Patents

Literature

69results about How to "Reduce soot content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

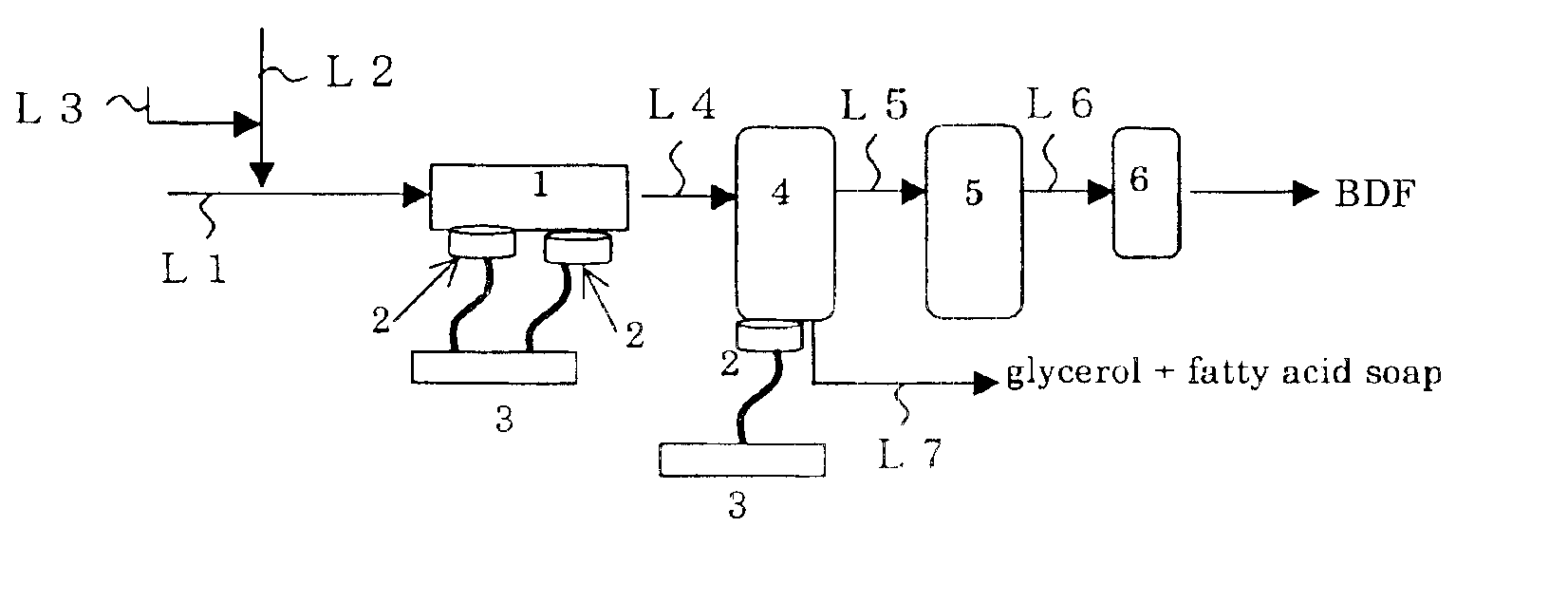

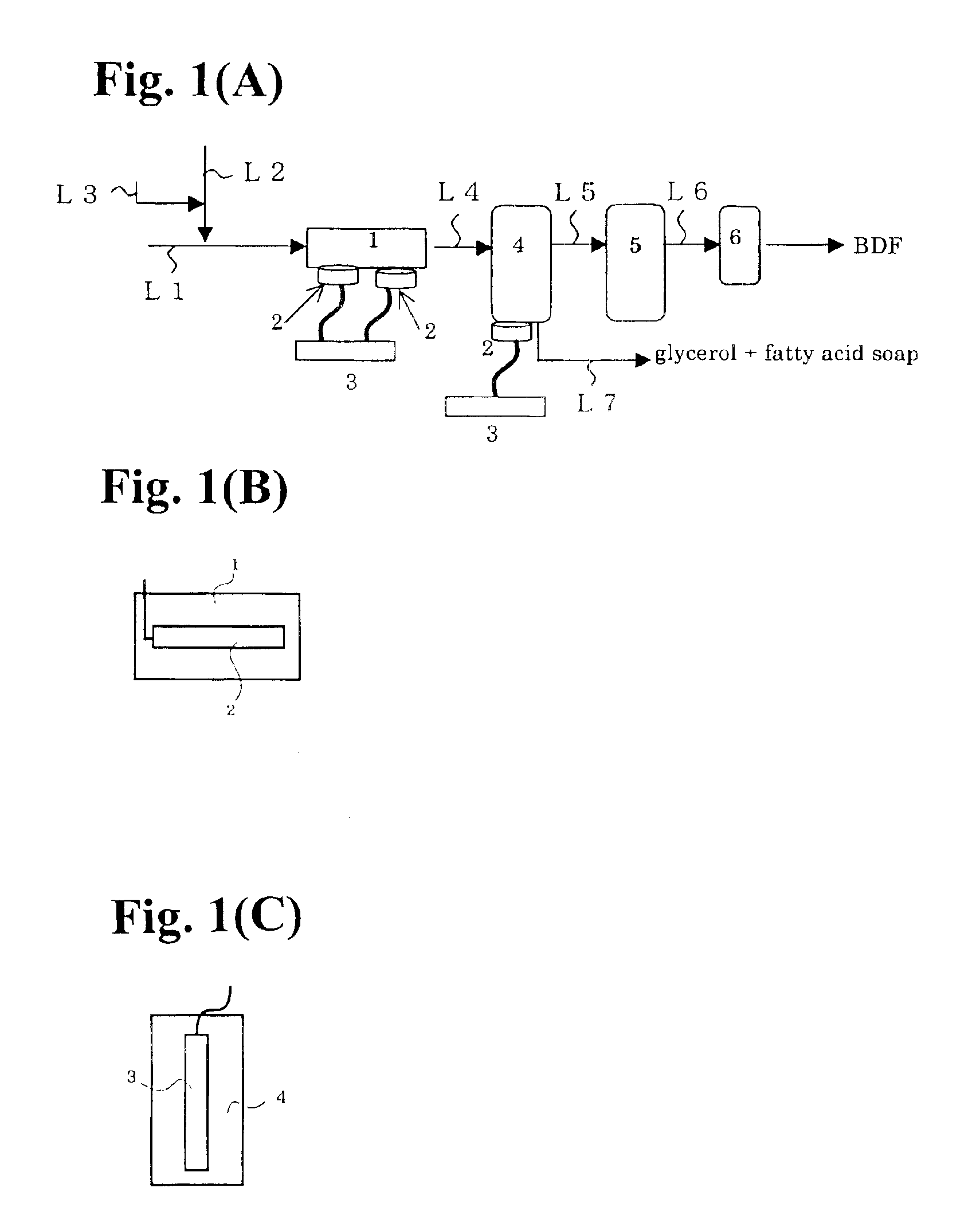

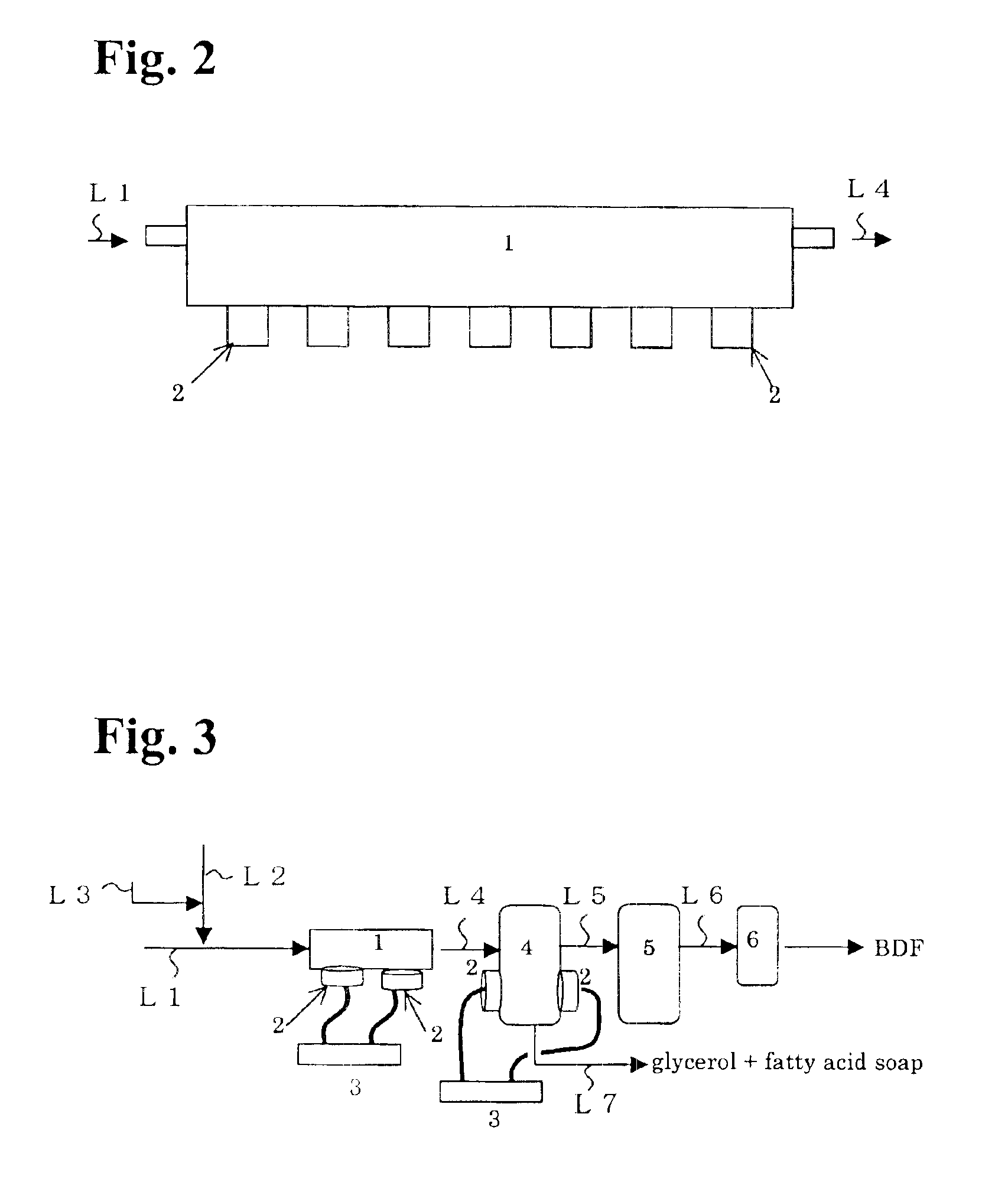

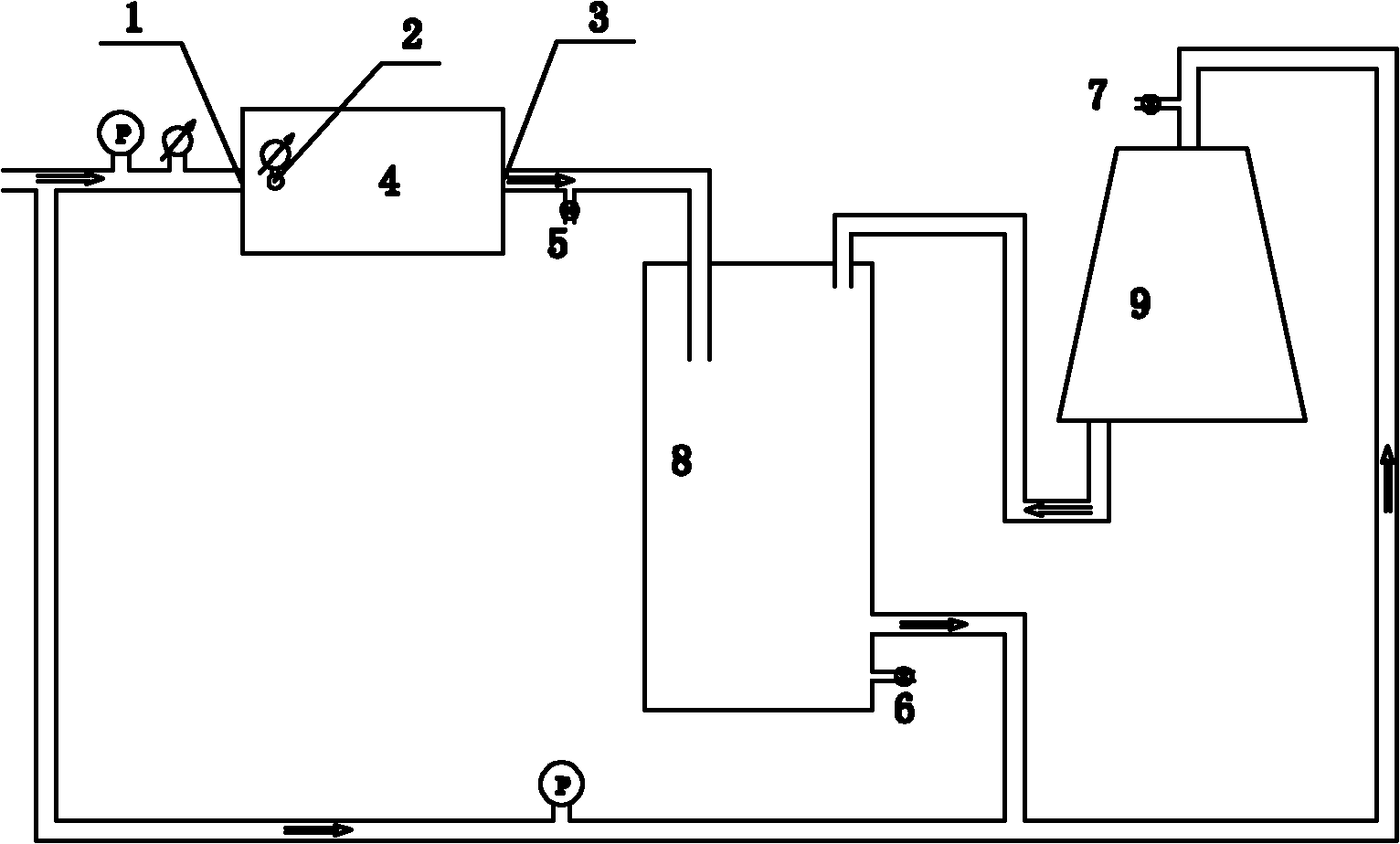

Method for producing fatty acid alcohol ester

InactiveUS6884900B2Efficient productionImprove reaction efficiencyFatty oils/acids recovery from wasteFatty acid esterificationAlcoholGlycerol

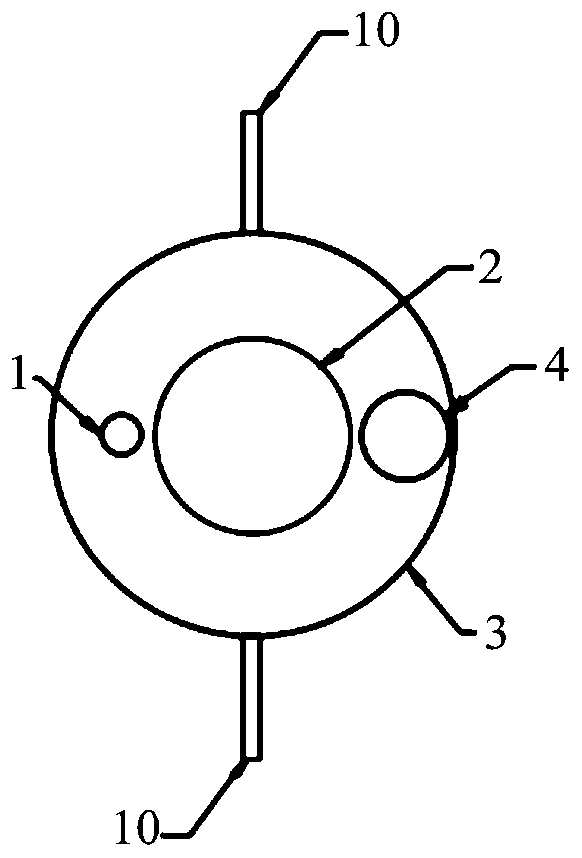

There is provided a method for producing fatty acid alcohol ester useful as a substitute fuel for light oil in which an ester interchange reaction between fats or oils and alcohol is carried out in a reactor 1 by applying ultrasonic irradiation at a frequency of 15 to 100 kHz and irradiation intensity of 0.5 to 20 W / cm2 in the presence of a catalyst, followed by an application of ultrasonic irradiation at a frequency of 200 to 3,000 kHz and irradiation intensity of 0.5 to 20 W / cm2 to the reaction product in a separation tank 4 to separate fatty acid alcohol ester and glycerol. Such ultrasonic irradiation in the separation tank 4 may be applied to an interface between fatty acid alcohol ester and glycerol.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY

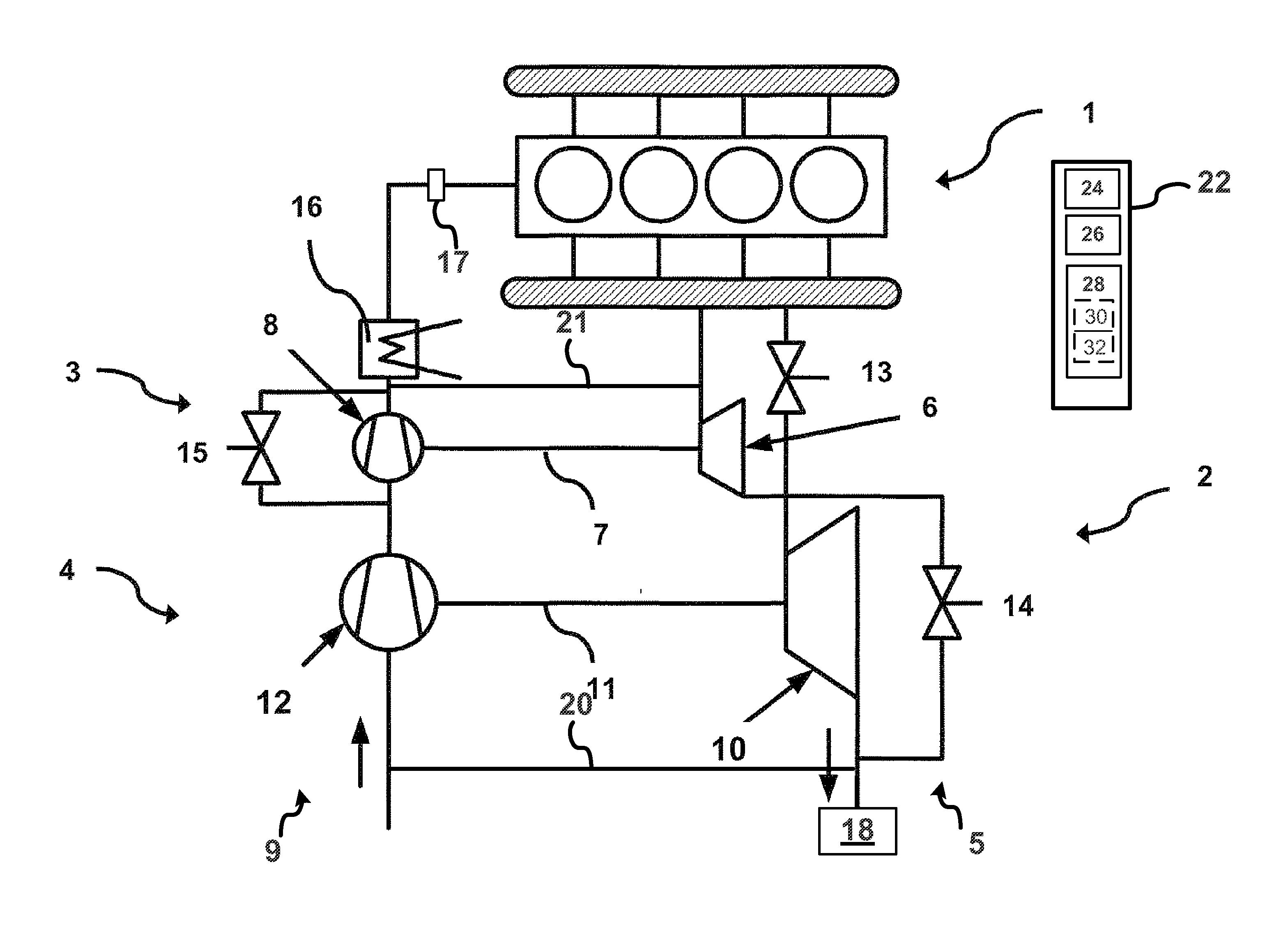

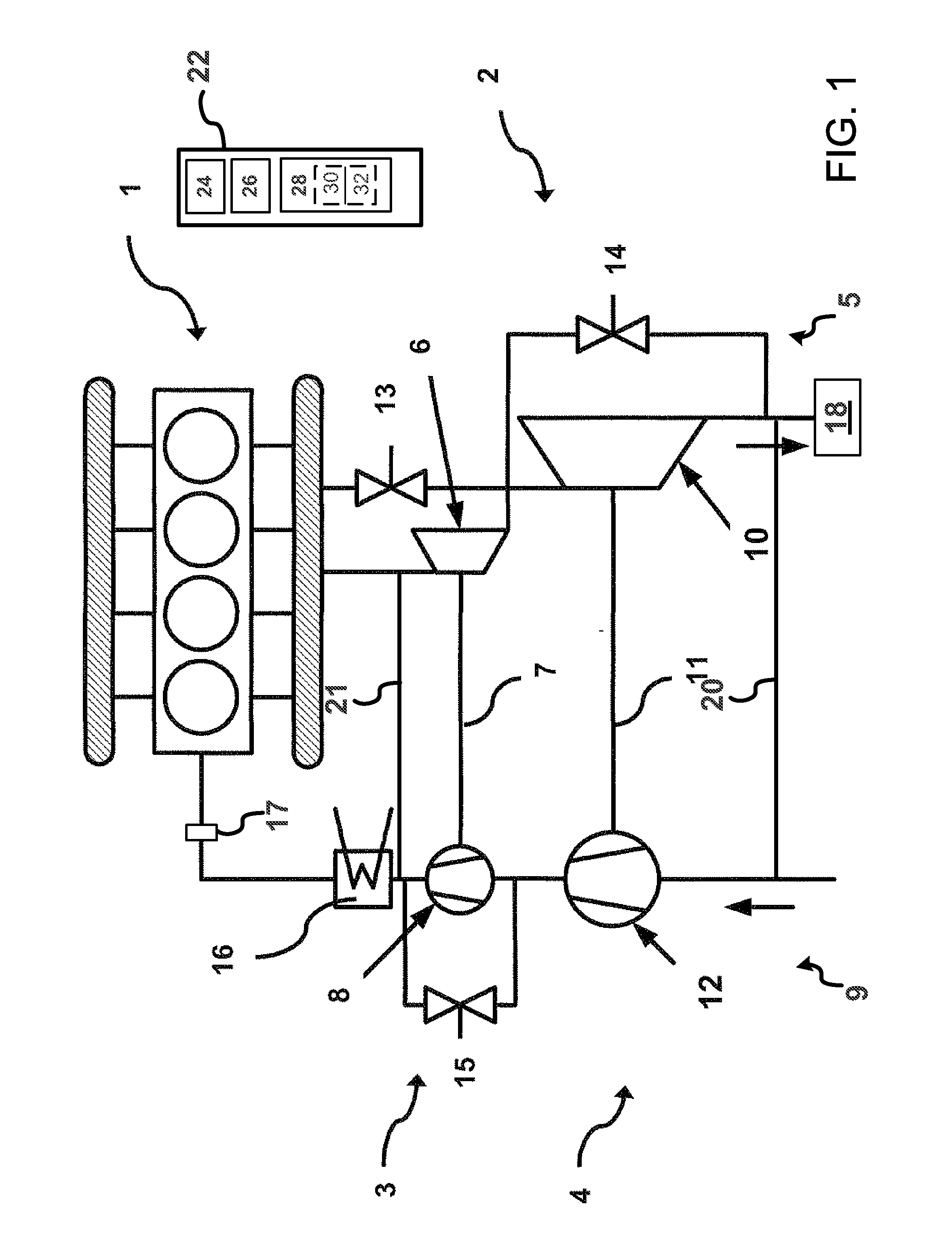

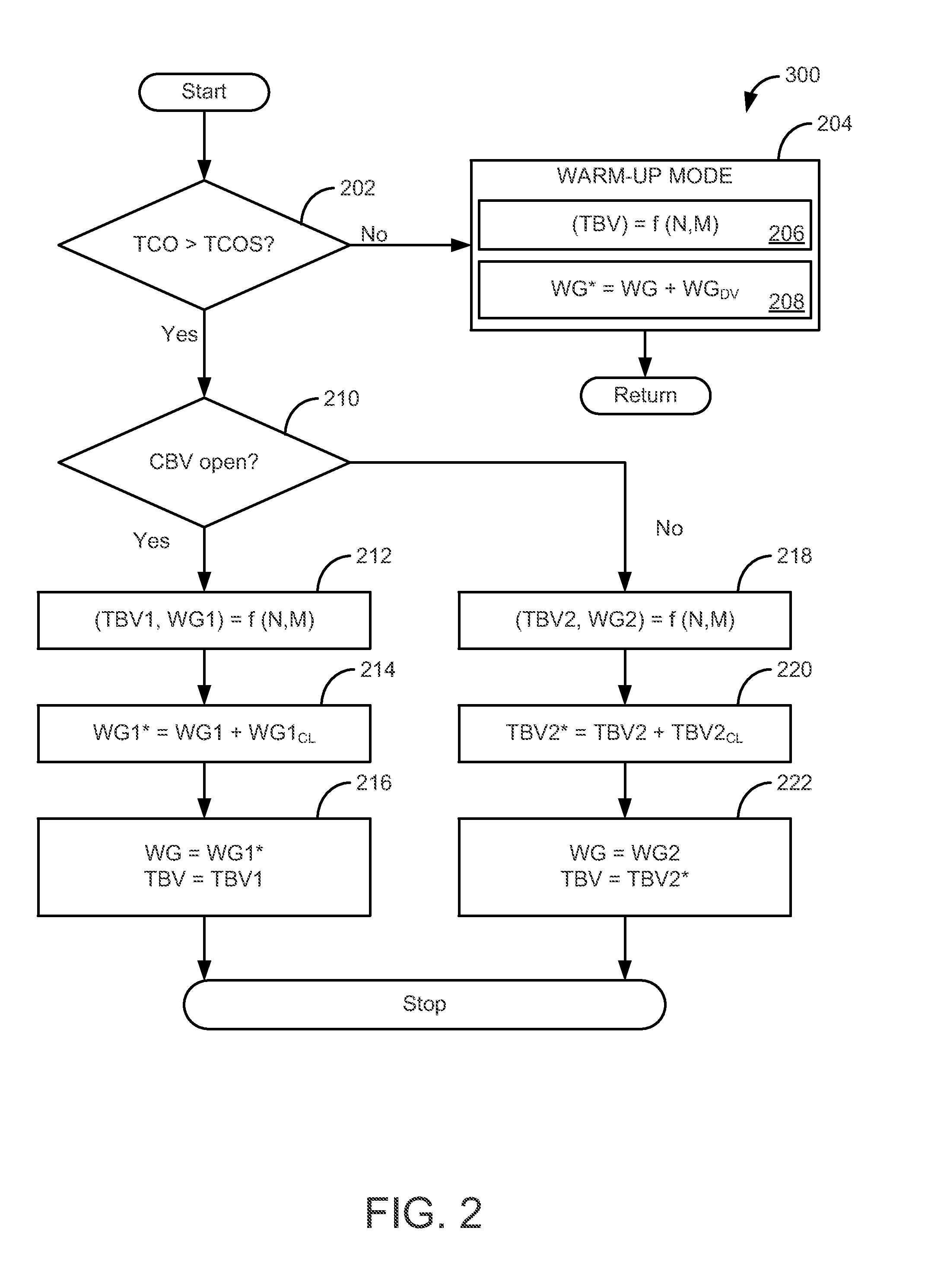

Method for controlling a turbocharger arrangement of an internal combustion engine, and control device

InactiveUS20130006494A1Improve performanceCompact and lightweight designAnalogue computers for vehiclesElectrical controlExternal combustion engineTurbocharger

Embodiments for controlling exhaust gas turbines are provided. In one embodiment, a method for controlling a turbocharger arrangement of an internal combustion engine, the turbocharger arrangement having at least a first exhaust-gas turbine and a second exhaust-gas turbine arranged downstream of the first, and an exhaust-gas aftertreatment system being arranged downstream of the second exhaust-gas turbine comprises, in a warm-up mode, controlling at least one exhaust-gas turbine so as to increase an inlet temperature of an exhaust-gas flow at the inlet into the exhaust-gas aftertreatment system. In this way, the exhaust-gas aftertreatment system may be rapidly heated.

