Patents

Literature

75results about How to "Dust fully" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

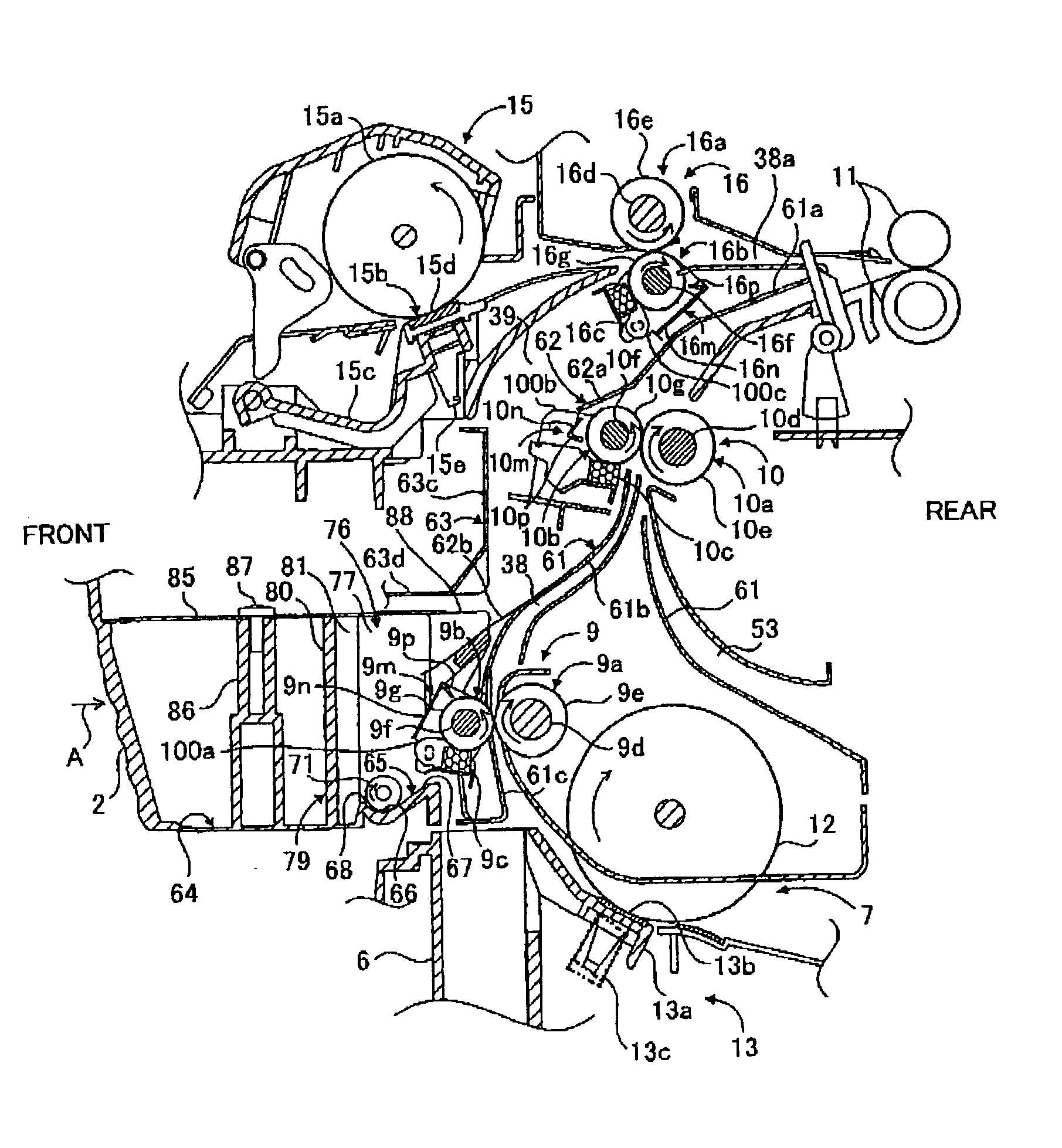

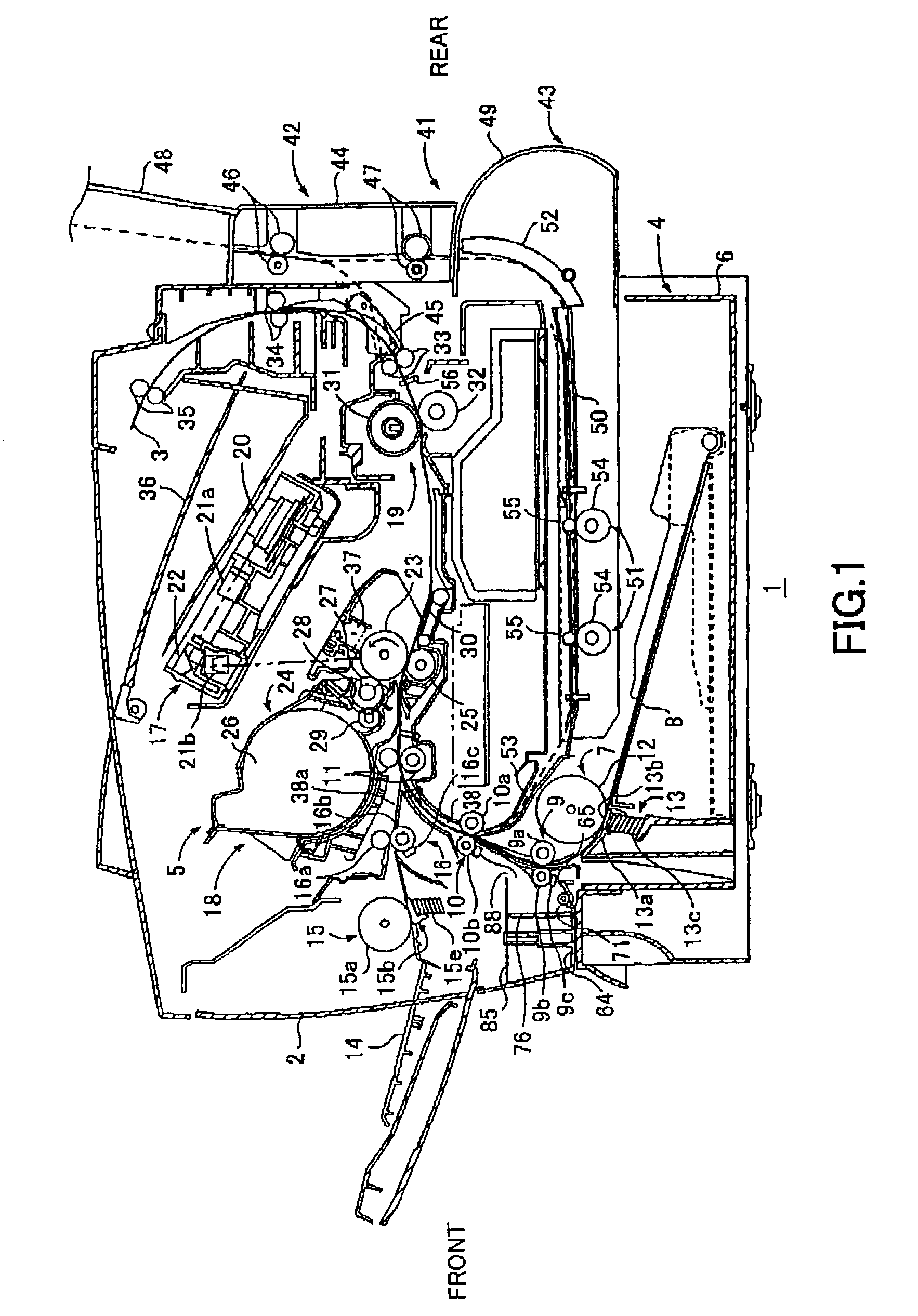

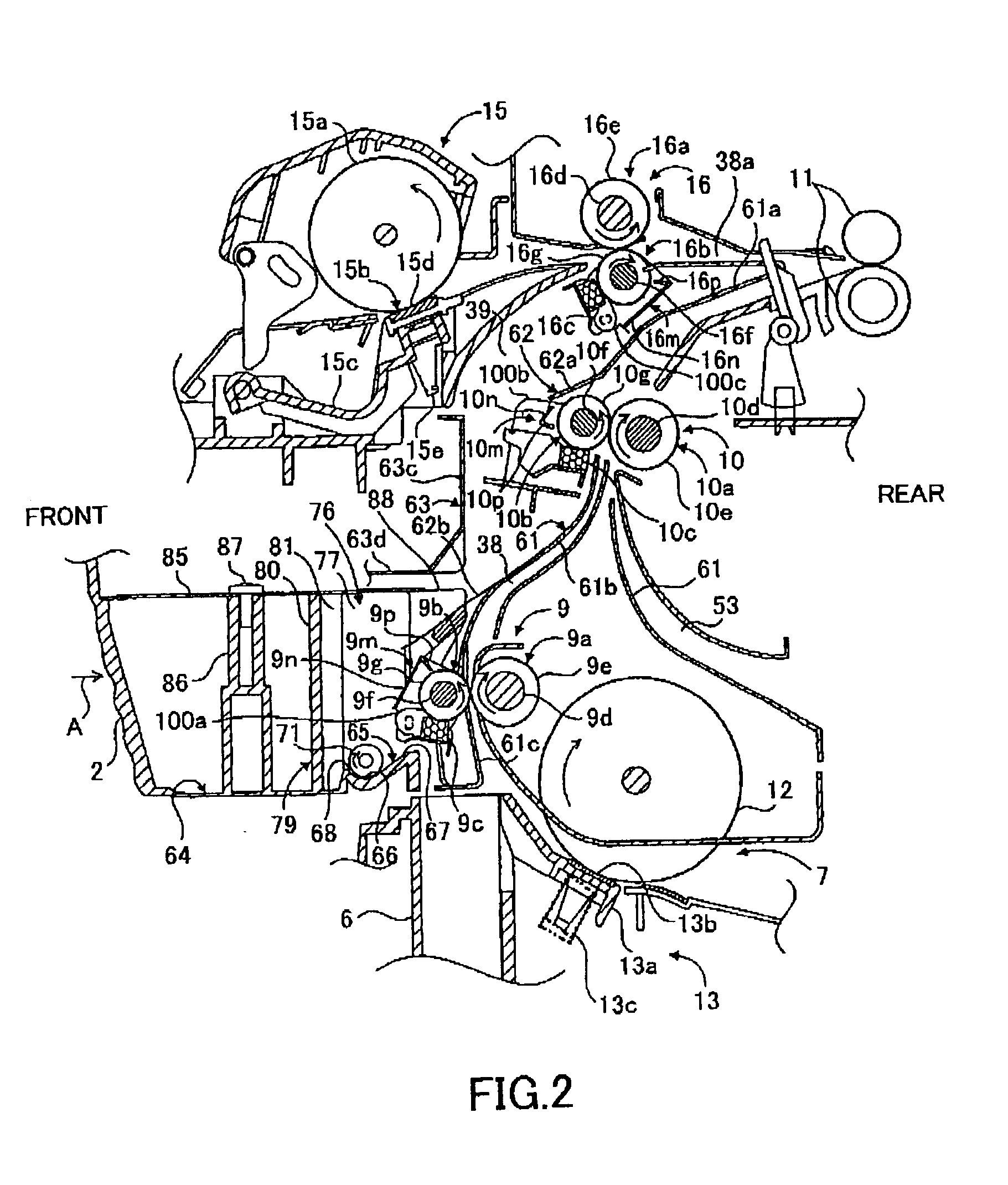

Image forming device having paper dust removing units

InactiveUS20030049043A1Efficient removalHigh quality imagingBrushesWork treatment devicesPaper dustImage formation

An image forming device capable of sufficiently removing paper dusts on a sheet thereby providing high quality image. A sheet transport path 38 is defined between a sheet supply section 7 provided with a separation pad 13 and a sheet supply roller 12 and an image forming section 5. Along the sheet supply section 7, at least a first paper dust removing roller 9b having a width slightly greater than the width of the separation pad 13 and a second paper dust removing roller 10b having a width slightly greater than the sheet width are disposed. Paper dusts generated upon friction against the separation pad 13 are removed by the first paper dust removing roller 9b, and paper dusts spreading over entire surface of the sheet are removed by the second paper dust removing roller 10b.

