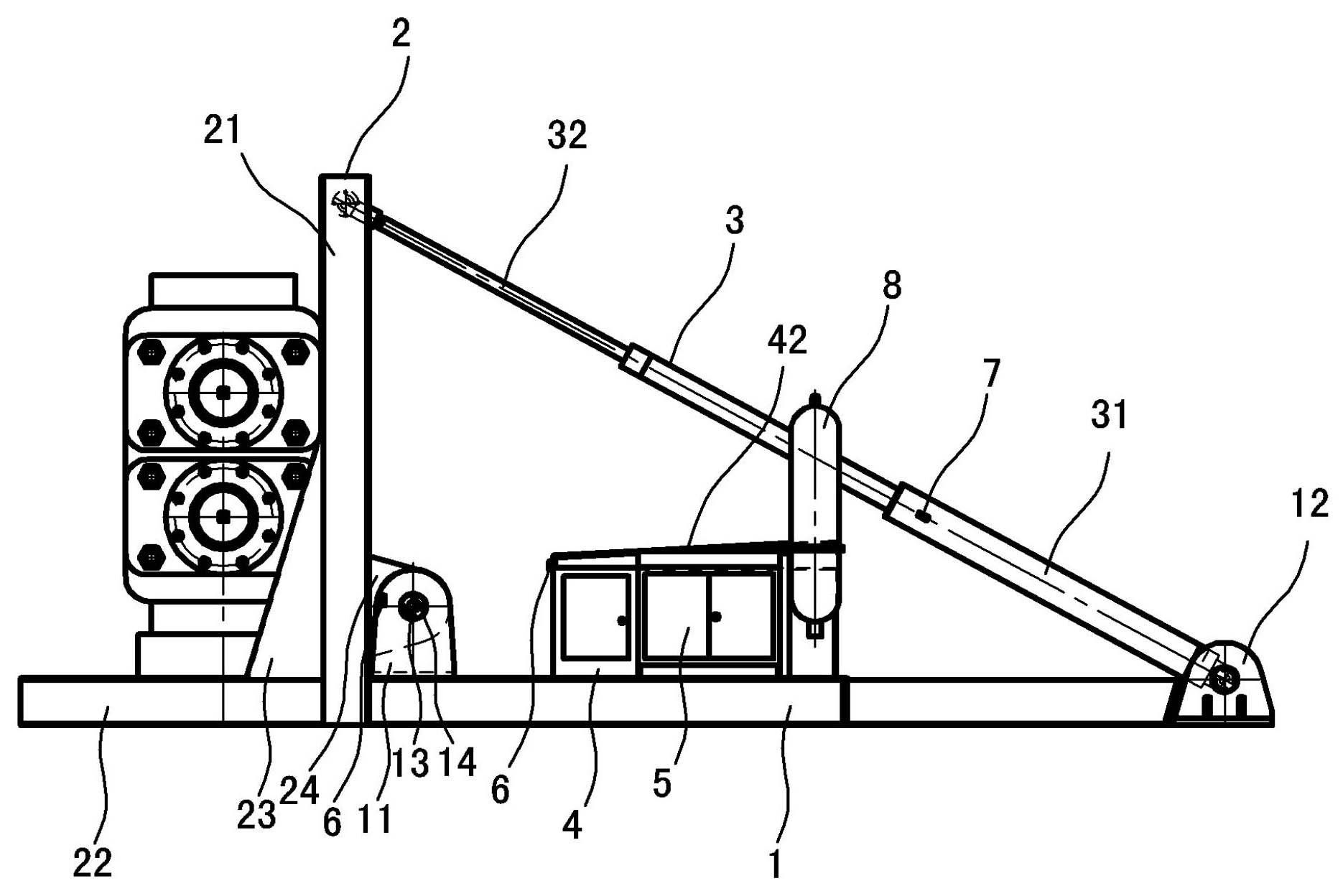

InactiveCN101858204ASafe and reliable maintenanceSafe and reliable cleaningSealing/packingPush and pullTurning frames

The invention relates to a petroleum machinery maintenance device, in particular to a blowout preventer turning system for turning a blowout preventer during maintenance and cleaning. The blowout preventer turning system comprises a base (1), a bearing turning frame (2), a hydraulic tuning oil cylinder (3), a hydraulic station assembly (4) and an electric control device (5); the bearing turning frame (2) is transversely hinged on the base (1); the cylinder body (31) of the hydraulic tuning oil cylinder (3) is hinged on the base (1), and the end part of the piston rod (32) of the hydraulic tuning oil cylinder (3) is articulated with the bearing turning frame (2) to push and pull the bearing turning frame (2) to turn; the hydraulic tuning oil cylinder (3) is connected with the hydraulic station assembly (4) through a high-pressure oil pipeline; and the hydraulic station assembly (4) is connected with the electric control device (5). The blowout preventer turning system is time-saving and labor-saving to use, safely and reliably turns a ram preventer, a drill spool and other heavy devices in maintenance or cleaning, improves the production efficiency, ensures safe production and fills a blank in the blowout preventer maintenance field at home and abroad.

Owner:MUDANJIANG DONGXU MACHINERY

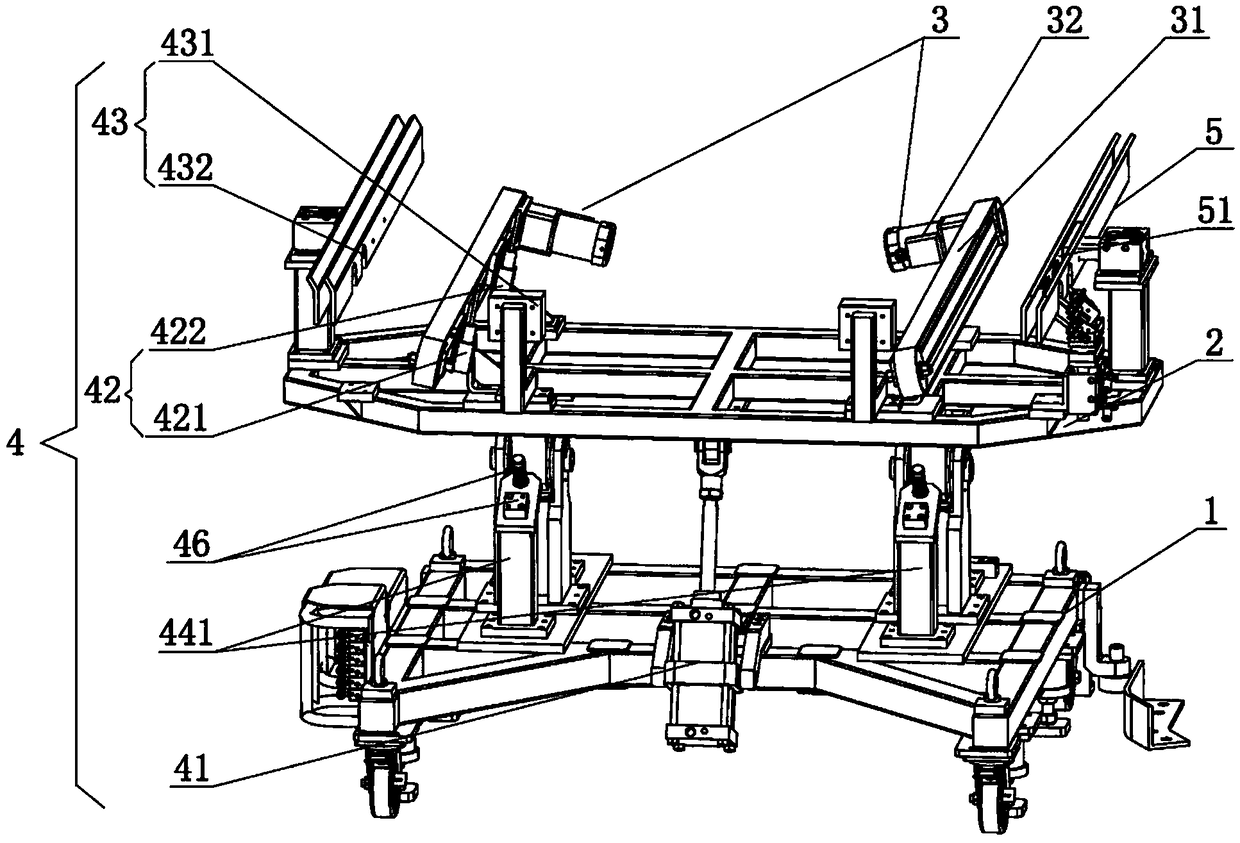

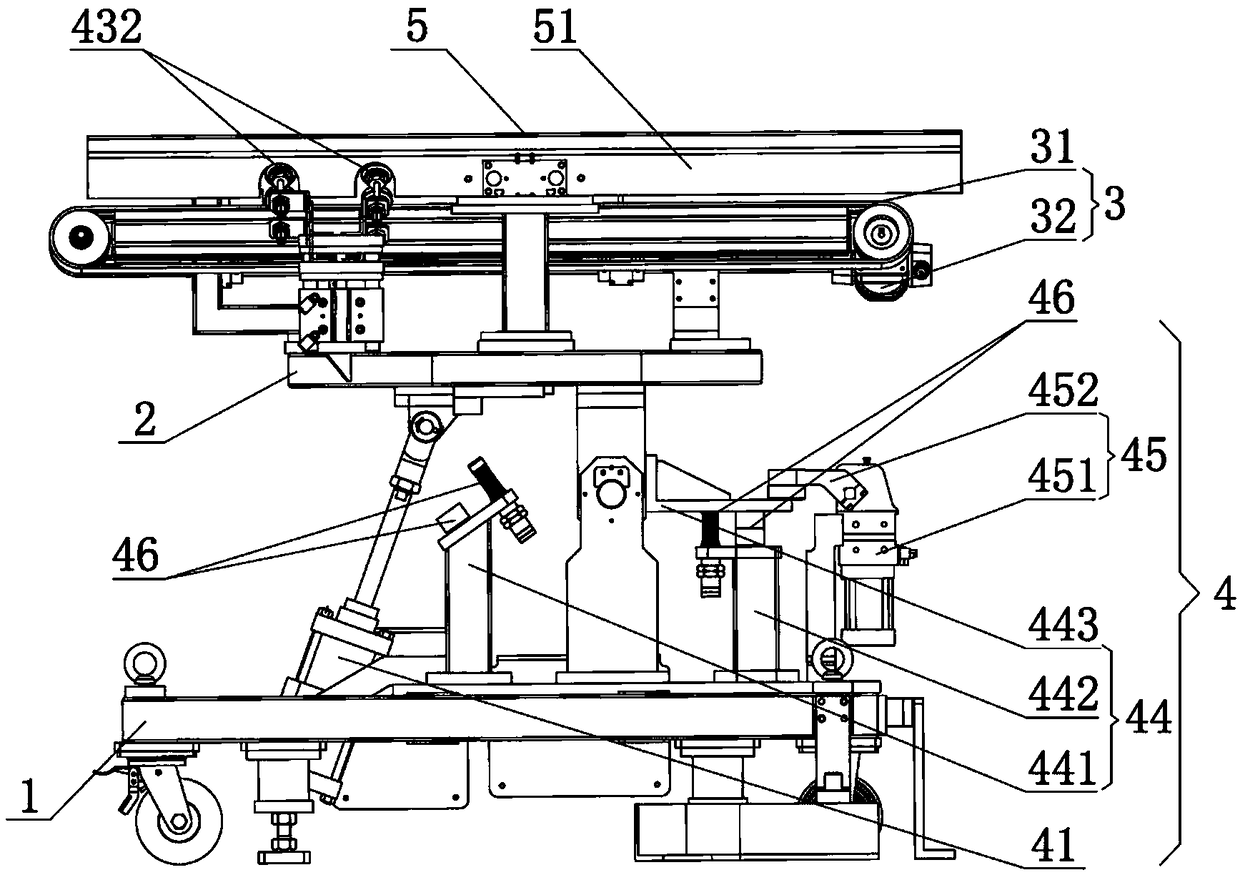

Automatic car door cover conveying and feeding equipment and feeding method

InactiveCN108657783AReduce labor intensityCompact structureConveyorsControl devices for conveyorsCar manufacturingExecution unit

The invention provides automatic car door cover conveying and feeding equipment and feeding method and belongs to the field of car manufacture industry machining and conveying. The automatic car doorcover conveying and feeding equipment comprises a bottom frame, a supporting frame, a conveying mechanism fixed to the supporting frame, and a turning-over mechanism for automatically turning over andresetting the supporting frame, wherein the bottom frame and the supporting frame are connected in a hinged manner. The turning-over mechanism comprises an execution unit for driving the supporting frame to be turned over, a detecting unit for detecting the position of a car door cover, and a control unit for receiving the signal of the detecting unit and driving the execution unit to act. The feeding method comprises the steps of locating and clamping a workpiece, turning over the supporting frame to the horizontal position, conveying the workpiece and obliquely turning over and resetting the supporting frame. The equipment has the beneficial effects that automatic turning over, feeding and conveying are achieved, feeding is more stable and convenient, the activity distance of operatorsis shortened greatly, the labor intensity of workers is reduced, the working efficiency is improved, and meanwhile safety and quality risks existing in the transportation process are avoided.

Owner:CHERY AUTOMOBILE CO LTD

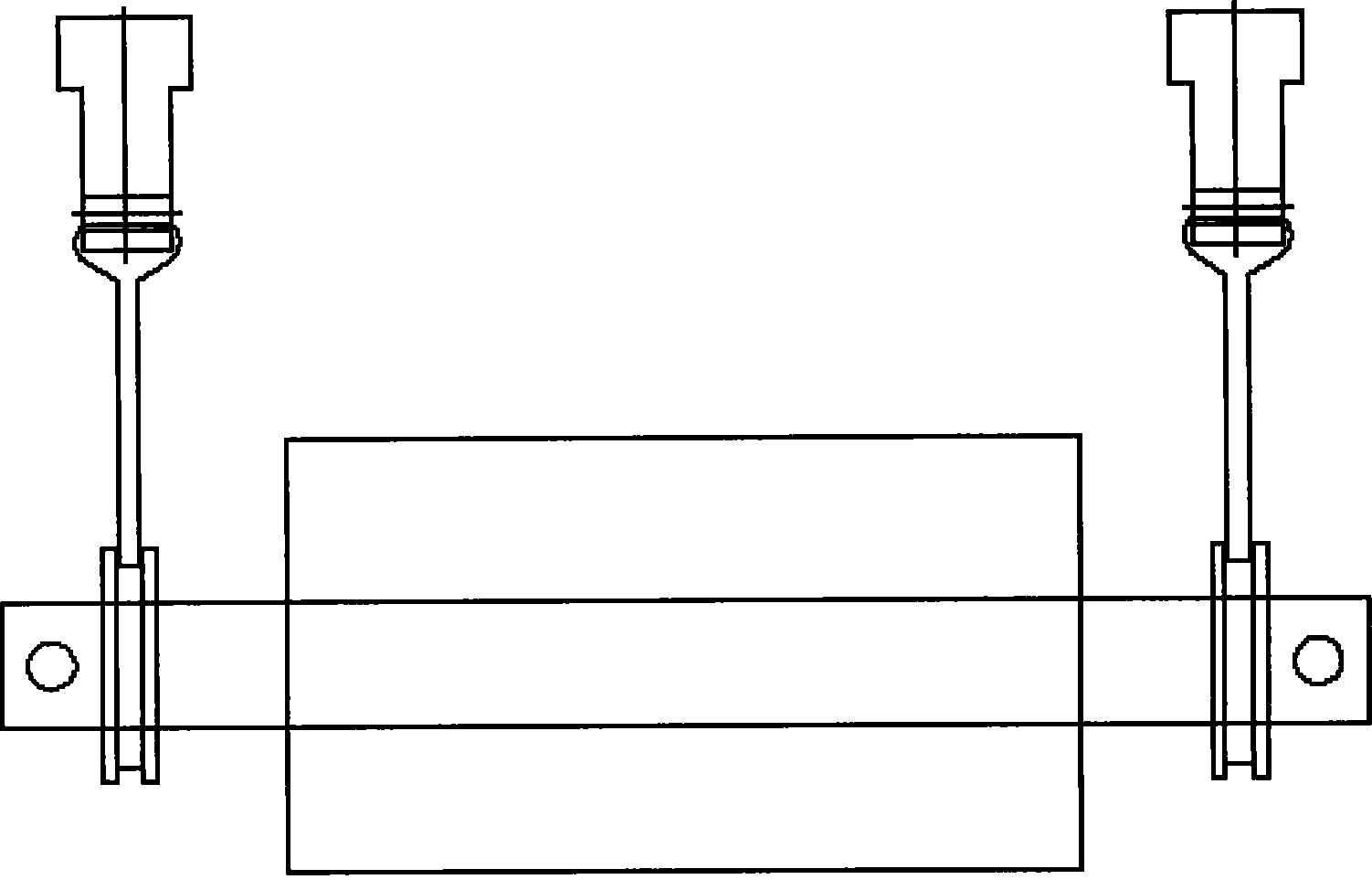

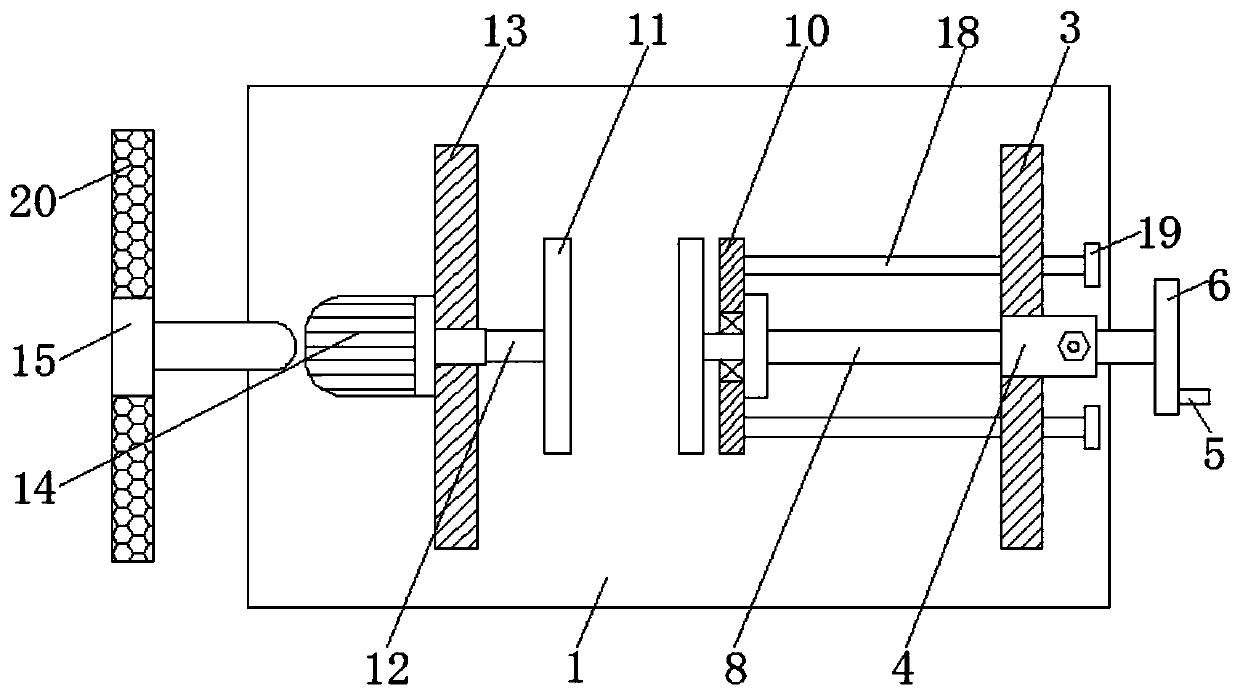

Riveting turnover mechanism for heavy truck cross beam assembling unit

The invention discloses a riveting turnover mechanism for a heavy truck cross beam assembling unit, and belongs to the technical field of turnover mechanisms. The riveting turnover mechanism solves the problems of low work efficiency and poor safety reliability since an existing turnover mechanism mainly depends on manual overturning. The riveting turnover mechanism is characterized by comprising a rack, movable PU (Poly Urethane) wheels, fixed PU wheels, rotary fixing blocks, a rotating disc, a pedal device, a rotating shaft a, a rotating shaft b, connecting seat bearings and flying rings, wherein the movable PU wheels and the fixed PU wheels are mounted at the four corners of the bottom end of the rack; the connecting seat bearings are arranged at the front end and the rear end of the rack and are fixed on the rack by bolts; the rotating shaft a and the rotating shaft b are respectively arranged on the front connecting seat bearing and the rear connecting seat bearing; the rotary fixing blocks are fixed on the rotating shafts by bolts; the pedal device is arranged between the rack and the rotating disc. The riveting turnover mechanism is simple in structure, flexible and convenient to operate, time-saving and labor-saving, the turnover precision can be effectively guaranteed, and the work efficiency is improved.

