Patents

Literature

33results about How to "Guaranteed molding efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

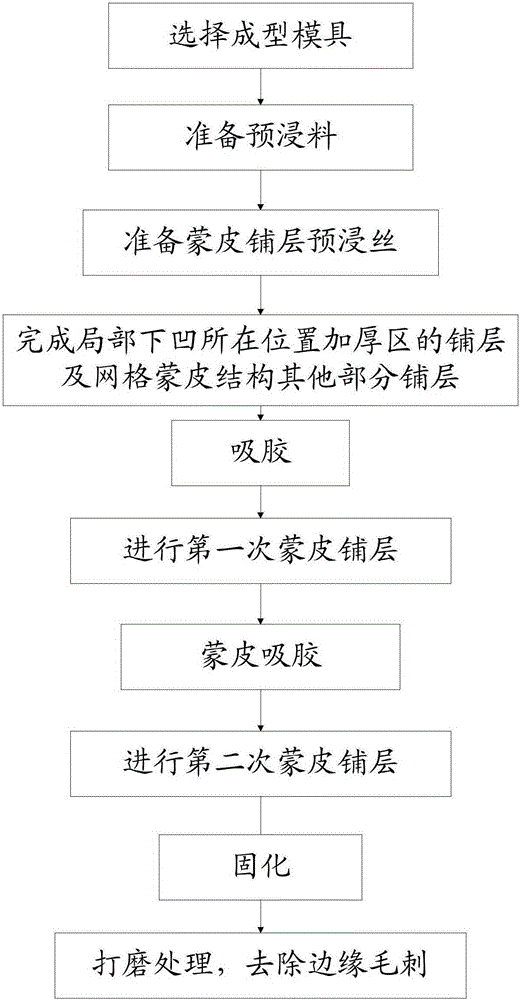

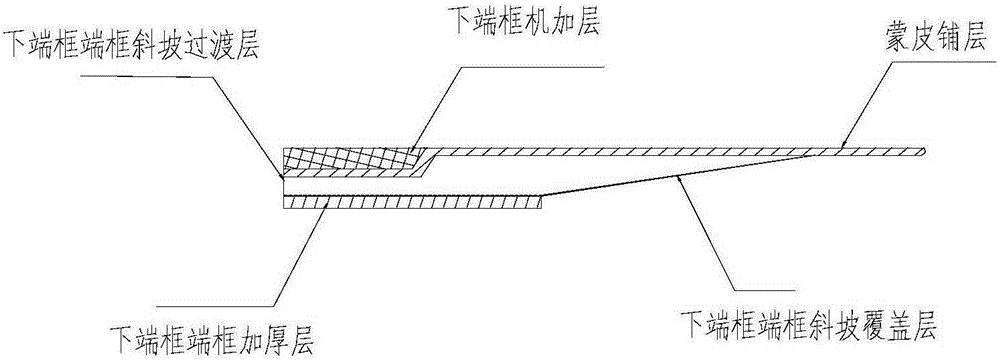

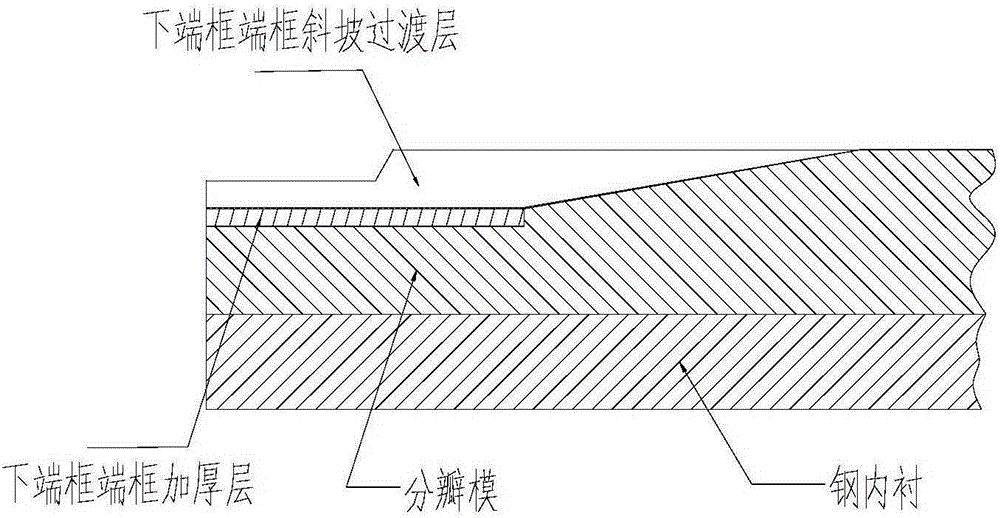

Automatic fiber placement forming method for grid skin structure with part concave structure

The invention discloses an automatic fiber placement forming method for a grid skin structure with a part concave structure. The method comprises the following steps that a forming mold is selected; material is presoaked with the adoption of a hot melting method; presoaked fibers are prepared; placement in the thickened area of the part concave position and placement for other parts of a grid shell body are completed with the aid of hands by using the presoaked material; glue absorption is conducted in a hot-pressing pot; a first skin placement is conducted; skin glue absorption is conducted in the hot-pressing pot; a second skin placement is conducted; solidification is conducted; and polishing treatment is conducted, and automatic fiber placement forming for the grid skin structure with the part concave structure is completed. According to the method, the technical problem that automatic fiber placement can not be conducted in the concave position is solved, and the application of an automatic fiber placement technique on a composite typical structure component is achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