Owner:FORD GLOBAL TECH LLC

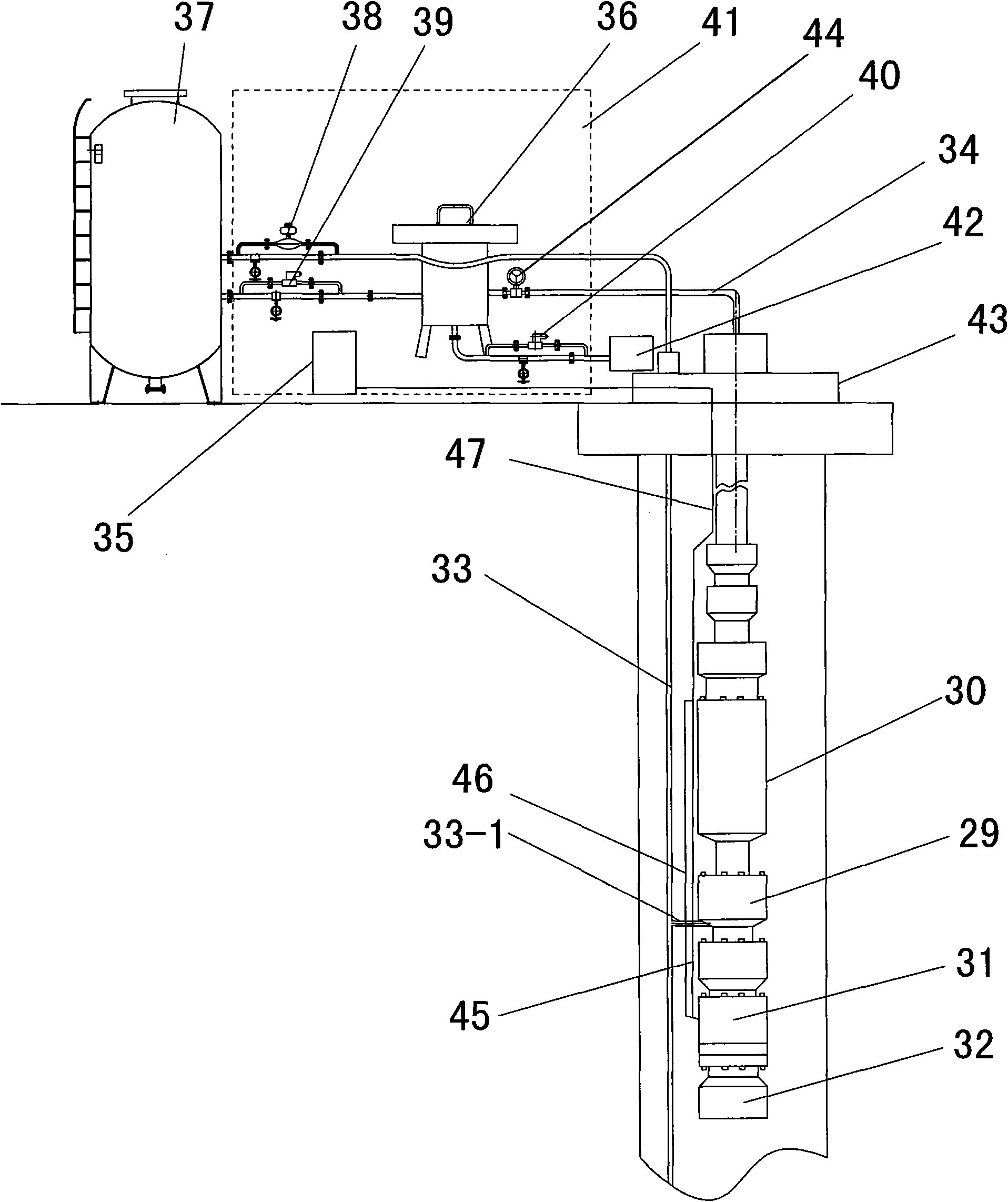

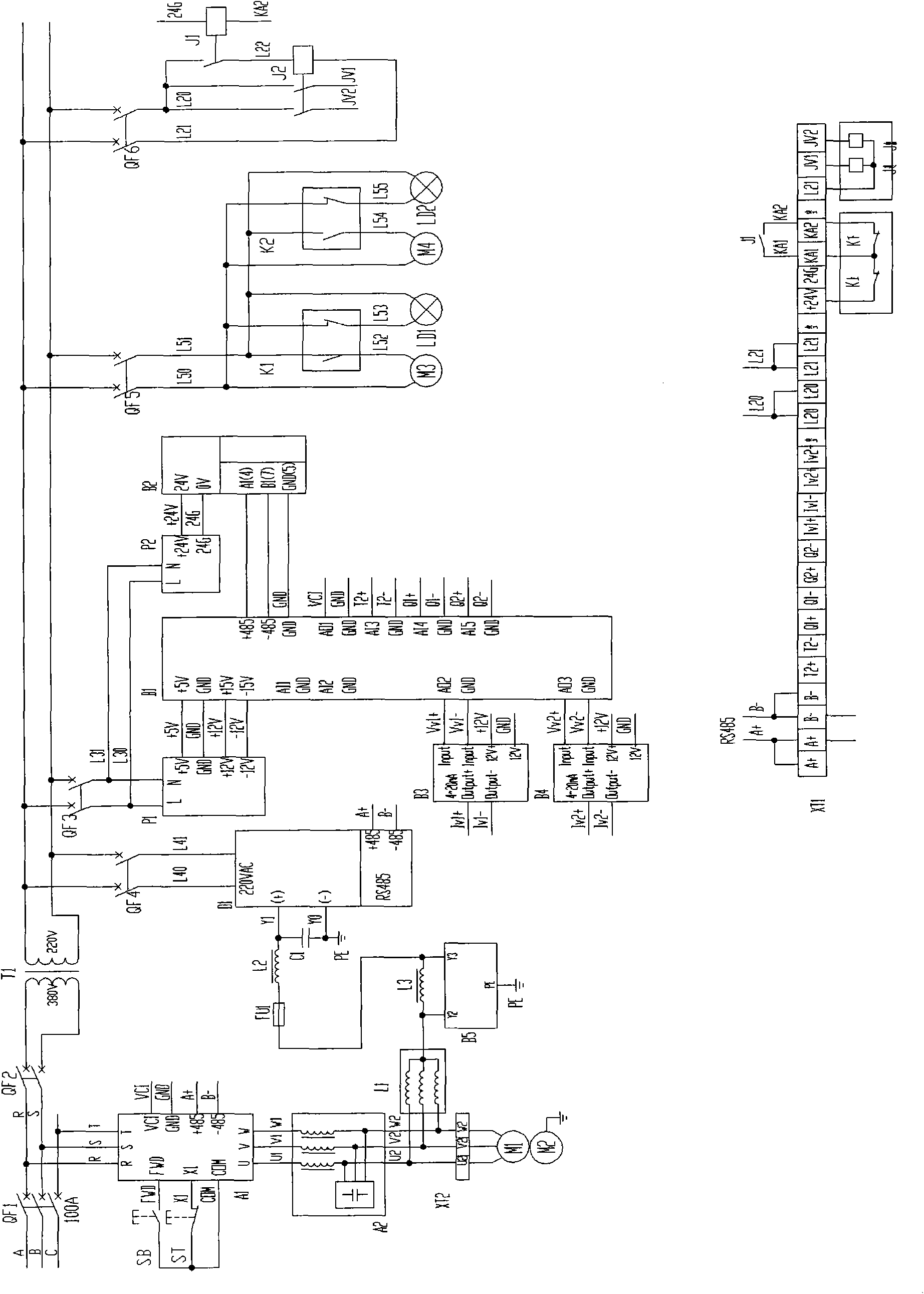

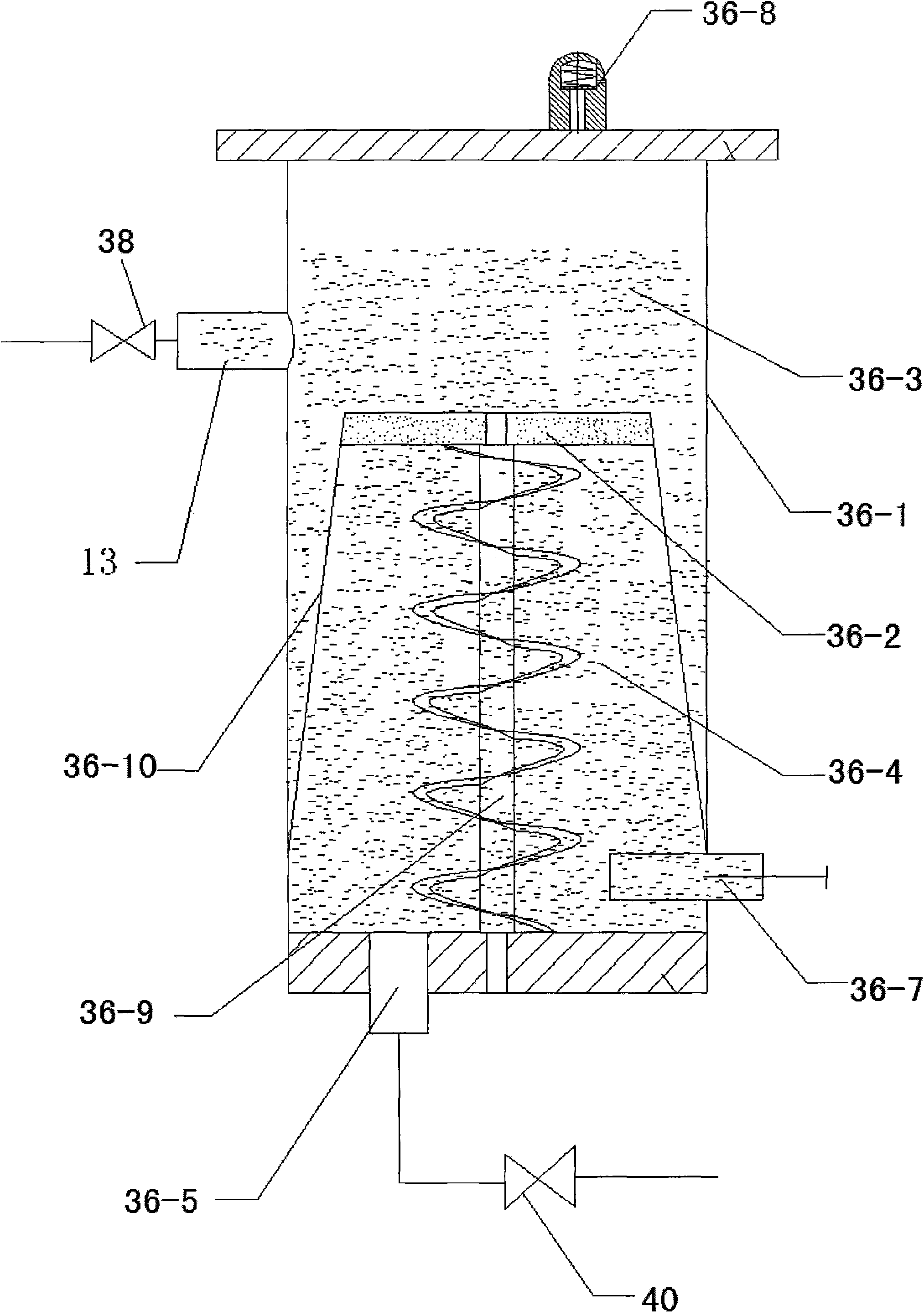

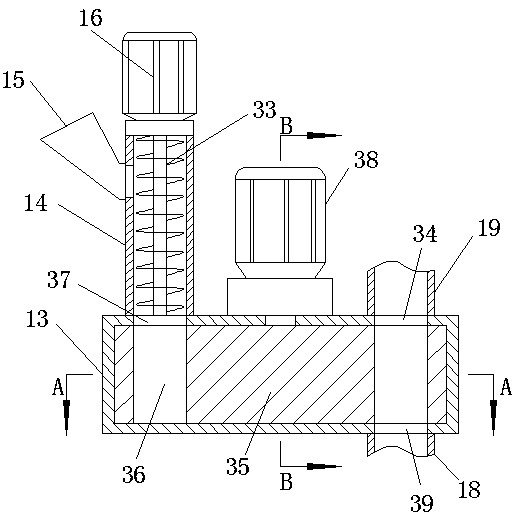

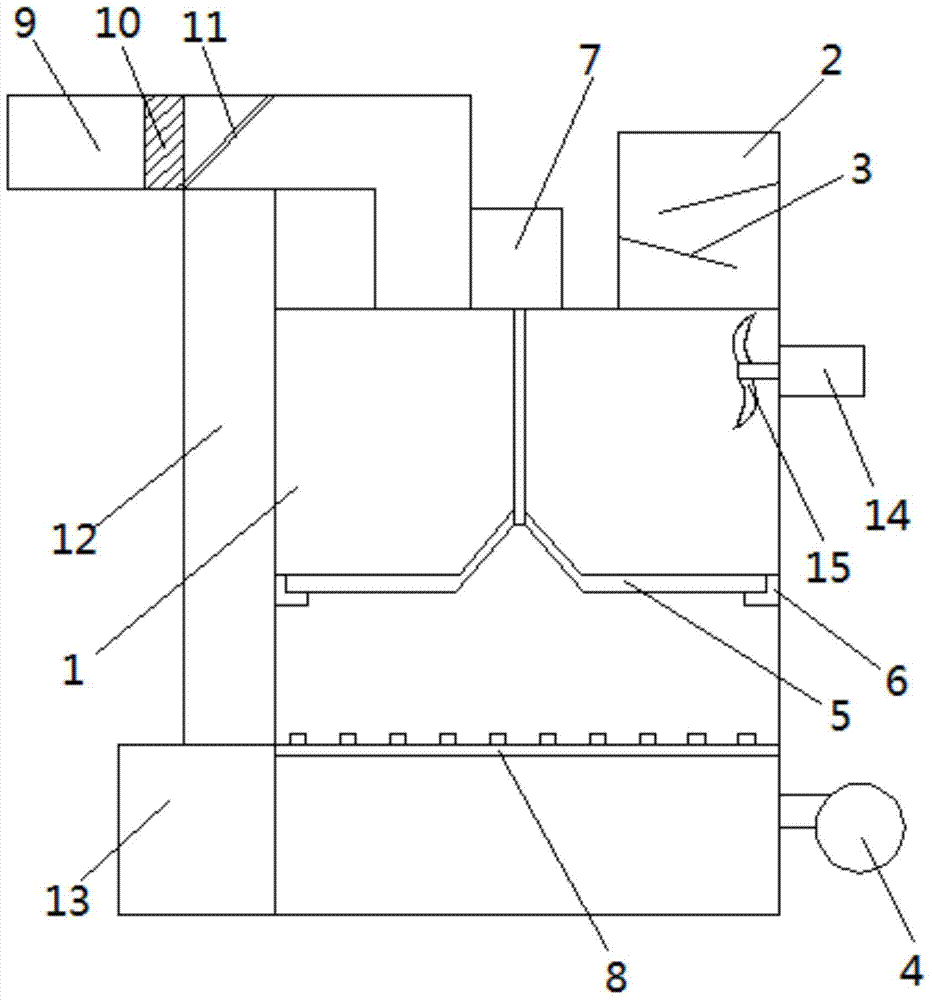

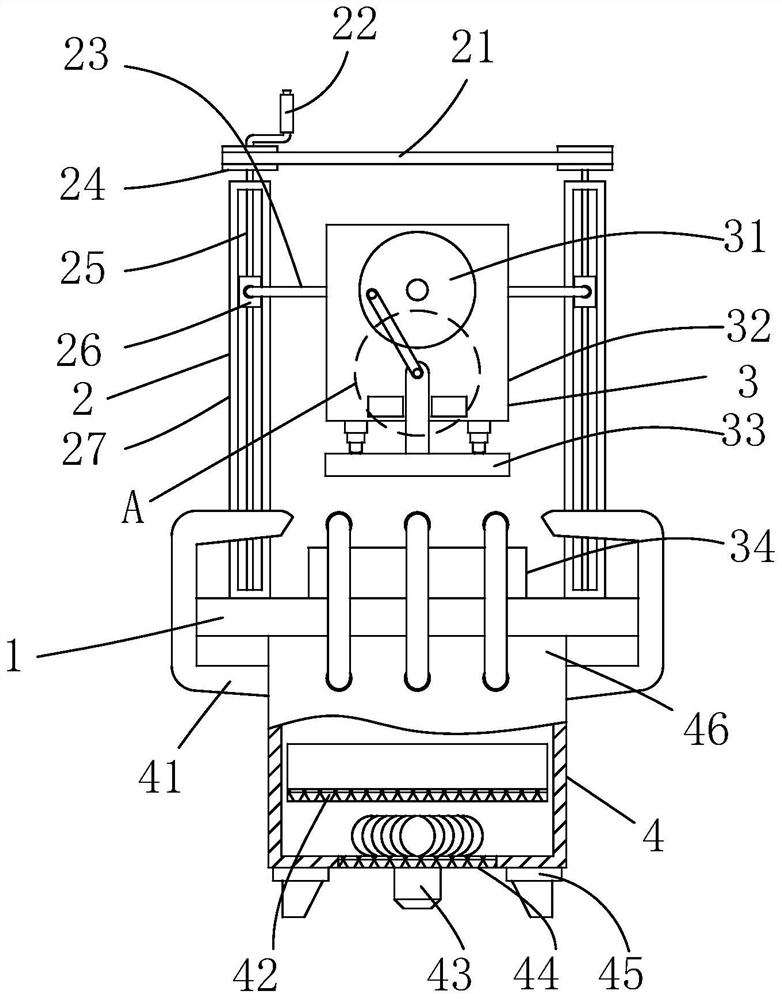

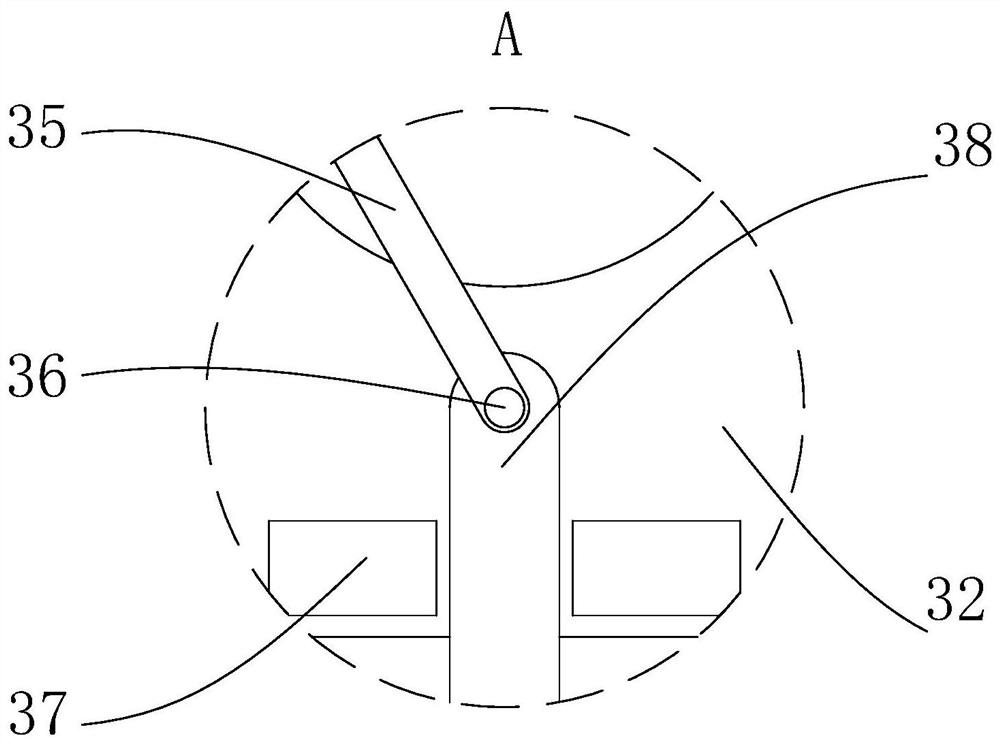

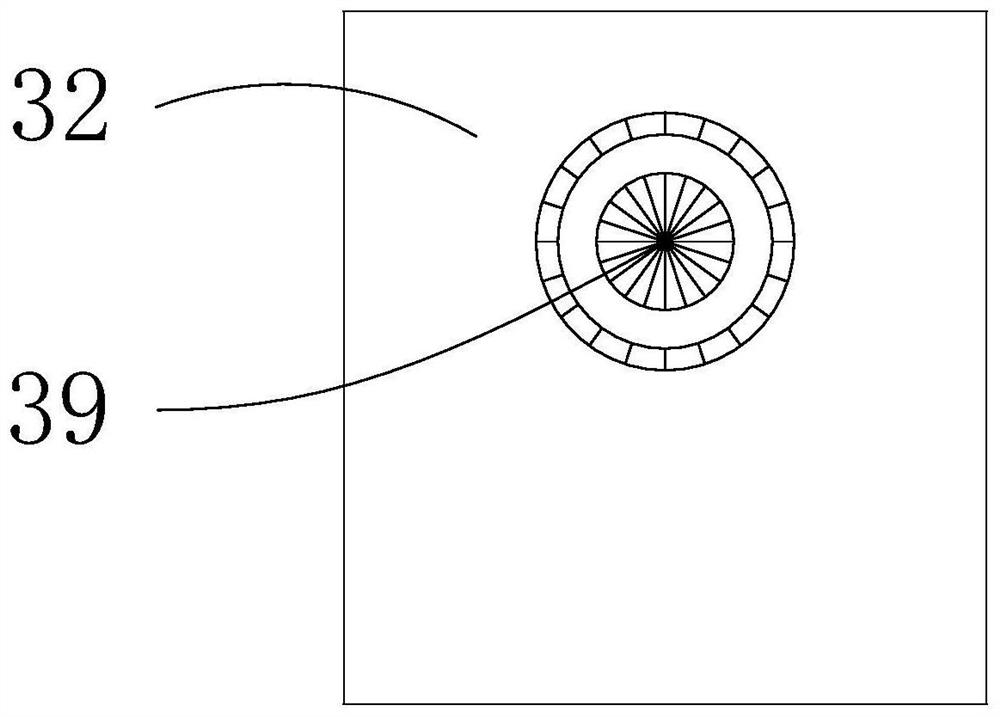

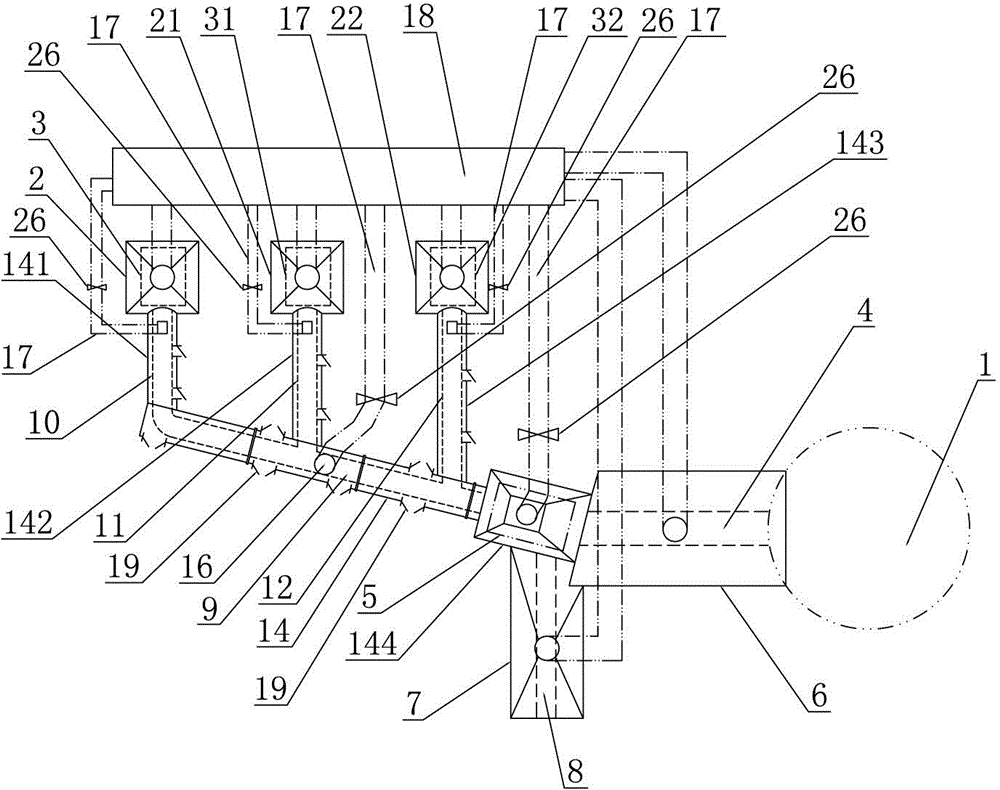

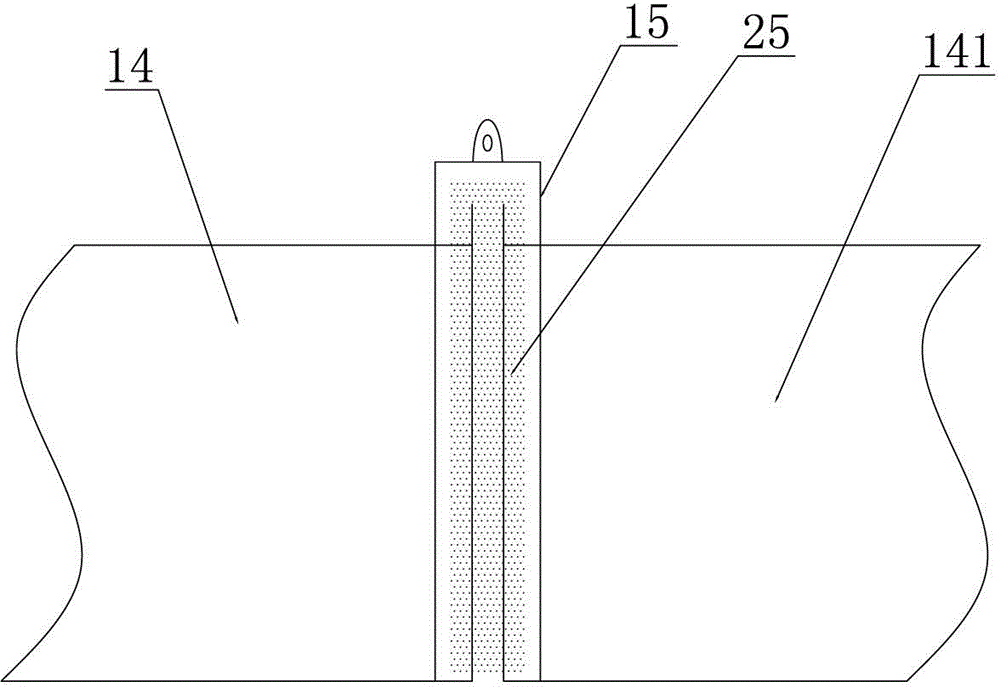

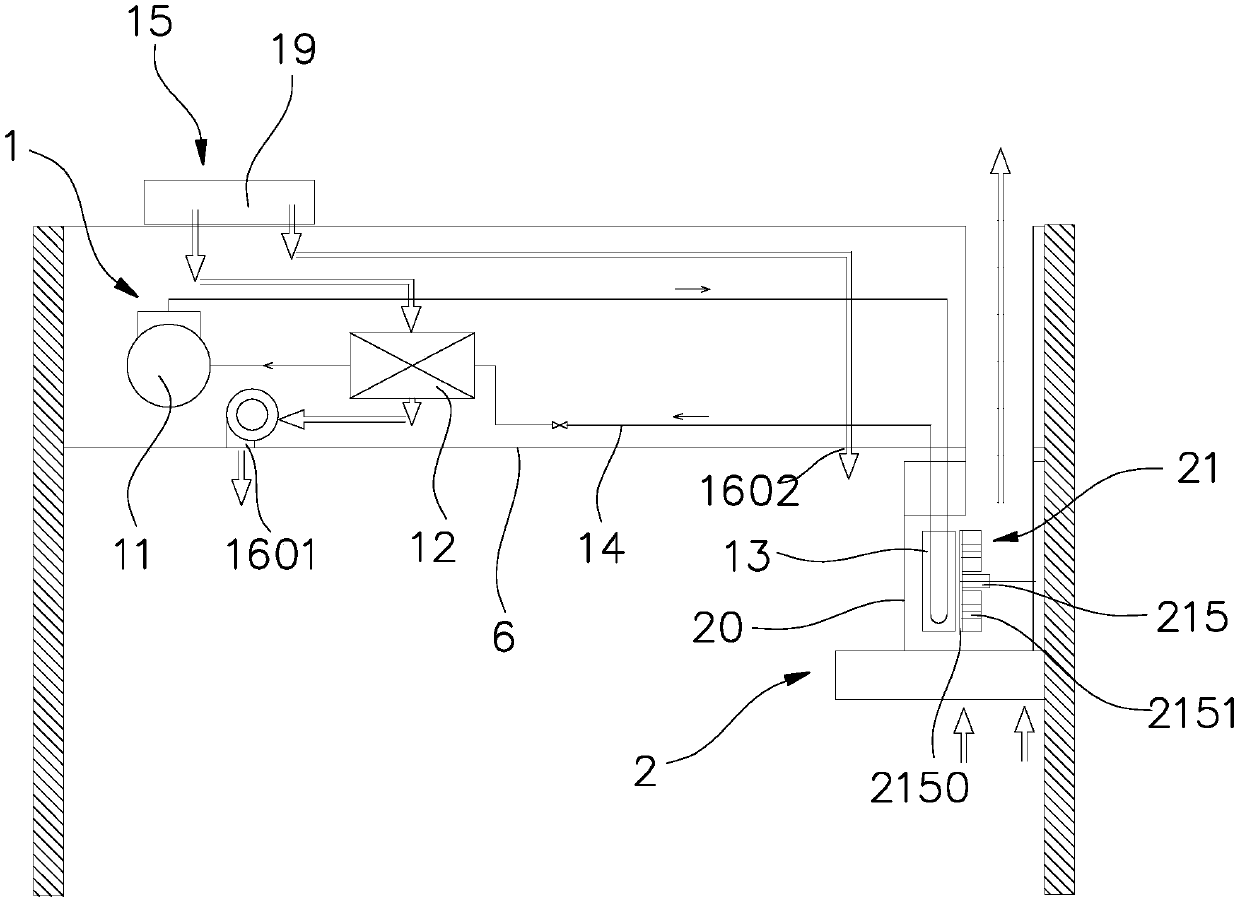

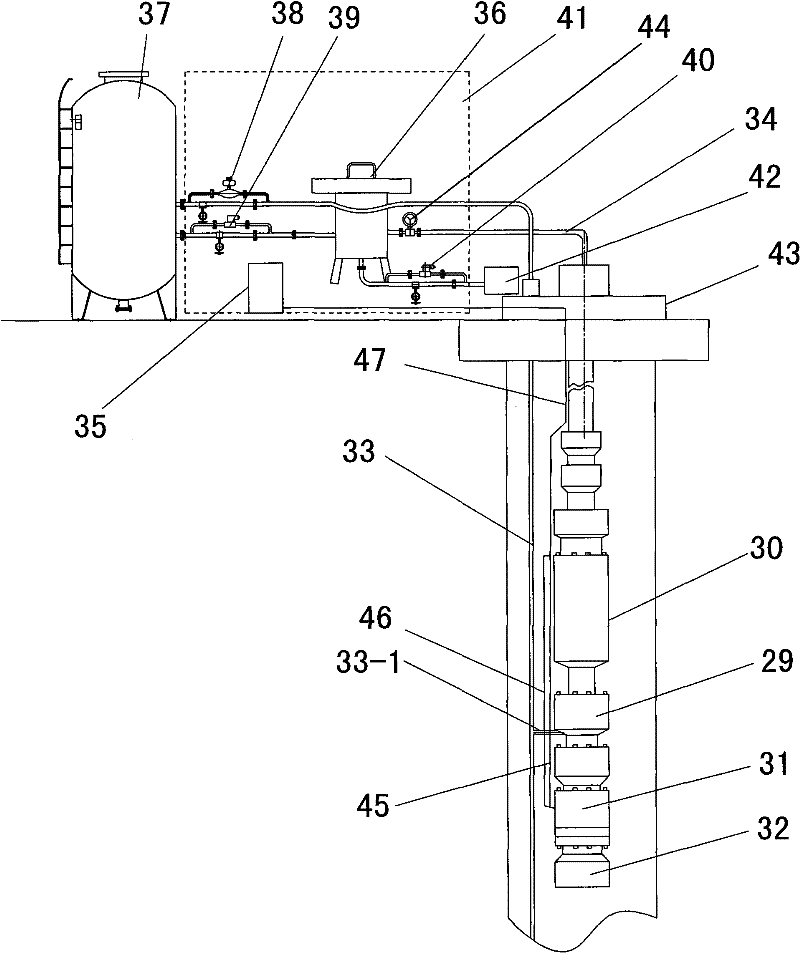

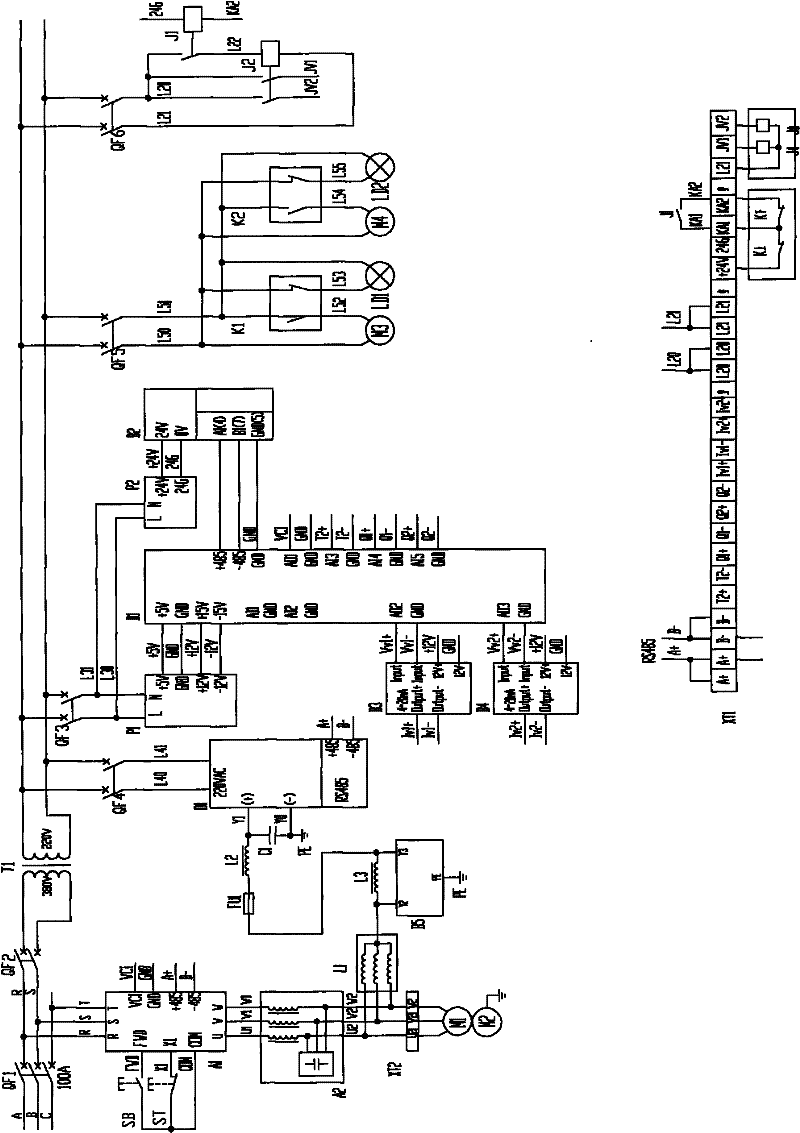

Intelligent drainage and mining method of coalbed methane well and intelligent drainage and mining equipment of coalbed methane well immersed pump

InactiveCN101666223ASolution conditionsSolve the problem that the liquid is viscous and easy to jam the pump and burn the pumpFlexible member pumpsFluid removalWater qualityStreamflow

The invention discloses an intelligent drainage and mining method of a coalbed methane well and intelligent drainage and mining equipment of a coalbed methane well immersed pump. The intelligent drainage and mining method is realized as follows: in the pumping and sucking process, liquid the water quality of which confirms to requirements is supplied for underground liquid by a set flux when a liquid replenishing condition is met so that the height and the descent speed of an underground liquid level as well as the viscidity and the output of the underground liquid all confirms to the normal drainage and mining requirement. The drainage and mining equipment comprises a drainage and a water replenishing device; the water replenishing device consists of a water supply device and a water replenishing pipe, wherein the water supply flow of the water supply device is controlled by a control cabinet, the water replenishing pipe is connected with a water outlet of the water supply device, andthe outlet of the water replenishing pipe is arranged near an underground immersed pump. The intelligent drainage and mining method and equipment can continuously replenish, release and drain liquidaccording to the well condition, thereby solving the problems that a submergible motor is easy to burn out due to deteriorative radiating condition and the pump is easy to clamp and burn due to viscidliquid under the conditions that the liquid supply of a coalbed methane reservoir is lowered, the coal ash content of liquid is increased and the tonnage is lower; in addition, the periods for sand bailing and pump inspection are prolonged.

Owner:濮阳市鑫益实业有限公司

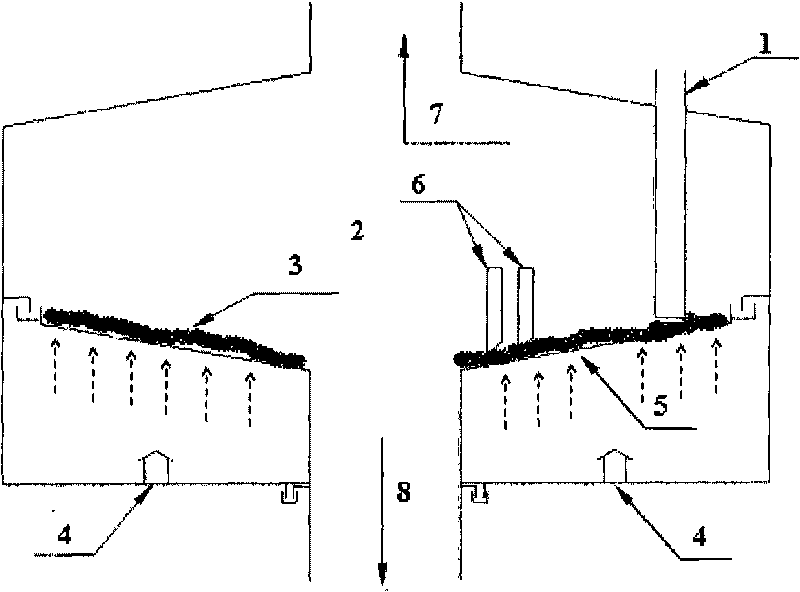

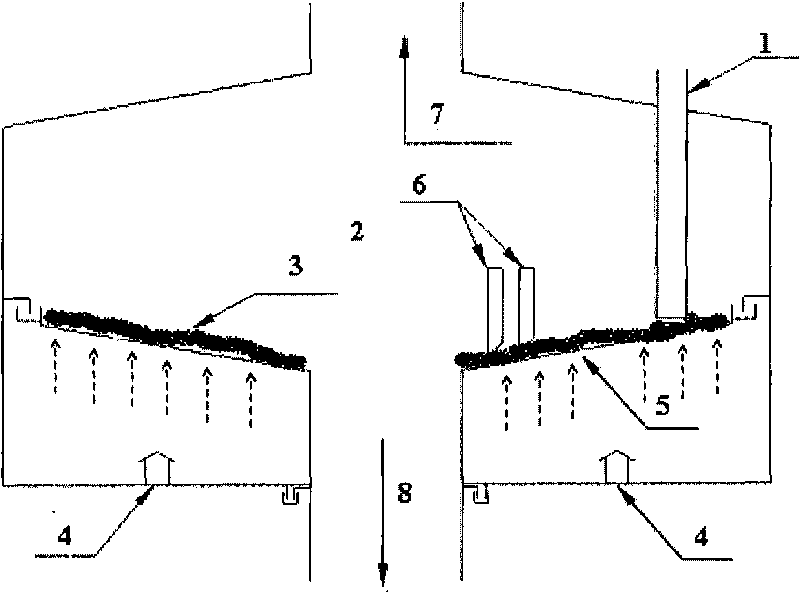

Process for upgrading low-rank coal in an internally heating way with heated gas carrier

InactiveCN101701158ALower energy consumption ratioImprove thermal efficiencyDirect heating destructive distillationSolid fuelsFlue gasProduct gas

The invention discloses a process for upgrading low-rank coal in an internally heating way with the heated gas carrier, comprising the following steps: (1) the crushed and screened raw coal is added to a rotating furnace grate arranged at the bottom of a reactor through a raw coal feeding elephant trunk; (2) hypoxic heated gas enters the reactor from a heating gas inlet arranged below the reactor to directly contact the raw coal sample and transfer heat to the raw coal sample through a hole chiseled on the rotating furnace grate, and the hypoxic