Patents

Literature

56results about How to "Flip reliable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

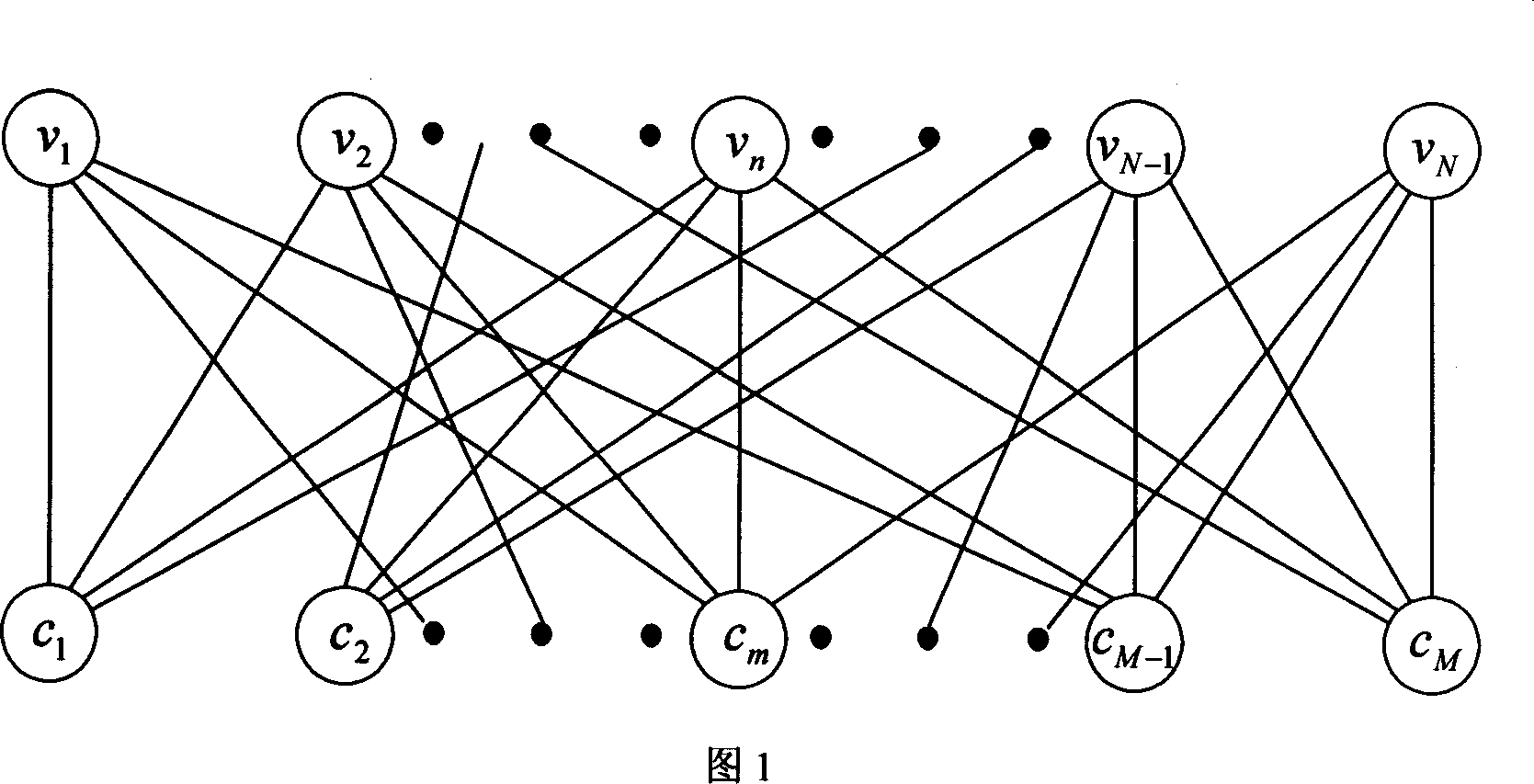

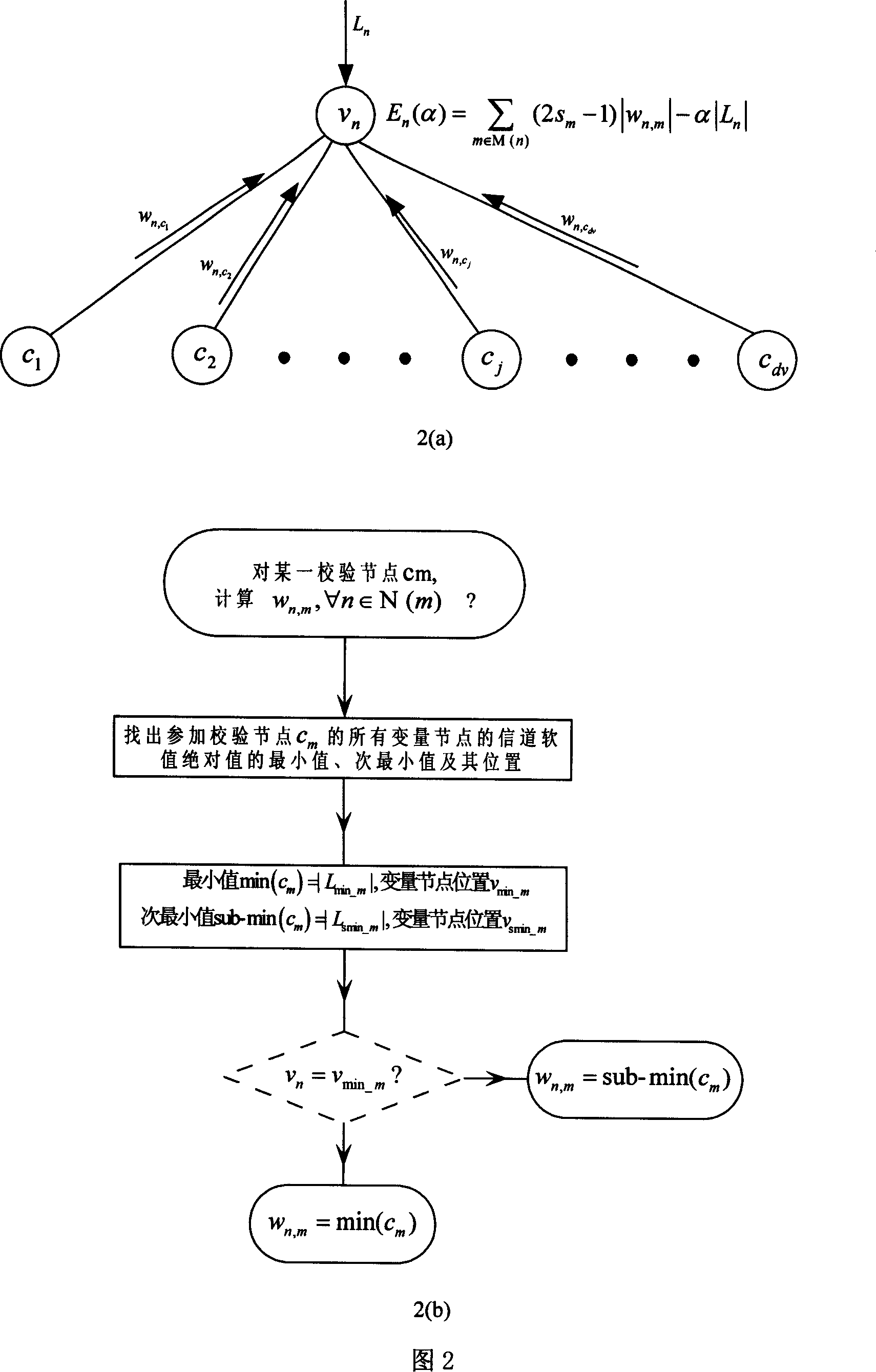

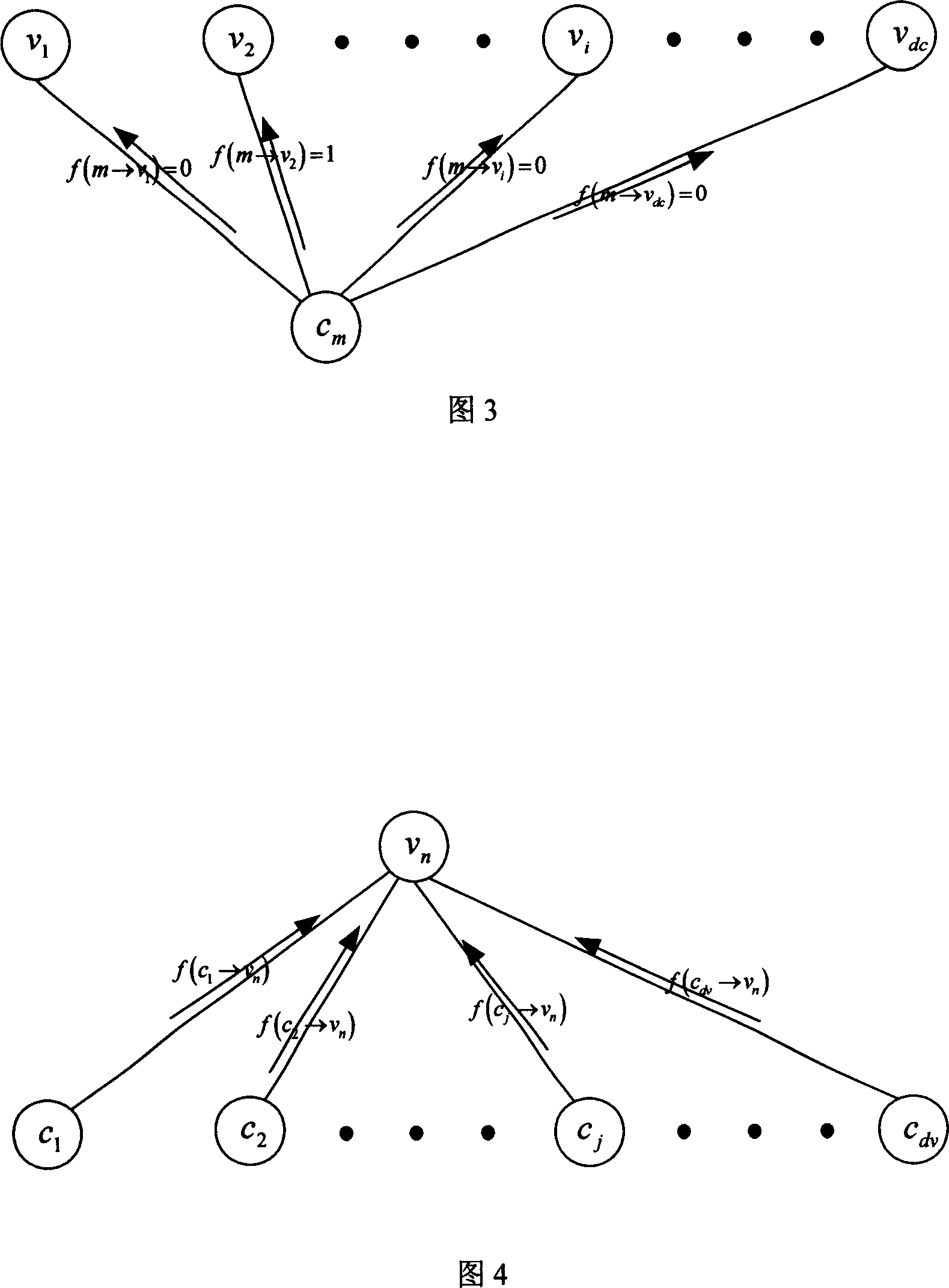

Parallel weighting bit upturn decoding method of low density check code

InactiveCN101018060ADecoding convergence speed improvedOverall Computational Complexity ReductionError correction/detection using multiple parity bitsCode conversionHard codingLow-density parity-check code

Compared with prior art, the parallel-WBF coding method for soft decision coding on LDPC improves convergence speed greatly, and comprises exactly: hard deciding received signal to obtain a hard-decision code and try to decide whether it satisfies all check relation, yes to end; or else, to any failure node, finding out the variable node with the largest WBF decision, and sending unique signal to this node; then, counting signal quantity, selecting all nodes whose signal quantity over a threshold, taking parallel WBF to the position of hard-code; updating the hard-code, going to next iteration.

Owner:SOUTHEAST UNIV

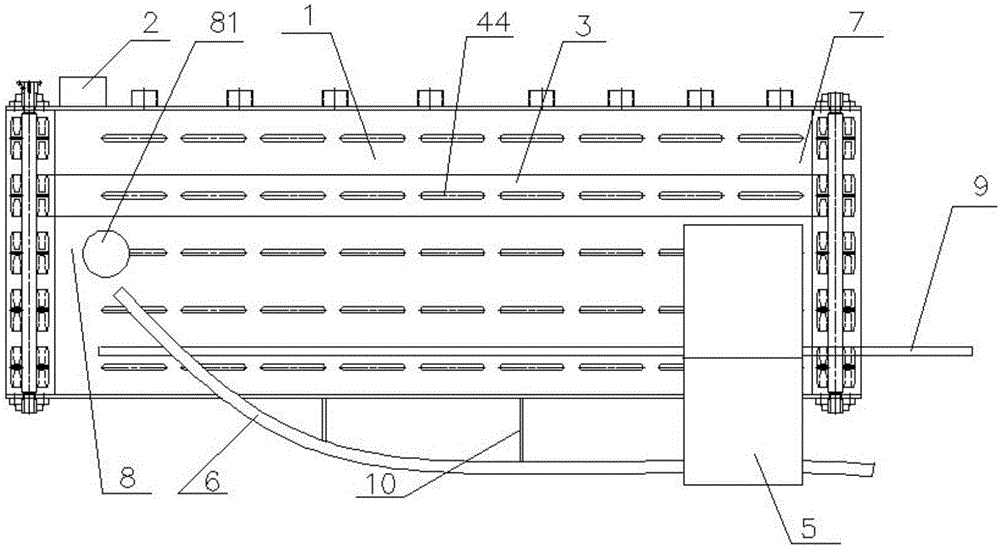

Automatic dust removal equipment for electric energy meters

The invention discloses automatic dust removal equipment for electric energy meters. The automatic dust removal equipment for the electric energy meters comprises a rack, a conveying device and a dust removal device. The automatic dust removal equipment is characterized in that the conveying device and the dust removal device are arranged on the front part and the rear part of the rack in parallel; the dust removal device comprises a location fixture used for fixing the plurality of electric energy meters, an air-blowing device and a turnover mechanism used for driving the location fixture to turn over up and down; and a transferring-loading mechanism is further arranged above the rack, and between the conveying device and the location fixture, and used for grabbing the electric energy meters to be subjected to dust removal on the conveying device and moving the electric energy meters onto the location fixture or grabbing the electric energy meters subjected to dust removal on the location fixture and moving the electric energy meters onto the conveying device. According to the automatic dust removal equipment for the electric energy meters, the conveying device and the dust removal device are mutually separated, so that dust in the electric energy meters can be adequately eliminated.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

Mechanical arm device with return and reversal function

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

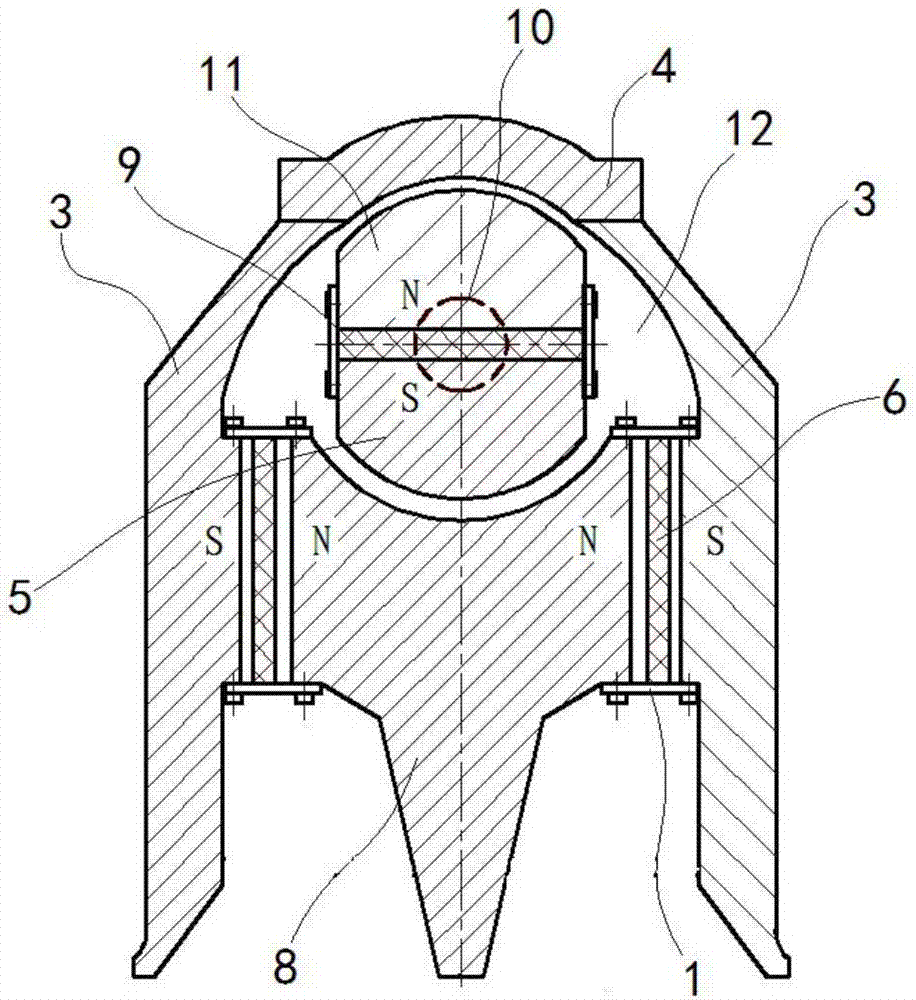

Double-arm drying type hoisting permanent magnet

The invention relates to a double-arm drying type hoisting permanent magnet. The double-arm drying type hoisting permanent magnet comprises a magnetic system and a driving system, wherein the driving system is arranged on the magnetic system; the magnetic system is positioned at the lower part of the driving system; and the driving system achieves the goal of sucking heavy objects and unloading the heavy objects through the rotation of a rotary composite permanent magnet in the magnetic system. The double-arm drying type hoisting permanent magnet is characterized in that the driving system comprises driven cylindrical gears, a driving cylindrical gear, a hanging ring, a front small hanging chain, front hoisting chains, a back small hanging chain, back hoisting chains and a shaft system; the two driven cylindrical gears are respectively connected onto the end parts of a rotating shaft, and are engaged with the driving cylindrical gear arranged in the middle; the driving cylindrical gear is connected with the end part of the shaft system; one ends of the two front hoisting chains and the two back hoisting chains are respectively connected with an upper cover through a hanging lug arranged on the upper cover, and the other ends are connected onto the hanging ring; one end of the front small hanging chain is connected with the end part of a front swinging rod arranged on the shaft system; one end of the back small hanging chain is connected with the end part of a back swinging rod arranged on the shaft system; and the other ends of the front and back small hanging chains are connected onto the hanging ring. The permanent magnet has the advantages that the structure is simple and reasonable; and the application range of the hoisting permanent magnet is expanded.