Owner:HEFEI CHANGQING MACHINERY

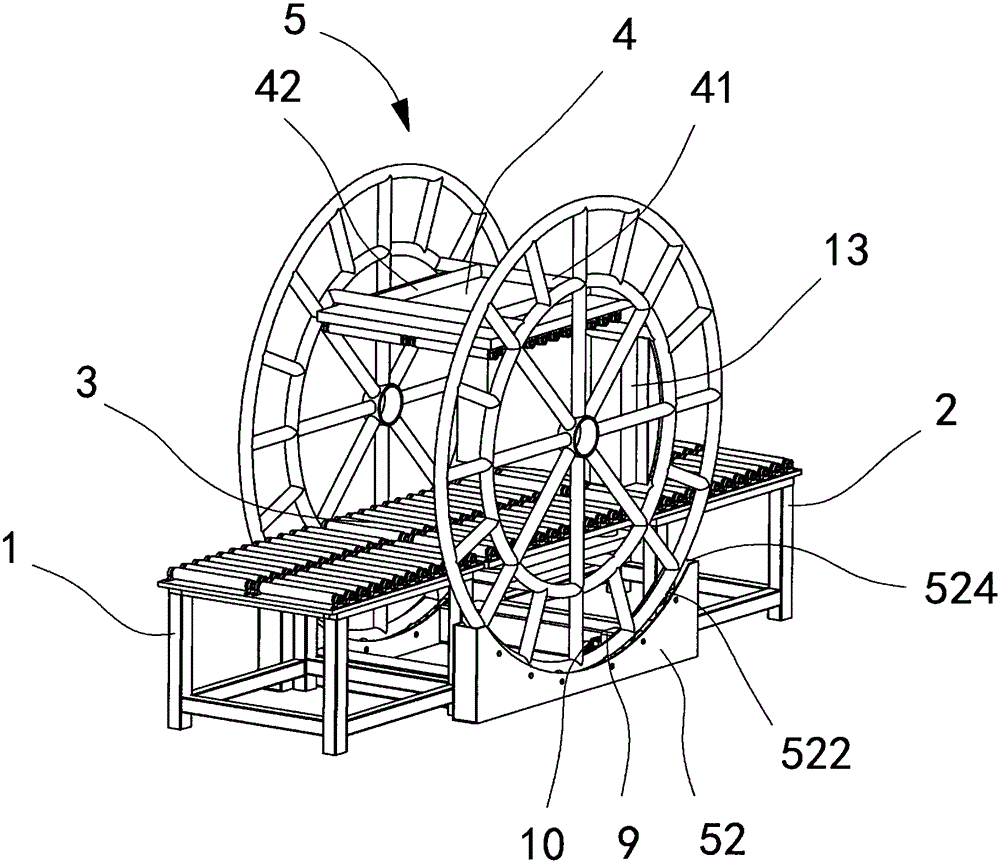

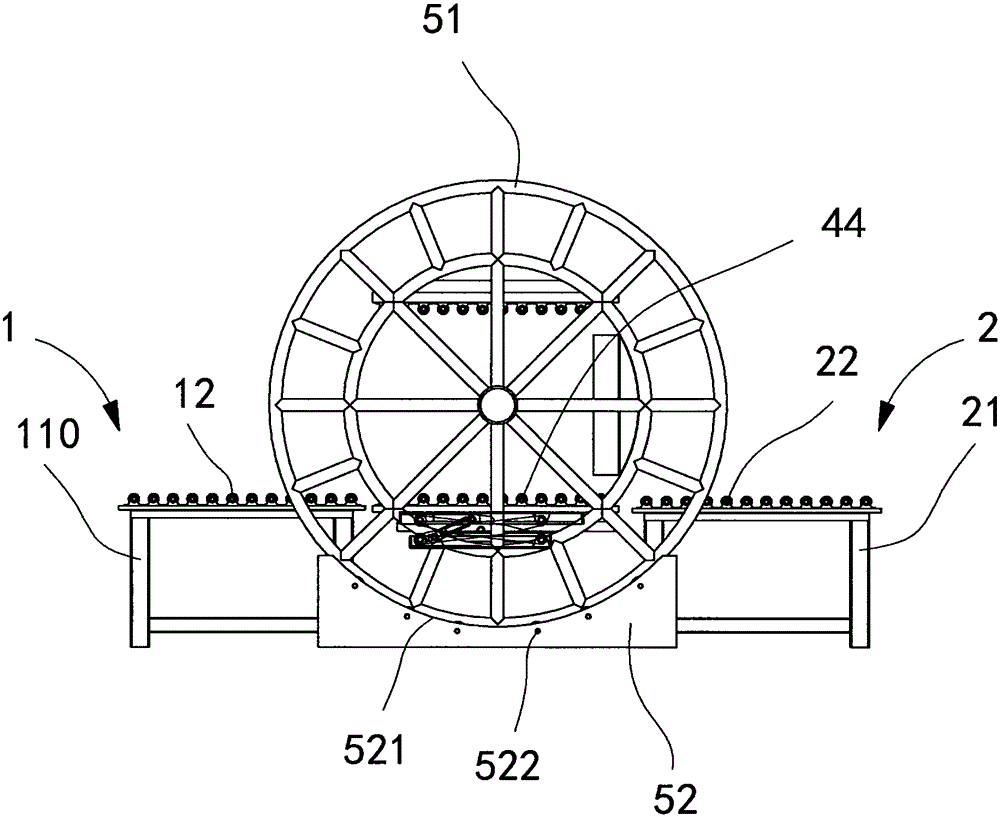

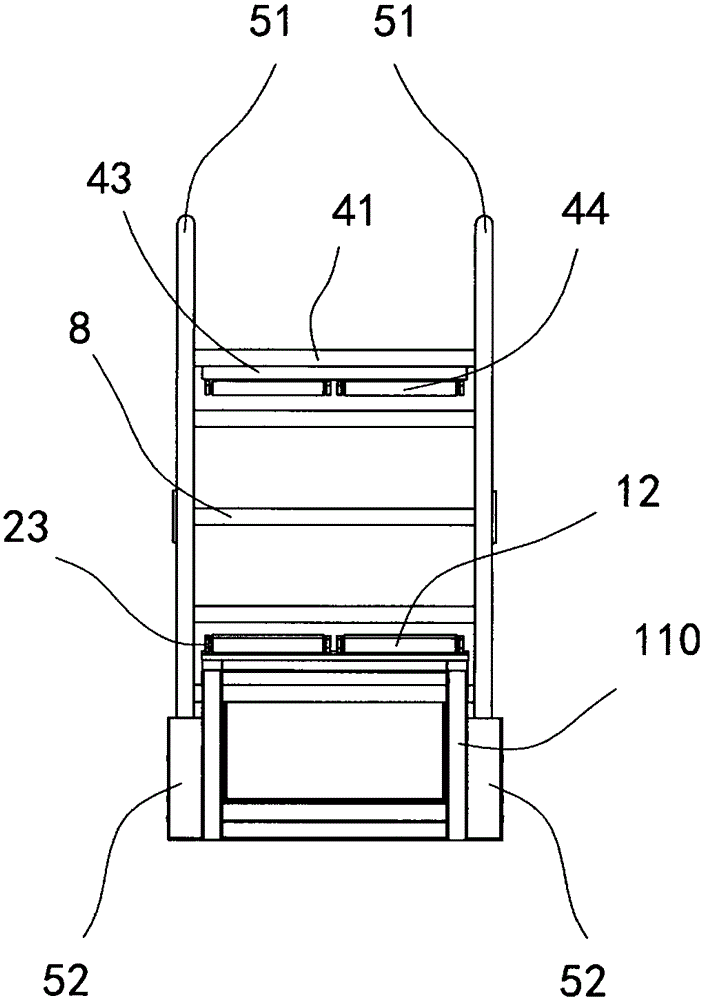

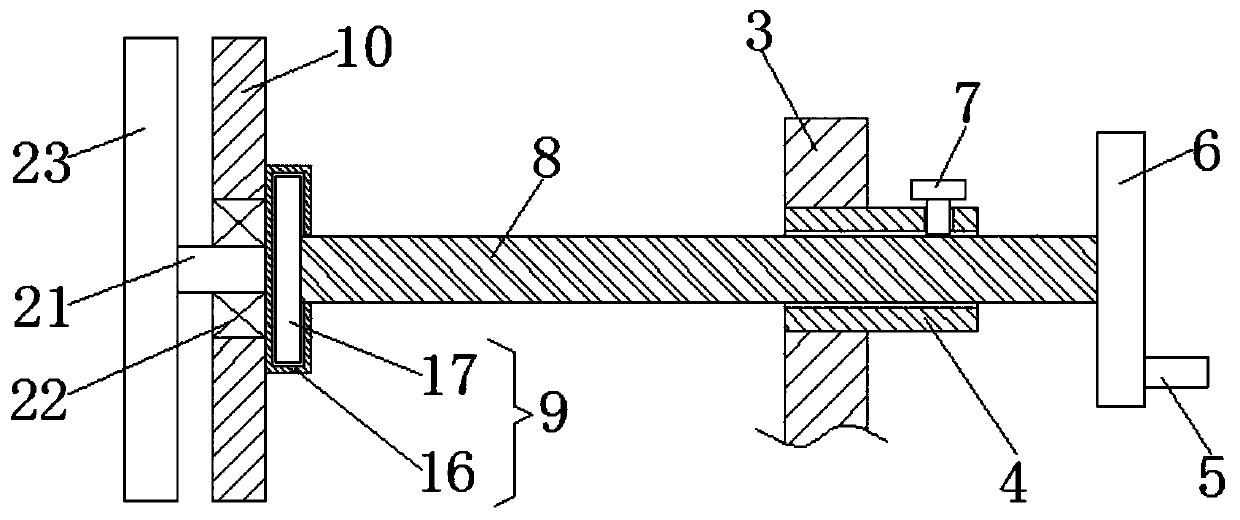

Wheel-type automatic turnover equipment with hydraulically-driven clamping mechanism

InactiveCN105173651AImprove turnover efficiencySafety flipConveyor partsEngineeringMechanical engineering

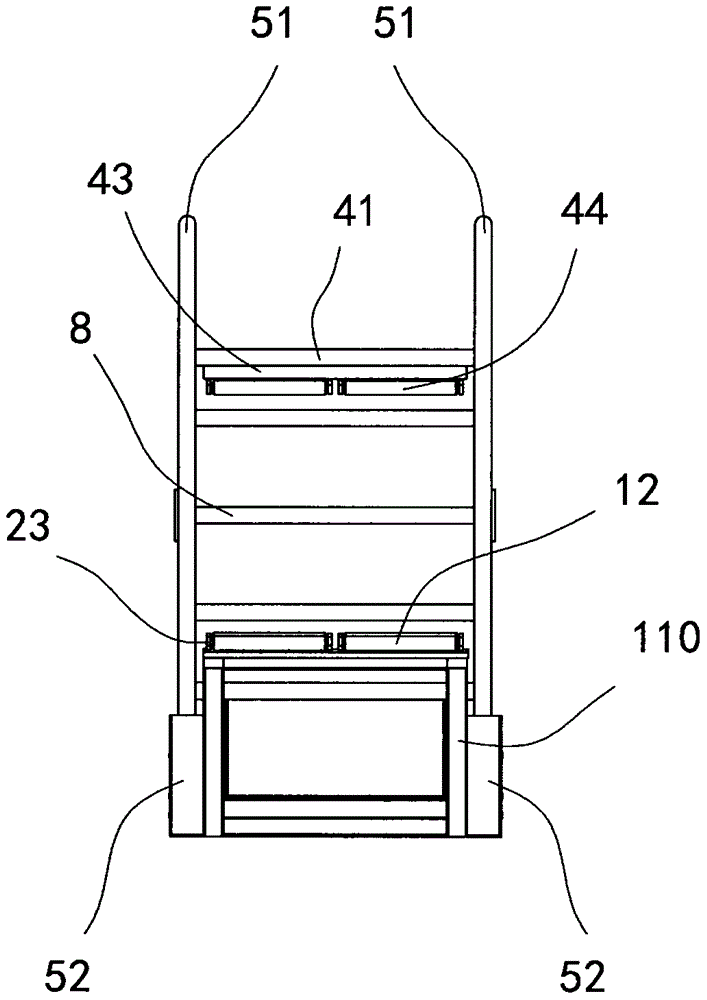

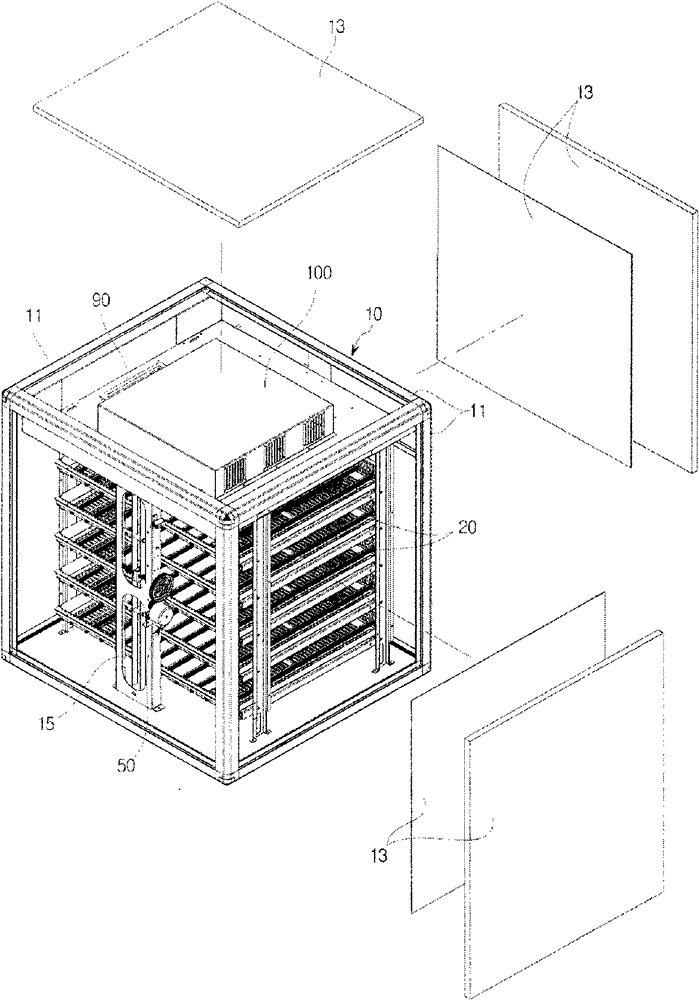

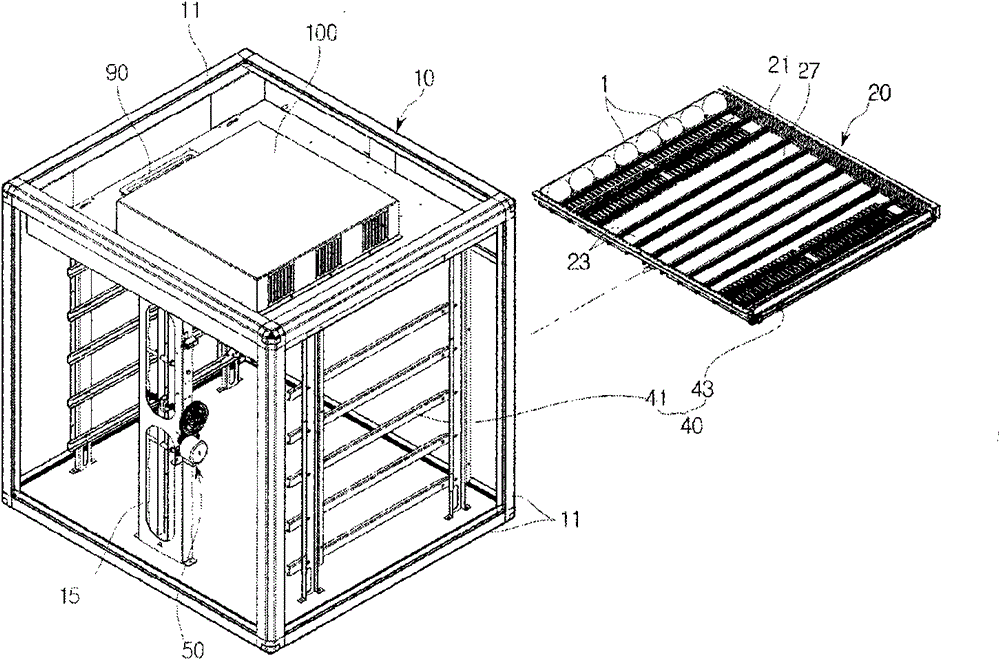

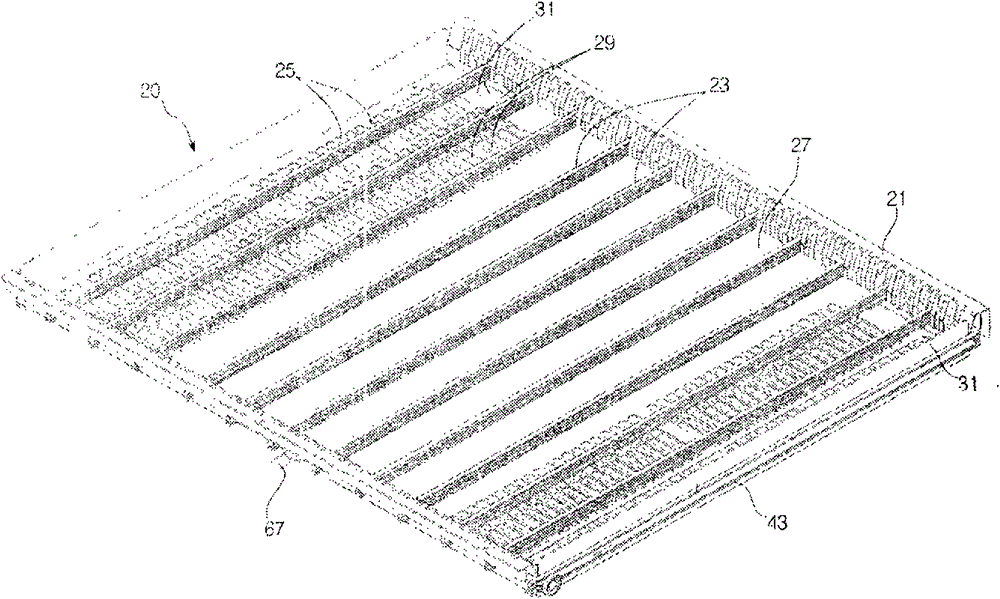

The invention discloses wheel-type automatic turnover equipment with a hydraulically-driven clamping mechanism. The wheel-type automatic turnover equipment comprises an inlet conveying mechanism and an outlet conveying mechanism. A turnover mechanism is arranged between the inlet conveying mechanism and the outlet conveying mechanism and provided with a first intermediate conveying mechanism and a second intermediate conveying mechanism. The first intermediate conveying mechanism and the second intermediate conveying mechanism are arranged on the turnover mechanism in parallel. A lifting mechanism is arranged below the first intermediate conveying mechanism. The turnover mechanism is further provided with the clamping mechanism which is a hydraulically-driven plane-type clamping mechanism. According to the wheel-type automatic turnover equipment, the turnover efficiency is improved, and the turnover process is safer and more accurate; meanwhile, the wheel-type automatic turnover equipment has the characteristic of being simple in structure.