heated gas and the raw coal sample are dried and subjected to the pyrolysis reaction; and (3) after a certain time of reaction, with the rotation of the rotating furnace grate, the processed raw coal sample is fixed on a plow-type mechanical stirrer which is arranged above the rotating furnace grate and is pushed to a discharge opening, and the tail gases of the heated gas are discharged out of a gas exhausting opening. The invention uses the hypoxic cyclic flue gas as the heat source to distill the low-rank coal and ensures that the hypoxic cyclic flue gas directly exchanges heat with the solid low-rank coal, thereby having high thermal efficiency and low energy consumption ratio. In addition, the invention has low requirement for the size of the granules of the processed low-rank coal and wide application range and can effectively reduce the content of the dust in the tail gases to be good for the transportation of the final product.

Owner:HUNAN HUAYIN ENERGY TECH

Preparation method of clinker-free cement and concrete prepared with same

InactiveCN101037308AStable manufacturingPumping normalSolid waste managementSulfateUltimate tensile strength

The invention discloses a producing method for clinker-free cement and the produced beton thereof, including 90-94 wt.% of industrial waste, 4-10 wt.% of sulfate booster, 0.05-0.15 wt.% of retarder. The invention has the industry aggregate as the primary material, and adopts a simple process of powder mixing which stably produces the clinker-free cement of 60-95MPa by adding sulfate booster and retarder. The beton pumping is normal and not isolated, not bleeding. The cohesiveness, compactibility and strength are high. It may fully utilize the solid wastes and reduce to discharge the atmosphere pollution.

Owner:北京东方建宇混凝土科学技术研究院有限公司

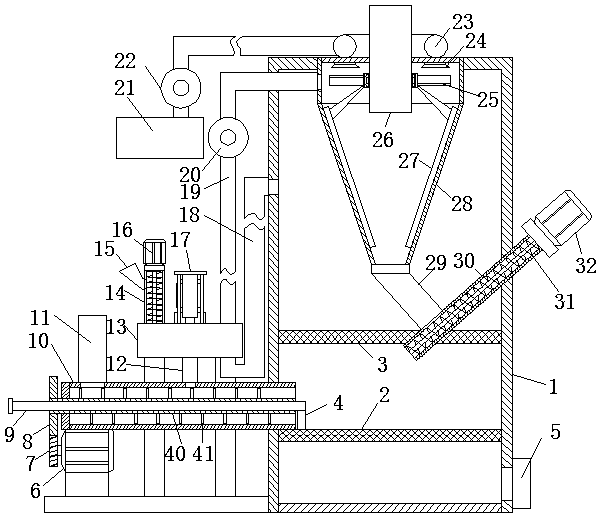

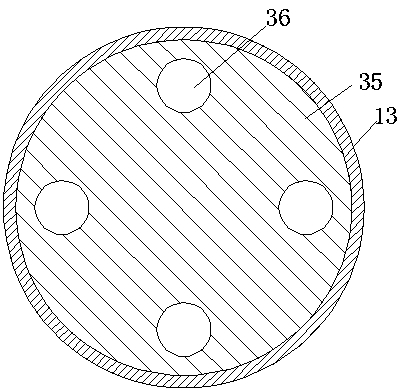

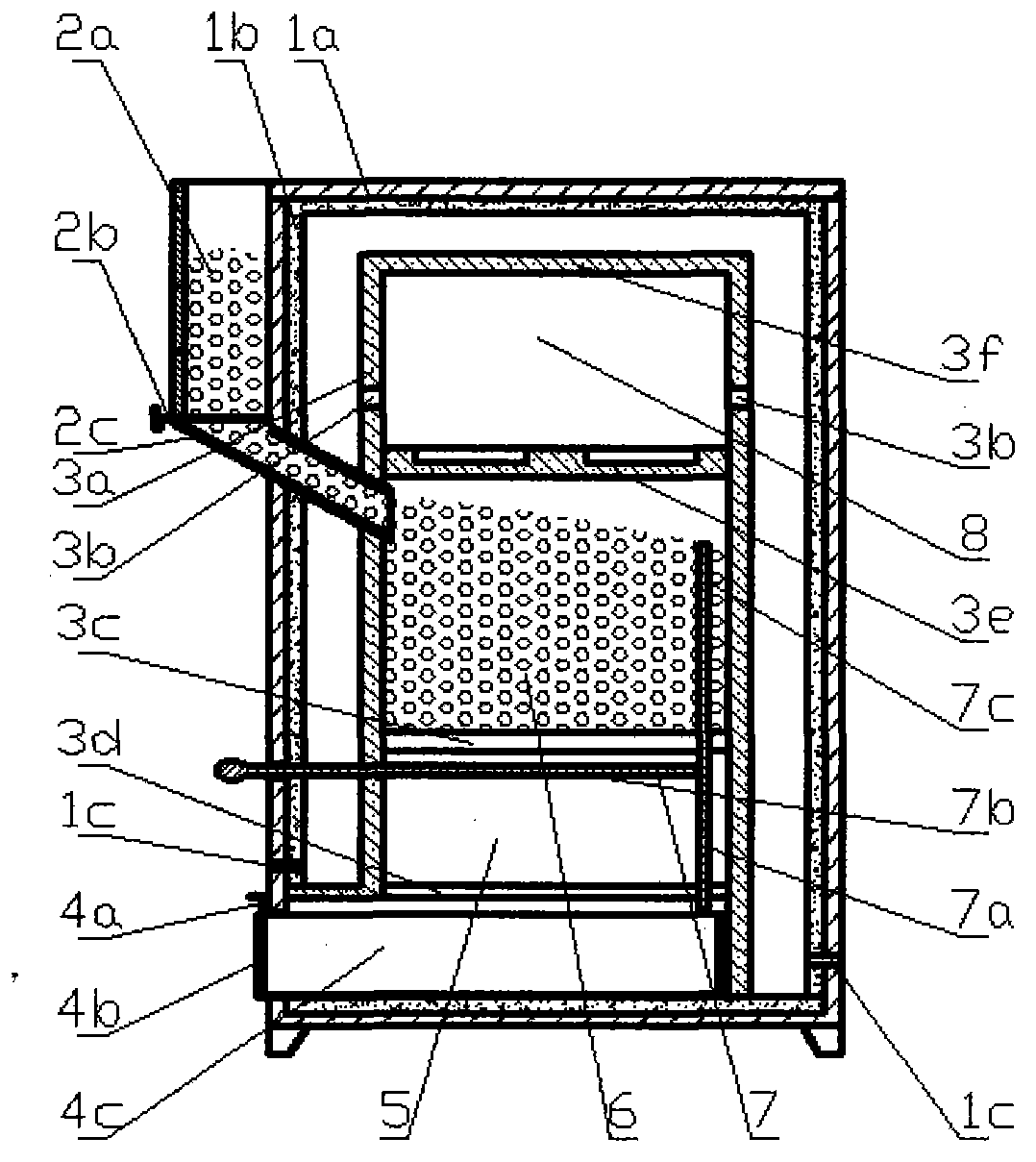

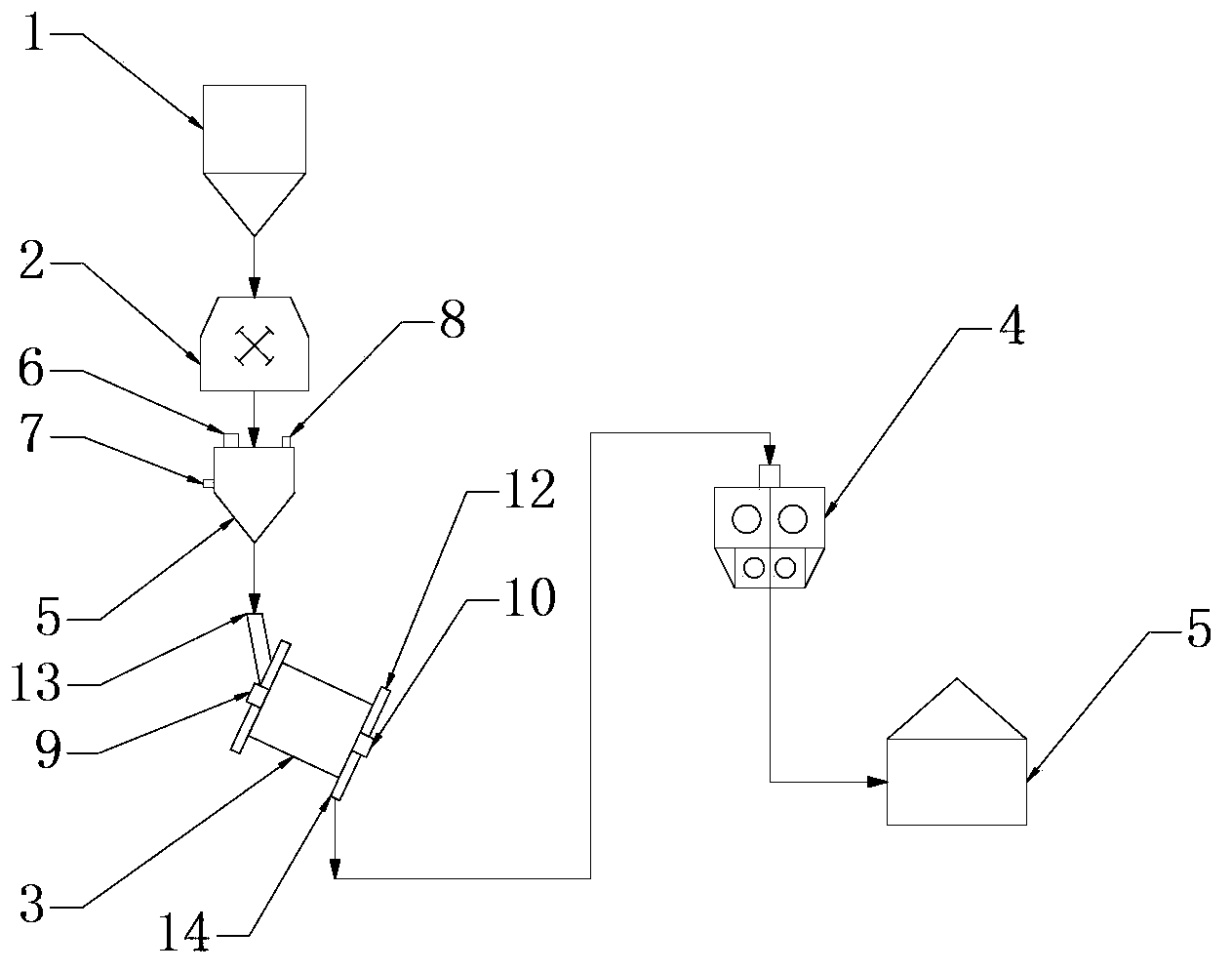

Composite biomass staged gasification furnace

The invention relates to the technical field of gasification furnaces, and in particular to a composite biomass staged gasification furnace. The furnace comprises a furnace body; a fire grate is fixedon the side wall of the lower part in the furnace body; a space below the fire grate is a slag cavity; an ash discharge port is formed in the side wall of the furnace body corresponding to the slag cavity; a filter screen is also fixed on the inner wall of the furnace body; the filter screen is positioned above the fire grate; a fine filter is fixed to the top wall of the interior of the furnacebody, a feeding mechanism is fixed to the outer side of the furnace body, a primary filtering mechanism is fixed to the feeding mechanism and connected with the feeding mechanism through a feeding pipe, and the primary filtering mechanism is connected with the upper portion of the side wall of the furnace body and a fine filtering mechanism through a first air pipe and a second air pipe. Accordingto the composite biomass staged gasification furnace, the content of tar and smoke dust in fuel gas is greatly reduced, the fuel gas quality is improved, equipment is protected, the filtered tar is returned to the furnace again to be subjected to high-temperature cracking to generate small molecular fuel gas, then the fuel gas generation efficiency is improved again, and the tar generation amountis reduced.