Owner:CHANGCHUN UNIV

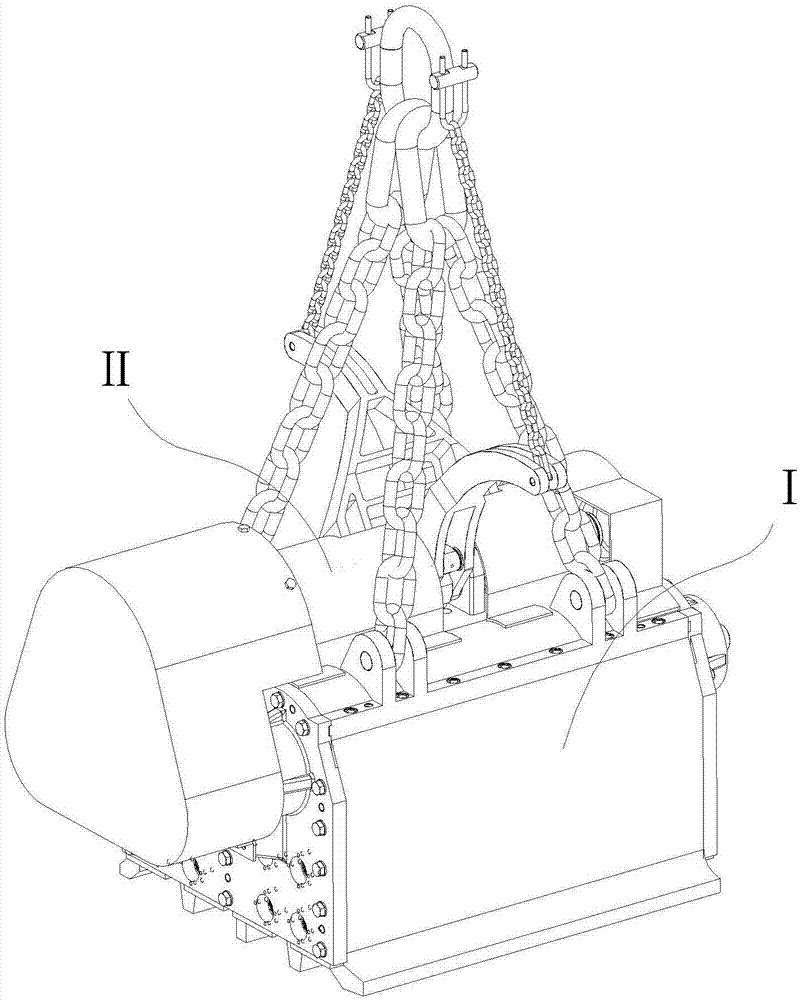

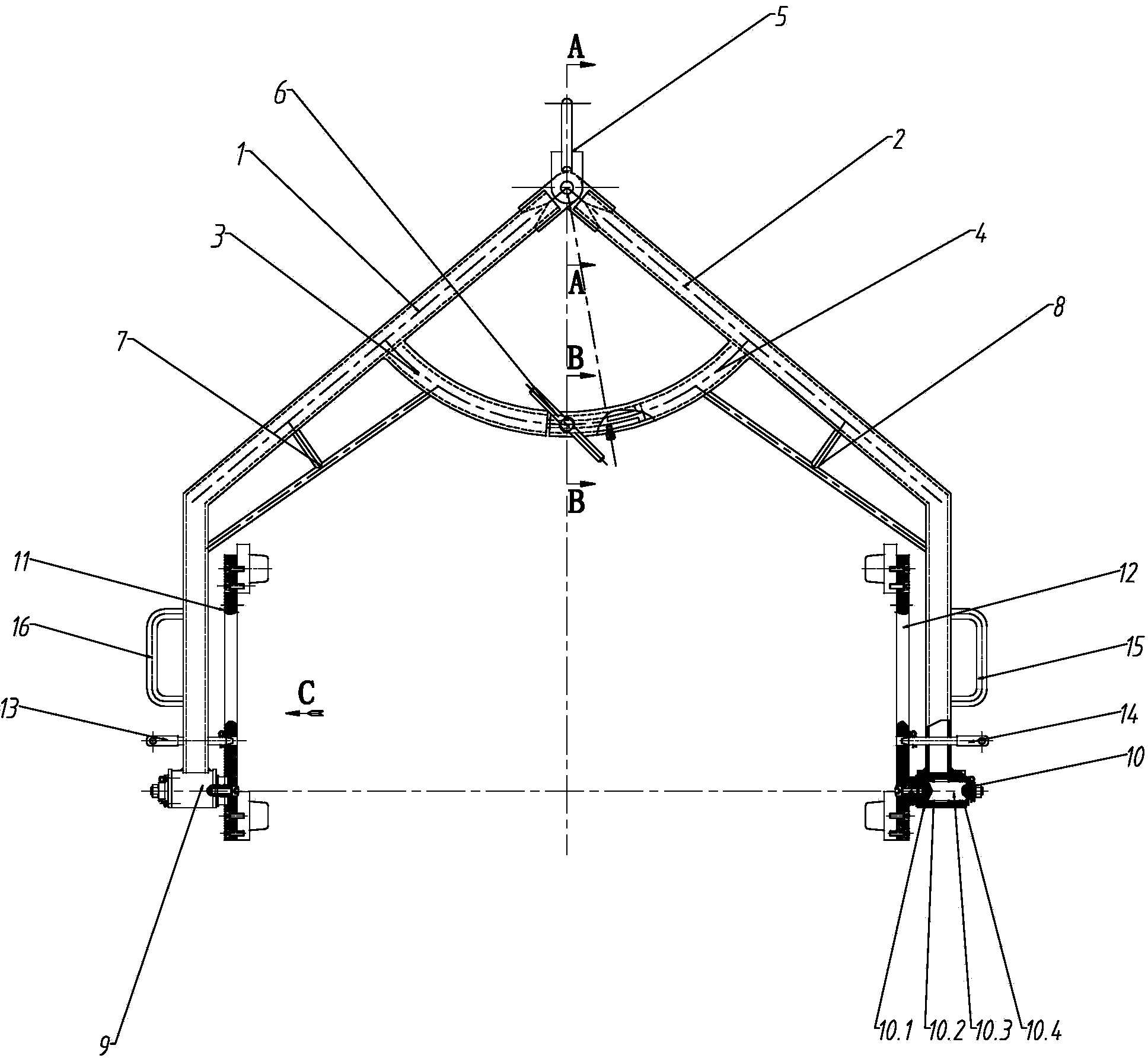

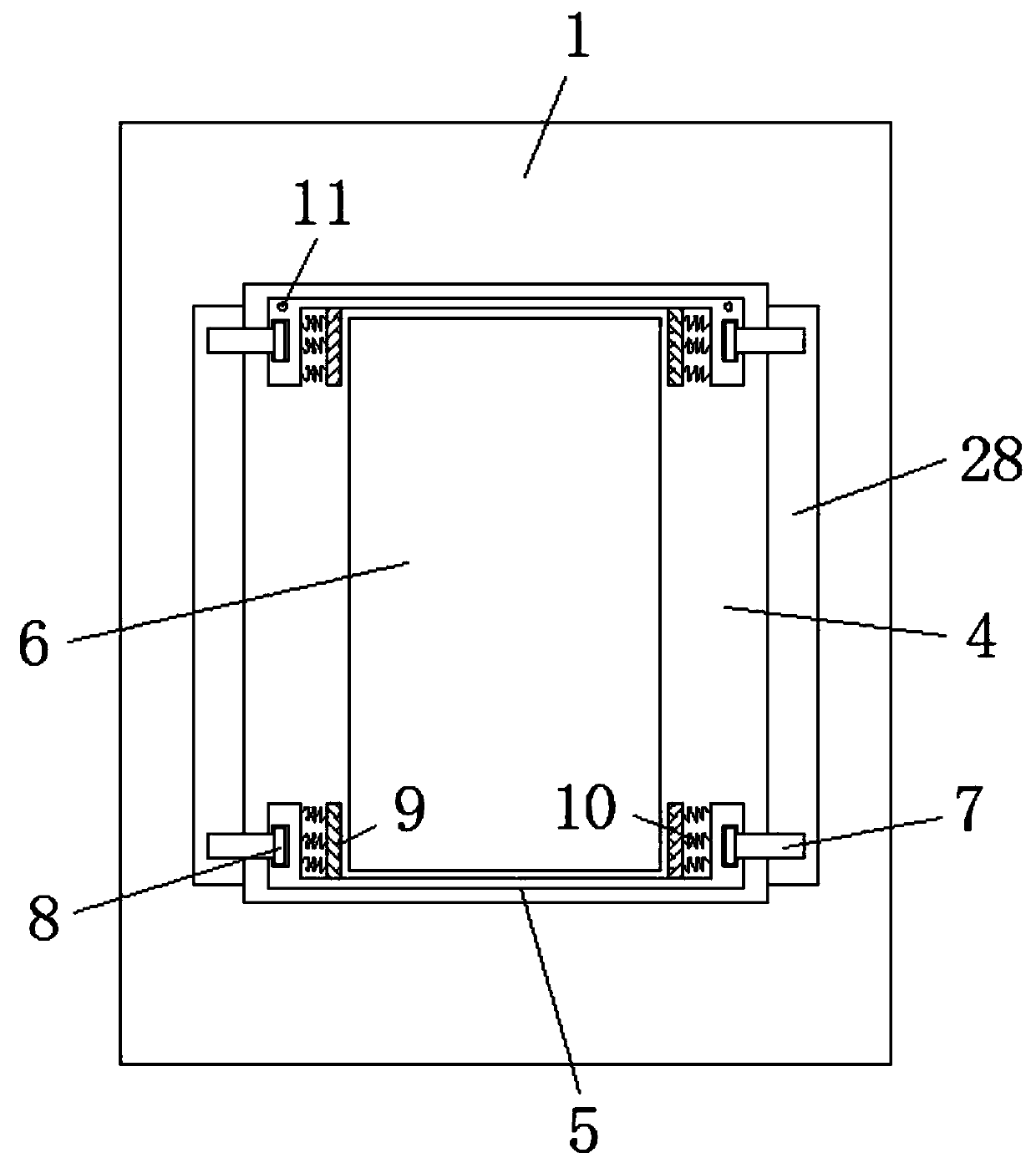

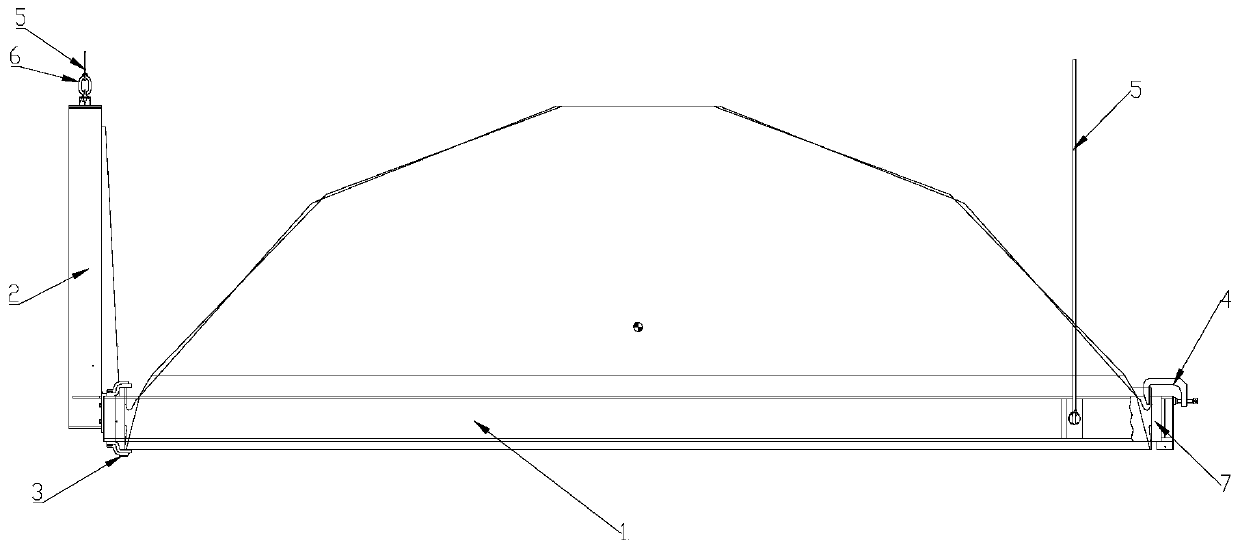

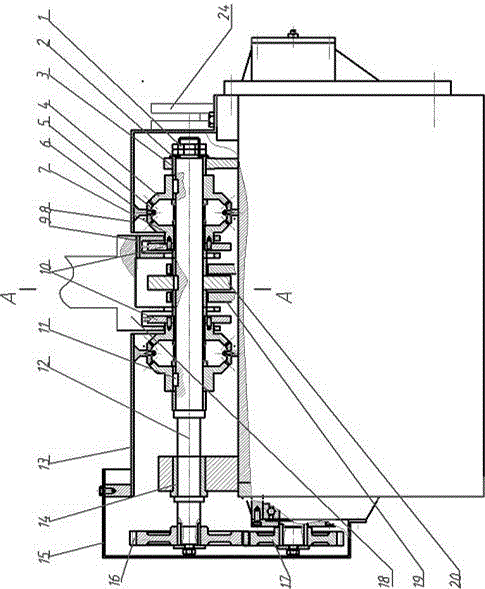

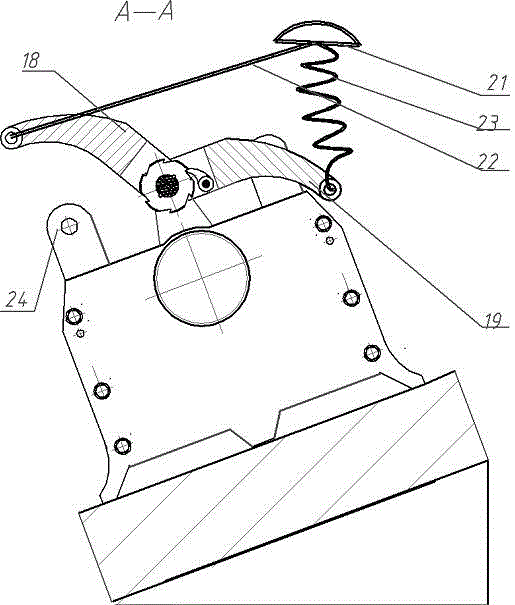

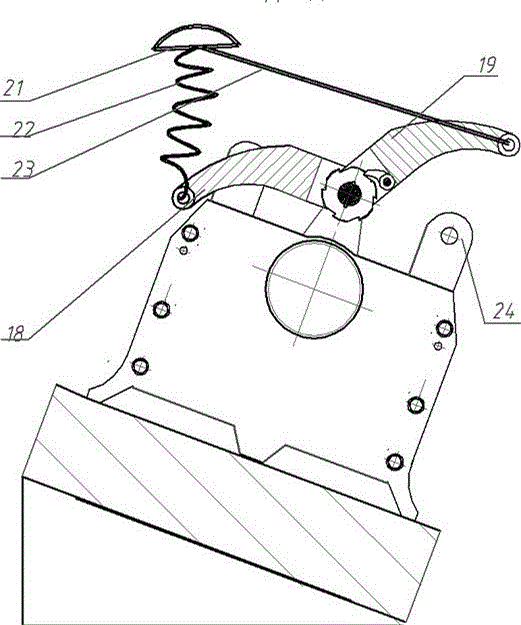

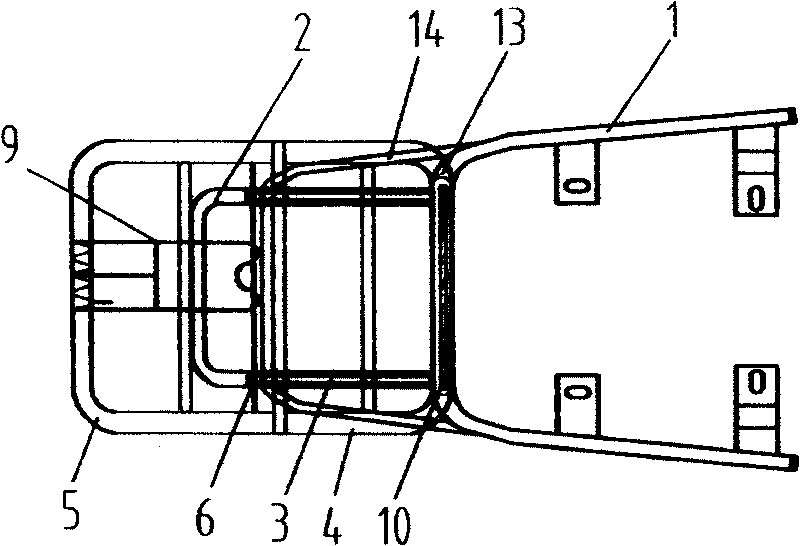

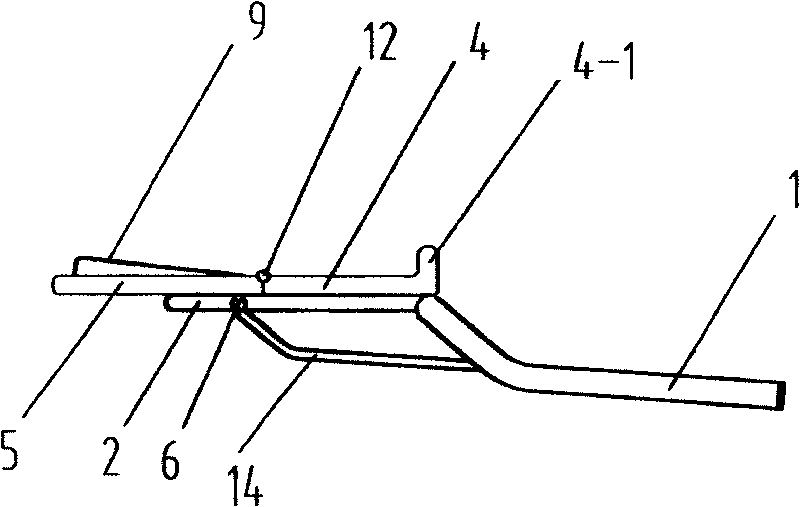

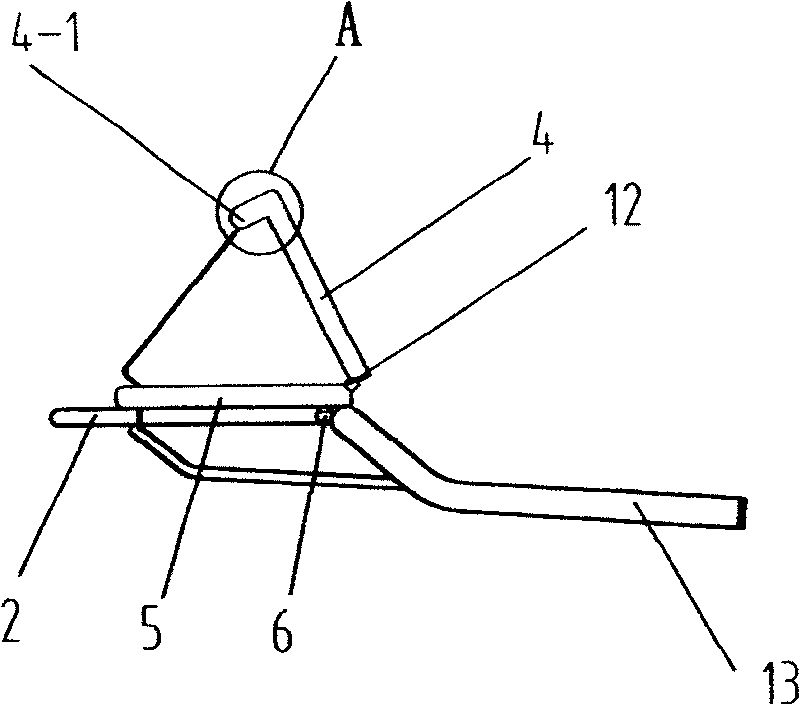

Herringbone overturn lifting appliance for cylinder body bobbin core set

The invention relates to an overturn lifting appliance, specifically relates to a herringbone overturn lifting appliance for hoisting cylinder body bobbin core set, and belongs to the technical field of lifting appliance. The herringbone overturn lifting appliance comprises a left lifting arm and a right lifting arm, the upper end of the right lifting arm and the upper end of the left lifting arm are in a rotation connection through a lifting assembly so as to form an integrated herringbone structure; one side, which faces the right lifting arm, of the left lifting arm is provided with a lifting arm slide track; one side, which faces the left lifting arm, of the right lifting arm is provided with a lifting arm slide block, which matches with the lifting arm slide track; the lifting arm slide block is arranged in the lifting arm slide track; the lower end of the left lifting arm is provided with a left-rotating assembly, the left-rotating assembly faces the right lifting arm side and is connected to a left clamping plate assembly; the lower end of the right lifting arm is provided with a right-rotating assembly, the right-rotating assembly faces the left lifting arm side and is connected to a right clamping plate assembly. The herringbone overturn lifting appliance has a simple, compact, and reasonable structure, can overturn agilely and reliably, can make work safe and stable, is laborsaving in operation, and avoids the falling off of the bobbin core set during the hoisting process.

Owner:无锡一汽铸造有限公司

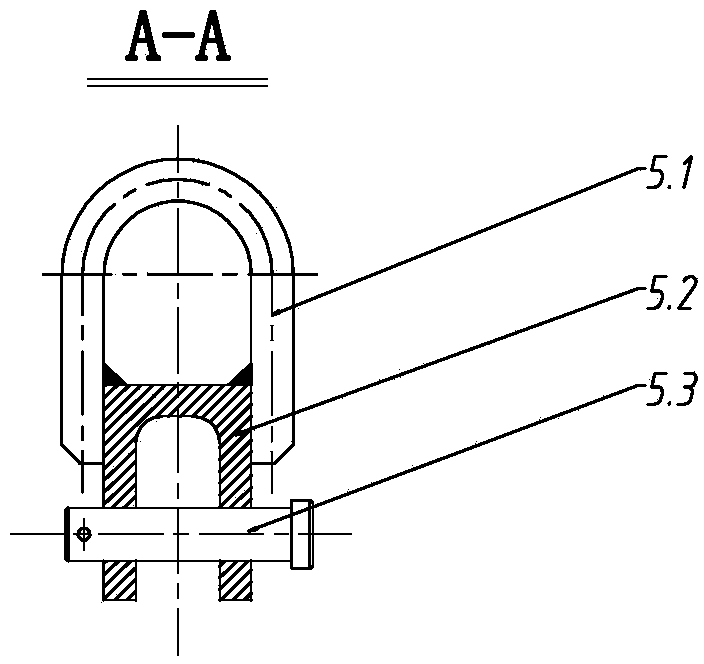

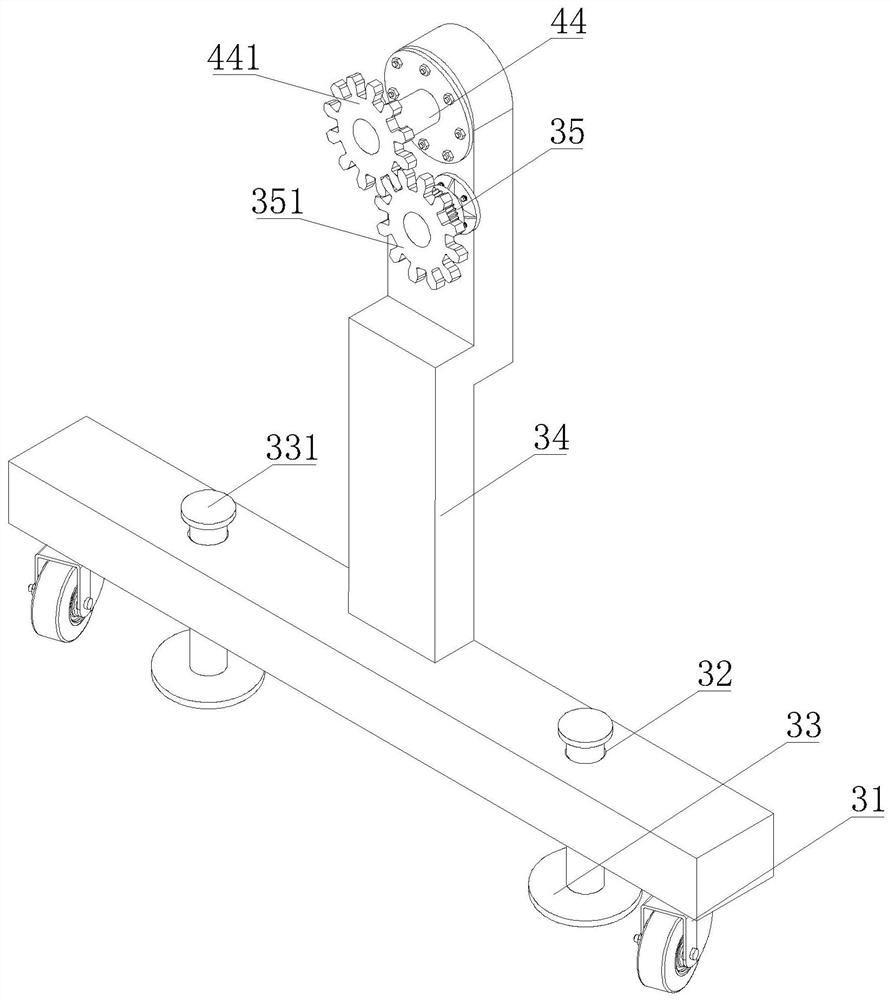

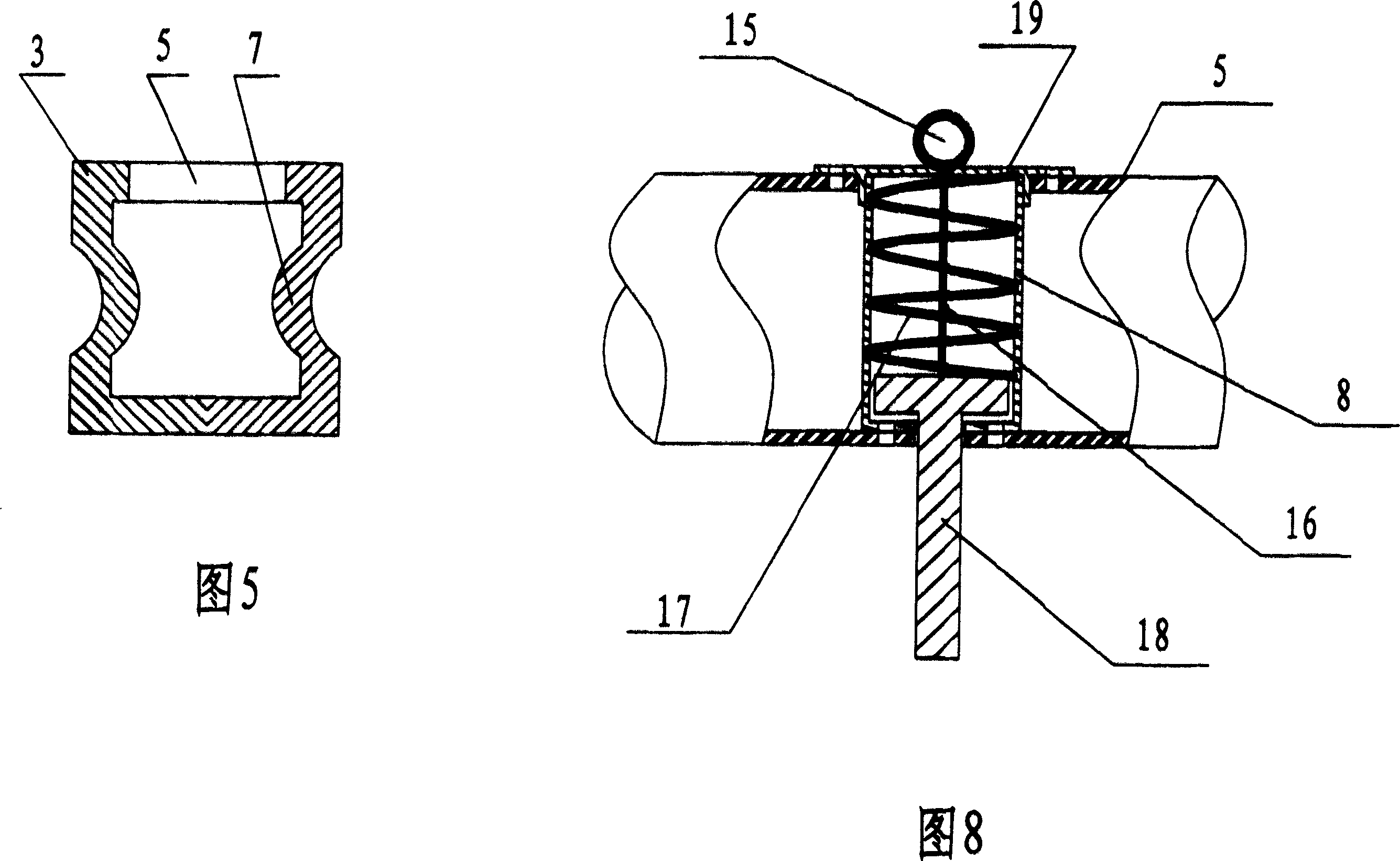

Turnover mechanism for packaging plastic package diode and implementation method of turnover mechanism

InactiveCN113140498ARealize location movementFlexible useSemiconductor/solid-state device manufacturingConveyor partsStructural engineeringOperation safety

The invention discloses a turnover mechanism for packaging a plastic package diode and an implementation method of the turnover mechanism. The overturning mechanism comprises a first conveying belt and a second conveying belt, an overturning support is arranged between the first conveying belt and the second conveying belt, moving wheels are symmetrically connected to the two ends of the overturning support, threaded holes are formed in the portion, between the moving wheels, of the overturning support. A fixing base plate is meshed in the threaded hole, a supporting plate is fixedly connected to the middle position of the upper surface of the overturning support, and an overturning device is connected to the upper end of the supporting plate. According to the overturning mechanism for packaging the plastic-packaged diode and the implementation method of the overturning mechanism, the arc-shaped support is arranged in the through hole, the gravity of the discharging piece and the spherical supporting block is used for pushing the arc-shaped support to move, the supporting spring plays a buffering role, the discharging piece is slowly overturned to be connected with the movable roller, and the situation that the overturning speed is too high, and the discharging piece is damaged is avoided. And meanwhile, the influence of resistance on the blanking piece in the overturning process is reduced, the operation is safe, and the overturning is reliable.

Owner:赣龙微电子科技(定南)有限公司

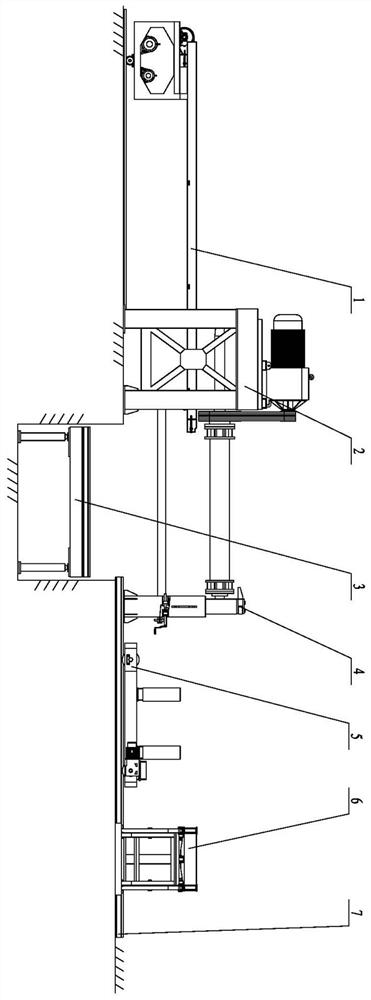

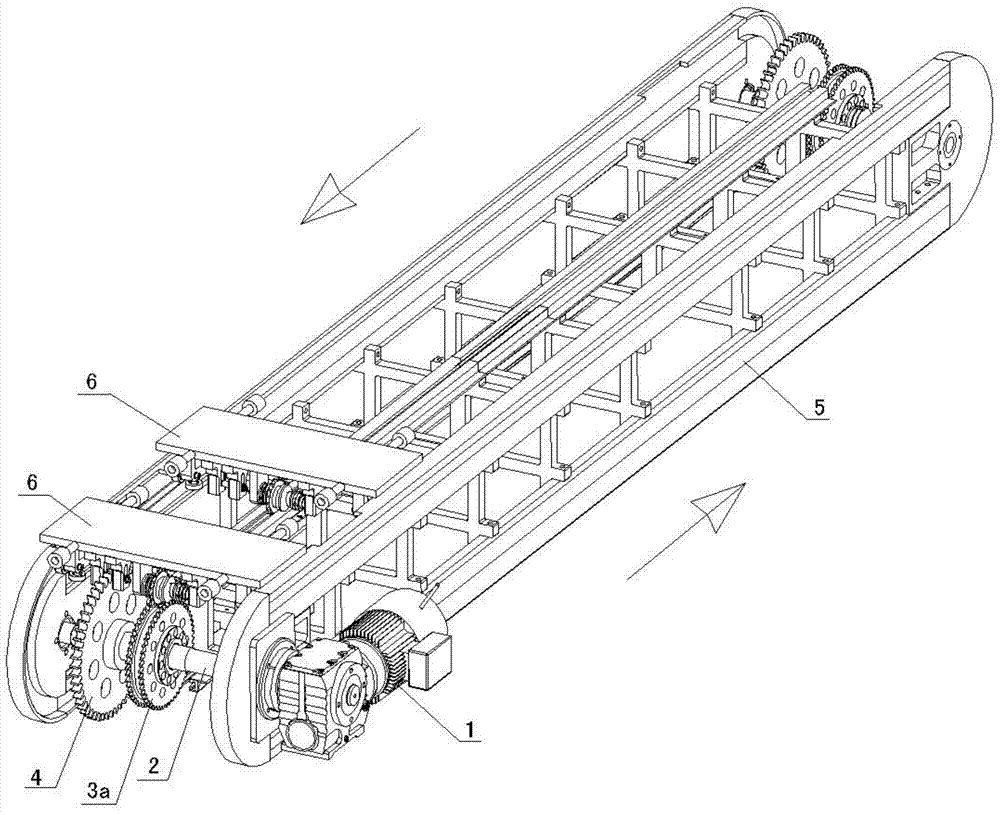

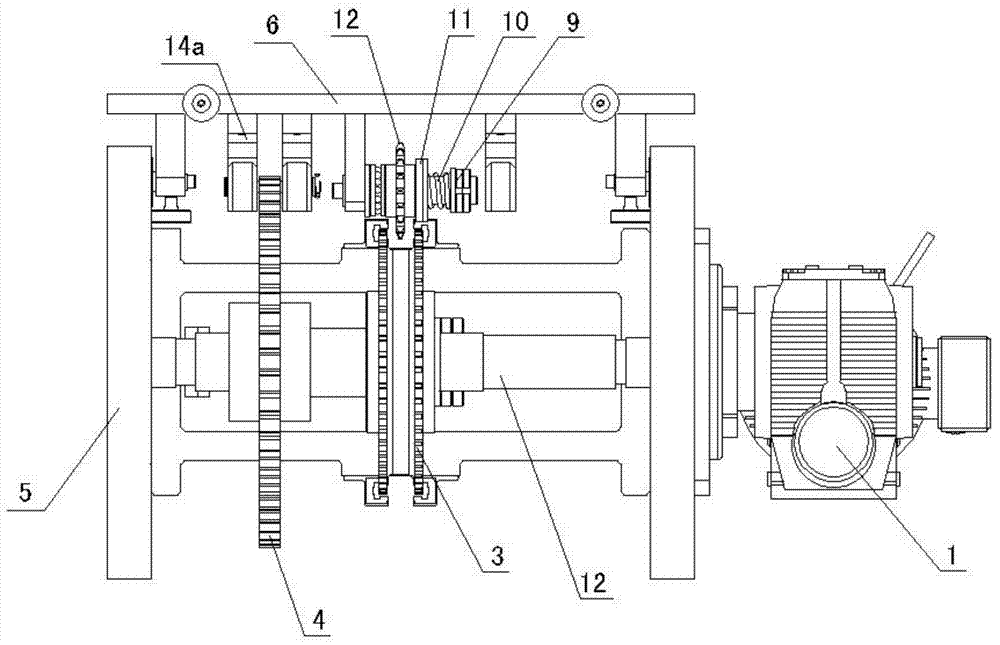

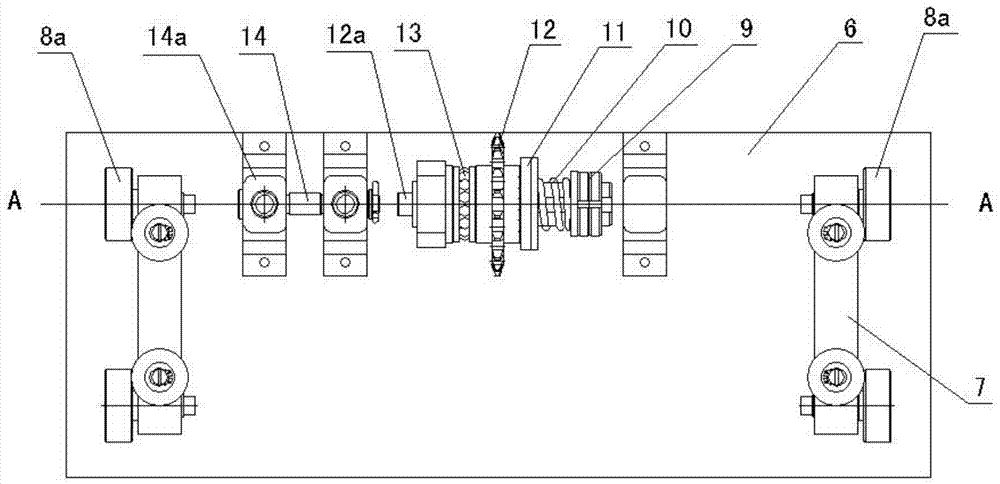

Working method of hanging roller overturning vertical demolding pipe manufacturing equipment

ActiveCN113043447AAchieve recyclingAchieve mass productionCeramic shaping plantsVehicle frameBatch production

The invention relates to a working method of hanging roller overturning vertical demolding pipe manufacturing equipment in the field of cement machinery. A hanging roller machine comprises a hanging roller rack, a driving system, a hanging roller shaft and a portal. A feeding machine comprises a feeding system, a feeding track and a walking system. A lifting platform comprises a platform body, a jacking oil cylinder and a trolley walking guide rail. A positioning shifting fork comprises a shifting rod, a positioning oil cylinder and a fixing base. A lifting turnover machine comprises a base, a cross balance fork, a lifting frame, a roller set, an oil cylinder and a telescopic support rod; and a transport trolley comprises a frame, a driven walking wheel, a bracket and a driving walking wheel. According to the working method of the hanging roller overturning vertical demolding pipe manufacturing equipment, the time of auxiliary procedures in the production process can be shortened through the method, the production process becomes smooth, the vertical type vertical demolding technology is achieved, and the purpose of immediate demolding is achieved; and meanwhile, mold recycling is achieved, the production efficiency is improved, and batch production of concrete pipelines is achieved.