Owner:KENMEC MECHA TRONICS (SUZHOU) CO LTD

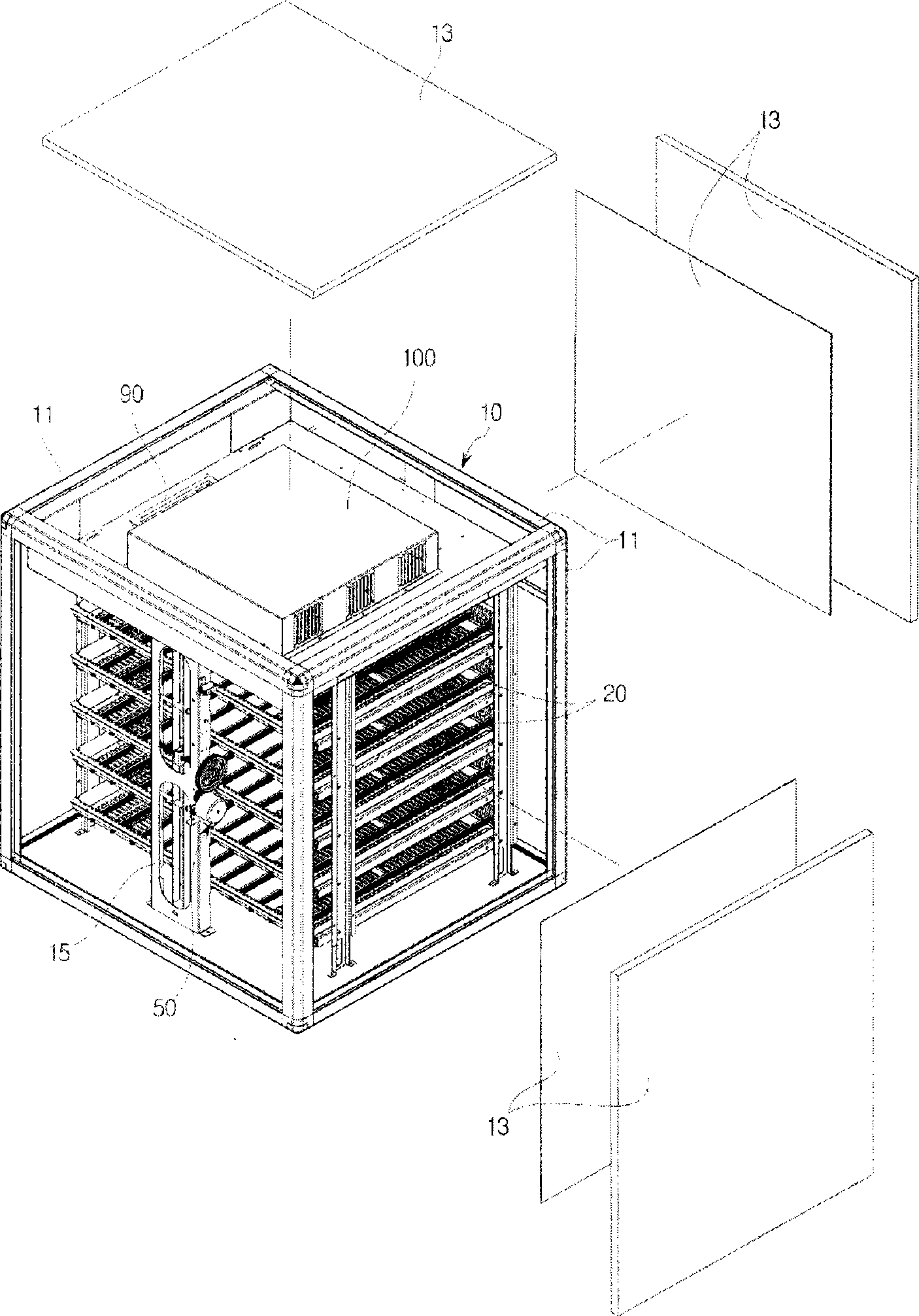

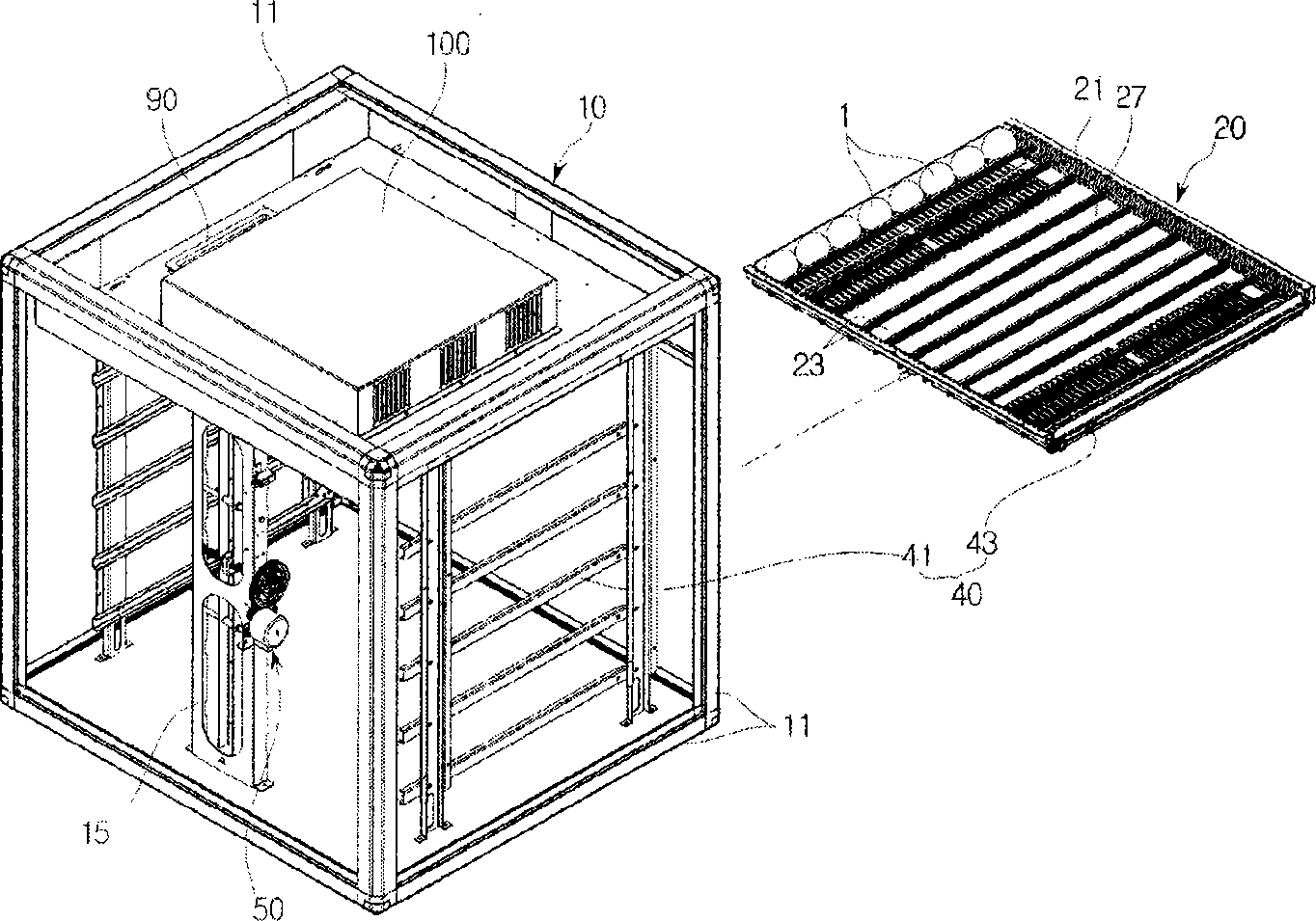

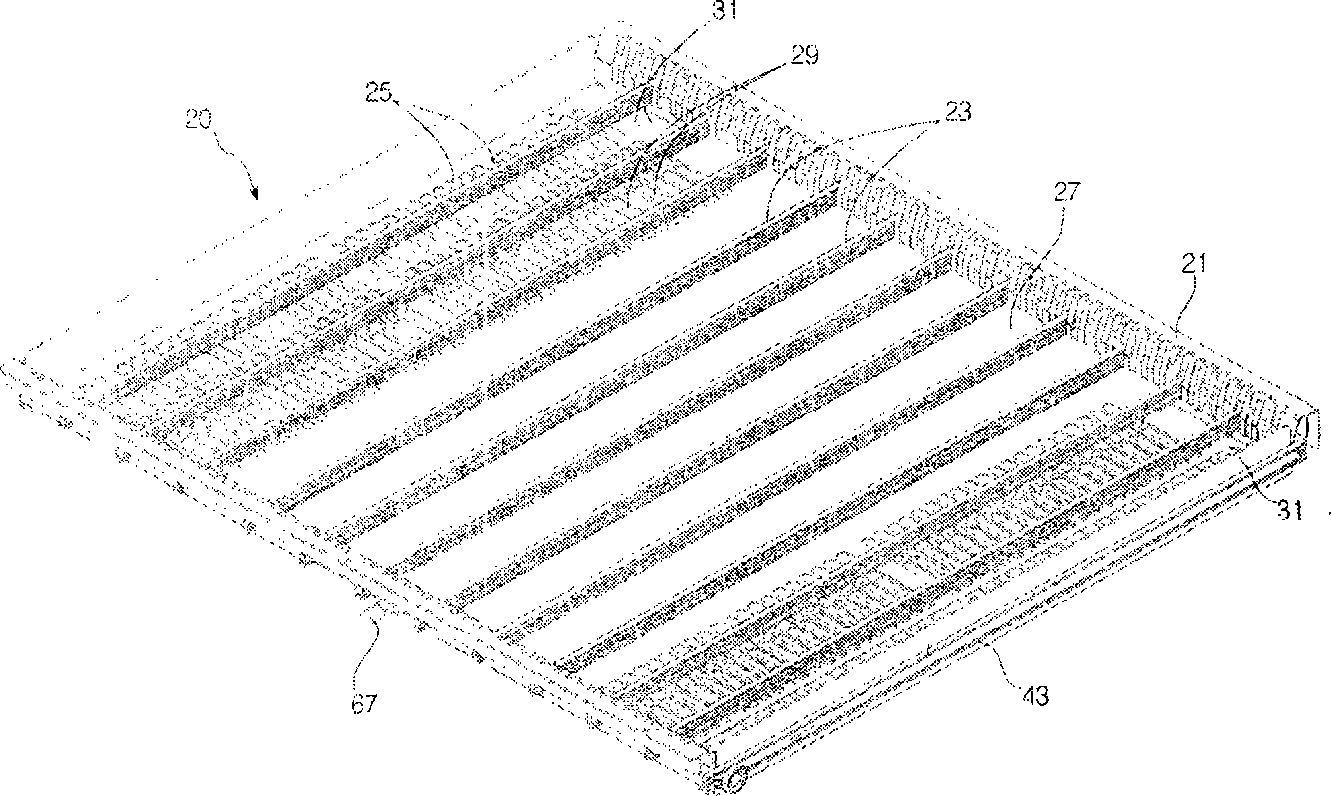

Incubator

ActiveCN102753015ASafety flipImprove space utilization efficiencyPoultry incubationEngineeringMultiple layer

An incubator is provided to decrease the volume of the incubator and secure an optimal condition to incubation. CONSTITUTION: An incubator comprises: a body frame(10); a turning tray which receives a plurality of fertilized eggs; a plurality of turning units(20) which are prepared in a turning tray, are equipped with a turning member and are received in the body frame; and a turning member driving part(50) which is prepared in the body frame and reciprocates a plurality of turning members.

Owner:AUTOELEX

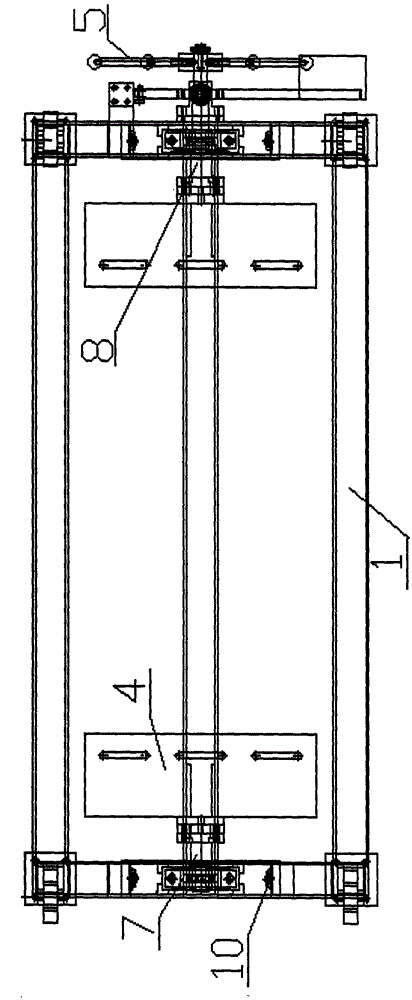

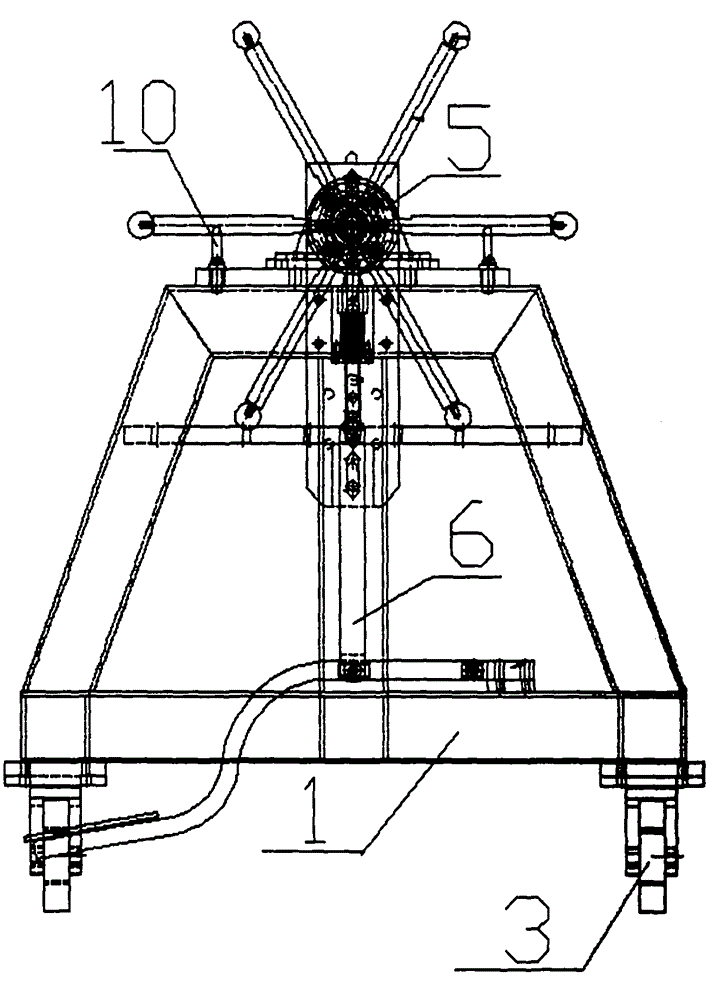

Multifunctional elevator

The invention discloses a multifunctional elevator. The multifunctional elevator comprises a counterweight device, a tractor, a car, a pulley block and steel wire ropes, wherein the car comprises a front plate, a rear plate, a left plate, a right plate, a top plate and a bottom plate; a first car door is arranged on the front plate; a second car door is arranged on the top plate; a first fixing part, a second fixing part, a third fixing part, a fourth fixing part, a fifth fixing part and a sixth fixing part are arranged on the car; a left guide rail is arranged on the outer wall of the left plate; a right guide rail is arranged on the outer wall of the right plate; the steel wire ropes comprise a main rope, a first accessory rope, a second accessory rope, a third accessory rope and a fourth accessory rope; the first accessory rope is fixed to the first fixing part; the second accessory rope is fixed to the second fixing part; the third accessory rope is fixed to the left guide rail; the fourth accessory rope is fixed to the right guide rail. Through adoption of the multifunctional elevator, the steel wire ropes are fixed to the car through a special manner so as to form multiple operation modes; the car space is fully used while good user experience of passengers is ensured; the volume and the cost of the car are reduced.

Owner:HOMEFRIEND & FUJI ELEVATOR CO LTD

Manufacturing method of pressing mould turner, turning device and turning method

The invention provides a pressing mould turner which comprises a clamp hoop, four clamp rings, two wire ropes, two T-shaped hanging blocks and a screw rod, wherein two clamp rings clamp the clamp hoop and are screwed through screws to obtain a T-shaped groove sliding block and fixed with one ends of the wire ropes; the other ends of the wire ropes are tightly locked by the T-shaped hanging blocks; and the T-shaped groove sliding block is fastened with the screw rod. The invention also provides a mould turning method which comprises the following steps of: (1) adjusting the position of the T-shaped groove sliding block; (2) locking the mould with a tightening lock on the screw rod; (3) starting a driver, and pulling the mould upwards; and (4) pushing the turning mould. The method is simple and safe to operate, and solves the problems that the conventional manual mould turning operation needs large working space, is time-consuming and labor-consuming, easily causes industrial injury and the like.

Owner:广东新志密封技术有限公司

Large equipment turnover device

The invention discloses a large-scale equipment turnover device which comprises a turnover mechanism which comprises a supporting assembly and a turnover assembly matched with the supporting assembly. The clamping mechanism is matched with the overturning assembly and comprises a clamping assembly, a contraction assembly arranged at the lower end of the clamping assembly and a moving assembly arranged at the bottom end of the contraction assembly; through cooperation of the clamping mechanism and the turnover mechanism, turnover at any angle can be completed, and the turnover process is safe.

Owner:BEIFANG WEIJIAMAO COAL POWER CO LTD

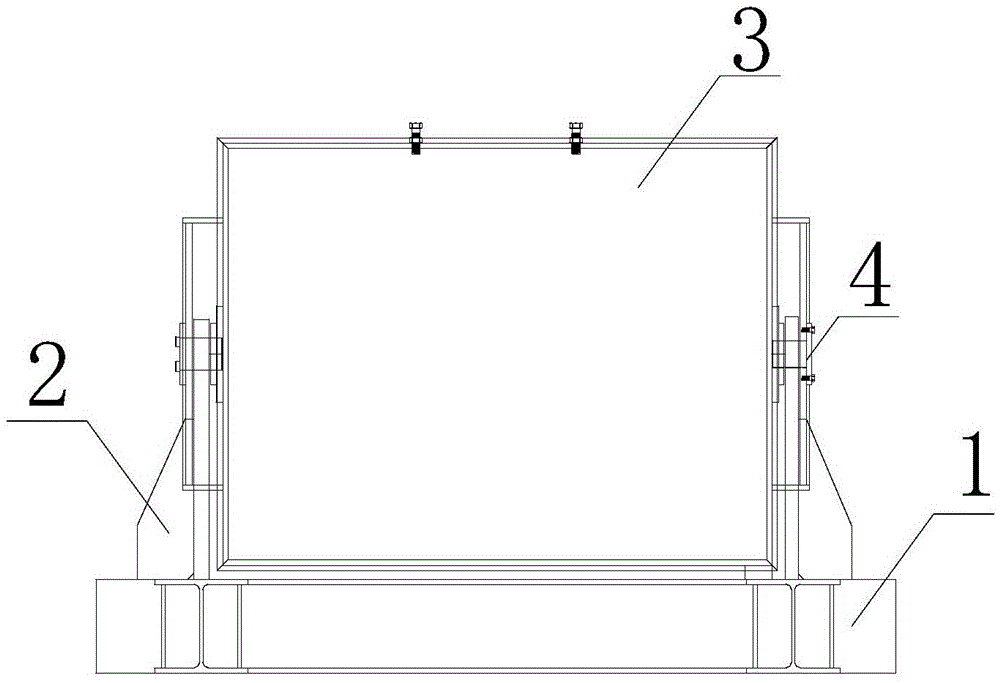

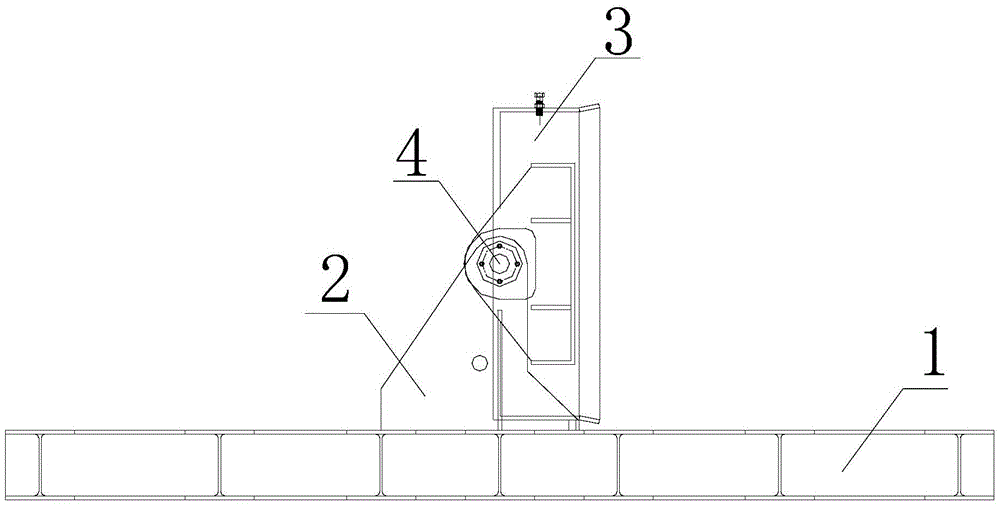

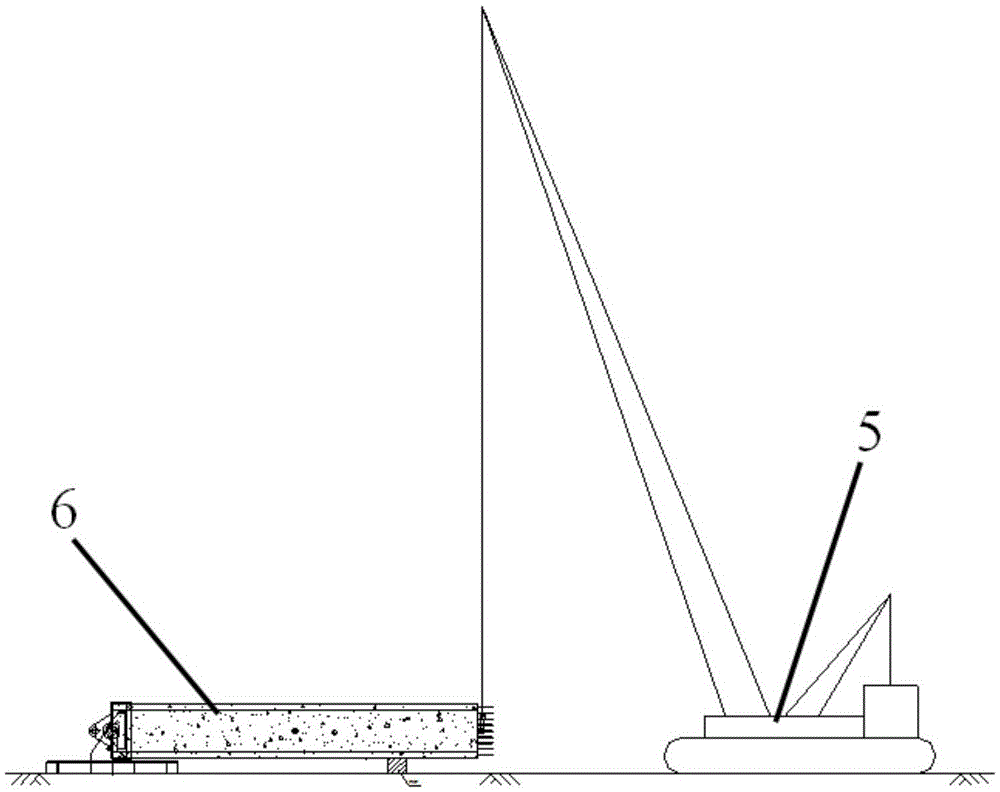

Turnover device and method used for single crane hoisting of prefabricated stand pillars

ActiveCN105463996ASimple and fast operationSmall construction impactBridge erection/assemblyEngineeringSupport point