Owner:BROTHER KOGYO KK

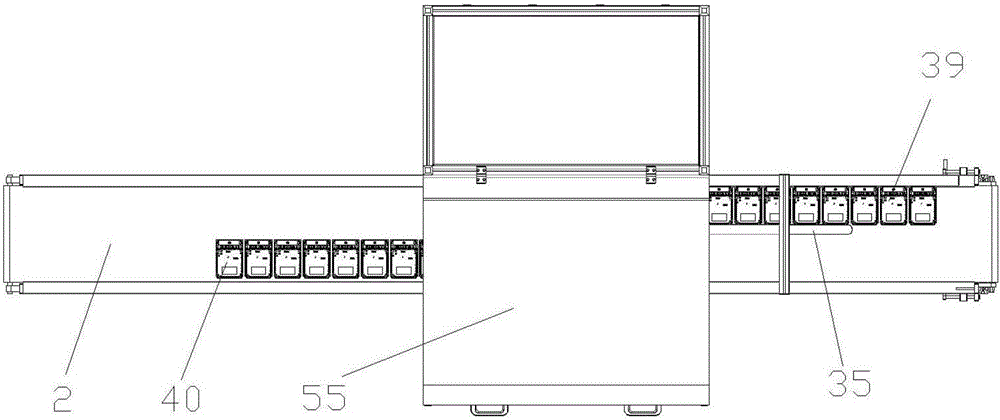

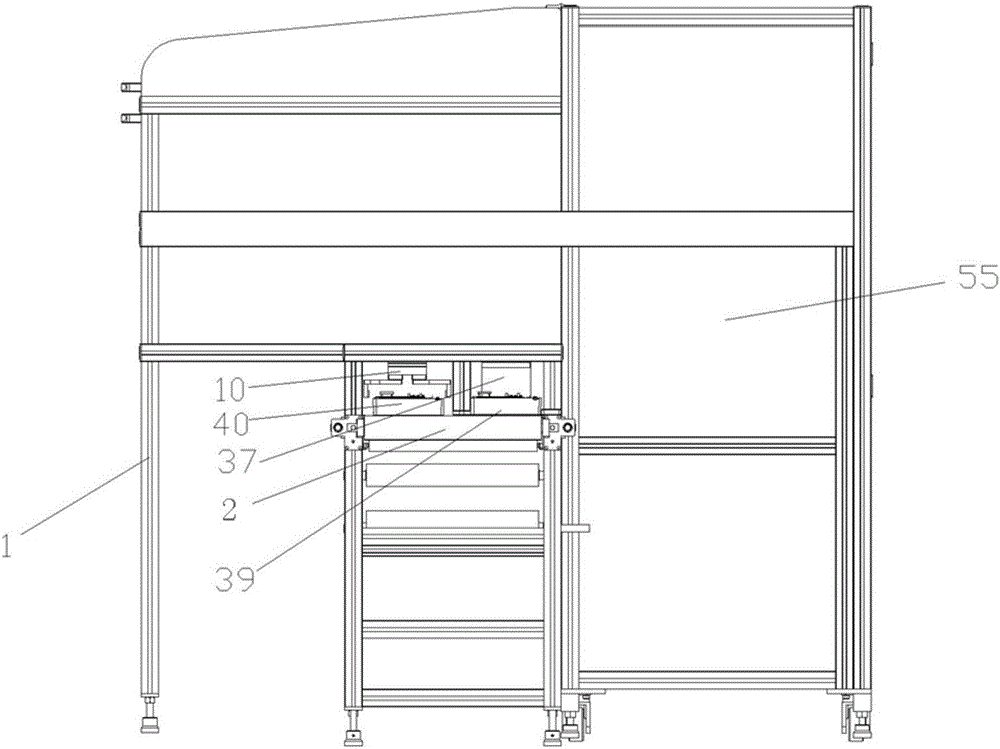

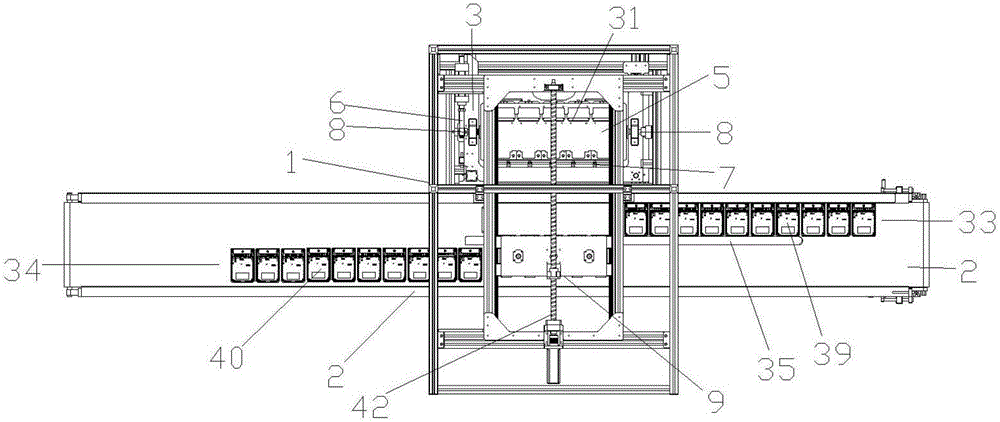

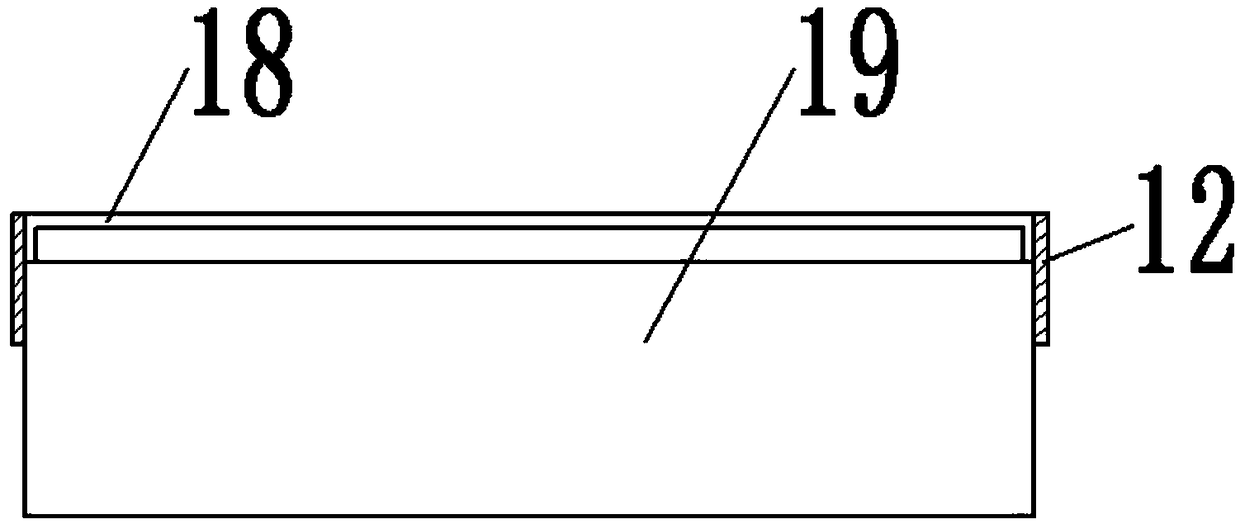

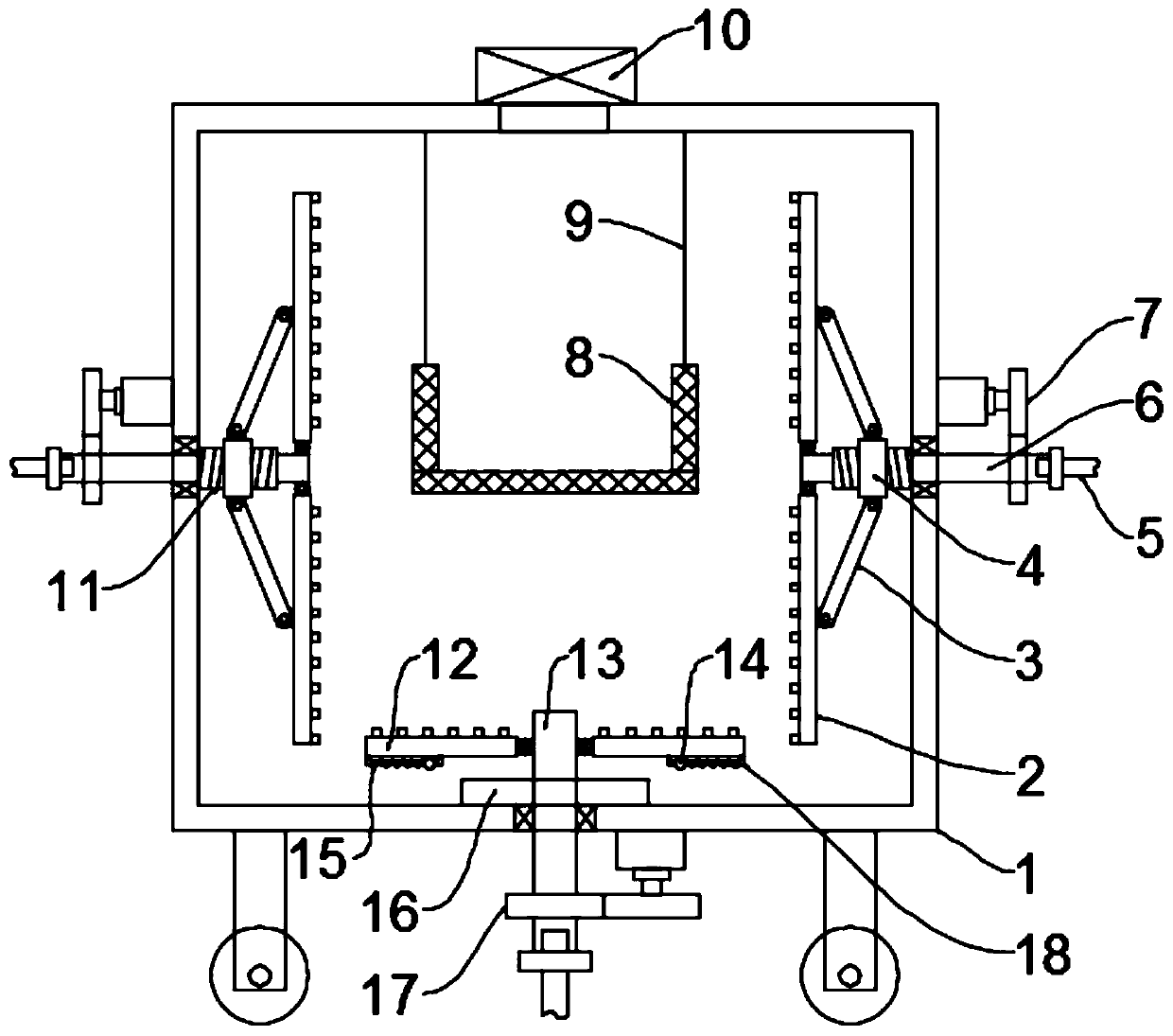

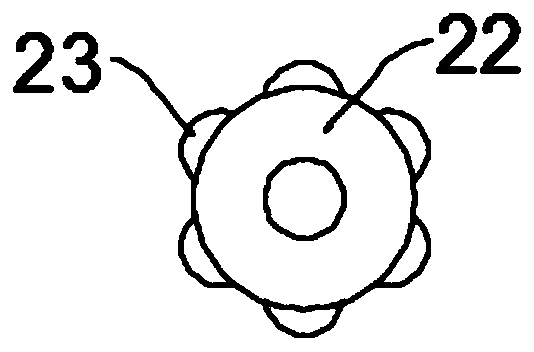

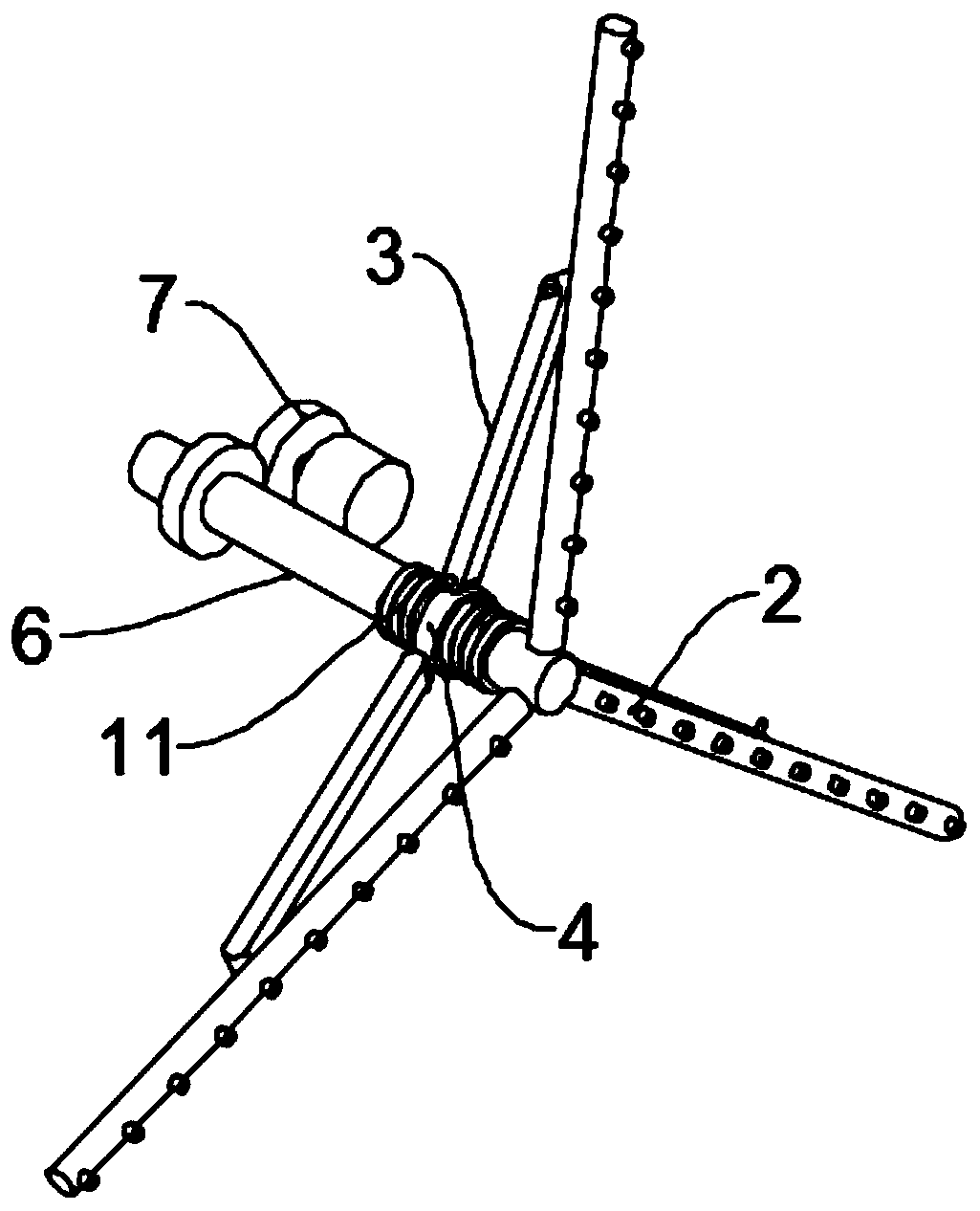

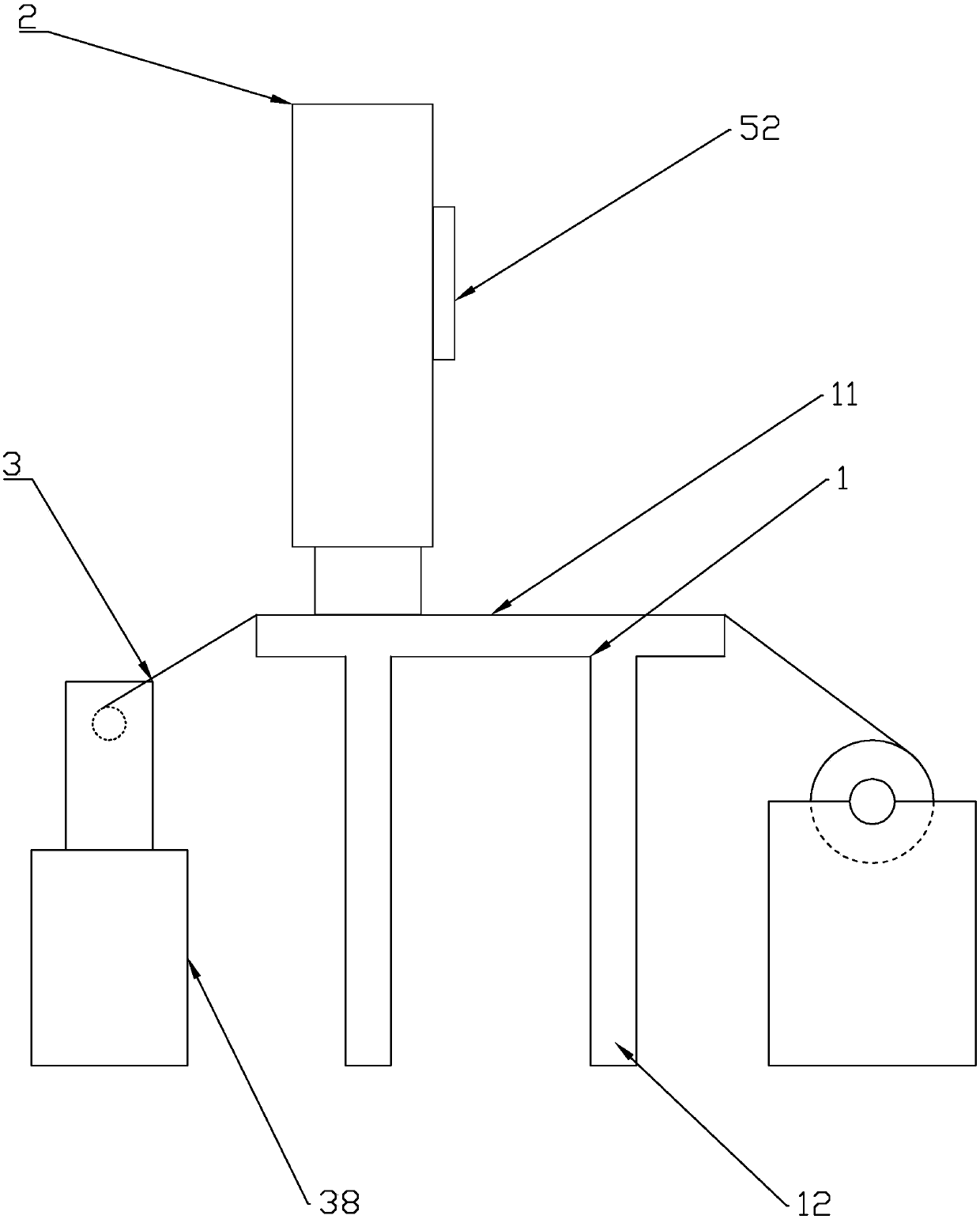

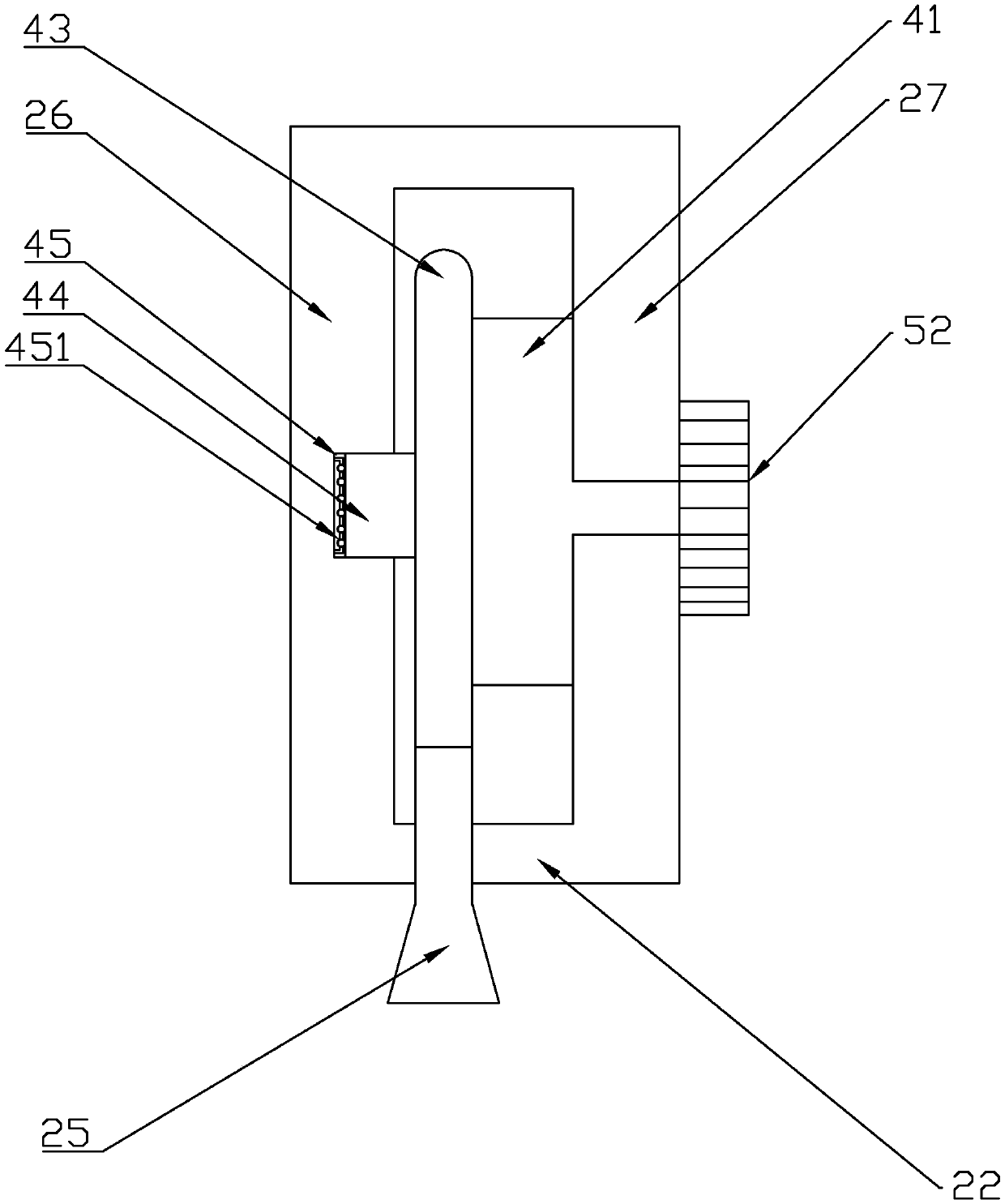

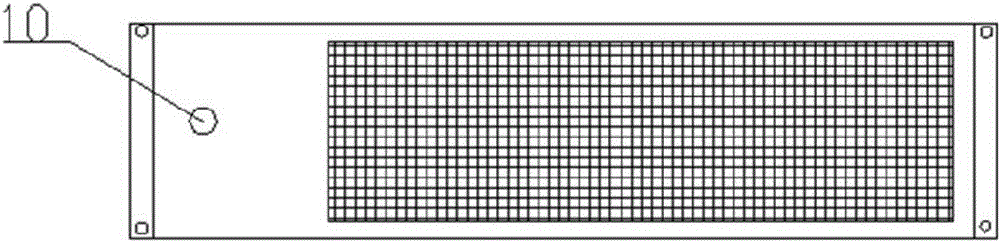

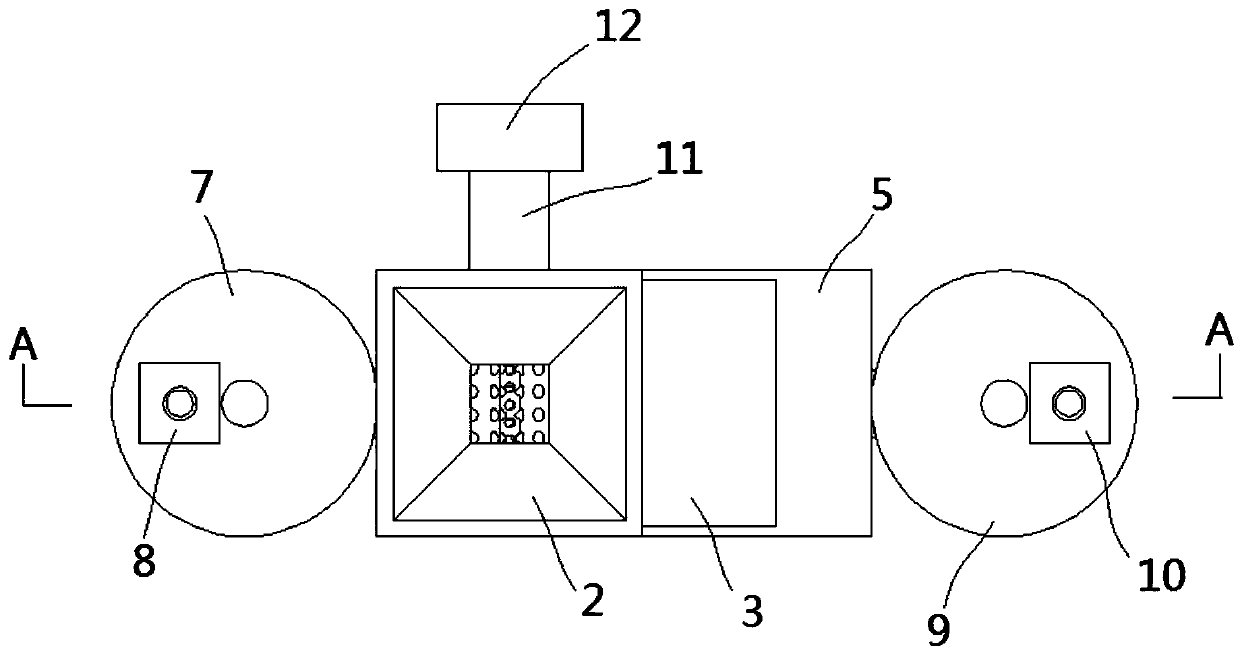

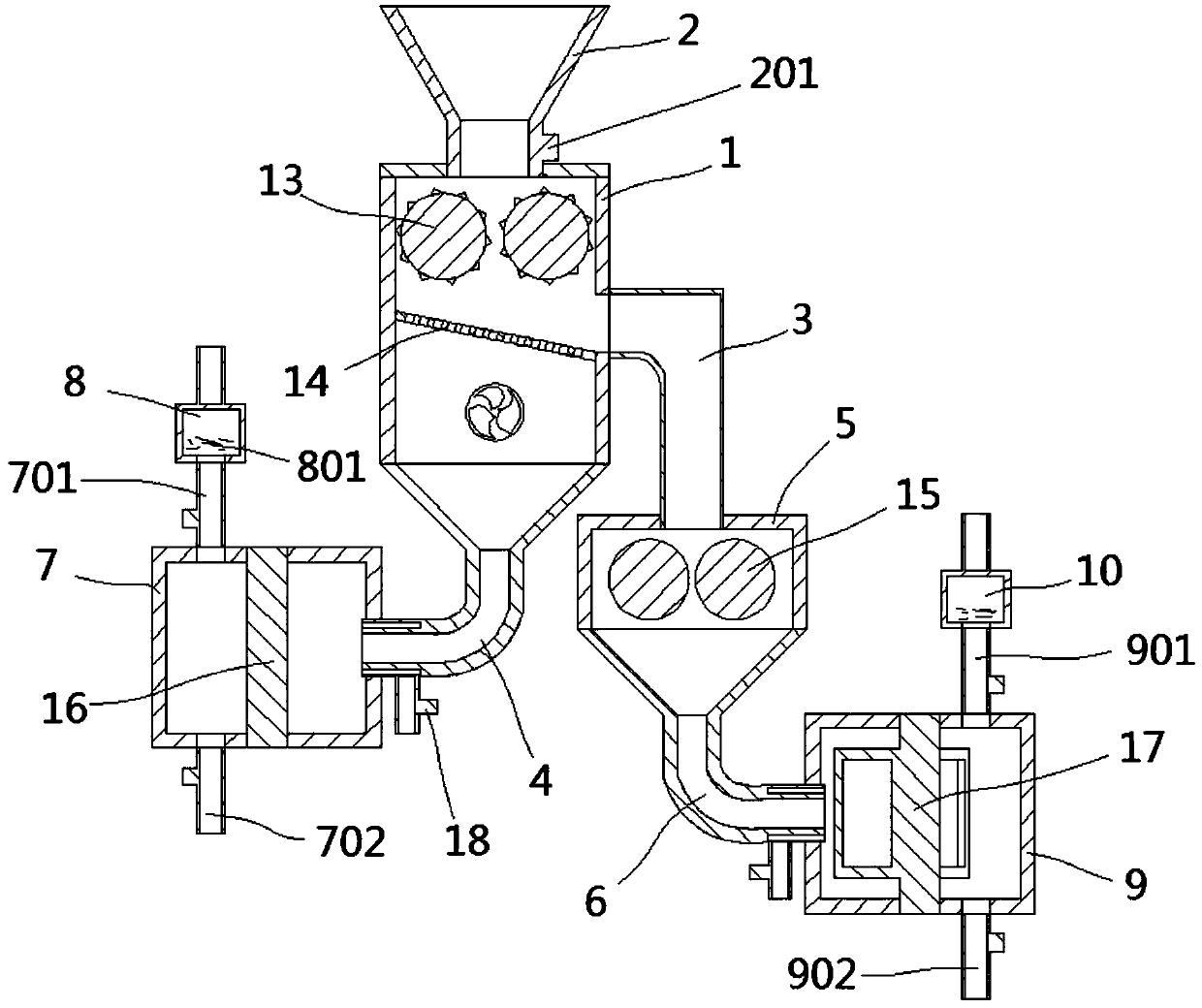

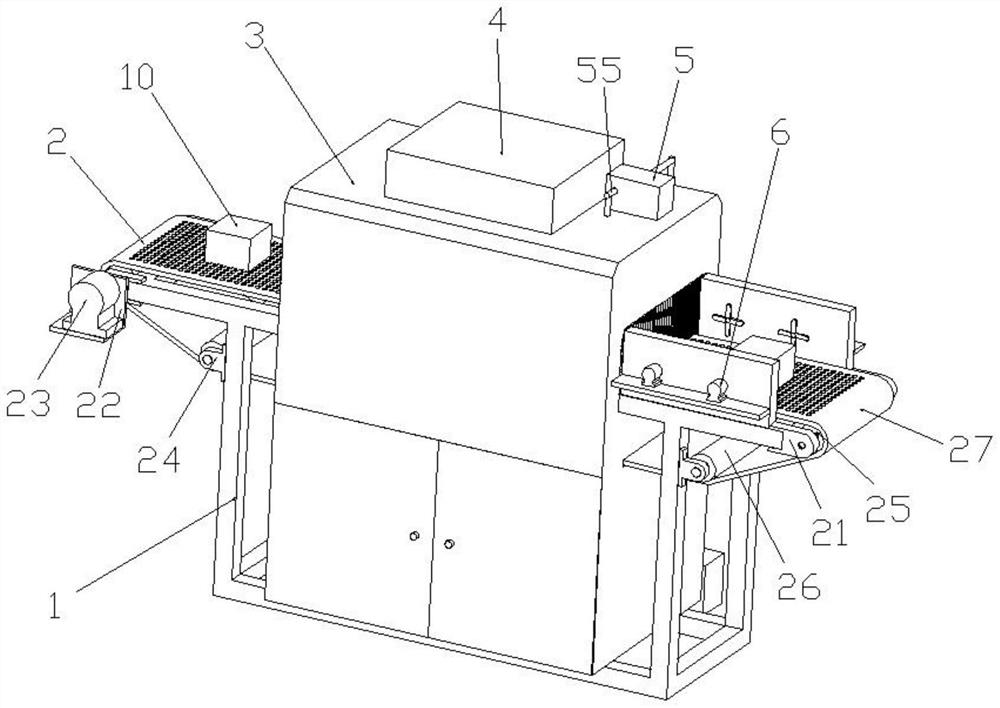

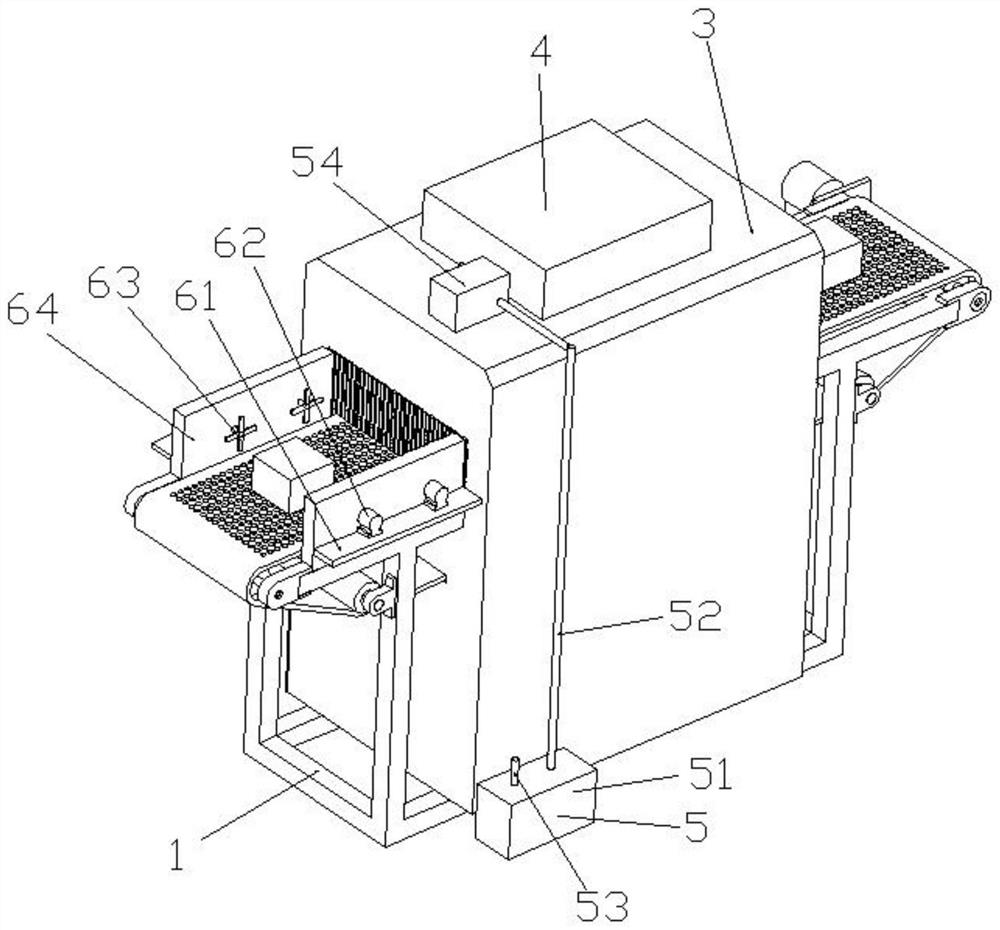

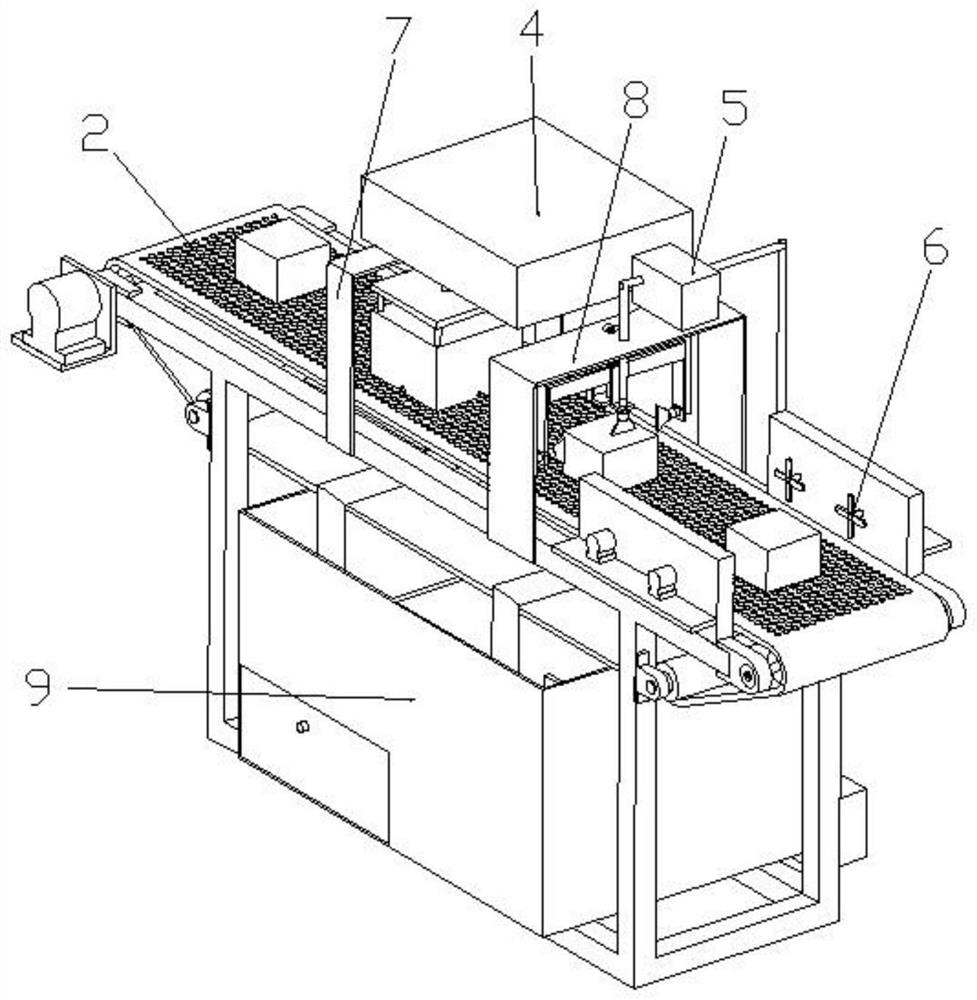

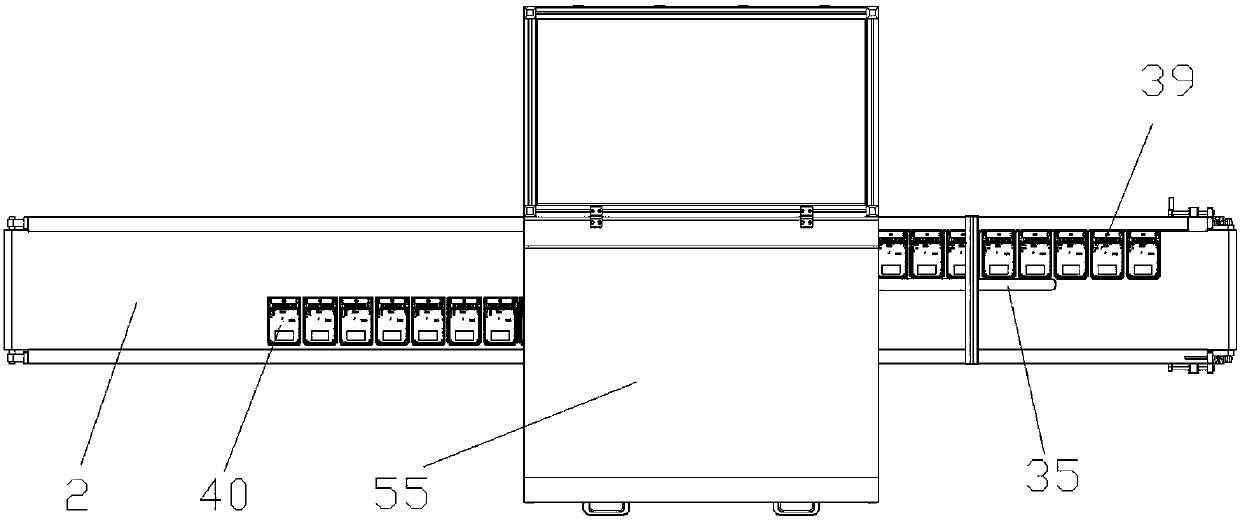

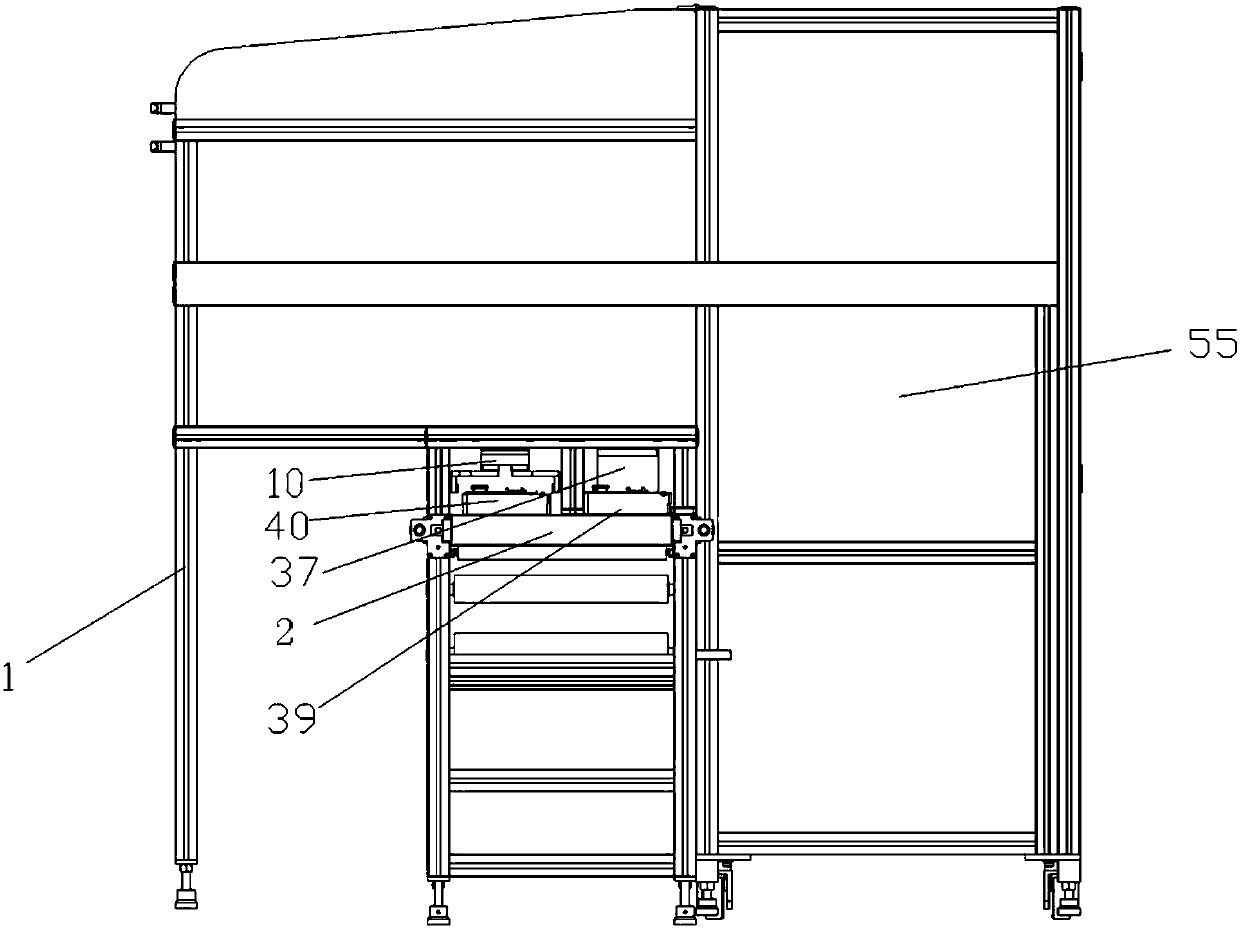

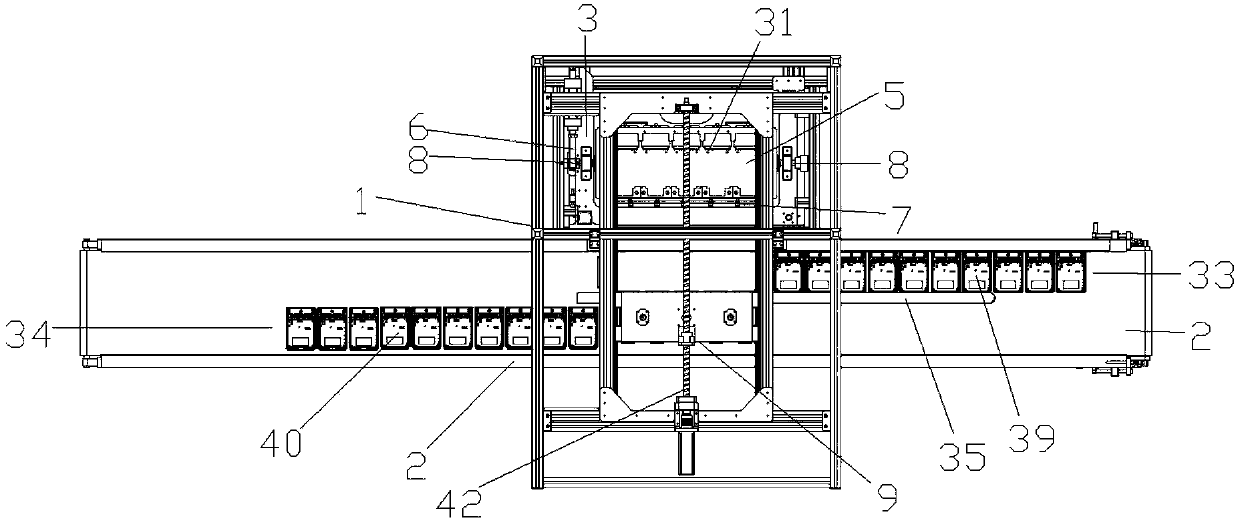

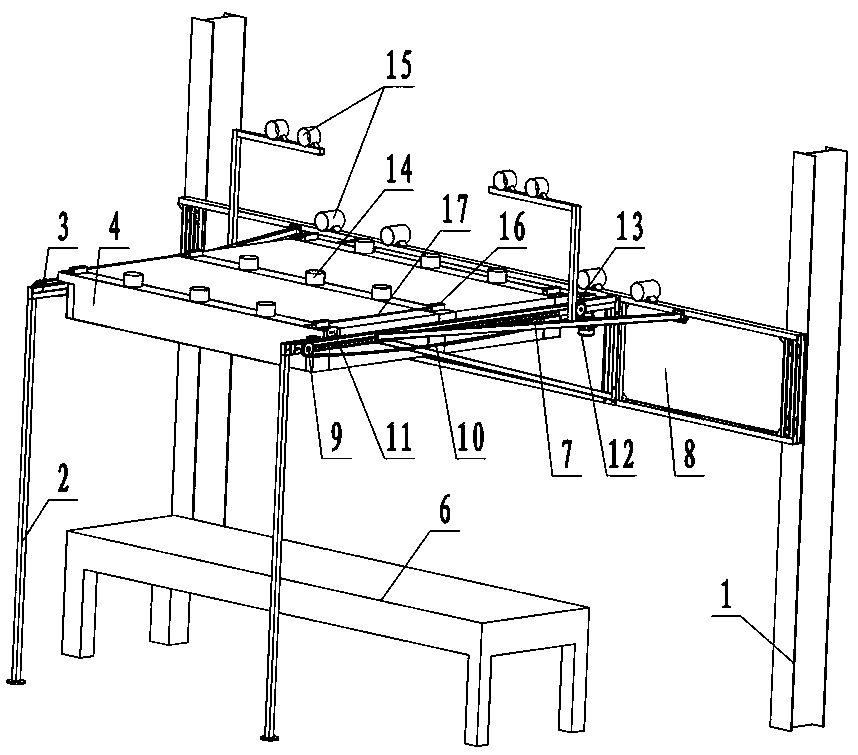

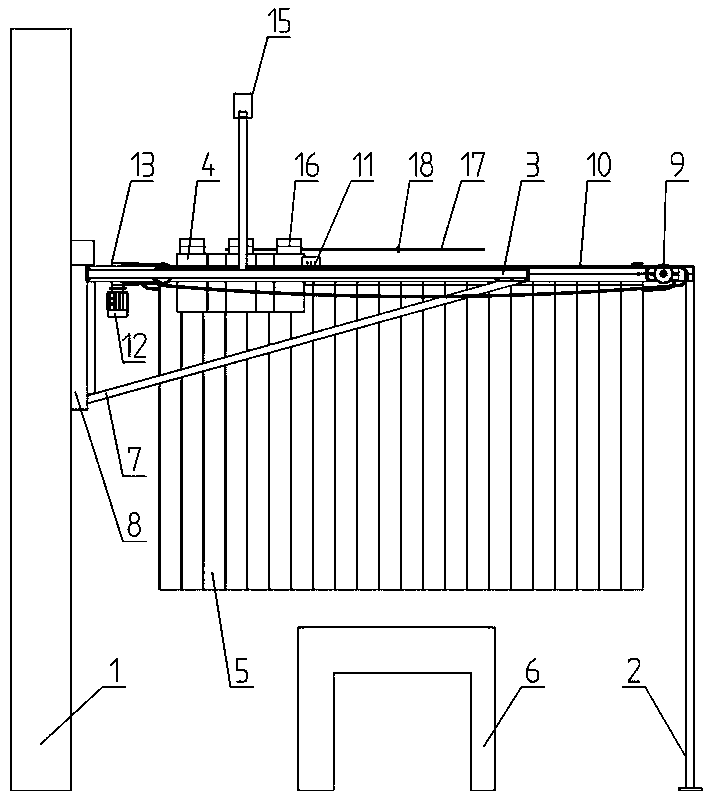

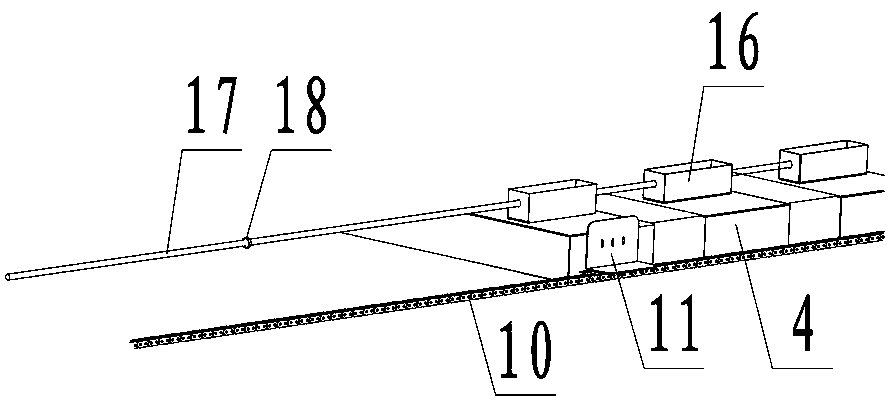

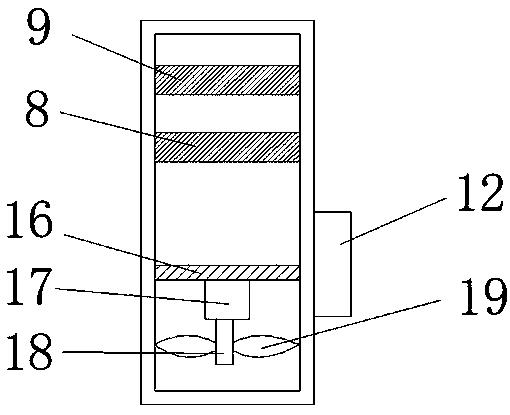

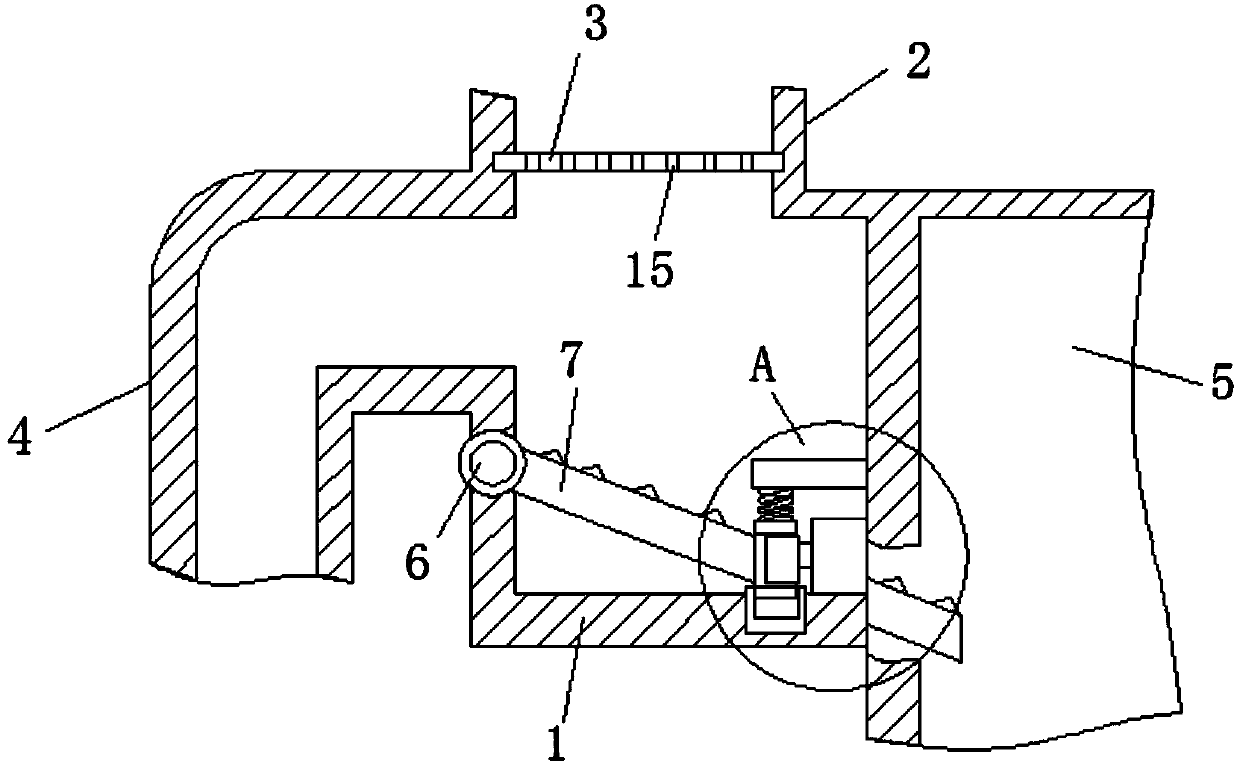

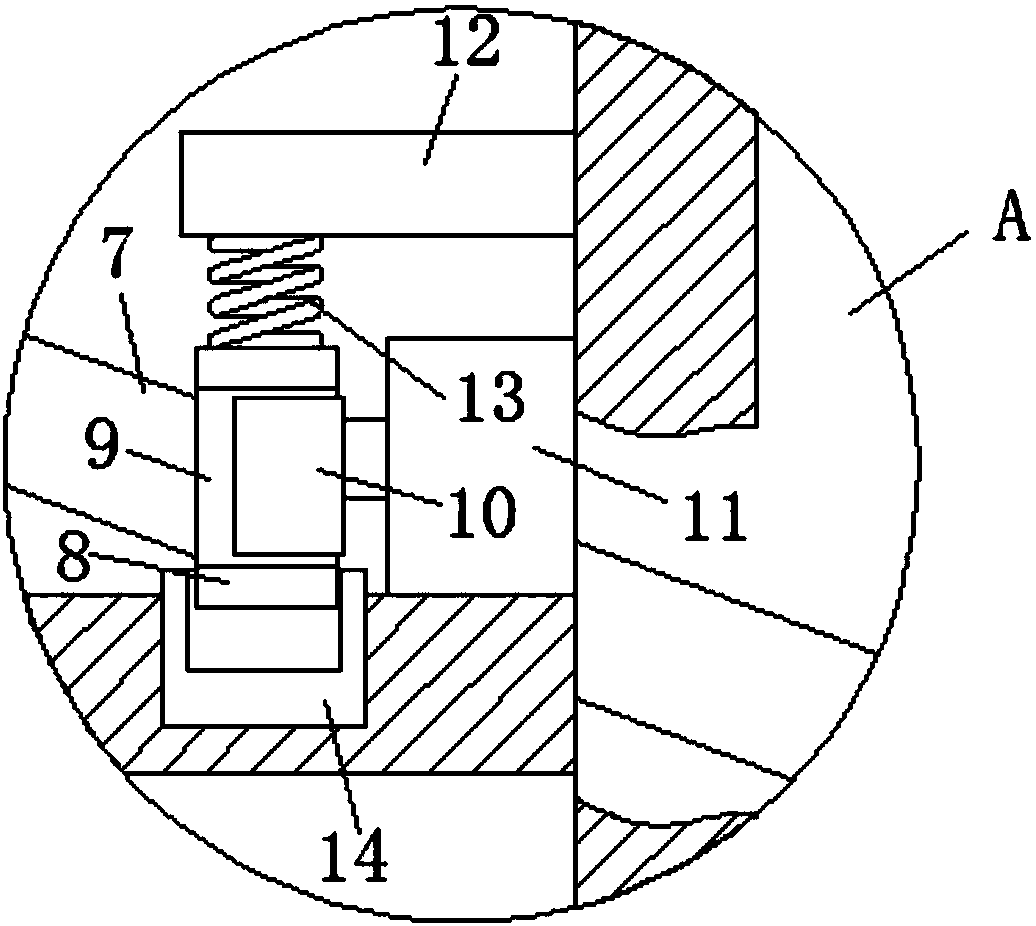

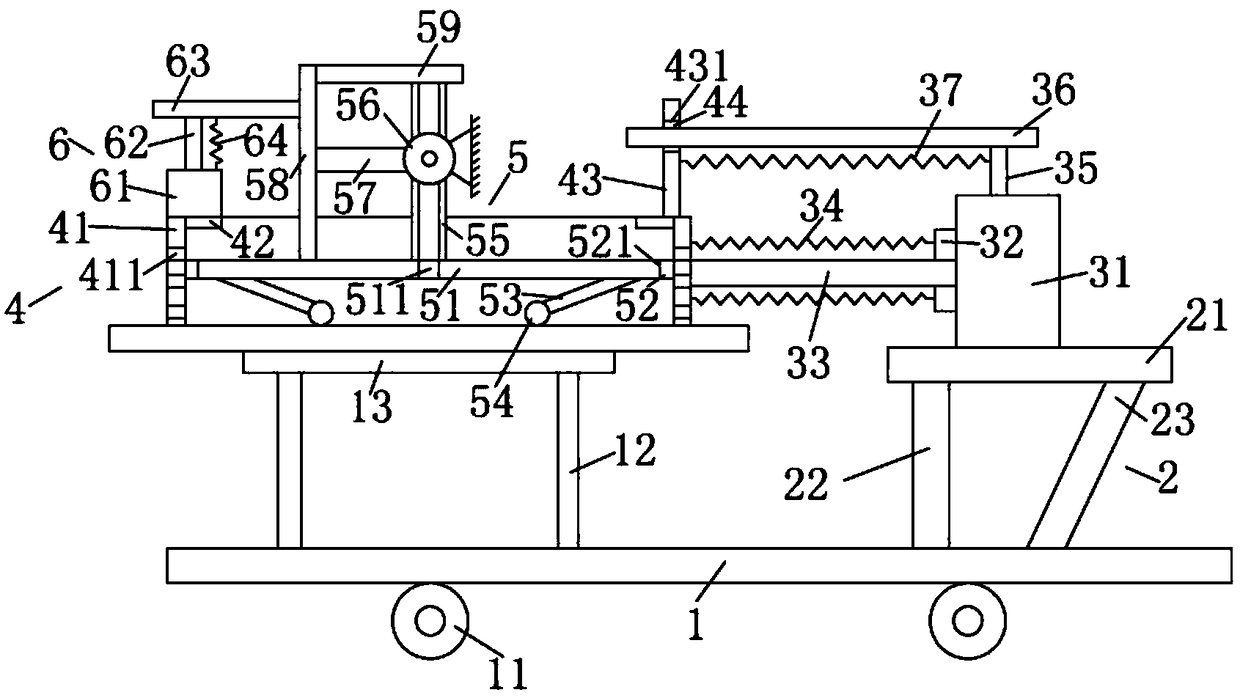

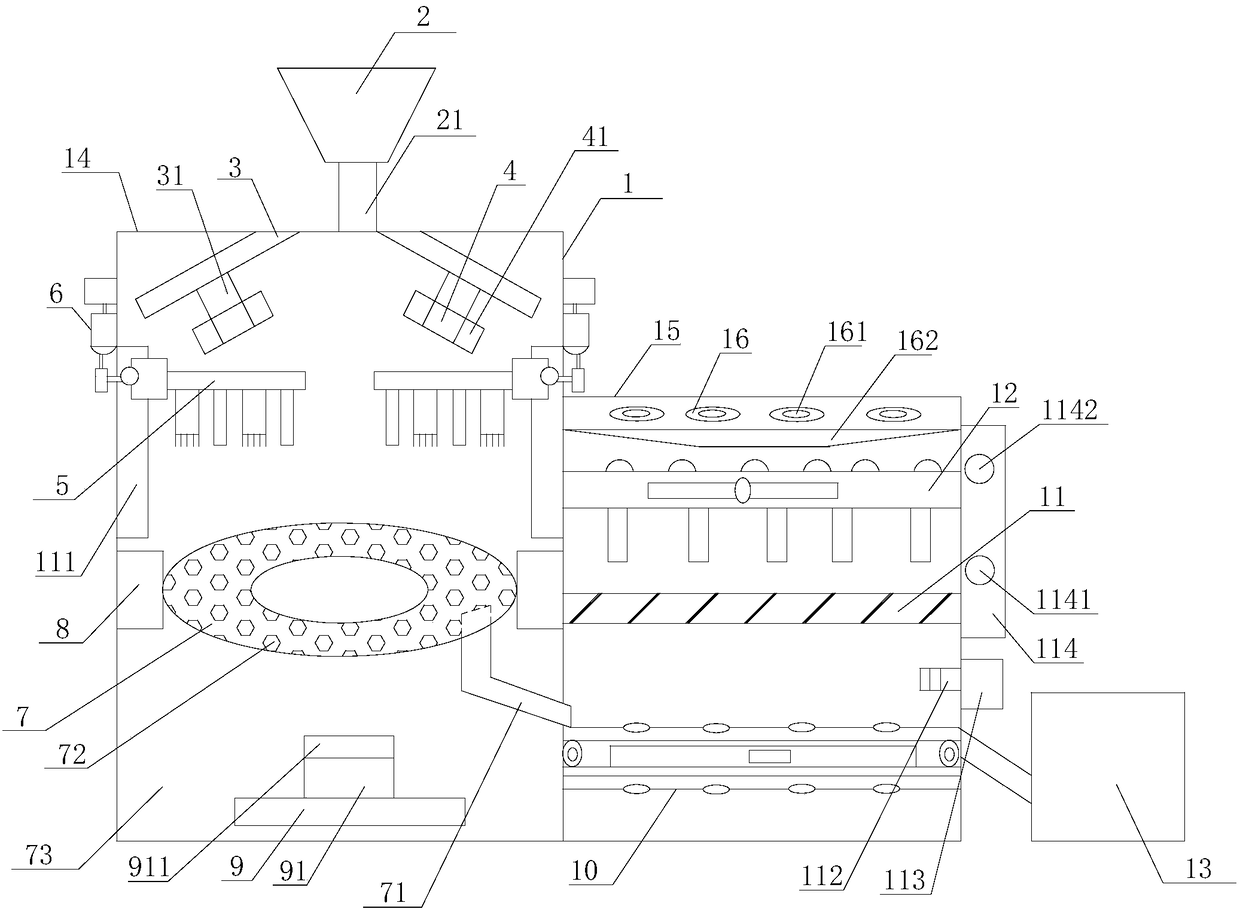

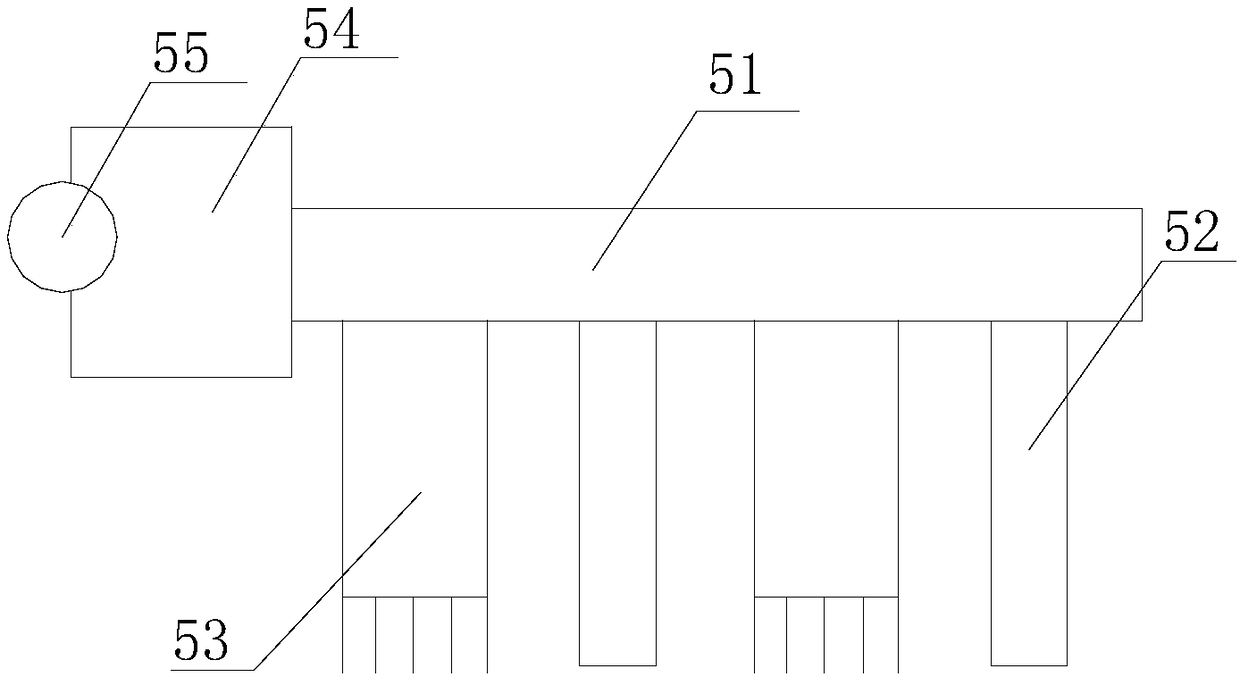

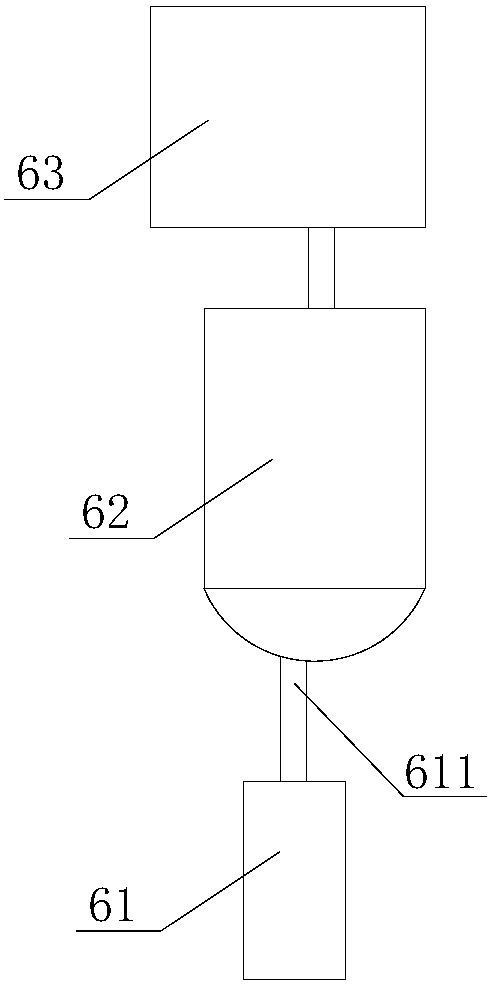

Automatic dust removal equipment for electric energy meters

The invention discloses automatic dust removal equipment for electric energy meters. The automatic dust removal equipment for the electric energy meters comprises a rack, a conveying device and a dust removal device. The automatic dust removal equipment is characterized in that the conveying device and the dust removal device are arranged on the front part and the rear part of the rack in parallel; the dust removal device comprises a location fixture used for fixing the plurality of electric energy meters, an air-blowing device and a turnover mechanism used for driving the location fixture to turn over up and down; and a transferring-loading mechanism is further arranged