Owner:江苏江桥机械制造有限公司

Automatic turning device used for workpiece spraying

The invention discloses an automatic turning device used for workpiece spraying. The automatic turning device used for workpiece spraying comprises a workbench. Supporting frames are symmetrically andfixedly connected to the two sides of the upper end of the workbench. A workpiece groove is formed in the inner wall of the workbench, and two concave fixing frames are symmetrically arranged in theworkpiece groove. The two sides of the inner wall of each concave fixing frame are each connected with clamping blocks through a plurality of springs. A movable rod is fixedly connected to one side ofeach round fixture block. Moving grooves corresponding to the movable rods are formed in the inner wall of the workpiece groove. Pull ropes are symmetrically connected to the two sides of the upper end of one concave fixing frame, and a rotary shaft is arranged at the ends, penetrating through a fixing plate and extending outwards, of the pull ropes. A spraying pipe is connected to the lower endof a movable block through a supporting column, and the bottom of the spray pipe evenly communicates with a plurality of spraying heads. The automatic turning device used for workpiece spraying is simple in structure, easy to operate and capable of stably and reliably turning large-area workpieces; and meanwhile, labor is saved, and the production efficiency is improved.

Owner:泰州市嘉新包装制品有限公司

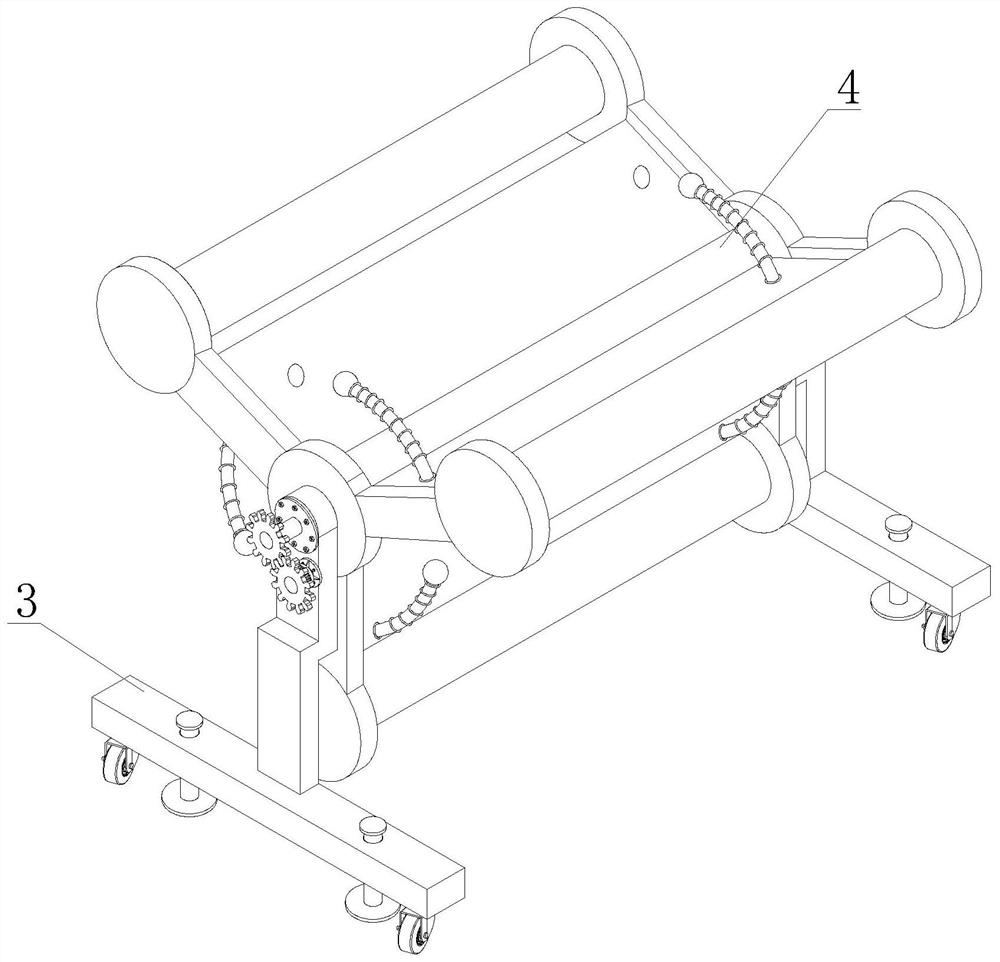

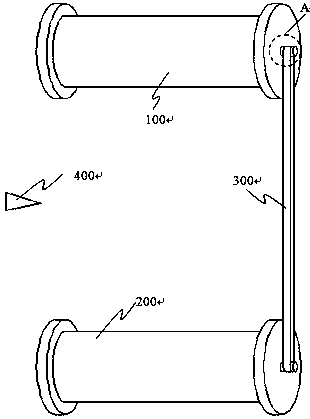

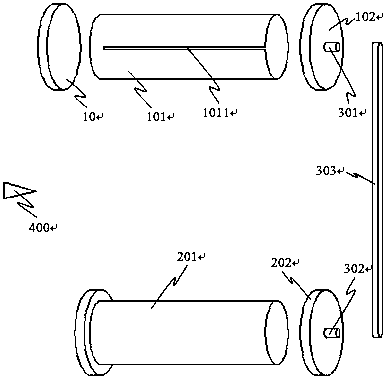

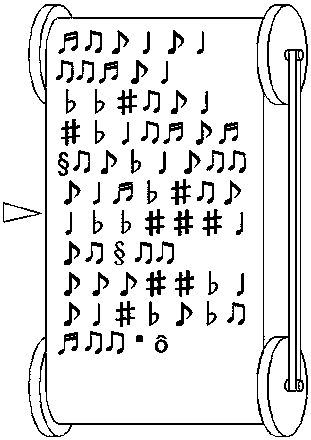

Music score prompting device

The invention discloses a music score prompting device. The device is composed of a first driver, a first roller shaft, a second roller shaft, a synchronous mechanism and an indicator. The first driver is connected with one end of a first roller, and the other end of the first roller is connected with a first end portion mechanism. The first synchronous end of the synchronous mechanism is fixedlyconnected with the first end portion mechanism. The second synchronous end is fixedly connected with one end of a second end portion mechanism, and the other end of the second end portion mechanism isconnected with a second roller. The indicator is located at the position between the opposite end portions of the first roller shaft and the second roller shaft. A mechanism body of the synchronous mechanism comprises gear and gear engaging, gear and gear belt engaging or roller shaft and belt transmission. By means of the device, the driver drives automatic music score page turning, and meanwhile the indicator has a good prompting function on music score note positioning for a player. The device is simple in structure and operation, stable in running and good in display effect.

Owner:王翔

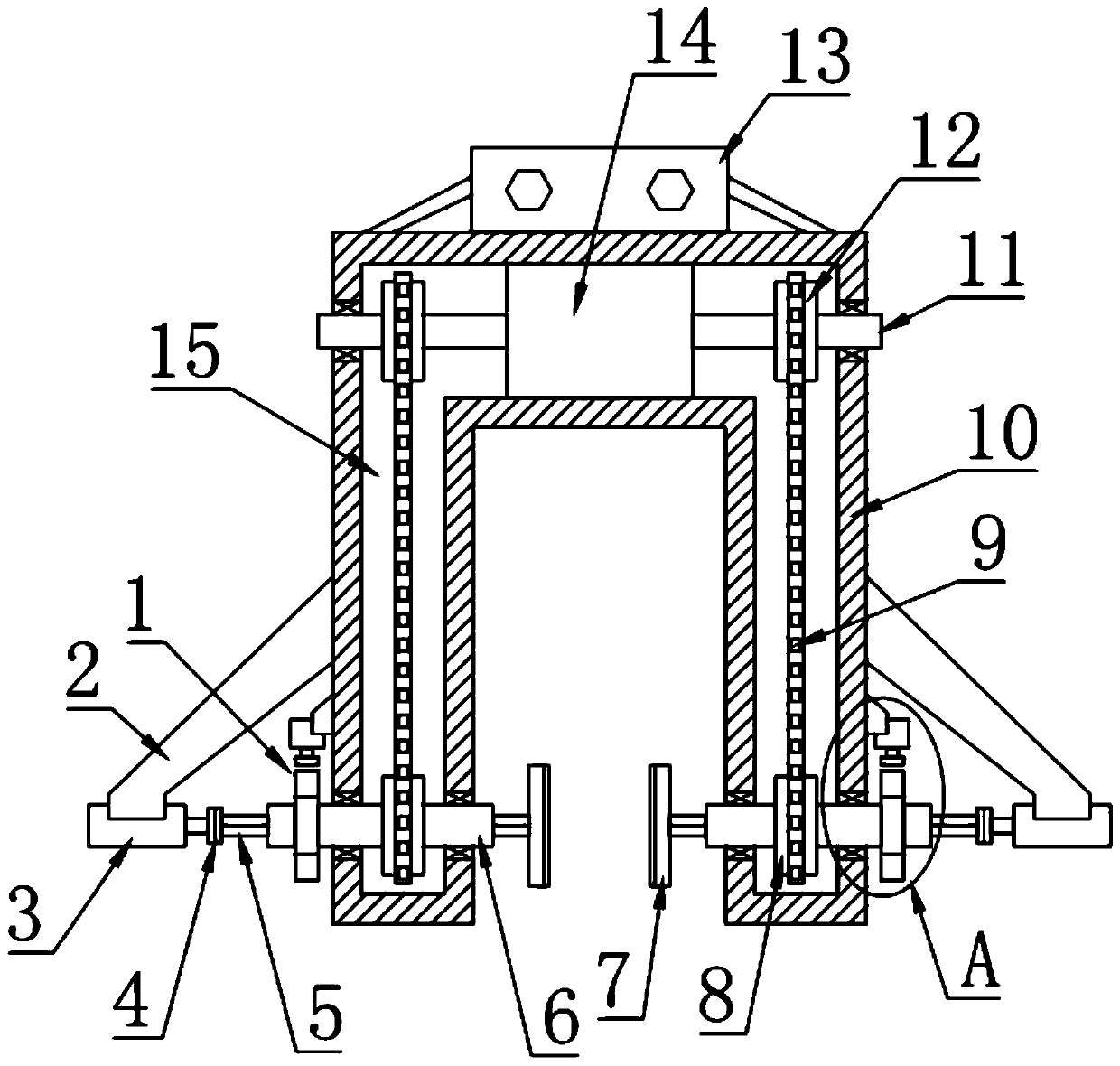

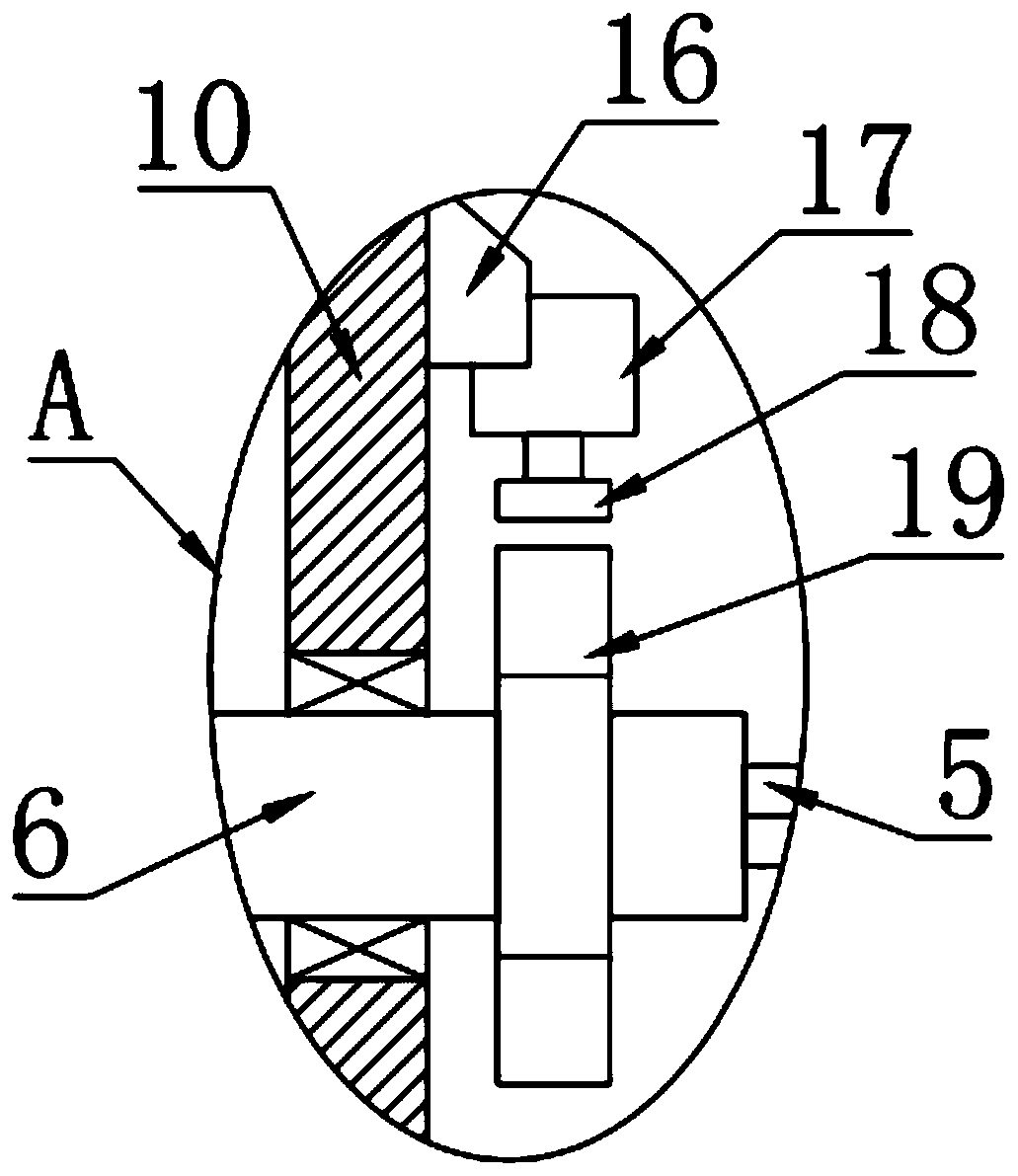

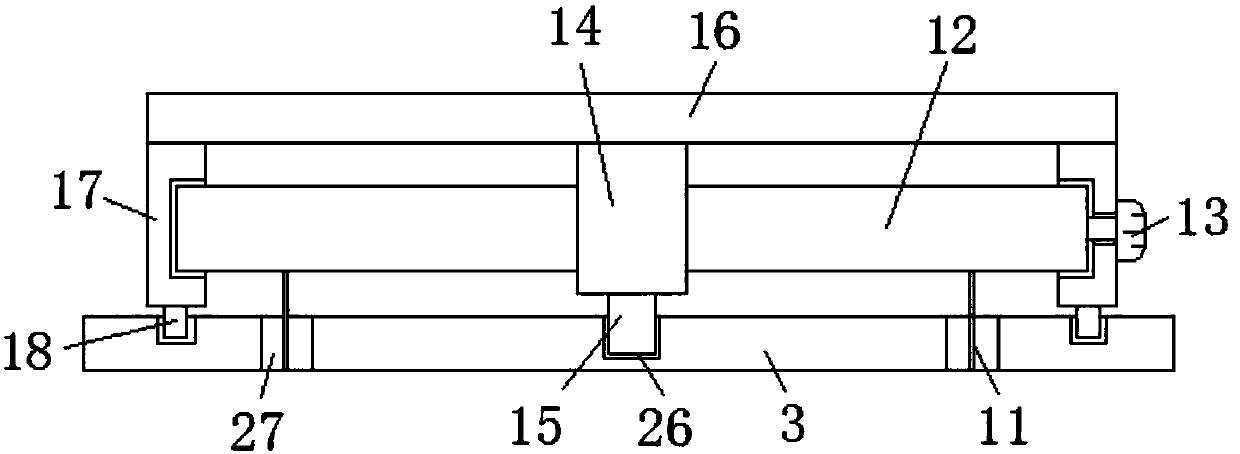

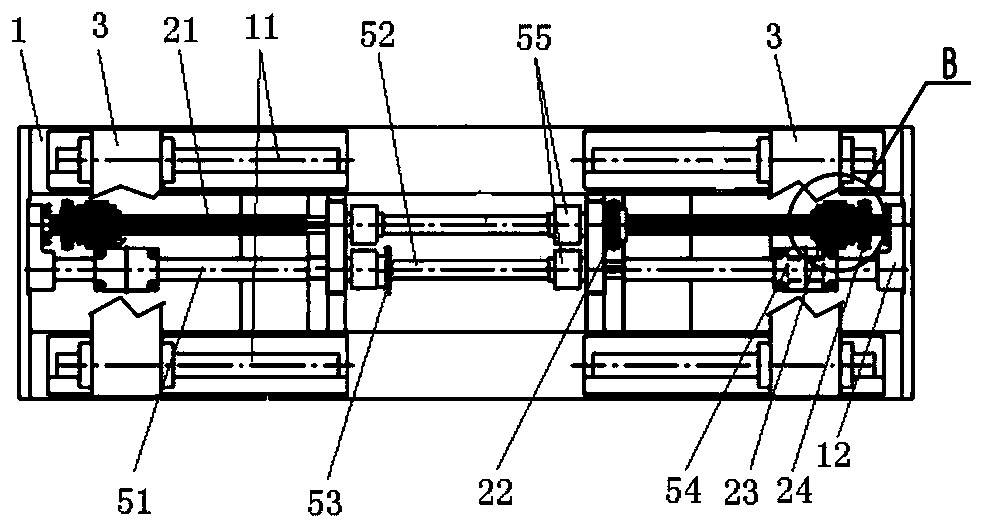

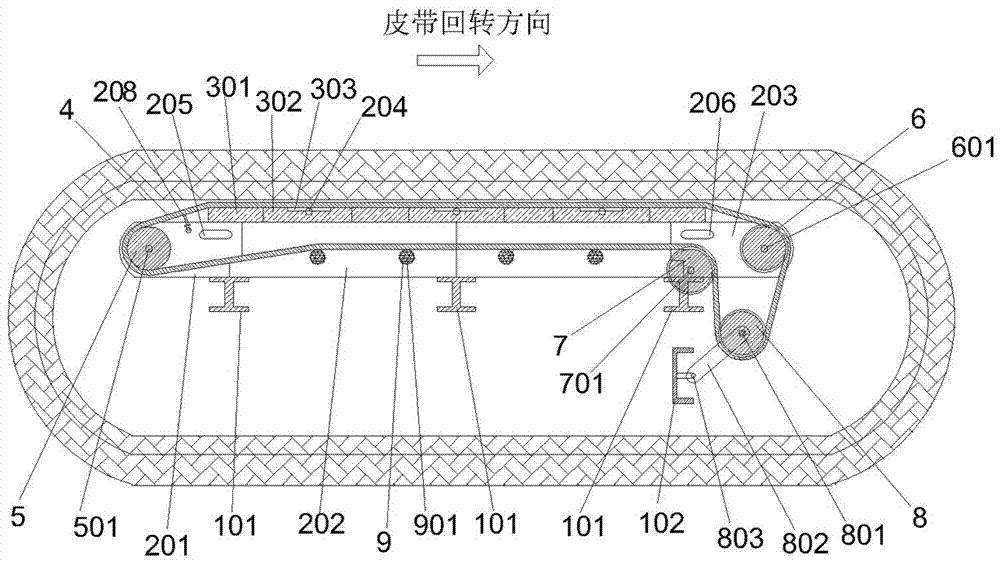

Synchronous clamping and turnover mechanism

PendingCN111017550AStable clampingRoll over stabilityConveyorsConveyor partsMedicinePharmaceutical drug

The invention provides a synchronous clamping and turnover mechanism, which comprises a support. The mechanism is characterized in that clamping mechanisms, a clamping driving mechanism, turnover mechanisms and an turnover driving mechanism are arranged on the support, wherein the number of the clamping mechanisms is two, the two clamping mechanisms are both connected to the support in a sliding mode and connected with the same clamping driving mechanism; each clamping mechanism is rotationally connected with the corresponding turnover mechanism; and the two turnover mechanisms are both connected with the same turnover driving mechanism. The two clamping mechanisms are driven by the same clamping driving mechanism to slide in a face-to face manner to synchronously clamp an object, and movein a back-to-back manner to synchronously loosen clamping of the object; and two turnover mechanisms are driven by the same turnover driving mechanism to overturn the clamped object, so that clampingis firm and reliable, turnover is flexible, and no pollutant is generated; and the synchronous clamping and turnover mechanism is suitable for clamping various articles, especially for clamping of amedicine extraction basket and turnover of medicines or extracts on the turnover face.