Owner:HUNAN INSTITUTE OF ENGINEERING

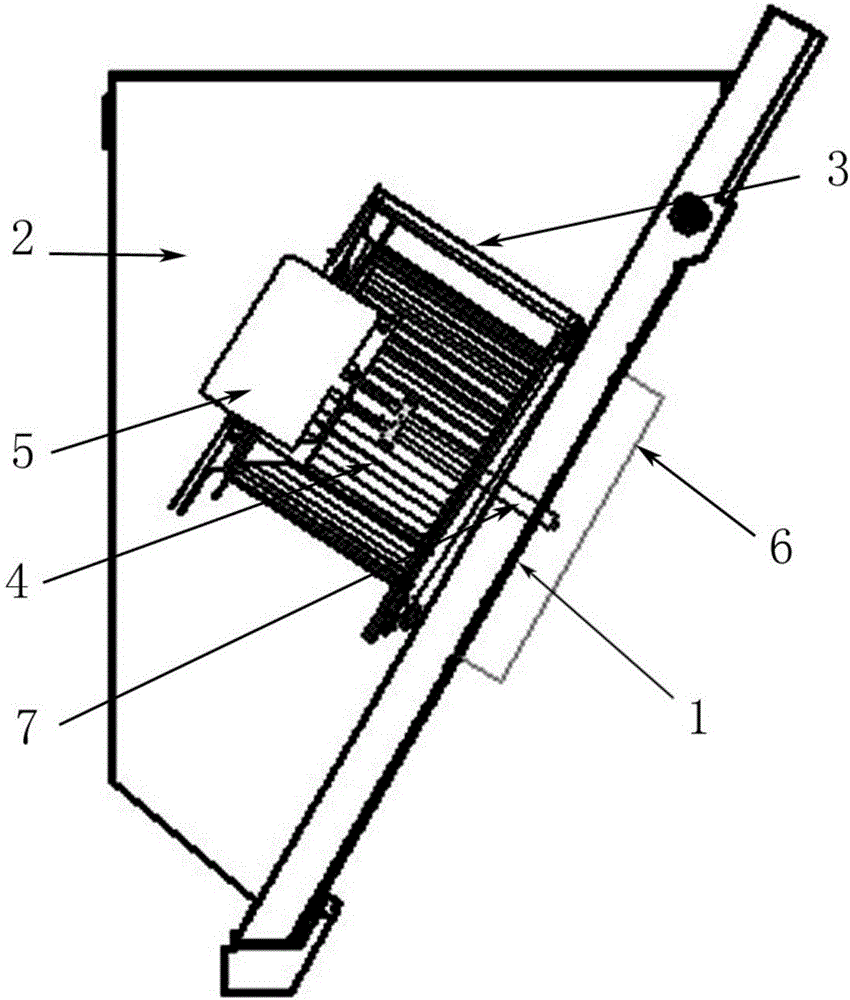

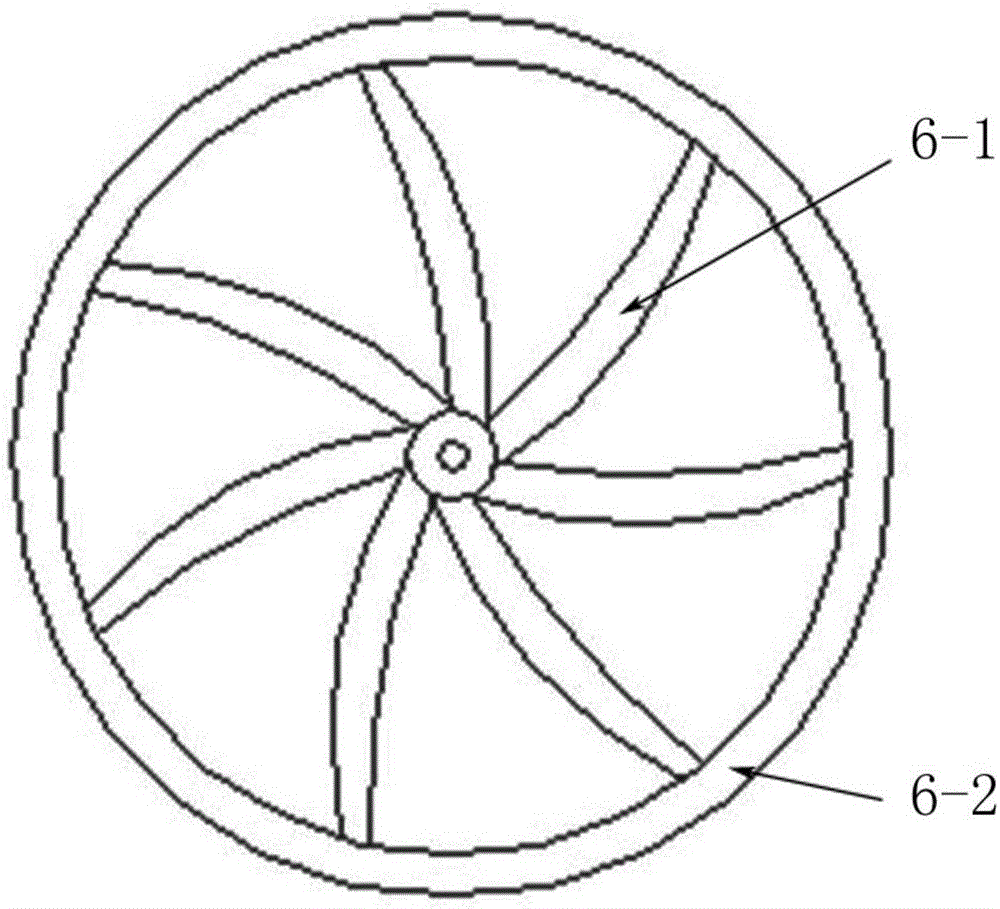

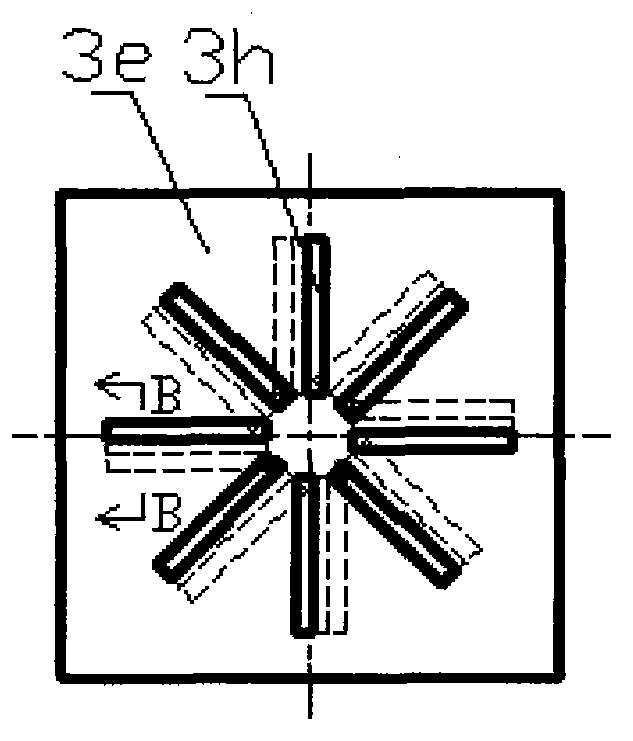

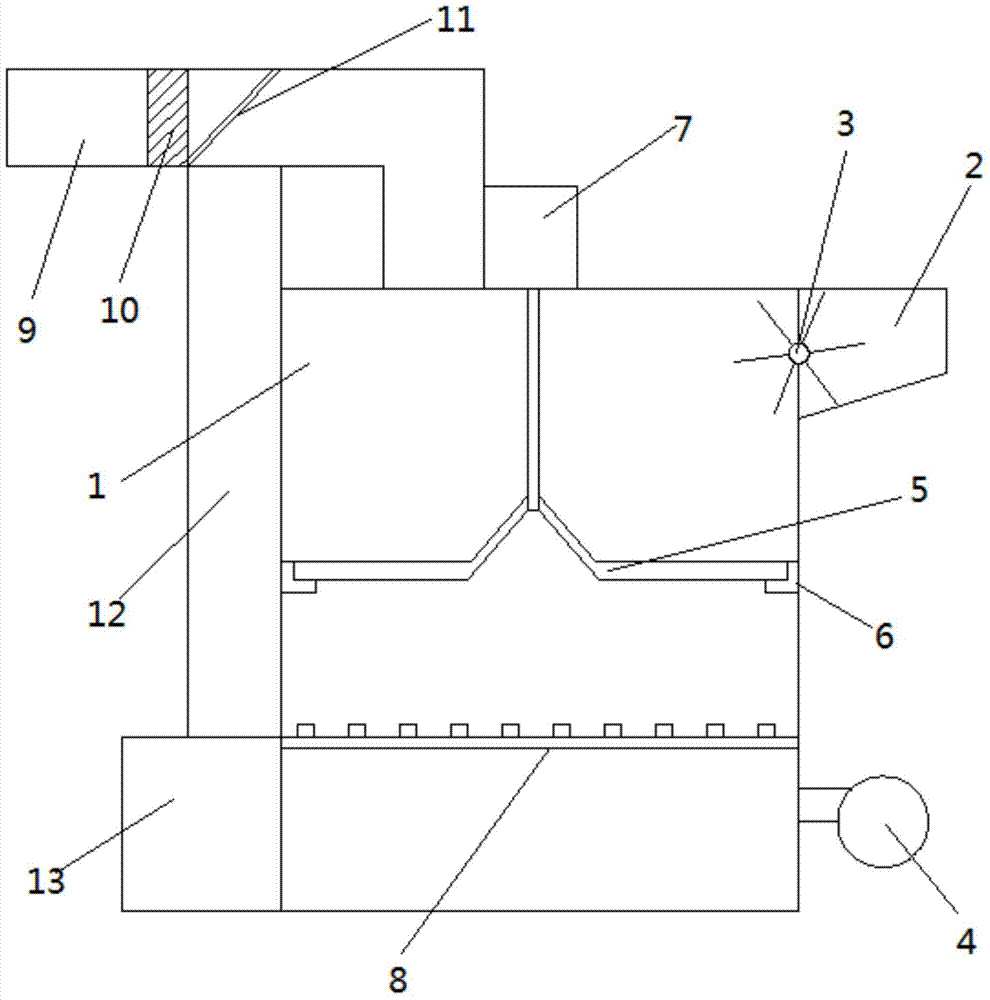

Centrifugal type kitchen ventilator provided with axial fan

InactiveCN106091060AIncrease air volumeExtend your lifeDomestic stoves or rangesLighting and heating apparatusExhaust fumesEngineering

The invention discloses a centrifugal type kitchen ventilator provided with an axial fan. The centrifugal type kitchen ventilator comprises an exhaust fume collecting hood, a volute mounted in the exhaust fume collecting hood, a centrifugal type fan mounted in the volute, a motor driving the centrifugal type fan, and an oil-filter screen mounted at an air inlet of the exhaust fume collecting hood and is characterized in that the axial fan is arranged at the air inlet of the exhaust fume collecting hood; and the oil-filter screen blocks the outer side of the axial fan and collects greasy dirt thrown out by the axial fan. When the centrifugal type kitchen ventilator is under operation, the axial fan rotates along with the centrifugal type kitchen ventilator. When lampblack contacts the axial fan, the lampblack is thrown around under the action of centrifugal force, collected by the oil-filter screen, and flows into an oil cup along the oil way, so that the lampblack separating effect of the oil-filter screen is improved, and the supply air rate of the centrifugal type kitchen ventilator is increased at the same time. Compared with the traditional kitchen ventilator, the centrifugal type kitchen ventilator greatly improves the first-time lampblack separating capacity, increases lampblack entering into the kitchen ventilator and decreases the kitchen ventilator cleaning times with fewer cleaning times or even zero cleaning.

Owner:GUANGDONG MACRO GAS APPLIANCE

Biological alcohol ether fuel

InactiveCN101974355AClean combustion exhaust gasReduced soot contentLiquid carbonaceous fuelsFuel oilDiethyl ether

The invention relates to a biological alcohol ether fuel. The biological alcohol ether fuel is totally free from fossil fuel, prepared by combining the biological alcohol ether resource or coal chemical industry alcohol ether resource and biological fatty oil and can replace gasoline, diesel oil, boiler fuel oil and oil for ships. 50-70% of methanol (or ethanol), 20-40% of dimethyl ether (or diethyl ether, methylal and the like), 3-7% of IPB (or isopropanol), 1.27-7.27% of normal butanol, 0.09-0.11% of castor oil, 0.1-0.3% of rape seed oil, 0.005-0.015% of pentafluoride butane, 0.01-0.03% of ferrocene, 200.2-200.6% of tween are added to a pressure vessel and evenly mixed to form a basic alcohol ether fuel, the basic alcohol ether fuel is used as the main raw material to be further blended into the biological alcohol ether fuel which can replace gasoline and diesel oil for vehicles, the boiler fuel oil and the oil for ships according to different uses. The biological alcohol ether fuel is a low-carbon oxygen-containing fuel which features clean combustion gas and obviously reduced soot.

Owner:贾崇新

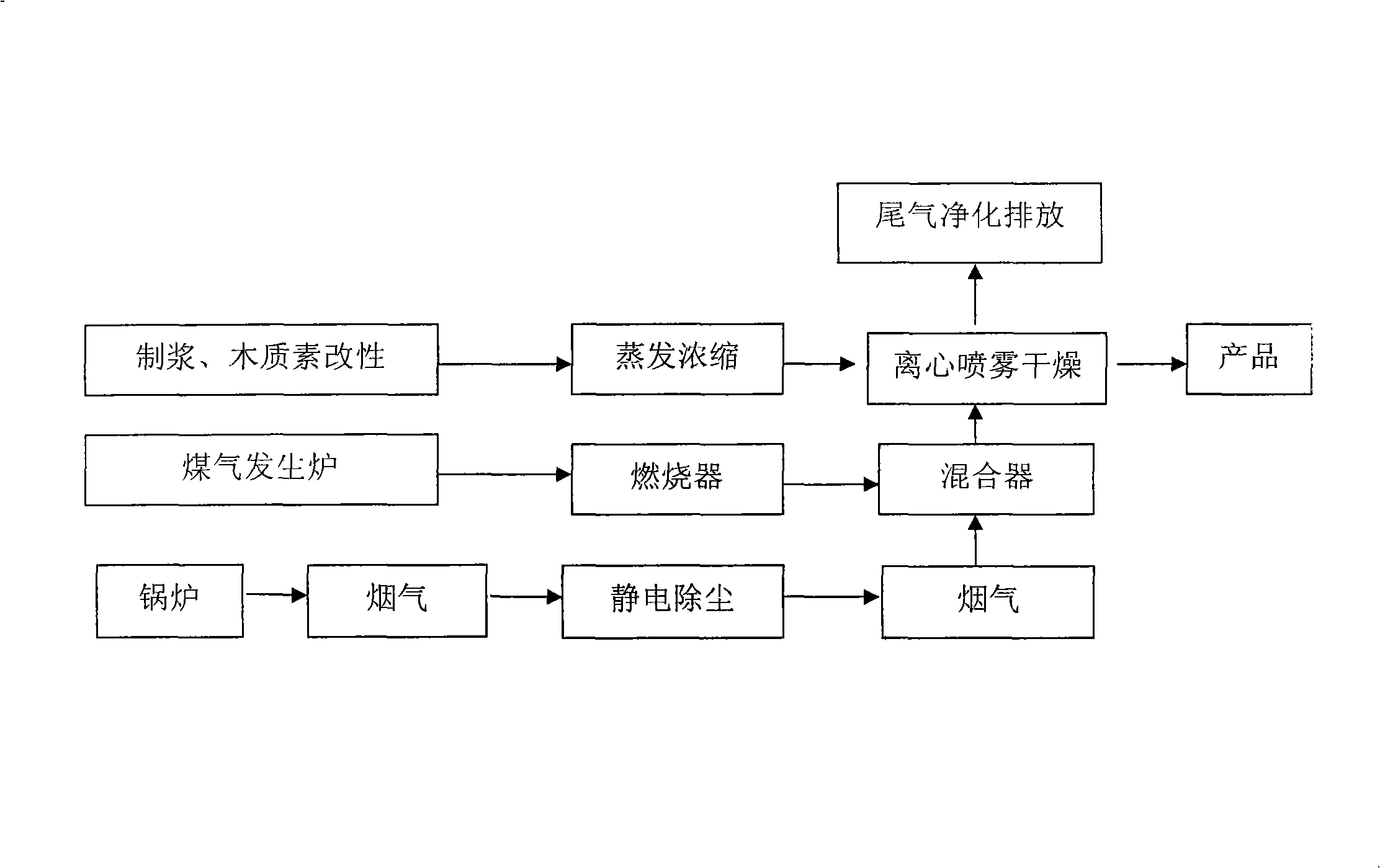

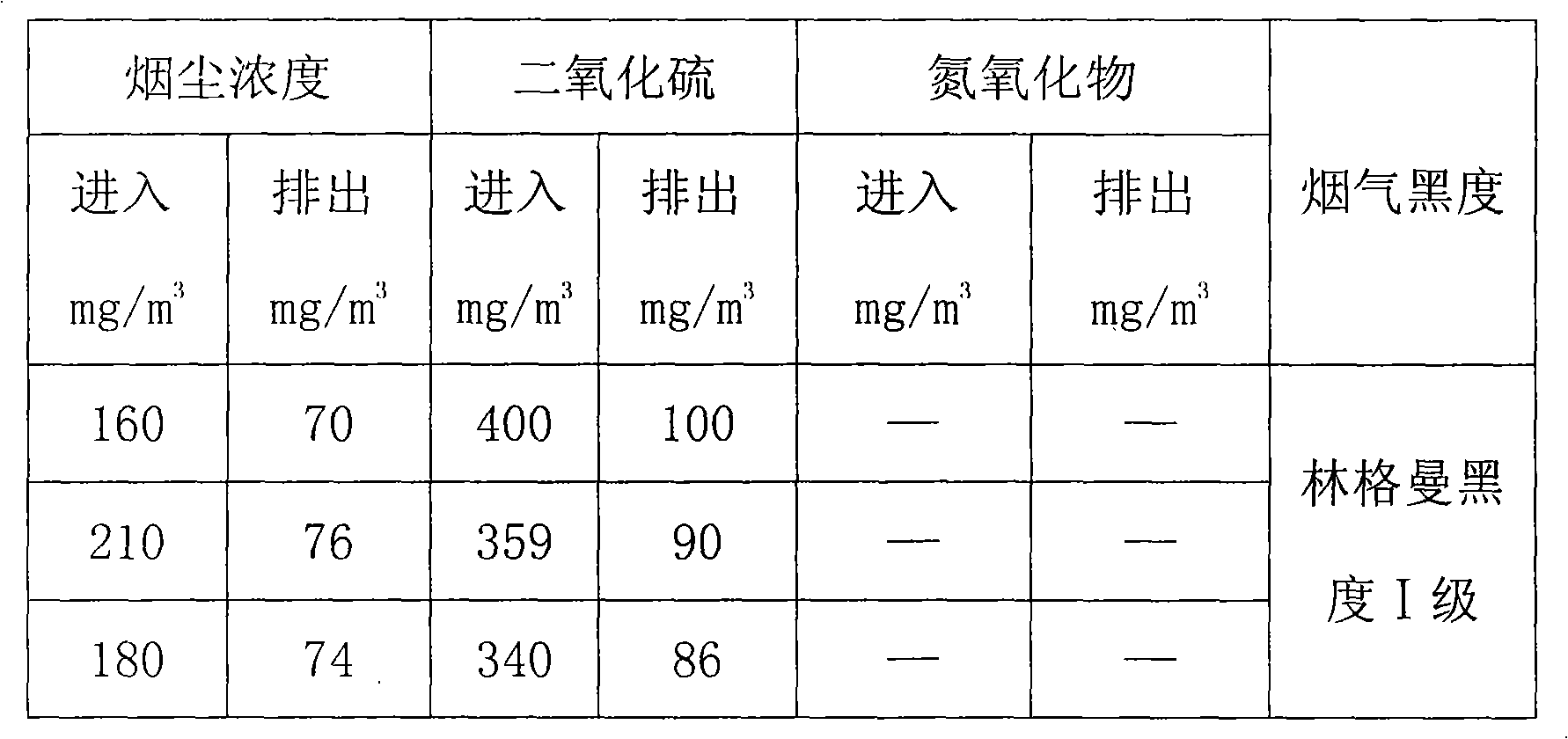

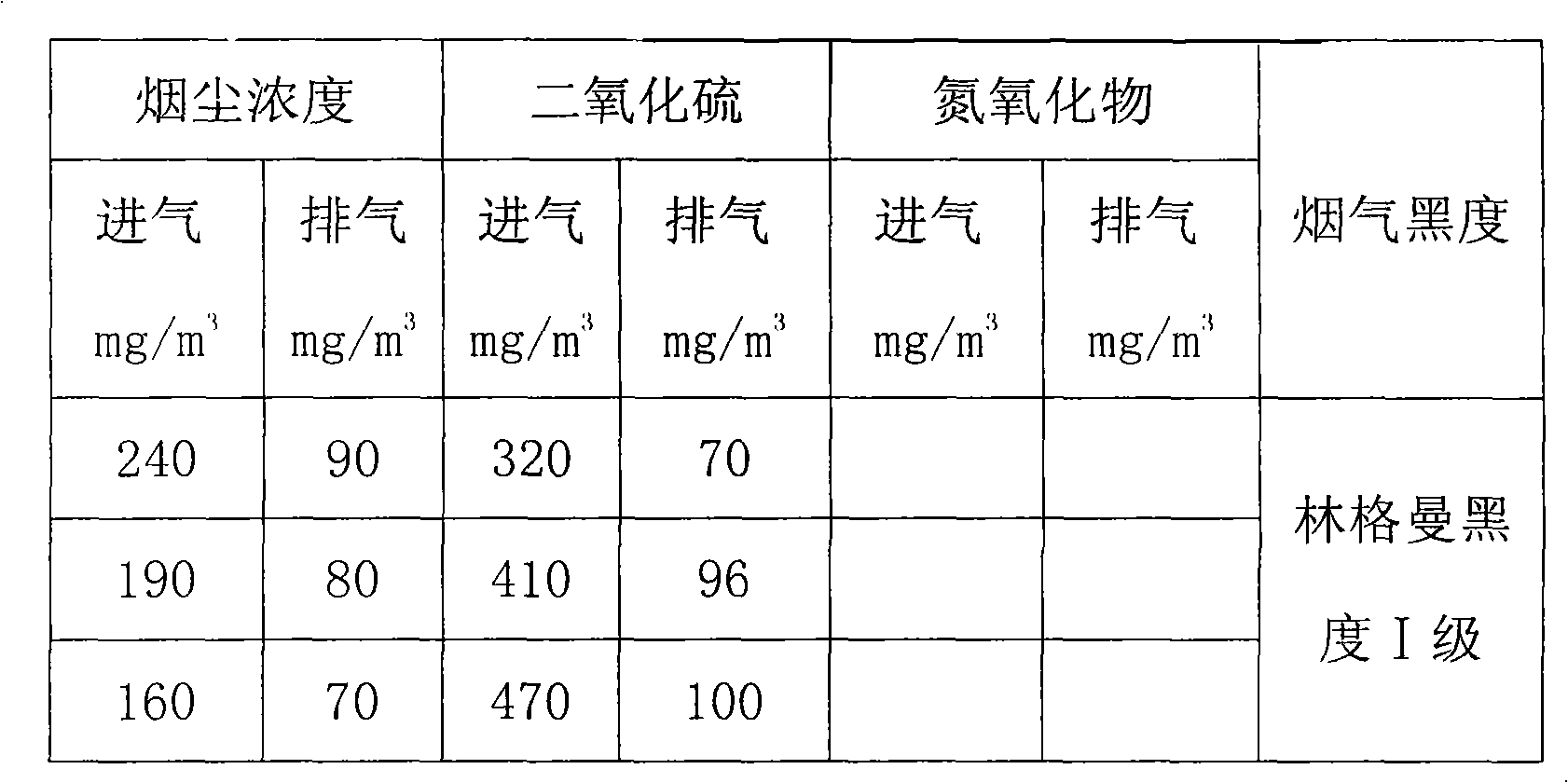

Boiler flue gas recycling method

InactiveCN101298916AImprove qualityQuality improvementDrying solid materials with heatDrying gas arrangementsElectricityFlue gas

The invention belongs to the energy source circulating reuse field and discloses a boiler flue gas reuse method, which integrates the boiler flue gas use and the clean pulping production improved wood, namely using the fume of the boiler and the cogeneration boiler, through the electro dedust to remove the dust in the fume, as one of the hot wind source of the centrifugal spray drying means to produce the improved wood, realizes the utilization of the fume remaining heat. Meanwhile in the spray drying process, the sulfur dioxide, the nitric oxides in the fume are adsorbed and used in the spray drying means of the improved wood, which advances the quality of the improved wood, purifies the boiler off gas, to make the boiler fume standard discharge develop waste cyclic utilization means, and reduce the pulping paper making and the off gas contamination.

Owner:舞钢市海明科技有限公司 +2

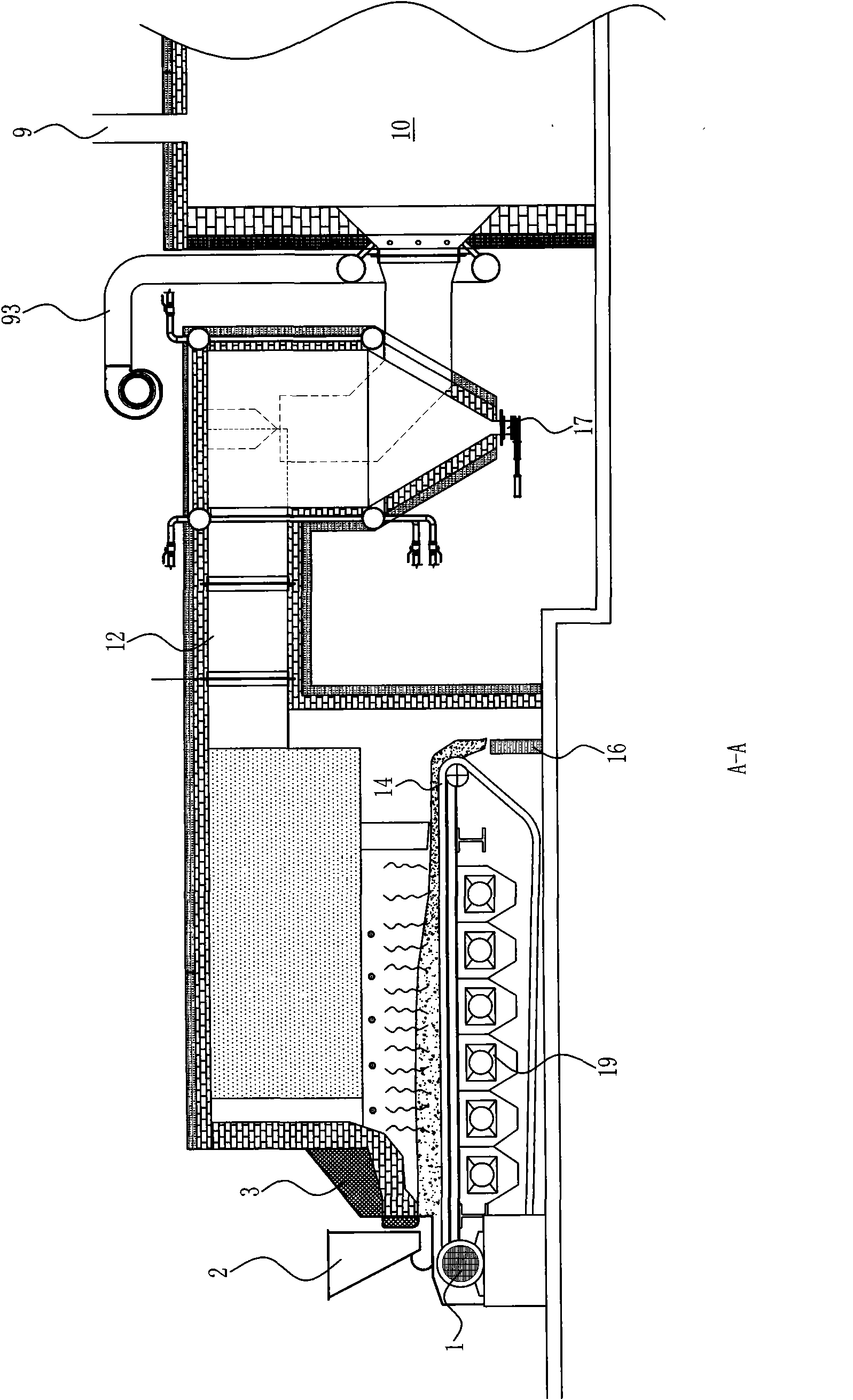

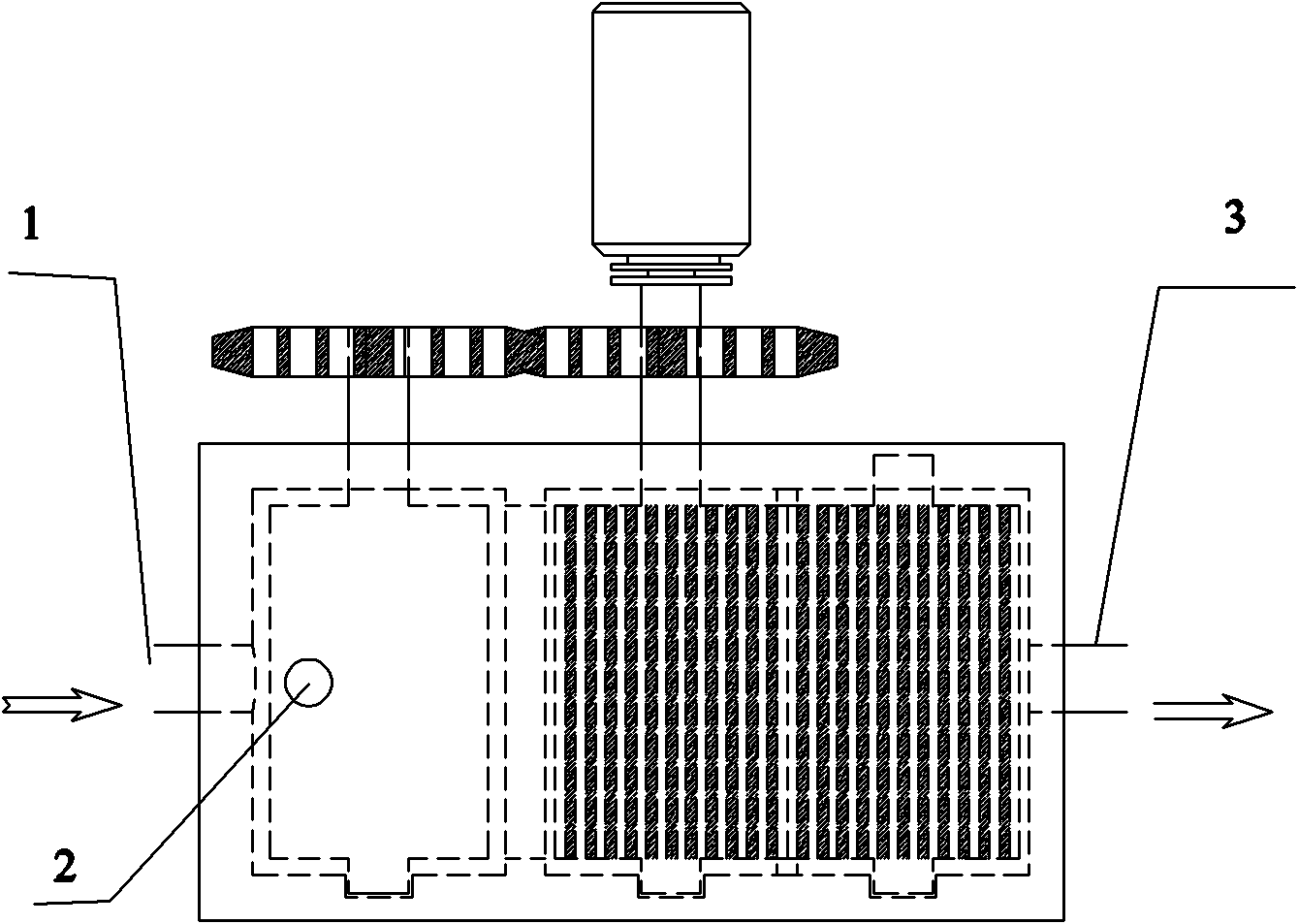

Horizontal mobile grate gasifier

InactiveCN101776260AEmission reductionImprove protectionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorFlue gas

The invention relates to a horizontal mobile grate gasifier, which comprises a furnace body with a grate and an air supply device. The air supply device consists of a primary air supply pipe and an upper-layer air supply pipe, the primary air supply pipe is connected with a plurality of air chambers and is arranged below the grate, the upper-layer air supply pipe is arranged on the two sidewalls of the furnace body and is communicated with the inner chamber of the furnace body, the rear part of the furnace body is provided with a flue gas channel, the rear end of the flue gas channel is connected with the combustor of a boiler, a flue gas circulating pipe which is connected with the rear part of the combustor communicates circulating flue gas and the upper-layer air supply pipe to form a mixed gas channel, the mixed gas channel and a steam pipe respectively extend into the air chamber and the cavity of the furnace body through a primary air Venturi pipe and a secondary air Venturi pipe; and mixed gas can flow to the front side of the combustor of the boiler through a gas mixing fan. The invention has the advantages of reducing Ringelman black and smoke emission, allowing the use of coal raw materials which are each to be coked, expanding the flexibility of the boiler use and the diversity of operating modes, and realizing the online real-time control and adjustment of parameters of steam output variables, grate operation and gasification dosage, thereby achieving the best operating conditions.

Owner:NINGBO YINUO ENERGY TECH

High-efficiency garbage incinerator

The invention discloses a high-efficiency garbage incinerator which comprises an incinerator body, a feeding port and a soot collection box. The feeding port is arranged at the top of the incinerator body and communicated with the inside of the incinerator body, two guide grooves are formed in the feeding port, obliquely mounted on the side wall of the feeding port and arranged oppositely, a fire grate, an incineration net and a rotating knife are arranged inside the incinerator body, the rotating knife is positioned right below the feeding port, an auxiliary motor is mounted on the outer wall of the incinerator body, the rotating knife is fixed on an output shaft of the auxiliary motor, and the incineration net is positioned above the fire grate. The rotating knife is arranged in the incinerator body to break garbage entering the incinerator body; by driving the motor to rotate the incineration net, garbage falling onto the incineration net is enabled to be uniformly laid, so that the garbage is ensured to be burned sufficiently; by arranging a baffle plate and the soot collection box, soot content in discharged smoke is greatly reduced; soot is collected in a centralized manner, so that labor intensity of workers is reduced.