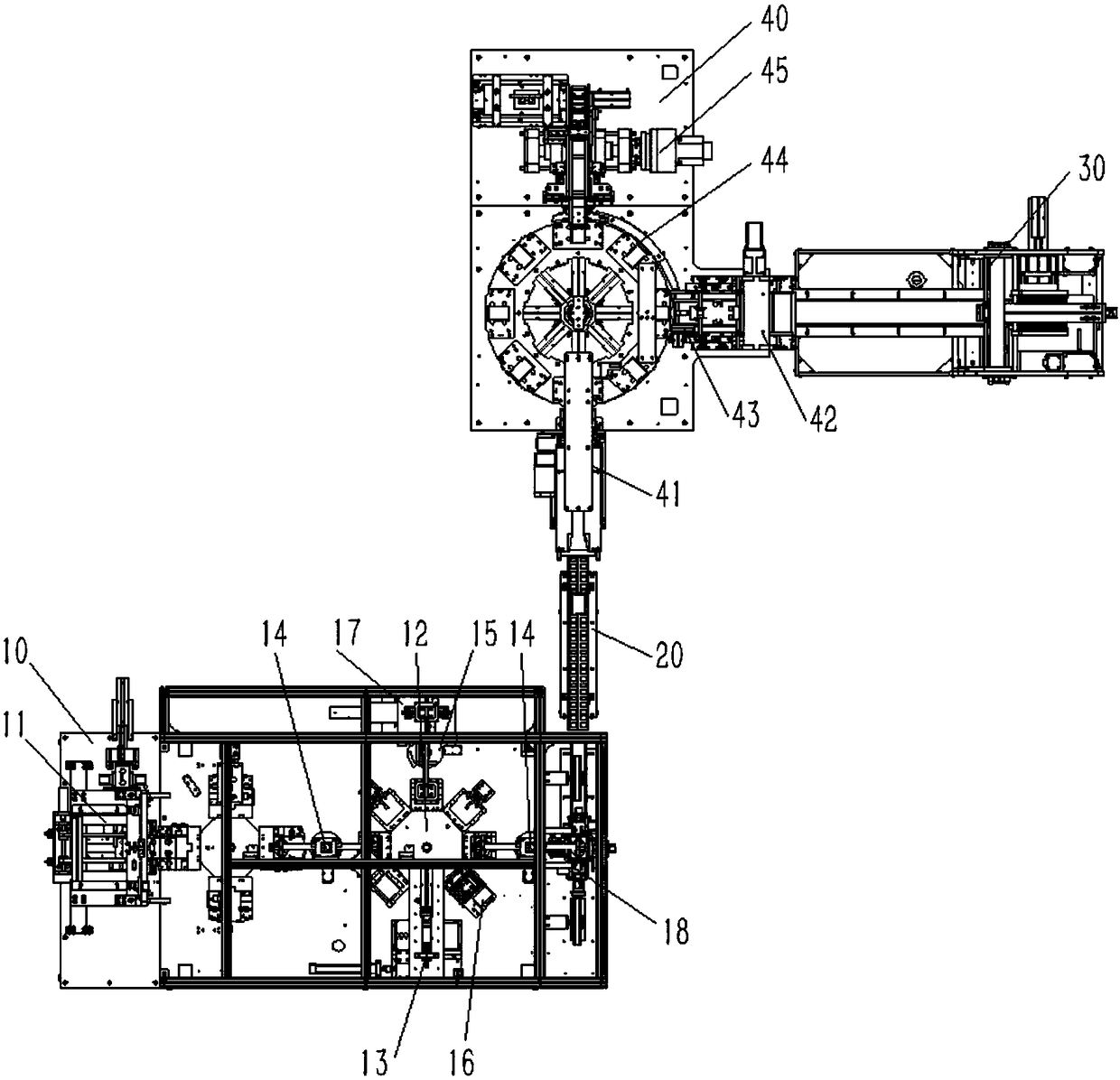

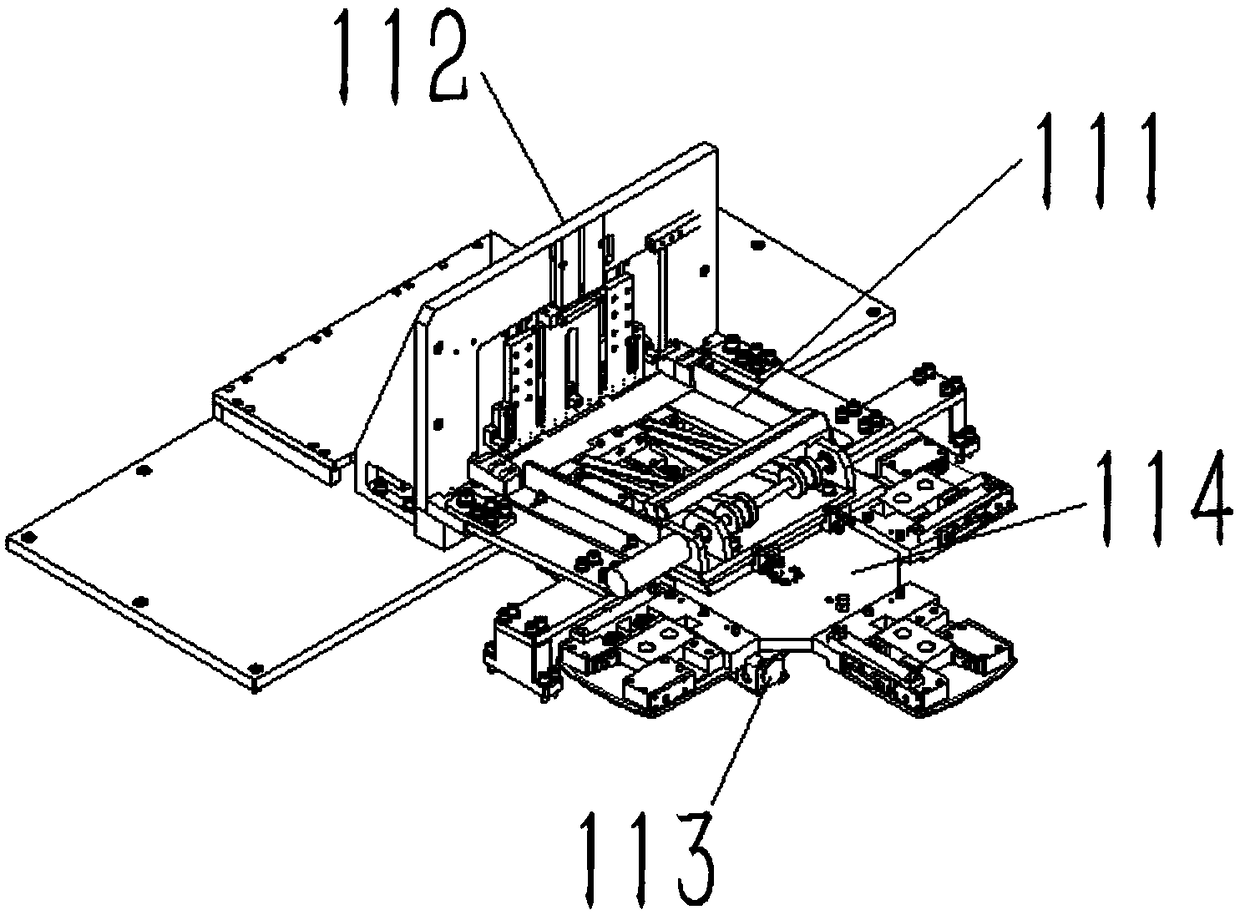

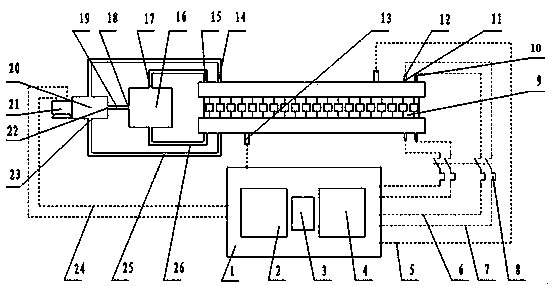

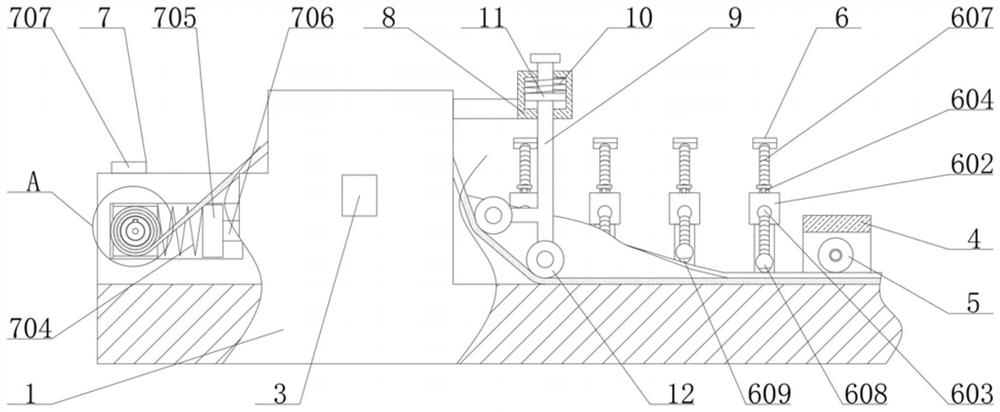

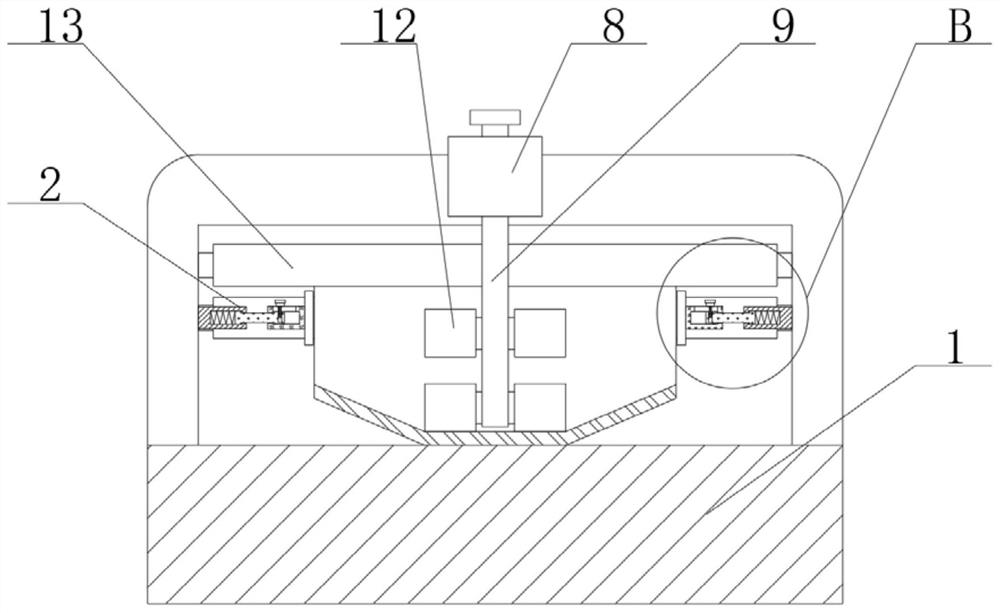

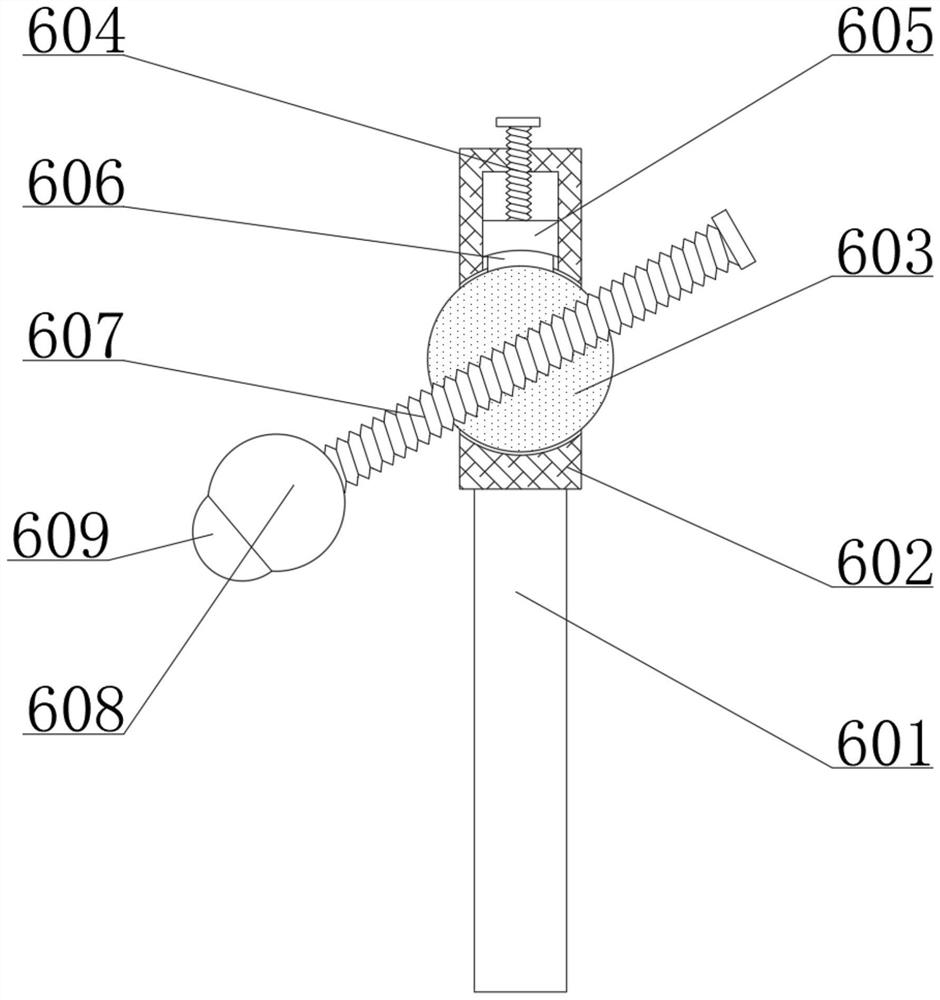

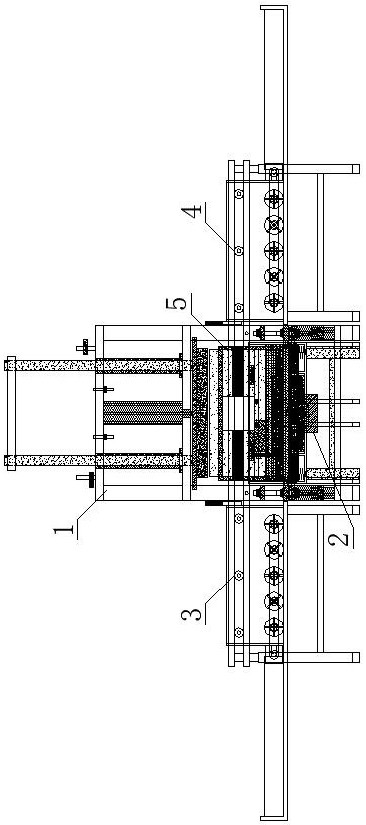

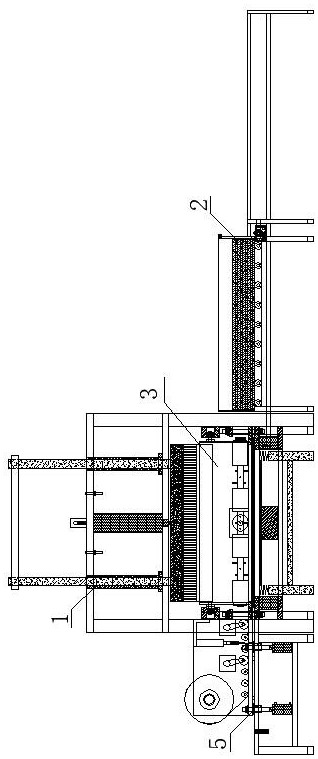

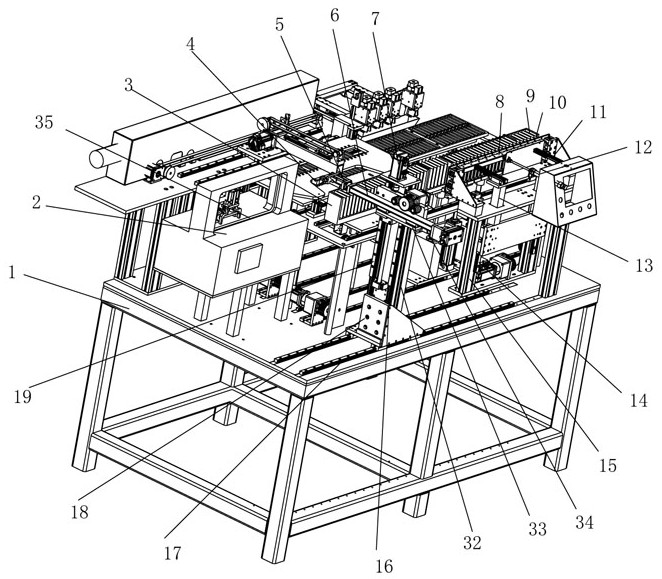

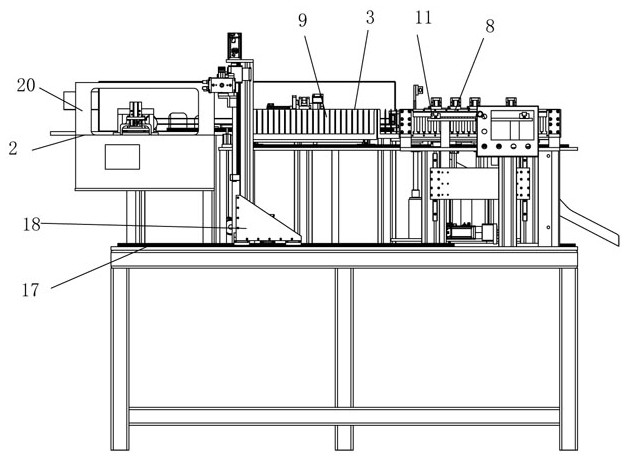

Paper box making equipment and box making method thereof

ActiveCN108544795AReduce manufacturing costLow application costBox making operationsPaper-makingContinuous/uninterruptedPulp and paper industry

The invention discloses paper box making equipment and a box making method thereof, and belongs to the technical field of packaging equipment. Through the arrangement of a surrounding strip die forming mechanism, a box blank forming rotation disc mechanism, a box blank pressure maintaining gluing mechanism and the like, accurate paper box blank forming is achieved. Through the arrangement of a lower cover feeding mechanism, an upper cover feeding mechanism and a face paper supply glue feeding assembly, accurate feeding of a lower cover, an upper cover and face paper is finished, and a finishedproduct box pasting assembly is arranged to achieve face paper and box blank positioning and forming. The whole box making process is continuous and is not stopped, and continuity and control precision are high. According to the paper box making equipment and the box making method thereof, through coordinated work of multiple mechanisms or devices, constant accurate paper box preparing can be achieved; compared with traditional manual box making, accuracy of various control links in the box making process is effectively guaranteed, the paper box preparing efficiency is greatly improved, the paper box production cost is reduced, and extremely high application value is achieved.