Owner:KUNMING XUBANG MACHINERY

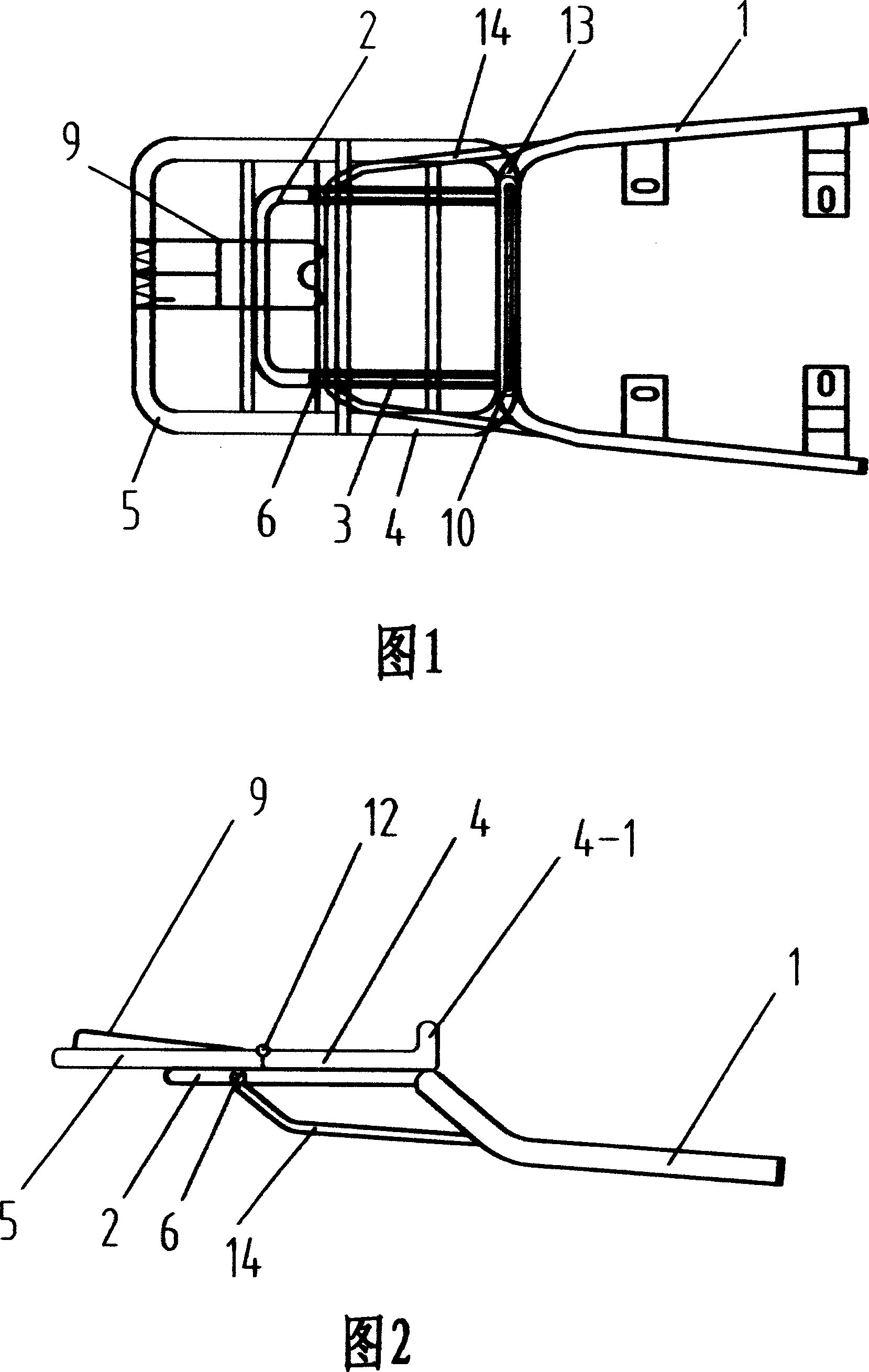

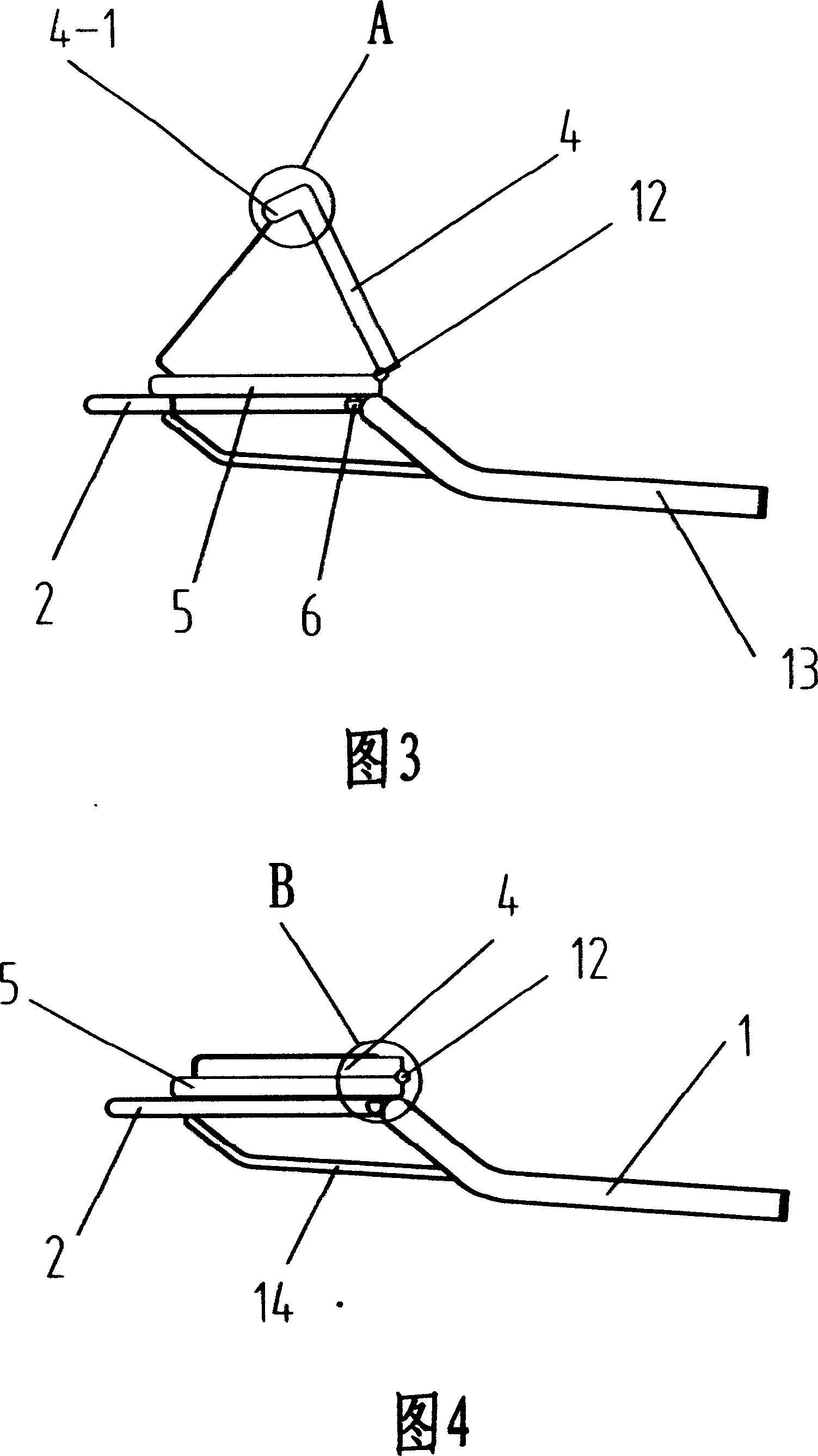

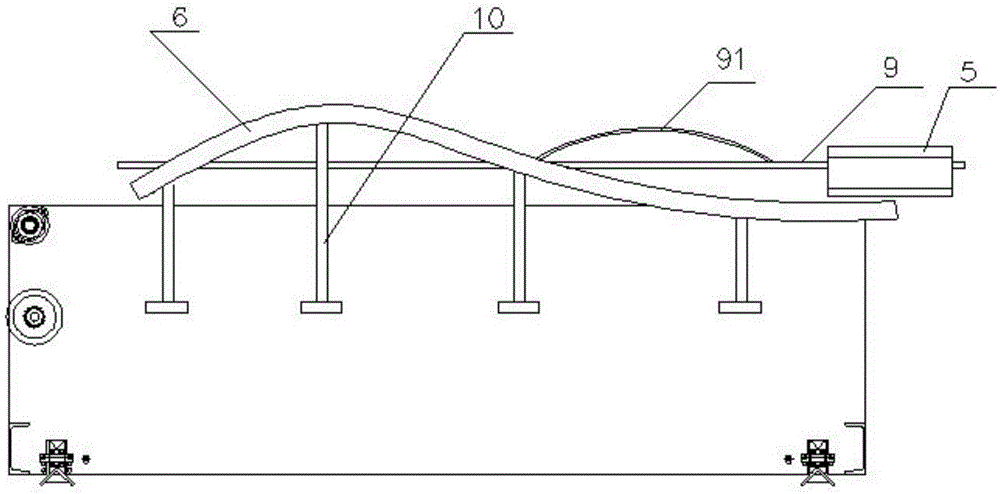

Foldable motorcycle carrier

The foldable motorcycle carrier includes one basic carrier, one frame with at least two runners welded to the tail of the basic carrier, one tray with ends welded separately to the basic carrier and the frame, one sliding rack matched with the runners, one folding rack hinged to the sliding rack, one spring clamp and one withdrawn arrester. The foldable motorcycle carrier may be developed to increase use space and folded to reduce occupied space, and has simple structure, convenient use, less running noise and other advantages.