Owner:苏州科锐恒机械科技有限公司

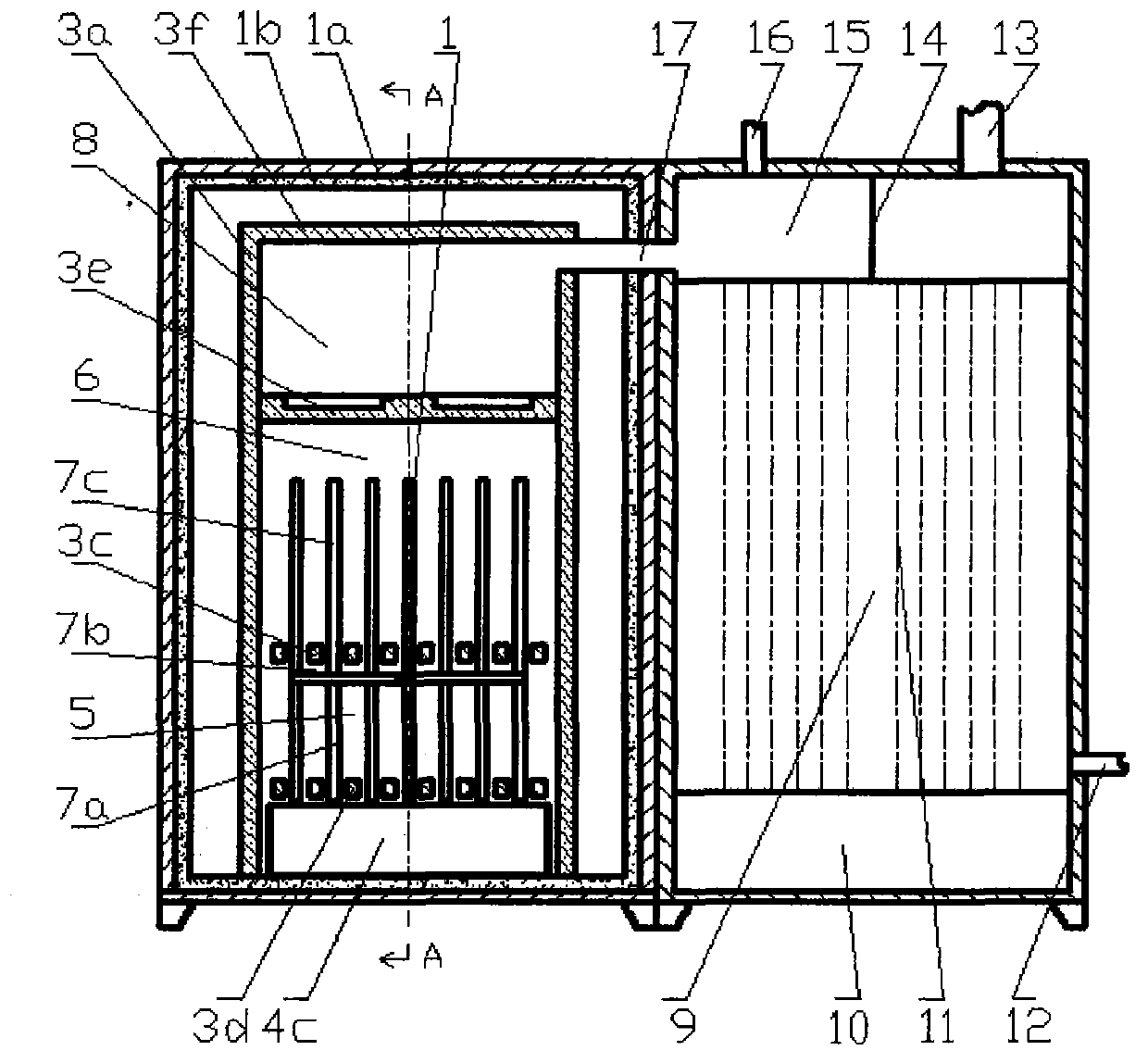

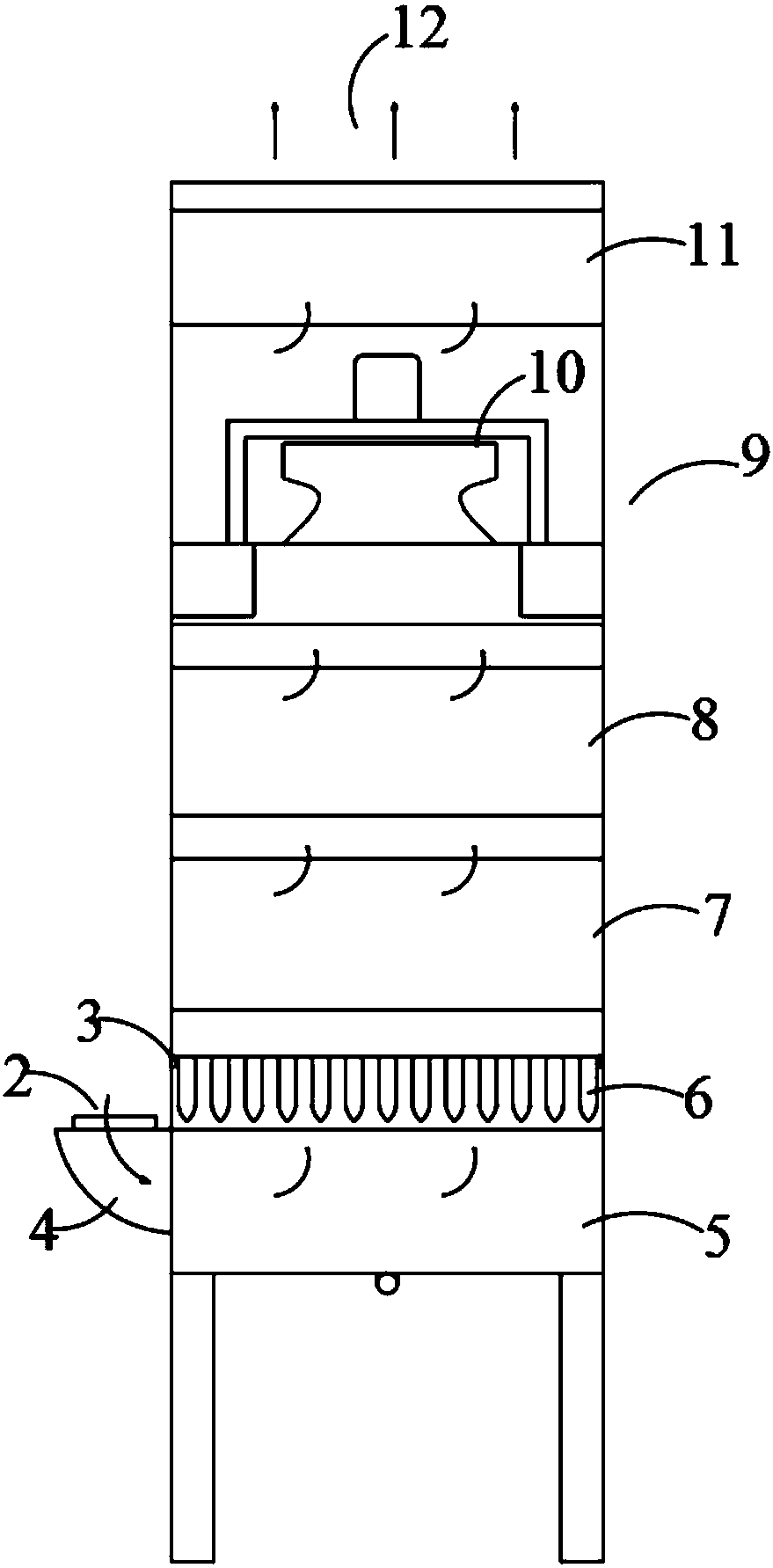

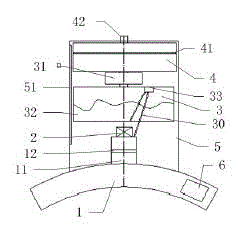

Biomass particle fuel clean combustion stove

InactiveCN103277790AReduce soot contentImprove combustion efficiencySolid fuel combustionCombustion apparatusCombustion chamberEngineering

Disclosed is a biomass particle fuel clean combustion stove. The biomass particle fuel clean combustion stove is composed of a combustion stove body and a smoke water heat exchanger which are arranged in parallel, and is characterized in that a liner is divided into a fuel combustion chamber, a vaporizing chamber and an ash accumulating chamber through an upper cover plate, a flame stabilization plate, an upper stove grate and a lower stove grate; a feeding pipe arranged at the bottom of a feeding bin penetrates through the lateral wall of an outer cover and the lateral wall of the liner, and is inserted in the vaporizing chamber from outside to inside in an inclined mode; a primary air inlet is formed in the outer lateral side of an ash discharge drawer; a secondary air inlet is formed in the lower portion of the peripheral lateral wall of the outer cover; air vents are formed in the lower portion of the peripheral lateral wall of the combustion chamber of the liner; a smoke duct is arranged on the upper portion of the lateral wall of the combustion chamber of the liner. The biomass particle fuel clean combustion stove ensures that biomass particle fuel is completely and stably vaporized and is complete in combustion and high in temperature, improves combustion efficiency of the fuel, obviously reduces the dust carrying amount in smoke, ensures that smoke generated after fuel combustion is clean, effectively avoids ash accumulation and slagging, improves heat exchange efficiency of heat exchange equipment, and is simple and compact in structure, convenient to operate and low in operating cost.

Owner:HEFEI UNIV OF TECH

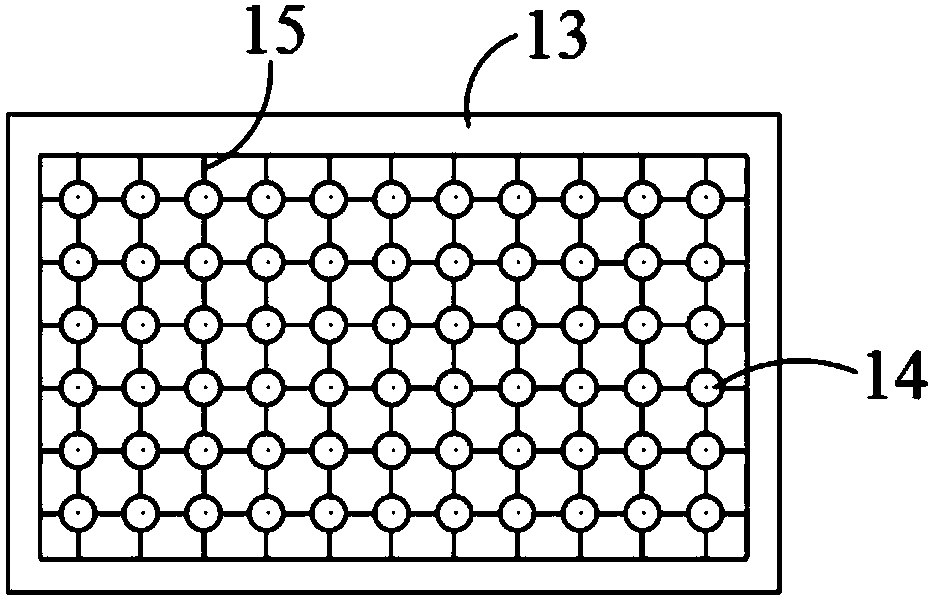

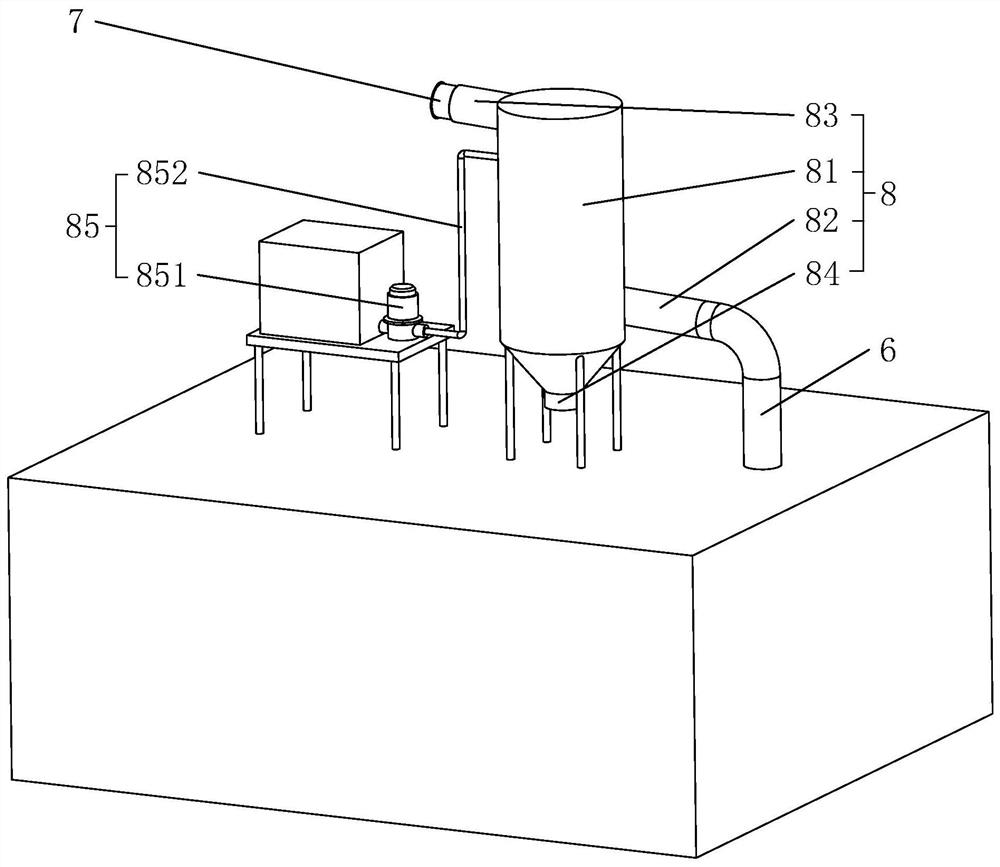

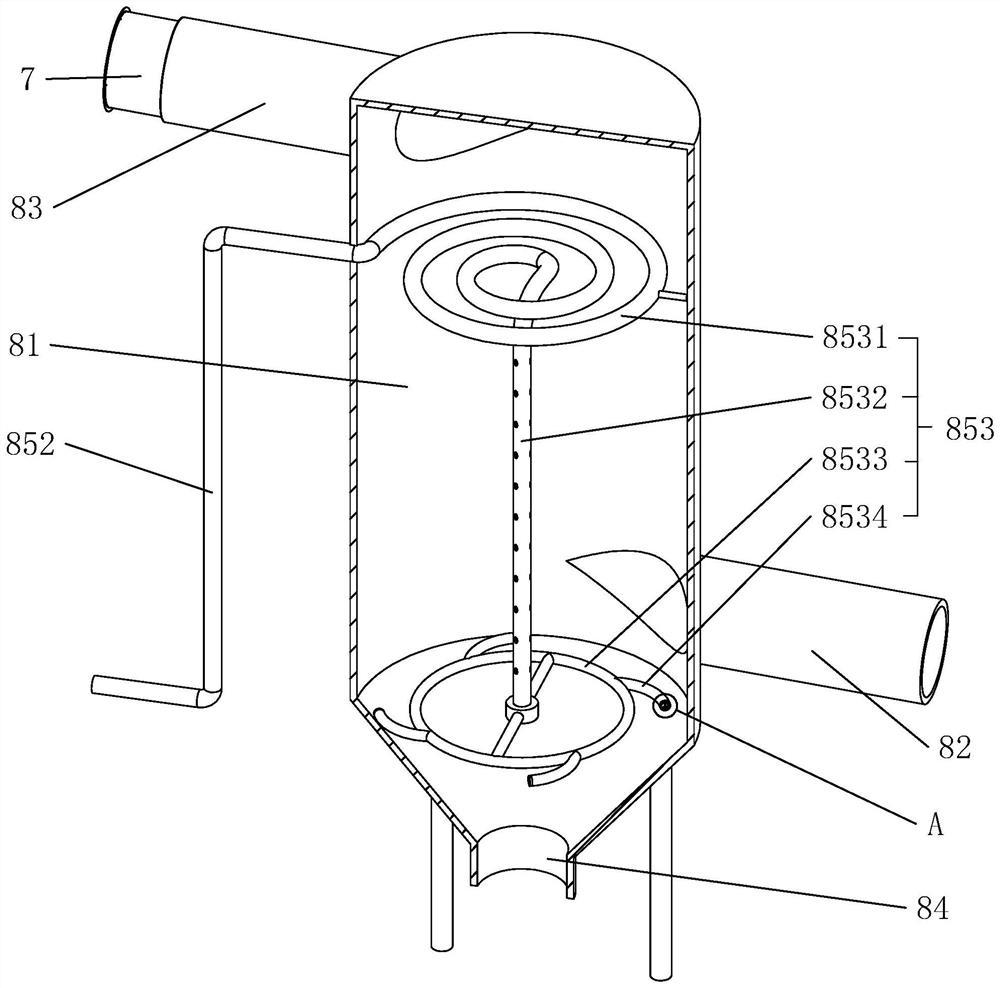

Vertical oil mist collector

PendingCN108211643AAvoid congestionImprove oil mist removal efficiencyCombination devicesEngineeringWaste management

The invention discloses a vertical oil mist collector. The vertical oil mist collector comprises a vertical shell, wherein one side of the bottom of the shell is provided with an air inlet; the top isprovided with an air outlet; a primary filter, a secondary filter, a fan and an efficient filter are arranged in the shell from bottom to top in sequence; an oil collection box is arranged below theprimary filter, wherein an oil collector is arranged between the primary filter and the oil mist collector, the oil collector comprises an outer frame and oil collection columns which are distributedin the outer frame at intervals; gaps through which oil mist can pass are formed among adjacent oil collection columns; the bottom of each oil collection columns is of an inverted conical body; the primary filter comprises a cylinder body, as well as uniform air plates, oil collection baffle plates and filtering screens which are arranged from bottom to top; vent holes are uniformly distributed onthe uniform air plates; oil falling holes are formed in the middle part; oil collection baffle plate is partitioned into an upper layer and a lower layer; the oil collection baffle plates are uniformly distributed on each layer; the oil collection baffle plates are arranged in a staggered way.

Owner:浙江易德环境设备有限公司

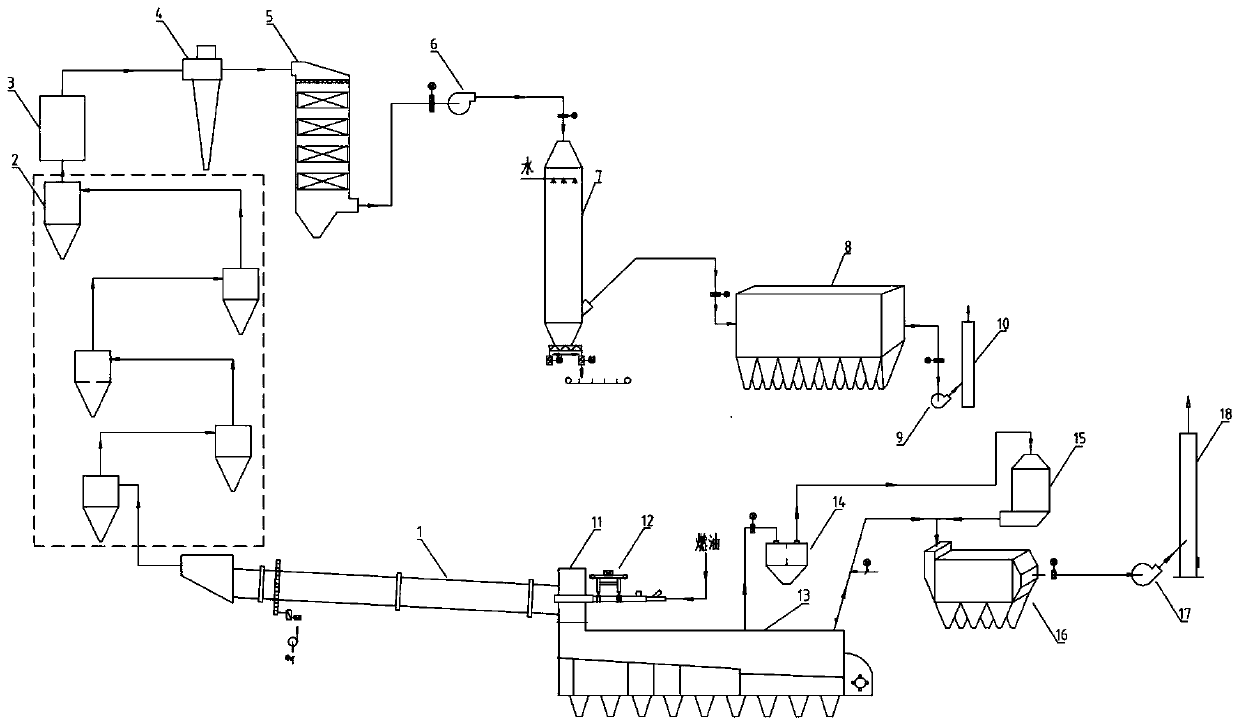

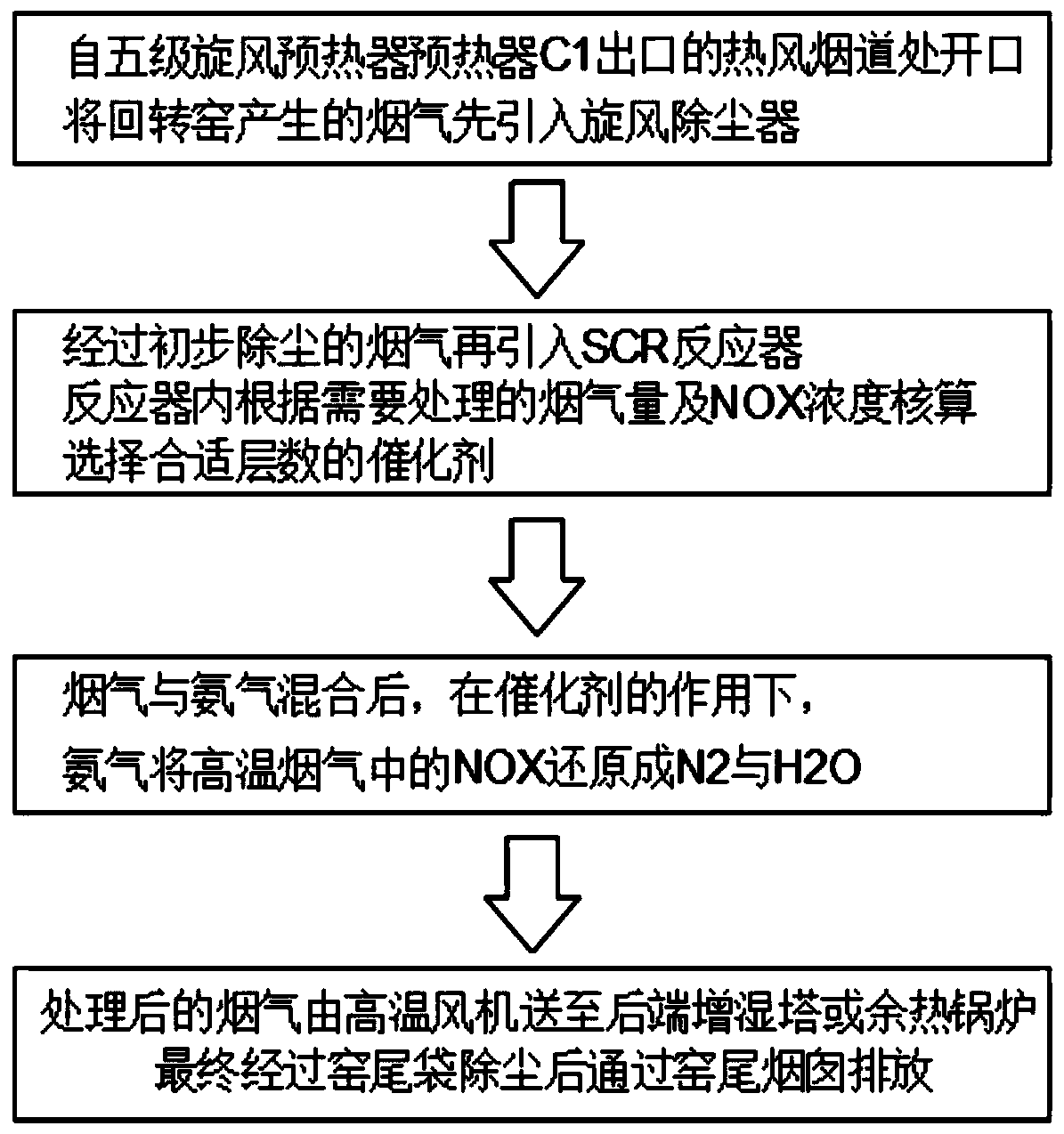

Dust SCR denitration device and technology for cement kiln

PendingCN110314543AReduce soot contentLower the altitudeGas treatmentDispersed particle separationCycloneEngineering

The invention belongs to the technical field of flue gas treatment and environmental protection for cement kilns, and particularly relates to a dust SCR denitration device and technology for a cementkiln. The dust SCR denitration device comprises a rotary kiln, a kiln tail residual gas treatment system and a kiln head residual gas treatment system; the kiln tail residual gas treatment system comprises a five-stage cyclone preheater, an SP furnace, a dust remover, an SCR reactor, a high-temperature blower, a humidifying tower / waste heat boiler, a kiln tail bag dust removing unit, a kiln tail exhaust blower and a kiln tail chimney; the five-stage cyclone preheater is connected to the kiln tail of the rotary kiln; the cyclone dust remover is arranged in front of the SCR reactor for flue gasdust removal, the content of flue gas dust at the SCR reaction is lowered, the number of pores of a honeycomb catalyst can be increased, and the overall height of the catalyst and the reactor can be effectively lowered on the condition that the cubic number and the number of layers of the catalyst are not changed; the pressure loss of the whole reactor is lowered, power of the blower at the rear end can be reduced, and energy consumption is lowered.