above the rack, and between the conveying device and the location fixture, and used for grabbing the electric energy meters to be subjected to dust removal on the conveying device and moving the electric energy meters onto the location fixture or grabbing the electric energy meters subjected to dust removal on the location fixture and moving the electric energy meters onto the conveying device. According to the automatic dust removal equipment for the electric energy meters, the conveying device and the dust removal device are mutually separated, so that dust in the electric energy meters can be adequately eliminated.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

SMT workshop dust monitoring system

InactiveCN105547939ADust fullyGuaranteed dust-free workCleaning using gasesParticle suspension analysisFixed positionEngineering

The invention discloses an SMT workshop dust monitoring system. The system comprises a controller, a display, dust concentration detection sensors, and a movable dust collecting facility, each dust concentration detection sensor is provided with a unique ID number; each station is provided with a dust concentration detection sensor, the ID number comprises the fixed position information of the station; each moving shelf is provided with a coordinate detecting module, which is used to obtain the coordinate information of the position where the moving shelf stays in real time, and the controller can control the dust collecting facility to move according to the ID number of the dust concentration detection sensor and corresponding coordinate information of position. The provided system can monitor the dust around stations in an SMT workshop, and is capable of monitoring dust around moving shelves. The monitoring is pertinent, the dusts can be fully eliminated, the dust-free environment can be achieved in an SMT workshop, and thus the yield of electronic products is improved.