Owner:SINOTECHO WUHAN INTELLIGENT TECH CO LTD

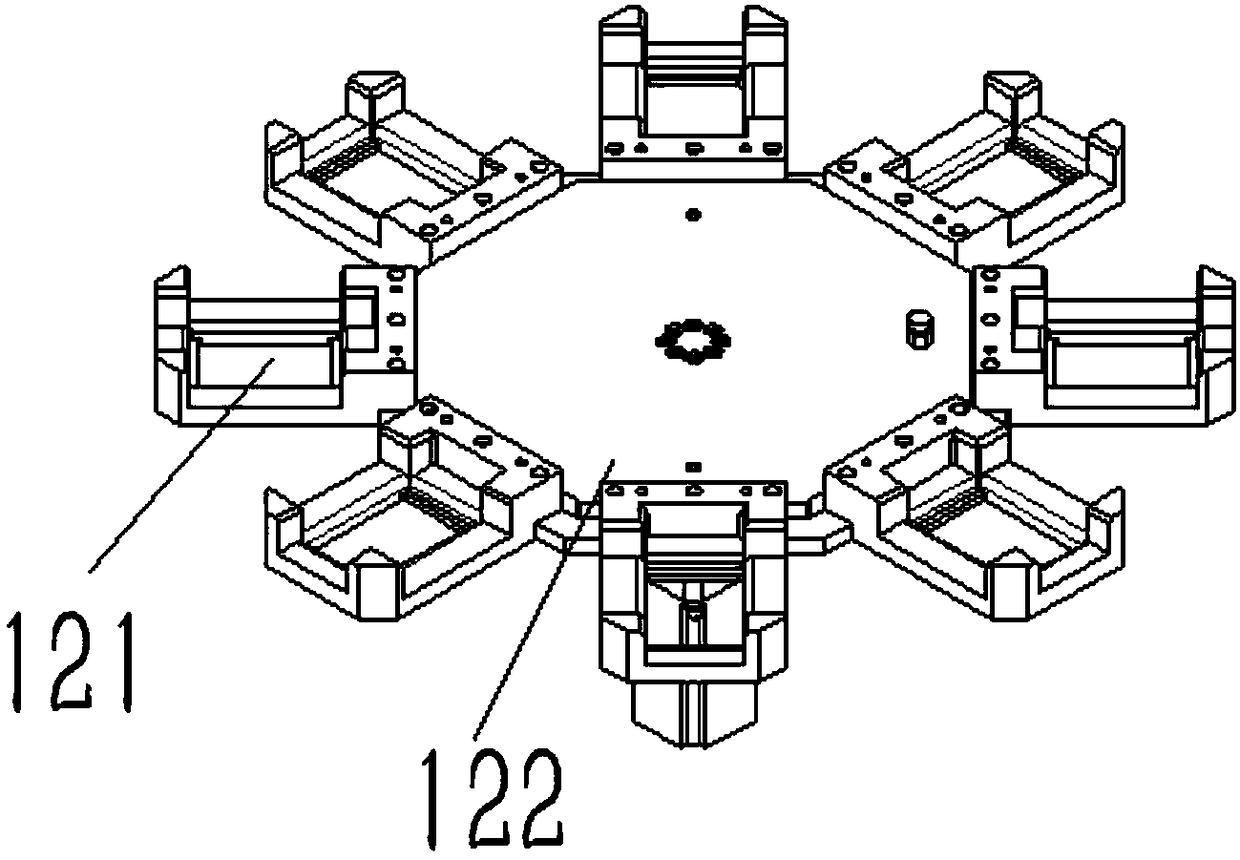

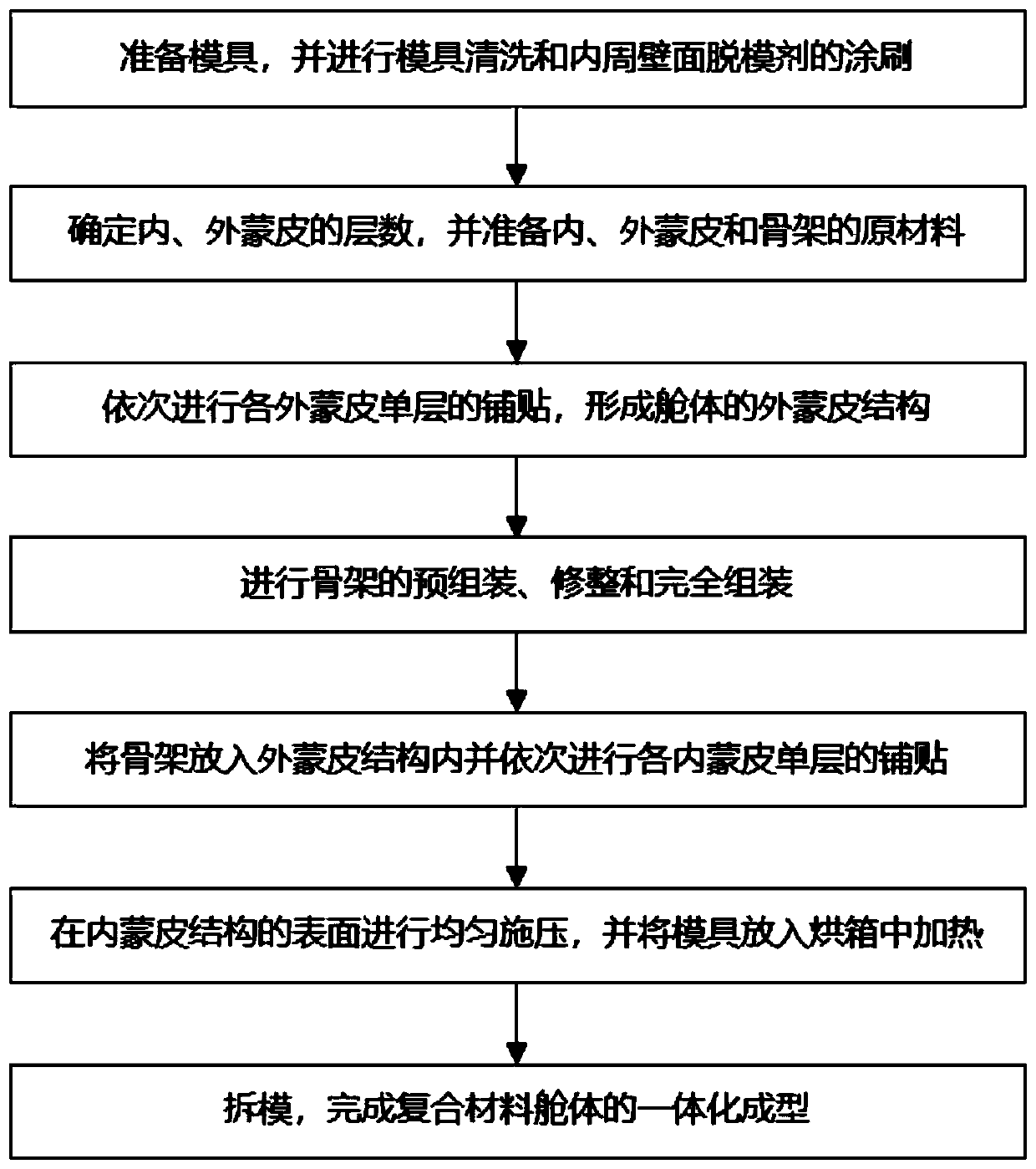

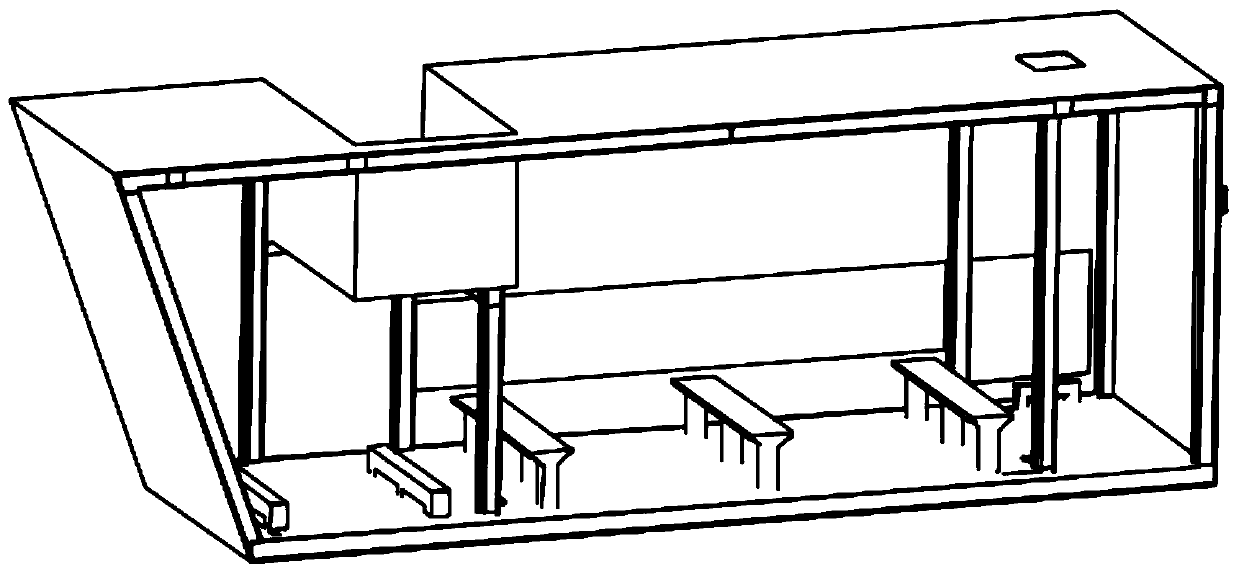

Integrated forming method for composite material cabin

The invention discloses an integrated forming method for a composite material cabin, and belongs to the technical field of cabin forming. According to the integrated forming method, a die corresponding to the cabin in shape is arranged and internally and sequentially provided with an outer skin structure, a framework and an inner skin structure; through layering paving and pasting of inner and outer skin materials, the framework can be effectively wrapped in the inner skin structure and the outer skin structure, an integrated integral structure is formed, and the weight of the cabin is greatlyreduced under the situation that the structure strength of the cabin is guaranteed. According to the integrated forming method for the composite material cabin, the steps of the integrated forming method are simple, operation is simple and convenient, integrated forming of the composite material cabin can be effectively achieved, and it is ensured that the cabin has good integral performance after being formed; and the weight of the cabin is greatly reduced compared with an existing metal cabin, the maneuverability of a weapon system loading the cabin is effectively improved, and good application prospects and popularization value are achieved.