Owner:LONCIN MOTOR

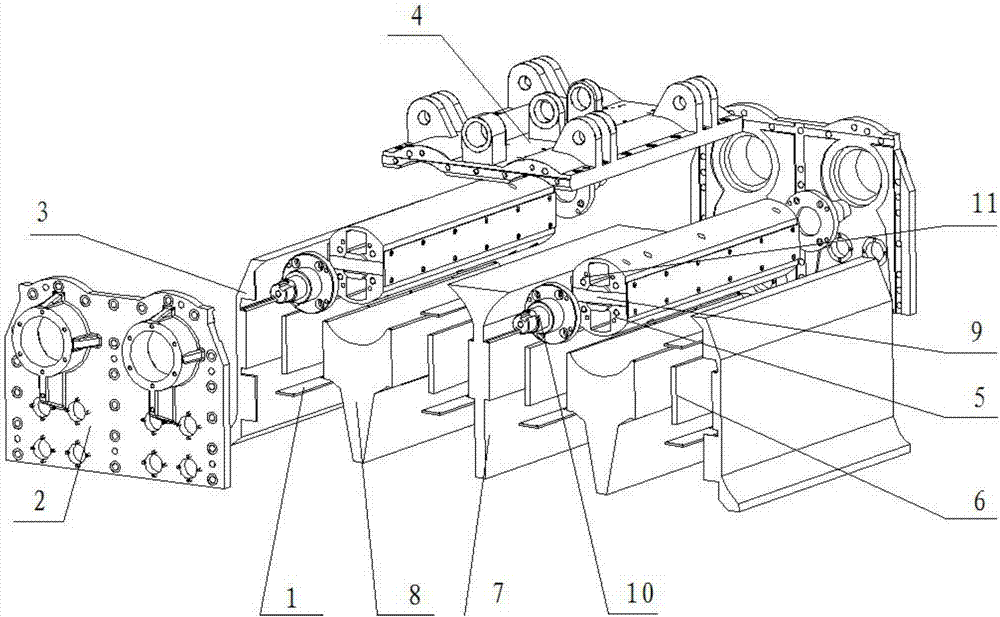

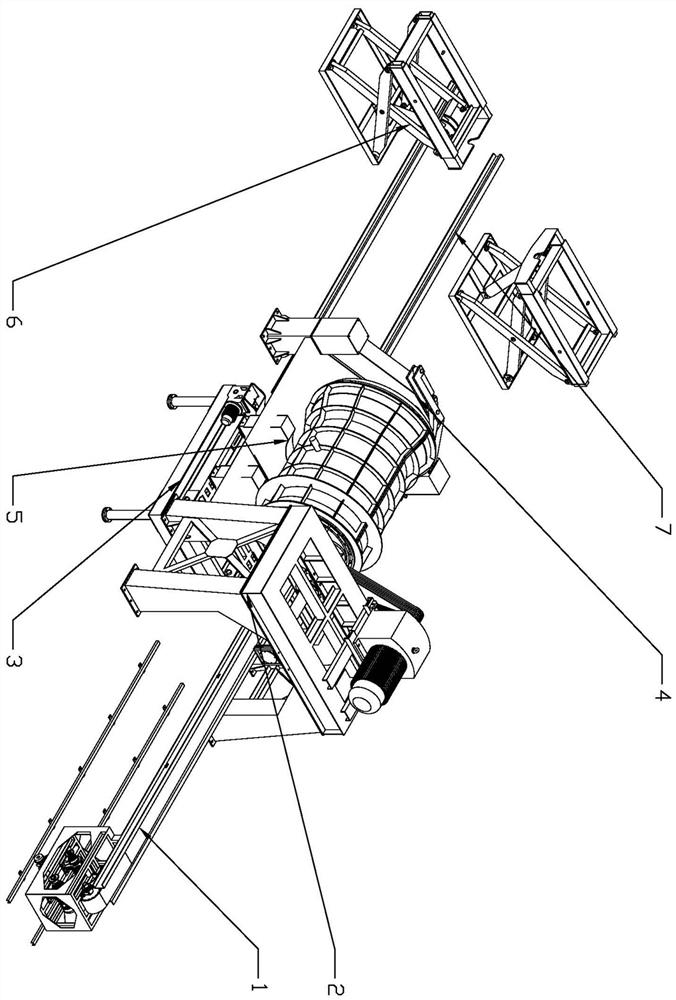

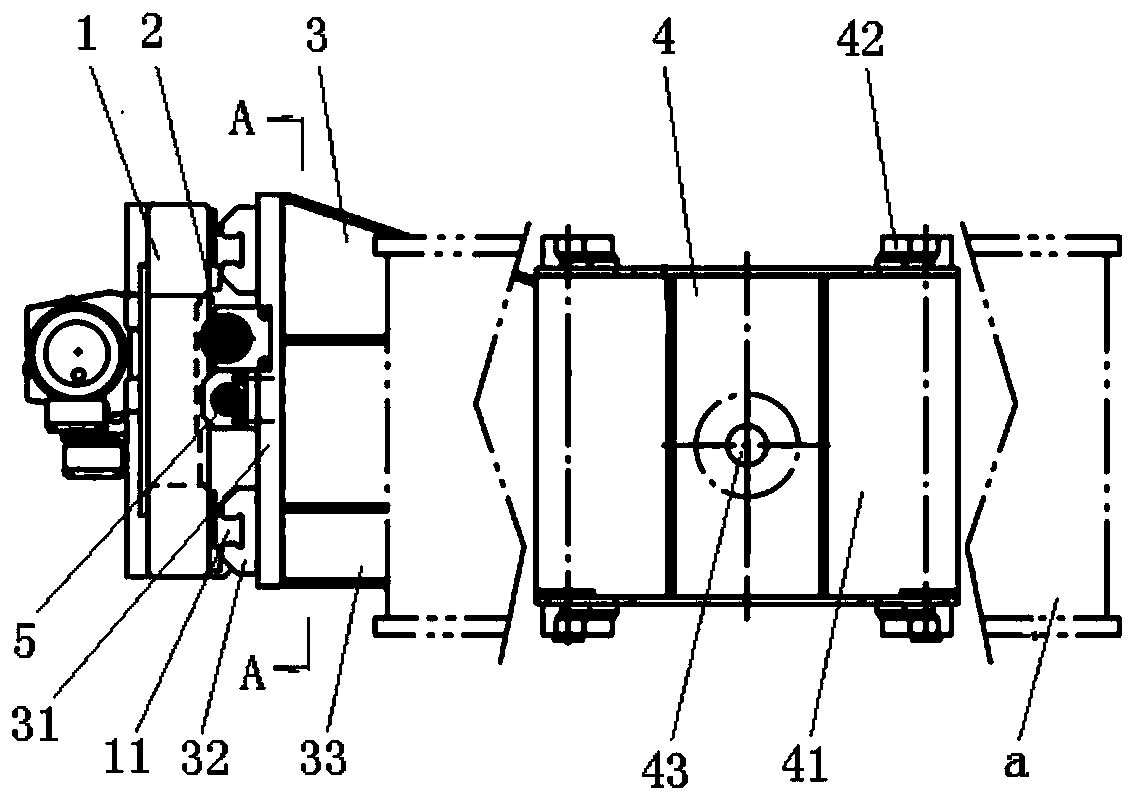

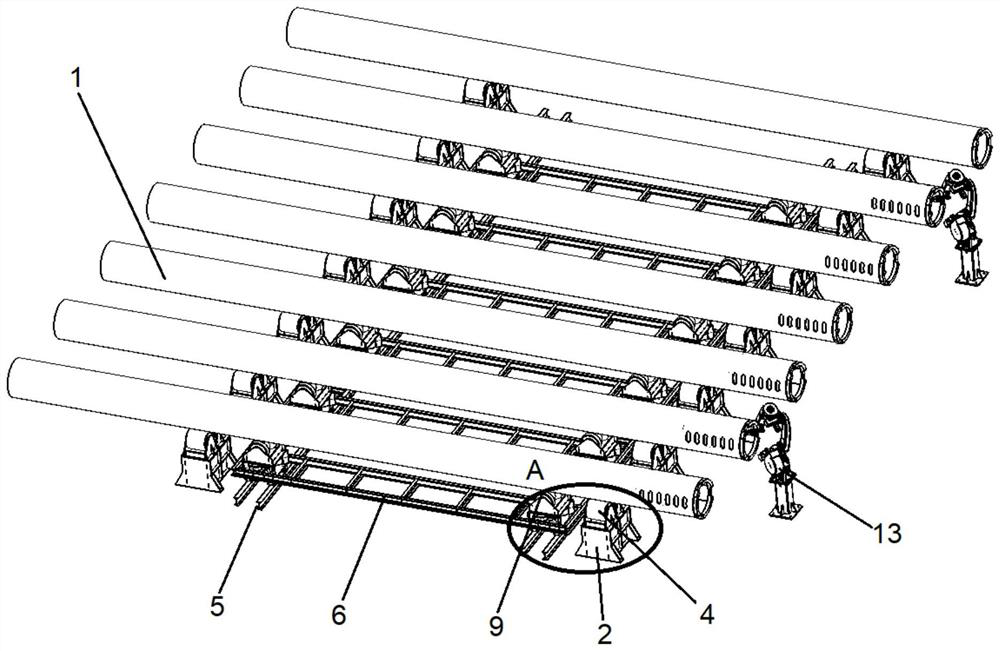

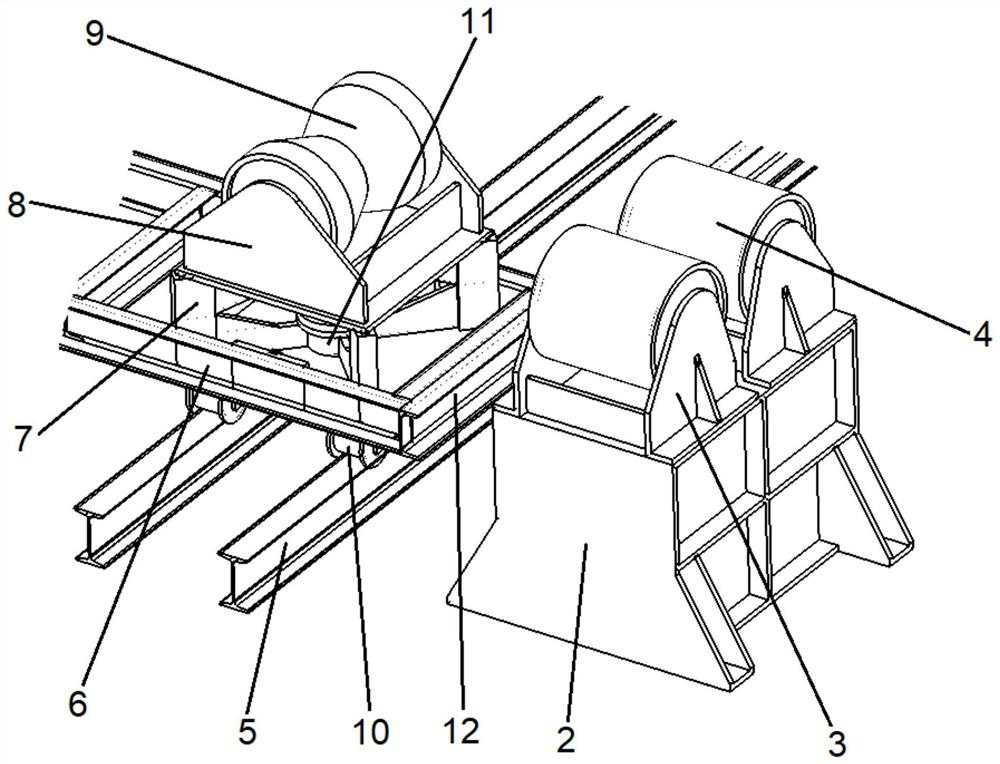

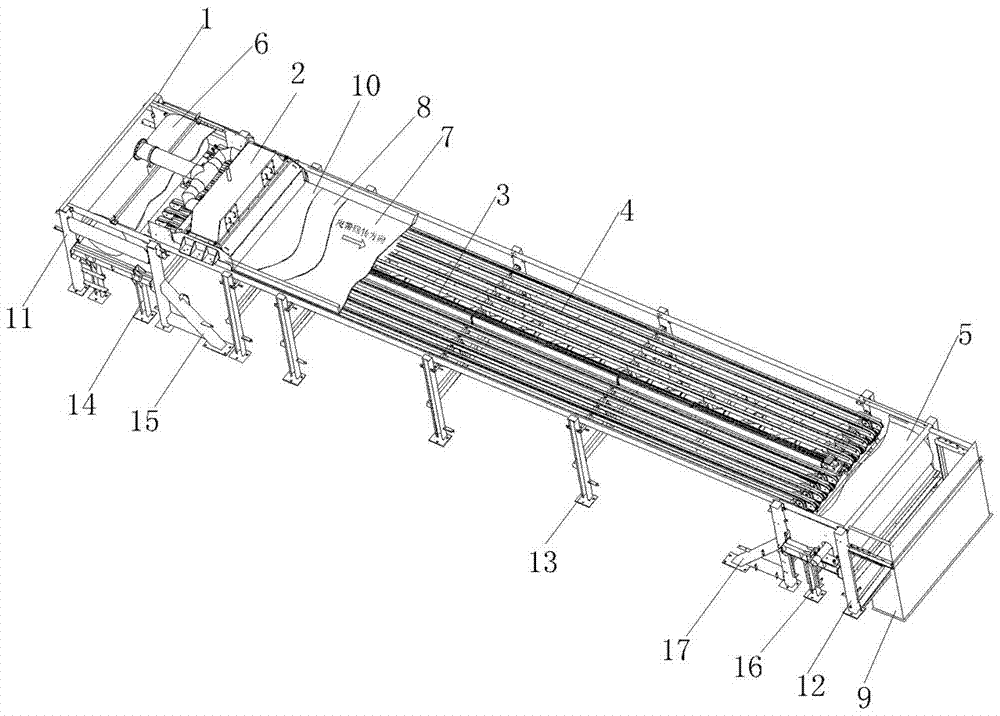

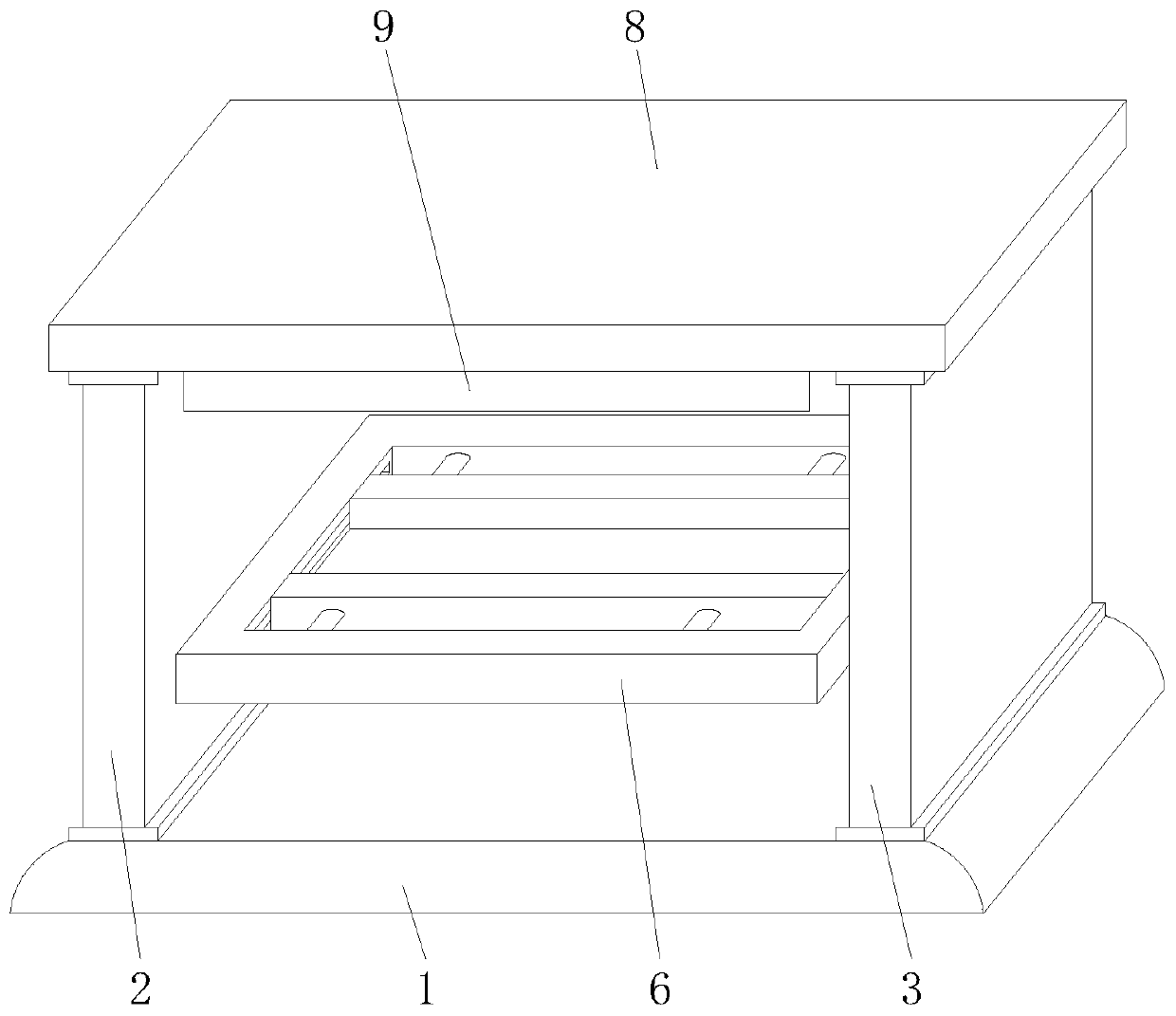

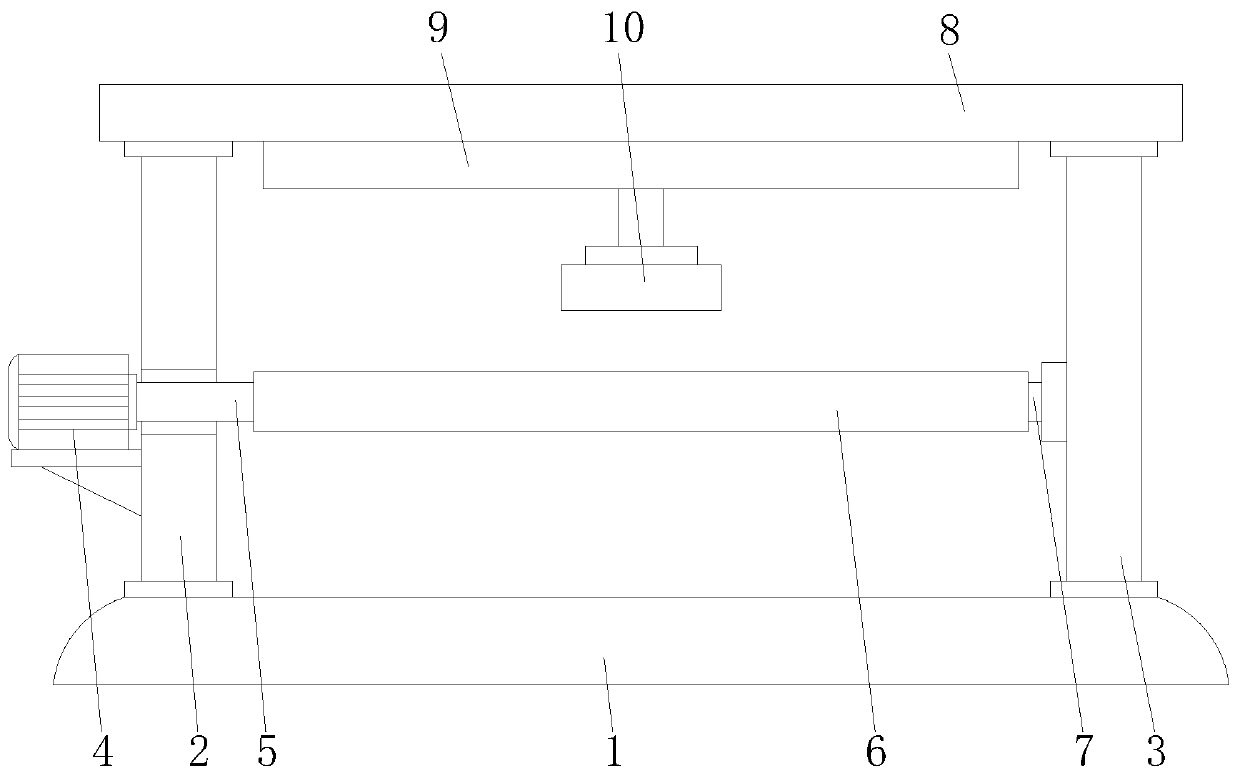

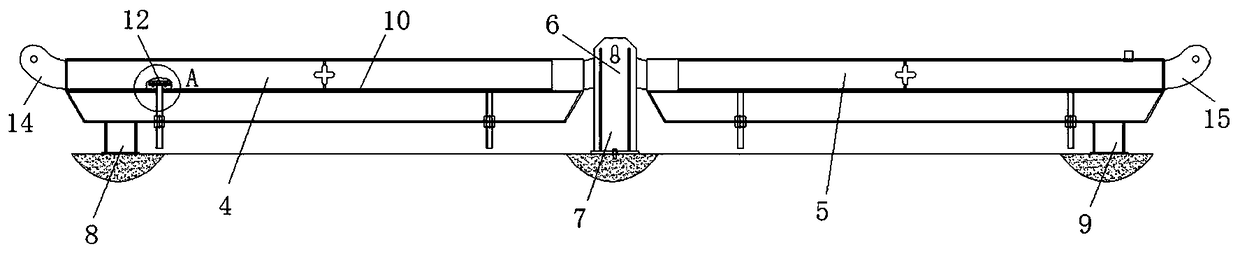

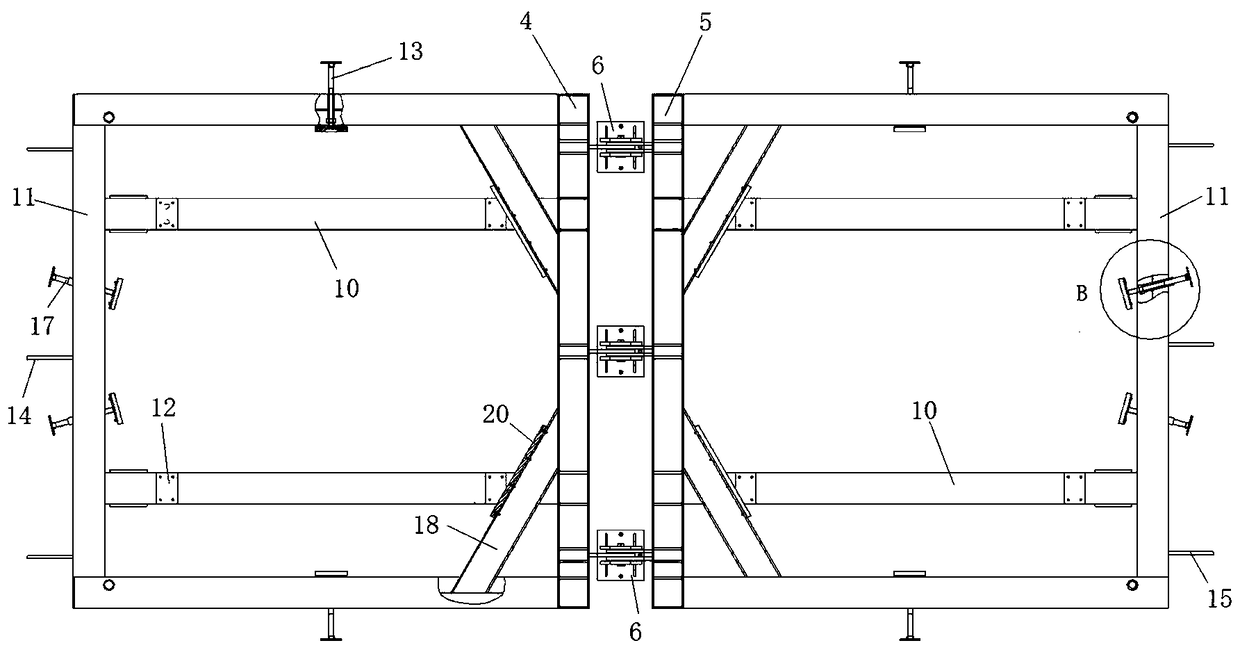

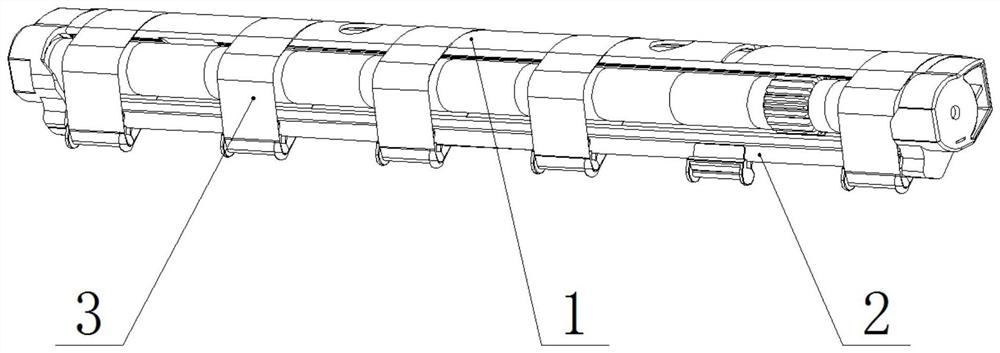

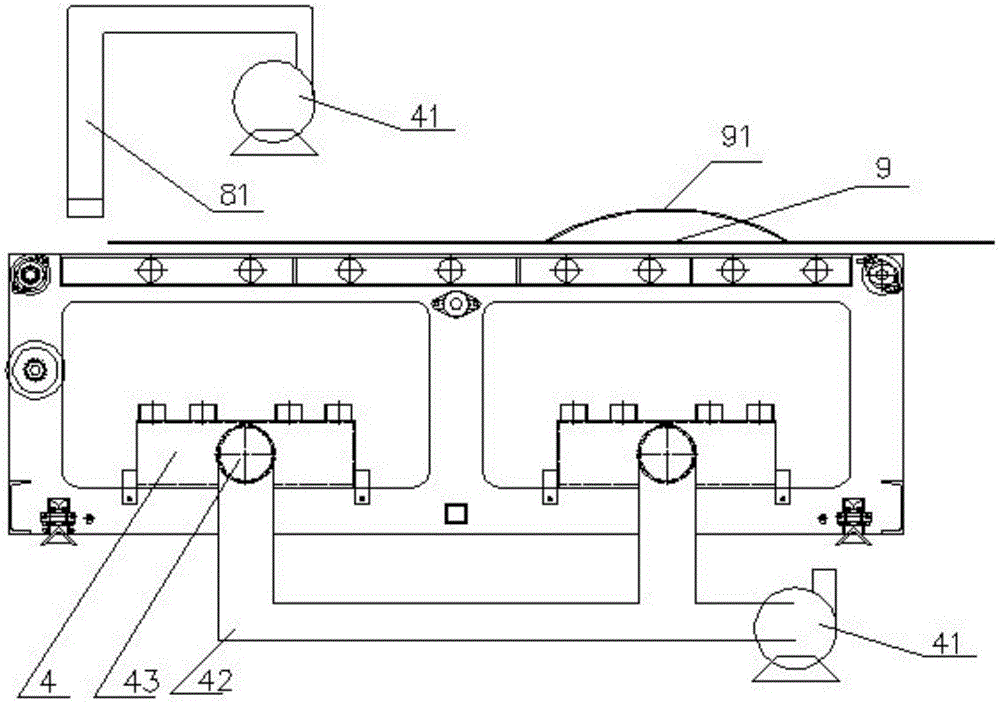

Large pipe fitting assembly equipment

InactiveCN111805201AStable supportFlip reliableMetal working apparatusPipe fittingStructural engineering

The invention provides large pipe fitting assembly equipment. The large pipe fitting assembly equipment comprises an assembly mechanism, a turnover mechanism and a movable feeding mechanism, wherein the turnover mechanism comprises a supporting base, at least two longitudinal roller racks arranged on the supporting base, and a longitudinal roller which is rotatably arranged on each longitudinal roller rack; the movable feeding mechanism comprises at least two feeding guide rails, a bridge rack movably arranged on the feeding guide rails, a bearing frame arranged on the bridge frame, a transverse roller rack arranged on the bearing frame and a transverse roller which is rotatably arranged on the transverse roller rack; and a jacking drive part which drives the transverse roller rack to liftis further arranged on the bearing frame. The large pipe fitting assembly equipment is reasonable in integral structure design, is compact in jointing fitting, is reliable in large pipe fitting support, turnover and displacement, effectively improves assembly type processing efficiency of large pipe fittings, and reduces production cost.