Owner:陕西大秦环境科技有限公司

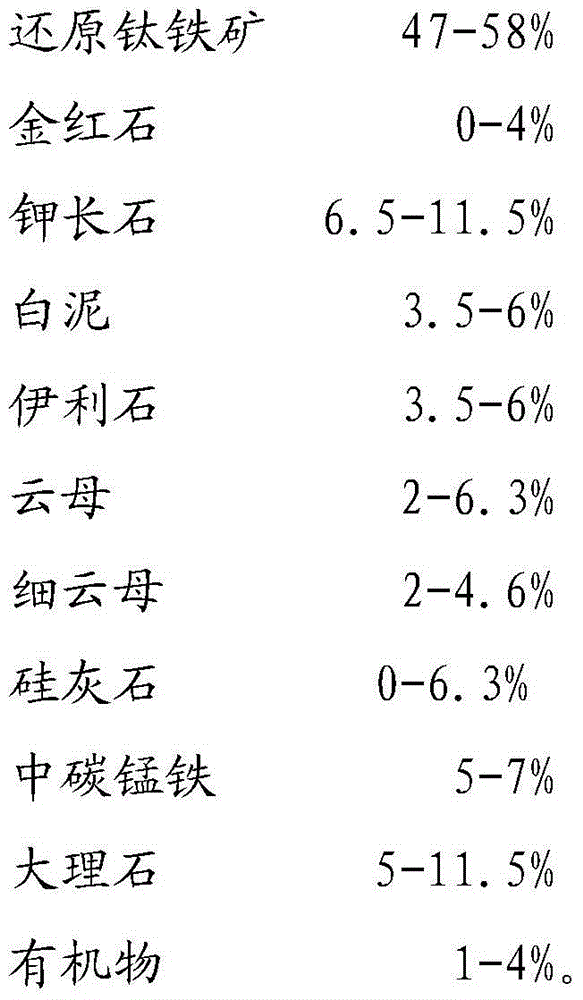

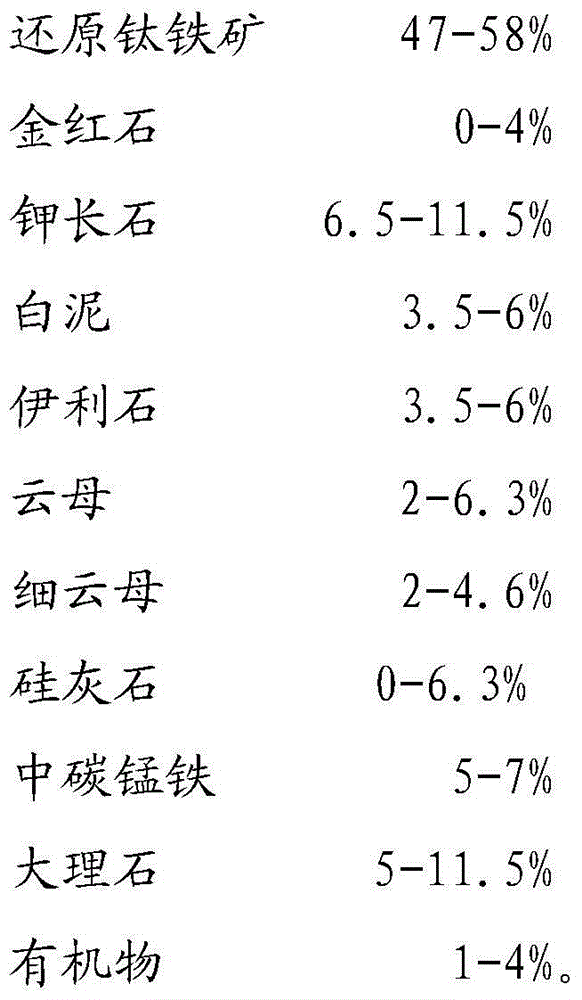

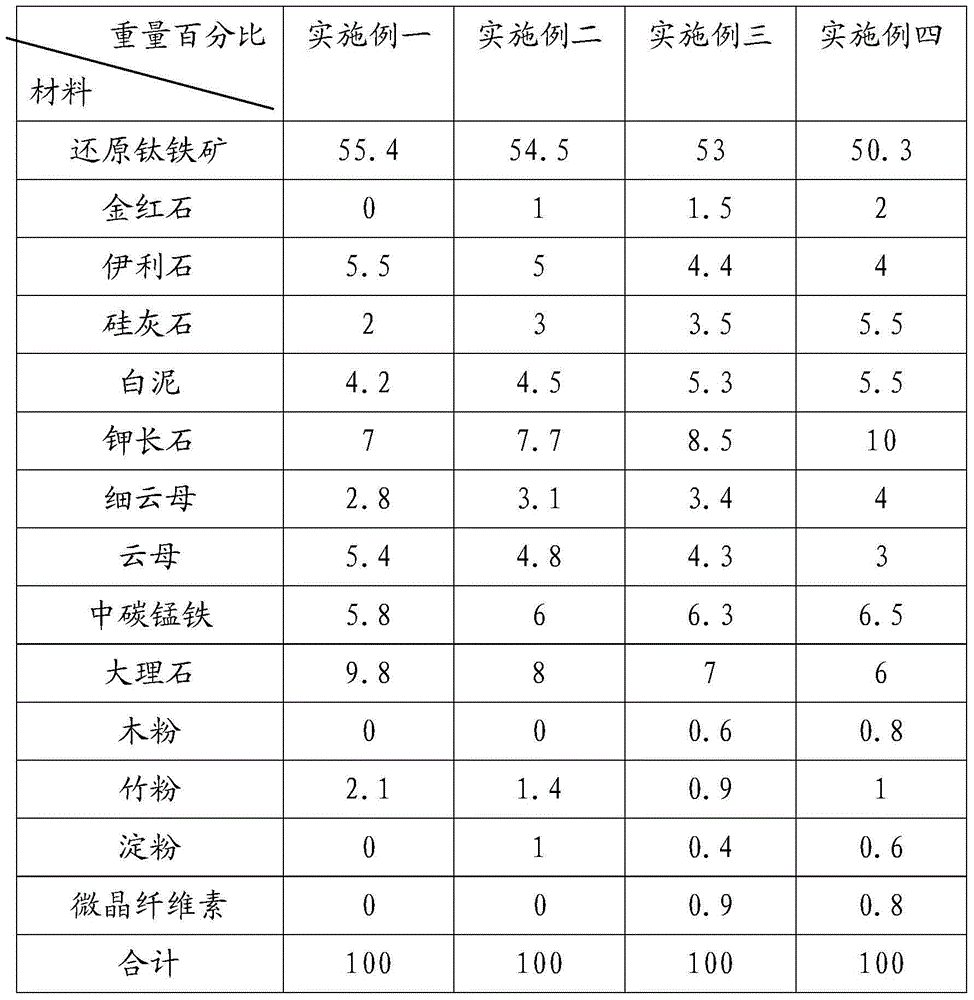

42 kg-level titania type carbon steel covered electrode and preparation method thereof

ActiveCN103551754AReduce pollutionReduce energy consumptionWelding/cutting media/materialsSoldering mediaPotassium feldsparWollastonite

The invention discloses a 42 kg-level titania type carbon steel covered electrode and a preparation method thereof. The 42 kg-level titania type carbon steel covered electrode comprises a core wire; the formula of a covered electrode coating comprises the following components in percentage by weight: 47-58% of reduced ilmenite, 0-4% of rutile, 6.5-11.5% of potassium feldspar, 3.5-6% of lime mud, 3.5-6% of illite, 2-6.3% of mica, 2-4.6% of fine mica, 0-6.3% of wollastonite, 5-7% of mid-carbon ferromanganese, 5-11.5% of marble and 1-4% of organic matters. The covered electrode can be prepared through a universal manufacturing technology of screw-type or hydraulic-type production equipment in the industry without special requirements, has excellent welding technological properties, mechanical properties and production press coating performance, and can be in AC / DC use.

Owner:天津大桥龙兴焊接材料有限公司

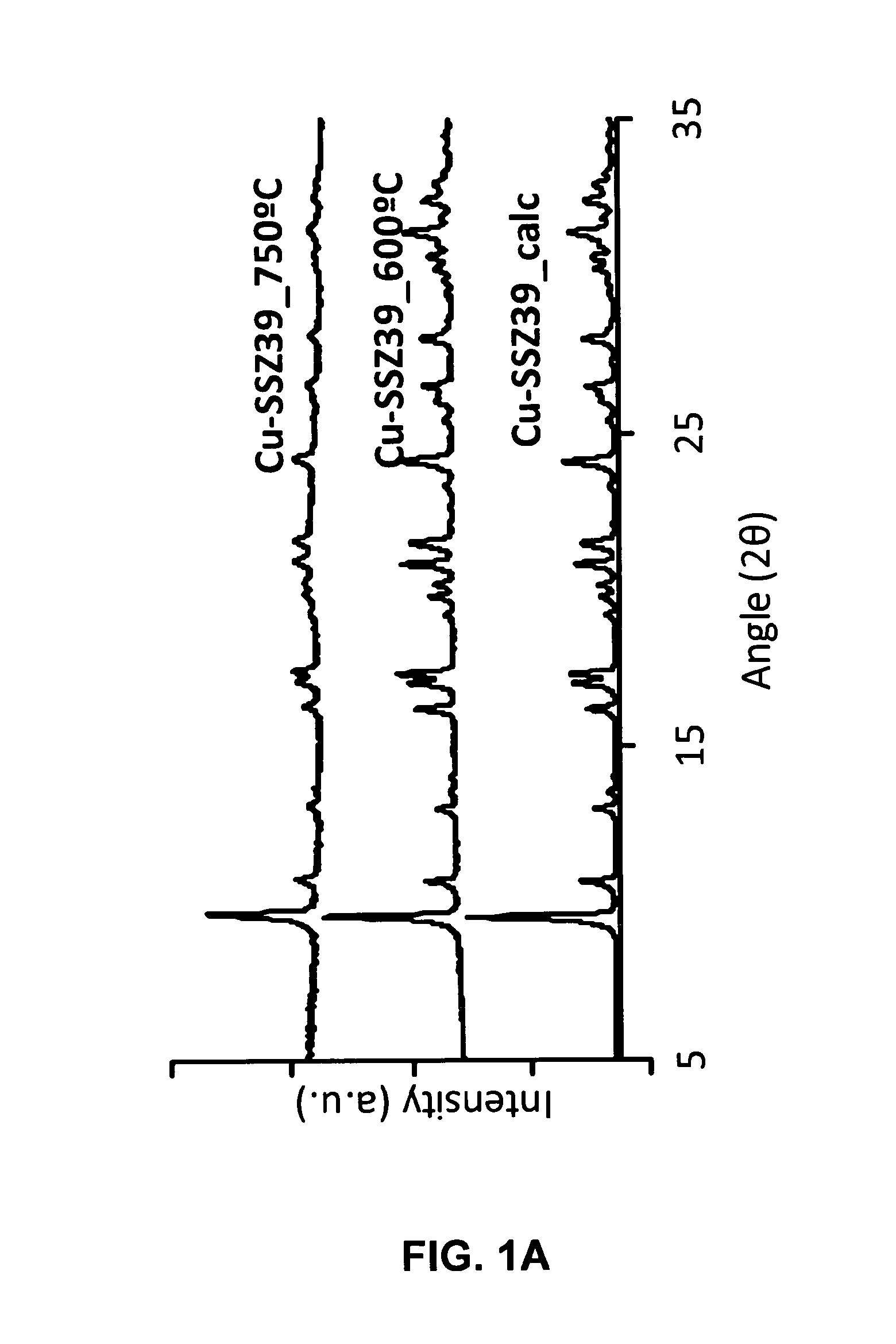

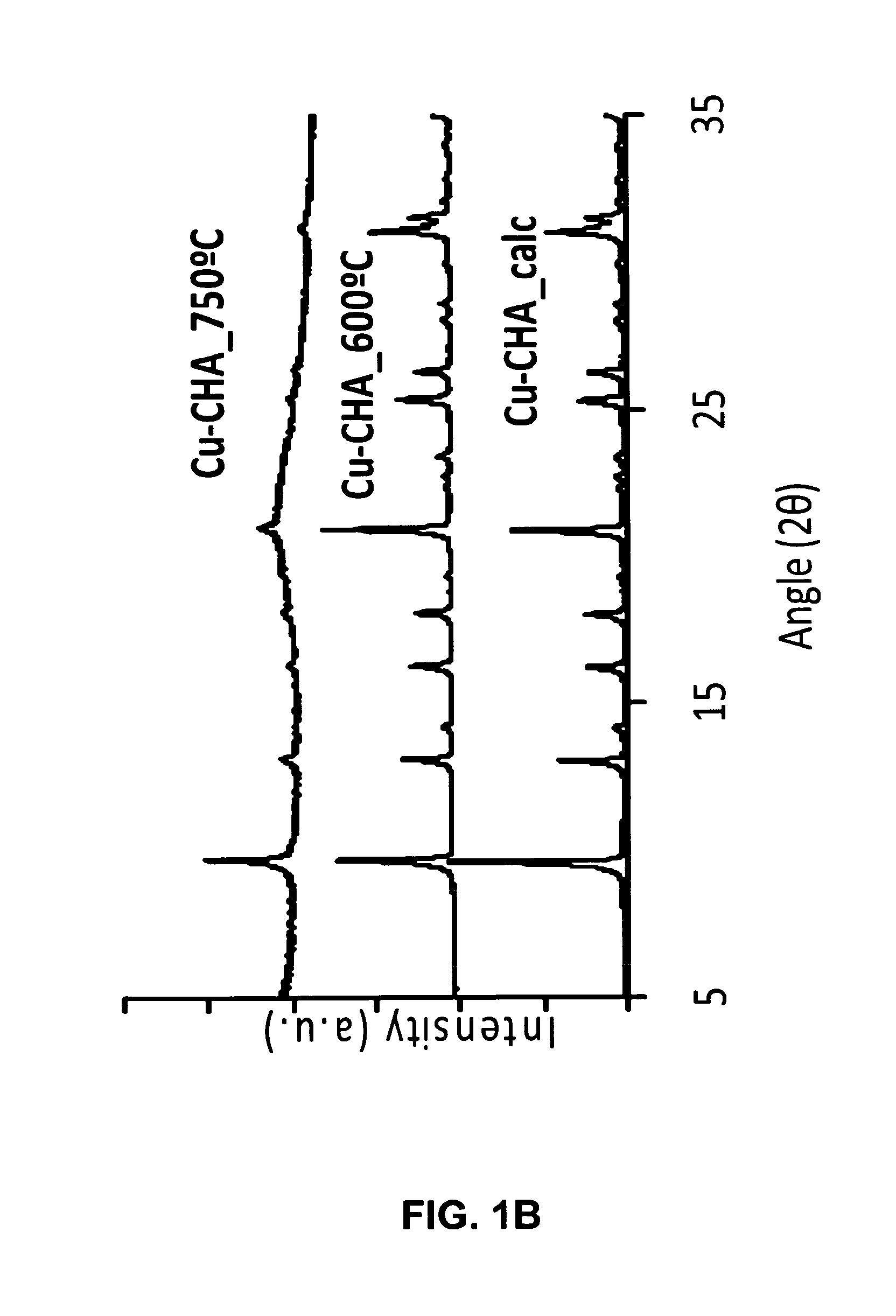

Method and system for the purification of exhaust gas from an internal combustion engine

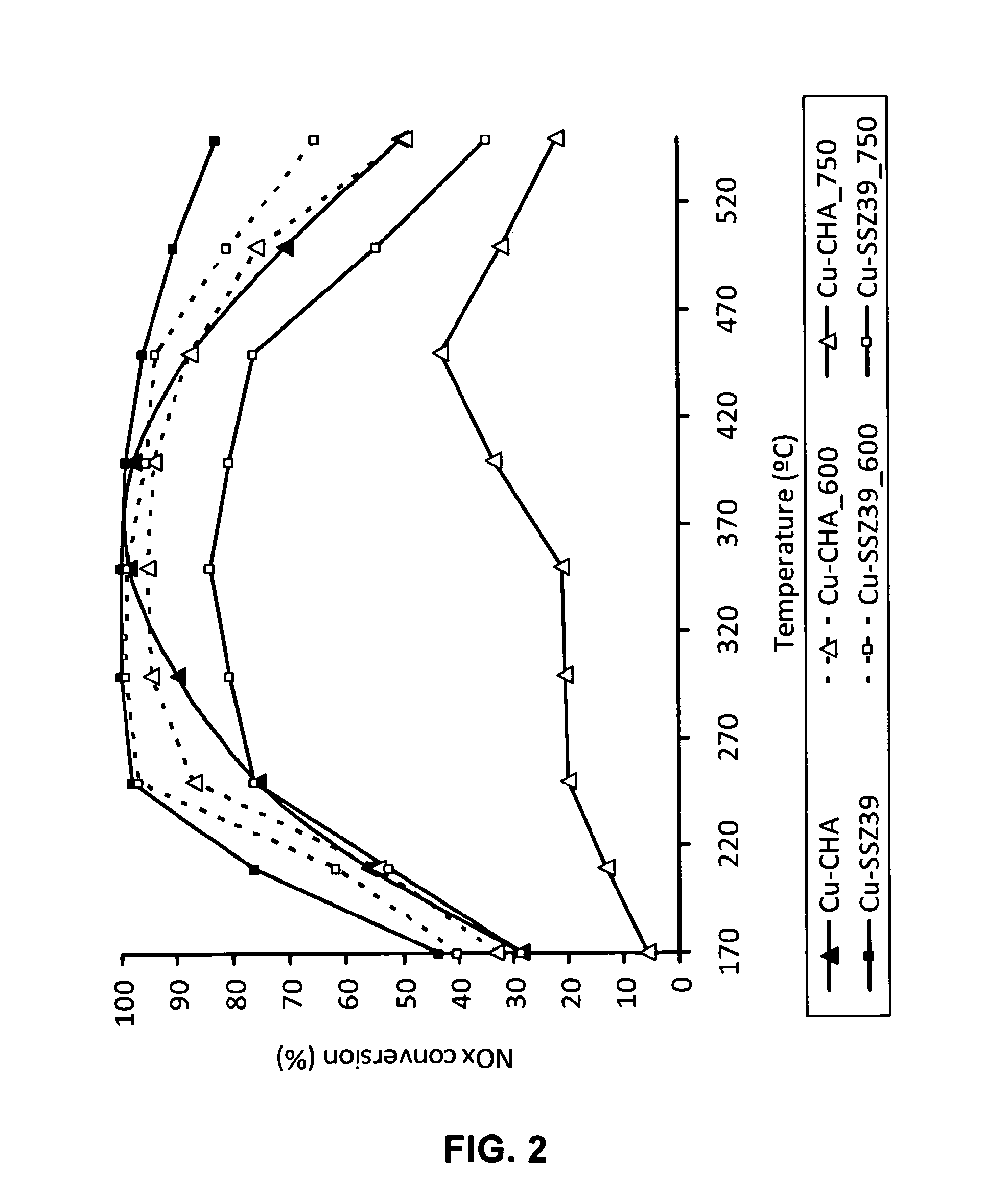

ActiveUS9561468B2Reduce soot contentGas treatmentInternal combustion piston enginesWater vaporExternal combustion engine

The invention provides a method and system for the purification of exhaust gas from an internal combustion engine, comprising a filter and a SCR catalyst. The filter is periodically regenerated increasing the temperature of the exhaust gas up to 850° C. and the water vapor content up to 100% by volume. The SCR catalyst comprises a hydrothermally microporous stable zeolite and / or zeotype having the AEI type framework and being promoted with copper.

Owner:UMICORE AG & CO KG

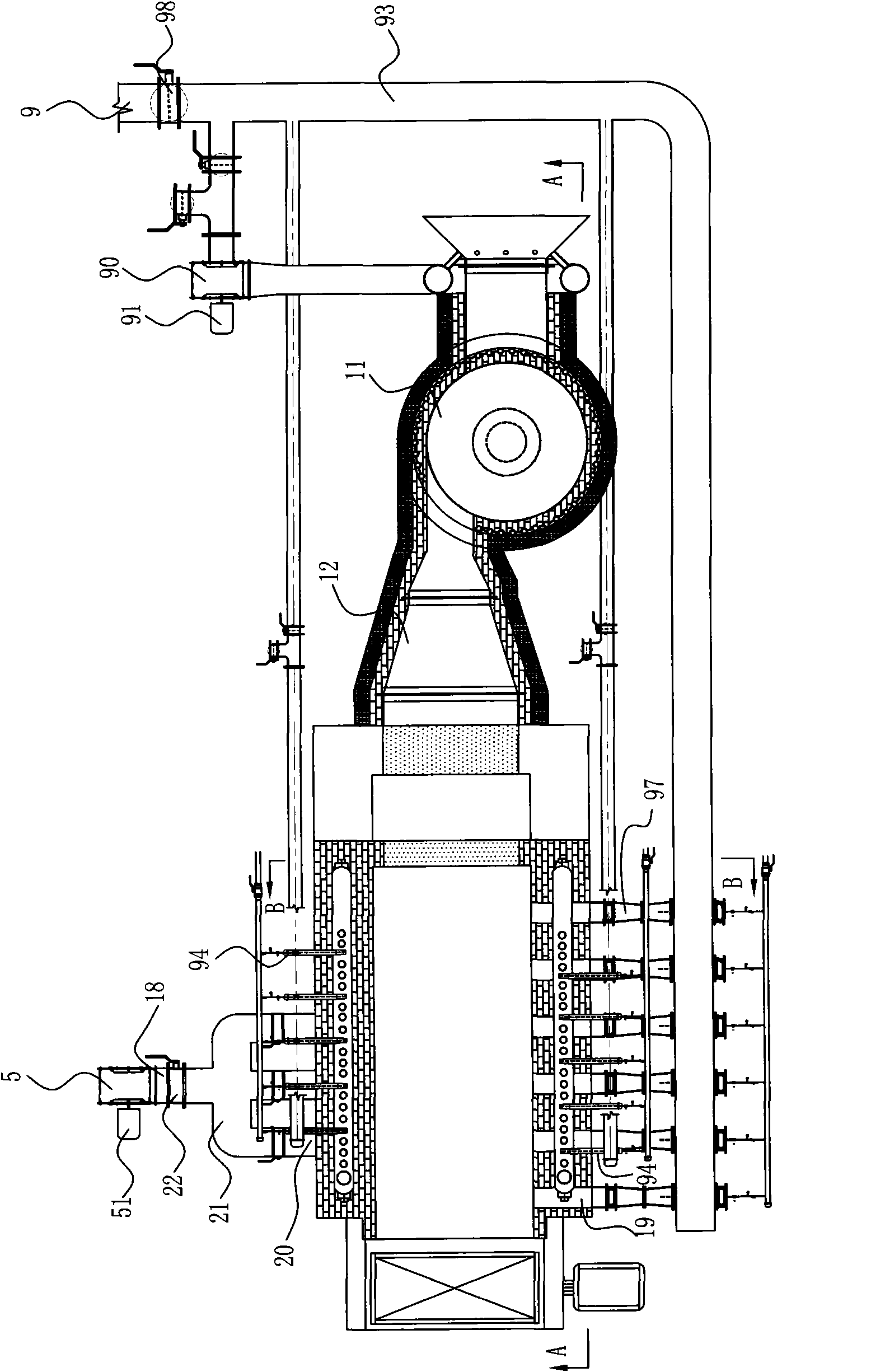

Method and equipment for upgrading, drying and forming lignite

The invention discloses a method and equipment for upgrading, drying and forming lignite. The method comprises the steps of 1) pulverizing the lignite into pulverized lignite, 2) adding sodium hydroxide to the pulverized lignite, stirring, filling in water vapor, allowing the lignite to react sufficiently, and 3) drying the lignite after the reaction, conducting pressure forming, and obtaining the lignite. According to the method for upgrading, drying and forming the lignite, raised dust in a drying process is reduced greatly, so that atmospheric pollution is reduced and a working environment is improved; the content of lignite ash in moisture volatilized by a drying machine is reduced, so that the moisture is recovered greatly; and the density and the strength of the formed lignite are increased and improved, so that a binder is not required to be added in a forming process, and requirements of transportation and production can be met conveniently. In addition, the equipment for upgrading, drying and forming the lignite achieves upgrading, drying and forming integrated continuous cleaning production of the lignite, and is suitable for large-scale industrial production of upgrading, drying and forming of the lignite.

Owner:ZHENGZHOU CITY OF MINING EQUIP

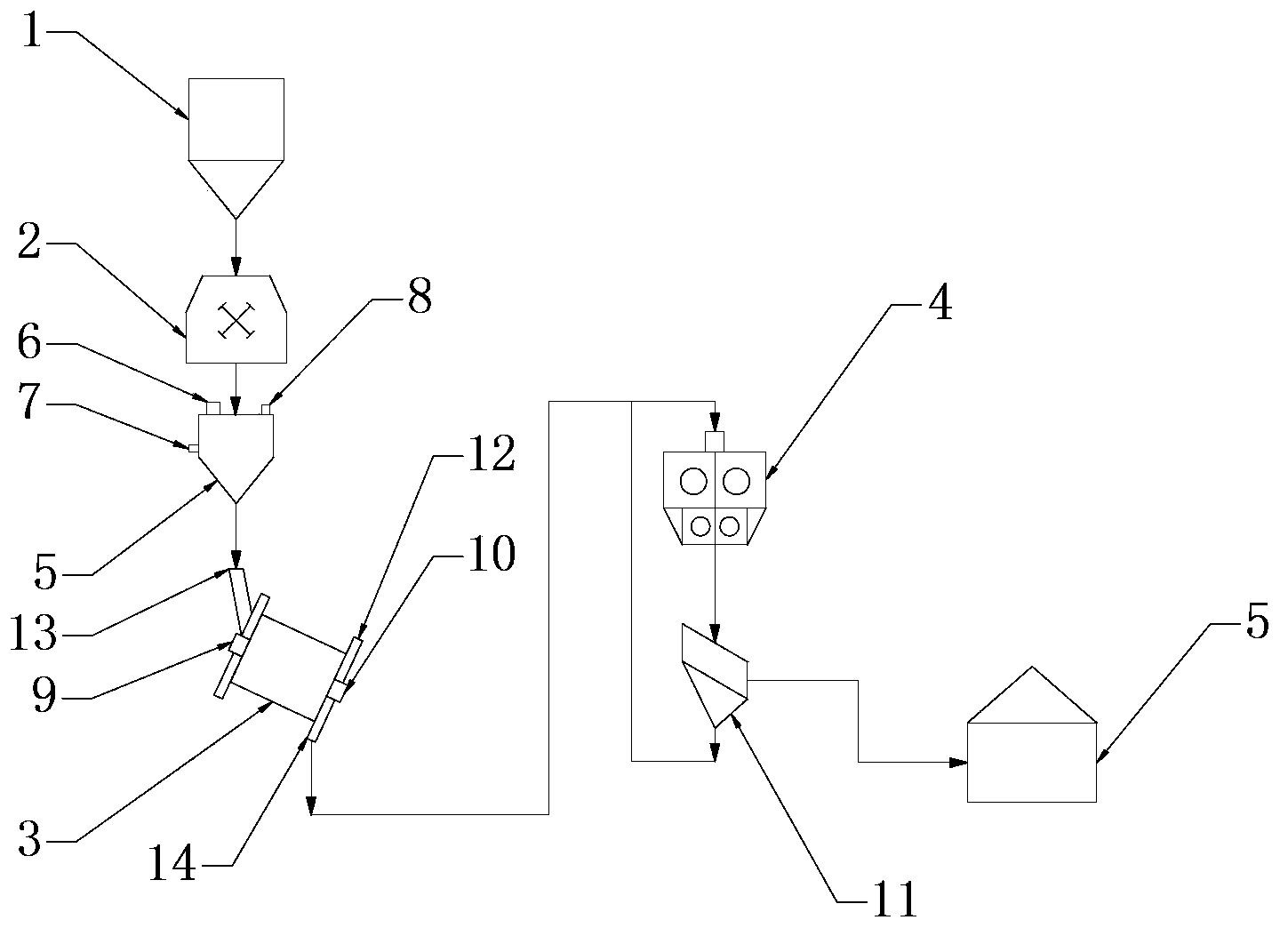

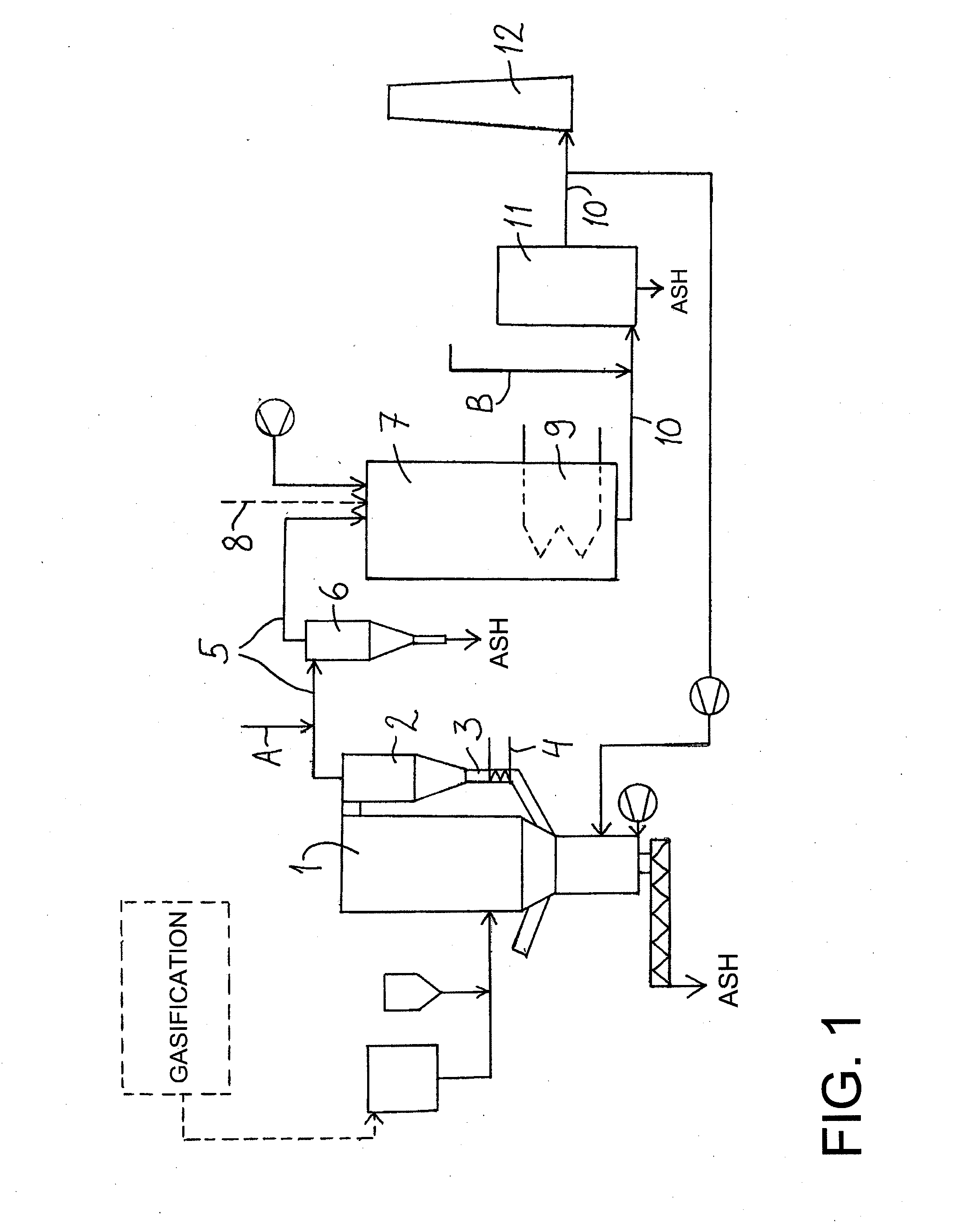

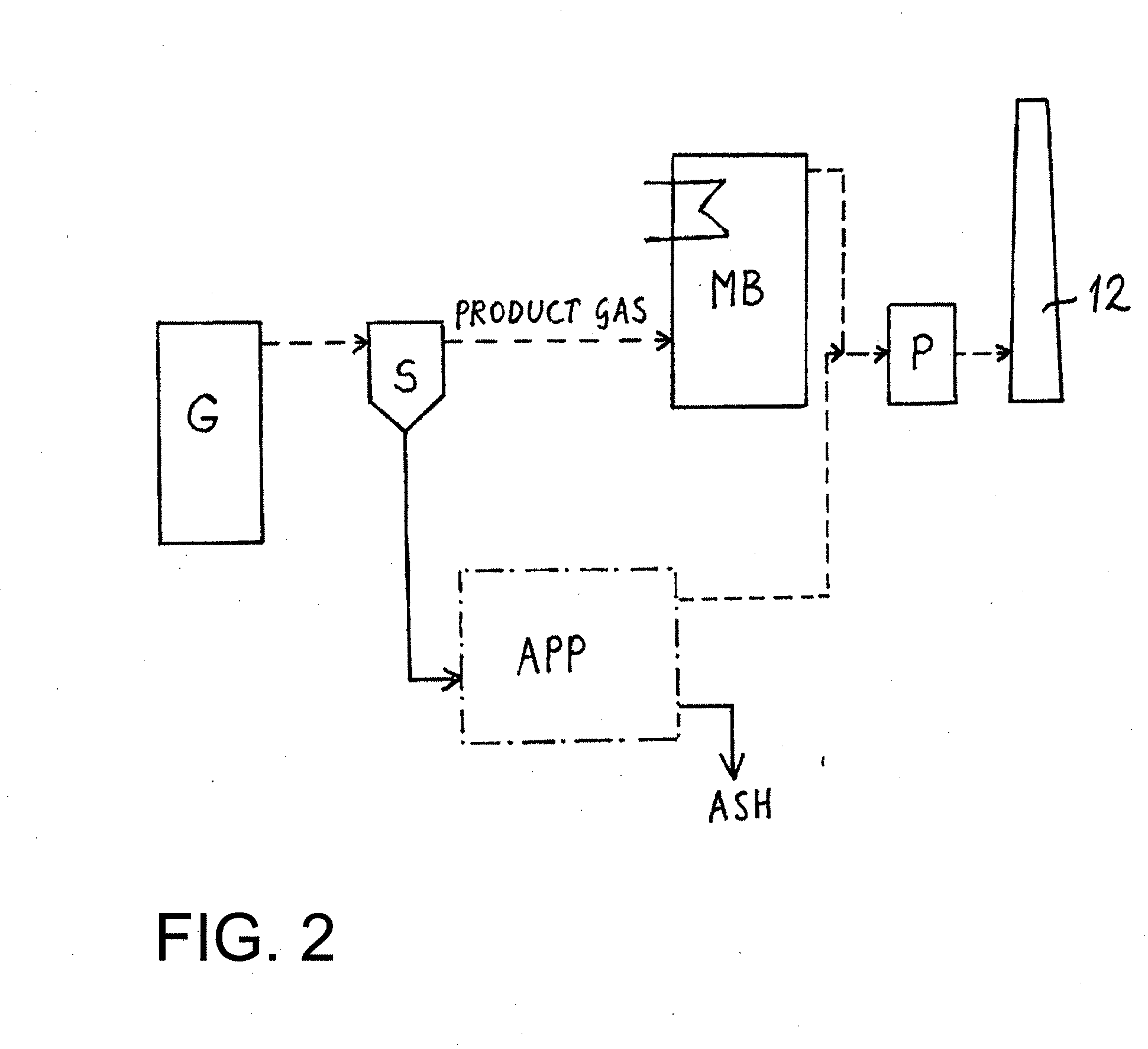

Method for processing ash, and an ash processing plant

InactiveUS20120234217A1Reduce soot contentFluidized bed combustionSpatial transmit diversityFlueProcessing plants

In a method for processing ash, fly ash is separated from a product gas flow obtained from gasification of fuel, which fly ash is burned in fluidized bed combustion to reduce the carbon content of the ash. After this, the flue gases from the combustion are processed. In a first step, the ash is burned in fluidized bed combustion (fluidized bed reactor 1) at a temperature of not higher than 800° C. to reduce the carbon content, and in a second step, the flue gases a burned in an independent combustion process (combustion chamber 7), the combustion conditions reaching the temperature of at least 850° C.