Owner:HUBEI SANJIANG AEROSPACE WANFENG TECH DEV

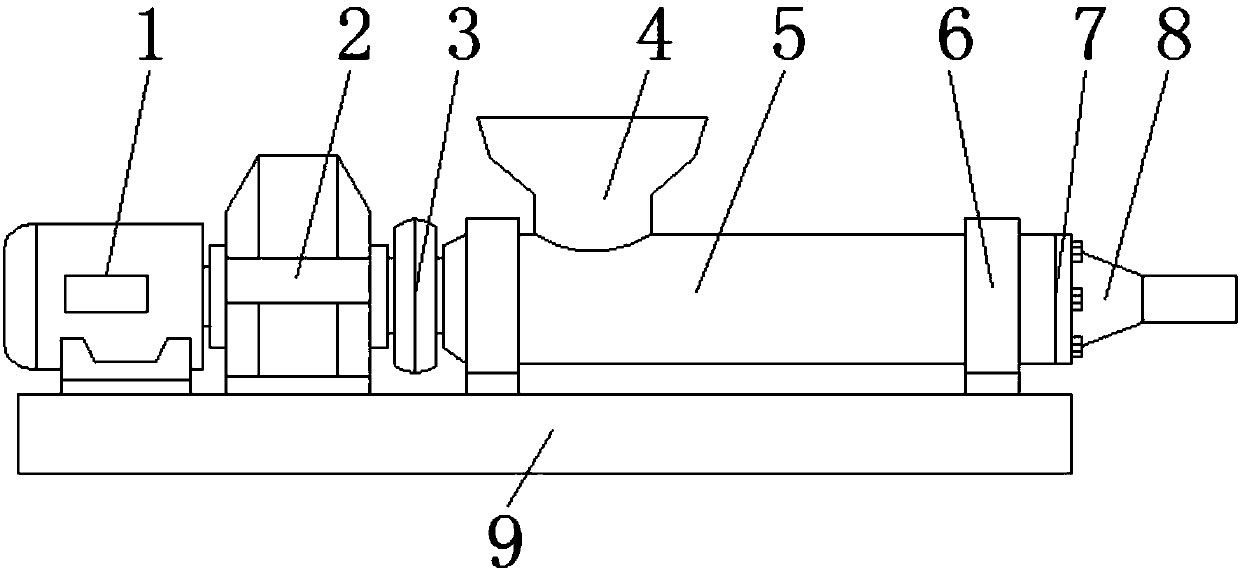

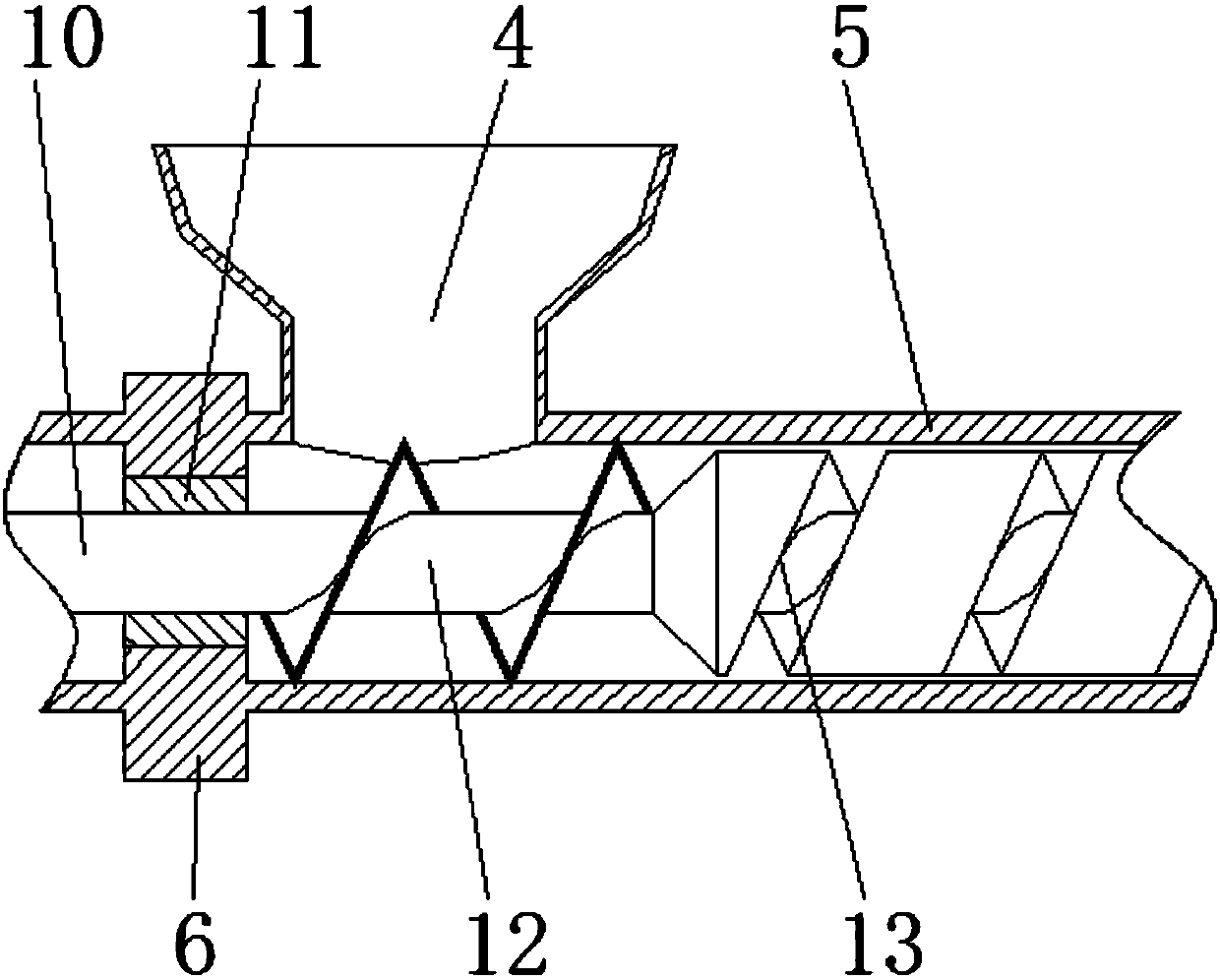

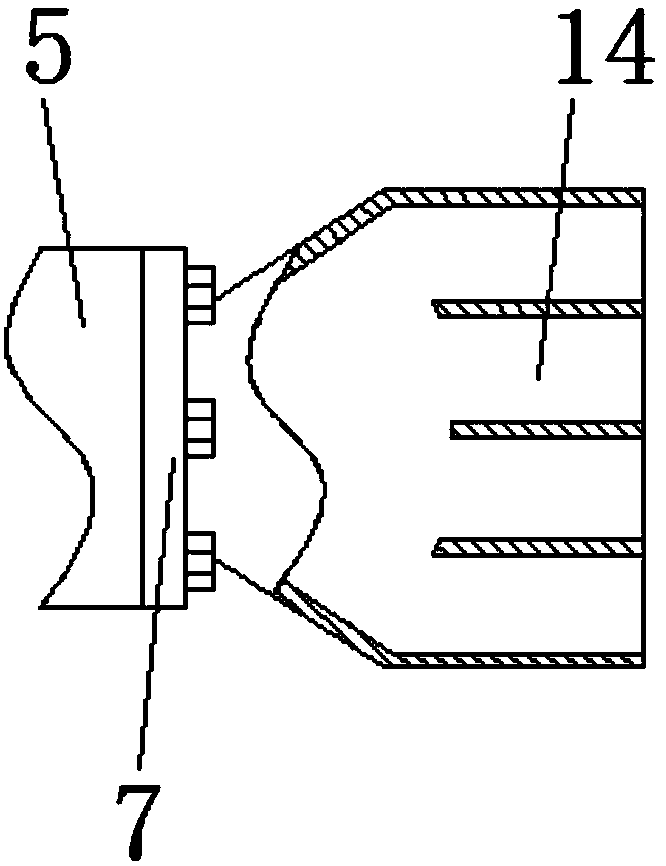

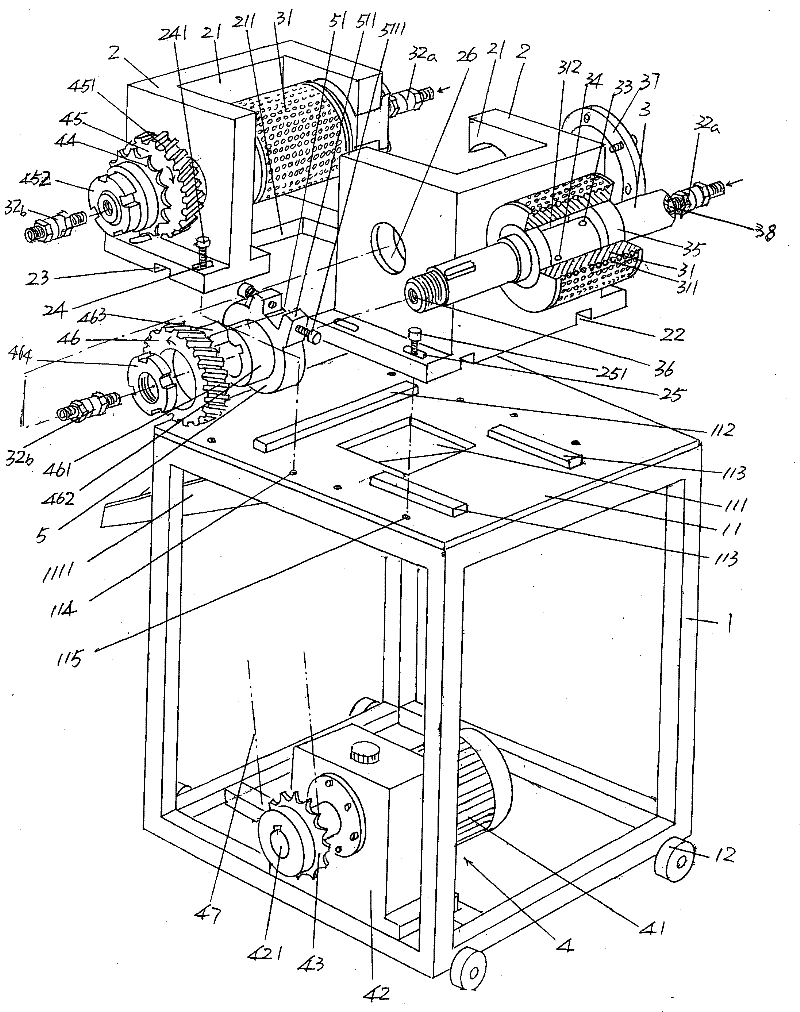

Mining blasting stemming machine for quick production

PendingCN107856169AImprove production efficiencyGuaranteed consistent specificationsCeramic extrusion diesBlastingCouplingReduction drive

The invention discloses a mining blasting stemming machine for quick production. The mining blasting stemming machine for quick production comprises a motor and a fixed ring; the right end of the motor is connected with a speed reducer; a coupling is fixed at the right end of the speed reducer; a main body is arranged at the right end of the coupling; a feed hopper is mounted on the upper side ofthe main body; the main body is fixed on the inner side of the fixed ring; a molding head is connected to the right end of the main body; the lower side of the fixed ring is connected with a fixed base; the inner side of the main body is connected with a rotating shaft through a rotating bearing; a first feed shaft and a second feed shaft are arranged at the right end of the rotating shaft; the second feed shaft is fixed at the right end of the first feed shaft; and discharge ports are formed in the inner side of the molding head. The mining blasting stemming machine for quick production is provided with the first feed shaft and the second feed shaft for quickly extruding and conveying stemming to guarantee the production efficiency of the stemming; and four discharge ports are formed in the molding head, so that the working efficiency of the stemming machine is improved.