Owner:SHAODONG INTELLIGENT MFG INNOVATIVE INST

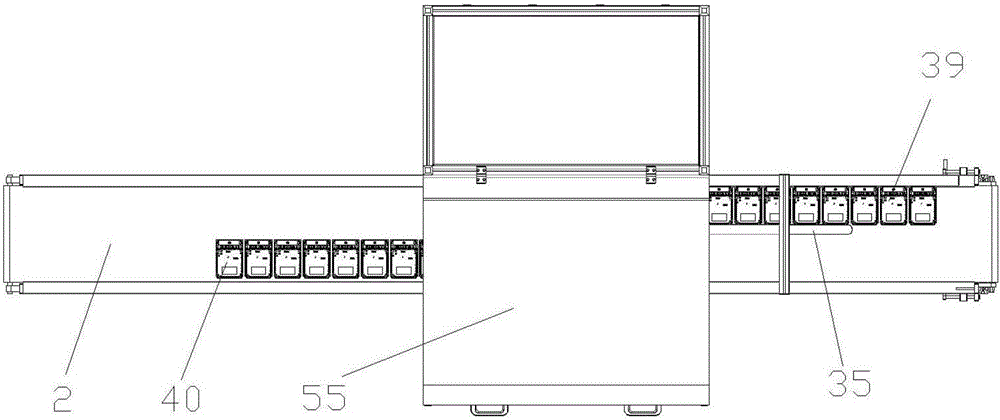

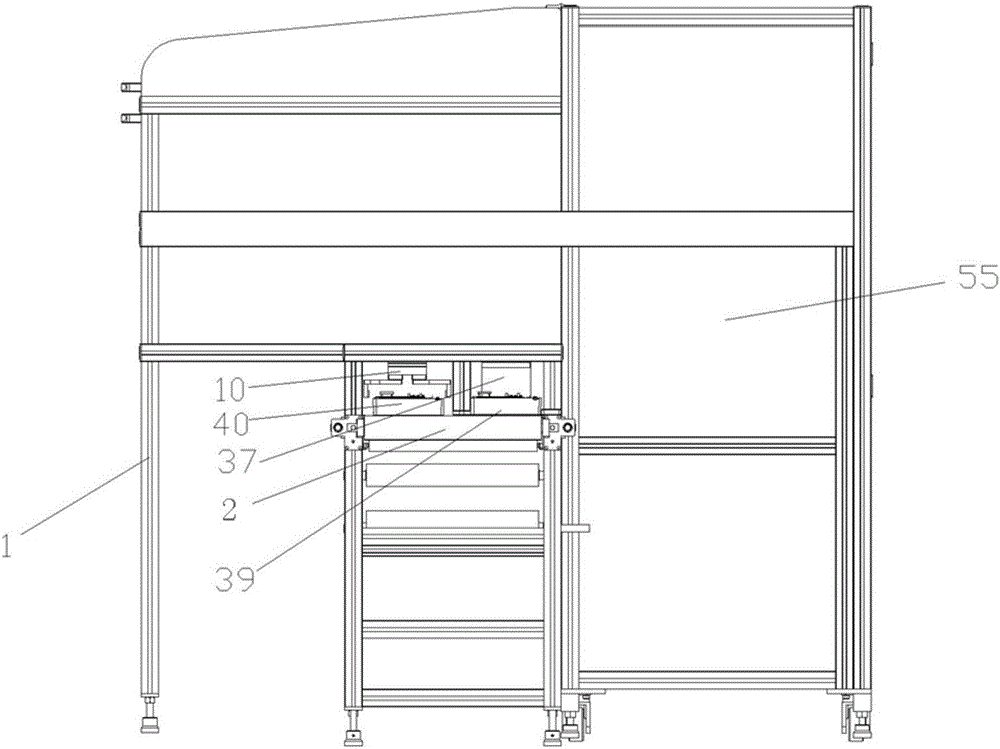

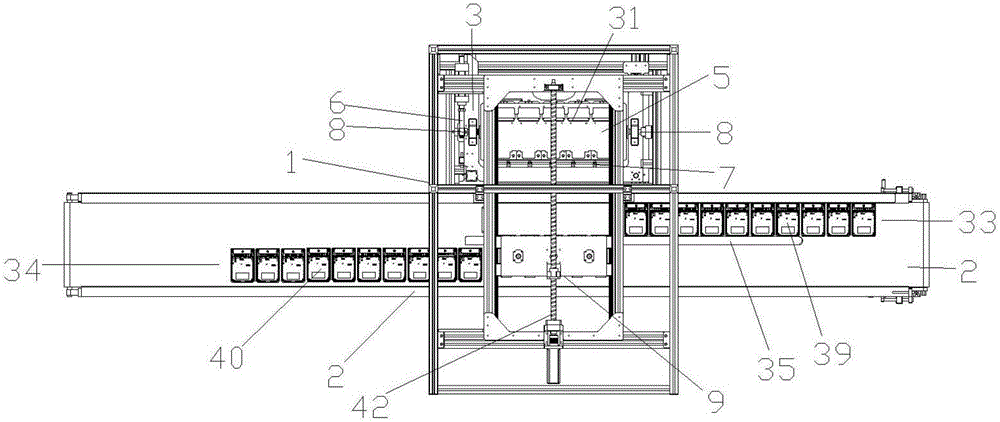

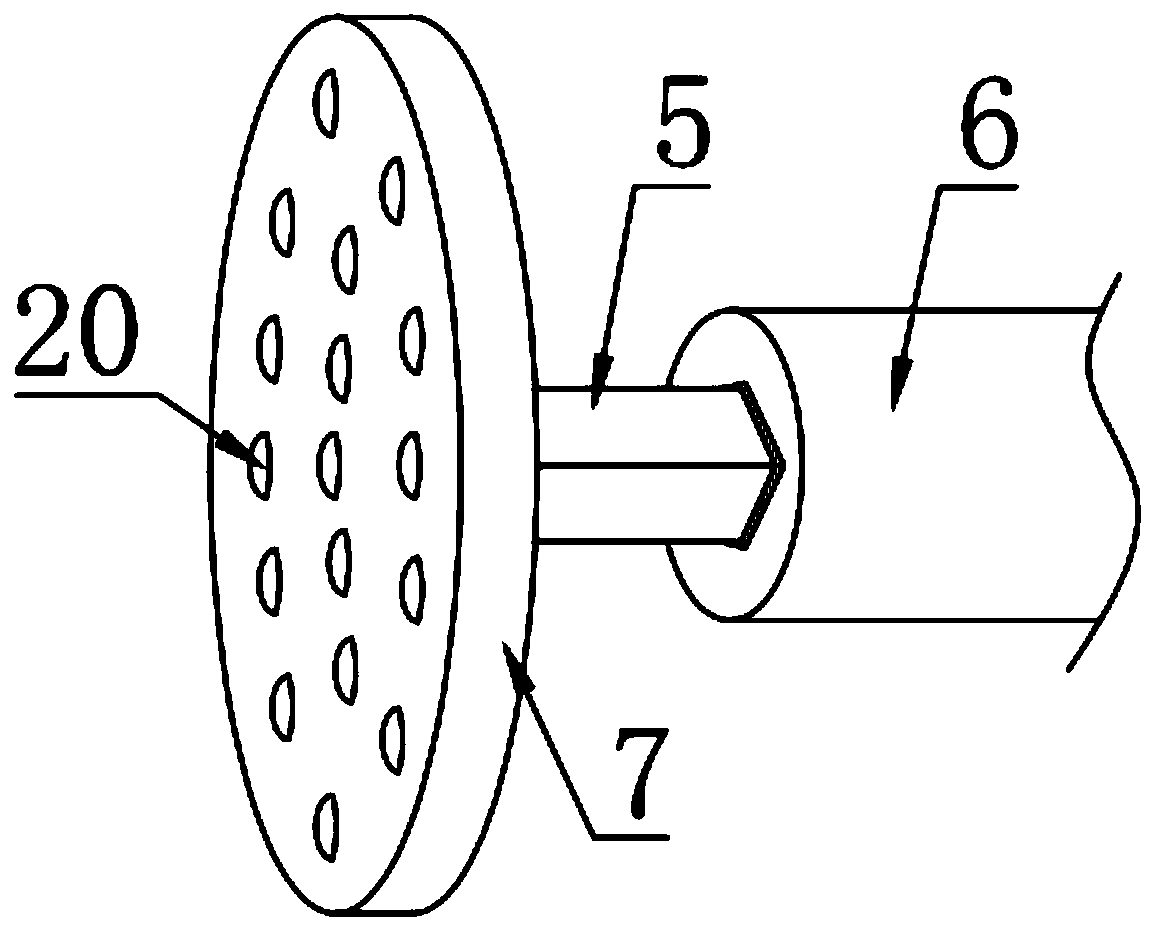

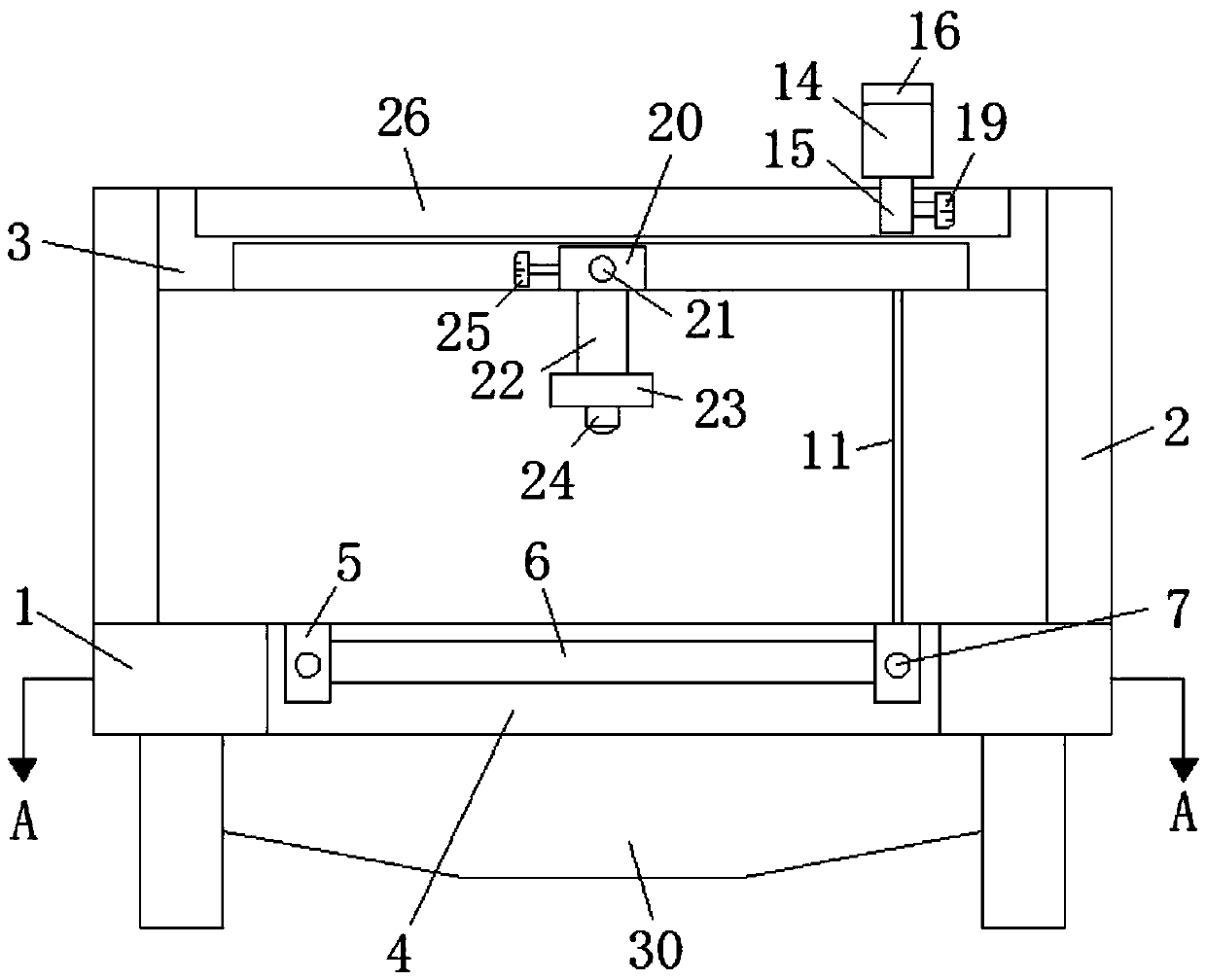

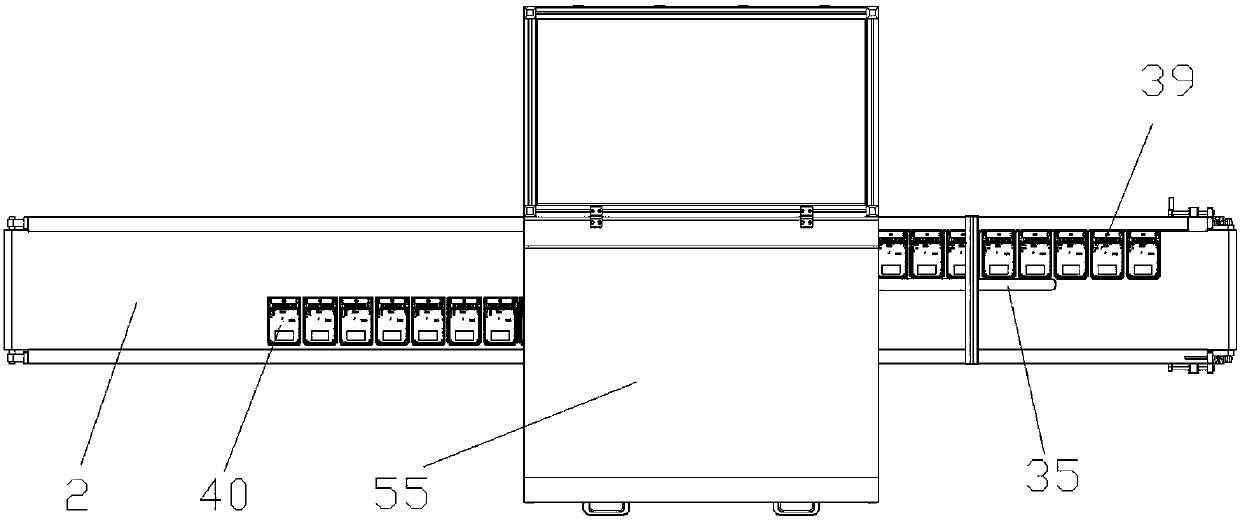

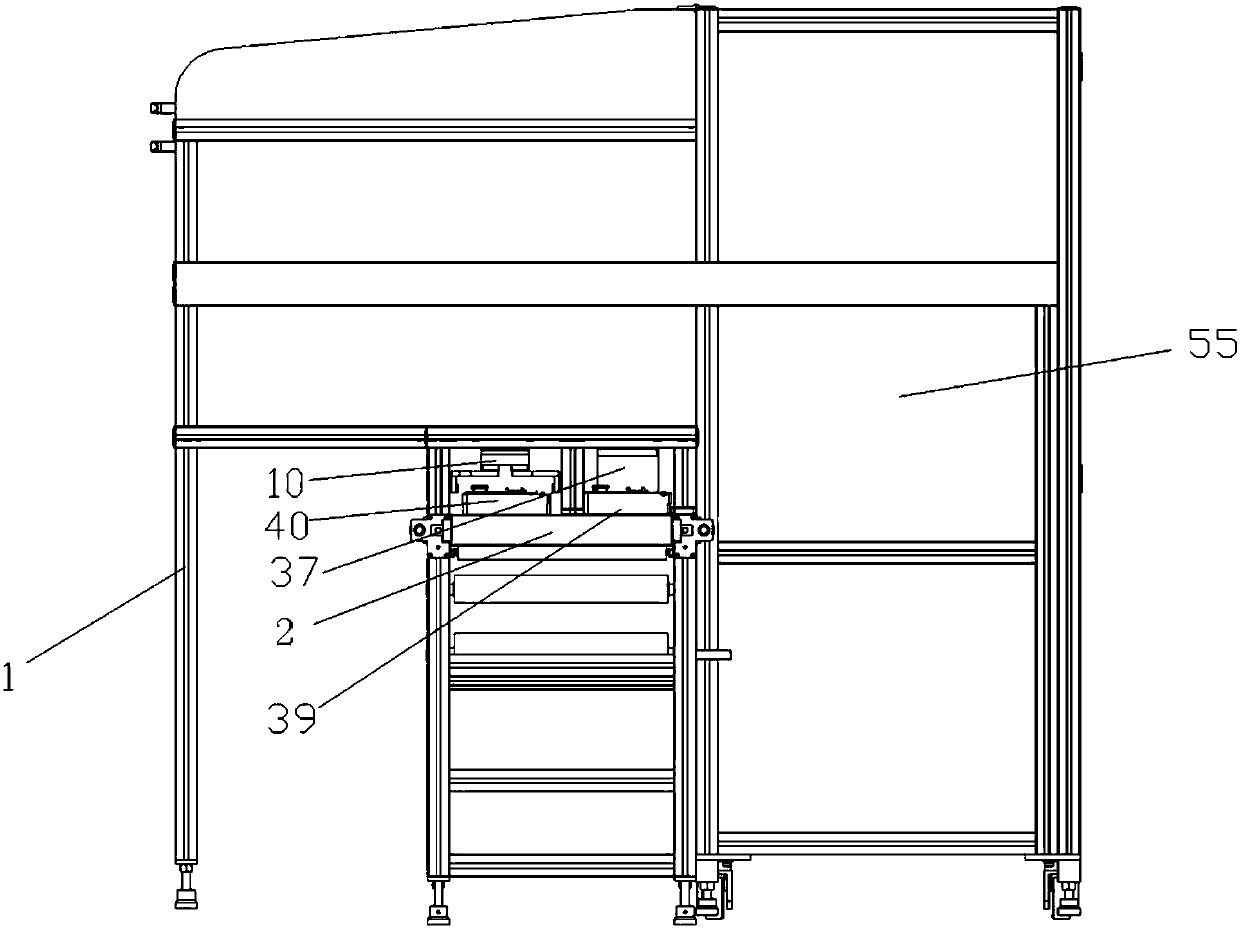

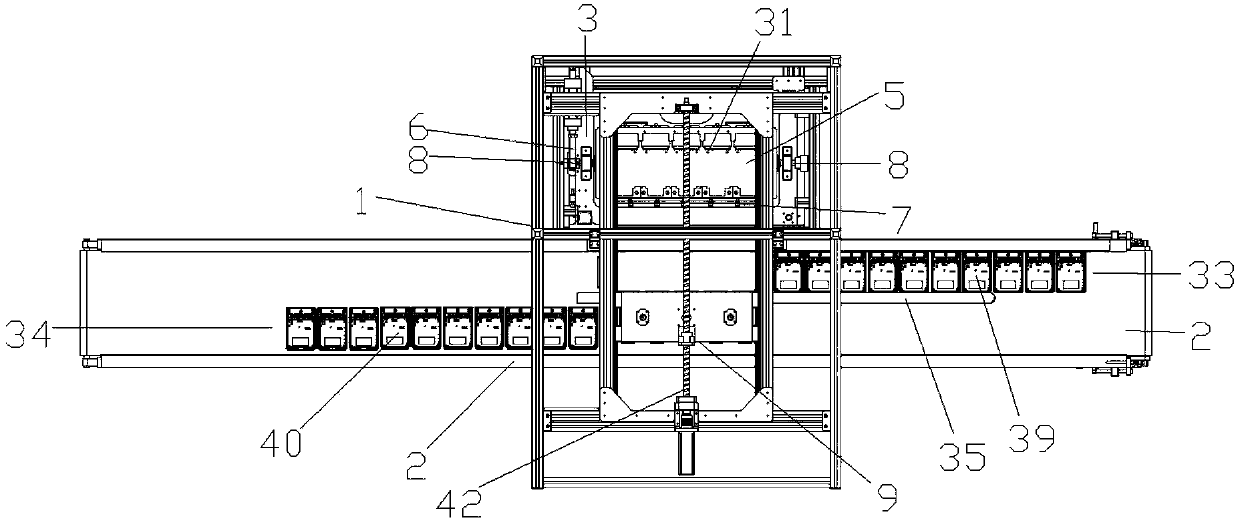

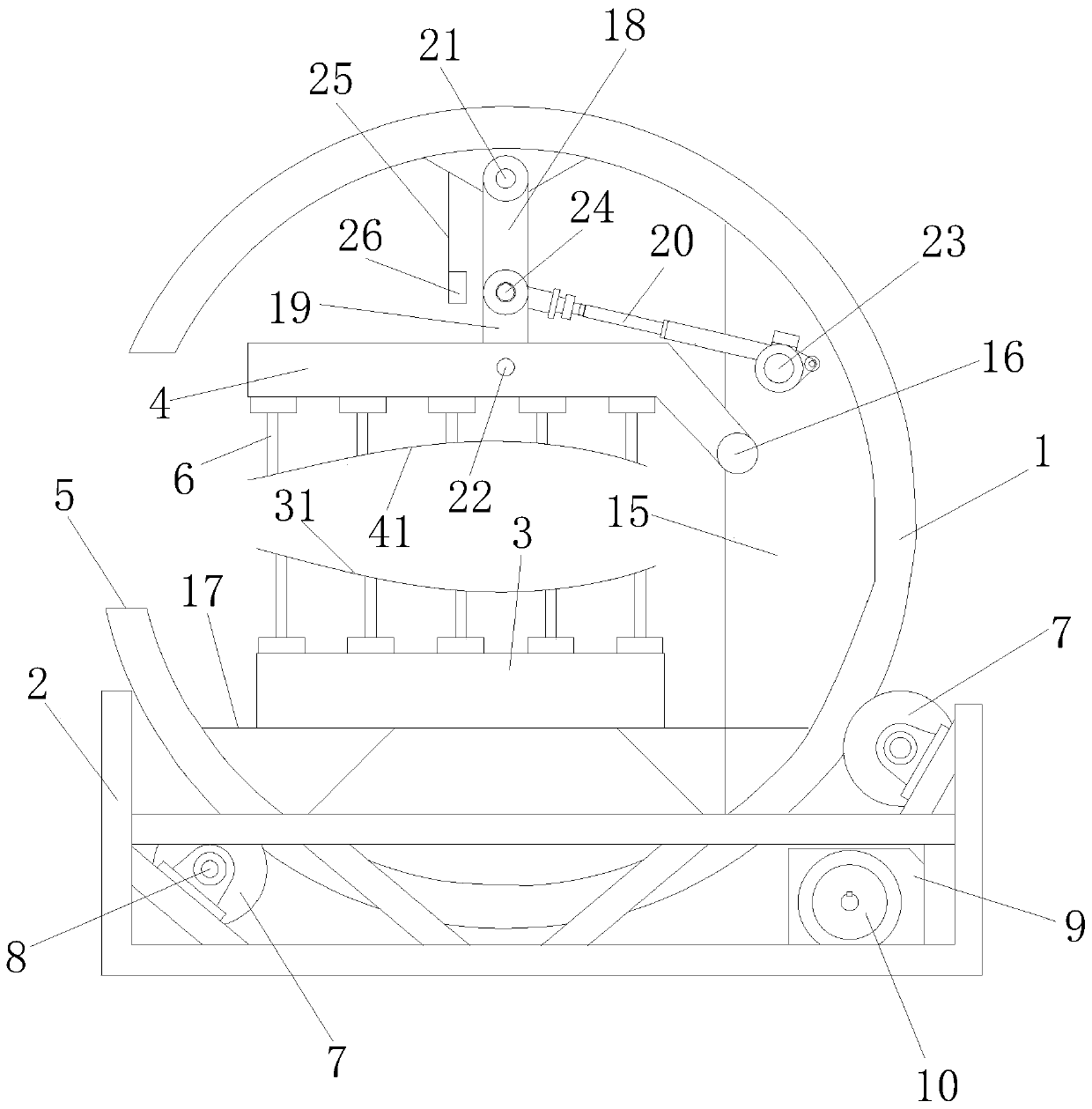

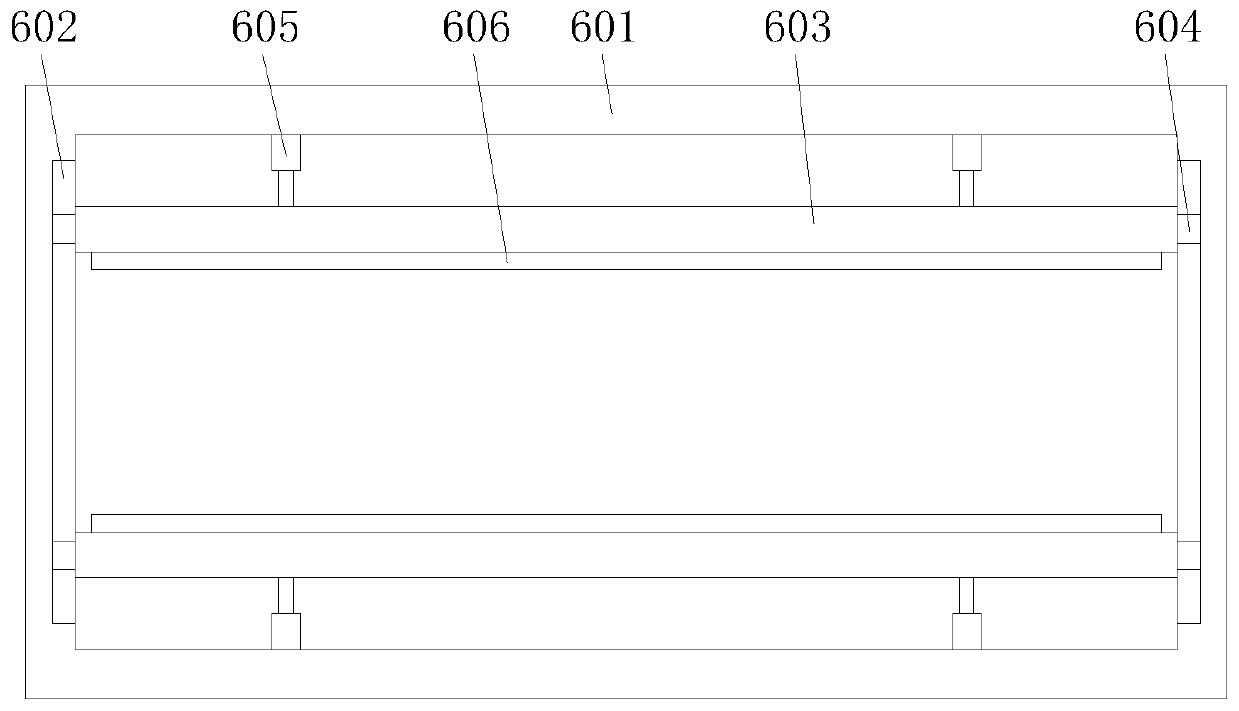

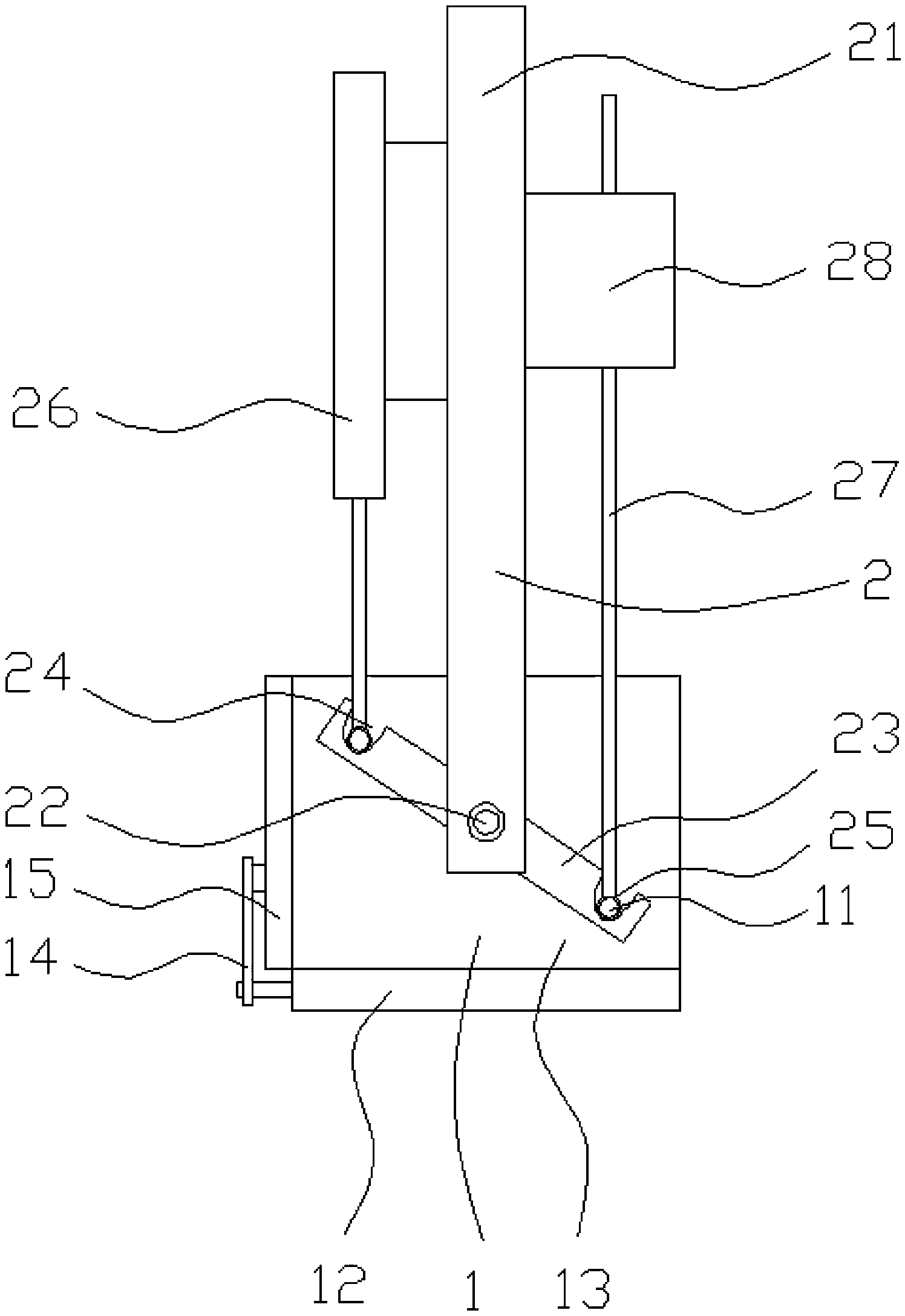

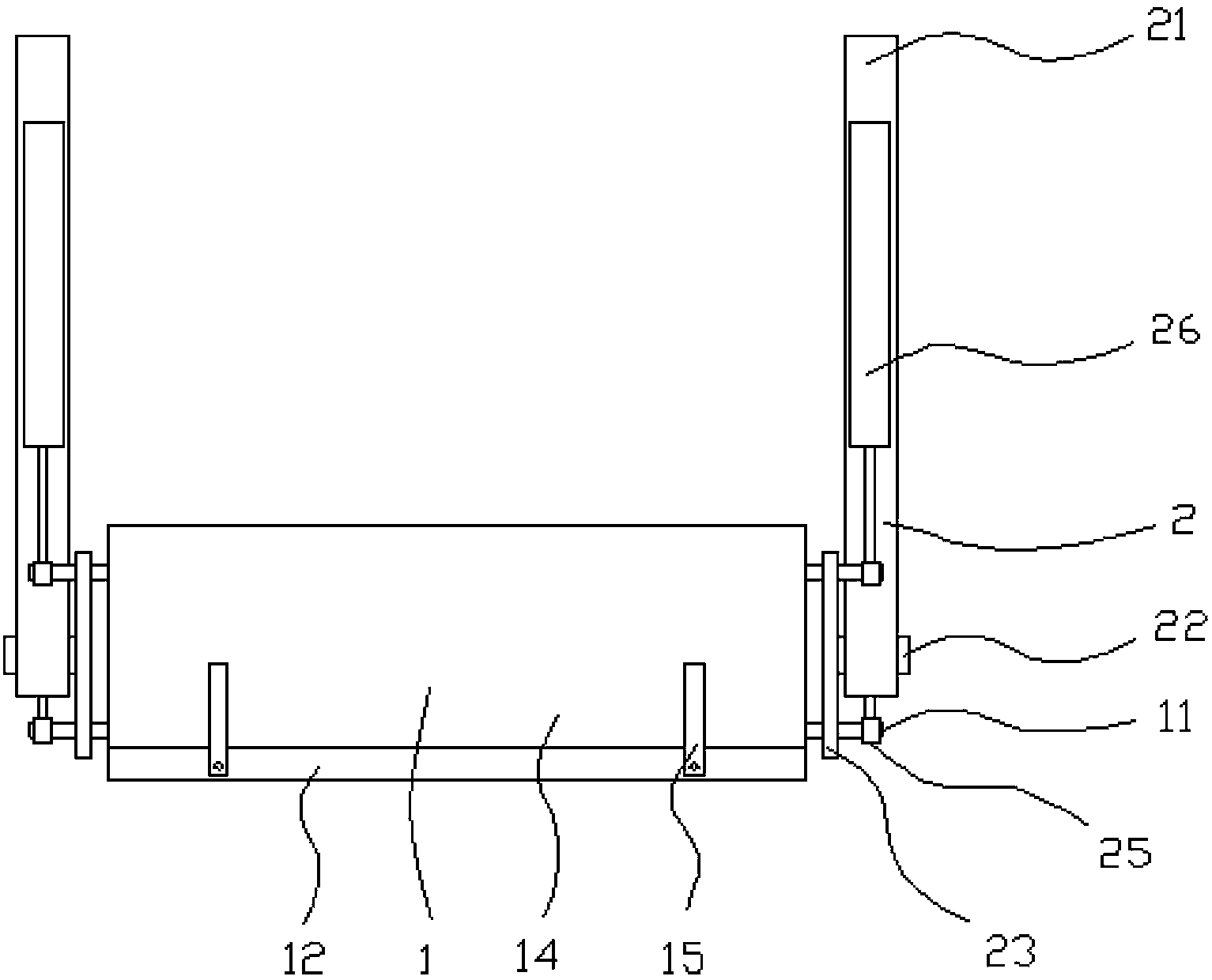

Automatic dust removal equipment for electric energy meters

The invention discloses automatic dust removal equipment for electric energy meters. The automatic dust removal equipment for the electric energy meters comprises a rack, a conveying device and a dust removal device. The automatic dust removal equipment is characterized in that the conveying device and the dust removal device are arranged on the front part and the rear part of the rack in parallel; the dust removal device comprises a location fixture used for fixing the plurality of electric energy meters, an air-blowing device and a turnover mechanism used for driving the location fixture to turn over up and down; and a transferring-loading mechanism is further arranged above the rack, and between the conveying device and the location fixture, and used for grabbing the electric energy meters to be subjected to dust removal on the conveying device and moving the electric energy meters onto the location fixture or grabbing the electric energy meters subjected to dust removal on the location fixture and moving the electric energy meters onto the conveying device. According to the automatic dust removal equipment for the electric energy meters, the conveying device and the dust removal device are mutually separated, so that dust in the electric energy meters can be adequately eliminated.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

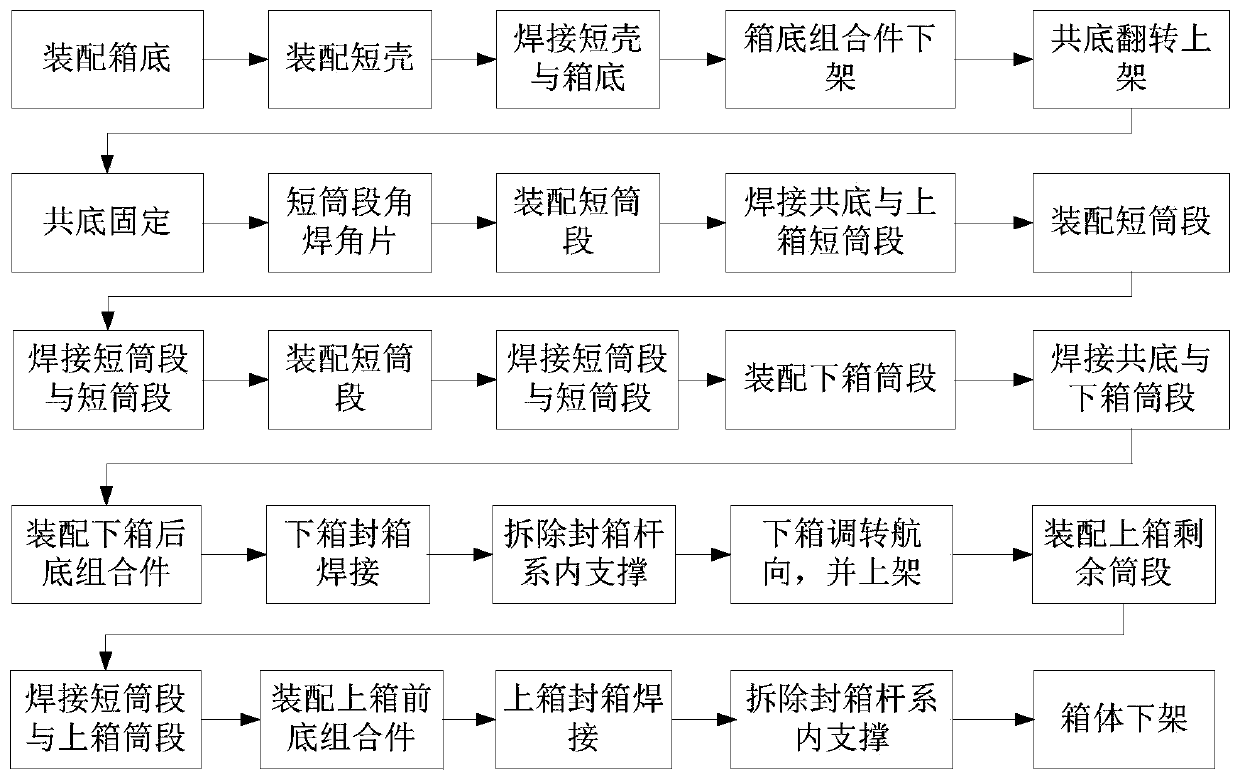

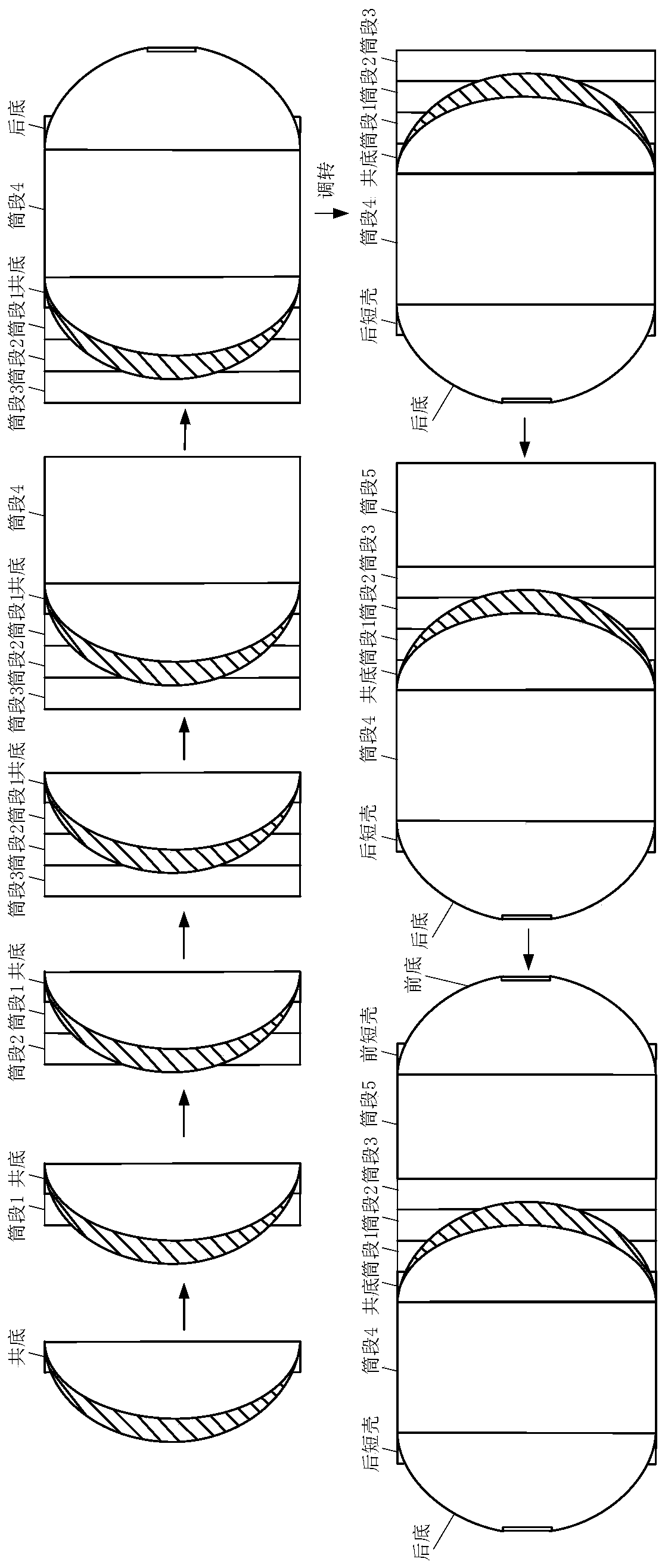

Common-bottom structure storage tank body assembling and welding process and overturning tool

ActiveCN110961820ASimple and reliable flippingSimple and reliable flipping processNuclear energy generationWelding/cutting auxillary devicesClassical mechanicsStructural engineering

The invention provides a common-bottom structure storage tank body assembling and welding process which comprises the following steps that (1) a front bottom assembling unit and a rear bottom assembling unit are welded; (2) the common bottom of the common bottom storage tank is overturned through an overturning tool and the upper frame is fixed to the tail of the equipment bed; (3) an upper box cylinder section is welded on the upper convex side of the common bottom; (4) the lower box cylinder section is mounted to the equipment bed tail, then the common-bottom transition ring and the lower box cylinder section are welded, the rear bottom assembly is mounted to the equipment bed tail and then the rear bottom assembly and the lower box cylinder section are welded to form a storage box partsection; and (5) the storage box section is lifted to turn the course, the rear bottom assembly end of the storage box section is connected with the equipment bed head, the upper box cylinder sectionis erected to the tail of the equipment bed, the upper box cylinder section and the remaining cylinder sections are assembled and welded and then the front bottom assembly is assembled to the tail ofthe bed and the front bottom assembly is welded with the remaining cylinder sections. The overturning process of the storage tank of the common-bottom structure storage tank body assembling and welding process is simple and reliable and overturning of a large-diameter tank bottom structure is realized.

Owner:TIANJIN AEROSPACE CHANGZHENG ROCKET MFGCO

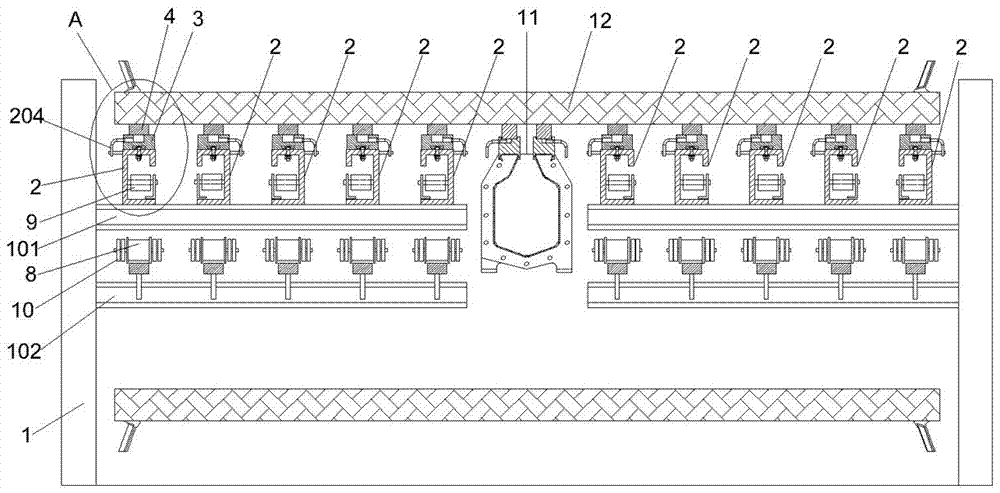

Horizontal vacuum belt type filter and filtering method thereof

ActiveCN107982993APrevent splashAvoid churnMoving filtering element filtersSupporting systemBuffer tank

The invention discloses a horizontal vacuum belt type filter which comprises a rack, a driving roller, a driven roller, a belt support system, an annular belt, a piece of filtering cloth, a vacuum boxmechanism and a feeder, wherein the belt support system comprises a support track and a support track sliding strip; the vacuum box mechanism comprises vacuum boxes, liquid collection branch tubes, airbags, push discs, mounting platforms and vacuum box chutes; the vacuum boxes consist of multiple sections of vacuum box bodies, vacuum box flanges, front vacuum box guides, rear vacuum box guides and vacuum box elbows; the feeder comprises a box-shaped overflowing mechanism, an upper cover and a feeding tube; and the box-shaped overflowing mechanism comprises a box-shaped overflowing cavity, a storage tank, a front buffer tank, a rear buffer tank, a front adjusting plate, a rear adjusting plate, a front inner support, a rear inner support, a front cover plate, a rear cover plate, a left sidesupport and a right side support. By adopting the horizontal vacuum belt type filter, an excellent filtering effect can be ensured, the overall deformation resistance of a vacuum box is improved in the operation process, the feeding amount can be increased, product consumption in the filtering process is reduced, and uniform feeding can be ensured.