Owner:WUXI TUONENG AUTOMATION TECH

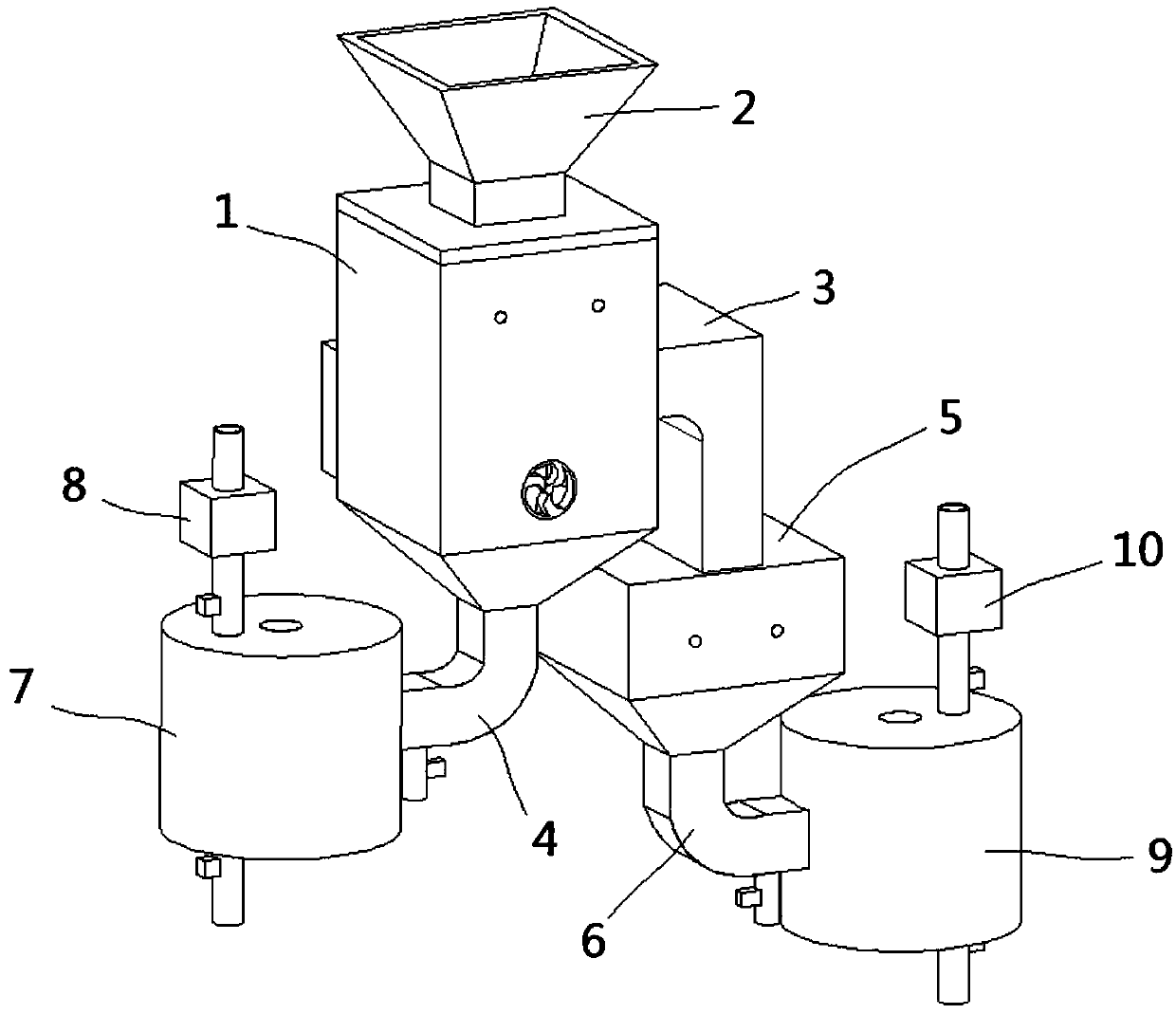

Efficient dust-removing equipment for raw materials before plastic product production

InactiveCN108890918AAdd at a constant speedEasy to remove dustGas current separationDust particlesRaw material

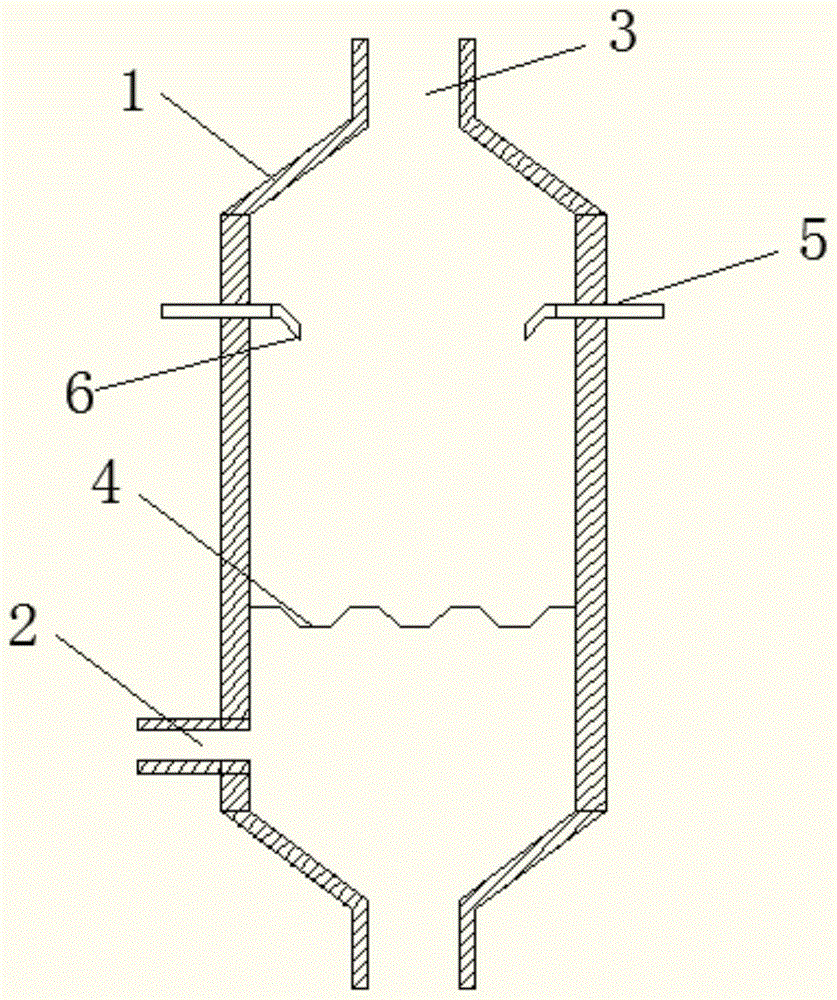

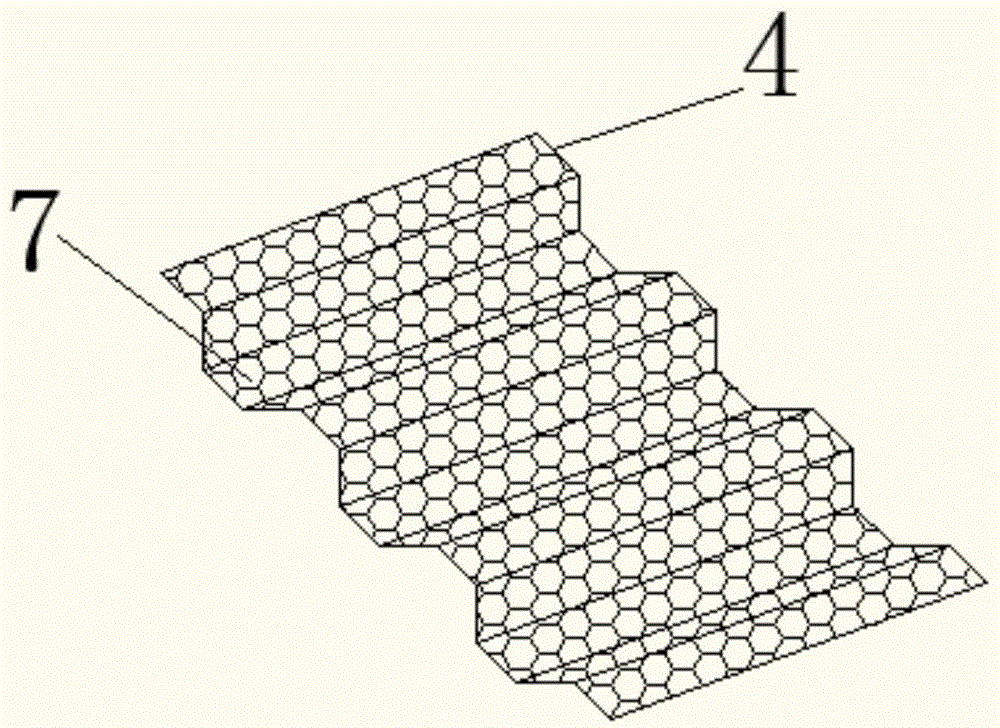

The invention relates to efficient dust-removing equipment for raw materials before plastic product production. The equipment comprises a tank, wherein the tank is a hollow cylinder having two ends which are communicated with each other, and is soldered by a steel plate; a top cover is arranged at the top opening of the tank, and a bottom cover is arranged at the bottom opening of the tank; a feeding device is arranged on the outer wall of the tank; a dust removing device is arranged inside the tank; a suction filter device is arranged on the outer wall of the tank symmetric to the feeding device. According to the equipment, the raw materials are added at a uniform speed by virtue of the feeding device, dust removal can be sufficiently performed on the raw materials, and occurrence of incomplete dust removal caused by over addition of the raw materials can be avoided; dust can be separated from the raw materials by virtue of the dust removing device, and efficient dust removal can be facilitated; blowing air can be added by utilizing a heater, the wet raw materials can be dried by utilizing hot air after the raw materials are washed; and an air flow is formed inside the tank by virtue of the suction filter device, dust particles among the raw materials can be carried away by utilizing the air flow, and the cleanliness of the raw materials can be improved.

Owner:HEFEI JINGMEI GRAPHIC TECH CO LTD

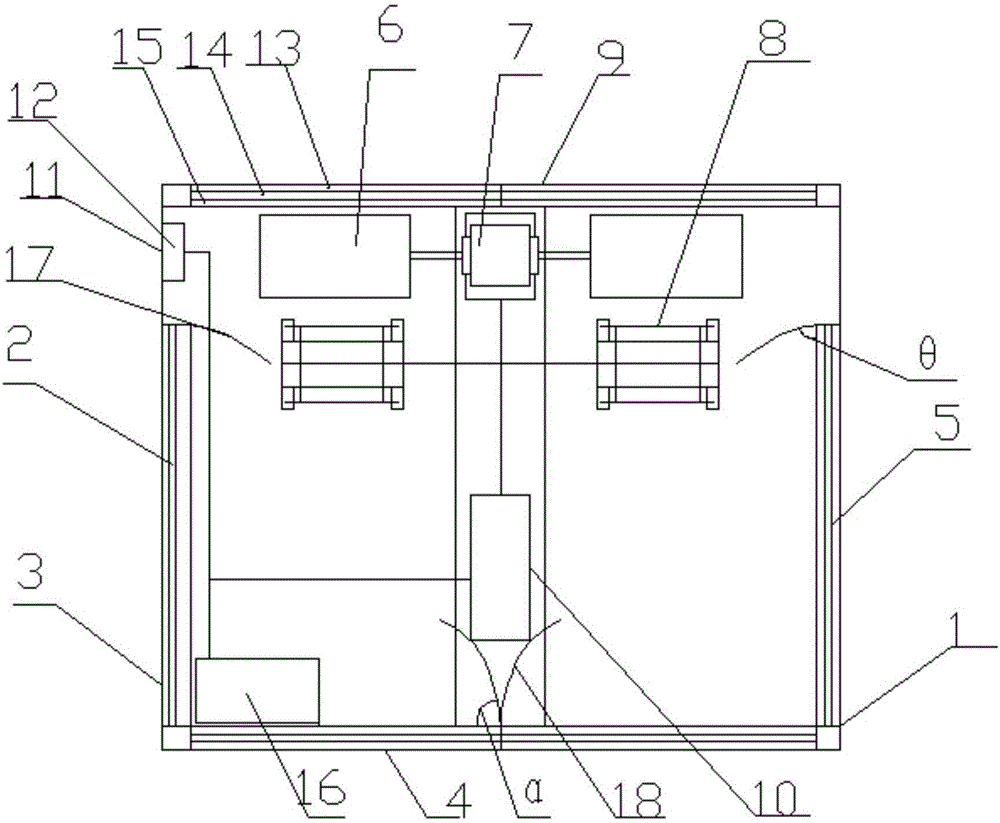

Dust removing system for dust-free workshop

InactiveCN105032843AGuaranteed air purificationDust fullyCleaning using gasesAir purificationElectrical and Electronics engineering

The invention discloses a dust removing system for a dust-free workshop. The dust removing system comprises air showers. Each air shower comprises a top plate, a bottom plate, a left side plate, a right side plate, a front side plate, a rear side plate, face recognition equipment or fingerprint recognition equipment, an infrared sensor and a dust sensor. The face recognition equipment or the fingerprint recognition equipment is used for conducting face recognition or fingerprint recognition on personnel to enter, the infrared sensors detect the personnel information in the air showers, and the dust sensors detect the air cleanliness information in the air showers. The number of the air showers which are sequentially arranged is two, and the same door body and the same external controller are shared between the two air showers. The personnel who enter the dust-free workshop can achieve sufficient dust removing, and therefore the air cleanliness of the dust-free workshop is guaranteed.

Owner:SUZHOU XUANHE IOT TECH

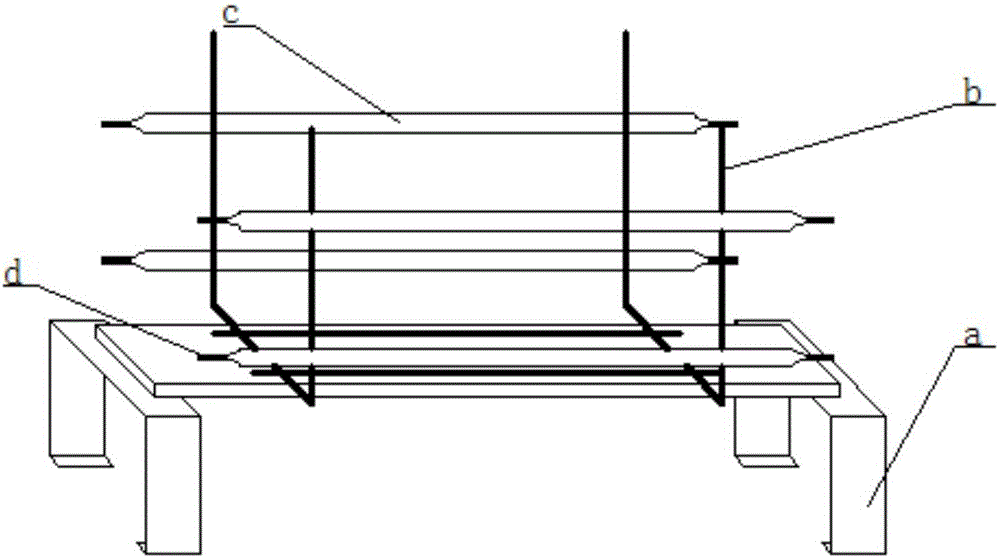

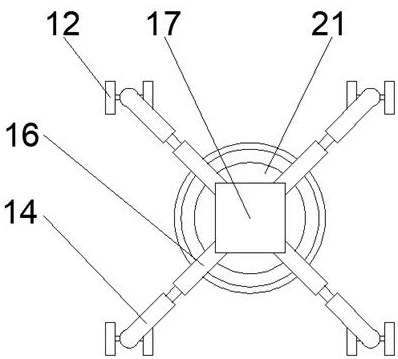

Multi-direction dust removal equipment for instruments and apparatuses

InactiveCN111420932AImprove directionImprove dust removal efficiencyCleaning using gasesDust controlEngineering

The invention discloses multi-direction dust removal equipment for instruments and apparatuses, which relates to the technical field of instruments and apparatuses, and mainly aims to solve the problems that existing dust removal equipment for the instruments and the apparatuses is single in dust-removal direction and is low in dust-removal efficiency. The multi-direction dust removal equipment comprises a box body and a dust removal unit, wherein a screen frame for placing the instruments and the apparatuses is arranged in the box body; the dust removal unit comprises a side dust removal assembly and a lower dust removal assembly; the side dust removal assembly comprises a first hollow rotary shaft, a first drive mechanism for driving the first hollow rotary shaft to alternatively rotatepositively and negatively, an outer threaded sleeve, an inner threaded sleeve, a connecting rod and a first hard gas tube; the lower dust removal assembly comprises a second hollow rotary shaft, a second drive mechanism for driving the second hollow rotary shaft to rotate, a second hard gas tube, a movable magnet, a compression spring and a drive part for driving the movable magnet to move; the top of the second hollow rotary shaft is horizontally provided with a first threaded rod through threads in a penetrating mode; and one end of the first threaded rod is in threaded connection to a second threaded rod. The dust removal unit is arranged, so that dust-removal cyclone range and direction is expanded, and dust removal efficiency is improved.

Owner:南京奥亚美电子科技有限公司

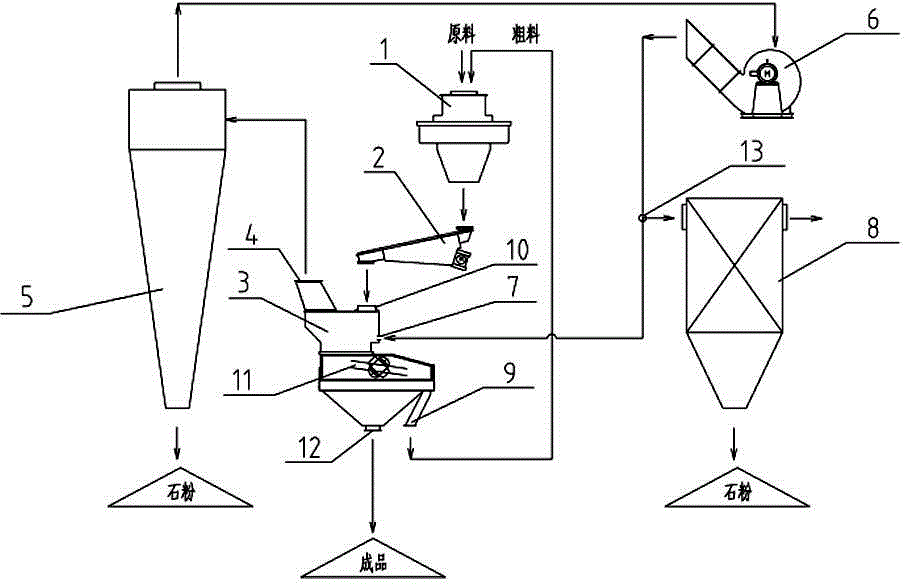

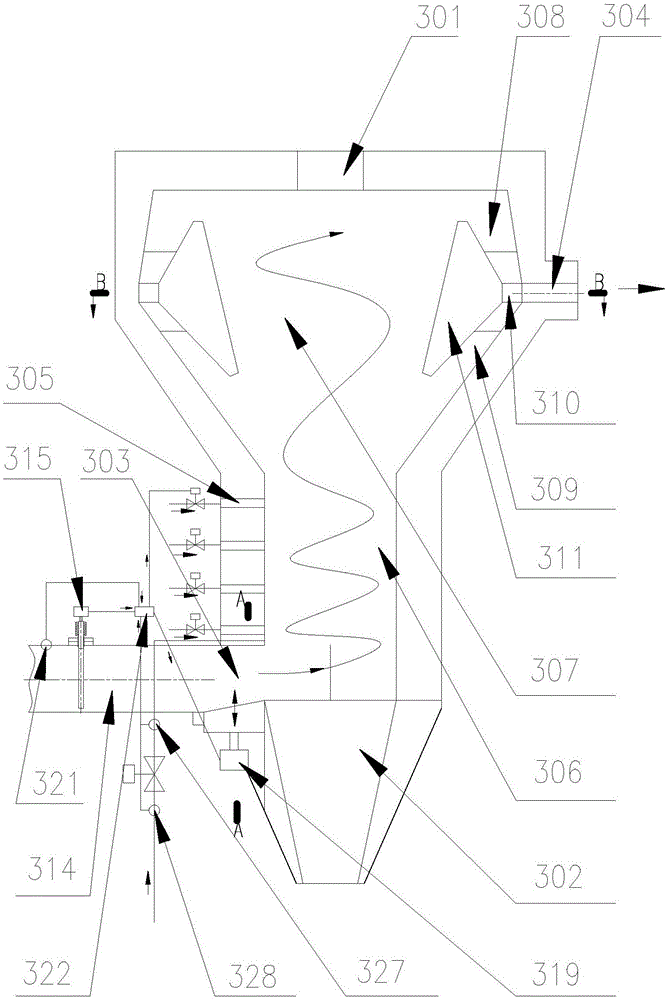

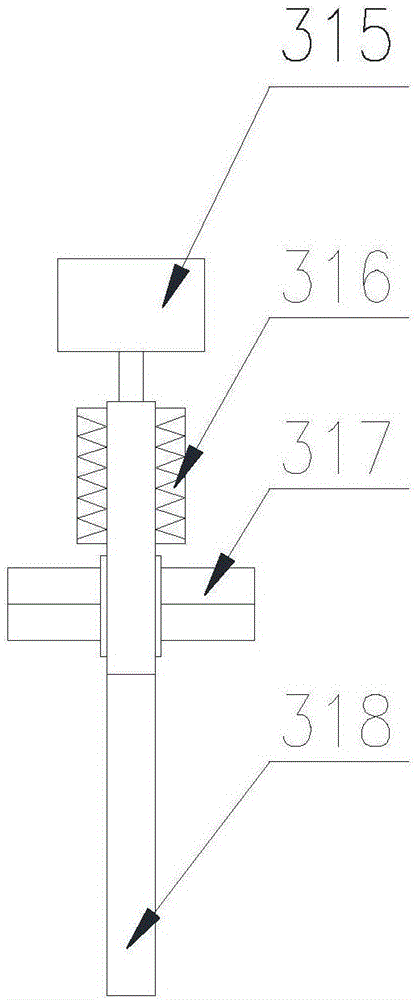

Dry machine-made sand production system

InactiveCN104876463AReduce configuration costsReduce configuration requirementsCrusherEnergy consumption

The invention discloses a dry machine-made sand production system, which comprises a crusher, a vibrating feeding mechanism and a winnowing screening device, which are sequentially connected with one another, wherein a dust outlet of the winnowing screening device is connected with an inlet of primary dust-removing equipment; an air outlet of the dust-removing equipment is connected with the inlet of a draught fan; an outlet of the draught fan is respectively connected with an air inlet of the winnowing screening device and the inlet of secondary dust-removing equipment; a crude product outlet of the winnowing screening device is connected with the inlet of the crusher; a dust outlet and a feeding opening are formed in the upper part of the winnowing screening device; a lateral air inlet is formed below the feeding opening; a sieve is arranged in the middle of the winnowing screening device; a finished product outlet below the sieve and a crude product outlet below the outlet at the lower end of the sieve are formed in the lower part of the winnowing screening device; and the feeding opening is connected with a discharge opening of the vibrating feeding mechanism. According to the dry machine-made sand production system, the energy consumption of the system is effectively reduced; and the equipment investment cost and the late maintenance cost are greatly reduced.