Owner:GUIZHOU UNIV

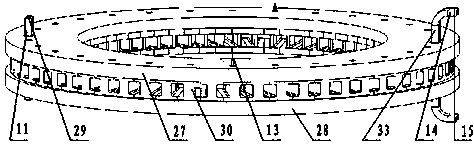

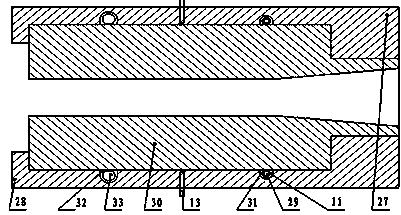

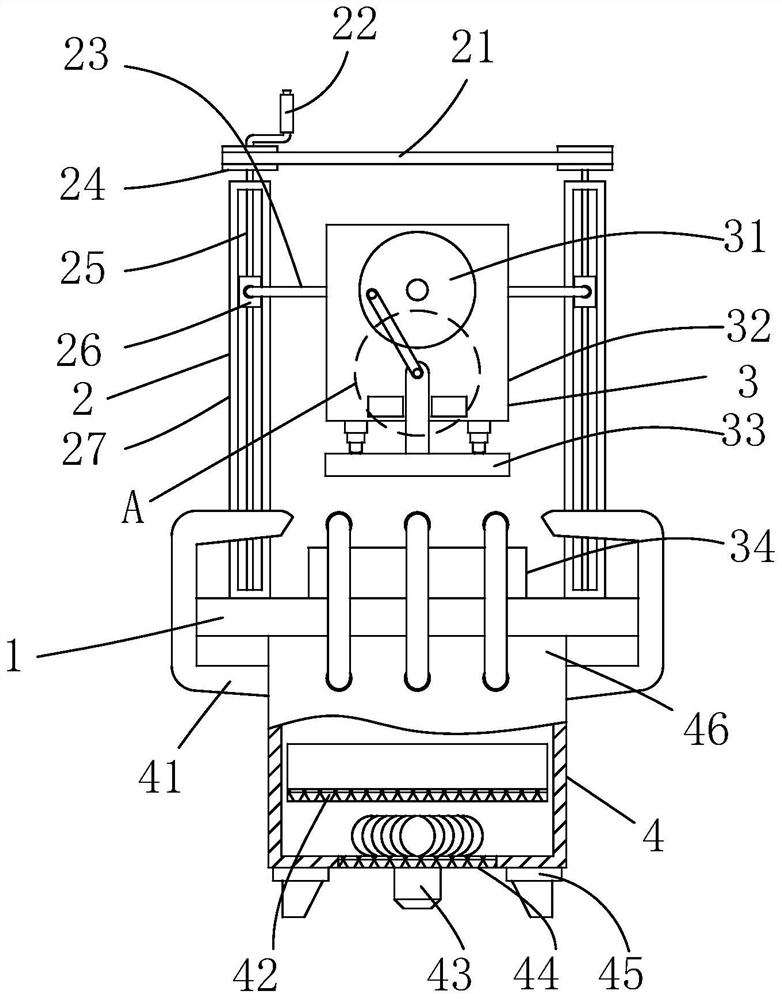

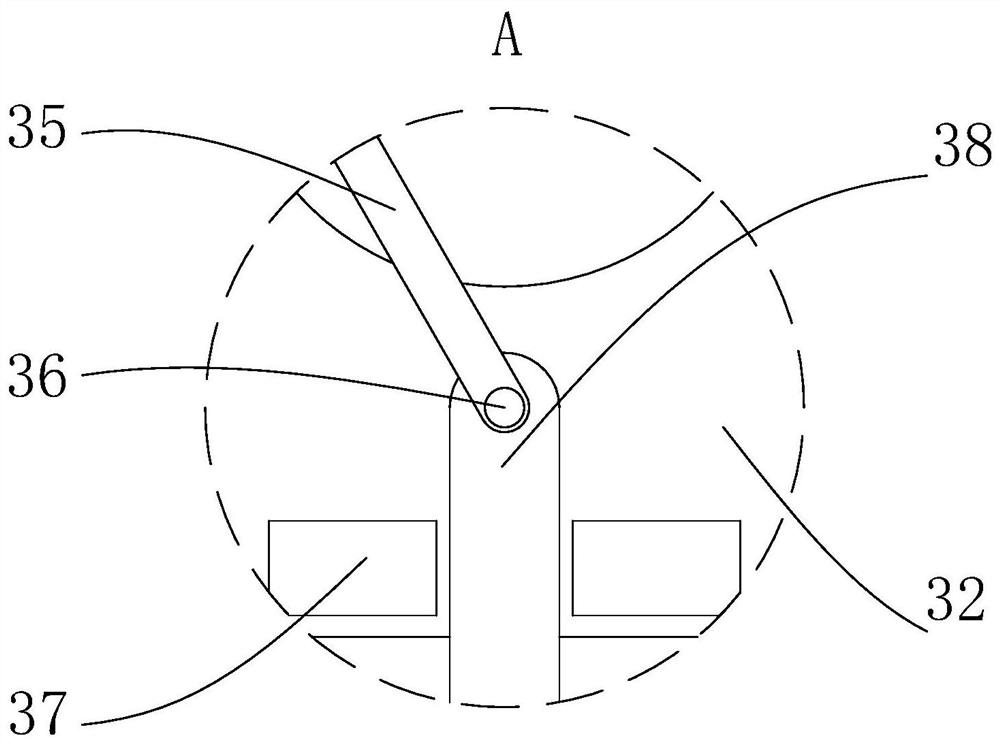

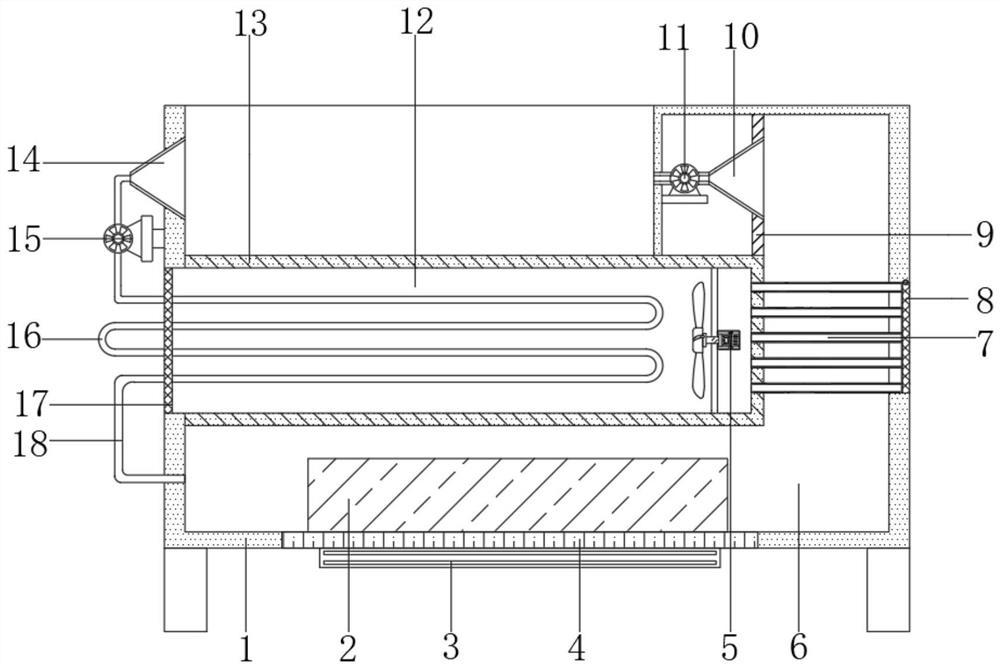

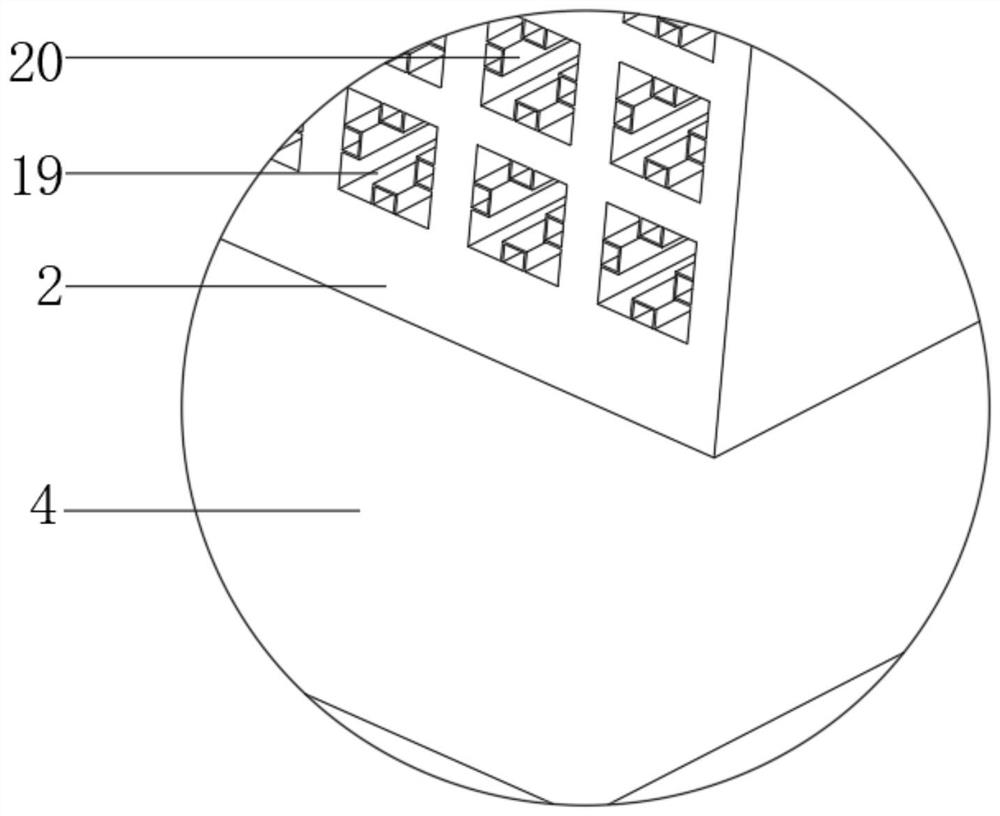

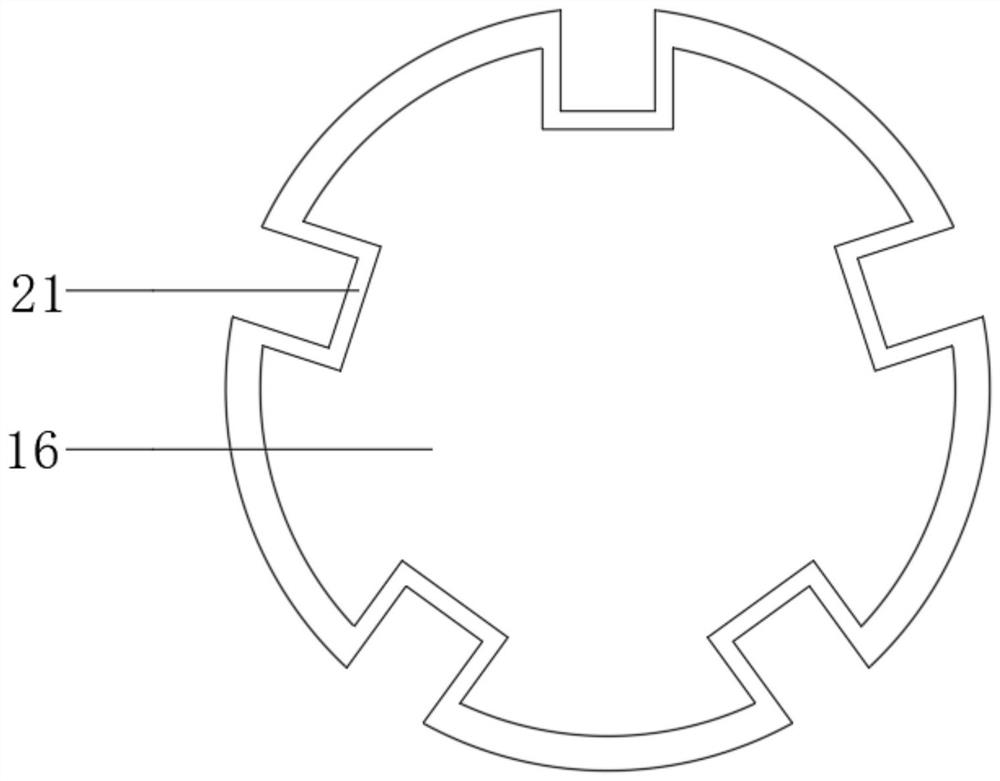

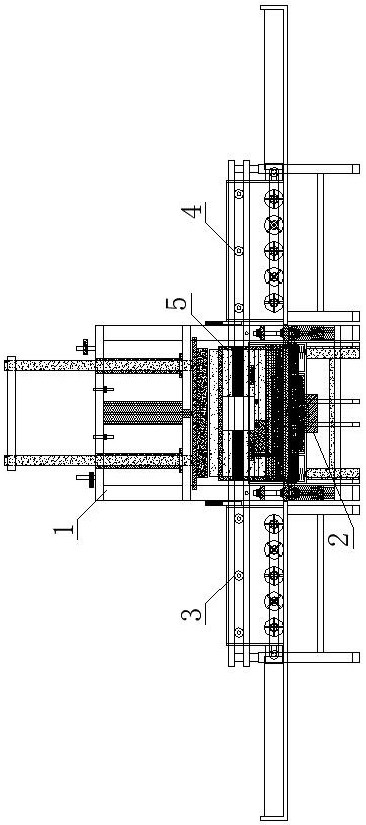

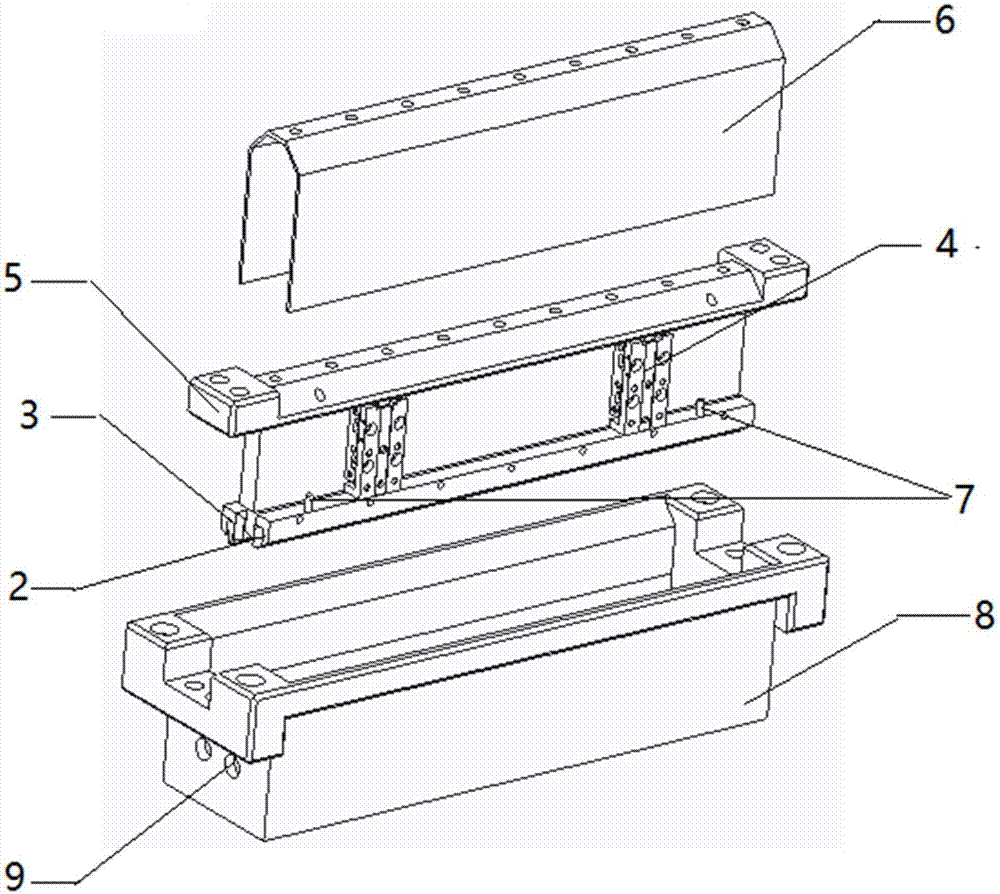

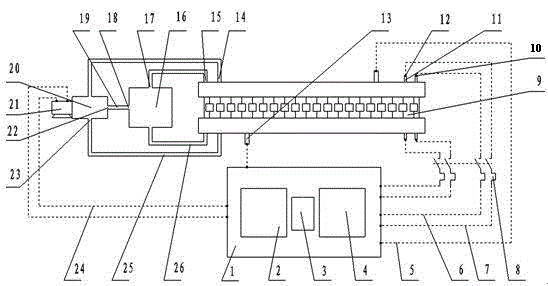

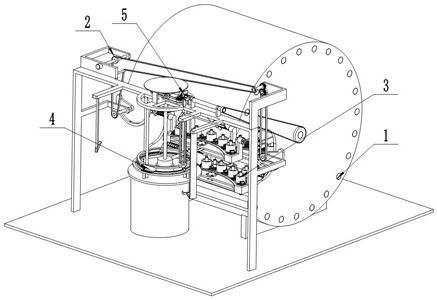

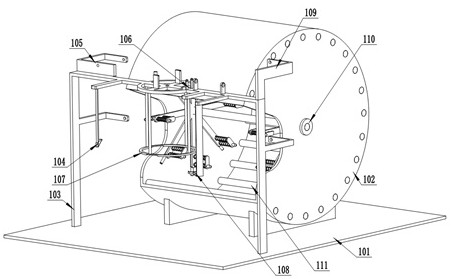

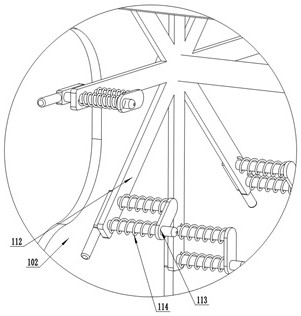

Circular mould type straw briquetting machine thermostat and control method thereof

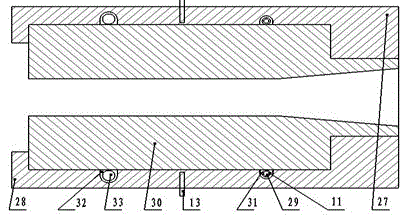

ActiveCN103407198AImprove stabilityImprove heat transfer efficiencyPressesLoop controlControl system

The invention relates to the technical field of crop straw processing, in particular to a circular mould type straw briquetting machine thermostat and a control method thereof. The thermostat comprises a circular mould, cooling devices, heating devices and a control system, the circular module comprises an upper press plate, a lower press plate and circular mould blocks, each of the upper press plate and the lower press plate is provided with the cooling devices and the heating devices, and the control system is a closed-loop control system, arranged in a control cabinet and composed of a temperature detection control end, a relay control end and a motor control end. When an actual temperature value of the circular mould is higher than T, a heating coil is powered off to stop heating, a motor is started, a water pump starts to work, and cooling water in a circular pipe starts to circulate to cool; when the actual temperature value of the circular mould is lower than T, the motor is powered off, the water pump stops working, the cooling water does not circulate, and the heating coil starts to be powered on to heat until the temperature value reaches T. The circular mould type straw briquetting machine thermostat and the control method are simple and low in cost, the temperature of the circular mould can be controlled in a relative constant state, and stability in the forming process is guaranteed.