Owner:杭州新蓝科技有限公司

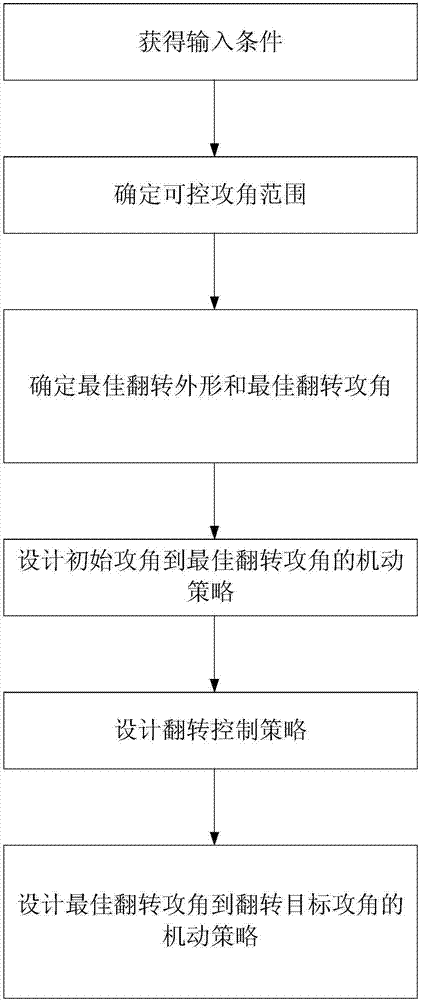

High-speed flight high-adaptability 180-degree flip control method

ActiveCN107390718AHigh flip reliabilityAerodynamic shape changePosition/course control in three dimensionsControl flowEngineering

The invention provides a high-speed flight high-adaptability 180-degree flip control method, which comprises the following steps: to begin with, obtaining input conditions; then, calculating a controllable attack angle range; determining an optimum flip shape and an optimum flip attack angle; designing a maneuvering path; and designing an attack angle maneuvering strategy and a flip control strategy according to the maneuvering path, and finishing high-speed flight 180-degree flip control. The method, with significant changes of aerodynamic shape of a novel high-performance aircraft in the180-degree flip process being taken into full consideration, determines the optimum flip attack angle, carries out reasonable planning of the attack angle maneuvering path and determines the optimum flip control flow, so that the whole maneuvering process is allowed to be carried out under reasonable stability and maneuverability conditions, and flip reliability is high; and the method can be suitable for great and violent changes of aerodynamic characteristics, stability and maneuverability of the aircraft in the flip process, and can realize quick and reliable flip.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

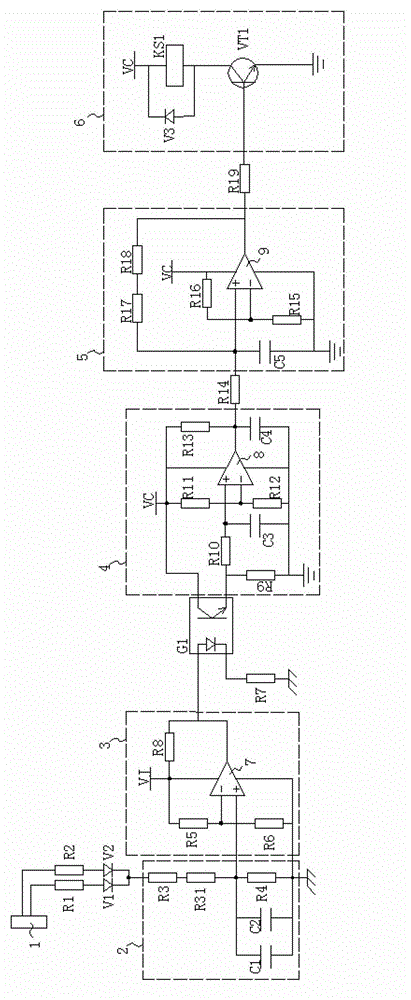

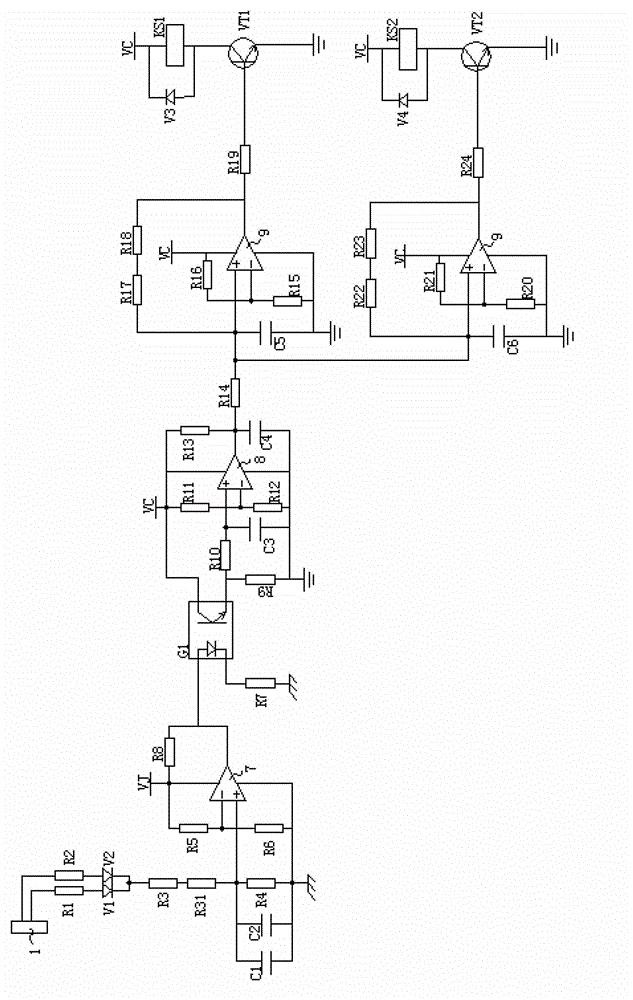

Single-phase source leakage detection circuit for isolated neutral system

ActiveCN103066554ANormal flipFlip reliableElectrical testingEmergency protective arrangements for automatic disconnectionElectricityRectifier diodes

The invention relates to a leakage detection circuit, in particular to a single-phase source leakage detection circuit applied to an isolated neutral system. Two electrodes of a single-phase source are respectively connected with a commutation diode, and a sampling unit is connected between the two commutation diodes and the ground. The output end of the sampling unit is connected with a comparison output unit. The comparison output unit is connected with a relay triggering unit. Through the adoption of the structure, a detection mutual inductor is saved, a voltage drive logic circuit of a leakage resistance in a half-wave rectifying circuit is utilized to achieve detection when a power source leaks electricity, and therefore cost is saved. In addition, misoperation caused by voltage floating is reduced, and the safety of mine power supply is improved.

Owner:CHANGZHOU LIANLI AUTOMATION TECH

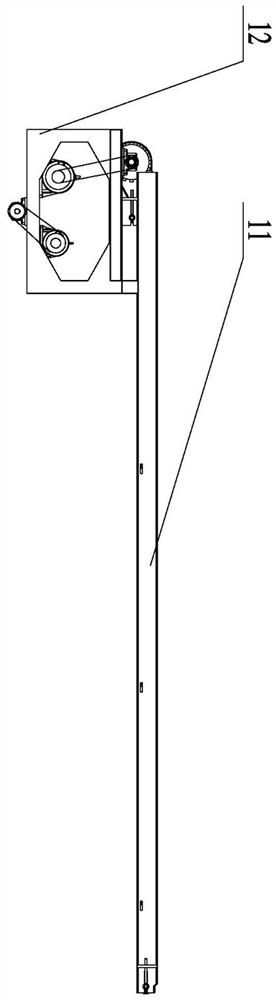

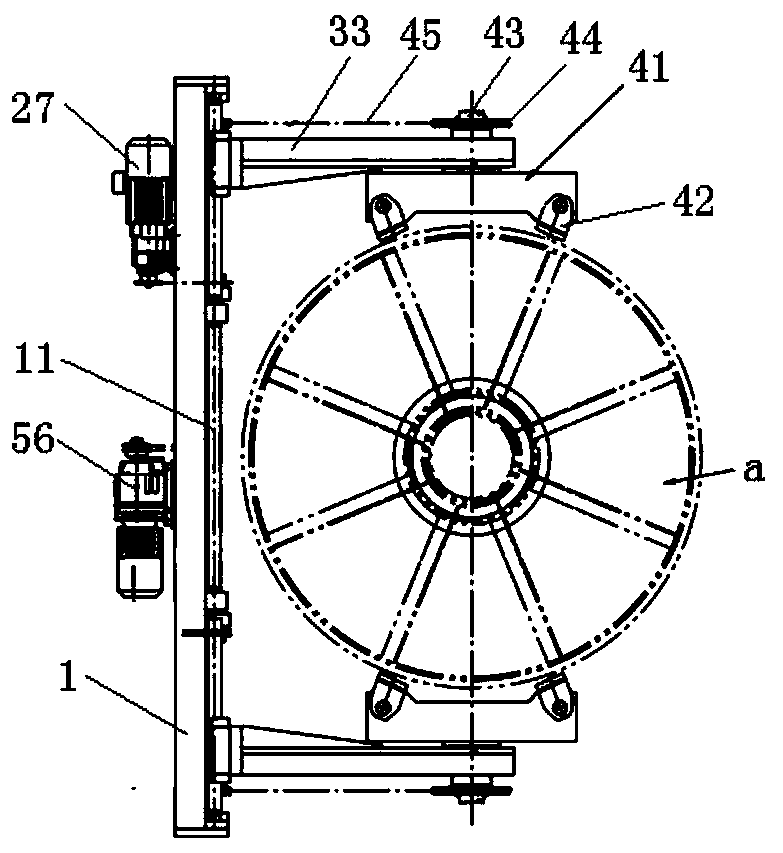

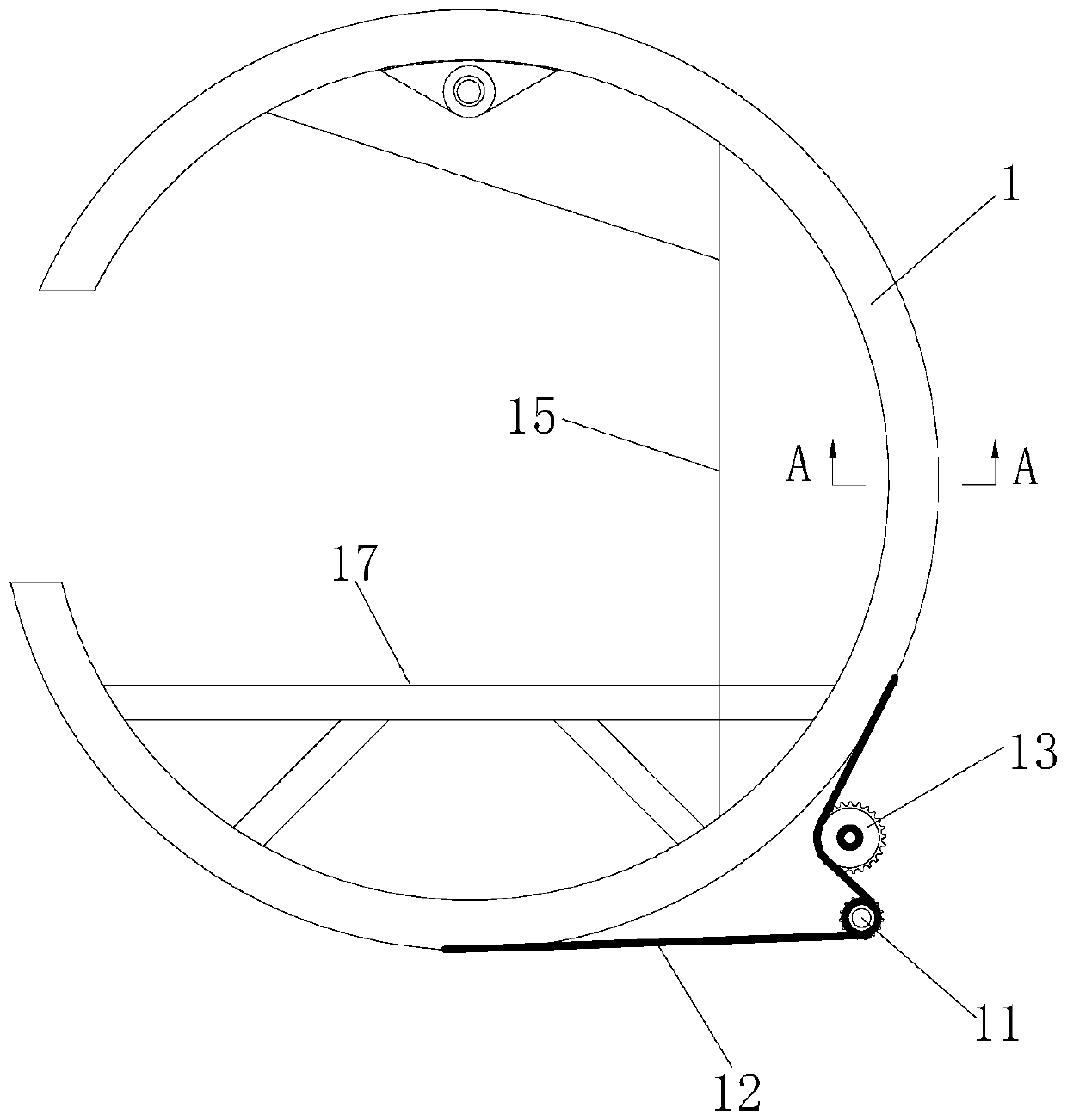

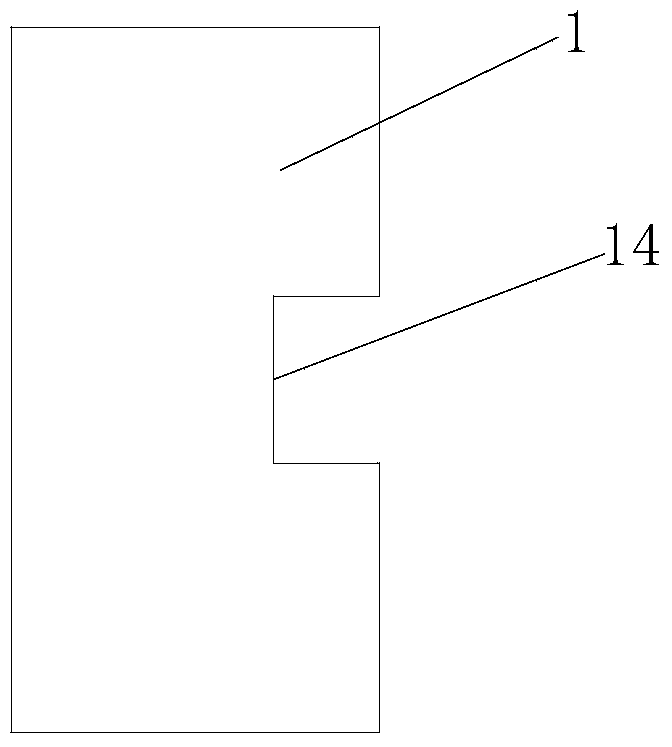

A wind turbine blade turning device

The invention discloses a turning device for wind power blades, which is characterized in that it comprises: a swivel ring provided with a gap; a clamping mechanism installed in the swivel ring and flipped synchronously with the swivel ring; a supporting base; And a driving mechanism, including a power part, a chain drive part connecting the power part and the swivel; wherein, the clamping mechanism includes a fixed clamp arm, a movable clamp arm matched with the fixed clamp arm, and a link assembly that drives the deflection of the movable clamp arm; the fixed clamp arm has a first clamping surface, the movable clamp arm has a second clamping surface facing the first clamping surface, and the The clamping area of the wind turbine blade is formed between the first clamping surface and the second clamping surface, and the notch faces the clamping area; the wind turbine blade turning device has the advantages of simple structure and large rotational torque, so that The flipping of wind turbine blades is more efficient, safe and reliable.

Owner:上海中帧机器人控制技术发展有限公司

Automatic overturn device for painting

The invention relates to the technical field of painting, and particularly relates to an automatic overturn device for painting. The device comprises a base plate, a first side plate, a second side plate, a driving motor, a rotary shaft, a fixed device, a top plate, a position shifting device and a painting machine. The first side plate and the second side plate are fixedly connected to the two sides of the base plate respectively. The driving motor is fixedly connected to the left side of the first side plate through a supporting frame. The rotary shaft is fixedly connected to an output end of the driving motor. The end, away from the driving motor, of the rotary shaft penetrates through the first side plate and extends to the right side of the first side plate. According to the automaticoverturn device for painting, every time the driving motor rotates for one circle during operation in work, the driving motor can drive the rotary shaft to rotate; and because the rotary shaft is fixedly connected with the fixed device, after one side of a workpiece is painted, the workpiece can automatically overturn, and then the other side of the workpiece is evenly painted by the painting machine; and the automatic overturn device for painting is simple in structure, convenient to operate and capable of stably and reliably overturning the workpiece with large area while manpower consumption is reduced, and the production efficiency is improved.

Owner:广东鸿利昌机械制造有限公司

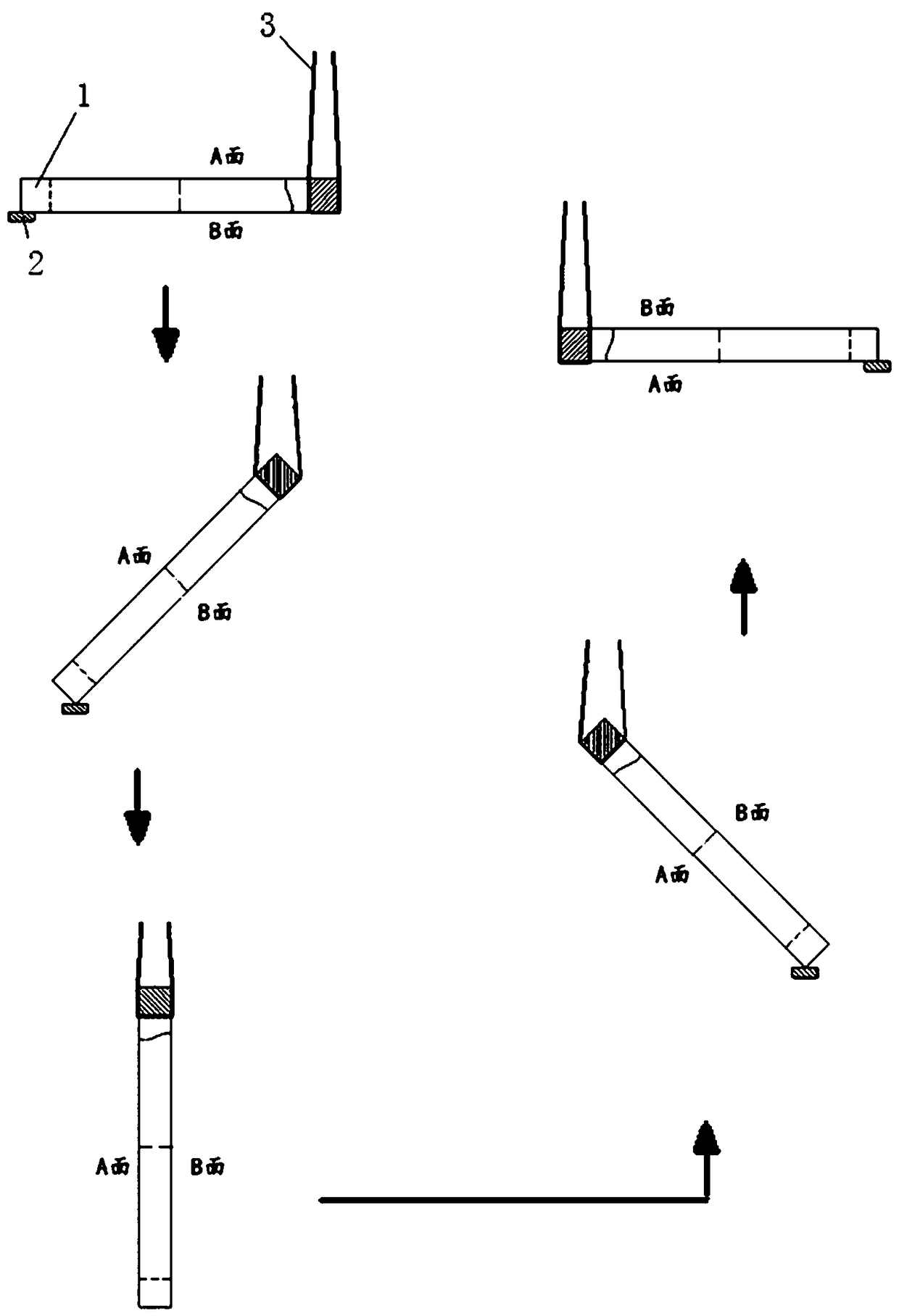

Overturning device and overturning method for large plate parts

The invention belongs to the technical field of machining tool devices, and discloses a large plate part turning device. One end of a first rotary part and one end of a second rotary part are connected to a rotating shaft. Body frames of the two rotary parts are each of a rectangular structure. Beams are arranged below the body frames. The height of the upper surfaces of the beams is smaller than the height of side beams on the peripheries of the frames. The height of the side beams is smaller than the thickness of plate parts. A plurality of lower supports are arranged on the beams. Side supports are arranged on the side beams on at least two opposite sides. The lower supports limit the perpendicular freedom degree of the parts. The side supports limit the horizontal freedom degree of the parts. Hanging lugs are arranged on the outer lateral sides of the two rotary parts respectively and are staggered. The invention further discloses a rotating method using the device. Workpieces are prevented from generating impact, external force and other effects in the turning process, safe, reliable and risk-free turning is implemented, product quality is ensured, and the cost for processing non-conformance terms is reduced.

Owner:上海第一机床厂有限公司

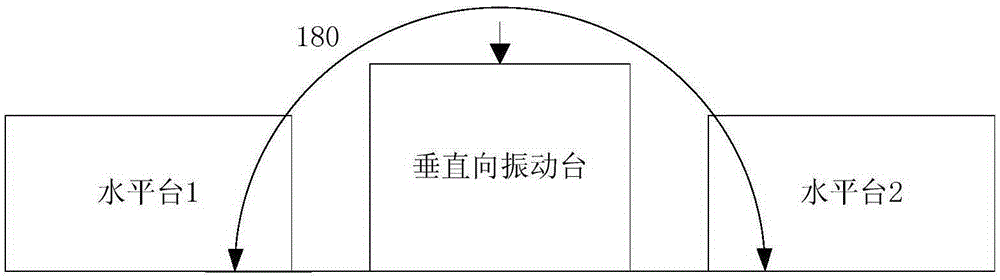

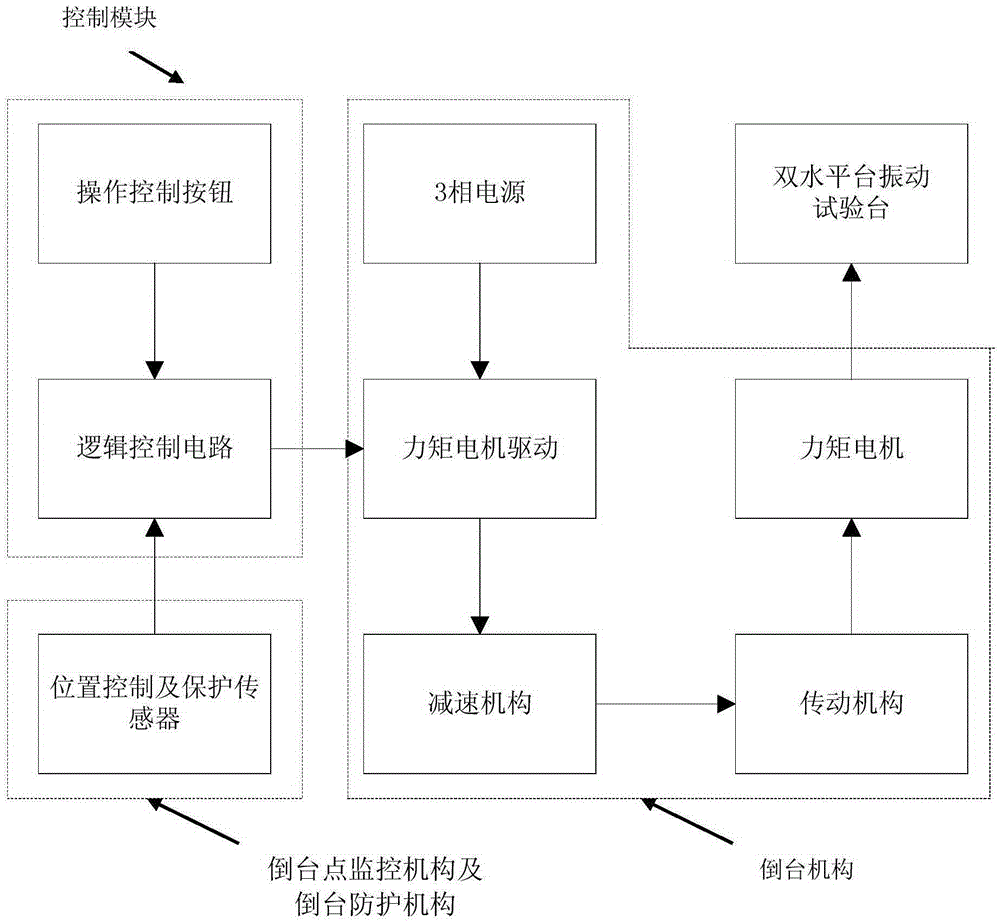

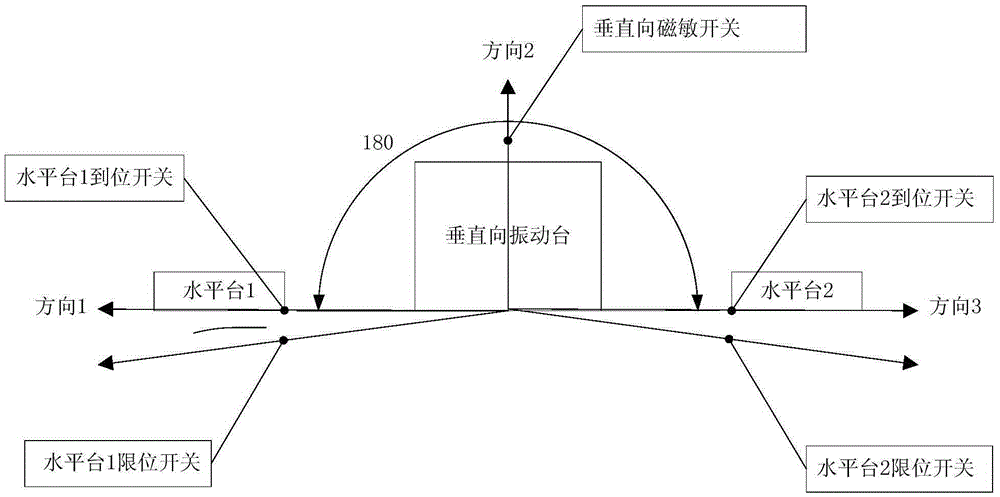

Three-direction inverse platform device of vibration test system

The invention discloses a three-direction inverse platform device of a vibration test system. The device comprises an inverse platform mechanism and an inverse platform point monitoring mechanism. The inverse platform mechanism is used for driving a vibration platform to rotate around an axis, and enables the vibration platform to stay at any selected station in first and second horizontal stations and a vertical station. First and second horizontal stations and the vertical station are located on the same plane. The vertical station is arranged between first and second horizontal stations. First and second horizontal stations are arranged in the same horizontal line. The inverse platform point monitoring mechanism is used for monitoring whether the vibration platform reaches any selected station in first and second horizontal stations and the vertical station when the vibration platform rotates. According to the invention, the device is simple in structure; on the premise that the vibration platform is safe, a dual horizontal platform structure can quickly inverse on left and right horizontal platforms and in the vertical direction; a user can determine inversing and staying manners of the platform body by himself or herself according to the use condition of the user; the burden of an operator can be significantly reduced; and the use efficiency of the device is improved.