Owner:HENAN LIMING HEAVY IND SCI & TECH

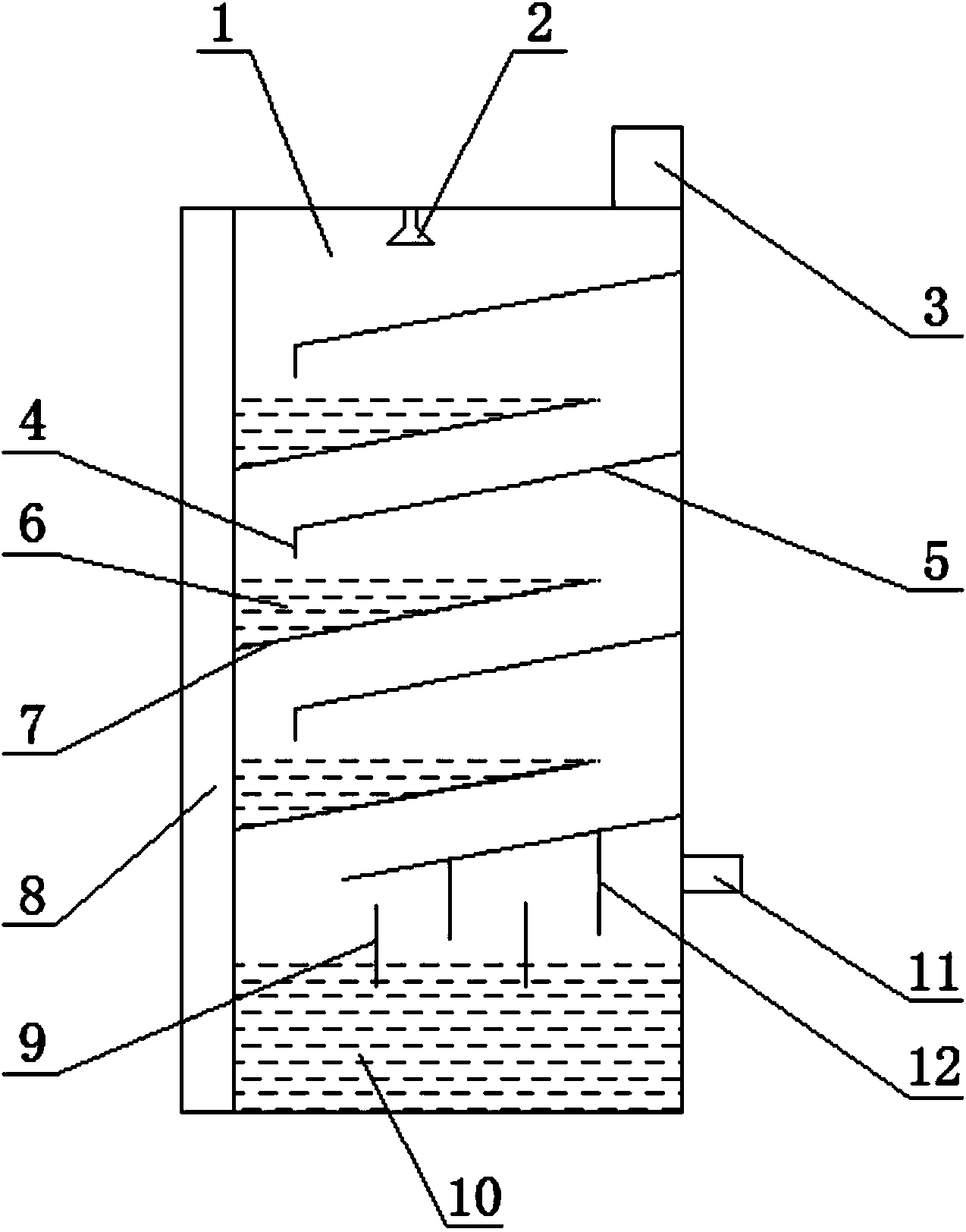

Water film desulfurization deduster

InactiveCN104107610AIncrease the number and magnitude of impactsDust fullyUsing liquid separation agentEngineeringFlue gas

The invention discloses a water film desulfurization deduster. The water film desulfurization deduster comprises a tower body, a plurality of gas guide baffles, water storage baffles and a drainage pipe, wherein the lower end of an inner cavity of the tower body is provided with a water storage groove; the water storage groove is provided with a water level adjusting chamber; the upper end of the inner cavity of the tower body is provided with a spraying pipe; the bottom of the tower body is provided with a gas inlet; the top of the tower body is provided with a gas outlet; the tower body is internally provided with the plurality of oblique gas guide baffles which are sequentially arranged from top to bottom and in parallel, and the lower end of each gas guide baffle is suspended; each water storage baffle is arranged between two adjacent gas guide baffles, and is parallel to the gas guide baffles, the higher end of each water storage baffle is suspended, and each water storage baffle and the inner wall of the tower body form a water storage cavity; the drainage pipe is provided with liquid discharge valves which are in one-to-one correspondence with the water storage cavities. According to the invention, the impact frequency of flue gas and a water body can be increased to improve the dedusting effect.

Owner:GUANGXI NANNING ZHONGJIA ENVIRONMENTAL PROTECTIONVALVE MFG

Dust removal device for spinning equipment

ActiveCN109576969ADust fullyHigh degree of automationMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention discloses a dust removal device for spinning equipment. The device comprises a workbench, a dust removal mechanism and a rolling mechanism. The workbench comprises a working tabletop anda support; the dust removal mechanism comprises a shell, a cavity is formed inside the shell, the shell comprises a first base plate, a first vertical rod connected to the first base plate and the working tabletop is arranged on the first base plate, an opening is formed inside the first base plate, a dust remover is movably arranged inside the cavity, a reciprocating mechanism is arranged insidethe cavity, the reciprocating mechanism comprises a rotating disc, the shell comprises a first side plate and a second side plate arranged at the two sides of the length direction of the first base plate, the rotating disc is movably arranged on the second side plate, a protrusion is arranged on the side, back onto the second side plate, of the rotating disc, a movable frame for embedding of theprotrusion is arranged on the dust remover, a sliding plate is arranged at the face, towards the first side plate, of the movable frame, a sliding groove is formed in the face, towards the cavity of the first side plate, and an intermittent mechanism is arranged on the second side plate. Due to reciprocating motion of the dust remover, sufficient dust removal is performed on a spinning fabric.

Owner:WENZHOU POLYTECHNIC

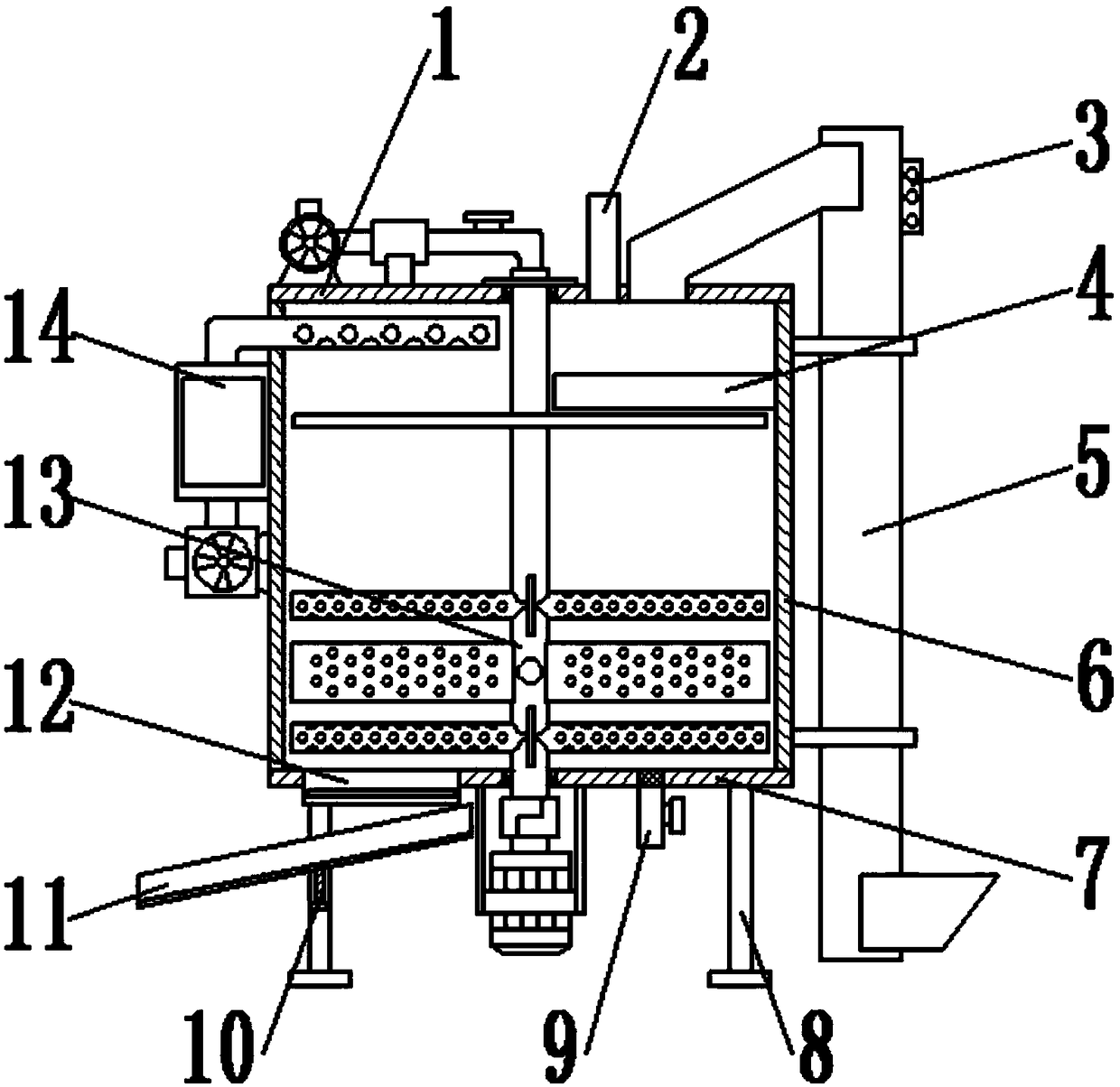

Grain drying and dedusting device and method

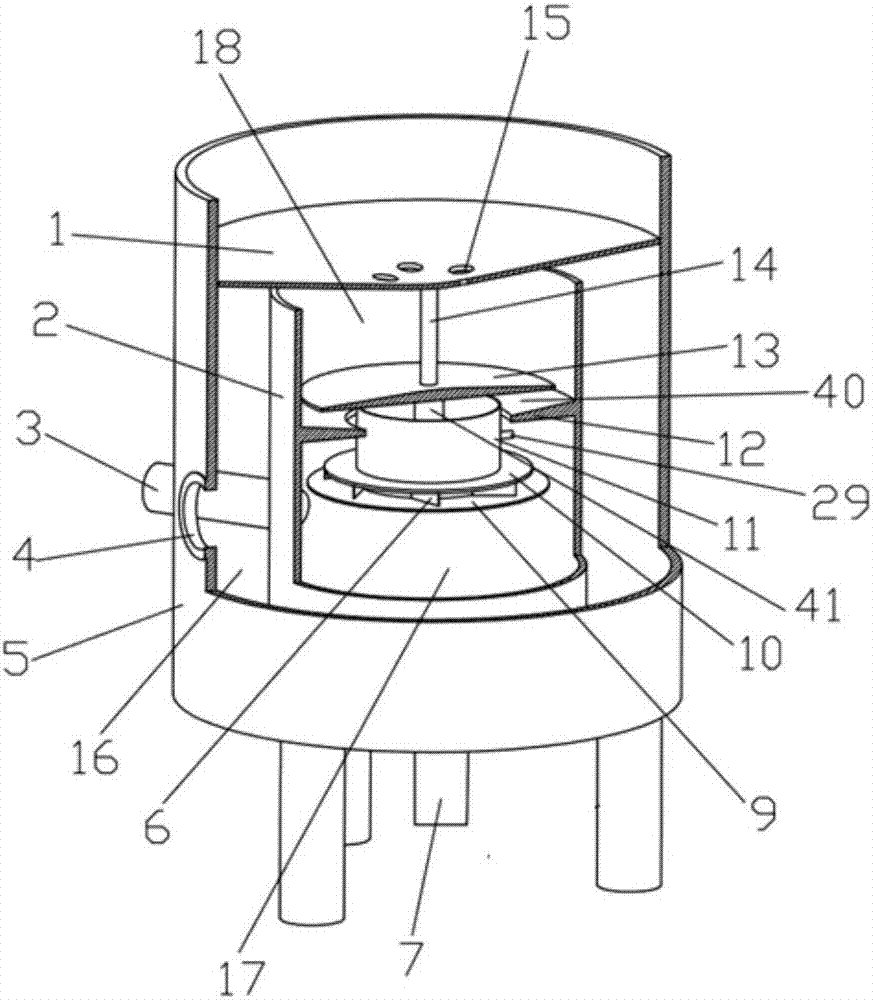

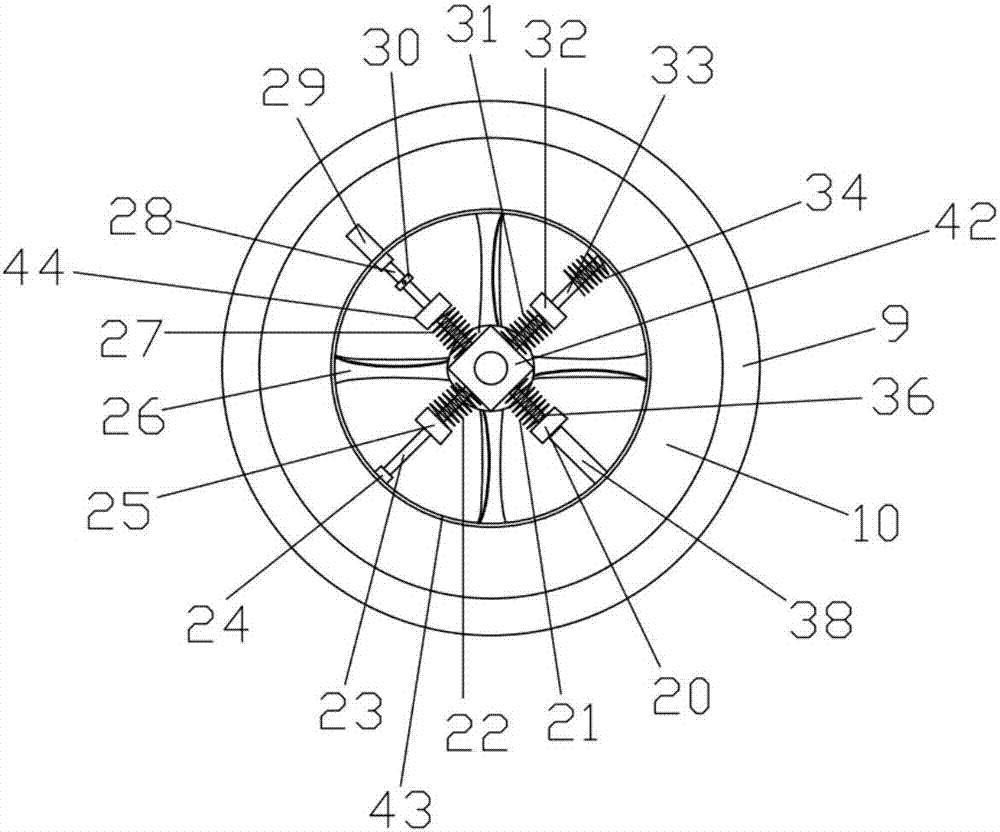

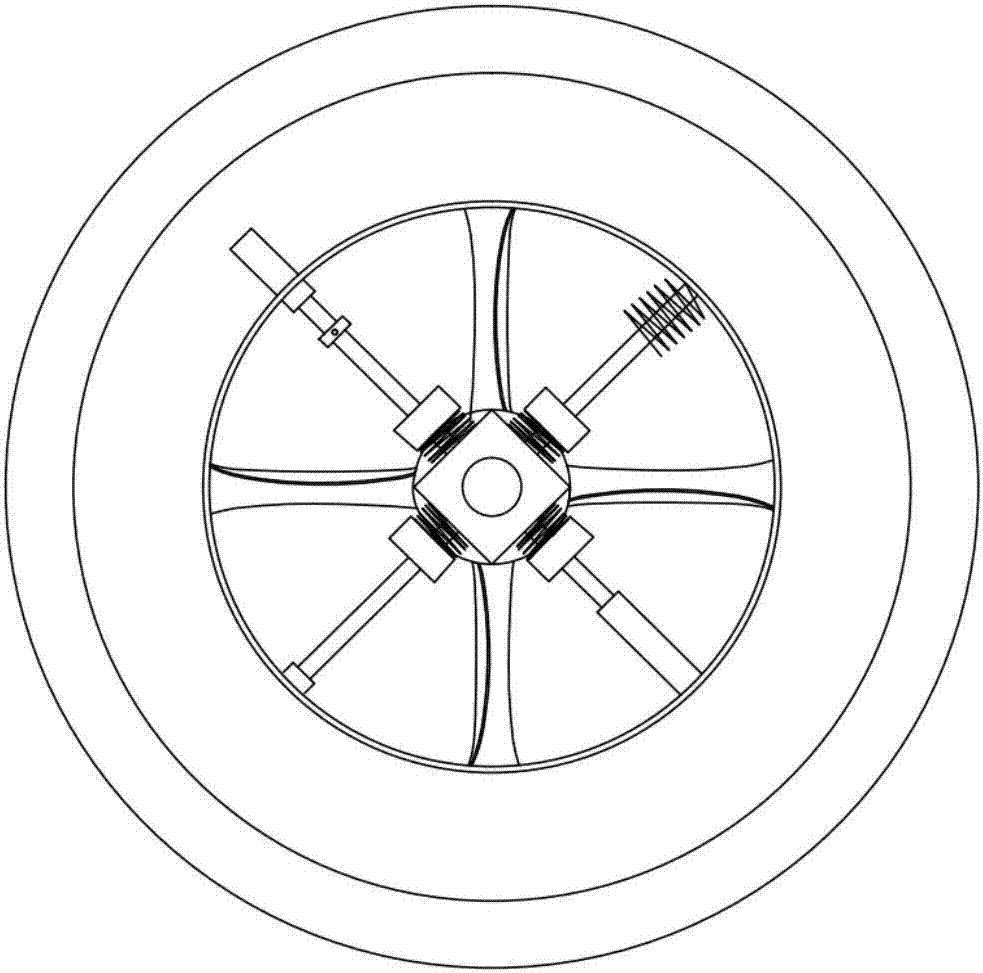

ActiveCN107006603ALow costVibrate evenlyGas current separationSeed preservation by dryingVibration amplitudeProtection mechanism

The invention discloses a grain drying and dedusting device and method. The grain drying and dedusting device comprises an outer container of a machine, a first banking plate, a dedusting reaction container, a second blanking plate, a third blanking plate and a fan vibration unit; grains are uniformly blanked and fully dried and de-dusted through multiple layers of blanking plates arranged according to a certain rule, of the device; a vibration device and a fan device are designed into a whole and located at the center of the equipment, so that vibrating and blowing are more uniform; the space is saved; the cost of multiple motors is reduced by adopting a single motor; and the vibration device is provided with a protection mechanism, so that the problem of damage to equipment due to the fact that the fan is over-high in rotating speed and over-large vibration amplitude is effectively solved.

Owner:ANHUI TIANQI FLOUR TECH CO LTD

Multistage filtering and anion generation coupled air purification device

InactiveCN106839160AFully purifiedDust fullyMechanical apparatusSpace heating and ventilation safety systemsAir pollutantsAir purification

The invention discloses a multistage filtering and anion generation coupled air purification device. The device comprises a cabinet, a first air inlet, a third air inlet, a second air inlet, an air outlet, four filter device assemblies, two first flow guide plates, two second flow guide plates, two fans and two groups of anion generators. Two opposite faces of the cabinet are provided with the first air inlet and the third air inlet respectively, the other two opposite faces of the cabinet are provided with the second air inlet and the air outlet respectively, and the four filter device assemblies are arranged in the cabinet. The first flow guide plates in an angle theta are arranged at the first air inlet and the third air inlet, the second flow guide plates in an angle beta are symmetrically arranged at the center of the second air inlet, and the filter device assemblies are arranged at the three air inlets and the air outlet respectively. The multistage filtering and anion generation coupled air purification device has advantages of effectiveness in removal of air pollutants and increase of concentration of anions in air.

Owner:NANJING NORMAL UNIVERSITY

Industrial solid waste disposal device

InactiveCN109595559AFully processedQuality improvementSievingScreeningMetal impuritiesMetal detectors

The invention discloses an industrial solid waste disposal device, and relates to the technical field of solid waste disposal equipment. The industrial solid waste disposal device comprises a first main body of which one surface fixedly communicates with a feeding hopper; one surface of the first feeding hopper is fixedly provided with a metal detector; one surface of the first main body fixedly communicates with a first material guide frame; one surface of the first main body fixedly communicates with a first material guide component; one surface of the first main body fixedly communicates with a dust collecting pipeline; and the other end of the dust collecting pipeline fixedly communicates with a dust collection box. According to the industrial solid waste disposal device, industrial waste residues are screened by using a filter plate, and metal impurities in the industrial waste residues are monitored through the metal detector; the dust removal efficiency is improved through two fans, and the industrial waste residues are uniformly stirred through a stirring component in an incinerator so that the industrial waste residues are incinerated uniformly; wet industrial waste residues are dried through a drying pipeline on the material guide component, and the industrial solid waste disposal device has the advantage that the waste residues are disposed fully.