Owner:SHANGHAI NO 4 CONSTR +2

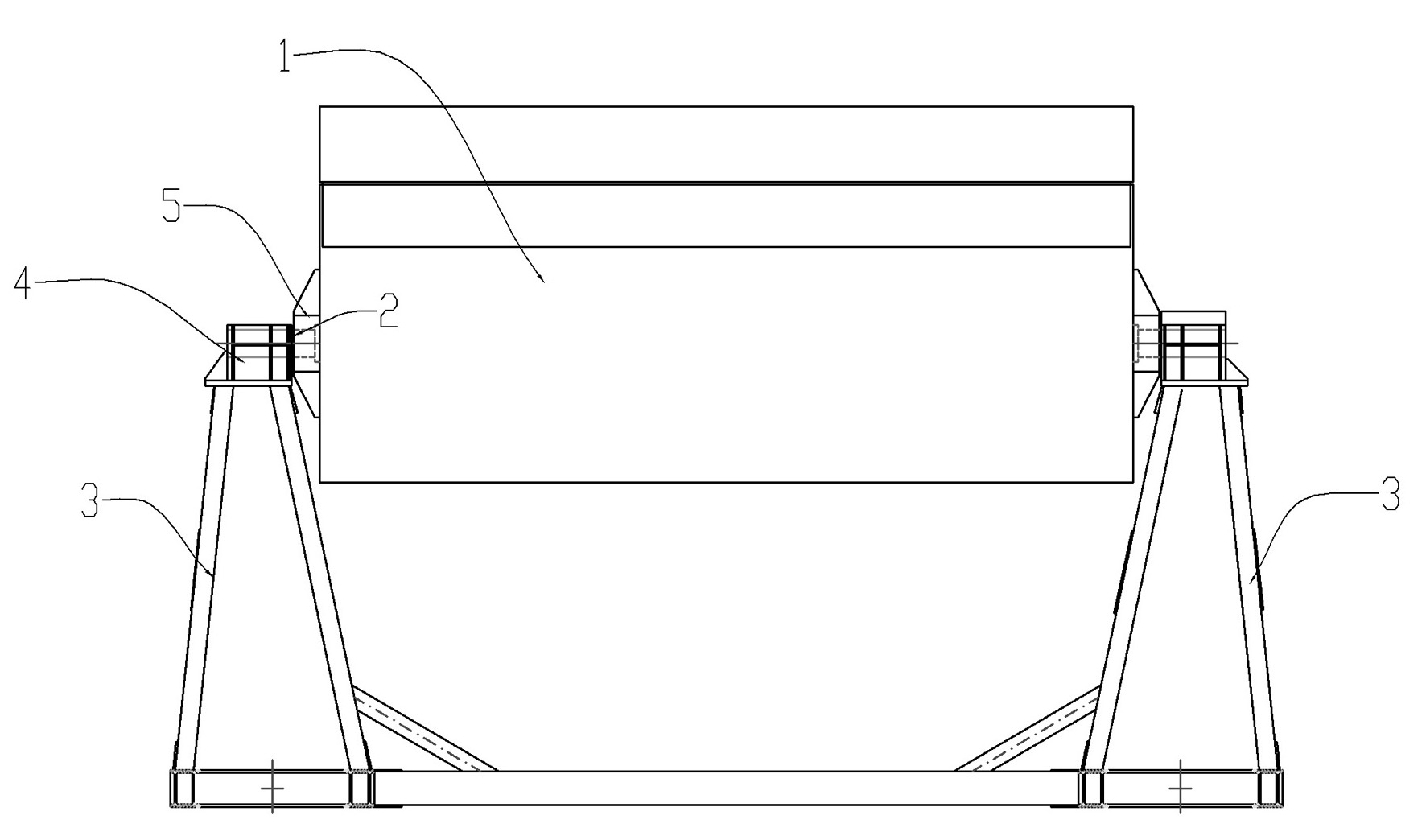

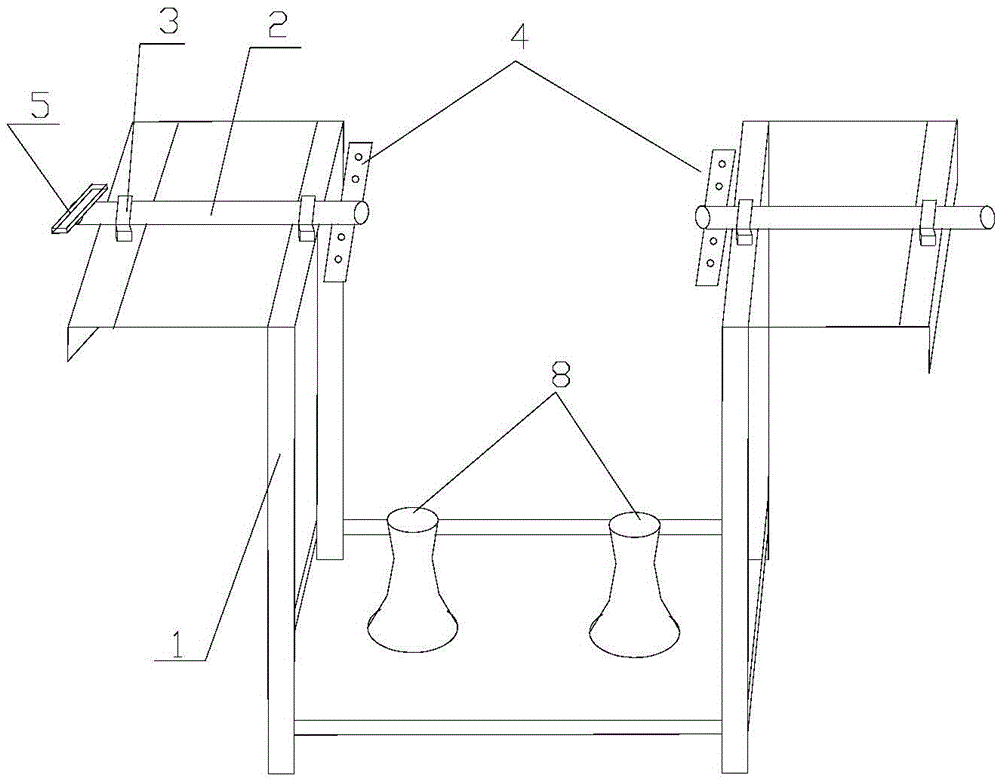

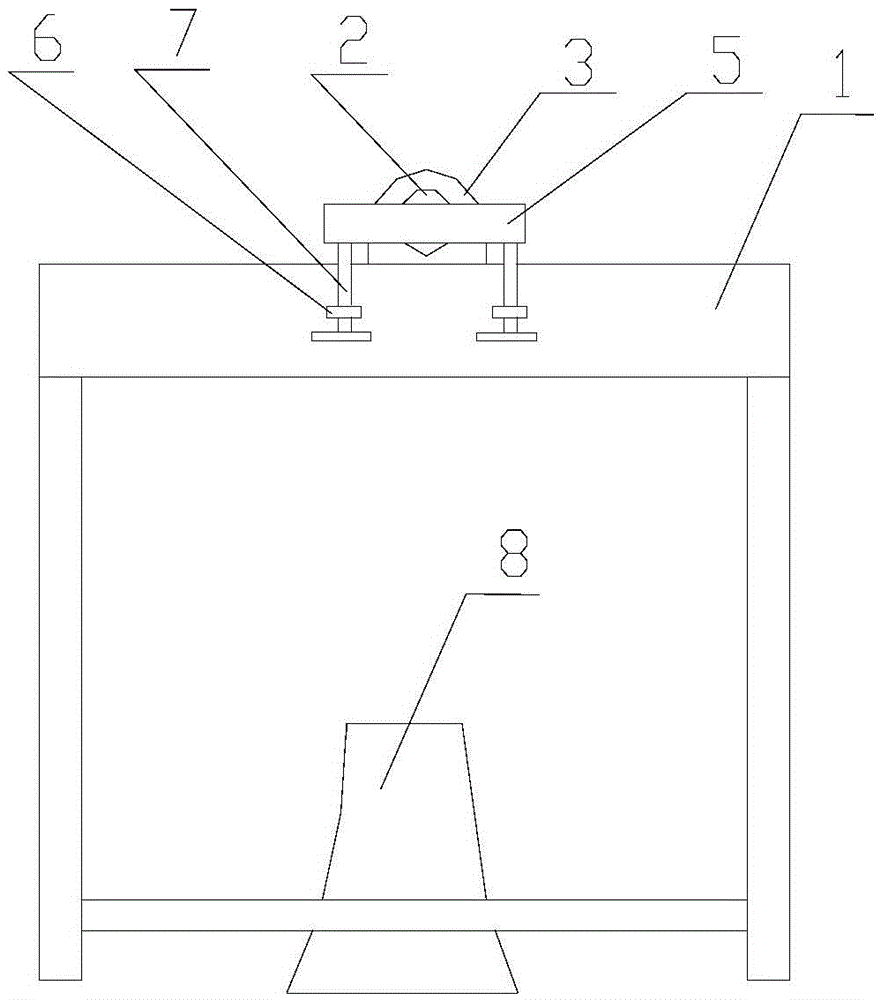

Polycrystalline silicon ingot overturning device

The invention discloses a polycrystalline silicon ingot overturning device, comprising a bottom supporting part and an overturning box which is erected on the bottom supporting part and is used for loading a polycrystalline silicon ingot, wherein the bottom supporting part comprises two oppositely-arranged fixing bottom plates and two supporting columns which are respectively placed on the fixing bottom plates; the overturning box is erected between the upper ends of the two supporting columns; the overturning box comprises an outer frame surrounding the periphery, and at least one upper transverse strip and at least one lower transverse strip; and at least one upper transverse strip and at least one lower transverse strip are arranged above and below the outer frame and are used for blocking the polycrystalline silicon ingot placed in the outer frame. The polycrystalline silicon ingot overturning device disclosed by the invention has a simple structure, is easy to machine and manufacture and is convenient to use; and the polycrystalline silicon ingot overturning device can rapidly, conveniently and safely overturn the polycrystalline silicon ingot and solves the problem in the prior art that the polycrystalline silicon ingot is difficult to overturn.

Owner:ZHENJIANG RENDE NEW ENERGY TECH

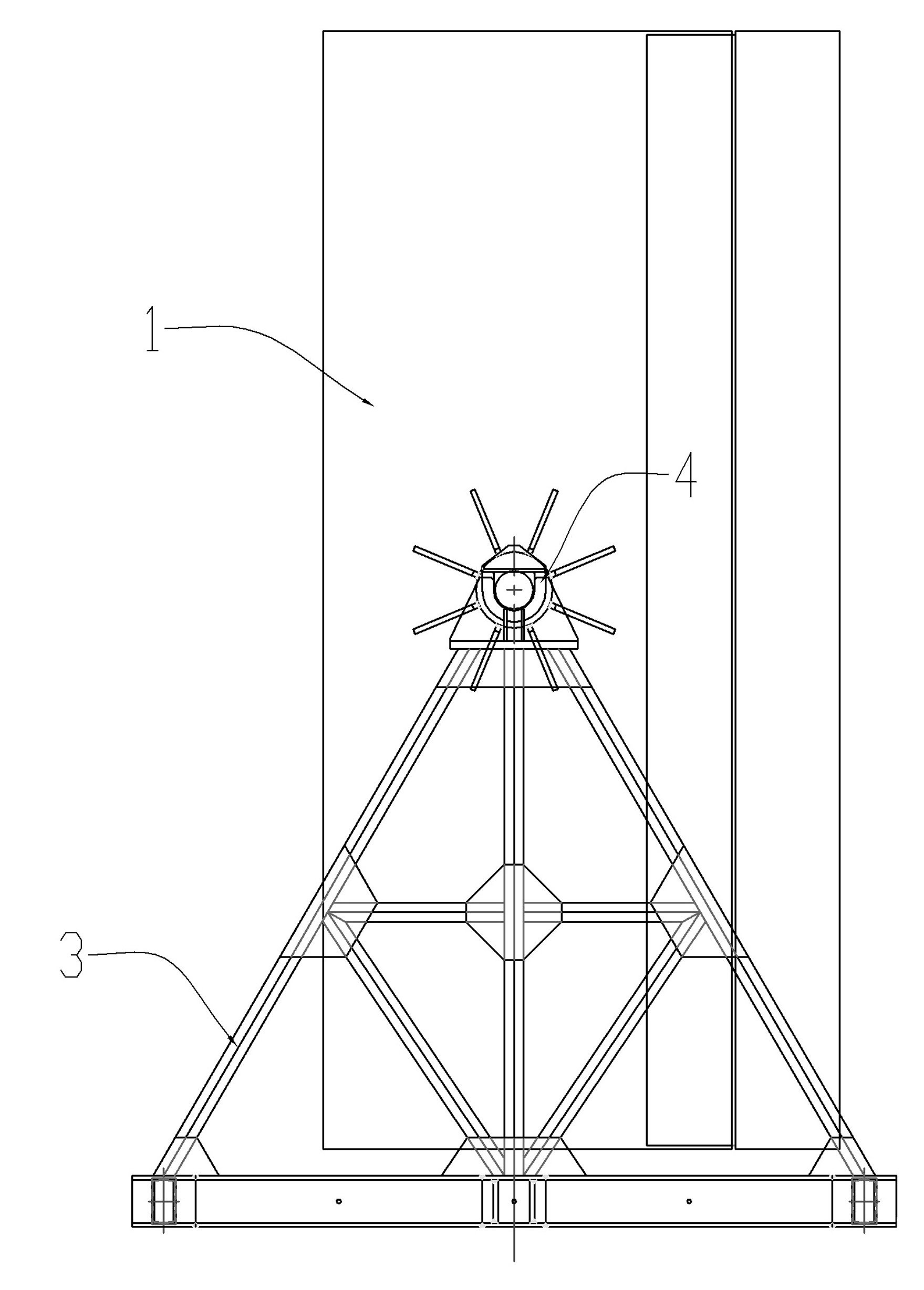

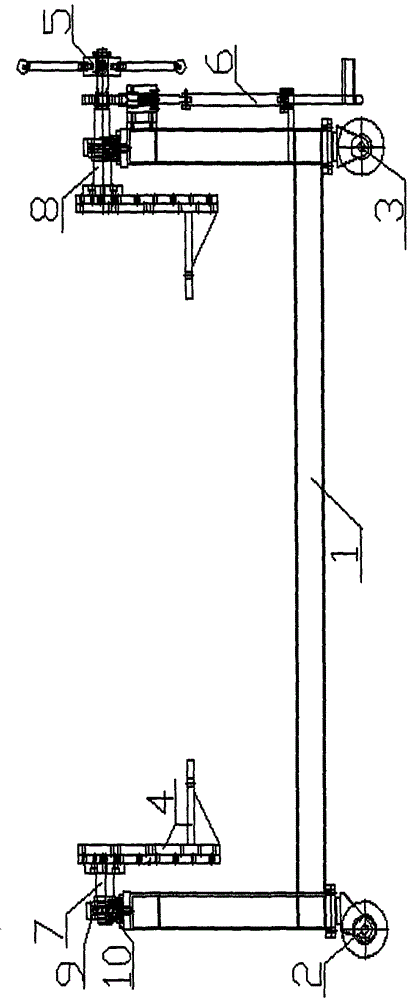

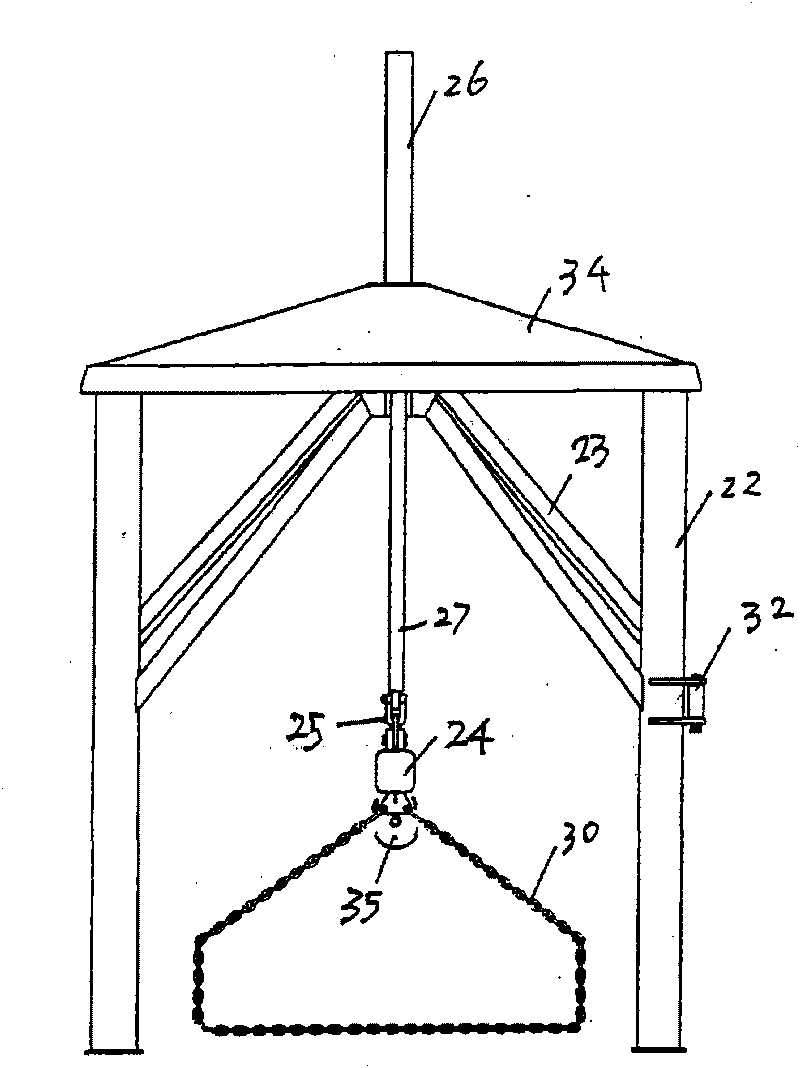

Bottom turnover mechanism used for monorail transportation of electric hoist

InactiveCN106744313AEnsure stabilityScientific and reasonable structureLoad-engaging elementsElectric machineryEngineering

The invention discloses a bottom turnover mechanism used for monorail transportation of an electric hoist. The bottom turnover mechanism comprises a turnover mechanism ejector rod, wherein a hoist hanger connecting ring is arranged on the top of the turnover mechanism ejector rod; a turnover mechanism triangular frame is arranged on the bottom of the turnover mechanism ejector rod; a framework vertical rod is arranged below the turnover mechanism triangular frame; a turnover mechanism framework cross rod is arranged on the bottom of the framework vertical rod; a drive motor supporting frame is arranged at one side of the framework vertical rod; and a turnover mechanism drive motor is arranged on the drive motor supporting frame. According to the bottom turnover mechanism disclosed by the invention, after a turnover rotary ring is arranged, a workpiece transportation slot can rotate in a mode of sliding a turnover slide slot inside the workpiece transportation slot, so that rotation is very labor-saving; and moreover, the turnover rotary ring achieves the effect of assisting rotation as a result of an independent rotation path, also can guarantee stability of the workpiece transportation slot very well, so that use is safer and more efficient.