Owner:VALMET POWER OY

Efficient environmental-friendly oil fume purifying device

InactiveCN104667681AImprove purification rateGood fume purification effectCombination devicesEnvironmentally friendlySmoke

The invention relates to an efficient environmental-friendly oil fume purifying device which comprises a smoke collecting plate (1), a fan (2), a filter chamber (3), a purification chamber (4) and a housing (5) which are sequentially connected, wherein a smoke conveying pipeline (11) and a screen (12) are arranged between the smoke collecting plate (1) and the fan (2); a plurality of parallelly arranged electrode rods (41) are arranged in the purification chamber (4); a oil fume outlet hole (42) is formed in the upper side of the purification chamber. Oil stain collecting pipelines are arranged on the smoke collecting plate (1), the smoke conveying pipeline (11), the screen (12) and the purification chamber (4). The oil stain collecting pipelines are communicated with an oil stain collecting box (6) which is arranged at the bottom of the housing. The efficient environmental-friendly oil fume purifying device provided by the invention is simple in structure, good in oil fume purification effect, high in purification rate, efficient and environmentally friendly.

Owner:SHANGHAI YAOHUA TECH DEV

Garbage incinerator

Owner:苏州科锐恒机械科技有限公司

Sand mould casting process

InactiveCN111644569ARapid compactionGuaranteed molding efficiencyFoundry mouldsMoulding machinesMolten stateMolding machine

The invention relates to the field of casting, in particular to a sand mould casting process. The sand mould casting process comprises the following steps of 1, preparing a tidal sand mold, wherein prepared model sand is screened, and the screened model sand is put into a tidal mold sand box molding machine; 2, putting prepared raw materials into a furnace, wherein the melt liquid temperature is 1400-1600 DEG C, the melt time is 4-5 hours, and the stirring is carried out every 30 minutes; 3, preheating the tidal sand mold prepared in the step 1, wherein the preheating temperature is 400-600 DEG C, the preheating time is 5-10 minutes, after preheating is finished, the molten liquid of the raw materials is injected into the tidal sand mold, then the tidal sand mold is placed in a constant temperature furnace, the tidal sand mold is slightly vibrated, the constant temperature time is 30-60 minutes, and the raw materials are kept in a molten state during constant temperature; and 4, takingout the tidal sand mould subjected to constant temperature treatment in the step 3, and cooling the tidal sand mould by using water cooling and air cooling. The tidal mold sand box molding machine can rapidly finish multiple collision molding, so that rapid compaction molding is achieved, and molding efficiency is guaranteed.

Owner:芜湖新从工业设计有限公司

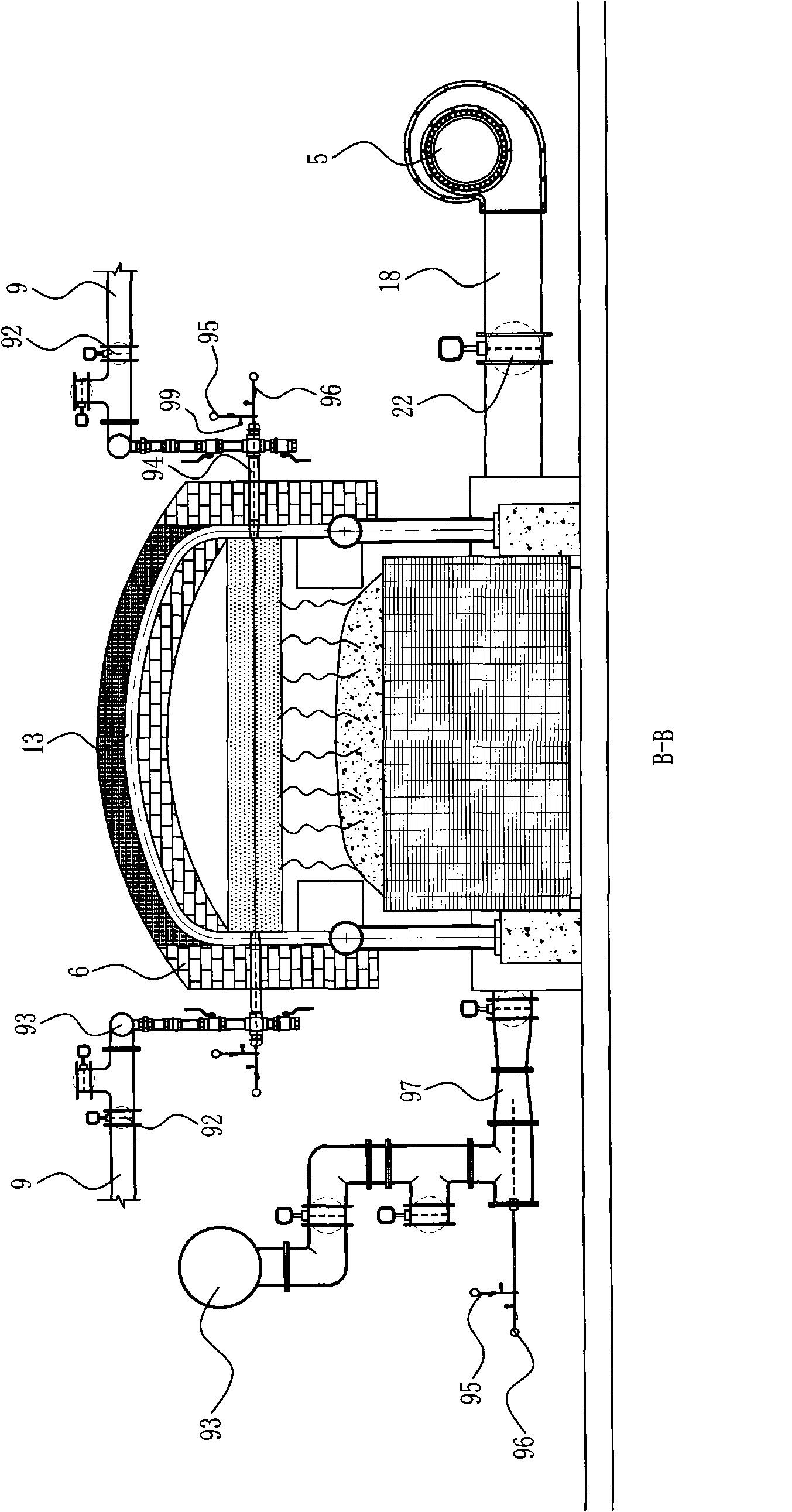

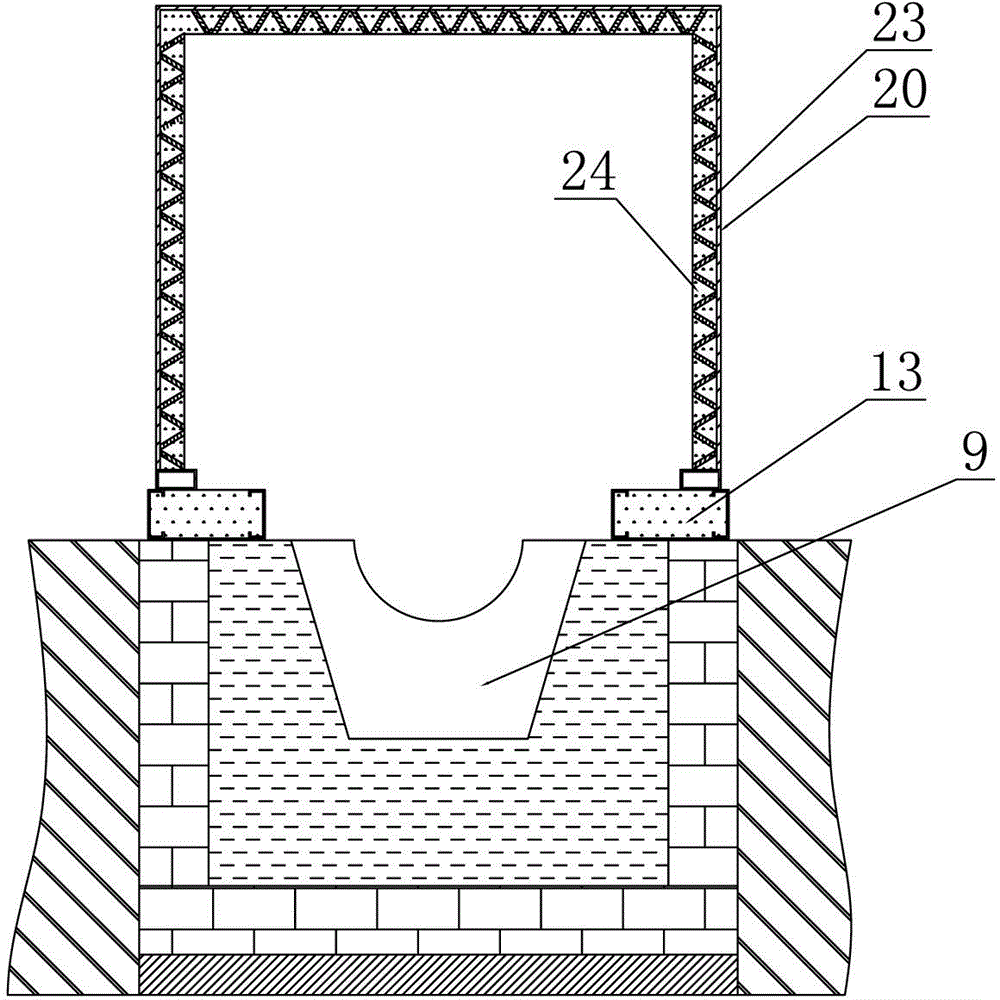

Dedusting structure of stokehold scrap iron runner of medium- and small-sized blast furnaces

InactiveCN104313220AImprove insulation effectReduce soot contentDischarge devicesDust arrestersSlagAtmosphere

The invention discloses a dedusting structure of a stokehold scrap iron runner of medium- and small-sized blast furnaces. The dedusting structure comprises a blast furnace and a plurality of molten iron tank positions, wherein the blast furnace is connected with a main runner which is connected with a skimmer; the skimmer is connected with a slag runner and a straight runner; each molten iron tank position is respectively connected with the straight runner by virtue of a branch runner; leveling layers are respectively formed on the top of the straight runner and each branch runner; a straight runner seal hood is arranged on the leveling layer on the top of the straight runner; a branch runner seal hood is respectively arranged on the leveling layer on the top of the branch runner; a skimmer seal hood is arranged on the top of the skimmer; the straight runner seal hood and the branch runner seal hood as well as the straight runner seal hood and the skimmer seal hood are respectively sealed by virtue of annular hoop bars; air outlets are formed on the tops of the straight runner seal hood, the branch runner seal hood and the skimmer seal hood, the air outlets are connected with a dedusting system, and inspection doors are formed on the branch runner seal hood in a branch runner work station and the straight runner seal hood in a straight runner work station. The dedusting structure provided by the invention has the advantage that the content of soot which is discharged to atmosphere is reduced.

Owner:JIANGSU YONGGANG GROUP CO LTD

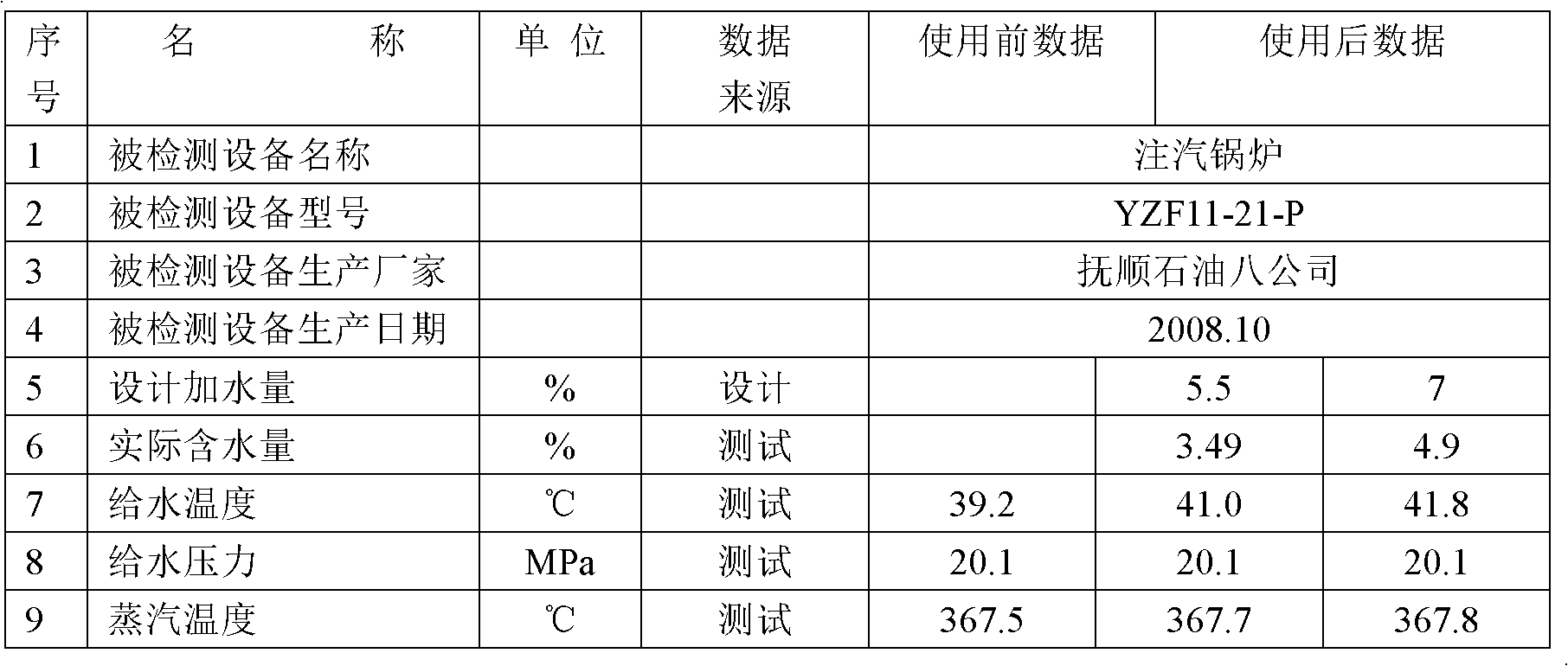

Materials measuring and proportioning control method in mechanical stirring type fuel oil watering device

InactiveCN102080829AStable waterRaise the ratioLiquid fuel feeder/distributionCombustionCore component

The invention discloses a materials measuring and proportioning control method in a mechanical stirring type fuel oil watering device which comprises the main devices: a mechanical stirring core component emulsifier, a watering fuel oil tank, a fuel oil metering pump, a water metering pump, a back pressure valve, a security valve, and a sampling point. The accurate control of a plunger type water metering pump ensures the stability of the water content in the oil, three oil samples heat constant temperature extraction feeds back the water content and changes in time, and heat efficiency measurement of boiler combustion ensures the effects of energy saving and exhaust reduction and optimizes the water and oil proportioning. The quantitative proportioning of the fuel oil watering enables carbon and smoke contents to be decreased, the smoke exhausting temperature is lowered, the output heat is reduced, and the oil saving effect is obvious.

Owner:DALIAN MARITIME UNIVERSITY

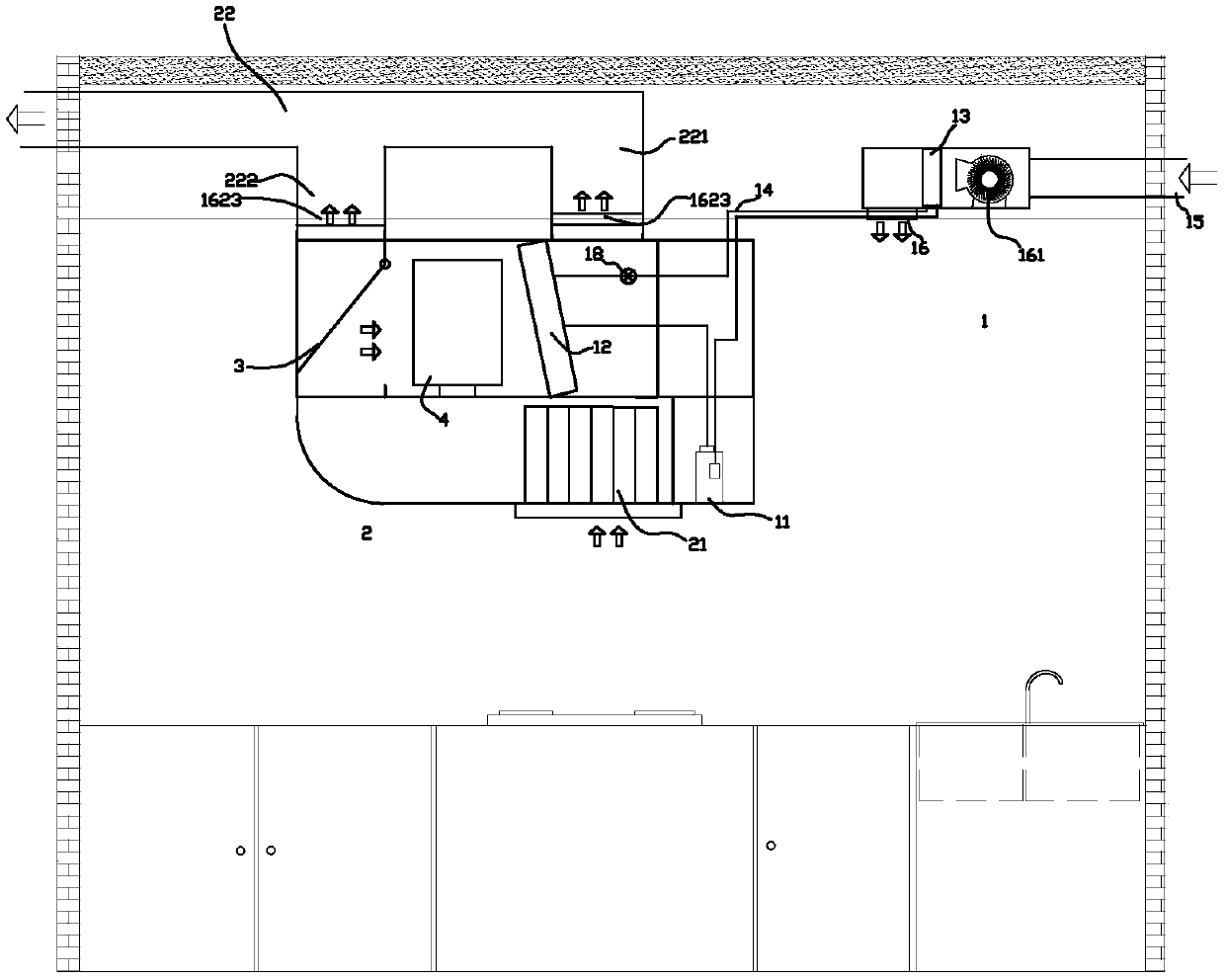

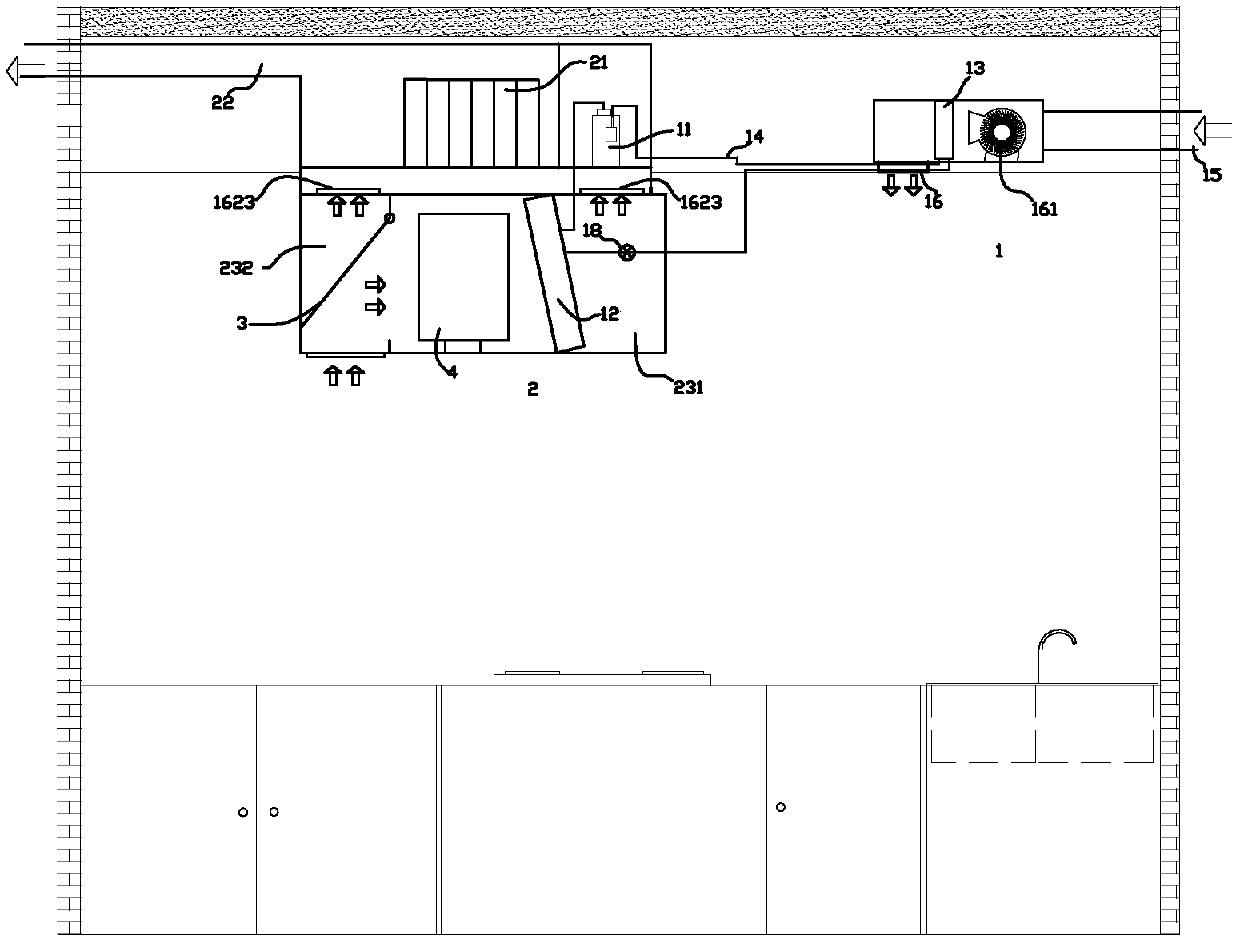

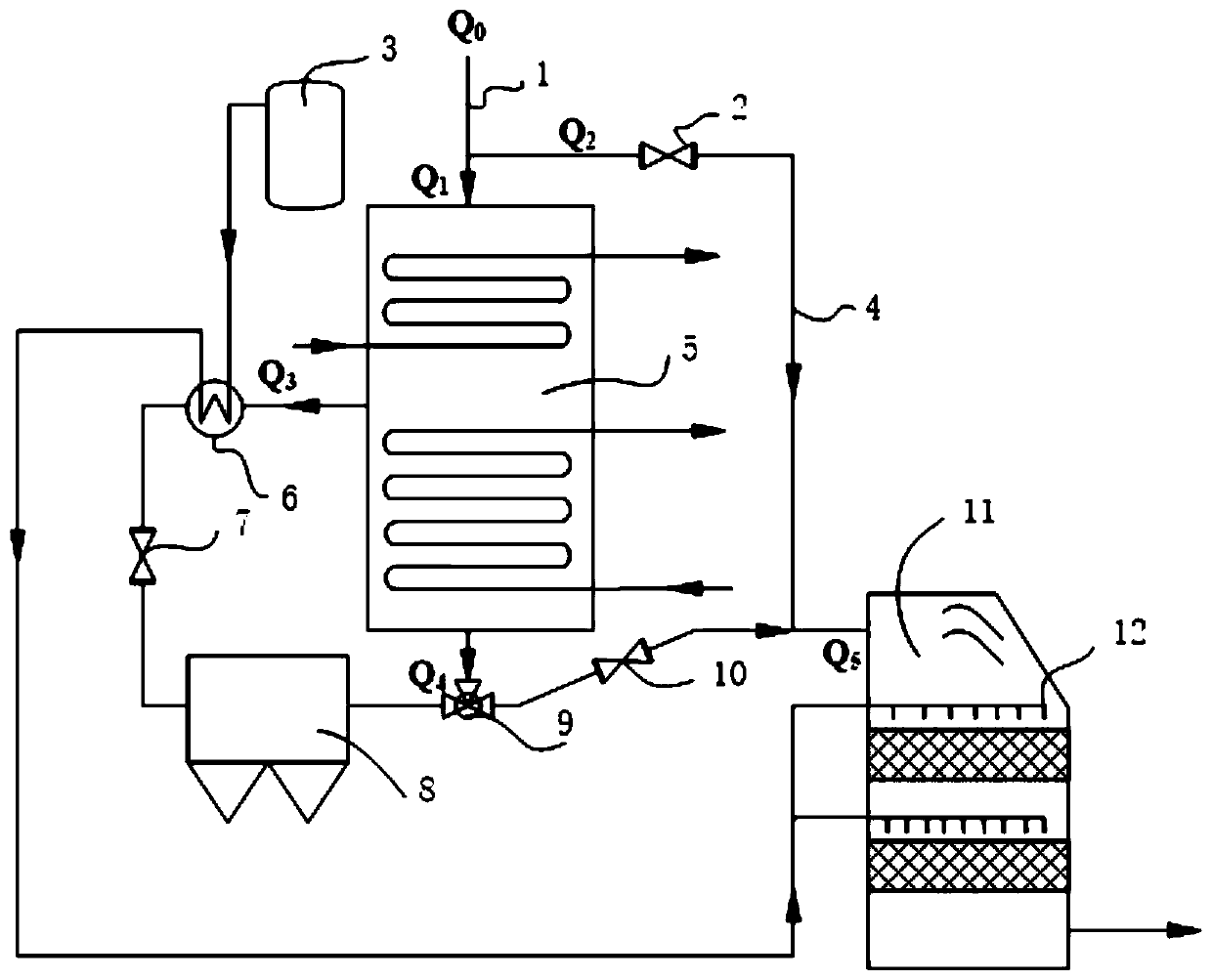

Kitchen air conditioning system

PendingCN110645654AAvoid soot pollutionExtend working lifeDucting arrangementsDomestic stoves or rangesFlue gasProcess engineering