Owner:FOSHAN UNIVERSITY

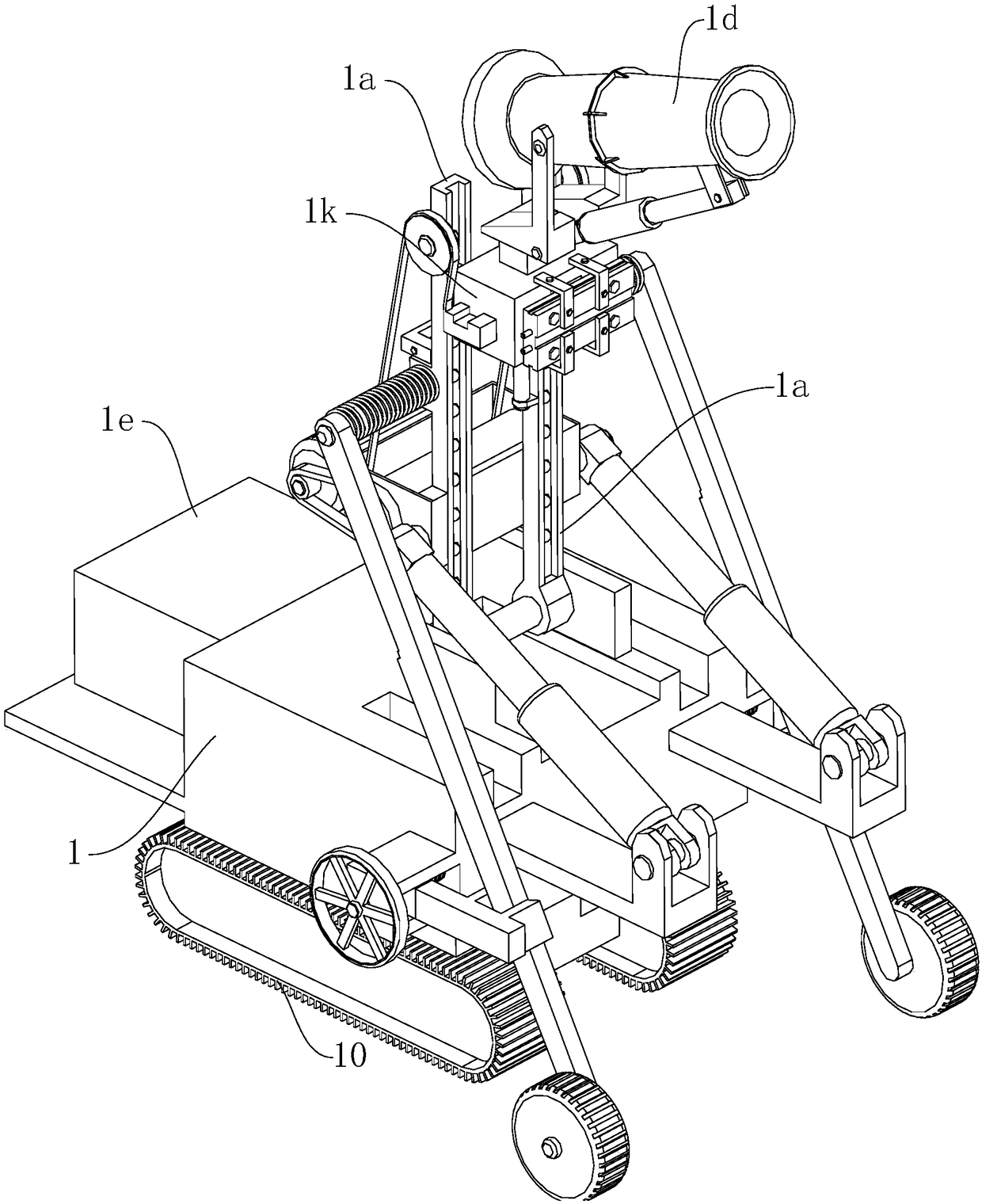

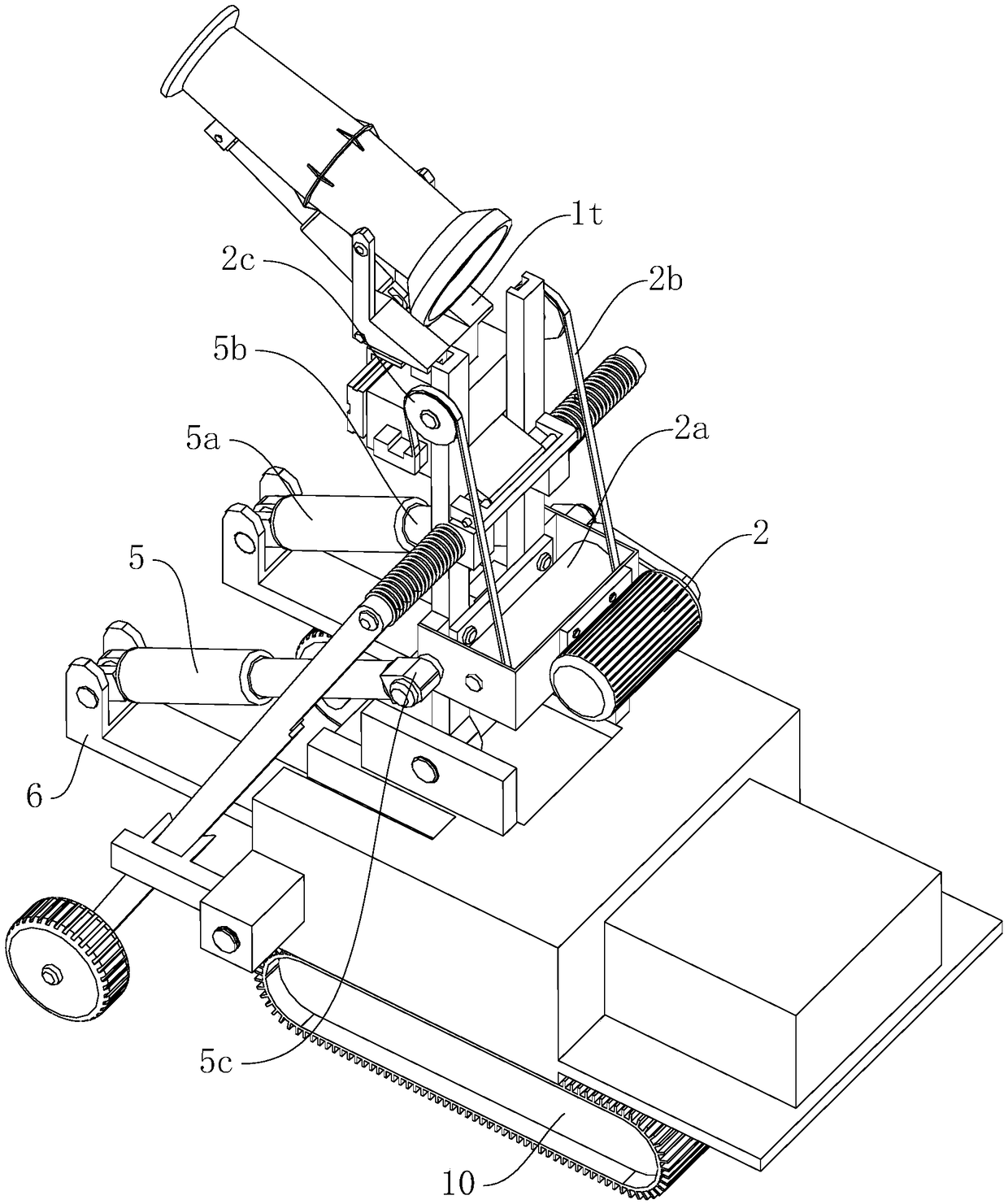

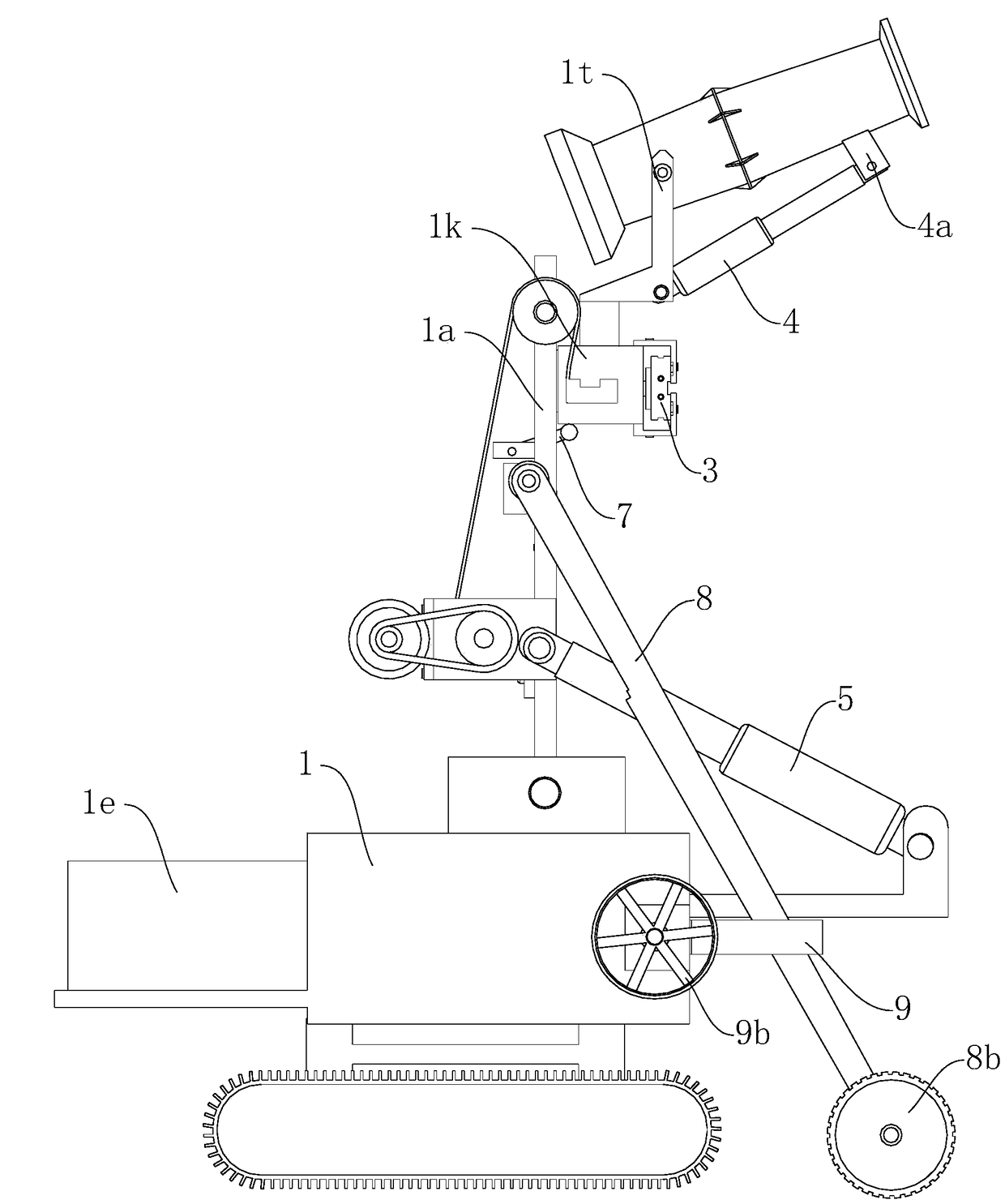

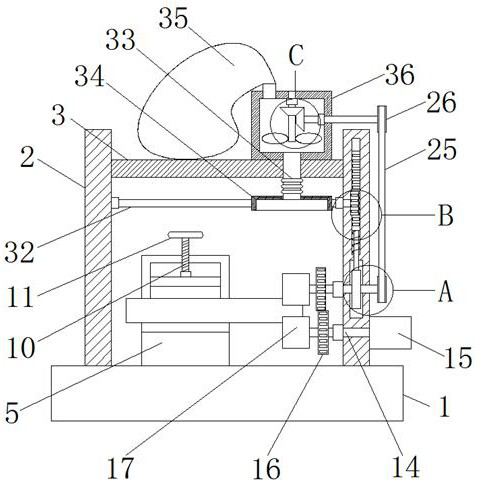

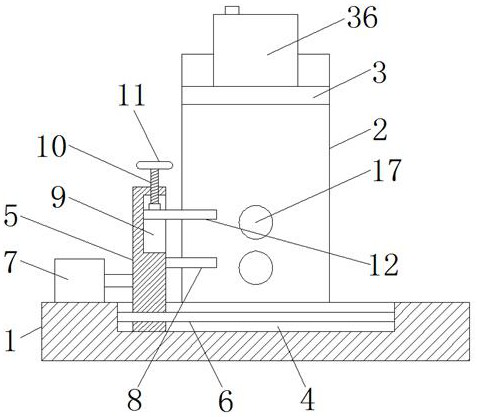

Flexibly adjusted environmental-protection fog gun machine applied to multiple occasions

ActiveCN109464867AReduce load forceReduce pushUsing liquid separation agentHigh pressureMechanical engineering

The invention relates to the field of environmental protection equipment, in particular to a flexibly adjusted environmental-protection fog gun machine applied to multiple occasions. The environmental-protection fog gun machine comprises a machine seat, a fog gun tube, a water supply tank, a lifting adjustment device, a swinging adjustment device and an angle adjustment device, wherein an automatic walking device is arranged at the bottom of the machine seat; two sliding rails are symmetrically arranged at the top of the machine seat; the lifting adjustment device is arranged on the back sidesof the two sliding rails; the front sides of the sliding rails are vertically and movably provided with a boss through the lifting adjustment device; the fog gun tube can be disposed in an up-down swinging manner through the angle adjustment device; the swinging adjustment device is arranged on the outer side of the boss and is used for enabling the angle adjustment device to rotate horizontally;the water supply tank is arranged at the rear end of the machine seat and is communicated with the fog gun tube through a high-pressure hose; the bottom ends of the two sliding rails are in shaftingfit with the top of the machine seat; the front side of the machine seat is provided with a collection device; a bearing device is arranged between the two sliding rails. By the liftable and collectable properties of the fog gun tube in the flexibly adjusted environmental-protection fog gun machine, the flexibly adjusted environmental-protection fog gun machine is suitable for moving in various special dust removal places and on complex roads.

Owner:林燕

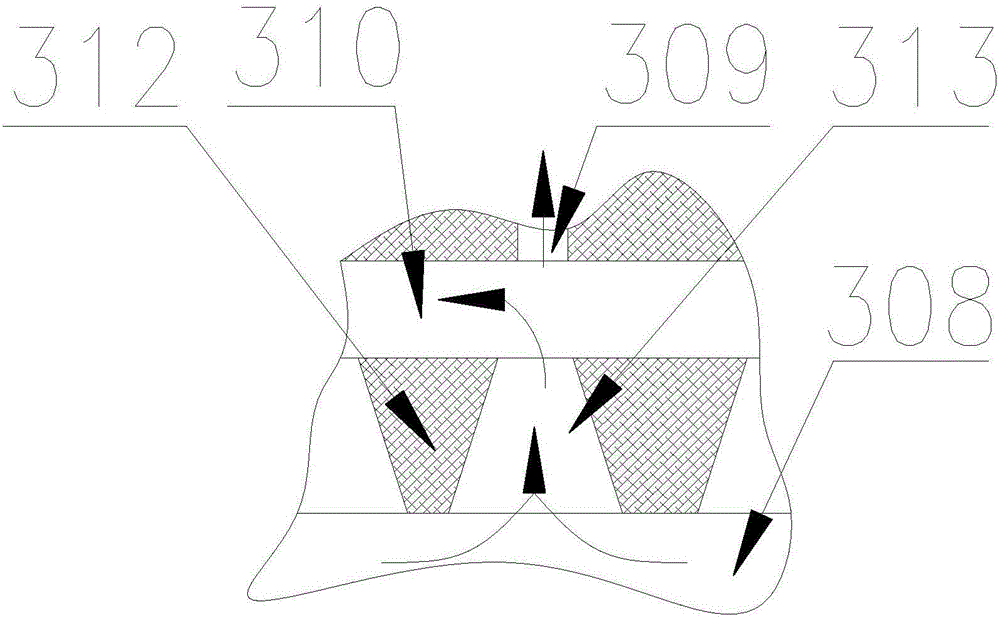

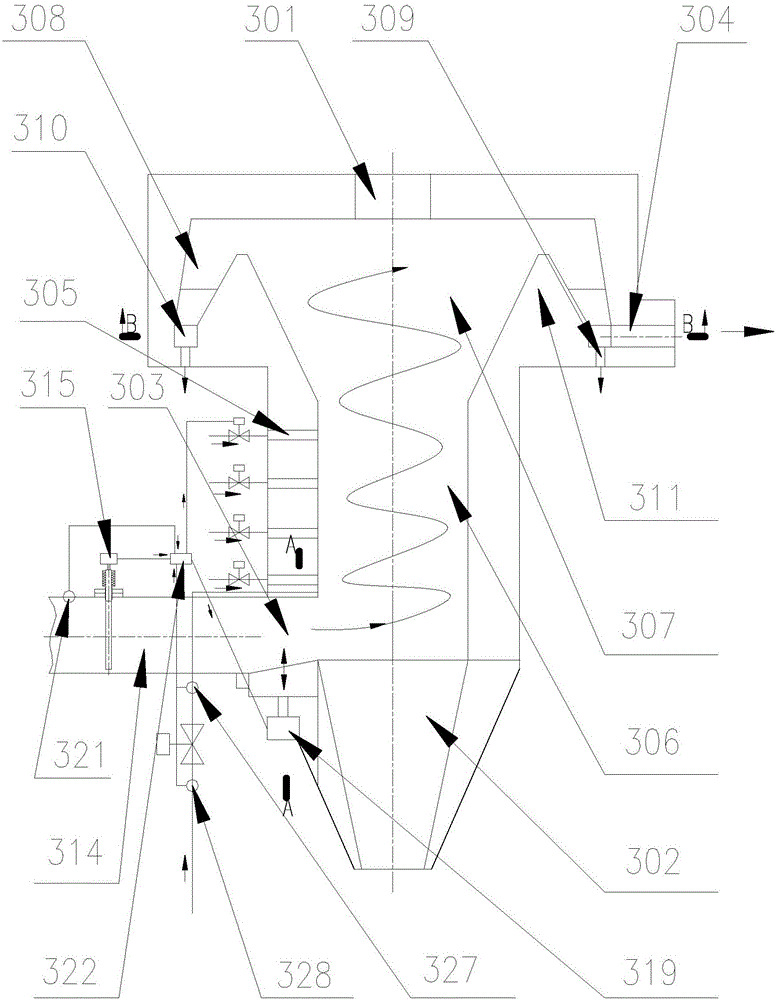

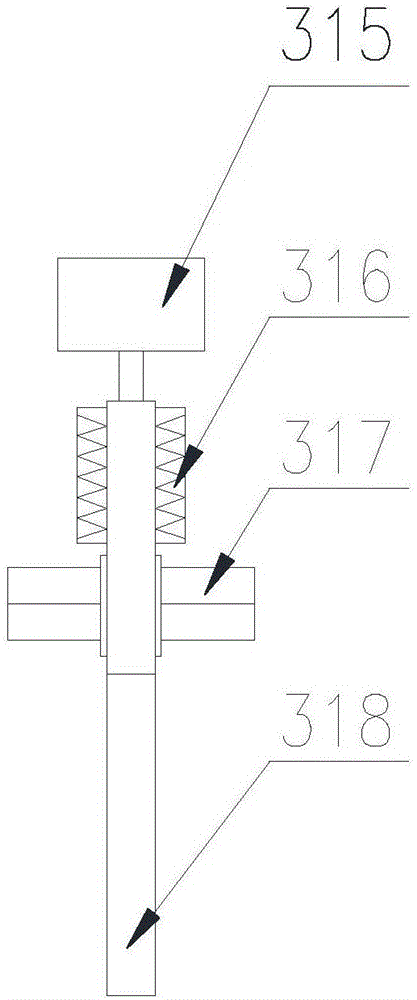

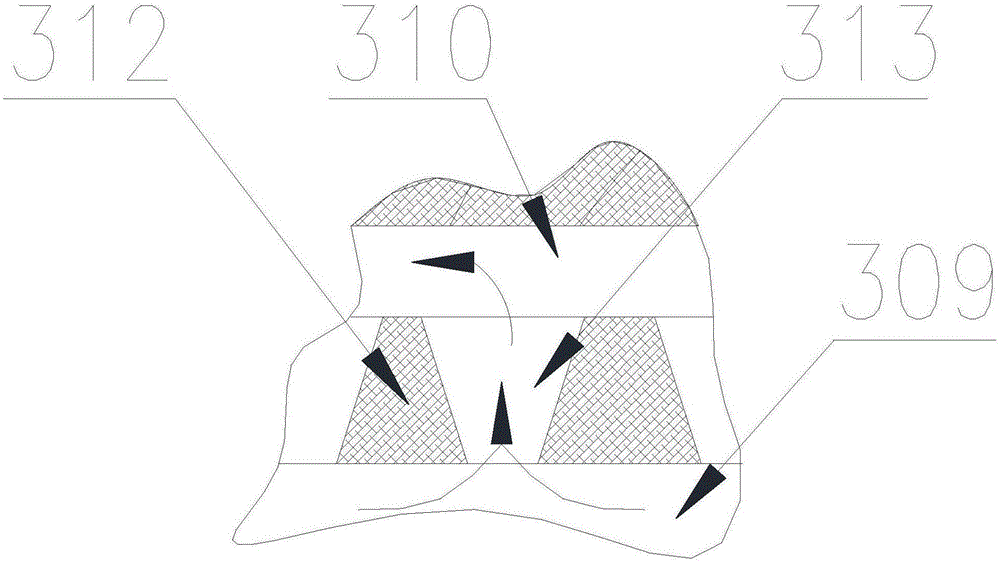

Mechanical grate type garbage gasifying and incinerating system and cyclone combustor

ActiveCN106224969ANovel ideaLarge amount of processingDispersed particle separationIncinerator apparatusSlagFlue

The invention discloses a mechanical grate type garbage gasifying and incinerating system and a cyclone combustor. A cavity of the cyclone combustor comprises a conical slag outlet, a combustion channel, a V-shaped conical channel, an annular smoke channel and an annular draught flue, wherein the conical slag outlet, the combustion channel and the V-shaped conical channel are arranged from bottom to top; the annular smoke channel and the annular draught flue surround the V-shaped conical channel from top to bottom; a cyclone combustor inlet is formed in the lower end of a side wall of the combustion channel in the tangential direction; the ventilating area of the annular smoke channel is gradually reduced from top to bottom; the upper end of the annular smoke channel communicates with the upper end of the V-shaped conical channel; a tangential smoke outlet is formed in the side wall of the cyclone combustor and communicates with the annular draught flue; and an annular ash discharge opening is formed in the lower end of the annular draught flue. The cyclone combustor has relatively high dust removal efficiency and combustion efficiency and relatively high heat recycling efficiency; controlled combustion and controlled collection can be realized; heat loss is reduced; and emission of pollutants can be reduced effectively.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

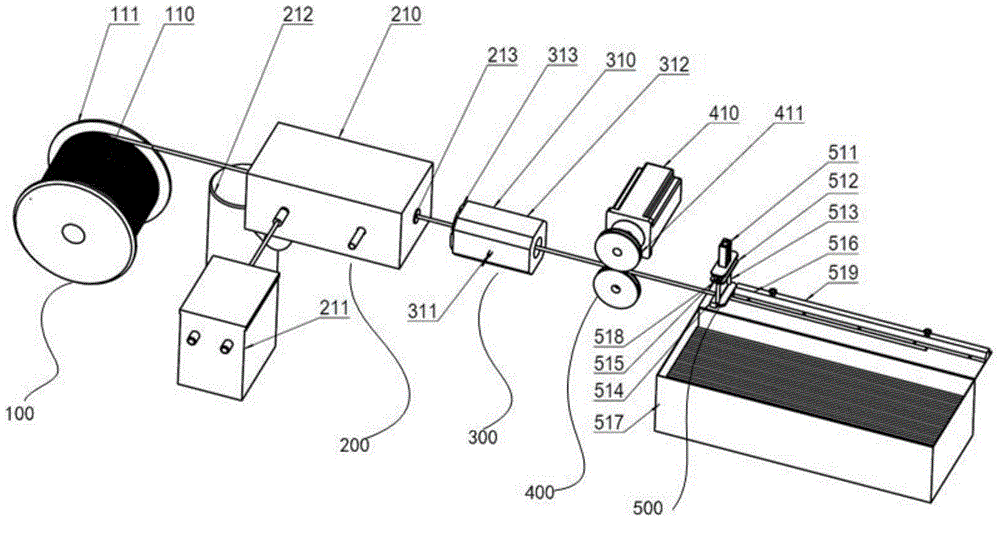

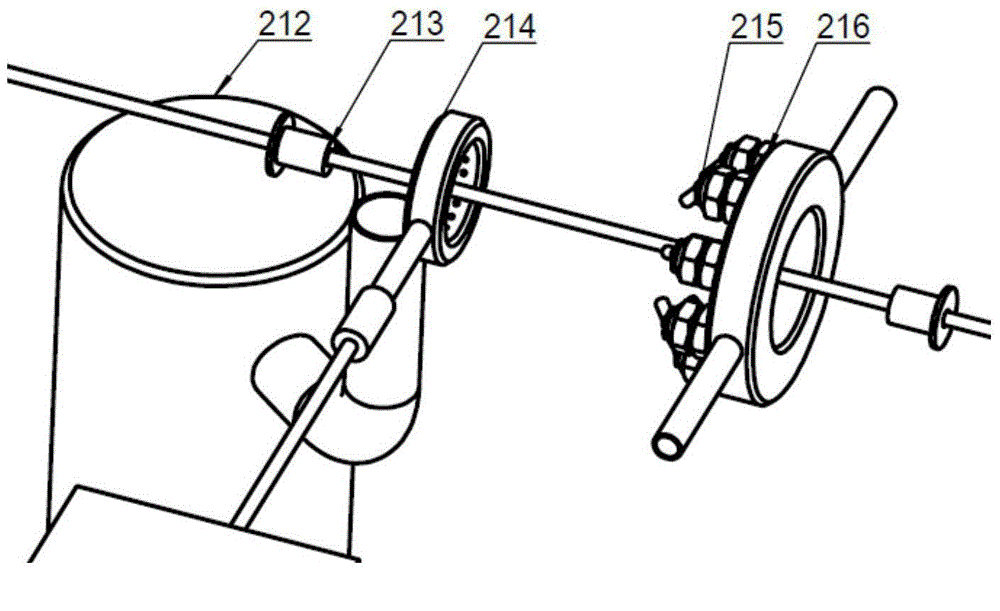

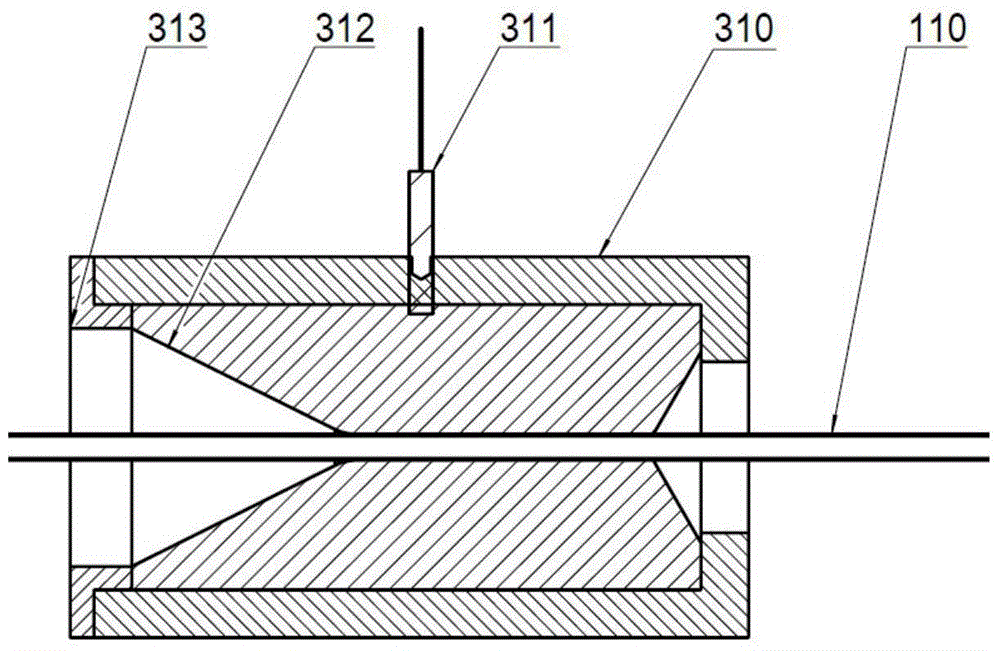

Tubular product trimming system

The invention discloses a tubular product trimming system which comprises a pay-off device, a dust removing device, a straightening device, a draft gear and a trimming device in sequence. The pay-off device comprises a winding disc and a drive device connected with the winding disc and is used for controlling paying off of tubular product raw materials. The dust removing device comprises a dust removing box, feed mouths, an ion spray ring, an ionizer, a compressed air spray ring, an air spray nozzle and a dust collector, wherein the feed mouths are arranged at the two ends of the dust removing box and used for guiding the feeding of the tubular product raw materials; the ion spray ring is arranged inside the dust removing box; the ionizer is connected with the ion spray ring and used for ejecting anions; the compressed air spray ring is arranged inside the dust removing box; the air spray nozzle is arranged on the compressed air spray ring and a certain angle is formed between the air blowing direction of the air spray nozzle and the tubular product raw materials; and the dust collector is connected with the dust removing box and used for removing waste gas inside the dust removing box.

Owner:SHANGHAI CHANGYUAN ELECTRONICS MATERIAL +1

Dust removal device for recycling waste lead-acid storage batteries

InactiveCN112354919AEasy to collectImprove transmission efficiencySievingFinal product manufactureDust controlEnvironmental engineering

The invention discloses a dust removal device for recycling waste lead-acid storage batteries. A transmission mechanism is mounted at the top of a supporting frame; a protective shell is arranged in the middle of the supporting frame; the transmission mechanism penetrates through the protective shell; an air drying mechanism is arranged on one side of the top of the transmission mechanism; a dustremoval mechanism and a cleaning mechanism are arranged in the middle of the top of the transmission mechanism; the cleaning mechanism is located between the air drying mechanism and the dust removalmechanism; a collecting box is arranged below the transmission mechanism; the collecting box is located inside the protective shell; a dust collector and a water circulation system are arranged at thetop of the protective shell; and the water circulation system is located on the side, close to the air drying mechanism, of the protective shell. By the adoption of the structure, dust removal can befully carried out on the recycled waste lead-acid storage batteries, the influence of floating dust, impurities and waste chips on subsequent procedures is avoided, meanwhile, dust removal and cleaning are integrated, the working efficiency is improved, and time is saved.