Owner:HUANGSHI CITY KAITAI MACHINE CO LTD

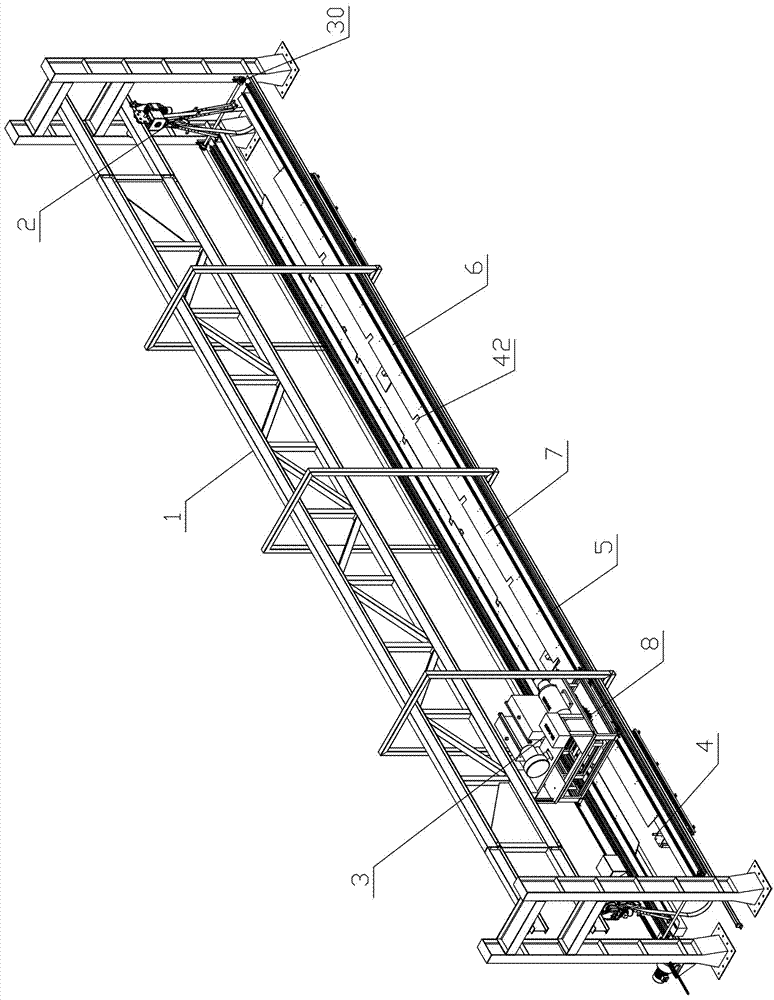

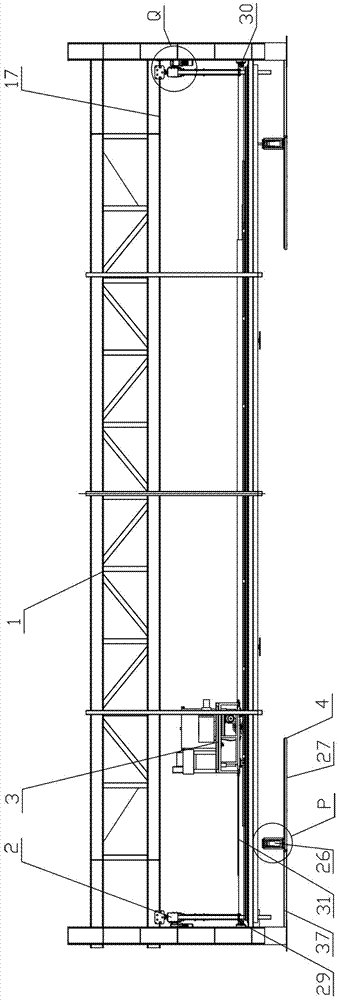

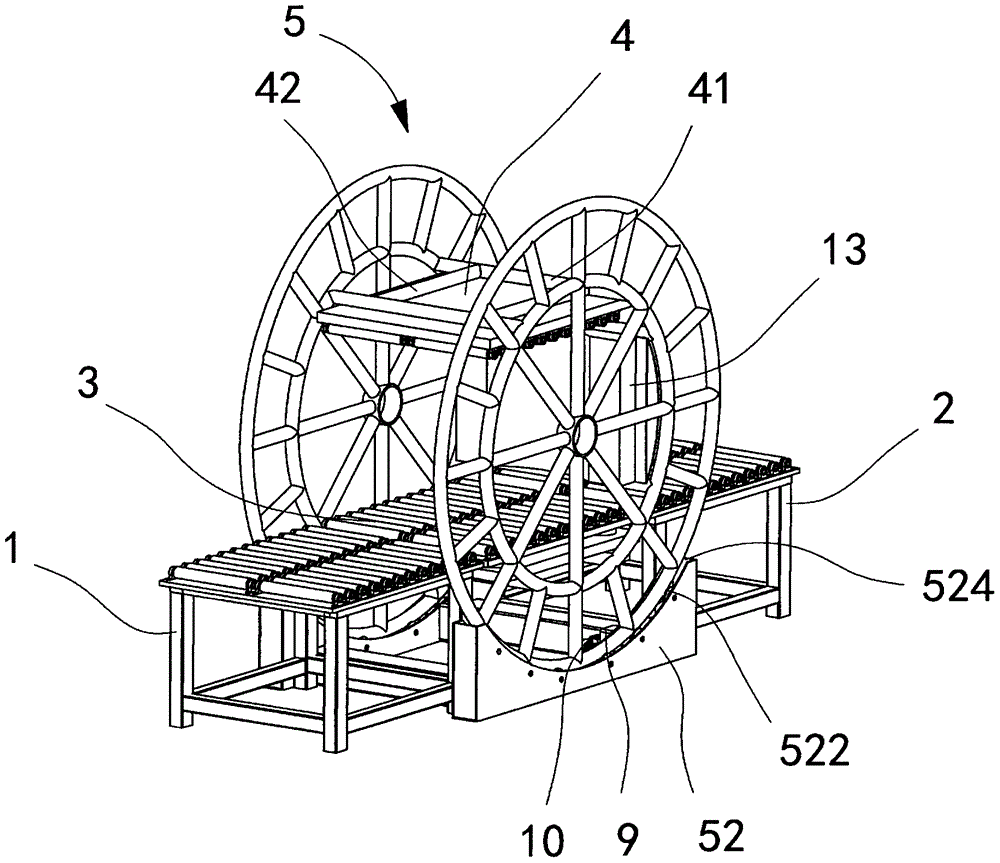

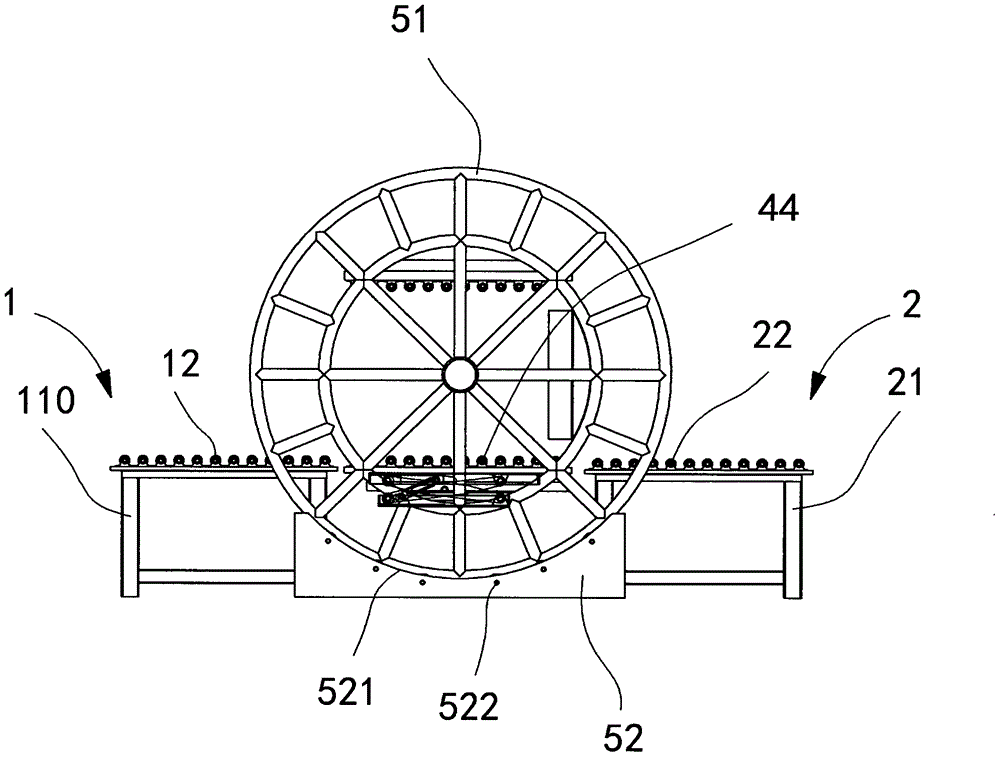

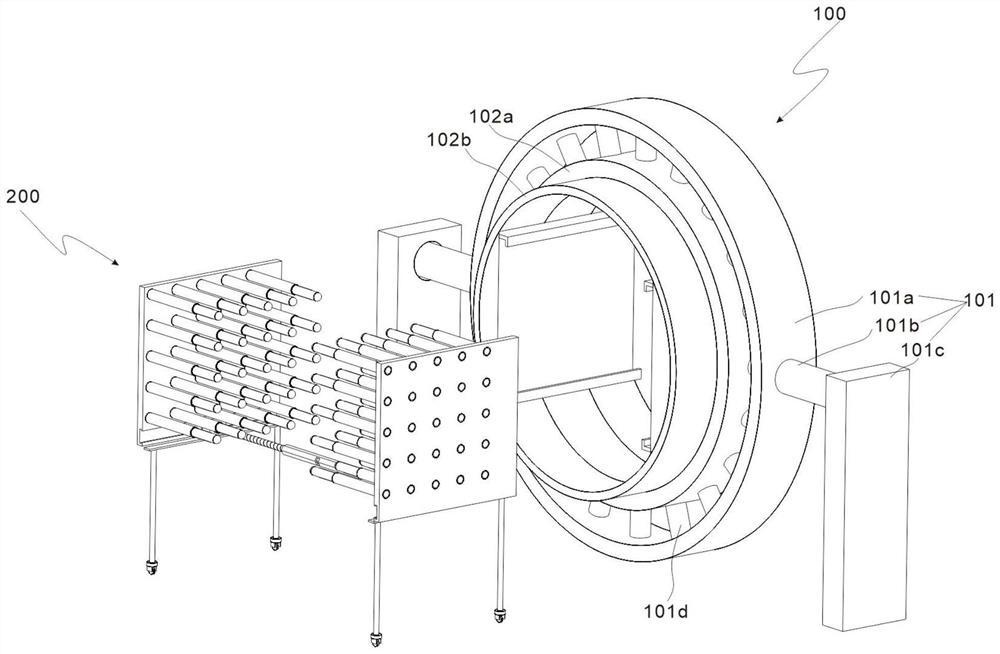

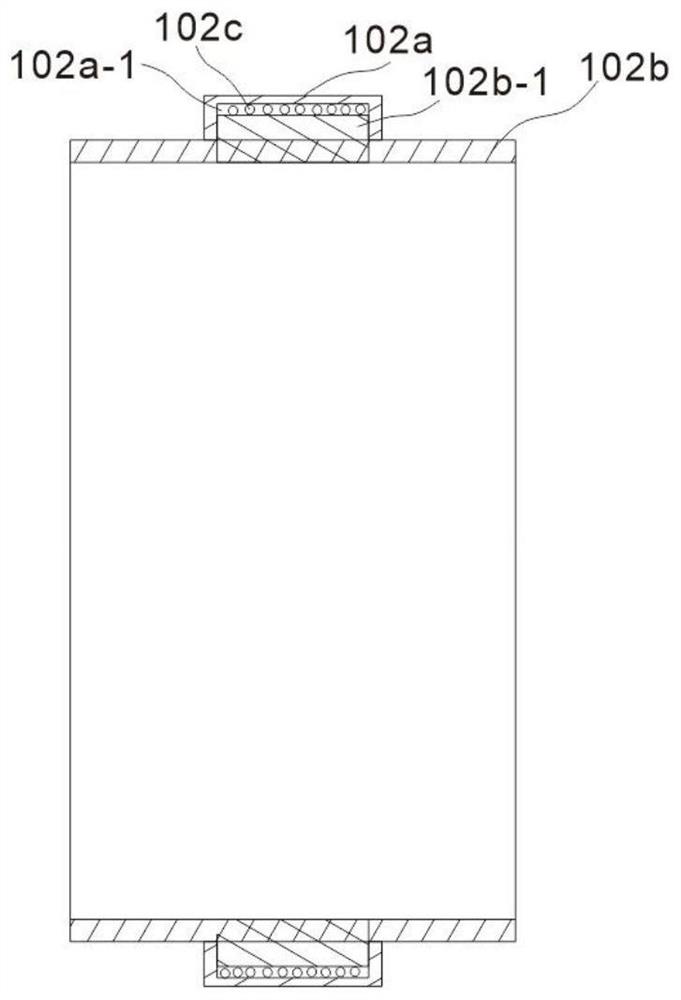

Wheel-type automatic turnover equipment with lifting mechanism

InactiveCN105173650AImprove turnover efficiencyFlip process safetyConveyor partsEngineeringMechanical engineering

The invention discloses wheel-type automatic turnover equipment with a lifting mechanism. The wheel-type automatic turnover equipment comprises an inlet conveying mechanism and an outlet conveying mechanism. A turnover mechanism is arranged between the inlet conveying mechanism and the outlet conveying mechanism and provided with a first intermediate conveying mechanism and a second intermediate conveying mechanism. The first intermediate conveying mechanism and the second intermediate conveying mechanism are arranged on the turnover mechanism in parallel. The lifting mechanism is arranged below the first intermediate conveying mechanism. The turnover mechanism is further provided with a clamping mechanism which is a hydraulically-driven plane-type clamping mechanism. According to the wheel-type automatic turnover equipment, the turnover efficiency is improved, and the turnover process is safer and more accurate; meanwhile, the wheel-type automatic turnover equipment has the characteristic of being simple in structure.

Owner:KENMEC MECHA TRONICS (SUZHOU) CO LTD

Turnover device for steel structure welding

InactiveCN110315270AEfficient flipEffectively fixedWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThreaded rod

The invention relates to the technical field of steel structures, in particular to a turnover device for steel structure welding. The device comprises a bottom plate, a first supporting plate is fixedly arranged on one side of the upper surface of the bottom plate, one end of an output shaft of a motor penetrates through a second supporting plate and is fixedly provided with a rotating shaft, oneend of the rotating shaft is fixedly provided with a second fixing plate, a threaded sleeve pipe is fixedly arranged at the upper part of the first supporting plate in a penetrating mode, the threadedsleeve pipe is in threaded connection with a threaded rod, one side of the rotating mechanism is fixedly provided with a first fixing plate, guiding rods are fixedly arranged at the two ends of one side of the first fixing plate, the other end of the threaded rod extends to the other side of the threaded sleeve pipe and is fixedly provided with a rotating disc, a rotating handle is fixedly arranged on one side of the rotating disc, a fastening nut is fixedly arranged on one side of the upper surface of the threaded sleeve pipe, and a pushing rod is fixedly arranged on one side of the upper surface of the bottom plate. The turnover device for steel structure welding has the advantages of being used for conveniently fixing and turning over steel structure welded parts, and being simple to operate, convenient to use and high in practicability.

Owner:HUBEI XINSUO CONSTR

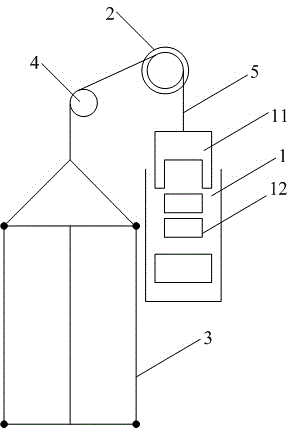

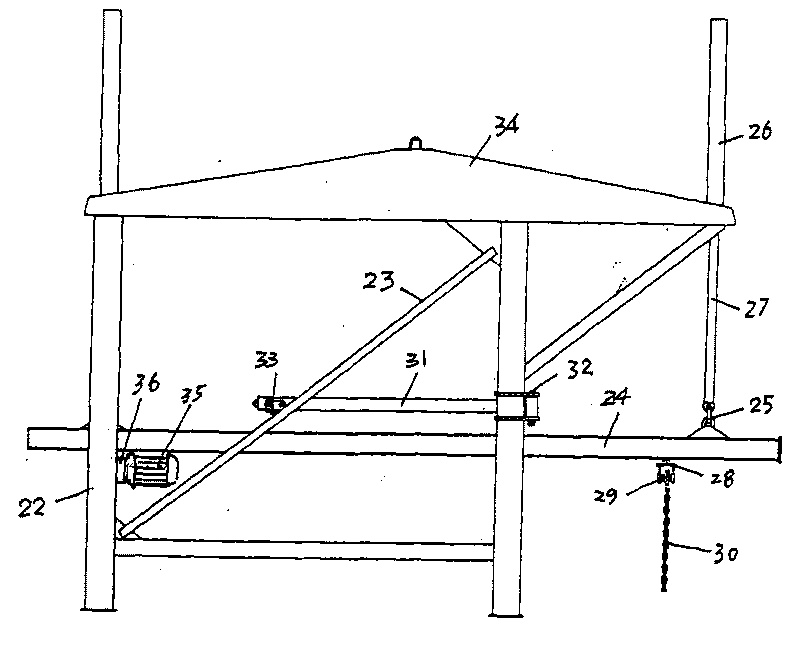

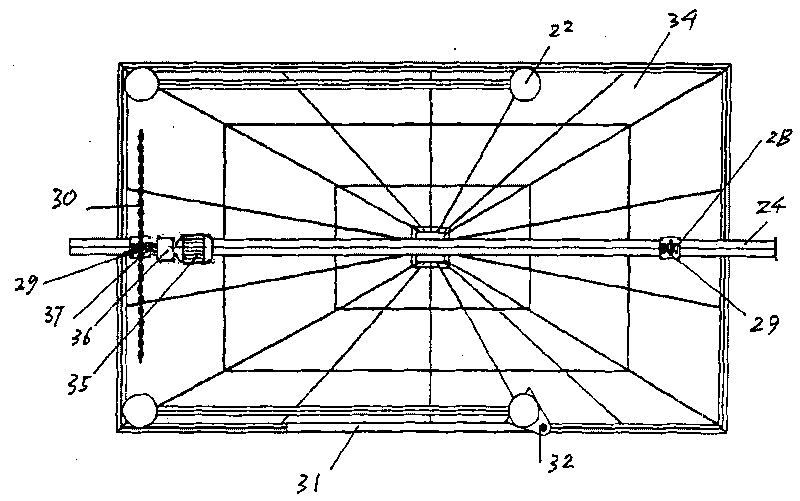

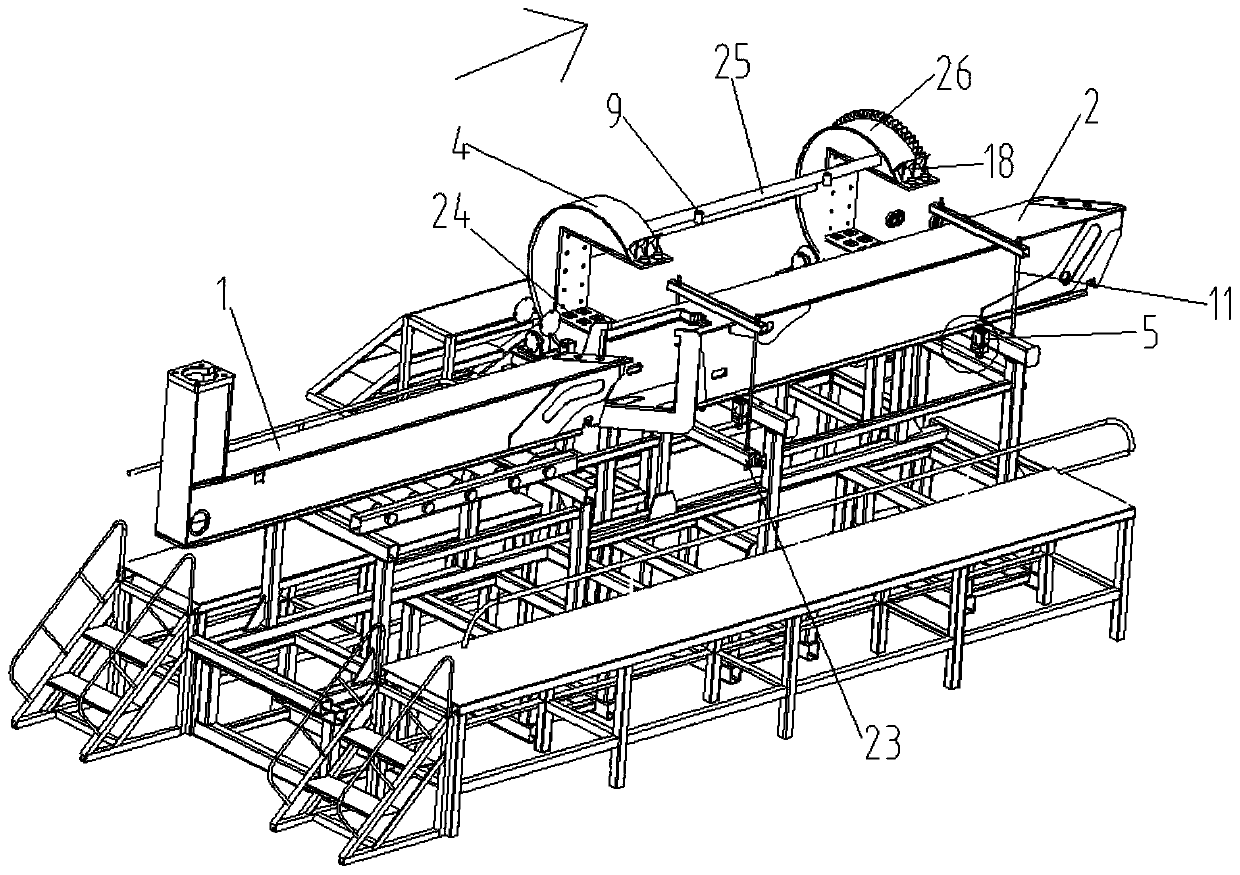

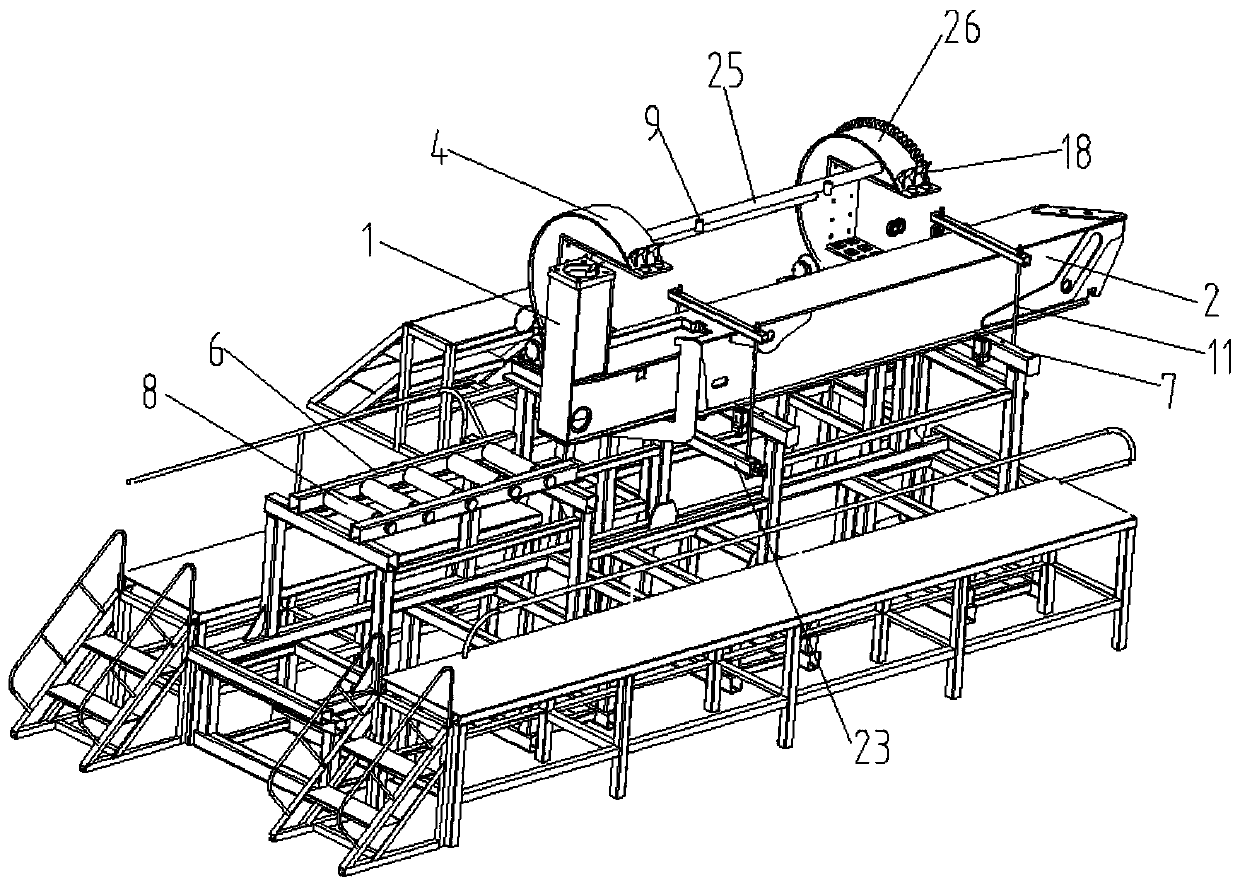

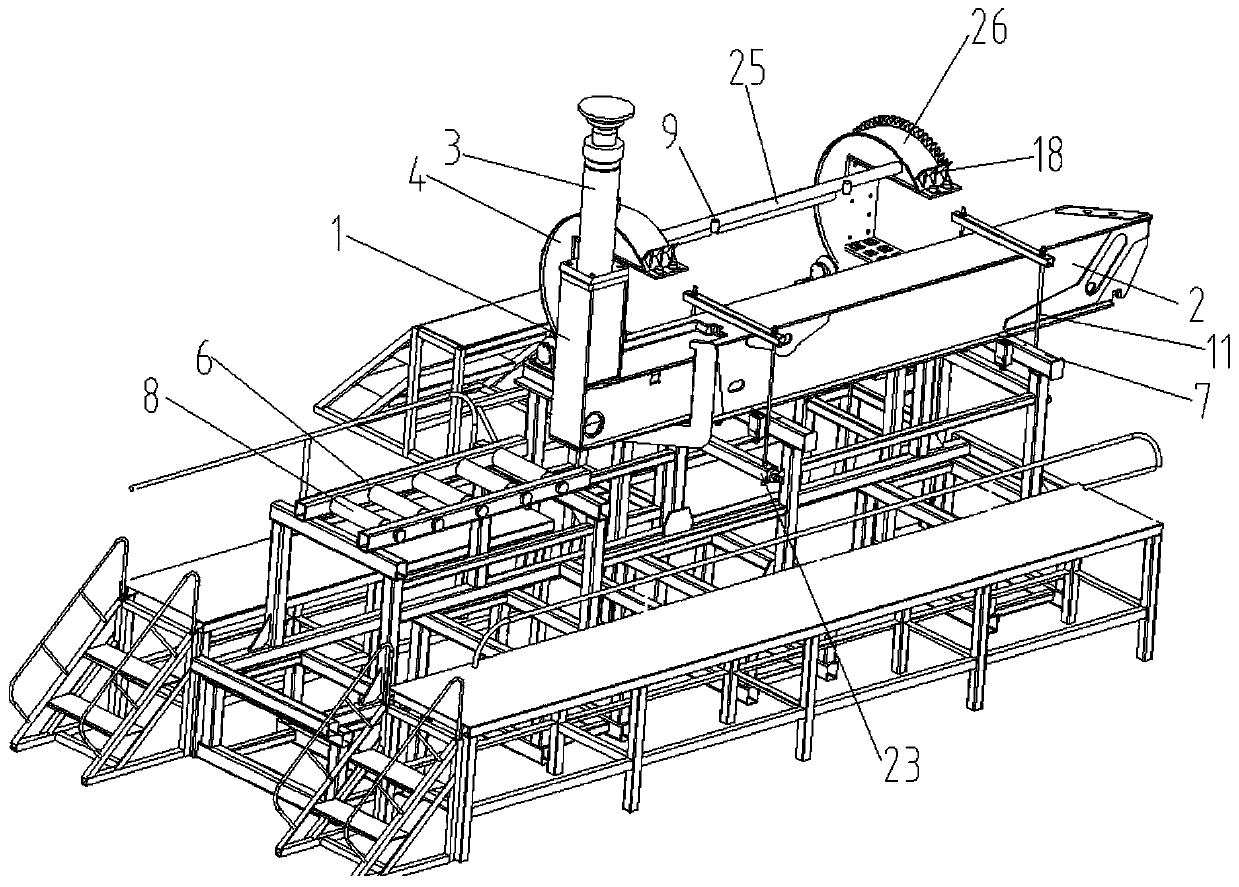

Planker overturning device

The invention relates to a planker overturning device which comprises the following five parts: a bracket part, a rain cover frame, a hydraulic system, an overturning part and a maintenance part. The lifting and landing operation of a planker can be realized by the vertical displacement change of a hydraulic cylinder of the hydraulic system; the overturning part consists of an overturning beam, a speed reducer, a chain wheel and a chain wheel system, the planker is positioned by hookers and chains; 0-180 degree overturning of the planker can be realized by the overturning of the overturning beam; the maintenance part is formed and implemented by a rotating beam, a displacement part of the rotating beam and a hand-drive block; and the rain-proof part is undertaken by a rain cover. The planker overturning device can realize safe, fast and stable overturning of the planker, and can be operated simply and easily so that the planker overturning device can be controlled by only one person in a remote way and maintenance workers can overhaul the planker safely and conveniently, thereby reducing expenses on planker overhauling and greatly improving the safety and convenience of the workers in maintenance operation.