The invention discloses a kitchen air conditioning system. The kitchen air conditioning system comprises an air conditioning assembly and an oil fume suction assembly, the air conditioning assembly comprises a compressor, a first heat exchanger and a second heat exchanger, wherein the compressor, the first heat exchanger and the second heat exchanger are communicating through a refrigerant pipeline, the oil fume suction assembly comprises a fan and an air outlet channel communicating with an air outlet of the fan, and the kitchen air conditioning system is characterized in that the compressoris integrated on the oil fume suction assembly, and the first heat exchanger is arranged in the air outlet channel. The kitchen air conditioning system has the advantages that the compressor is integrated on the oil fume suction assembly, the overall structure of the system is more compact, when the kitchen air conditioning system is installed, an air conditioner external unit does not need to beindependently installed, the installation is more convenient, in addition, the air conditioning system installs the first heat exchanger of the air conditioning assembly within the air outlet channelof the oil fume suction assembly, flue gas discharged into the air outlet channel can take away heat of the first heat exchanger or heat the first heat exchanger, and then the energy efficiency of anair conditioner is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

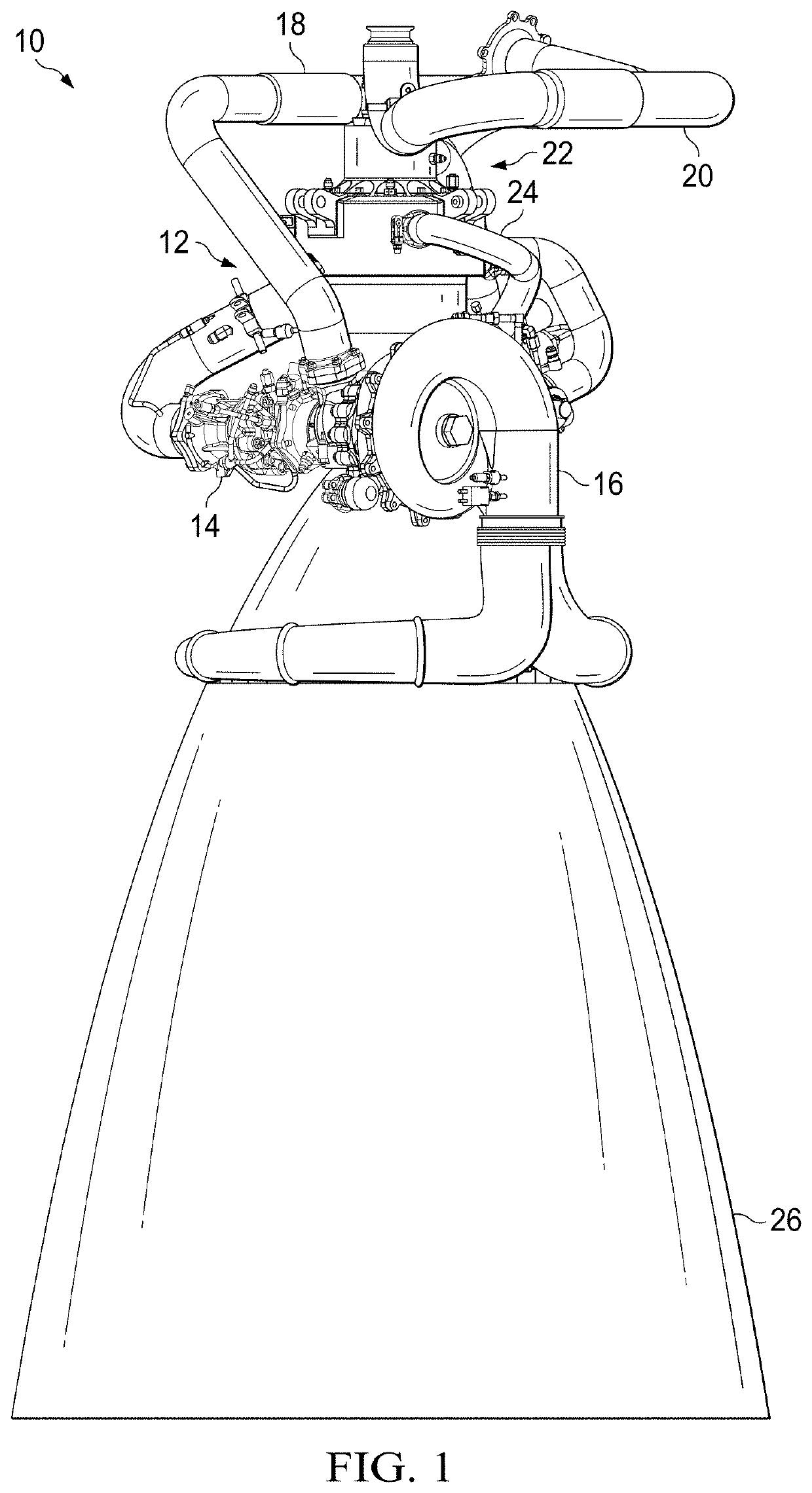

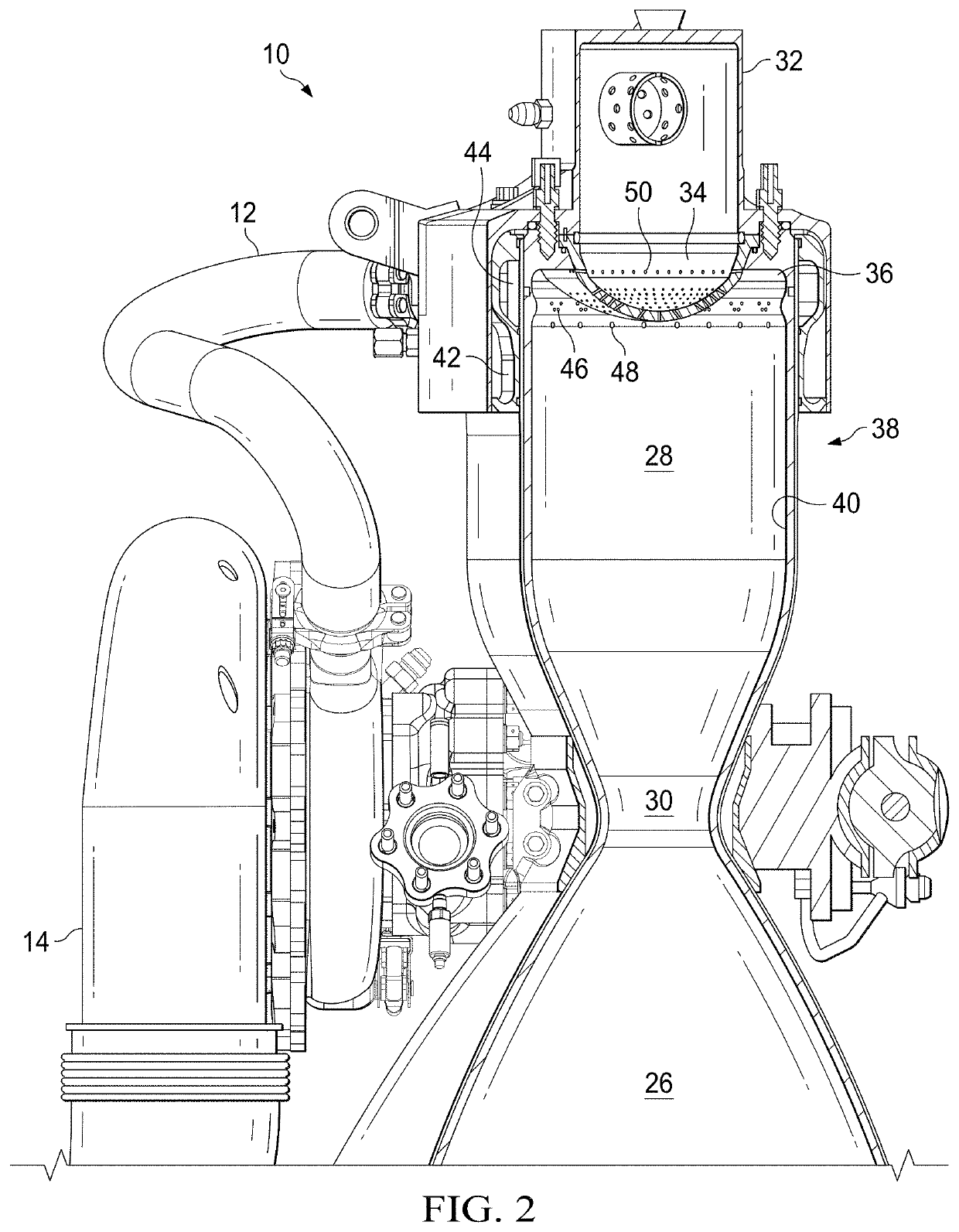

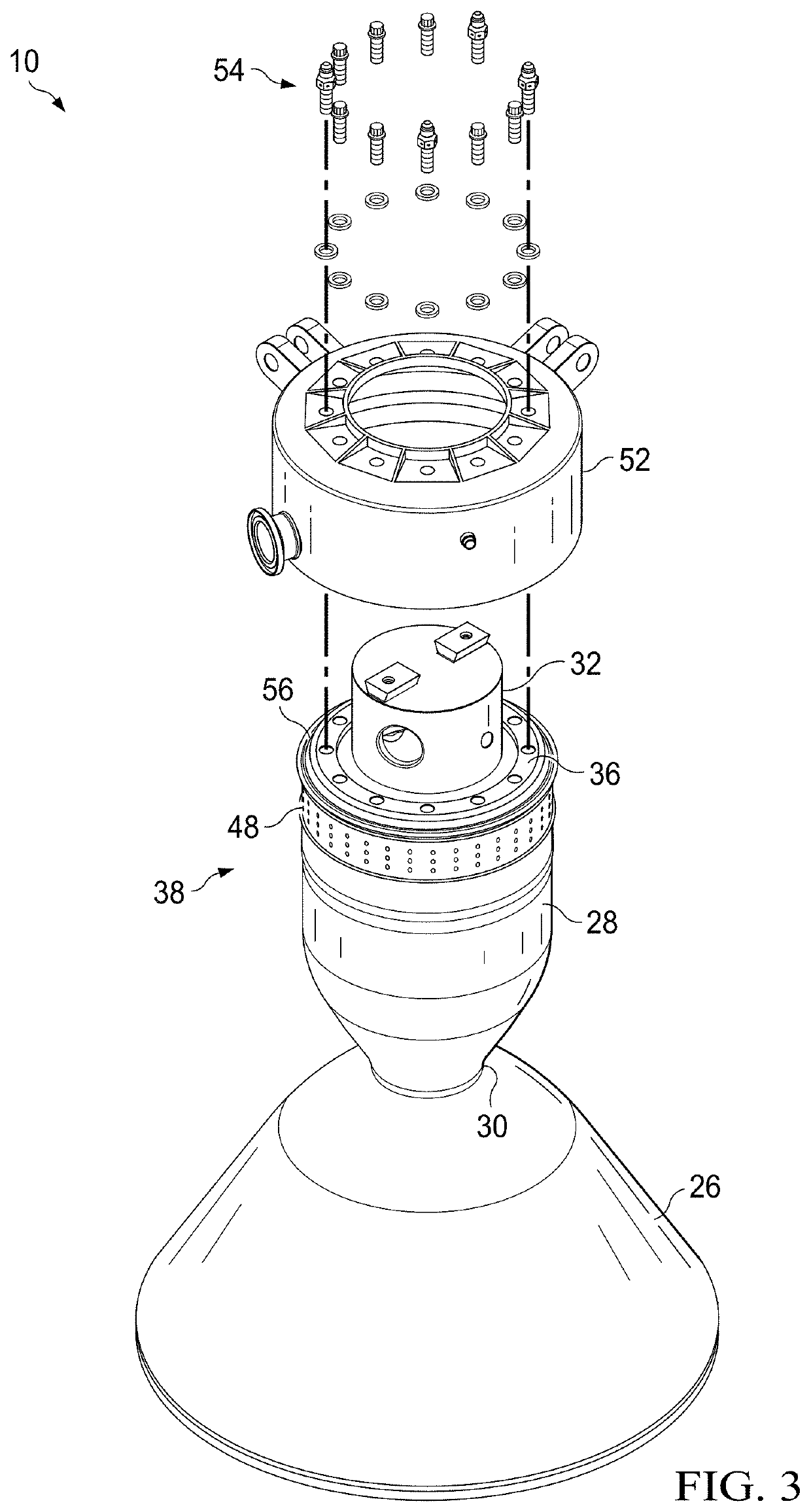

Liquid rocket engine tap-off power source

ActiveUS11008977B1Reduce disadvantagesReduce problemsCosmonautic vehiclesEngine manufactureCombustion chamberHeat management

Owner:FIREFLY IP CO LLC

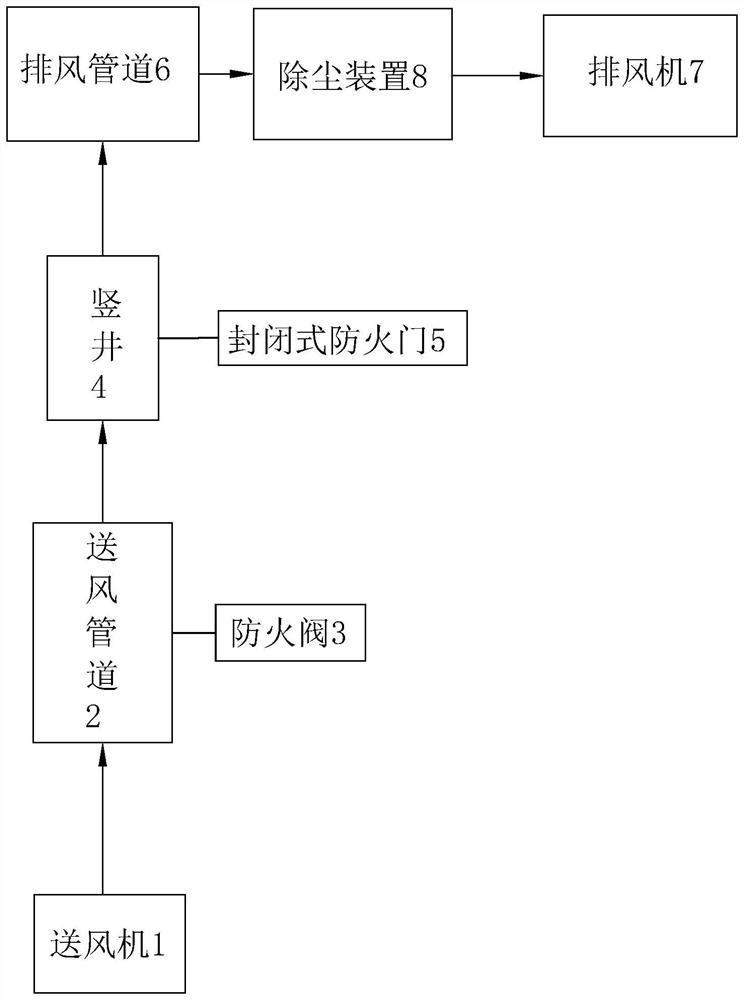

Fire-fighting smoke exhaust system

ActiveCN112197391AReduce soot contentReduce casualtiesMechanical apparatusLighting and heating apparatusFlue gasEnvironmental engineering

The invention relates to a fire-fighting smoke exhaust system, and relates to the field of fire-fighting system installation. The system comprises an air feeder, an air supply pipeline used for beinginstalled on a building body, a fireproof valve arranged on the air supply pipeline, a vertical shaft located in a staircase of the building body, a closed fireproof door used for being installed on the building body, an exhaust pipeline used for being installed on the building body, an exhaust fan used for being installed on the building body and a dust removal device used for being installed onthe building body, wherein the dust removal device comprises a dust removal tank, an air inlet pipe arranged on the dust removal tank, an air outlet pipe arranged on the dust removal tank, a residue outlet pipe arranged on the dust removal tank and a spraying assembly, the air inlet pipe is connected with the exhaust pipeline and tangent to the dust removal tank, the air outlet pipe is connected with the exhaust fan and tangent to the dust removal tank, and the spraying assembly is used for removing dust from the flue gas passing through the dust removal tank. According to the fire-fighting smoke exhaust system, the pollution of the smoke exhaust system to the atmosphere in the smoke exhaust process is reduced.

Owner:天津市安信通达机电设备安装工程有限公司

Medium-temperature SCR denitration system and denitration method for kiln tail flue gas

InactiveCN111551038ARaise the layout temperatureImprove denitrification efficiencyCombination devicesGas treatmentPtru catalystFlue gas

The invention provides a medium-temperature SCR denitration system and denitration method for kiln tail flue gas. The denitration system comprises a waste heat recovery device, a heat exchange deviceand an SCR denitration device, wherein a high-temperature flue gas outlet of the waste heat recovery device is connected with the heat exchange device, and an outlet of the heat exchange device and amedium-temperature flue gas outlet of the waste heat recovery device are combined into one path and then connected into the SCR denitration device. The medium-temperature SCR denitration system provided by the invention can meet the increasingly strict NOx emission standard of the kiln tail flue gas of a cement kiln and provide technical support for ultralow emission of NOx at the kiln tail of thecement kiln. Through flue gas back-mixing, on one hand, the temperature of the flue gas at the outlet of the waste heat recovery device can be increased, and on the other hand, the content of smoke dust entering the SCR denitration device is reduced, so that the SCR denitration efficiency is improved, and meanwhile, system dust accumulation and catalyst poisoning are reduced.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Intelligent drainage and mining method of coalbed methane well and intelligent drainage and mining equipment of coalbed methane well immersed pump

InactiveCN101666223BAffect the permeabilityAvoid harmFlexible member pumpsFluid removalWater dischargeStream flow

Owner:濮阳市鑫益实业有限公司

Industrial honey comb briquette

InactiveCN1831096AImprove the state of combustionHas sulfur fixation effectSolid fuelsSulfurBituminous coal

This invention relates to industrial briquette, it is mainly composed of powder coal, light burning powder and magnesia. Its main materials match is bituminous coal 100 parts, light burning powder 3-10 parts, magnesium sulplate 1-8 parts. For more bituminous coal, optimal matching is that bituminous coal 100 parts, light burning powder 5 parts, magnesium sulplate 3 parts. For most bituminous coal, optimal matching is that bituminous coal 100 parts, light burning powder 5 parts, magnesium sulplate 5 parts, and bituminous coal or light coal 1-2 parts can be added. Cold press molding method can be used in this kind molded coal, its single cold strength can reach 1000-1200N, heat strength can reach 400-500N, ash fusing point is 130 degree centigrade. During its stock and transportation, burning process, it will not crack, disperse, collapse, its burning state in furnace is good, burning is full, flue dust content is low, and with certain sulfur fixing effect, it is mainly used all kinds of pottery kiln, cement kiln and other industrial furnaces.

Owner:苗冠强

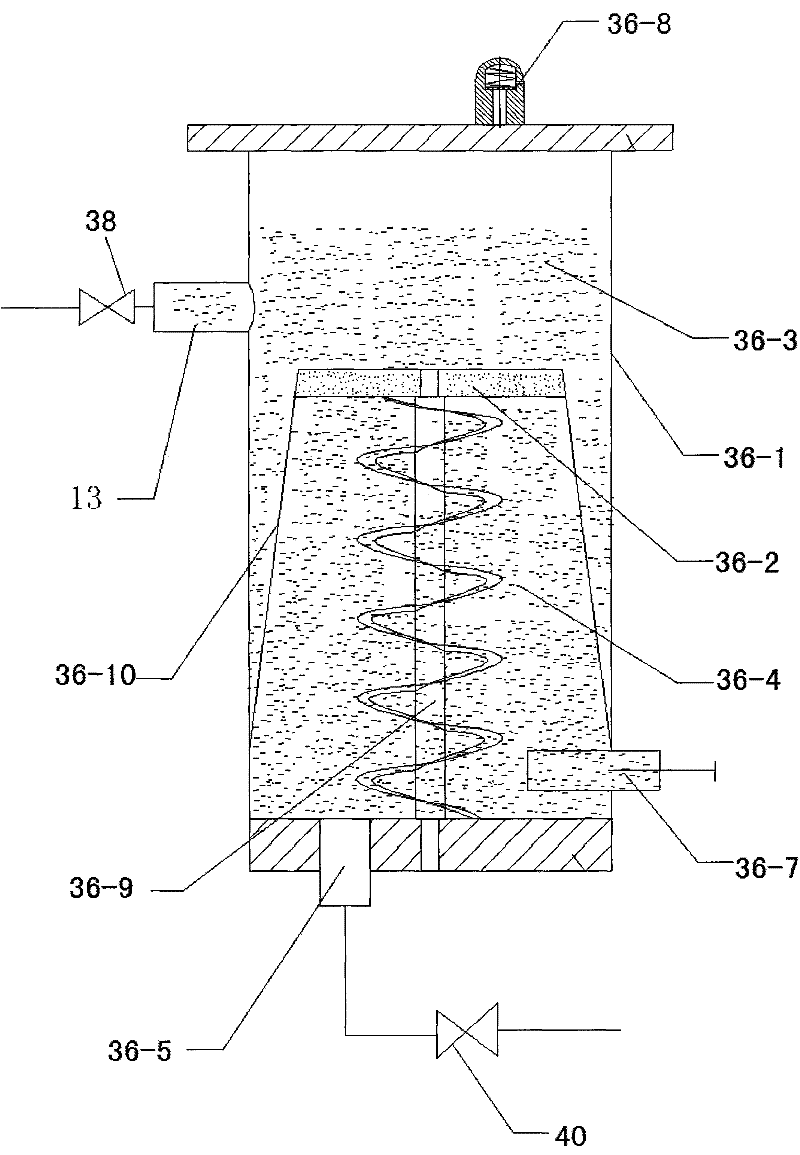

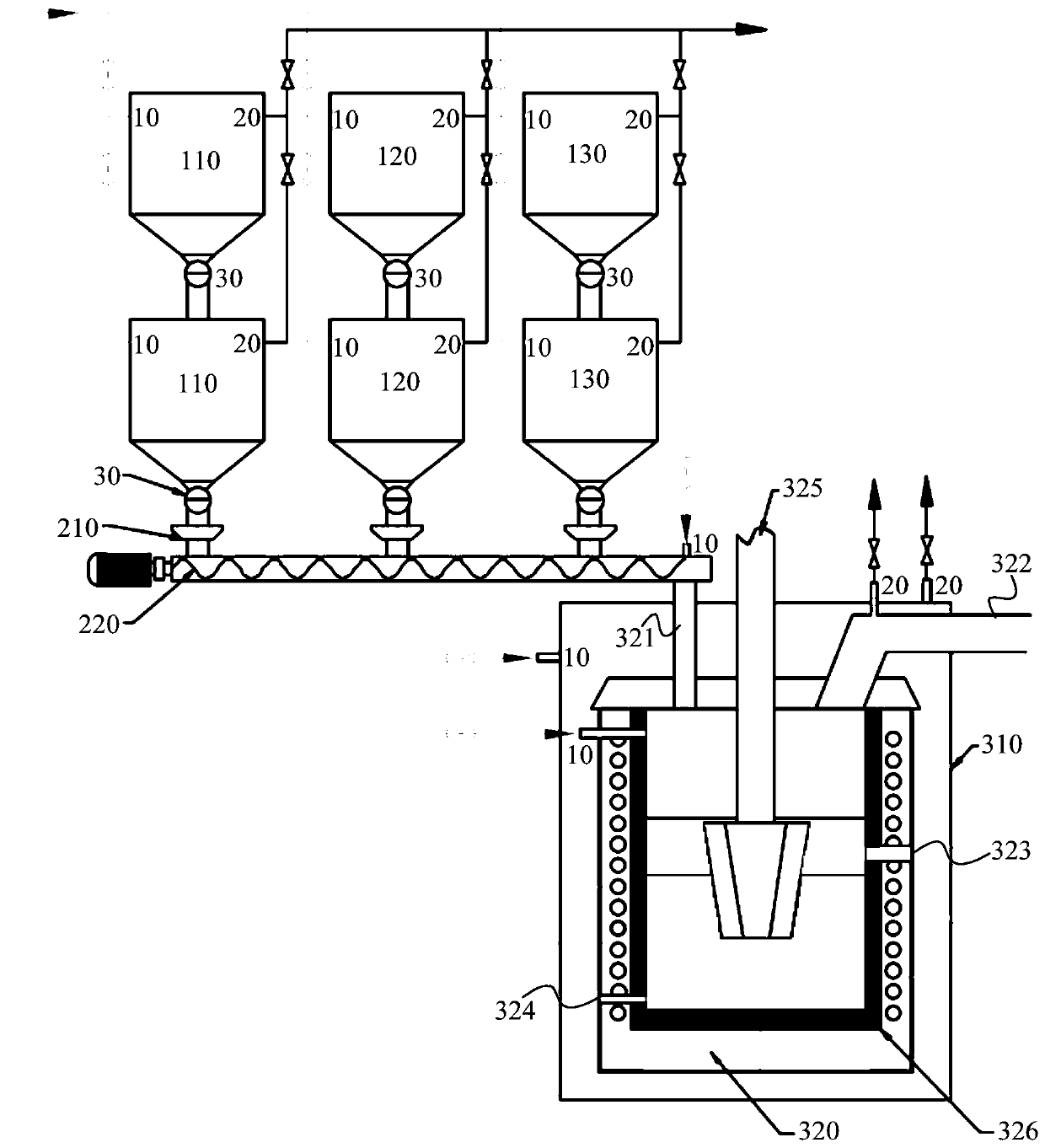

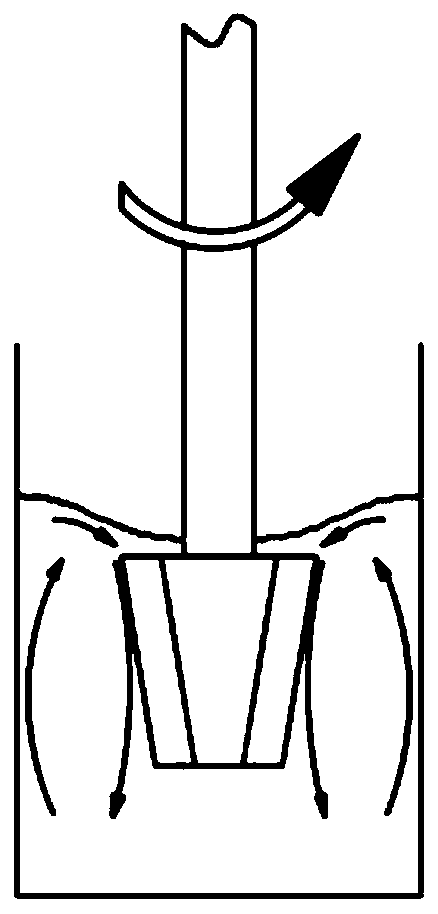

System and method of induction heating liquid mixing continuous magnesium production

PendingCN111270088AReduce the burden onReduce power consumptionProcess efficiency improvementChemistryScrew conveyor

The invention discloses a system and method of induction heating liquid mixing continuous magnesium production. The system comprises a silicon iron raw material bin, a magnesium ore raw material bin,a flux raw material bin, a feeding mechanism and a smelting mechanism. Each raw material bin is provided with an inert gas inlet and a vacuuming port. The smelting mechanism comprises an airtight chamber and an induction furnace. The induction furnace is arranged in the airtight chamber. A feeding pipeline and an exhaust gas pipeline are arranged on the top of the induction furnace. The feeding pipeline extends out of the airtight chamber and is connected with a screw conveyer. The exhaust gas pipeline extends out of the airtight chamber. A slag outlet and an iron outlet are arranged on the side on the induction furnace. The induction furnace is further provided with a stirring paddle. The airtight chamber is provided with an inert gas inlet on the side wall. The induction furnace is provided with an inert gas inlet on the side wall. The airtight chamber is provided with a vacuuming port on the top wall. The exhaust gas pipeline is provided with a vacuuming port. According to the system of induction heating liquid mixing continuous magnesium production, because the negative micro-pressure operation or normal-pressure operation is adopted, continuous feeding and discharging can be implemented, continuous production of the metal magnesium is implemented, and the production cost is reduced; and splashing can be effectively reduced, the quantity of soot is effectively reduced, thequality of original magnesium is improved, and the stable running state of equipment is improved.

Owner:CHINA ENFI ENGINEERING CORPORATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com