Owner:骆驼集团(安徽)再生资源有限公司

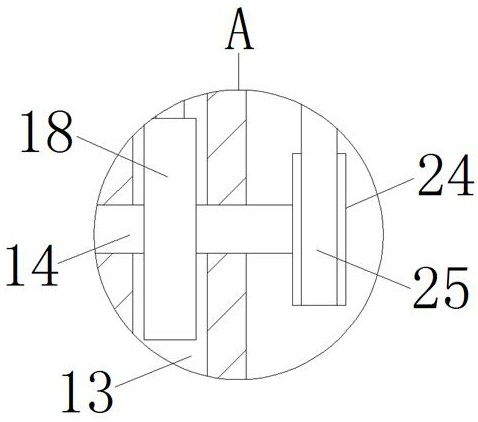

Automatic dust removal equipment for electric energy meters

The invention discloses automatic dust removal equipment for electric energy meters. The automatic dust removal equipment for the electric energy meters comprises a rack, a conveying device and a dust removal device. The automatic dust removal equipment is characterized in that the conveying device and the dust removal device are arranged on the front part and the rear part of the rack in parallel; the dust removal device comprises a location fixture used for fixing the plurality of electric energy meters, an air-blowing device and a turnover mechanism used for driving the location fixture to turn over up and down; and a transferring-loading mechanism is further arranged above the rack, and between the conveying device and the location fixture, and used for grabbing the electric energy meters to be subjected to dust removal on the conveying device and moving the electric energy meters onto the location fixture or grabbing the electric energy meters subjected to dust removal on the location fixture and moving the electric energy meters onto the conveying device. According to the automatic dust removal equipment for the electric energy meters, the conveying device and the dust removal device are mutually separated, so that dust in the electric energy meters can be adequately eliminated.

Owner:NINGBO SANXING MEDICAL & ELECTRIC CO LTD

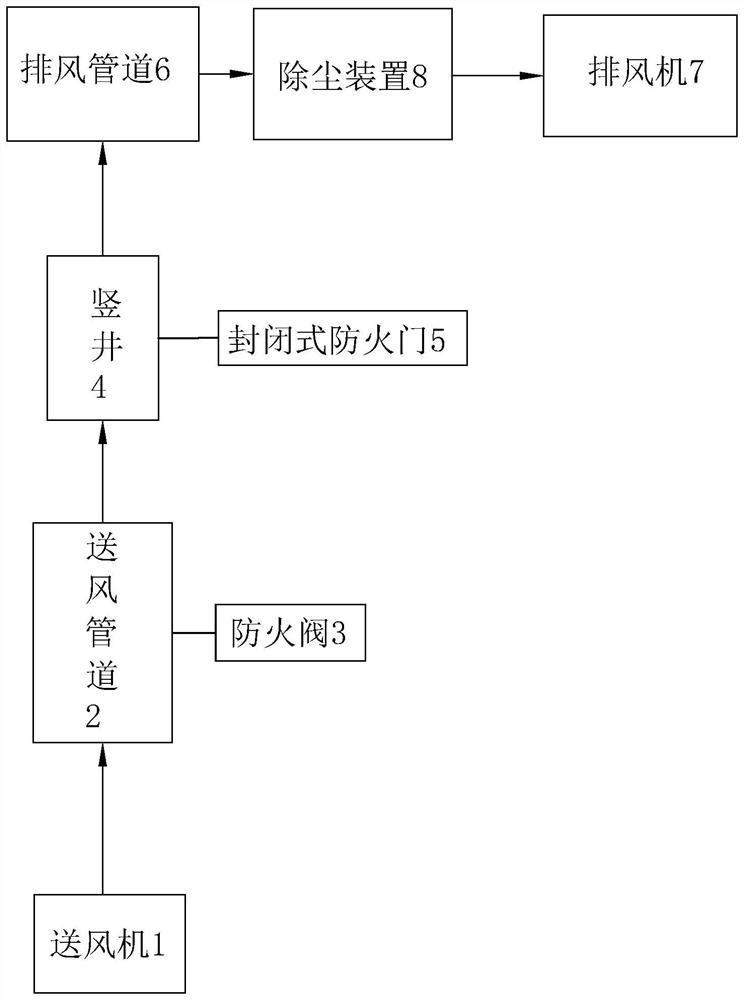

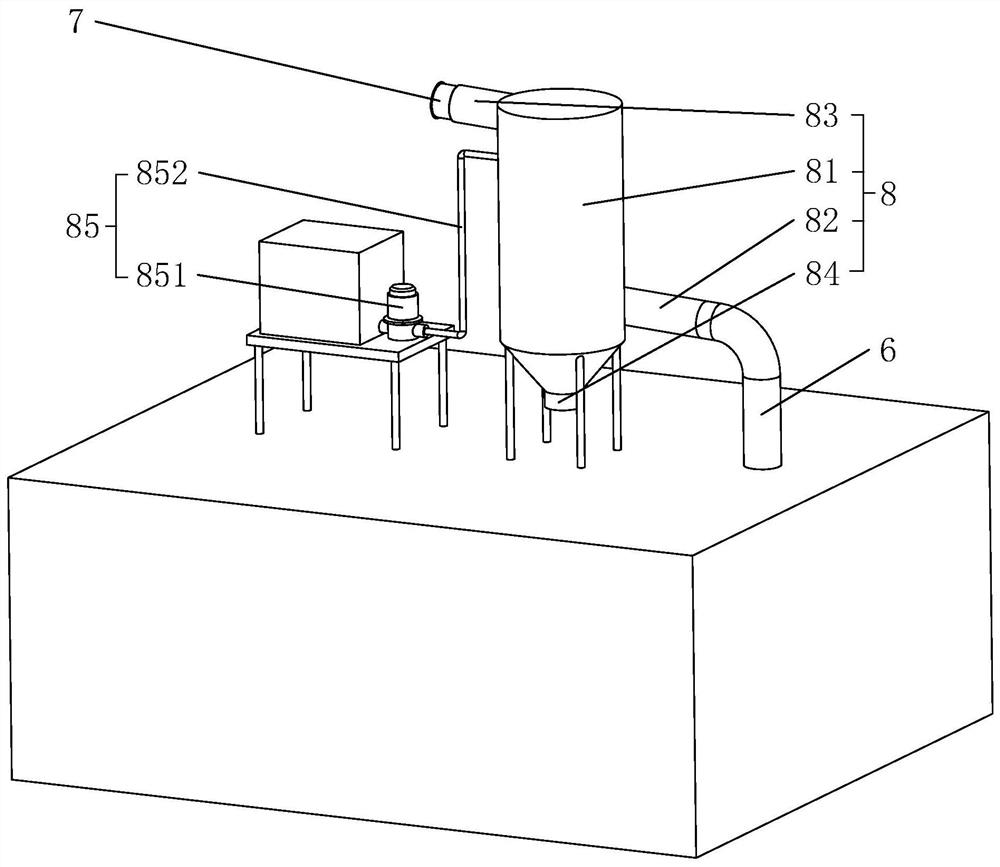

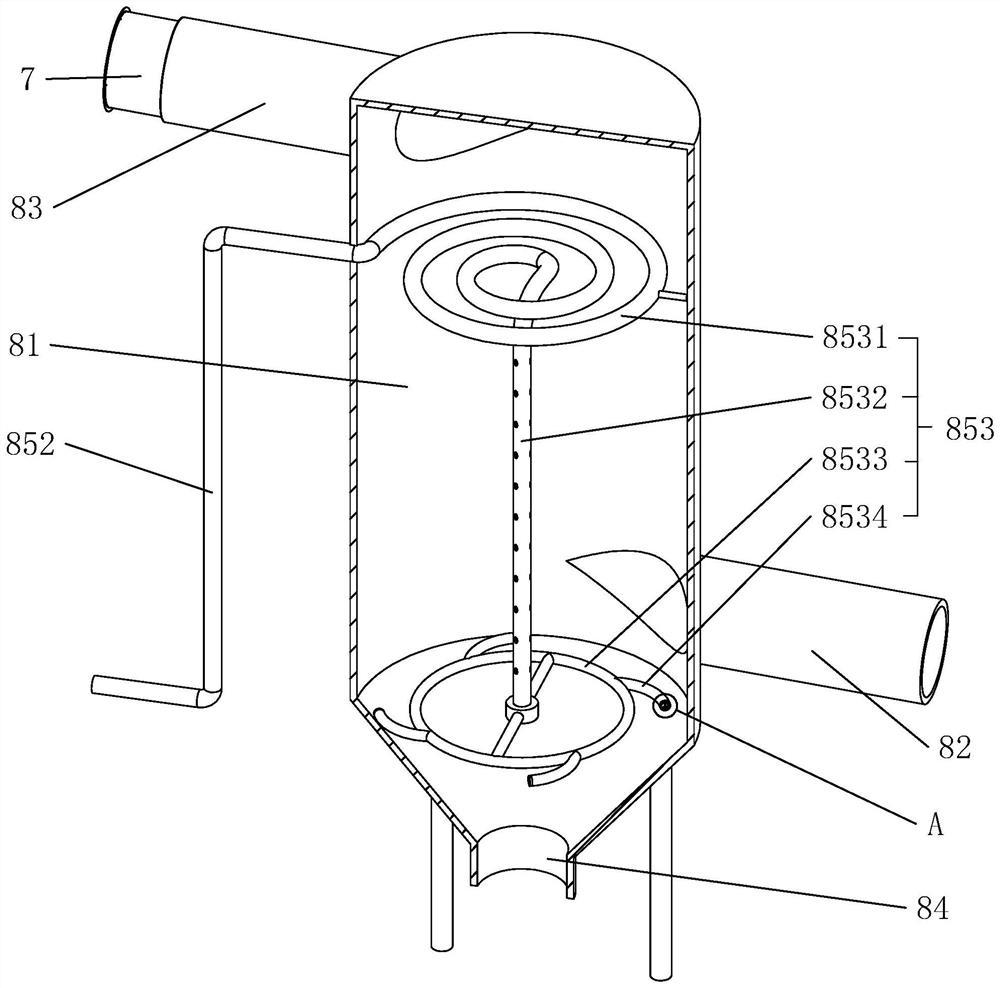

Fire-fighting smoke exhaust system

ActiveCN112197391AReduce soot contentReduce casualtiesMechanical apparatusLighting and heating apparatusFlue gasEnvironmental engineering

The invention relates to a fire-fighting smoke exhaust system, and relates to the field of fire-fighting system installation. The system comprises an air feeder, an air supply pipeline used for beinginstalled on a building body, a fireproof valve arranged on the air supply pipeline, a vertical shaft located in a staircase of the building body, a closed fireproof door used for being installed on the building body, an exhaust pipeline used for being installed on the building body, an exhaust fan used for being installed on the building body and a dust removal device used for being installed onthe building body, wherein the dust removal device comprises a dust removal tank, an air inlet pipe arranged on the dust removal tank, an air outlet pipe arranged on the dust removal tank, a residue outlet pipe arranged on the dust removal tank and a spraying assembly, the air inlet pipe is connected with the exhaust pipeline and tangent to the dust removal tank, the air outlet pipe is connected with the exhaust fan and tangent to the dust removal tank, and the spraying assembly is used for removing dust from the flue gas passing through the dust removal tank. According to the fire-fighting smoke exhaust system, the pollution of the smoke exhaust system to the atmosphere in the smoke exhaust process is reduced.

Owner:天津市安信通达机电设备安装工程有限公司

Movable welding fume dust collecting device

PendingCN108787684AEasy to stretchEasy to moveWelding/cutting auxillary devicesDirt cleaningExhaust fumesPulp and paper industry

The invention discloses a movable welding fume dust collecting device which comprises a workshop stand column, an exhaust fume collecting hood support and a telescopic exhaust fume collecting hood. Two horizontal cross beams in parallel are arranged between the workshop stand column and the exhaust fume collecting hood support; chain wheels are arranged at the front ends and the tail ends of the outer sides of the cross beams; a chain is connected between two chain wheels on the same cross beam; and the tail end of the telescopic exhaust fume collecting hood is fixed to the tail ends of the two cross beams, and the front end of the telescopic exhaust fume collecting hood is fixed onto the two chains, so that extension and compression are realized through the rotation of the chains. The exhaust fume collecting hood is convenient to stretch out and draw back, so that the welding environment pollution is low, and the space is further saved.

Owner:JINAN HUAXIN AUTOMATION ENG

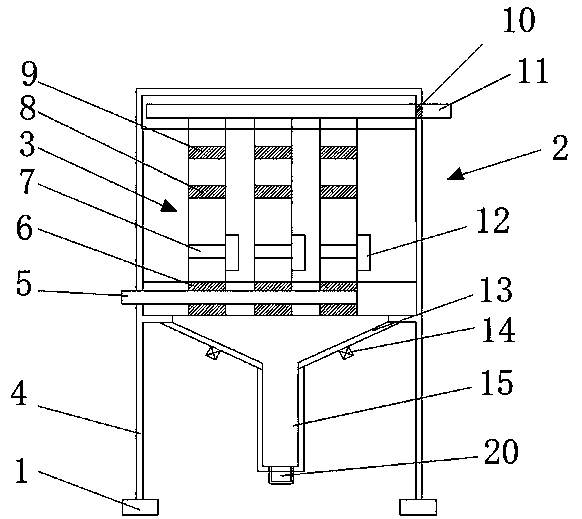

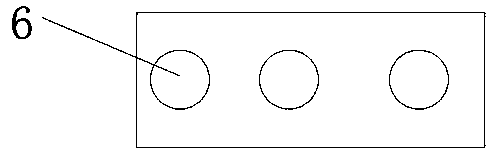

Filter cartridge dust collector for production of electronic-grade compound epoxy resin

PendingCN108993056ANot easy to blockSimple structureDispersed particle filtrationTransportation and packagingEpoxyEngineering

The invention discloses a filter cartridge dust collector for production of electronic-grade compound epoxy resin, wherein the filter cartridge dust collector comprises a box body, filter cartridges and an ash storage barrel. The box body is fixed on a base through a pillar, and an ash bucket is fixed below the box body; the ash storage barrel is fixed below the ash bucket, the bottom end of the ash storage barrel is provided with an ash outlet, and the bottom end of the box body is fixedly provided with a gas intake pipe; the gas intake pipe is provided with three groups of circular openings,and the three groups of circular openings are connected with the bottoms of three groups of cylindrical filter cartridges respectively; the top of the box body is fixedly provided with a gas outlet pipe; the box body is internally provided with the filter cartridges; each filter cartridge has a hollow cylindrical structure with openings at both ends; a first filter screen and a second filter screen are fixed above the interior of each filter cartridge, the bottom of each filter cartridge is fixedly provided with a fan, and the outer side of each filter cartridge is fixedly provided with a pressure controller. The filter cartridge dust collector for production of the electronic-grade compound epoxy resin has the advantages of simple structure and high dust removal efficiency, allows dust not to easily block the filter cartridges, and can be universally promoted and used.

Owner:JIANGSU TETRA NEW MATERIAL TECH

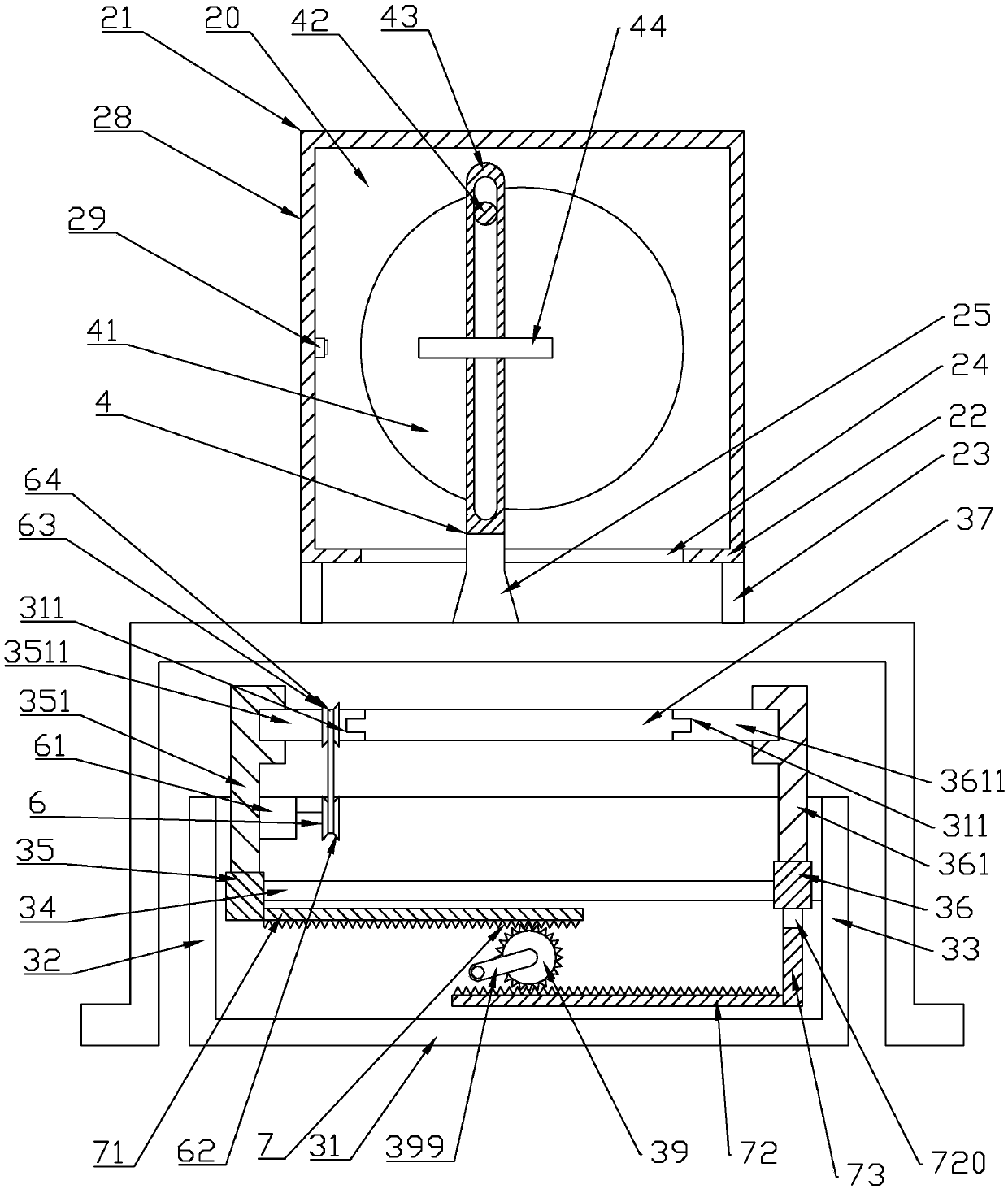

Carbon-carbon composite material production equipment and production process thereof

PendingCN113458918ADust fullyQuick dust removalGrinding drivesGrinding machinesCarbon compositesWorking environment

The invention belongs to the field of carbon-carbon composite material production and processing, particularly relates to carbon-carbon composite material production equipment and a production process thereof, and aims to solve the problem that the working environment of workers is worsen due to the fact that dust is inconvenient to fully and quickly remove in the tenoning process of a composite material by the existing carbon-carbon composite material production equipment. According to the technical scheme, the equipment comprises a base, two symmetrical vertical plates are fixedly installed at the top of the base, the outer sides of the two vertical plates are fixedly connected to the same mounting plate, a first sliding groove is formed in the top of the base, a positioning mechanism is arranged in the first sliding groove, an air bellow is fixedly installed at the top of the mounting plate, a mounting hole is formed in the bottom of the air bellow, and the mounting hole is fixedly provided with a corrugated pipe. According to the carbon-carbon composite material production equipment, in the tenoning machining process of the composite material, dust can be fully and rapidly removed conveniently so that the working environment of workers can be effectively improved, and the equipment is simple in structure and convenient to use.

Owner:张洪波

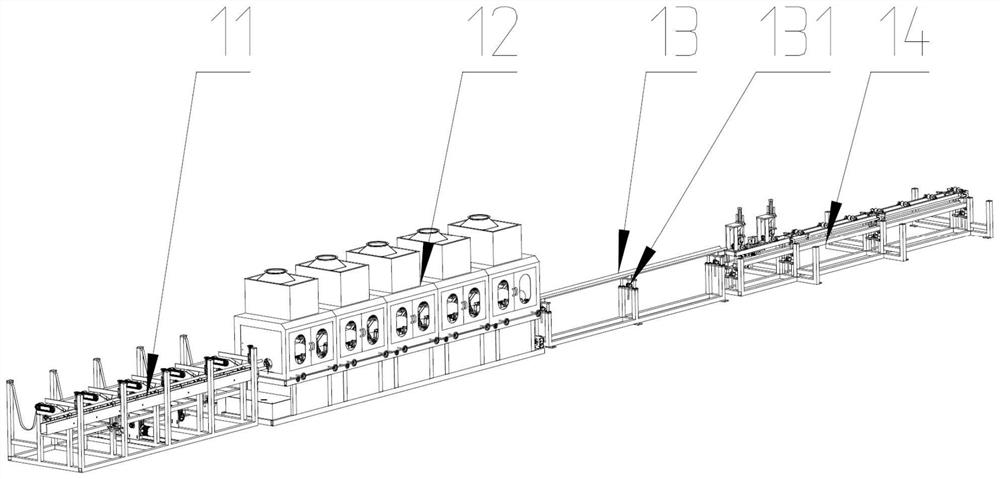

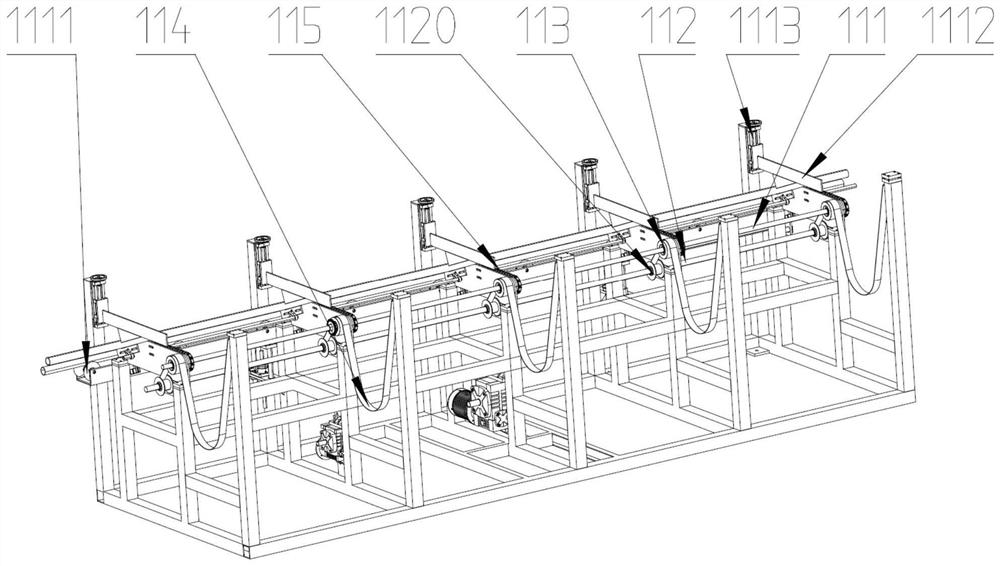

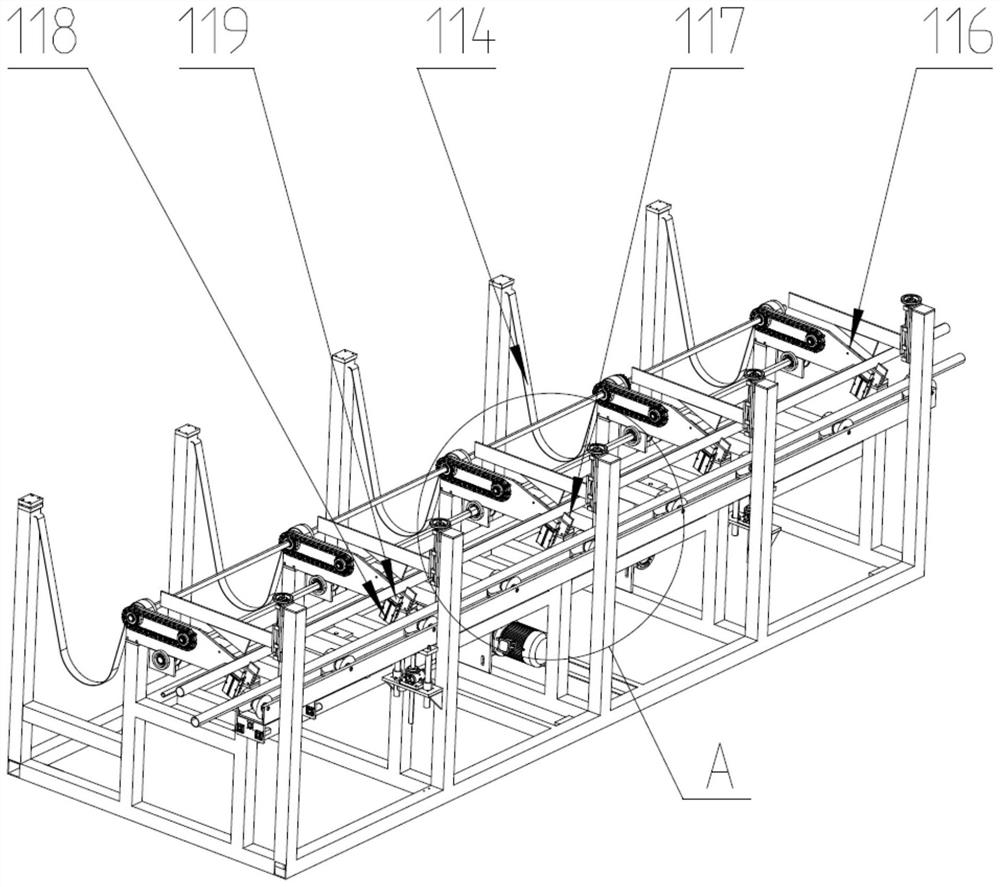

Pipe polishing and detecting integrated production line

ActiveCN113560980ANo manual operationPrevent overlapping, slow down the problem of transport speedEdge grinding machinesPolishing machinesProduction lineProcess engineering

The invention discloses a pipe polishing and detecting integrated production line. The production line comprises an automatic feeding frame used for pipe feeding, a pipe polishing machine is arranged behind the automatic feeding frame, a polishing transition frame is arranged behind the pipe polishing machine, and an eddy current flaw detection automatic detection device is arranged behind the polishing transition frame. A pipe is conveyed into the pipe polishing machine through the automatic feeding frame to be automatically polished, after polishing is completed, the pipe enters the eddy current flaw detection automatic detection device through the polishing transition frame to be detected, the pipe is detected to be qualified or unqualified, classification is conducted, full-automatic operation is conducted on the whole assembly line, manual operation is not needed, and great convenience is achieved; the production line is simple in structure, high in efficiency and convenient to operate.

