Method and equipment for upgrading, drying and forming lignite

A lignite and drying technology, applied in the petroleum industry, solid fuels, fuels, etc., can solve problems such as coal ash pollution, reduce dust, reduce coal ash content, and improve the working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for upgrading and drying the lignite of the present embodiment comprises the following steps:

[0028] 1) Pulverize lignite into coal powder below 3mm;

[0029] 2) Add 0.5% sodium hydroxide with a mass of 0.5% of the pulverized coal mass to the pulverized coal obtained in step 1), stir and feed water vapor with a volume of 3% of the pulverized coal volume to make it fully react. The temperature of the steam is 100°C, pressure 0.6MPa, reaction time 40min;

[0030] 3) Dry the reacted lignite with hot air at 120°C for 30 minutes; then perform compression molding with a linear pressure of 10T, a molding humidity of 20%, and a molding temperature of 90°C to obtain the product.

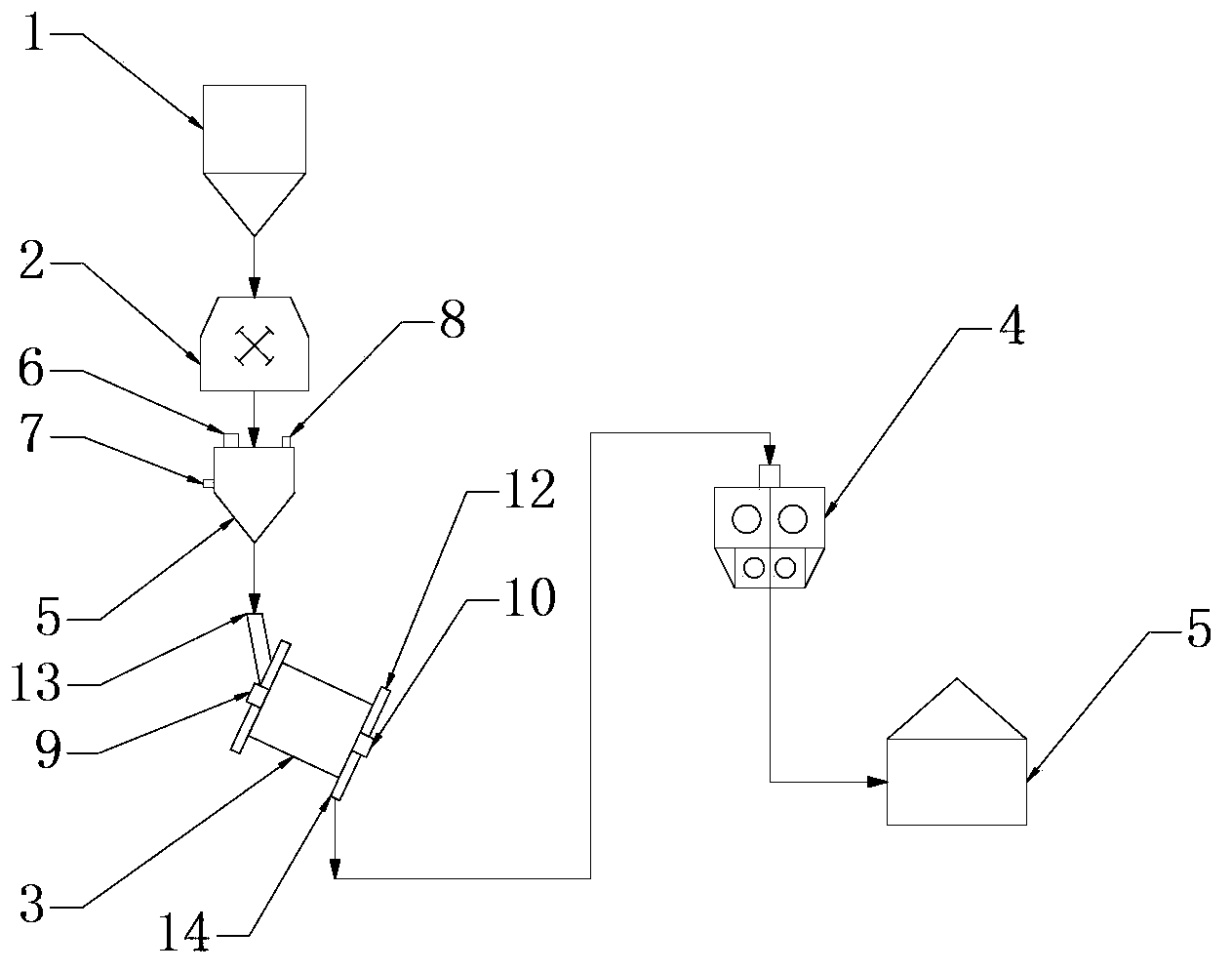

[0031] The lignite upgrading and drying molding equipment for realizing the above method of the present embodiment, such as figure 1 As shown, it includes a crusher 2, a dryer 3 and a molding machine 4, the molding machine 4 is provided with an inlet for the dry material from the dry mat...