Owner:天津港第五港埠有限公司 +2

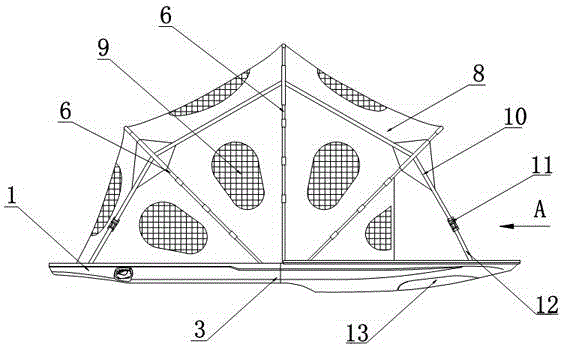

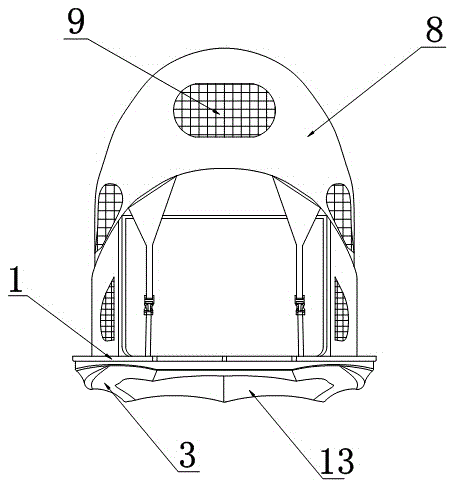

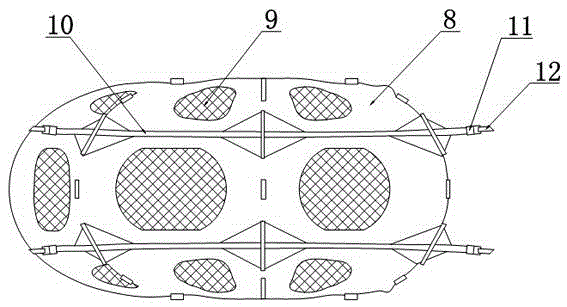

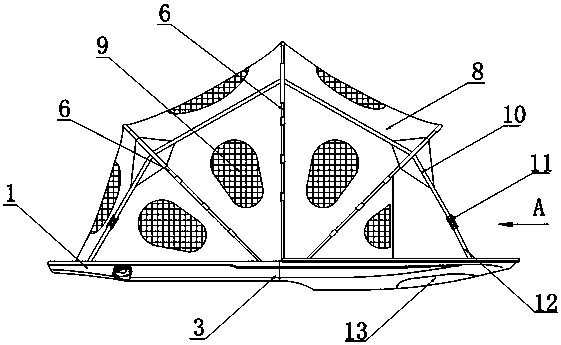

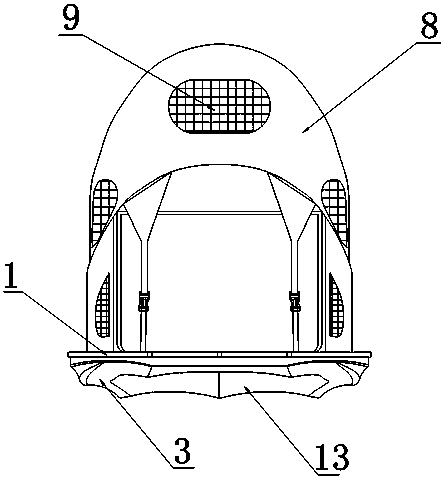

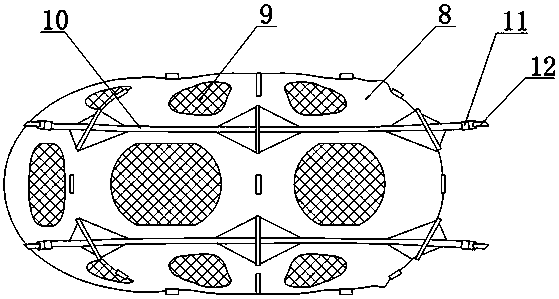

Portable double-cabin multilayer tent car top tent with high intensity and fast building function

The invention discloses a portable double-cabin multilayer tent car top tent with high intensity and a fast building function. The portable double-cabin multilayer tent car top tent comprises at least three reverse U-shaped tent support frames, inner tent cloth, an inlet, a water discharge opening and a tent cabin body, wherein the tent cabin body is formed by an outer cabin body and an inner cabin body, the tent cabin body is divided into a left tent cabin body and a right tent cabin body, the inner cabin body comprises a water separation plate, a support plate and a connecting bottom plate, a hollow layer is formed between the support plate and the connecting bottom plate, in addition, a rowed reinforcing rib mechanism positioned in the hollow layer is arranged on the connecting bottom plate, the at least three reverse U-shaped tent support frames are sequentially ranged and formed into a fan shape, the end points of all of the reverse U-shaped tent support frames are concentrated on a rotating element arranged in the middle part of the tent cabin body, and the inner tent cloth sleeves the U-shaped tent support frame positioned in the middle and is connected with the water separation plate through an elastic fixing device. The portable double-cabin multilayer tent car top tent has the advantages that the design is ingenious, the operation is convenient and fast, the time and the labor are saved, and the problems of heavy weight, low intensity, inconvenient installation and low building and folding speed of the existing car top tent are well solved.

Owner:深圳市摩崖汽车旅行装备有限公司

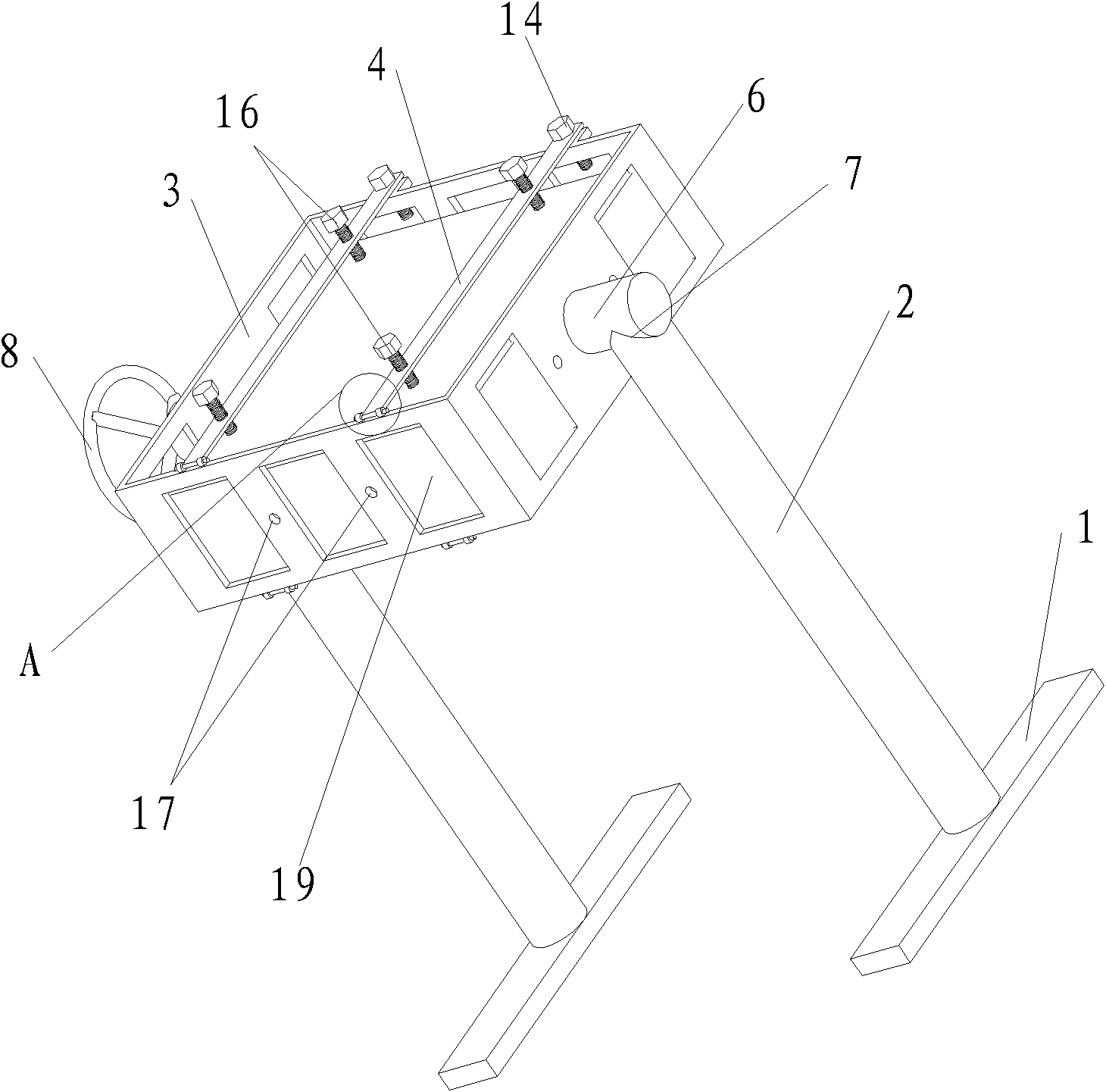

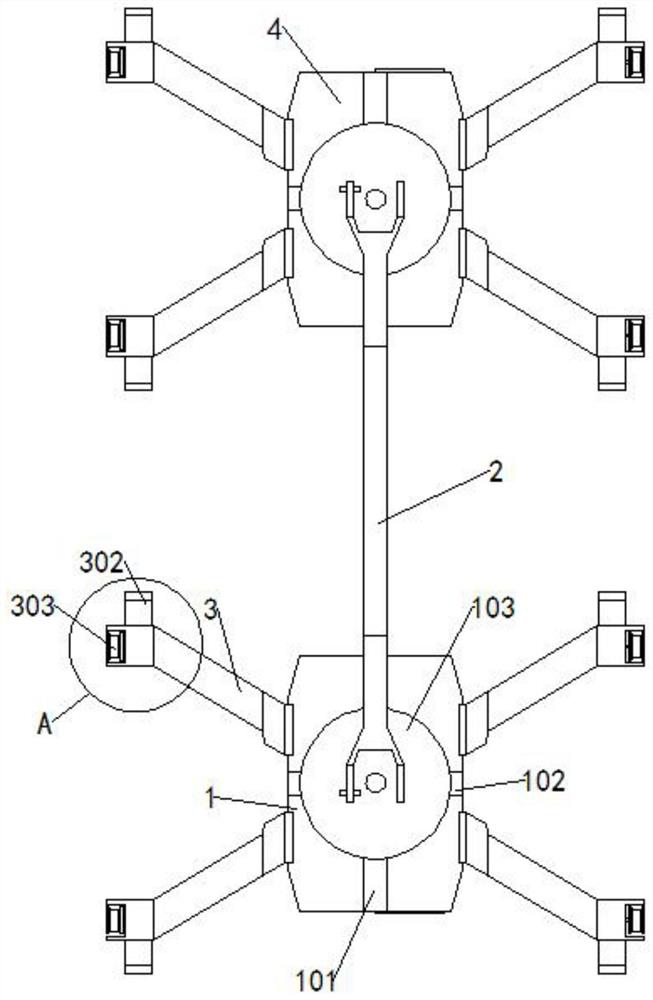

Device and method used for assembling and overturning supporting legs

The invention relates to a device and method used for assembling and overturning supporting legs. The device comprises a first-level supporting leg supporting frame, a second-level supporting leg supporting frame and an overturning mechanism. The second-level supporting leg supporting frame and the first-level supporting leg supporting frame are arranged transversely in sequence. The overturning mechanism is located on one side of the first-level supporting leg supporting frame and comprises a left overturning machine, a connecting rod and a right overturning machine. The left overturning machine and the right overturning machine are connected through a connecting rod and provided with supporting leg holding stations. A conveying riding wheel mechanism is arranged at the upper end of the first-level supporting leg supporting frame. The riding wheel transmission direction of the conveying riding wheel mechanism faces the supporting leg holding stations. A first idler wheel is arranged at the top end of the second-level supporting leg supporting frame. The idler wheel transmission direction of the first idler wheel faces the first-level supporting leg supporting frame. As the first idler wheel and the conveying riding wheel mechanism are arranged, assembling and overturning of supporting legs are more labor-saving and convenient. A driving assembly enables the overturning mechanism to overturn automatically, input of labor is saved, and the fact that people are not in danger in the overturning process is guaranteed.

Owner:CHANGDE KEJIAN MACHINERY MFG CO LTD

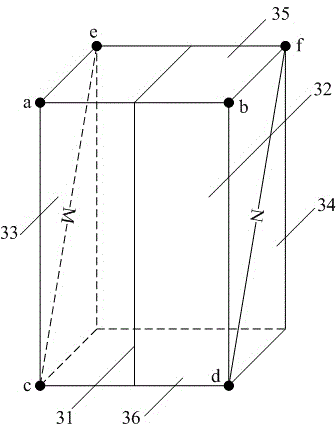

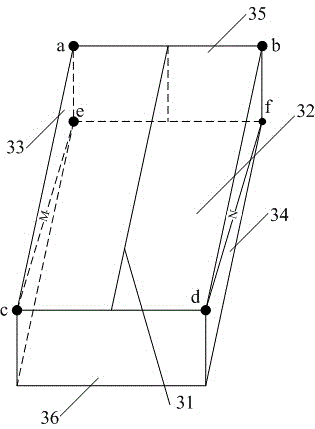

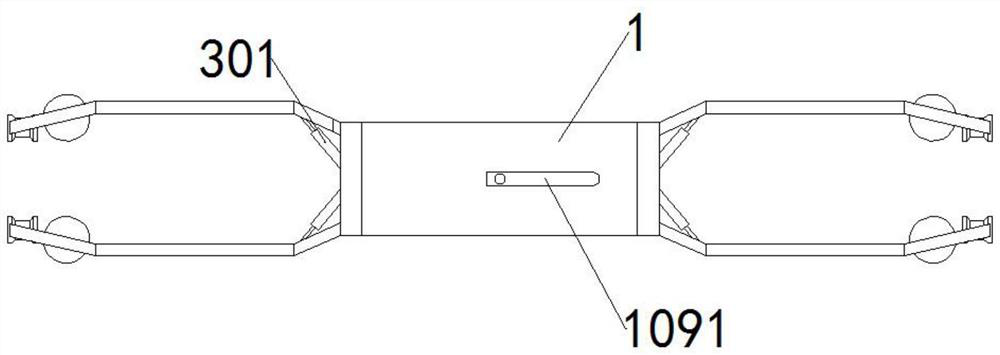

Overturning device and overturning method for large plate parts

The invention belongs to the technical field of machining tool devices, and discloses a large plate part turning device. One end of a first rotary part and one end of a second rotary part are connected to a rotating shaft. Body frames of the two rotary parts are each of a rectangular structure. Beams are arranged below the body frames. The height of the upper surfaces of the beams is smaller than the height of side beams on the peripheries of the frames. The height of the side beams is smaller than the thickness of plate parts. A plurality of lower supports are arranged on the beams. Side supports are arranged on the side beams on at least two opposite sides. The lower supports limit the perpendicular freedom degree of the parts. The side supports limit the horizontal freedom degree of the parts. Hanging lugs are arranged on the outer lateral sides of the two rotary parts respectively and are staggered. The invention further discloses a rotating method using the device. Workpieces are prevented from generating impact, external force and other effects in the turning process, safe, reliable and risk-free turning is implemented, product quality is ensured, and the cost for processing non-conformance terms is reduced.

Owner:上海第一机床厂有限公司

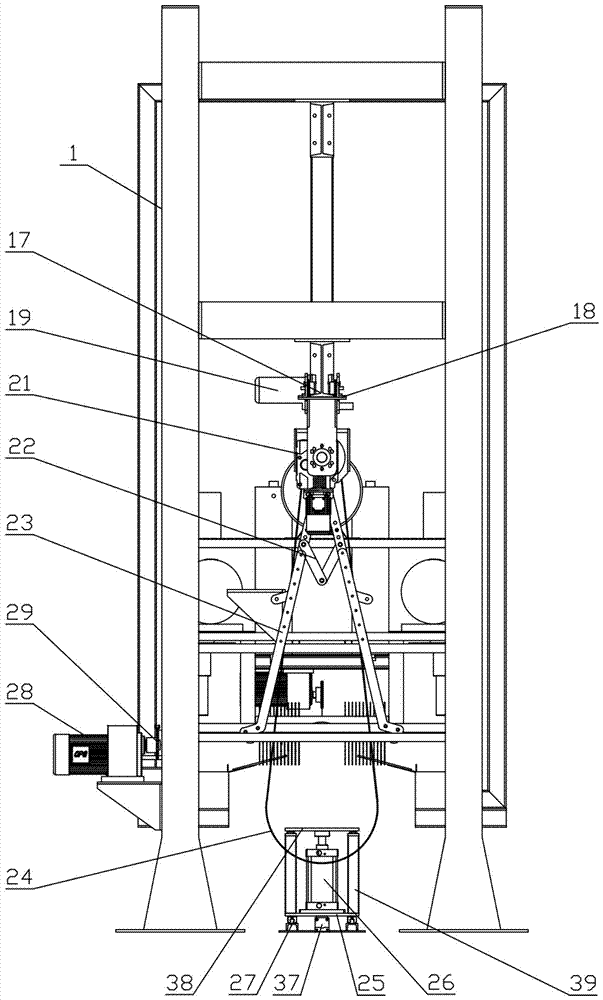

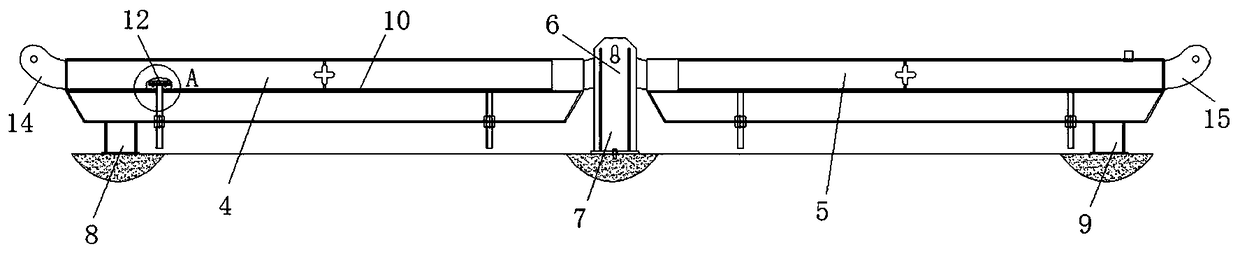

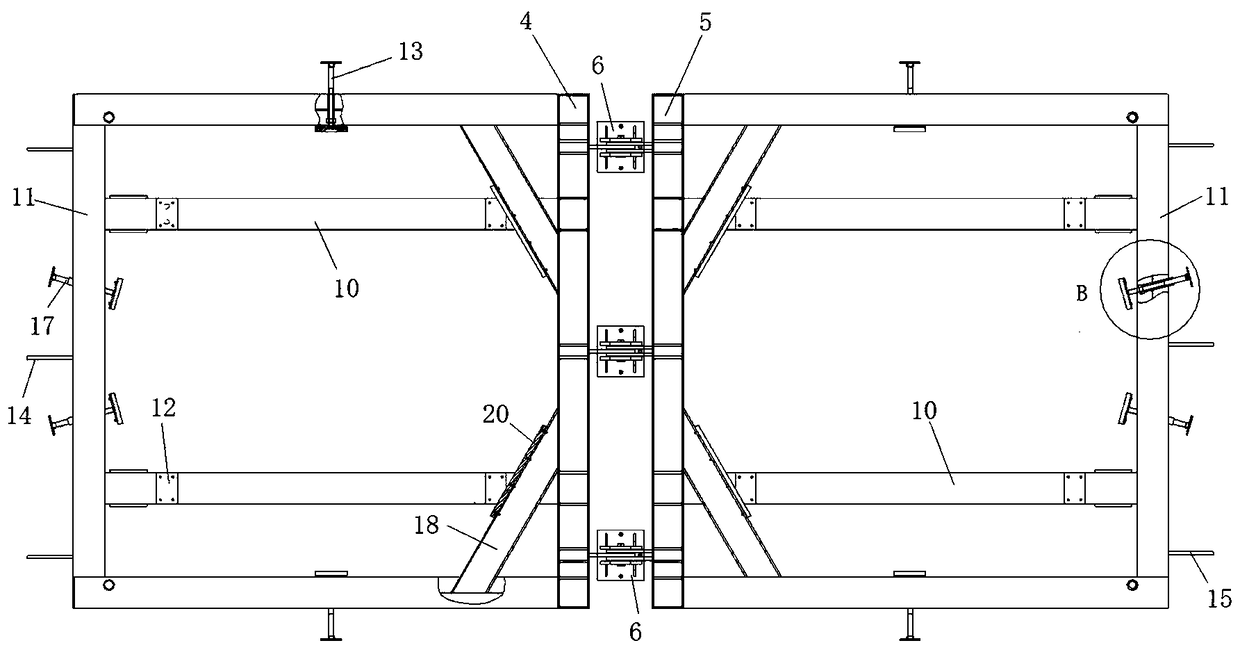

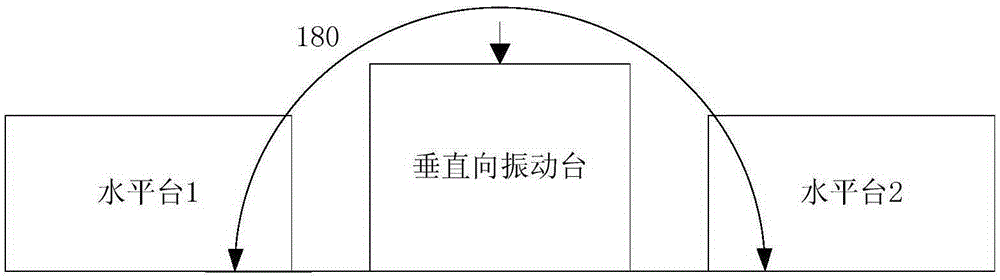

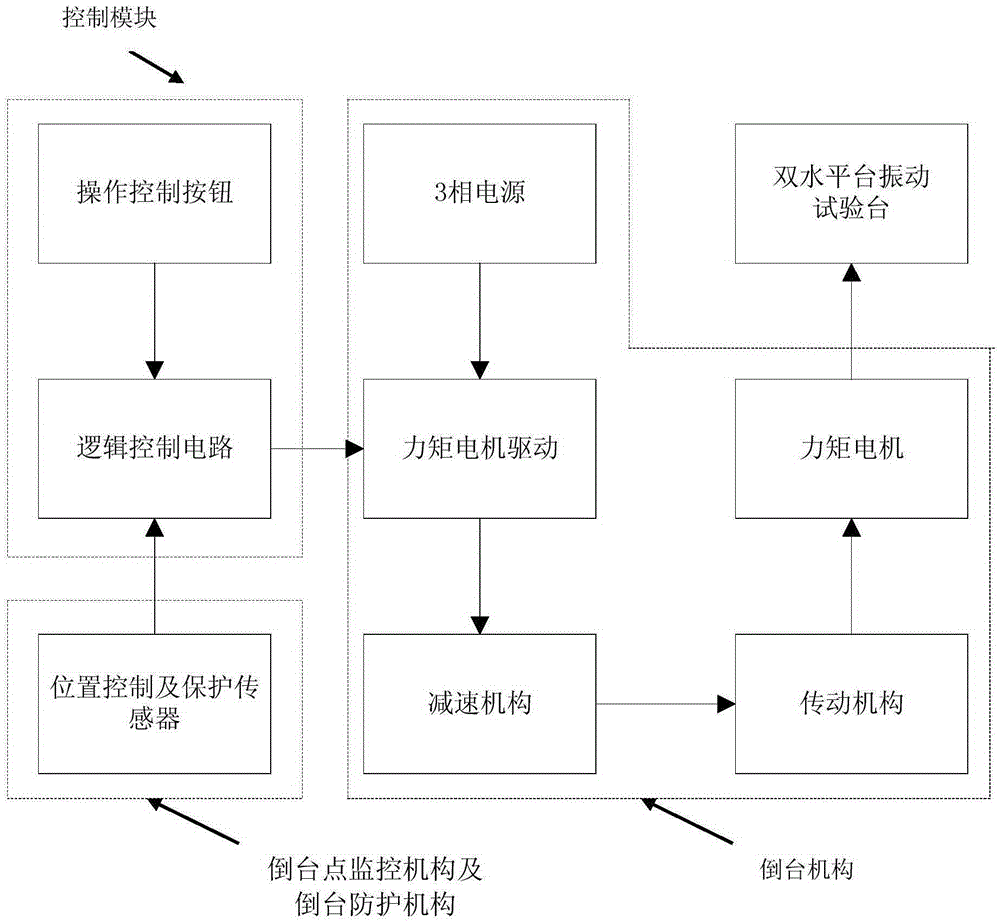

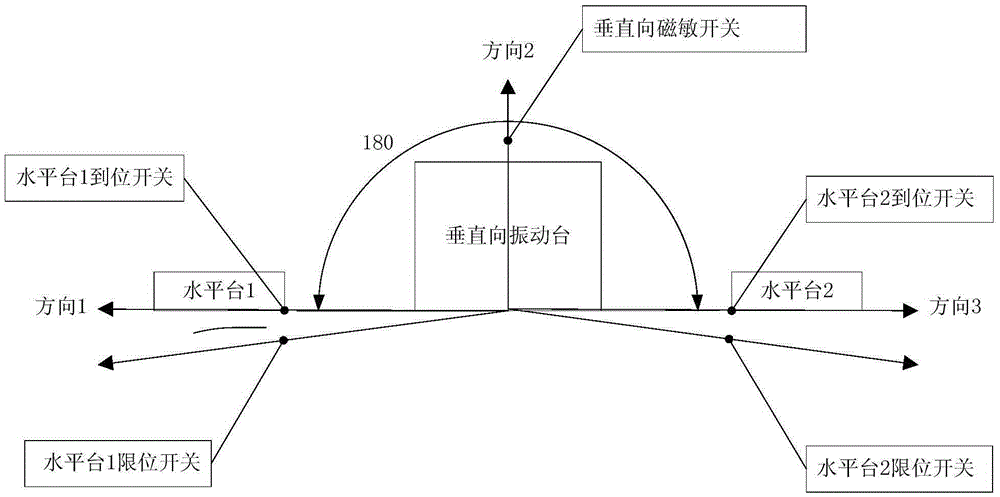

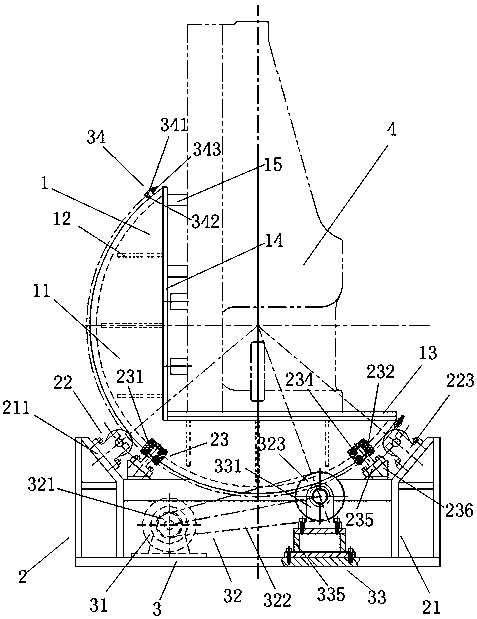

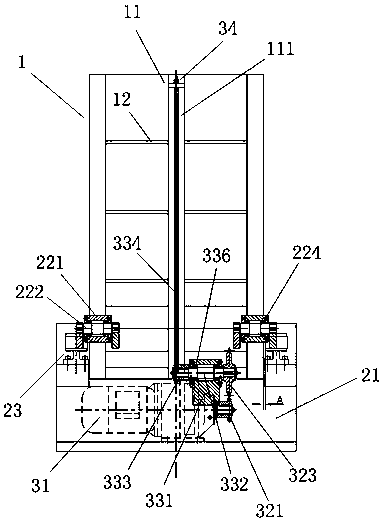

Three-direction inverse platform device of vibration test system

The invention discloses a three-direction inverse platform device of a vibration test system. The device comprises an inverse platform mechanism and an inverse platform point monitoring mechanism. The inverse platform mechanism is used for driving a vibration platform to rotate around an axis, and enables the vibration platform to stay at any selected station in first and second horizontal stations and a vertical station. First and second horizontal stations and the vertical station are located on the same plane. The vertical station is arranged between first and second horizontal stations. First and second horizontal stations are arranged in the same horizontal line. The inverse platform point monitoring mechanism is used for monitoring whether the vibration platform reaches any selected station in first and second horizontal stations and the vertical station when the vibration platform rotates. According to the invention, the device is simple in structure; on the premise that the vibration platform is safe, a dual horizontal platform structure can quickly inverse on left and right horizontal platforms and in the vertical direction; a user can determine inversing and staying manners of the platform body by himself or herself according to the use condition of the user; the burden of an operator can be significantly reduced; and the use efficiency of the device is improved.