Owner:SICHUAN MINHE PIPELINE CONSTR ENG CO LTD

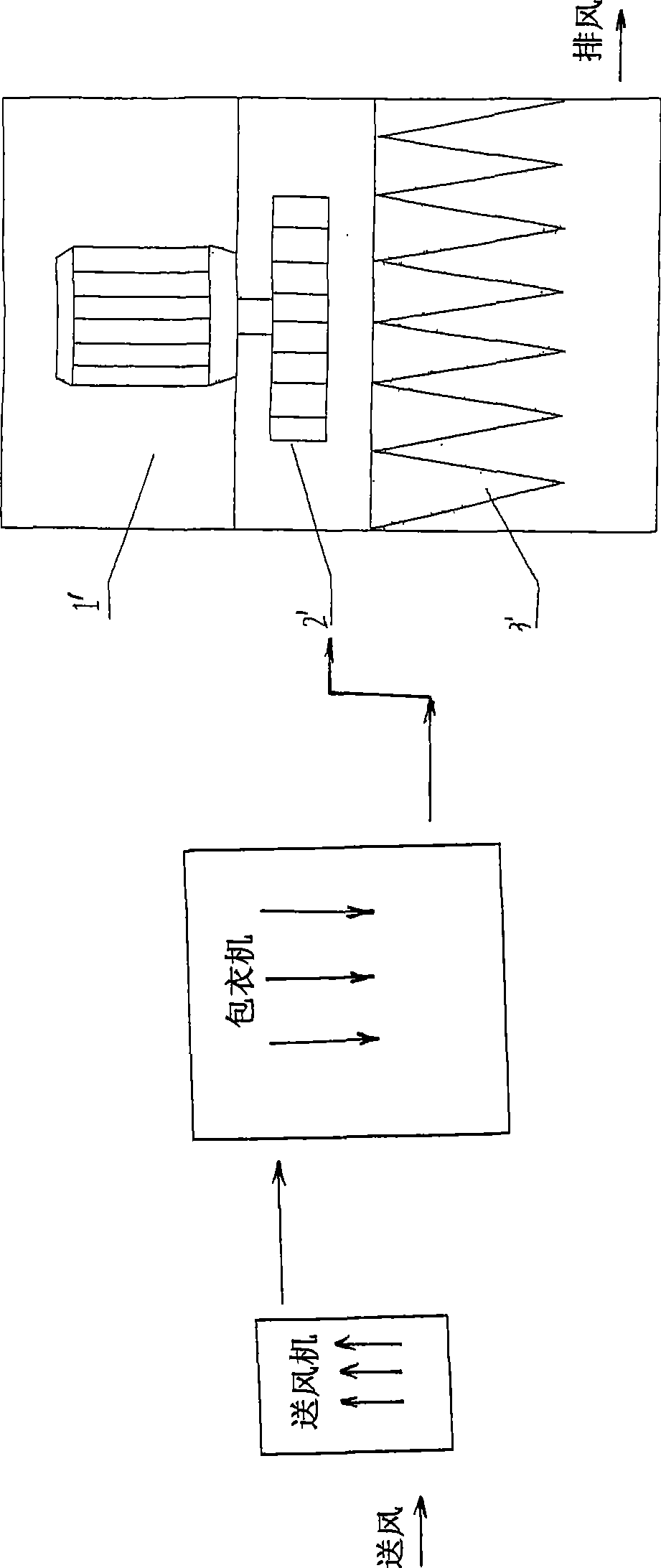

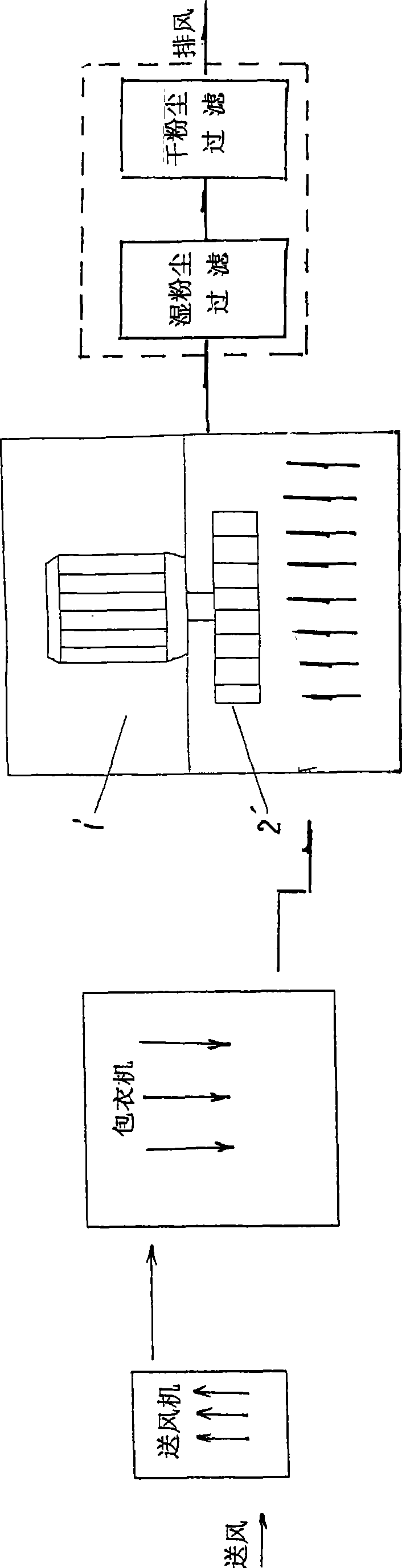

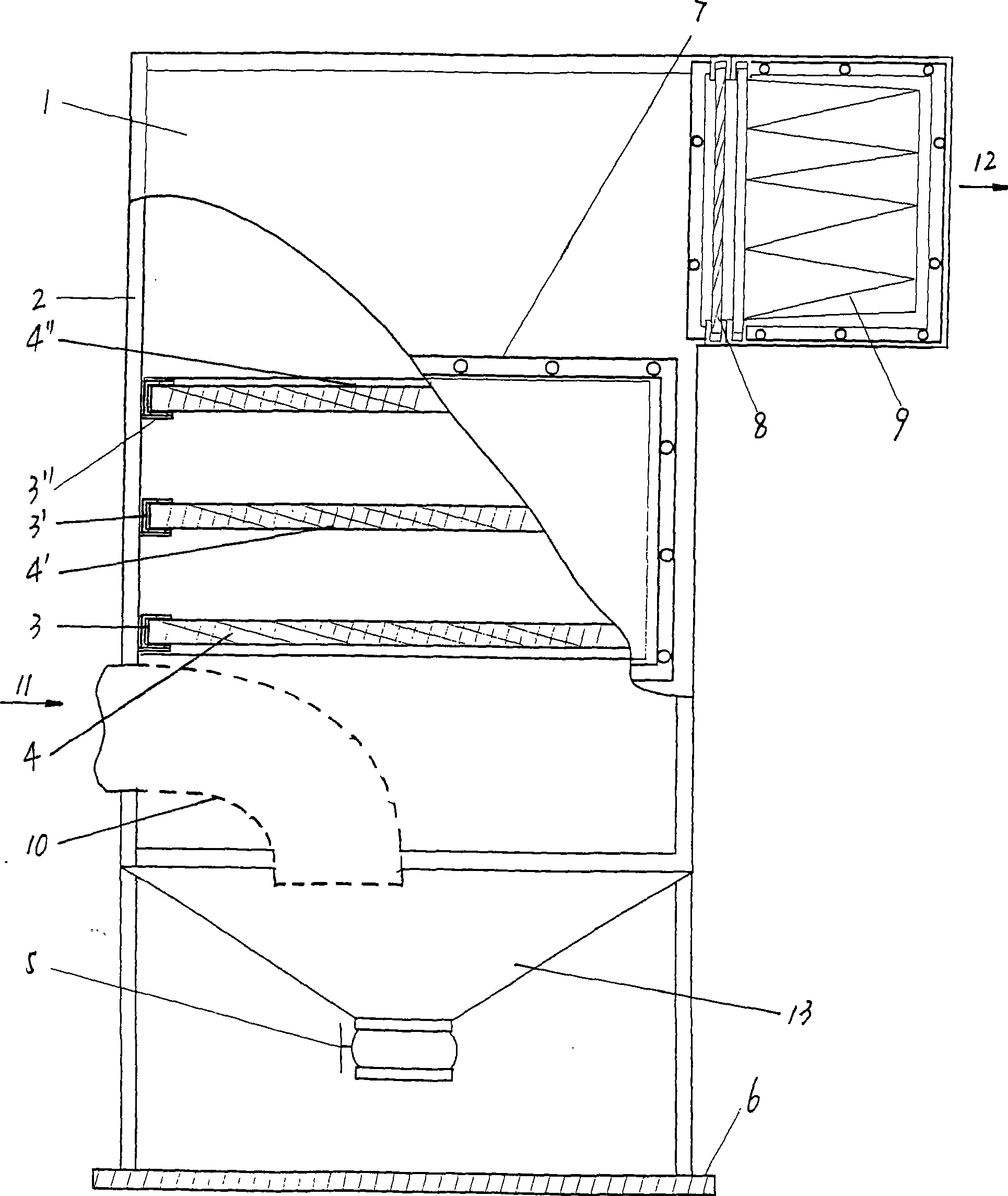

Dedusting technique and device thereof

InactiveCN101468357AEasy to removeExtended replacement cycleDispersed particle filtrationDirt cleaningEngineeringNonwoven fabric

The invention relates to a process and a device for dedusting, in particular suitable for dedusting in the production process of tablet coating. The dedusting process comprises: dust produced in the coating process of a coating machine is transported to air feeding equipment, enters the dedusting device from the air feeding equipment, and is discharged through an exhaust fan, wherein the dedusting process comprises wet dust filtering and dry dust filtering; firstly, the dust is subjected to the wet dust filtering; and subsequently, the dust is subjected to the dry dust filtering. The dedusting device comprises a box body, a draught fan and a nonwoven fabric filter bag; the box body is provided with an air inlet and an air outlet; a dust fluid is filtered by the filter bag from the air inlet, and is discharged from the air outlet, wherein the upper part of the air inlet in the box body is horizontally at interval provided with two or more than two filter screen layers; the lower part of the air inlet inside the box body is provided with a cone body of which peripheral wall surfaces contract downwards; a hollow cavity is formed between the upper part of the cone body and the filter screen layer; the bottom of the cone body is provided with a dust cleaning valve; and the air outlet is provided with the nonwoven fabric filter bag. The device does not occupy a production field, and has good filtering effect and high production efficiency.

Owner:SHANGHAI FOSUN PHARMA (GROUP) CO LTD +1

Negative pressure dedusting and rice lifting device with separation function

The invention provides a negative pressure dedusting and rice lifting device with a separation function. The negative pressure dedusting and rice lifting device comprises a dedusting box, and a negative pressure wind gap is formed in the upper end of the dedusting box in an interpenetrating manner; a mesh screen is detachably mounted at the opening part of the negative pressure wind gap; a negative pressure lifting pipe is fixedly connected to one side of the dedusting box in an interpenetrating manner; and the other side of the dedusting box is fixedly connected with a drying box. When the negative pressure dedusting and rice lifting device is utilized, the negative pressure lifting pipe is placed on to-be-dried rice, a negative pressure fan is started, the negative pressure fan sucks to-be-dried rice into the dedusting box, small dust and broken rice are sucked out from the negative pressure wind gap, the mesh screen retains rice in the dedusting box, rice falls onto a vibration plate, when a motor rotates, an eccentric rotating wheel eccentrically rotates, a vibration block is driven to slide up and down in a vibration seat, up-down sliding of the vibration plate is converted into up-down vibration through a spring, rice is continually overturned, dedusting is more thorough, and then, rice flows into the drying box from the vibration plate to be dried.

Owner:重庆六丰农业开发有限公司

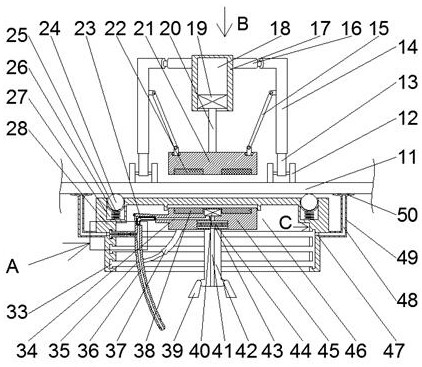

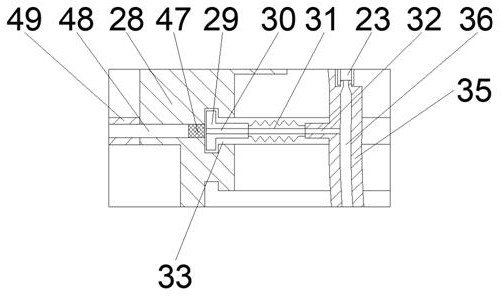

Environment-friendly dedusting device for solar cell panel

InactiveCN108856012ADust fullyAdequate dust removalPhotovoltaicsCleaning using toolsCells panelEngineering

An environment-friendly dedusting device for a solar cell panel comprises a bottom plate, a support device arranged on the bottom plate, a first electric cylinder device arranged on the support device, a moving frame device arranged on the first electric cylinder device, a dedusting device arranged on the moving frame device and a second electric cylinder device. The environment-friendly dedustingdevice for a solar cell panel can effectively dedust the solar cell panel, the dedusting effect is good, the flow rate of air entering a moving frame can be adjusted, and meanwhile the surface of thesolar cell panel can be sufficiently dedusted by a moving sponge rod, so that the dedusting range is wide, and the efficiency is high.

Owner:广州市妙伊莲科技有限公司

Dust removal device for computer case

The invention discloses a dust removal device for a computer case. The device comprises a housing, wherein the housing is provided with a working chamber with a downward opening, a driven block is arranged in the working cavity in an up-down moving mode, a circular ring-shaped driven magnet is fixedly arranged at the upper end of the driven block, a driving magnet is arranged directly above the driven magnet, the driving magnet and the driven magnet attract each other, a case side plate is arranged between the driving magnet and the driven magnet, and the driving magnet is fixedly connected toa driving block. The device is attracted to the inner side and the outer side of the computer case side plate through magnetic force, an inner magnet is driven to synchronously move through movementof an outer magnet, furthermore, the device can move in all directions on the inner side of the case so as to fully remove dust, and during dust removal, distance and orientation between a dust removal head and an inner component of the case can be adjusted, so that the device can adapt to components of different heights and remove dust in a hidden position.

Owner:威海火峰电脑有限公司

Capsule dedusting and drying integrated machine

InactiveCN108160555ADust fullyContinuous dust removalDrying gas arrangementsCleaning using toolsEngineeringAir blower

The invention provides a capsule dedusting and drying integrated machine. The capsule dedusting and drying integrated machine comprises a box body, a feeding funnel, material blocking plates, air blowers, stirring dedusting devices, moving devices, a dedusting disc, vibrators, a dust collector, a conveying device, an electric heating net, an air guiding device and a receiving box; a feeding opening is formed in the lower end of the feeding funnel, the material blocking plates are arranged on the two sides of the feeding opening, the air blowers are arranged at the lower ends of the material blocking plates, the stirring dedusting devices are arranged below the air blowers, the dedusting disc is arranged below the stirring dedusting devices, and the vibrators are arranged on the two sides of the dedusting disc; and the dust collector is arranged below the dedusting disc, the receiving box is arranged at the right end of the conveying device, the electric heating net is arranged above the conveying device, and the air guiding device is arranged above the electric heating net. According to the capsule dedusting and drying integrated machine, continuous dedusting and drying operation can be conducted on capsules, the working efficiency is improved, the processing cost is reduced, meanwhile, the capsules off size can be screened out, and multifunctionality is achieved.

Owner:潘金槐

Simple dust removal device

InactiveCN106669322AStrong ability to absorb collision energySlow ascentGas treatmentUsing liquid separation agentFlue gasEngineering

The invention relates to the technical field of environmental protection equipment, in particular to a simple dust removal device. The dust removal device has a good spraying effect and is sufficient in dust removal. The simple dust removal device comprises a cylinder body, a flue gas inlet and a purified gas outlet, wherein the flue gas inlet is formed in the lateral surface of the lower part of the cylinder body, and the purified gas outlet is formed in the upper end of the cylinder body; and the simple dust removal device further comprises a corrugated plate, jet pipes and sprinklers, wherein the corrugated plate is arranged at the upper end of the flue gas inlet, through holes densely formed are opened in the corrugated plate, the jet pipes are symmetrically arranged on two sides of the cylinder body, and the sprinklers is detachably connected at the end parts of the front ends of the jet pipes. According to the simple dust removal device disclosed by the invention, liquid is sprayed in a complete cone spray shape through the sprinklers, and a counter spray mode is further adopted, so that the spray effect is better and the spray coverage area is large and then spray and smoke dust can be better contacted and collided to achieve more sufficient and thorough dust removal.

Owner:攀枝花市旭鼎机械制造有限公司

Mechanical fire grate type garbage gasification and incineration system and turbulent combustion device

ActiveCN106224968ALarge amount of processingImprove energy conversion efficiencyBlast-producing apparatusIncinerator apparatusSlagPollutant emissions

The invention discloses a mechanical fire grate type garbage gasification and incineration system and a turbulent combustion device. An inner cavity of the turbulent combustion device comprises a conical slag outlet, a combustion channel, a V-cone channel, a lower annular smoke channel, an annular exhausting flue and an upper annular smoke channel, wherein the conical slag outlet, the combustion channel and the V-cone channel are sequentially arranged from bottom to top, and the lower annular smoke channel, the annular exhausting flue and the upper annular smoke channel are sequentially arranged around the V-cone channel from bottom to top. A turbulent combustion device inlet is formed in the lower end of the side wall of the combustion channel in the tangential direction, the ventilation area of the lower annular smoke channel is gradually decreased from bottom to top, and the ventilation area of the upper annular smoke channel is gradually decreased from top to bottom. A tangential smoke outlet is formed in the side wall of the turbulent combustion device and communicates with the annular exhausting flue. The turbulent combustion device has high dust removal efficiency, combustion efficiency and heat recovery efficiency, and can achieve controllable combustion and controllable collection, reduce heat loss and effectively reduce pollutant emission.

Owner:CHONGQING SANFENG ENVIRONMENTAL IND GRP +1

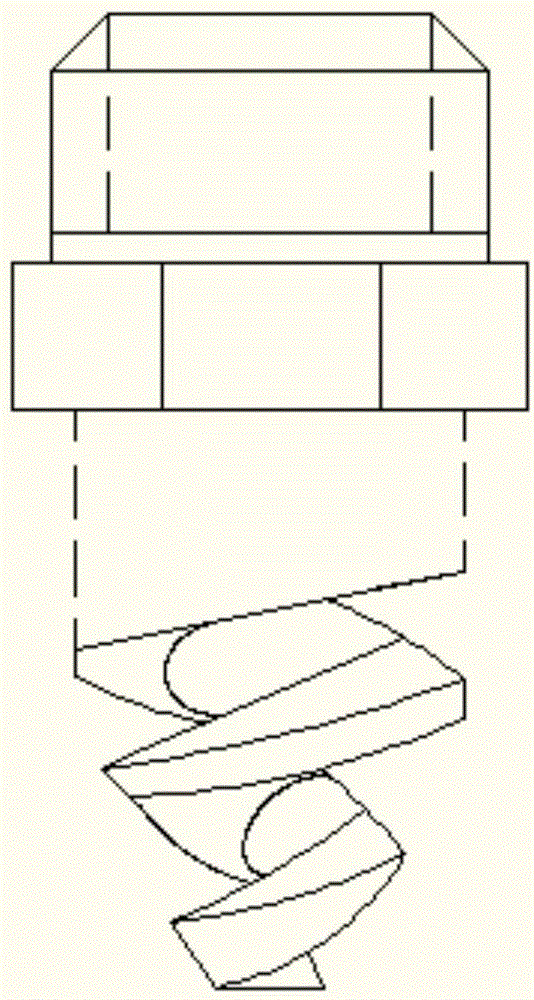

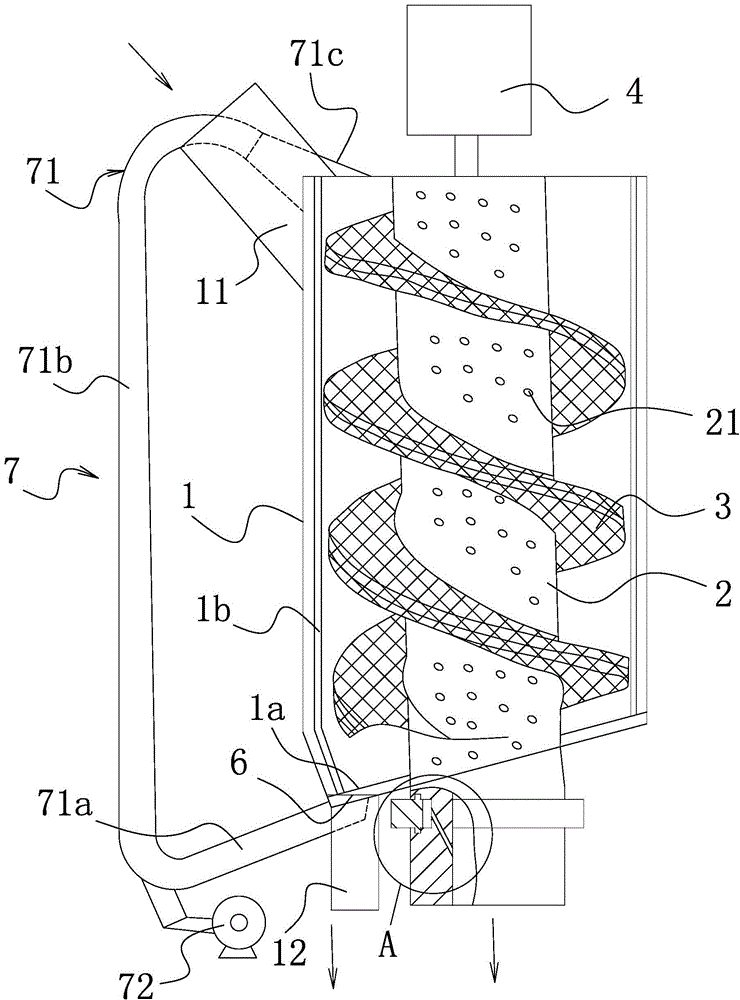

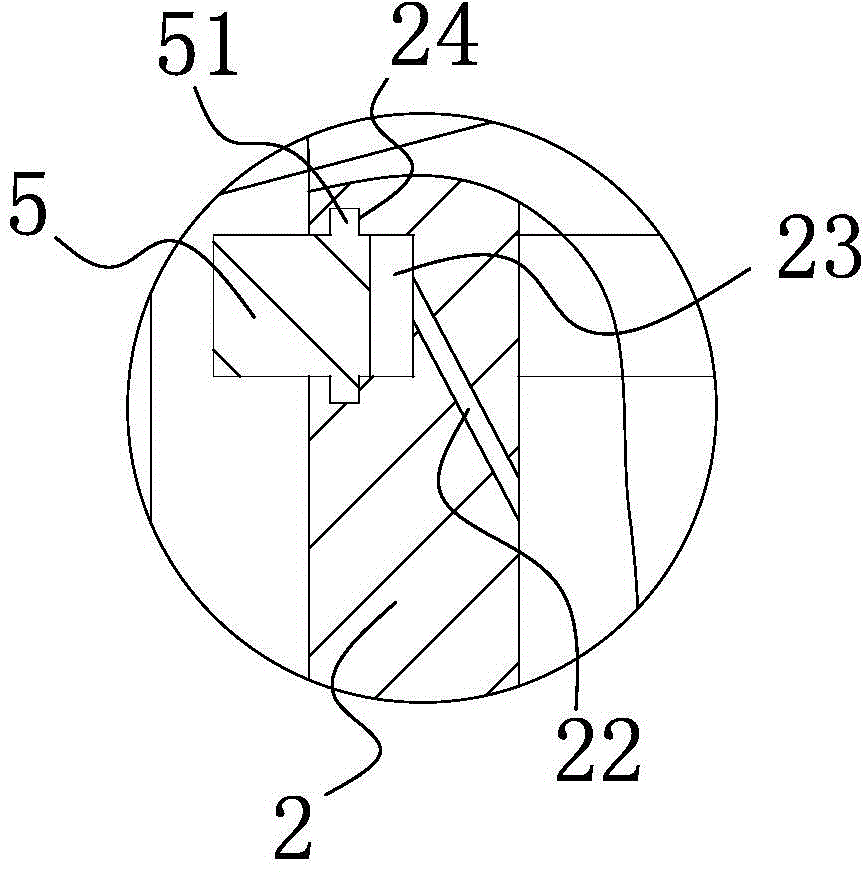

Cocoon feeding mechanism for silk processing device

The invention belongs to the technical field of silk manufacturing devices, particularly relates to a cocoon feeding mechanism for a silk processing device, and solves the technical problems of poor dust collection effect and the like in the prior art. The cocoon feeding mechanism for the silk processing device comprises a box, an inlet is formed in the top of the box, an outlet is formed in the bottom of the box, a vertical cylindrical body is arranged in the box, spiral blades are arranged on the cylindrical body, 1-10mm gap is reserved between the outer side of each spiral blade and the inner wall of the box, a plurality of through holes are formed in the cylindrical body, the inside of the cylindrical body is communicated with the inside of the box through the through holes, a negative pressure dust exhausting structure is arranged at the lower end of the cylindrical body, air flow in the cylindrical body flows downwards and is exhausted from the lower end of the cylindrical body through the negative pressure dust exhausting structure, and a circulation conveying structure connected between the bottom and the top of the box is arranged on the box. Compared with the prior art, the cocoon feeding mechanism is more reasonable in design, high in dust collection effect and fine in processing quality.

Owner:广西柳城县鸿艺丝绸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com