Dedusting technique and device thereof

A dust removal device and process technology, applied in the direction of dust removal, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of colored pollution, failure to perform normally, and affect the coating process, etc., to achieve the effect of extending the replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

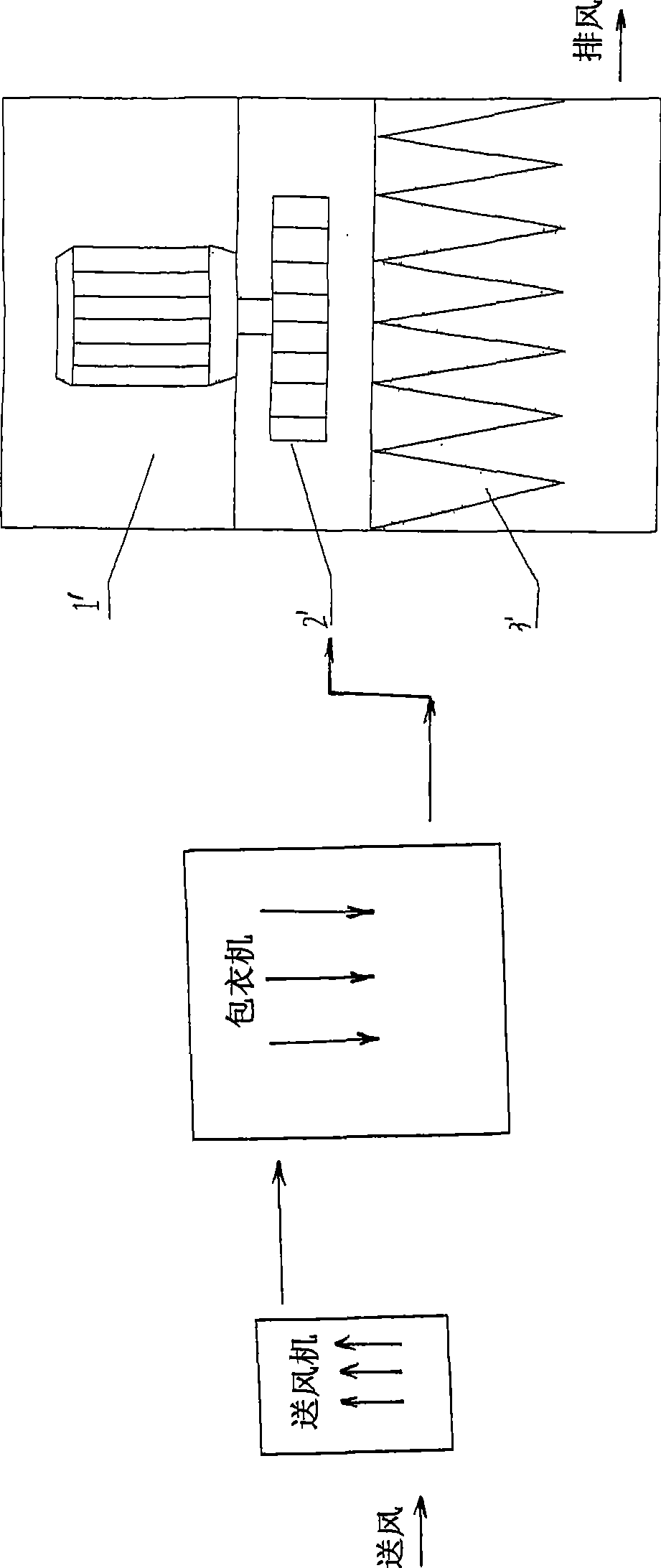

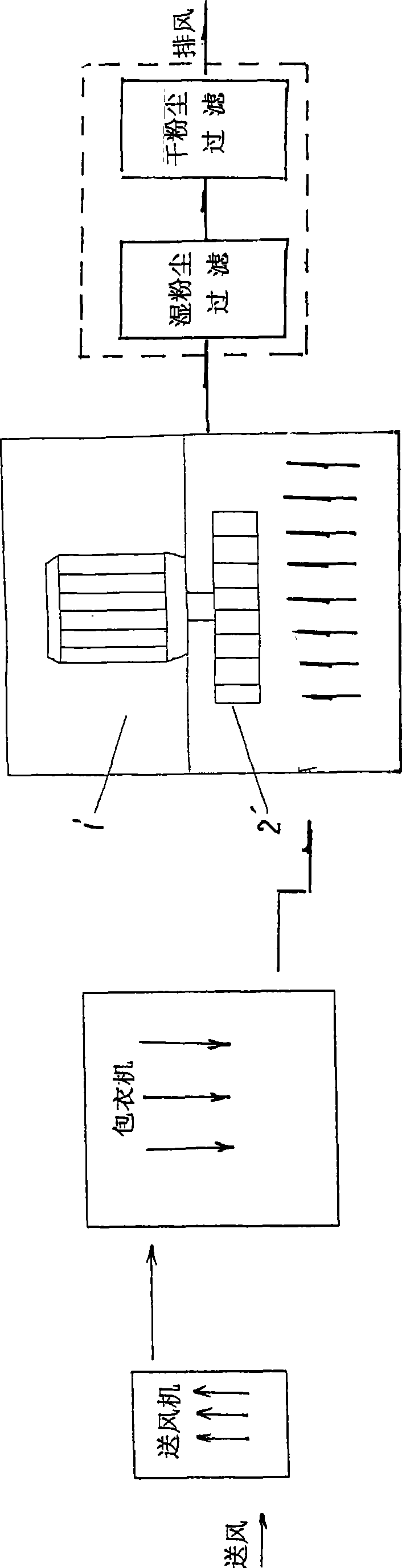

[0044] Such as figure 2 As shown in the flow chart of the dust removal process of the present invention: a dust removal process is used for the dust removal of the tablet coating process. Dust filtration is followed by dry dust filtration. After dust removal, it is discharged by the exhaust fan.