Embodiment 2

[0034] The method for upgrading and drying the lignite of the present embodiment comprises the following steps:

[0035] 1) Pulverize lignite into coal powder below 3mm;

[0036] 2) To the pulverized coal obtained in step 1), add sodium hydroxide with a mass of 3% of the pulverized coal mass, stir and feed water vapor with a volume of 4% of the pulverized coal volume to make it fully react. The temperature of the steam is 95°C, pressure 0.6MPa, reaction time 60 minutes, coal powder condensed into small spherical coal powder is the best;

[0037] 3) Dry the reacted lignite with hot air at 120°C for 30 minutes; then perform compression molding with a linear pressure of 10T, a molding humidity of 20%, and a molding temperature of 90°C to obtain the product.

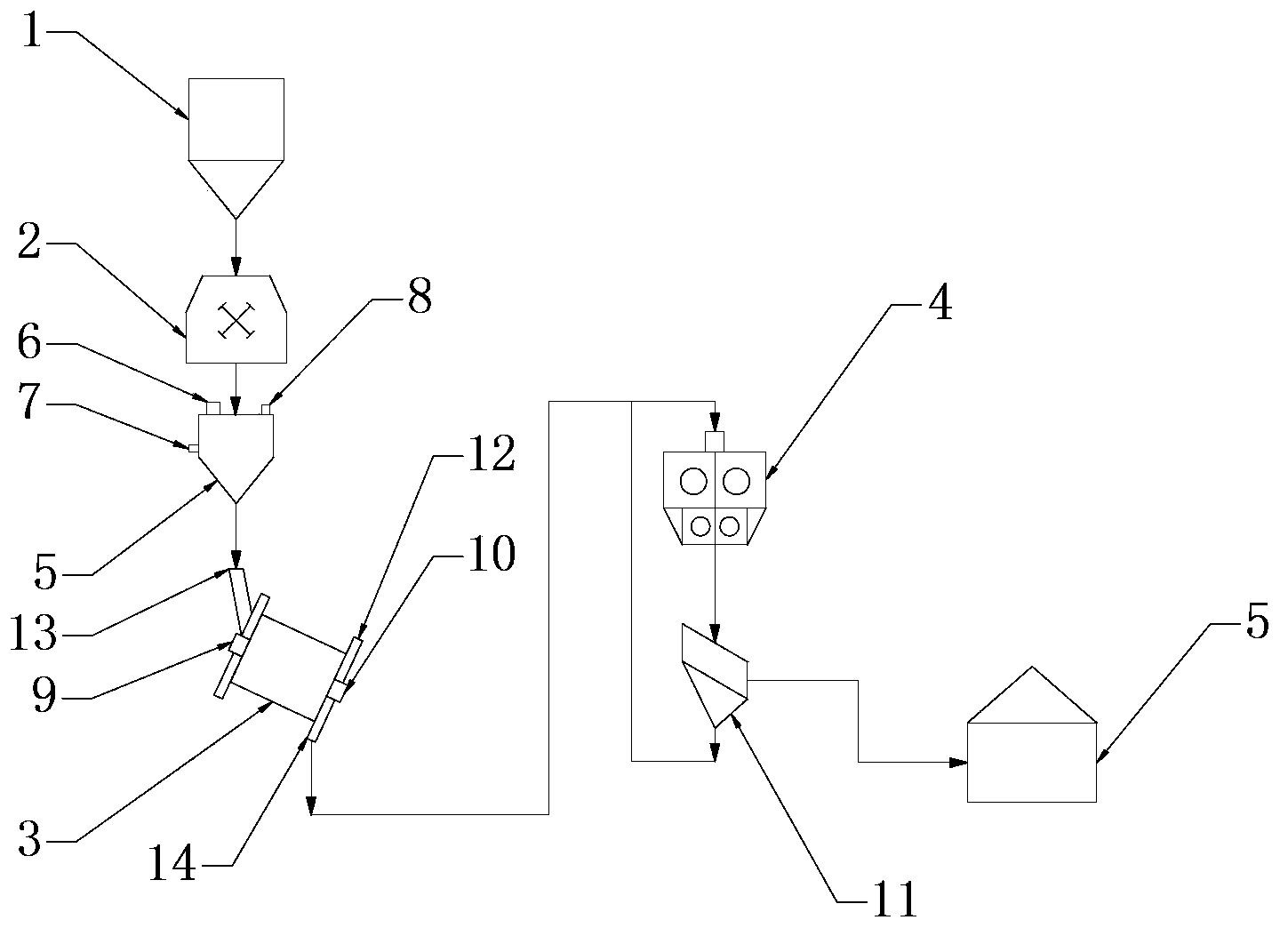

[0038] The lignite upgrading and drying equipment for realizing the above method of the present embodiment differs from the equipment in Example 1 in that: figure 2 As shown, the product outlet of the molding machine 4 is...

Embodiment 3

[0041] The method for upgrading and drying the lignite of the present embodiment comprises the following steps:

[0042] 1) Pulverize lignite into coal powder below 3mm;

[0043] 2) Add sodium hydroxide whose mass is 1.5% of the mass of coal powder to the coal powder obtained in step 1), stir and feed 5% water vapor whose volume is the volume of coal powder to make it fully react, and the temperature of the steam is 97 ℃, the pressure is 0.6MPa, and the reaction time is 20min;

[0044] 3) Dry the reacted lignite with hot air at 120°C for 30 minutes; then perform compression molding with a linear pressure of 10T, a molding humidity of 20%, and a molding temperature of 90°C to obtain the product.

[0045] The lignite upgrading and drying molding equipment of this embodiment is the same as the lignite upgrading drying molding equipment used in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com