Owner:苏州泰斯特测控科技有限公司

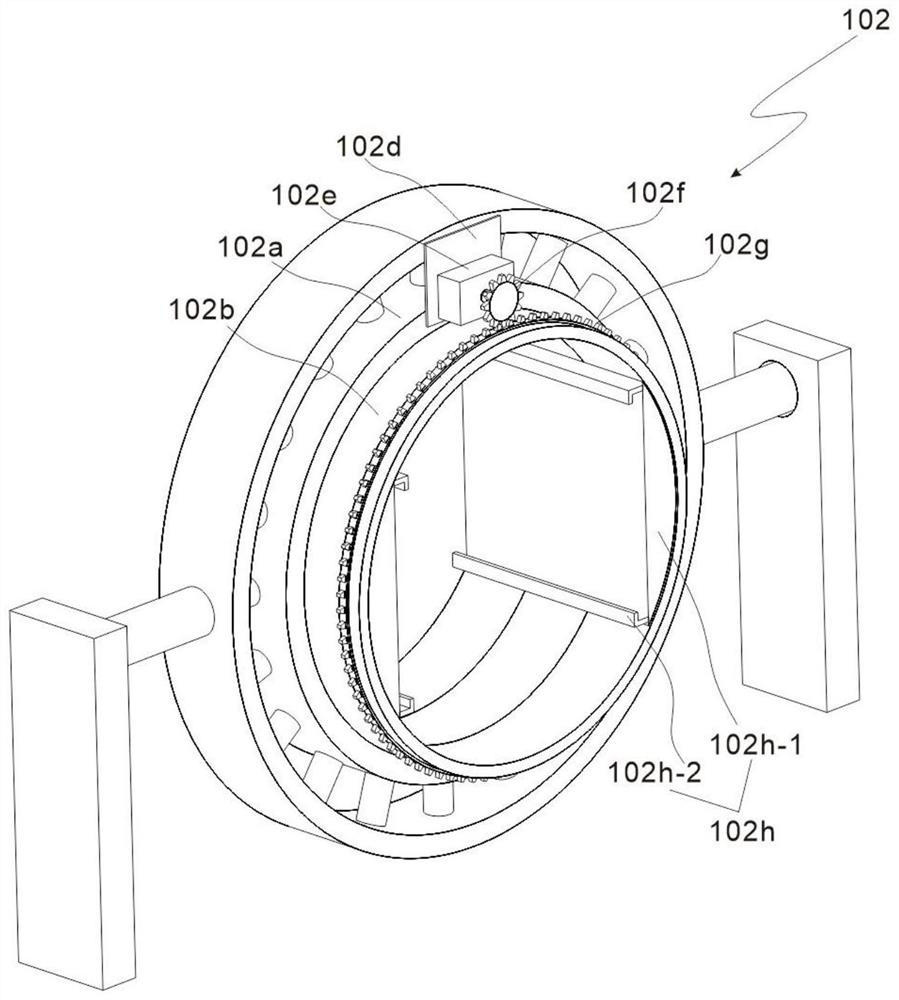

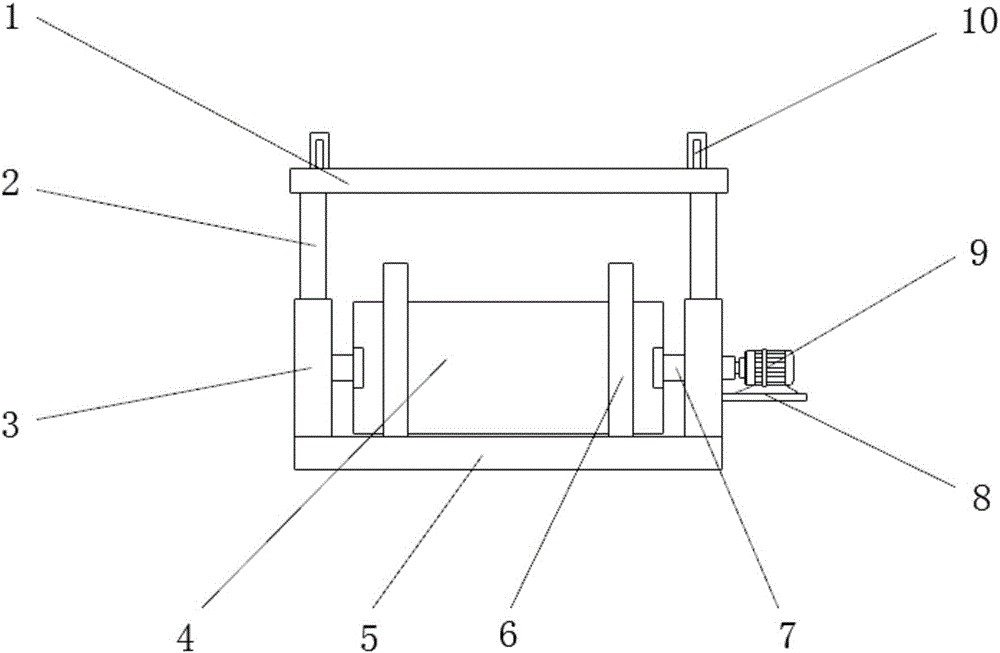

Slider Turner

ActiveCN105501912BEliminate potential safety hazardsImprove work efficiencyConveyorsConveyor partsMotor speedEngineering

The invention discloses a slide block turnover machine which comprises a slide block supporting frame, a supporting device and a supporting frame turnover drive device, wherein the slide block supporting frame is supported on the supporting device; the supporting frame turnover drive device is arranged at the outer side of the slide block supporting frame and in the supporting device. The supporting device comprises a base, a plurality of radial supporting rollers and a plurality of axial limiting supporting rolling mechanisms, wherein the slide block supporting frame turnover drive device comprises a motor speed reducer assembly, a chain transmission mechanism and a slide block supporting frame turnover transmission mechanism; and the motor speed reducer assembly is fixed in the base, and is connected to the slide block supporting frame turnover transmission mechanism through the chain transmission mechanism. According to the slide block turnover machine, the radial lower side of the slide block supporting frame is respectively supported on the base through a radial roller, and the axial two ends of the slide block supporting frame are respectively limited by axial rollers, so that the slide block supporting frame which supports a slide block safely and stably rotates by 90 degrees, and therefore, potential safety hazards generated when the slide block rotates are eliminated, and the working efficiency is improved.

Owner:WORLD PRECISE MACHINERY CO LTD CHINA

Incubator

ActiveCN102753015BSafety flipImprove space utilization efficiencyPoultry incubationEngineeringMultiple layer

An incubator is provided to decrease the volume of the incubator and secure an optimal condition to incubation. CONSTITUTION: An incubator comprises: a body frame(10); a turning tray which receives a plurality of fertilized eggs; a plurality of turning units(20) which are prepared in a turning tray, are equipped with a turning member and are received in the body frame; and a turning member driving part(50) which is prepared in the body frame and reciprocates a plurality of turning members.

Owner:AUTOELEX

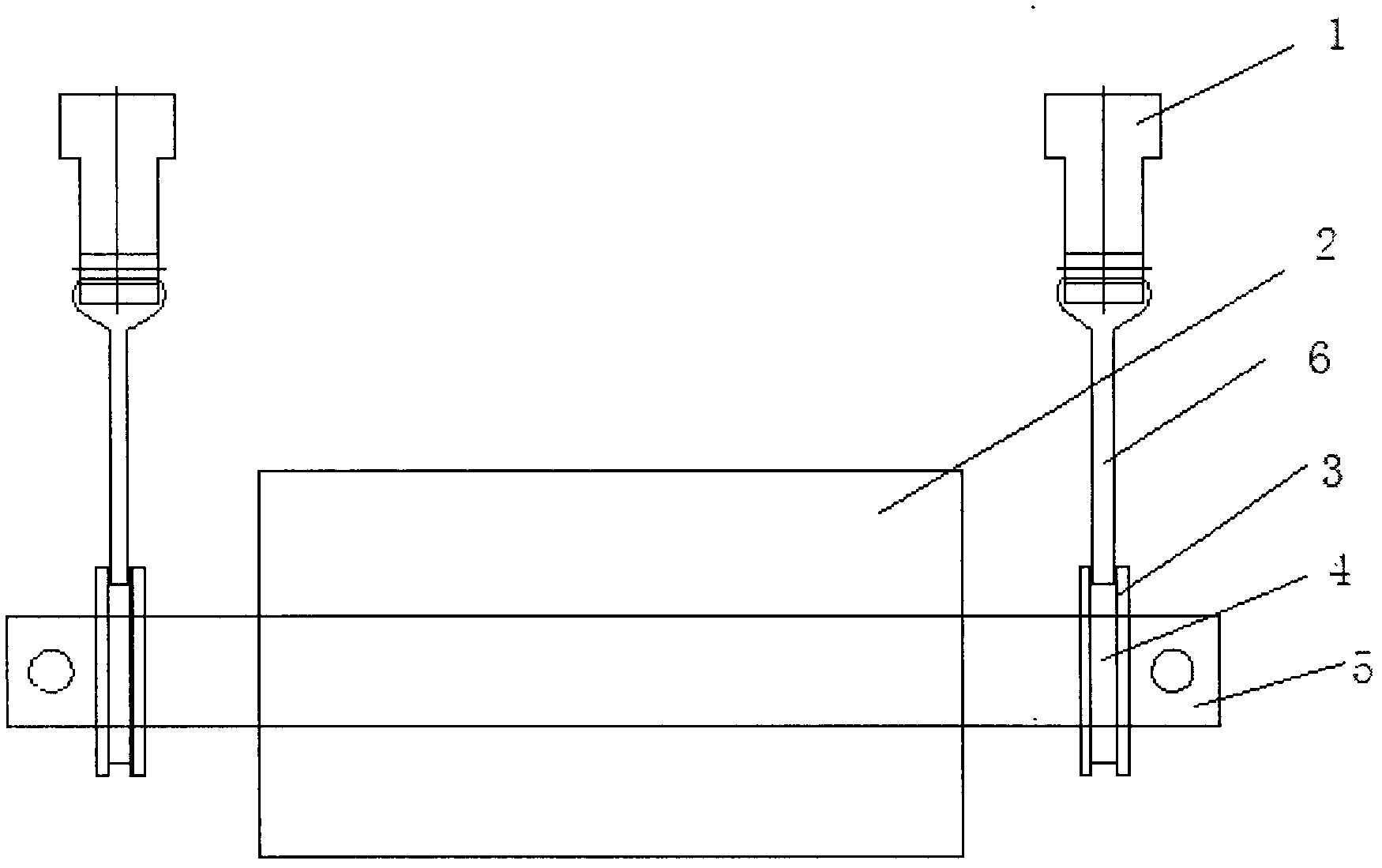

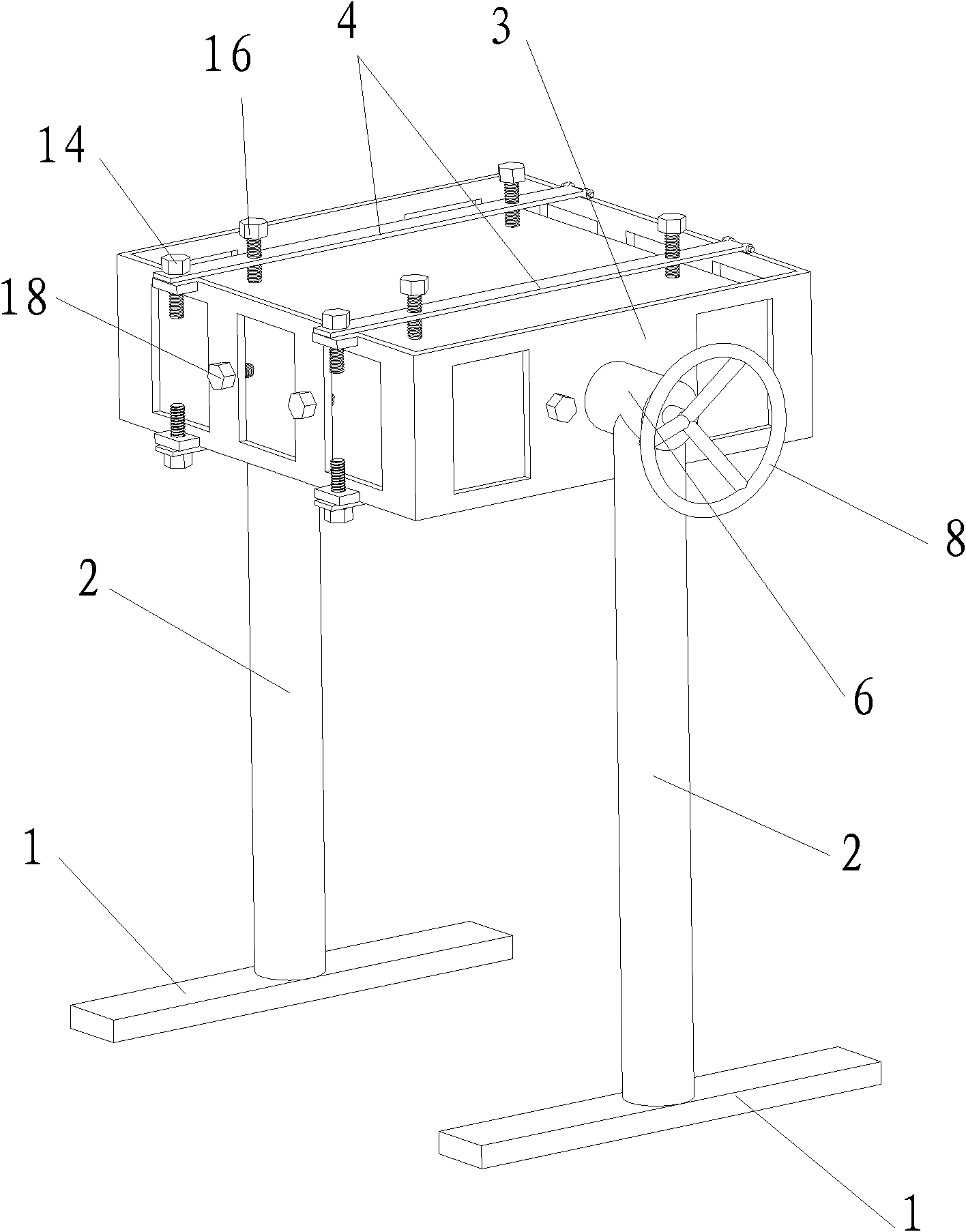

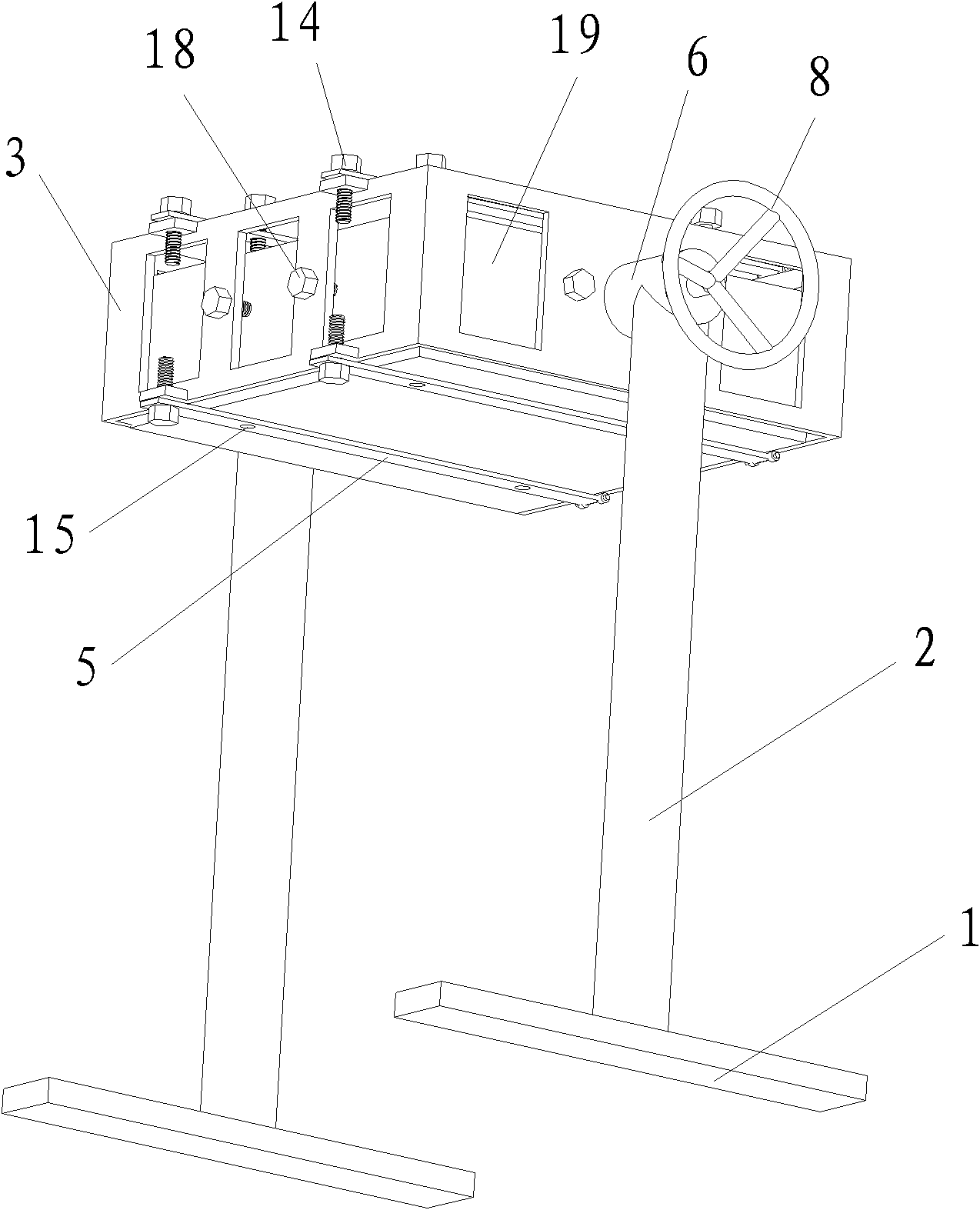

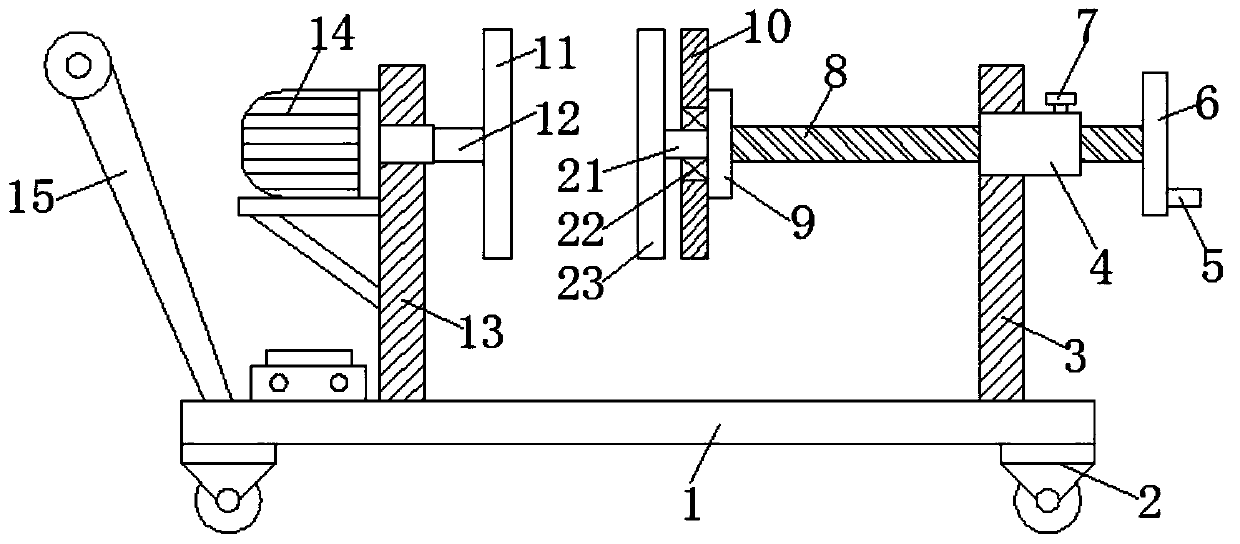

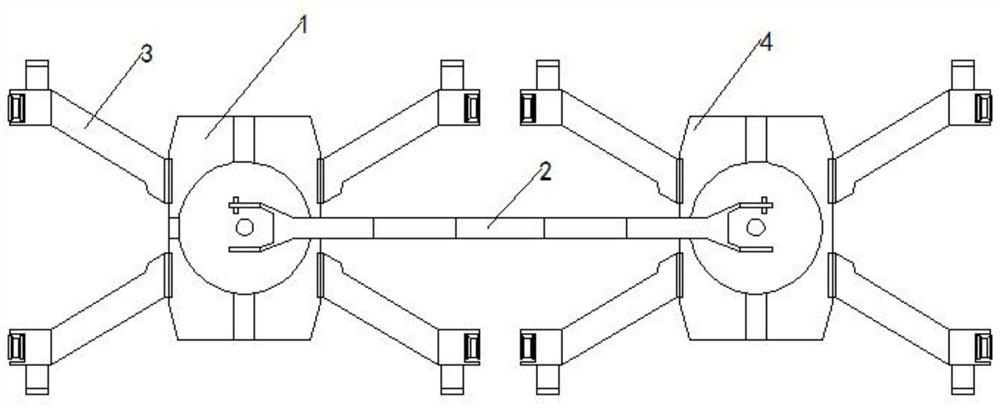

Rolling mill roll box assembly tooling

ActiveCN104550246BFlaws to avoid harmSafety flipMetal rolling stand detailsMetal rolling arrangementsEngineeringRolling mill

The invention discloses a roller box assembling fixture for a rolling mill. The roller box assembling fixture comprises a base (1), box body fixed rotating mechanisms and an adjustment and positioning mechanism, wherein a U-shaped slot is formed in the top of the base (1); one box body fixed rotating mechanism is arranged at each of the two ends of the top of the base (1); a roller box of the rolling mill is fixed on the box body fixed rotating mechanisms and can turn over around the axial lines of rotating shafts (2) of the two box body fixed rotating mechanisms; the adjustment and positioning mechanism is used for fixing the box body fixed rotating mechanisms. The roller box assembling fixture can be used for realizing turn over of the roller box of the rolling mill manually, safely and efficiently.