[0045] In this embodiment, the air supply device can be used after the filter bag is removed by the existing dust removal equipment. The purpose is to prevent the flow velocity from slowing down due to the increase of the dust airflow flow, and to prevent the increase of the flow flow from affecting the filtration speed.

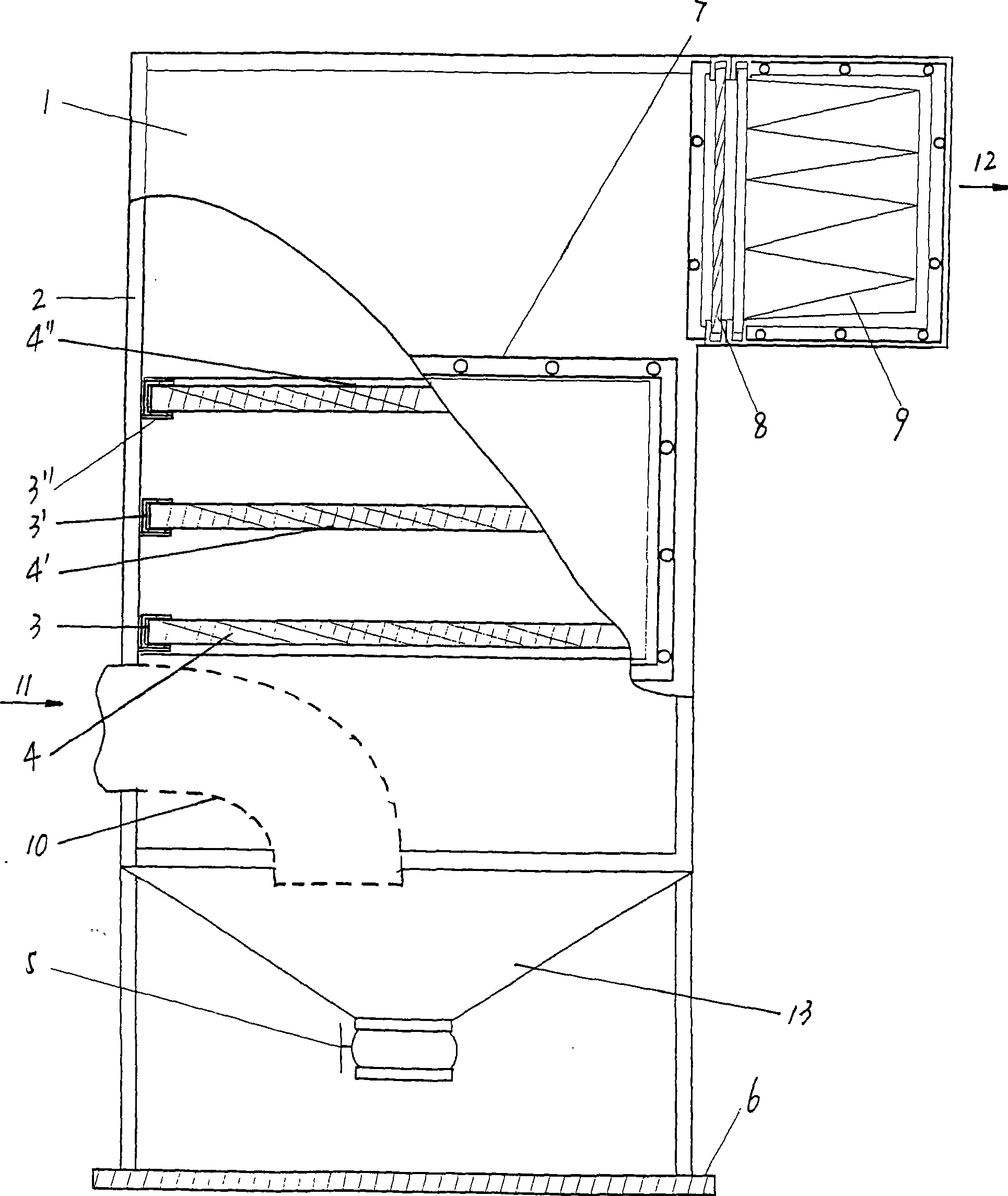

[0046] Such as image 3 It is a structural schematic diagram of the dust removal device of the present invention and Figure 4 Shown in the top view structural diagram of the stainless steel velvet ball filter net layer in the dedusting device of the present invention, the dedusting device of the present invention is arranged on the support 2, comprising a box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com