Owner:苏州泰斯特测控科技有限公司

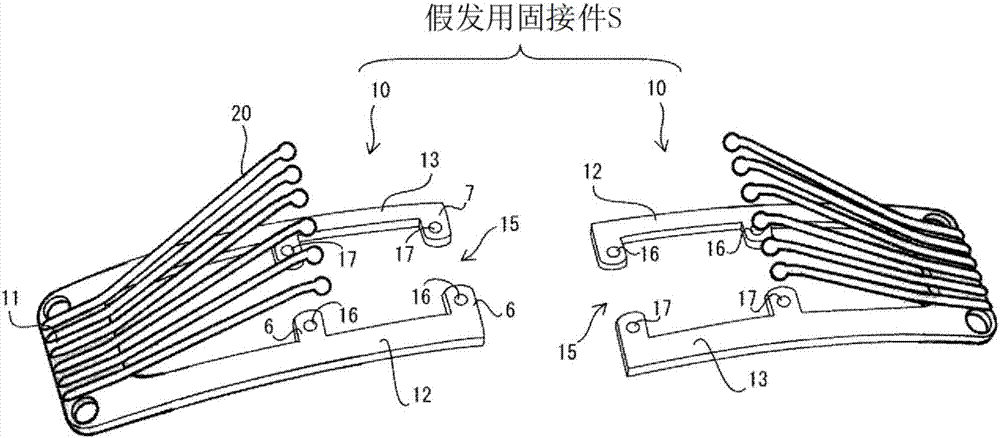

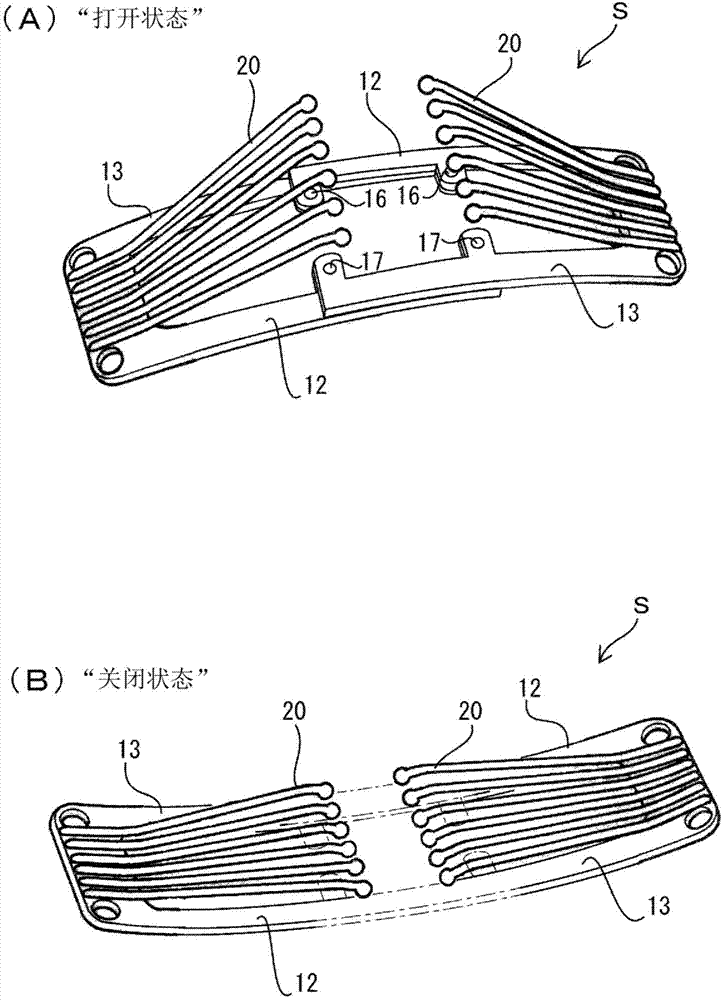

Wig fastening tool and wig using same

Owner:ADERANS CO LTD +1

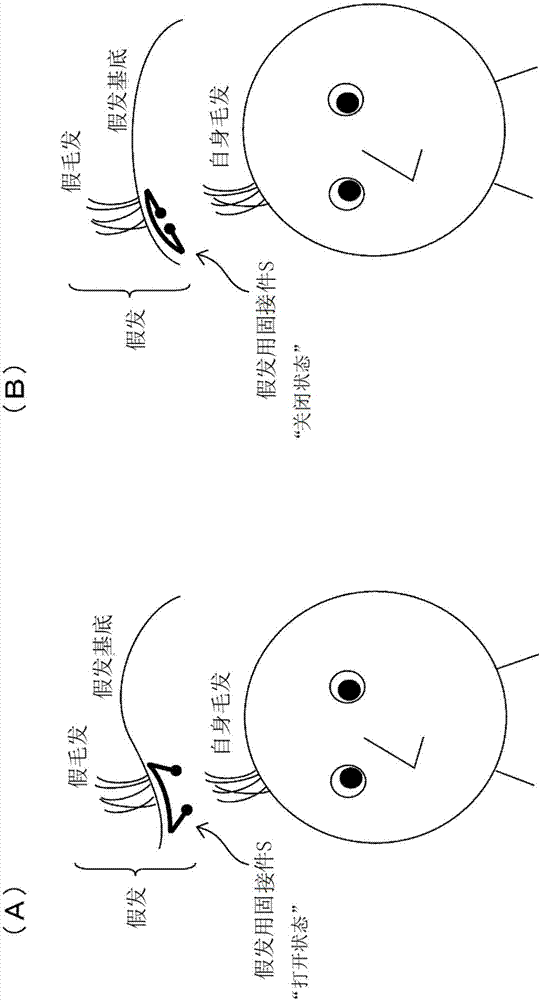

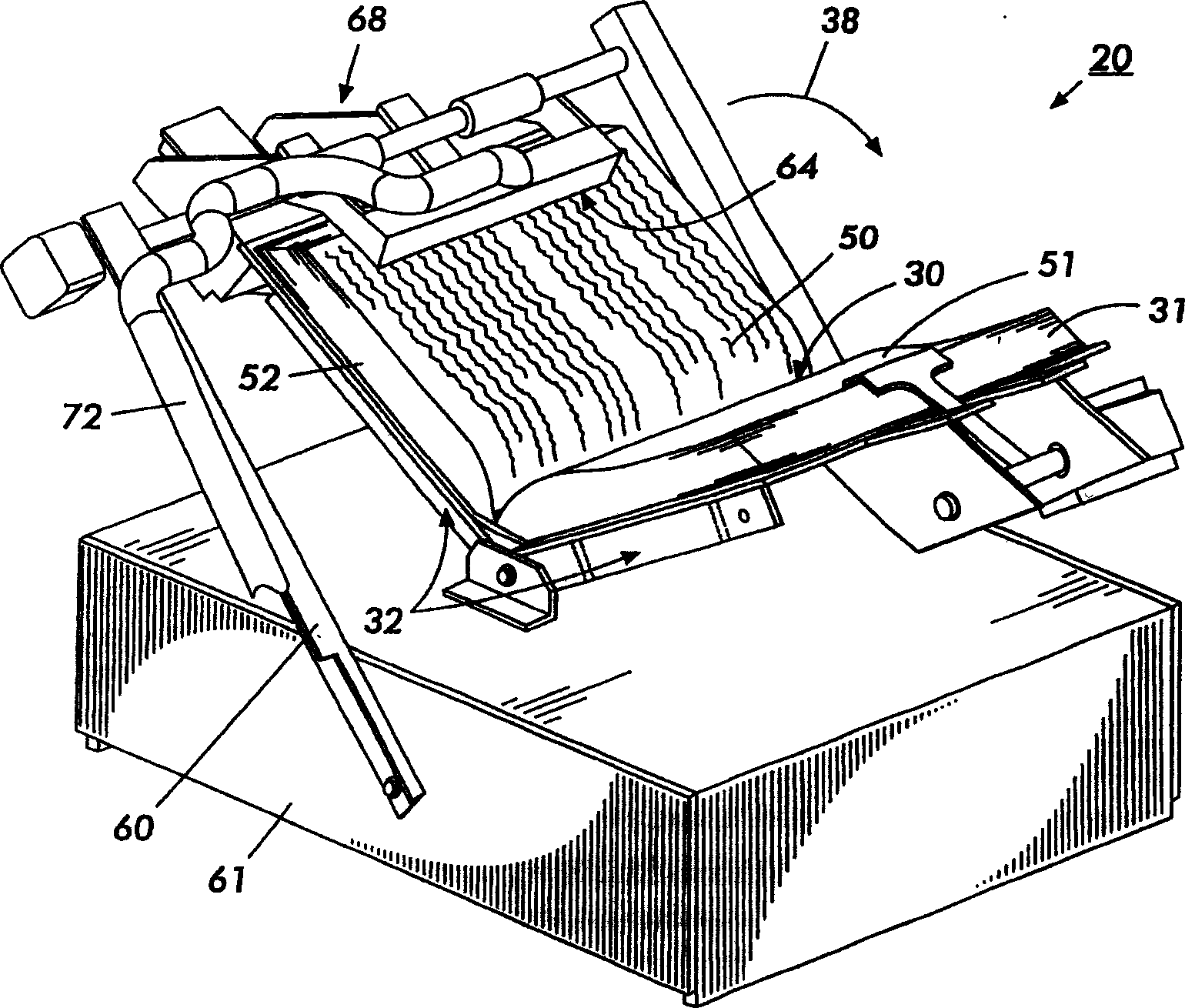

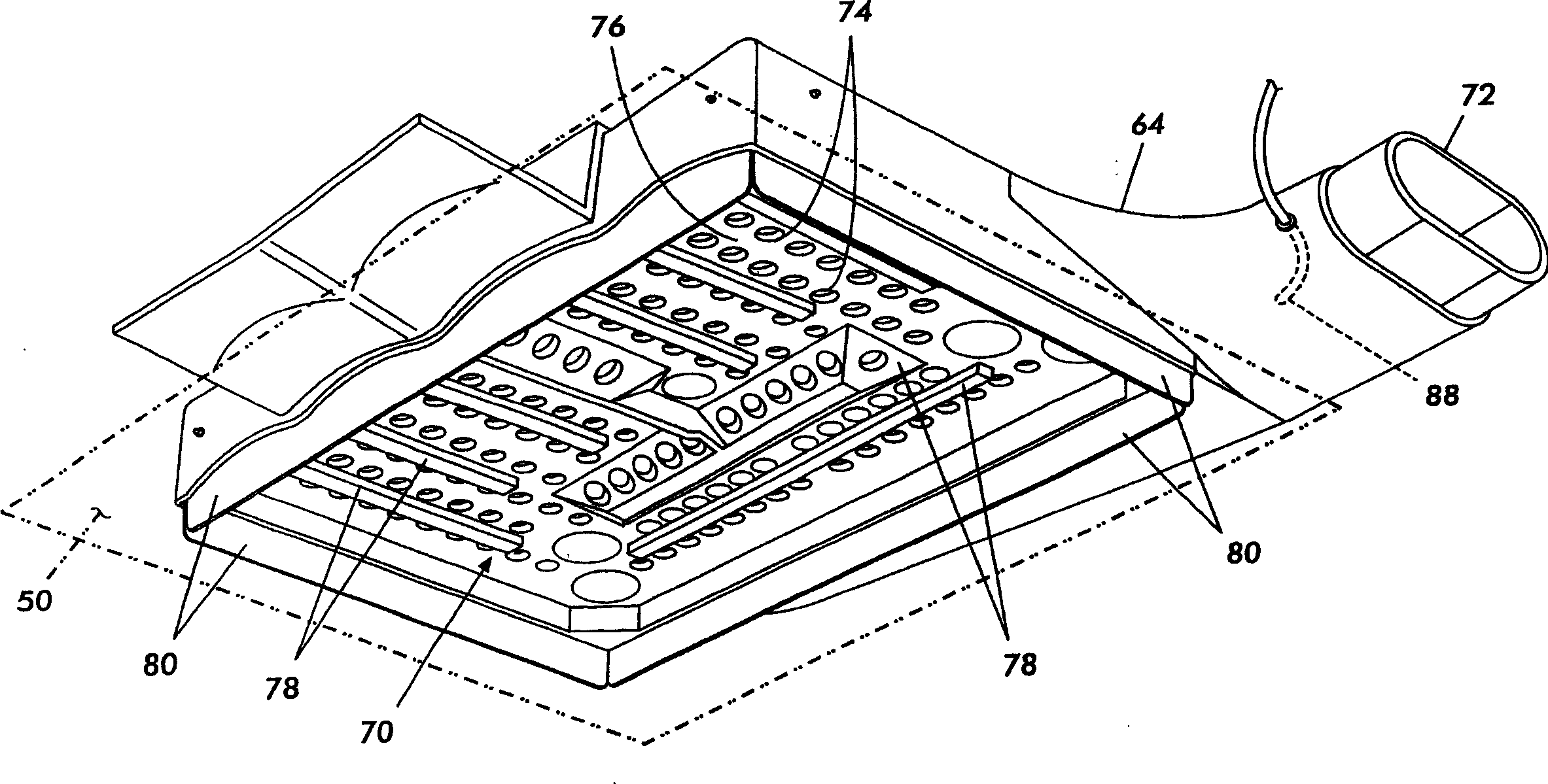

Page turning apparatus with a vacuum plenum and an adaptive air fluffer

InactiveCN1653438AFlip reliableRecords helpDigitally marking record carriersDigital computer detailsEngineeringMechanical engineering

Owner:KIRTAS TECH INC

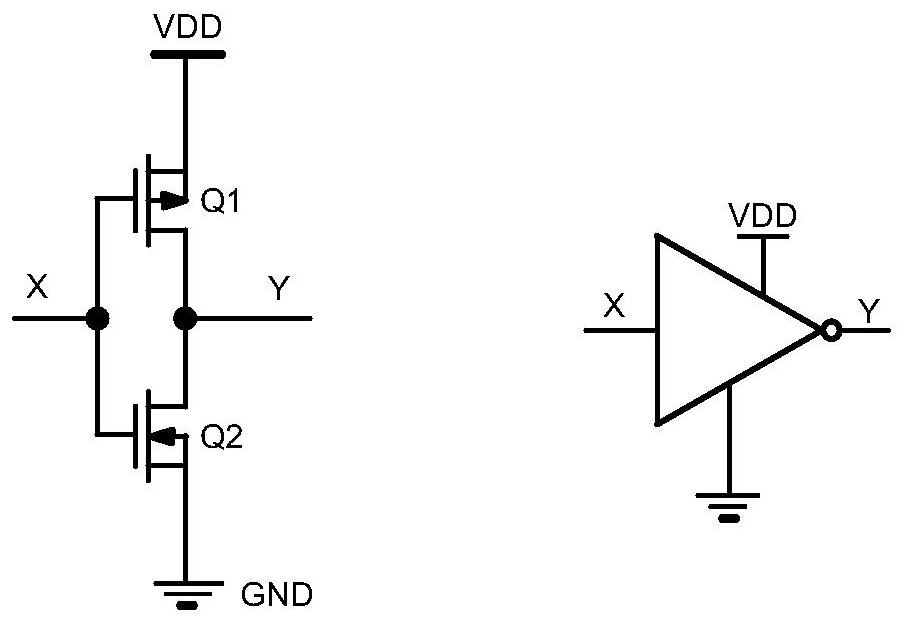

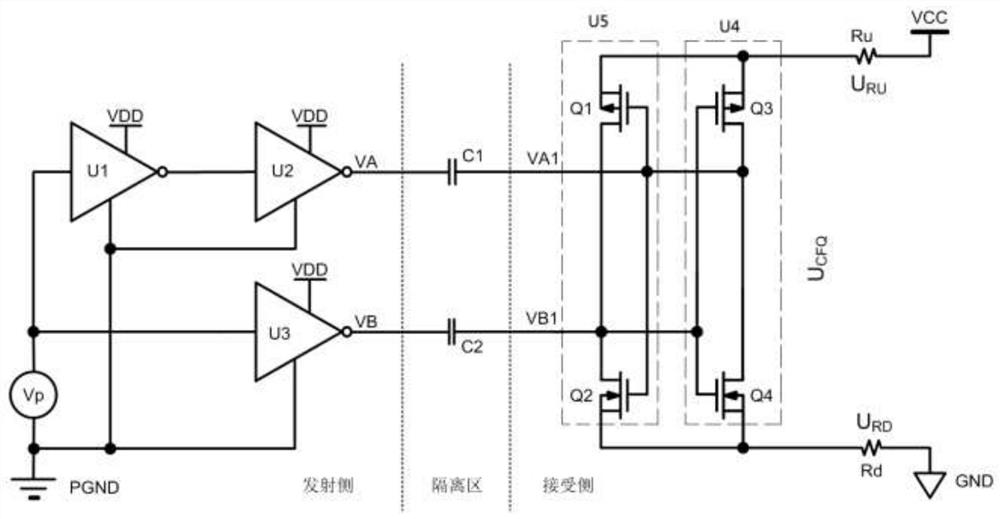

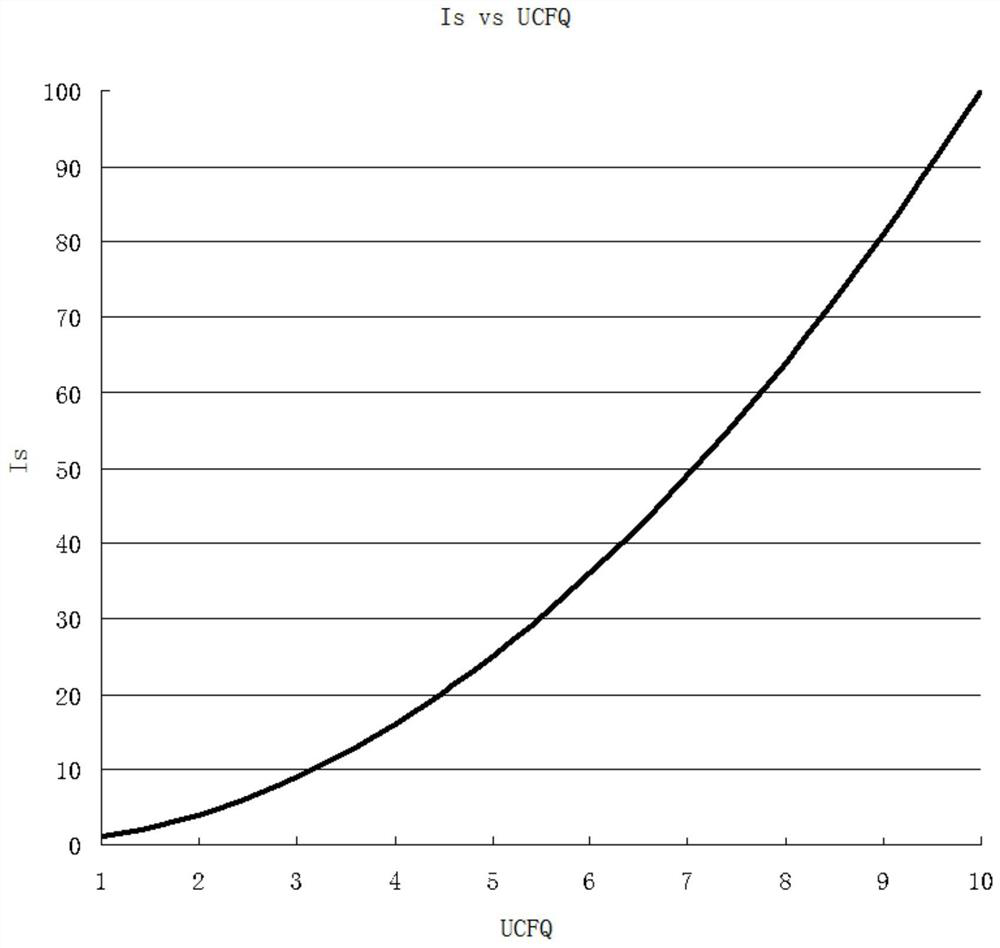

Transmission device for capacitive coupling isolation transmission of pulse signals and corresponding transmission method

PendingCN114448419ALow costReduced precision requirementsLogic circuit coupling arrangementsPower conversion systemsCapacitanceHemt circuits

The invention discloses a transmission device for capacitive coupling isolation transmission of pulse signals. The transmission device comprises a transmitting side, an isolation region and a receiving side, the transmitting side comprises three CMOS (complementary metal oxide semiconductor) logic inverters U1, U2 and U3, the isolation region comprises small-capacitance high-voltage capacitors C1 and C2, and the receiving side comprises a bistable trigger which consists of a PMOS (P-channel metal oxide semiconductor) and an NMOS (N-channel metal oxide semiconductor) and has input and output at the same end, and two resistors Ru and Rd with the same resistance value; and the bistable flip-flop comprises a complementary metal oxide semiconductor (CMOS) logic phase inverter U5 and a CMOS logic phase inverter U4. The invention further discloses a transmission method for transmitting the pulse signals through capacitive coupling isolation by means of the transmission device. According to the invention, isolated transmission of pulse signals can be completed by a quite simple circuit.

Owner:杭州欧佩捷科技有限公司

Turnover device for lime-cement solidification box

InactiveCN102862226BEasy to unloadEasy to operateCeramic shaping apparatusHydraulic cylinderEngineering

The invention discloses a turnover device for a lime-cement solidification box, relating to the technical field of lime-cement solidification boxes. The turnover device comprises a box body, and is characterized by further comprising turnover devices arranged at the both ends of the box body, wherein rotary shafts are fixed at the both ends of the box body, and the fixed rotary shafts are located at diagonal positions on the end surface of the box body; the turnover device comprises a support, a middle rotary shaft arranged below the support, and a rotary plate arranged on the middle rotary shaft, wherein shaft grooves are symmetrically arranged at the both ends of the rotary plate; and the fixed rotary shafts are located in the shaft grooves, wherein one fixed rotary shaft is connected with a hydraulic cylinder via a shaft sleeve, the hydraulic cylinder is fixed on the support, the other fixed rotary shaft is connected with a guide rod via a shaft sleeve, and the guide rod is connected with a guide block arranged on the support. The turnover device for a lime-cement solidification box disclosed by the invention is convenient to unload, easy to operate, capable of automatically realizing turnover, time-saving and labour-saving, as well as stable, reliable and easy to locate during turnover.

Owner:蚌埠市祥源新型建材有限公司

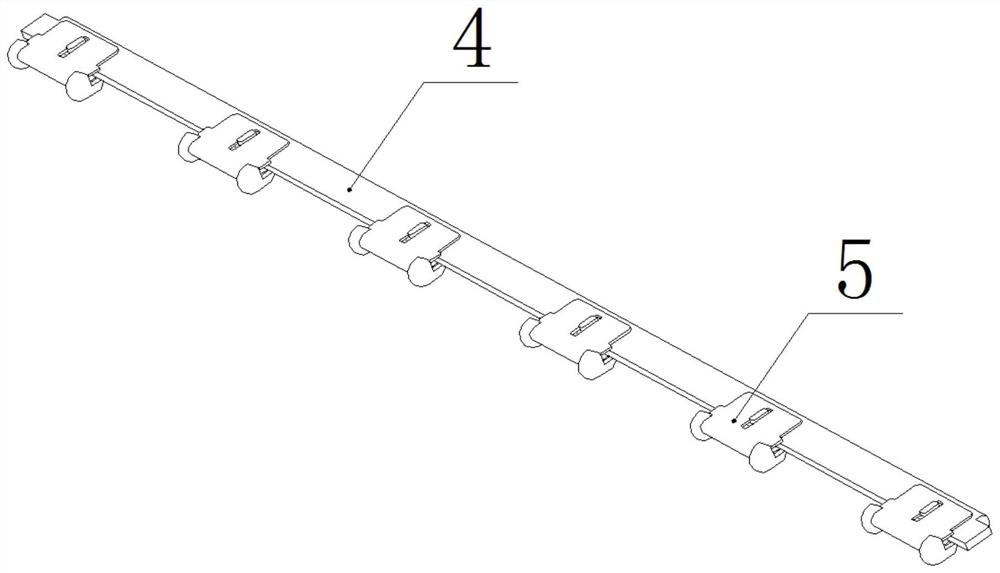

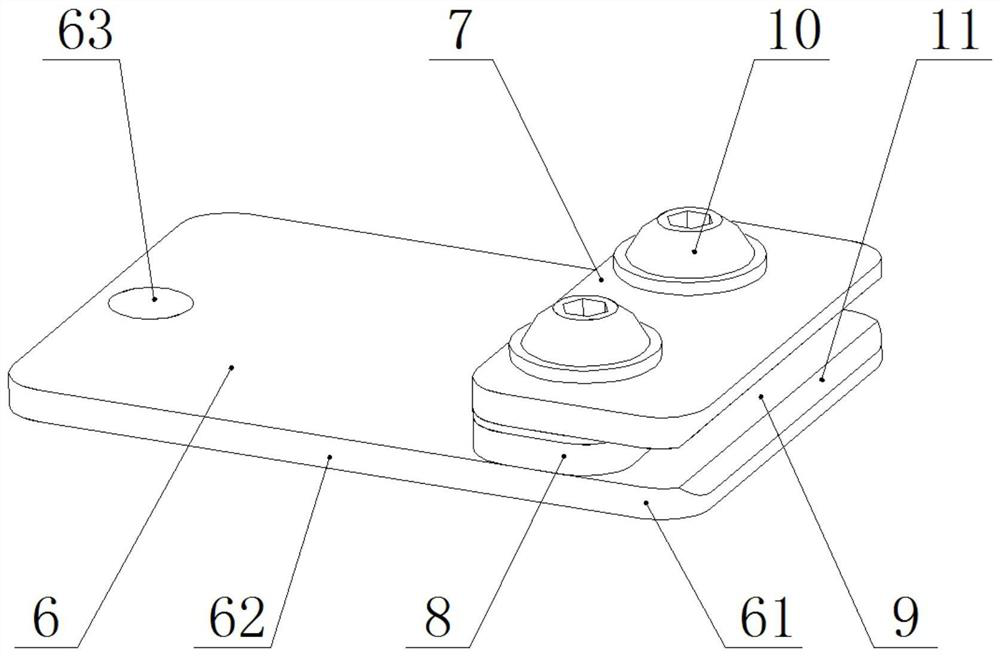

Compact spinning tension bracket overturning tool

The invention relates to a compact spinning tension bracket overturning tool. The tool comprises a base plate (6), the base plate (6) comprises a front clamping part (61) and a rear pinching part (62), a clamping plate (7) is arranged at the position of the front clamping part (61), a base plate (8) is arranged between the front clamping part (61) and the clamping plate (7), and the clamping plate(7) and the front clamping part (61) form a bayonet (9) in front of the base plate (8). According to the compact spinning tension bracket turnover tool, on the premise that the structure of an existing compact spinning tension bracket is not changed and normal use is guaranteed, the overturn problem of the existing compact spinning tension bracket can be solved, the overturn of the compact spinning tension bracket is easy, convenient and reliable, the tension bracket does not deform in the overturn process, and other parts are not polluted or deformed.

Owner:江阴市华方新技术科研有限公司

Product and free conveyor trolley turning mechanism

Owner:ANHUI JEE AUTOMATION EQUIP CO LTD

Double-circuit drive rotary lifting permanent magnet

The invention discloses a double-circuit drive rotary lifting permanent magnet. A double-circuit driving device consisting of a small lifting chain, a swing rod, a ratchet wheel, a bevel shaft sleeve gear and the like is used for simply and conveniently converting upward traction of a crane to torque applied to a driving shaft to rotate in the same direction; and a rotating magnetic system for driving a magnetic circuit rotates by 180 degrees to realize suction and unloading of absorbed steel and iron objects with large inclined angle with the ground. The double-circuit drive rotary lifting permanent magnet can quickly operate like a lifting electromagnet, and can absorb the absorbed steel and iron objects with a weight of dozens of tonnages. The double-circuit drive rotary lifting permanent magnet is a great breakthrough of a driving part technology of the lifting permanent magnet, and widens the application range of the lifting permanent magnet.

Owner:CHANGCHUN UNIV

Carton overturning device and method

The invention relates to the technical field of packaging , in particular to a carton overturning device and method on a carton production line. The carton overturning device comprises a base and a motor, wherein a conveying belt is arranged on the base. The carton overturning device is further provided with an air extractor. A guide pipe is arranged on one side of the base along the base and extends from the tail of the base to the head of the base. In the extension process, the height of the guide pipe is gradually increased and then decreased, and the guide pipe is bent towards the middle of the head of the base and finally extends to the position above the middle of the head of the base. A long strip-shaped positioning strip is further arranged above the part, near the guide pipe, of the base in parallel. The carton overturning device is suitable for in-situ overturning of cartons in the carton production line during production, the manpower resources are saved, and the production efficiency is improved.

Owner:无锡唐诚机械有限公司

Foldable motorcycle carrier

The foldable motorcycle carrier includes one basic carrier, one frame with at least two runners welded to the tail of the basic carrier, one tray with ends welded separately to the basic carrier and the frame, one sliding rack matched with the runners, one folding rack hinged to the sliding rack, one spring clamp and one withdrawn arrester. The foldable motorcycle carrier may be developed to increase use space and folded to reduce occupied space, and has simple structure, convenient use, less running noise and other advantages.

Owner:LONCIN MOTOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com