Owner:WUHU XINXING DUCTILE IRON PIPES

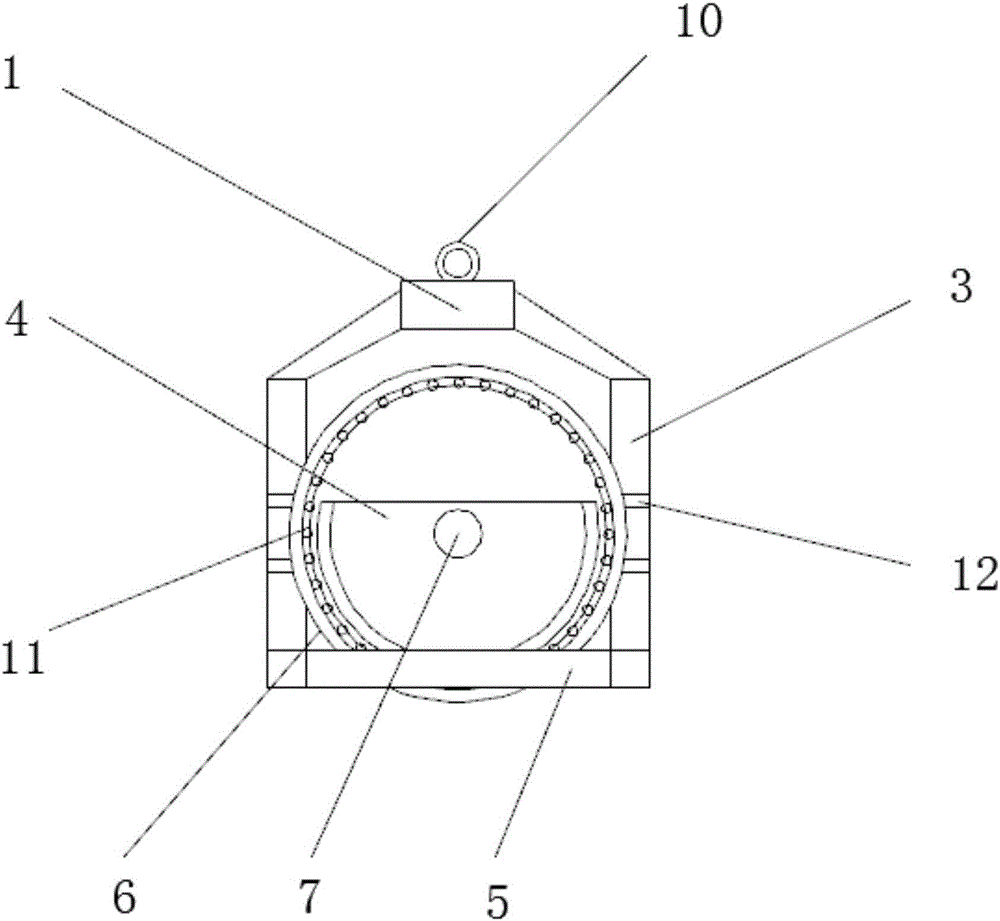

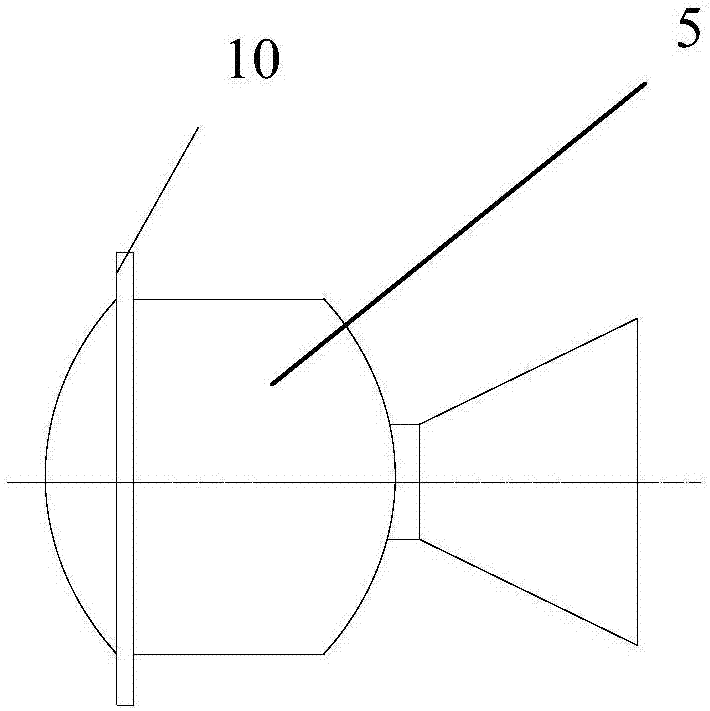

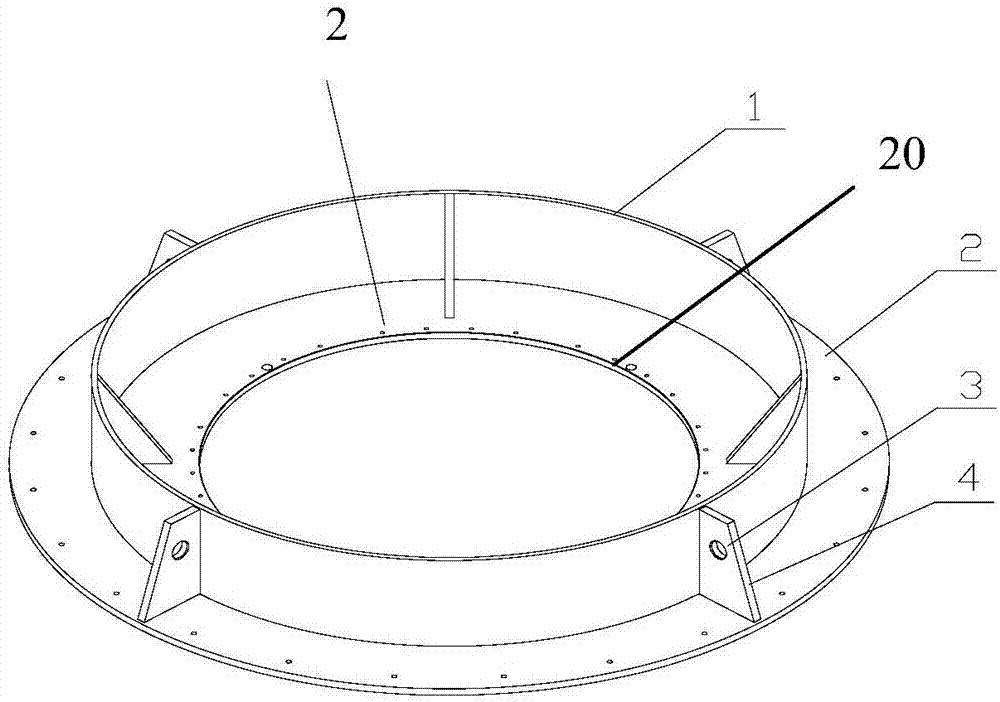

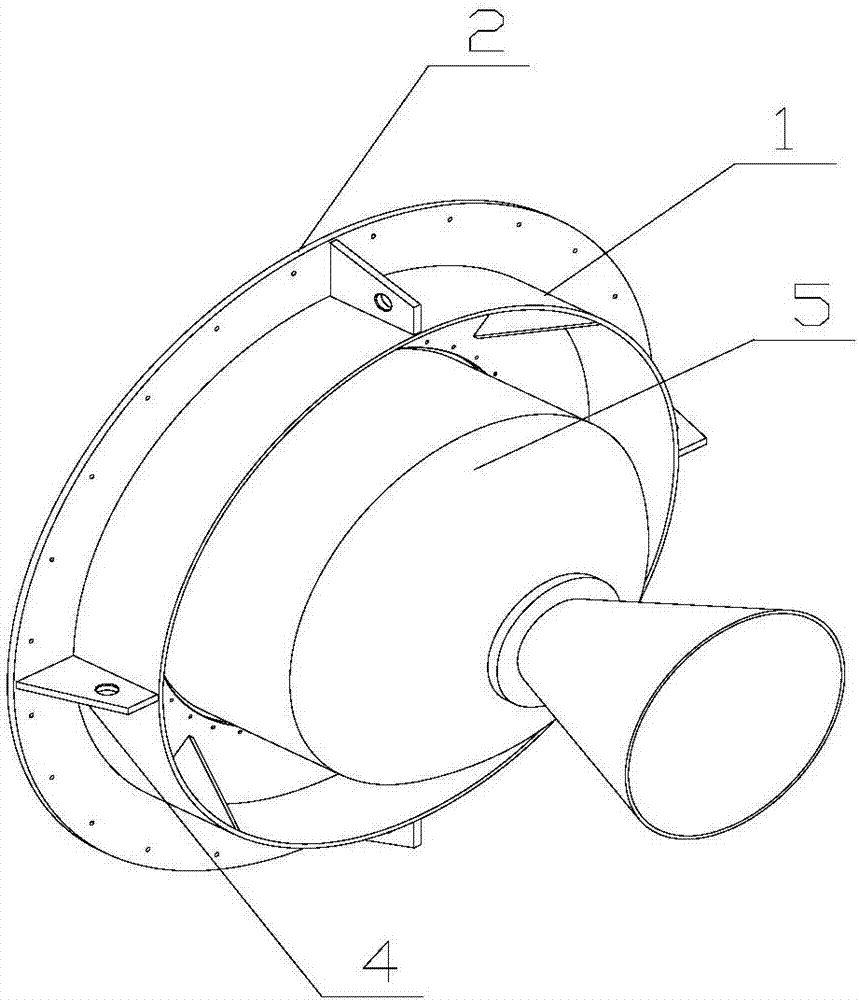

Turnover lifting tool of single skirt engine

The invention discloses a turnover lifting tool of a single skirt engine. The turnover lifting tool comprises a flange plate (2) in a circular ring shape. An engine fixing hole (20) is formed in the center portion of the flange plate (2). The engine fixing hole (20) is used for fixing the single skirt engine (5) needing to be turned over. An annularly-distributed barrel (1) is vertically arrangedon the top face of the flange plate (2). Four first reinforcing ribs (4) are distributed on the flange plate (2) at equal intervals in the radial direction. The inner side end of each first reinforcing rib (4) is fixedly connected with the outer side wall of the periphery of the barrel (1). A hoisting hole (3) is formed in each first reinforcing rib (4) in a penetrating manner. According to the turnover lifting tool, the single skirt engine can be safely and reliably subjected to single hook hosting and turnover, the problems of falling and the like are prevented from happening to the single skirt engine in the turnover process, wide application is facilitated, and important production practice significance is achieved.

Owner:TIANJIN AEROSPACE RELIA TECH +2

Lightweight double-cabin multi-layer tent roof tent with high strength and quick set-up function

The invention discloses a portable double-cabin multilayer tent car top tent with high intensity and a fast building function. The portable double-cabin multilayer tent car top tent comprises at least three reverse U-shaped tent support frames, inner tent cloth, an inlet, a water discharge opening and a tent cabin body, wherein the tent cabin body is formed by an outer cabin body and an inner cabin body, the tent cabin body is divided into a left tent cabin body and a right tent cabin body, the inner cabin body comprises a water separation plate, a support plate and a connecting bottom plate, a hollow layer is formed between the support plate and the connecting bottom plate, in addition, a rowed reinforcing rib mechanism positioned in the hollow layer is arranged on the connecting bottom plate, the at least three reverse U-shaped tent support frames are sequentially ranged and formed into a fan shape, the end points of all of the reverse U-shaped tent support frames are concentrated on a rotating element arranged in the middle part of the tent cabin body, and the inner tent cloth sleeves the U-shaped tent support frame positioned in the middle and is connected with the water separation plate through an elastic fixing device. The portable double-cabin multilayer tent car top tent has the advantages that the design is ingenious, the operation is convenient and fast, the time and the labor are saved, and the problems of heavy weight, low intensity, inconvenient installation and low building and folding speed of the existing car top tent are well solved.

Owner:深圳市摩崖汽车旅行装备有限公司

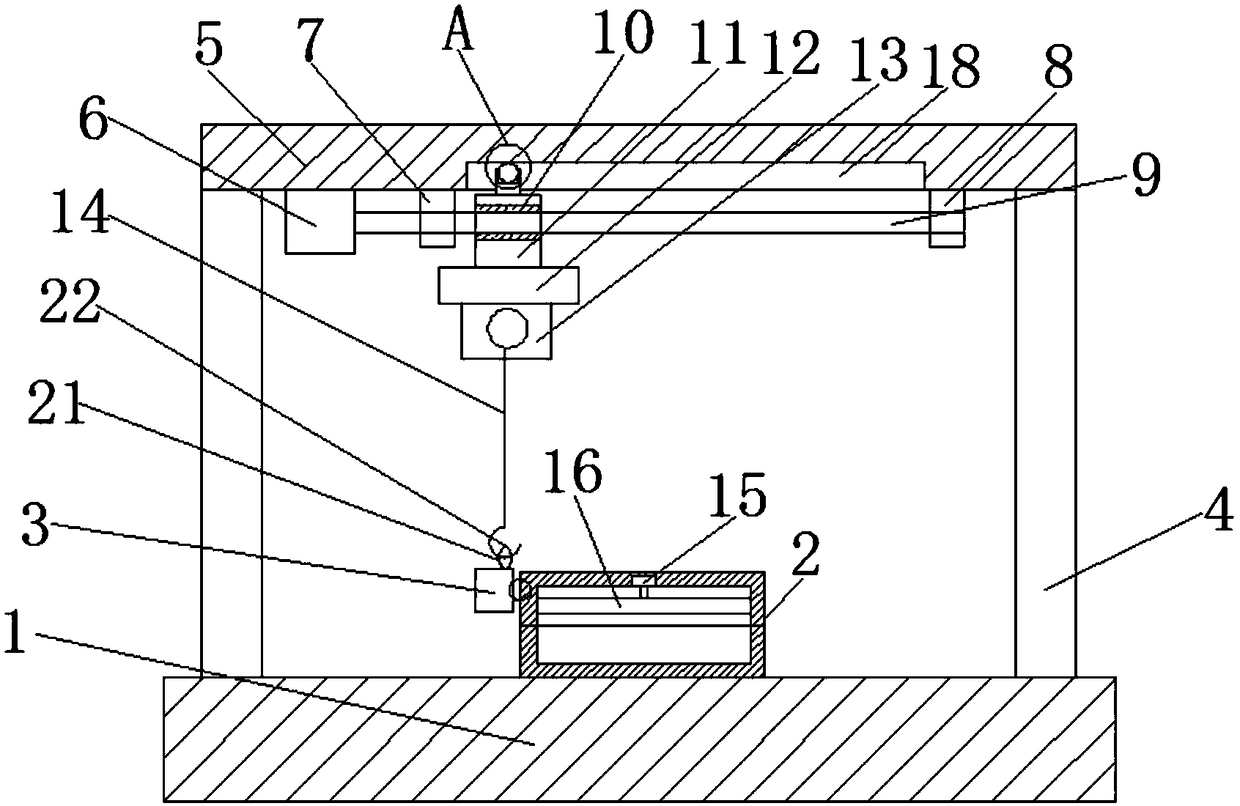

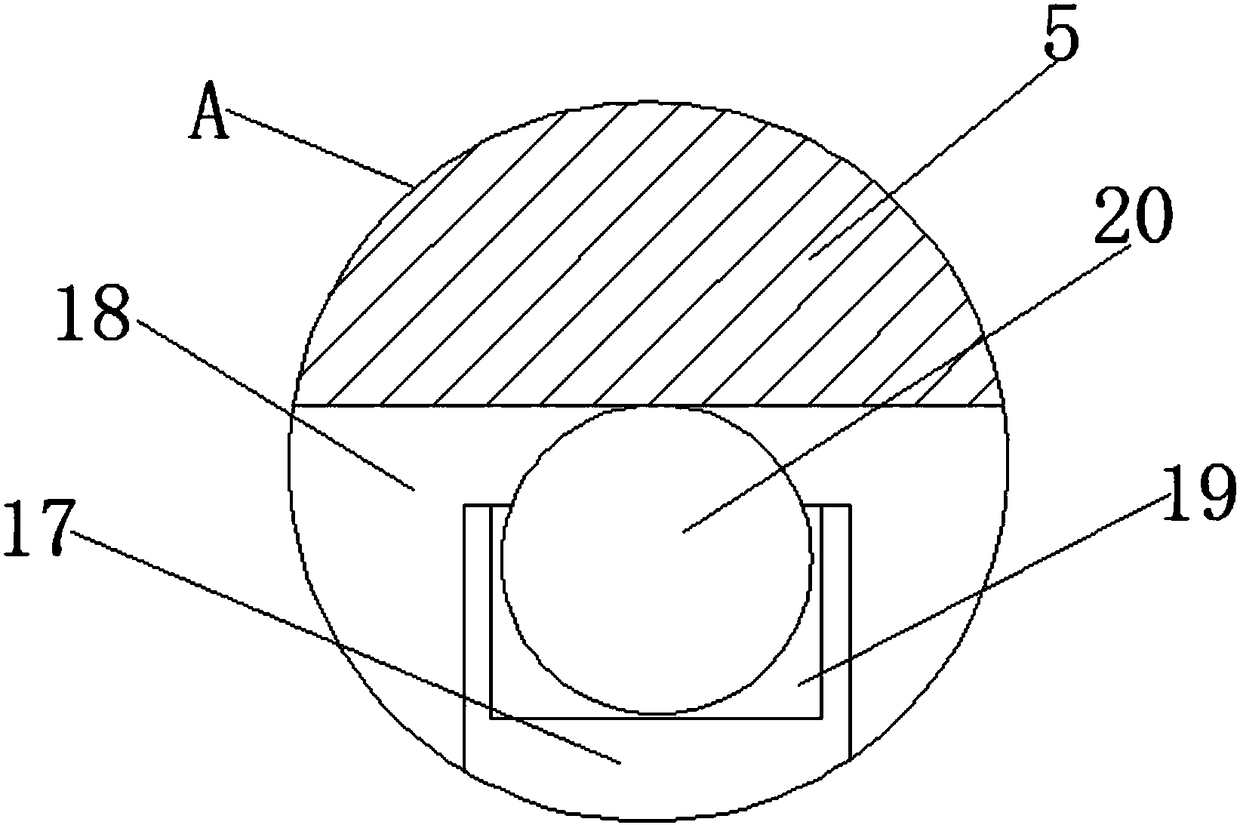

Mold turnover device for conveniently adjusting interior clamping diameter

The invention discloses a mold turnover device for conveniently adjusting an interior clamping diameter. The mold turnover device comprises a base. The upper surface of the base is provided with a mold, and a hinge on the side wall of the mold is connected with a connecting block. The connecting block is connected with a lifting ring, and the upper surface of the base is symmetrically connected with supporting columns. The top ends of the two supporting columns are jointly connected with a top plate, and the lower surface of the top plate is fixedly connected with a drive motor, a first bearing seat and a second bearing seat from the left to the right in sequence. The output end of the drive motor is connected with a lead screw through a coupling, and the other end of the lead screw passesthrough the first bearing seat and extends into the second bearing seat. The lead screw which is located between the first bearing seat and the second bearing seat is provided with a feed screw nut,and the outer wall of the feed screw nut is sleeved with a fixing seat. A fixing plate is fixed to the lower surface of the fixing seat, and the lower surface of the fixing plate is fixedly connectedwith a hoisting machine. The output end of the hoisting machine is connected with a lifting hook through a steel cable. The mold turnover device for conveniently adjusting the interior clamping diameter is simple in structure, and molds are turned over safely.

Owner:欧振云

Maintenance device for removing ice on surface layer of cable and winding between cables

ActiveCN111864632APromote sheddingConsistent structureOverhead installationApparatus for overhead lines/cablesGear wheelElectric machinery

The invention provides a maintenance device for removing ice on the surface layer of a cable and winding between cables. The invention belongs to the technical field of cable maintenance, the device comprises a device shell, grooves, lateral grooves, a rotary disc, a first gear, a first motor, a second gear, a second motor, a transmission gear, a third motor, a deflection column, a supporting frame, a rotary gear, a lifting frame, a lateral support, a hydraulic rod, a fourth motor, a rolling wheel, a neck, a clamping piece and an auxiliary device. The grooves are nested in the front and rear ends of the top surface of the device shell; and the lateral grooves are nested in the left side and the right side of the top surface of the device shell. The top of the device shell is rotationally connected with the rotary disc, the bottom end in the device shell is rotationally connected with the first gear, one side in the device shell is fixedly connected with the first motor, the middle of the top of the first gear is fixedly connected with the second gear, and the middle in the device shell is rotationally connected with the transmission gear.

Owner:山东道永盛信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com