Owner:万华禾香生态科技股份有限公司

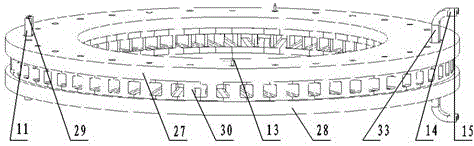

Annular modeling line

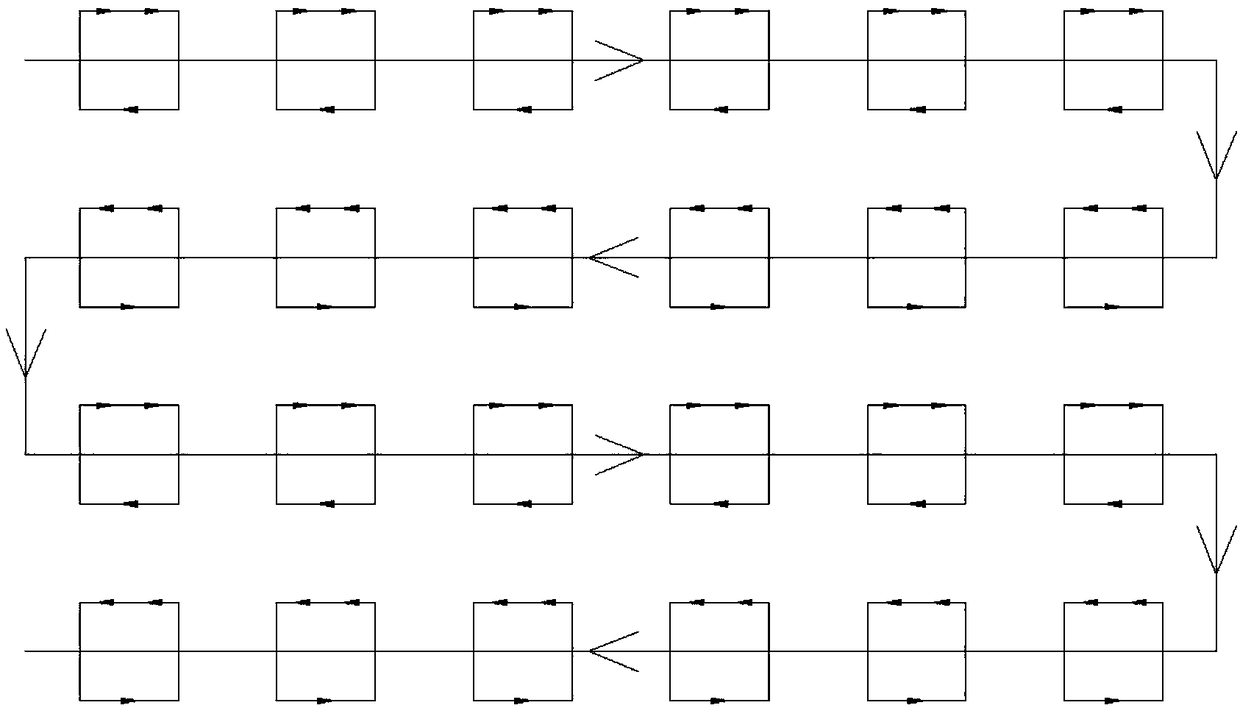

InactiveCN110773732AGuaranteed validityGuaranteed efficiencyCasting plantsMould handling equipmentsTransfer lineGeotechnical engineering

The invention is suitable for the technical field of clay sand modeling and provides an annular modeling line. The annular modeling line comprises a conveying rail, a transmission device and a pushingand poking device; the conveying rail comprises a box return rail, a transfer line and a pouring ball rail; the transmission device comprises a first transmission device and a second transmission device; and the pushing and poking device comprises a box pushing machine, a box poking machine, a box poking platform and a sand box. Thereby, effective forming production of molds can be realized, andthe working efficiency and the working quality can be improved.

Owner:潍坊市凯隆机械有限公司

Sand mould casting process

InactiveCN111644569ARapid compactionGuaranteed molding efficiencyFoundry mouldsMoulding machinesMolten stateMolding machine

The invention relates to the field of casting, in particular to a sand mould casting process. The sand mould casting process comprises the following steps of 1, preparing a tidal sand mold, wherein prepared model sand is screened, and the screened model sand is put into a tidal mold sand box molding machine; 2, putting prepared raw materials into a furnace, wherein the melt liquid temperature is 1400-1600 DEG C, the melt time is 4-5 hours, and the stirring is carried out every 30 minutes; 3, preheating the tidal sand mold prepared in the step 1, wherein the preheating temperature is 400-600 DEG C, the preheating time is 5-10 minutes, after preheating is finished, the molten liquid of the raw materials is injected into the tidal sand mold, then the tidal sand mold is placed in a constant temperature furnace, the tidal sand mold is slightly vibrated, the constant temperature time is 30-60 minutes, and the raw materials are kept in a molten state during constant temperature; and 4, takingout the tidal sand mould subjected to constant temperature treatment in the step 3, and cooling the tidal sand mould by using water cooling and air cooling. The tidal mold sand box molding machine can rapidly finish multiple collision molding, so that rapid compaction molding is achieved, and molding efficiency is guaranteed.

Owner:芜湖新从工业设计有限公司

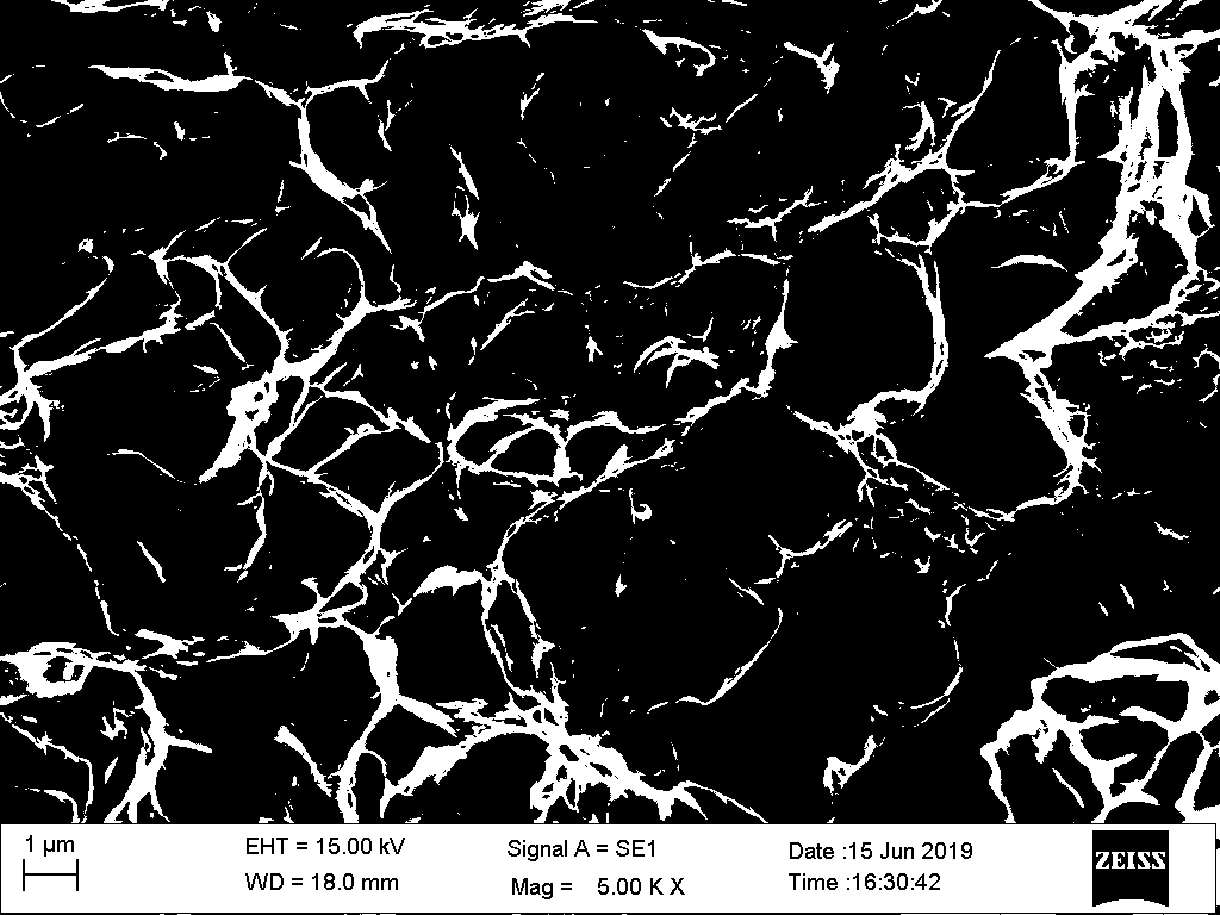

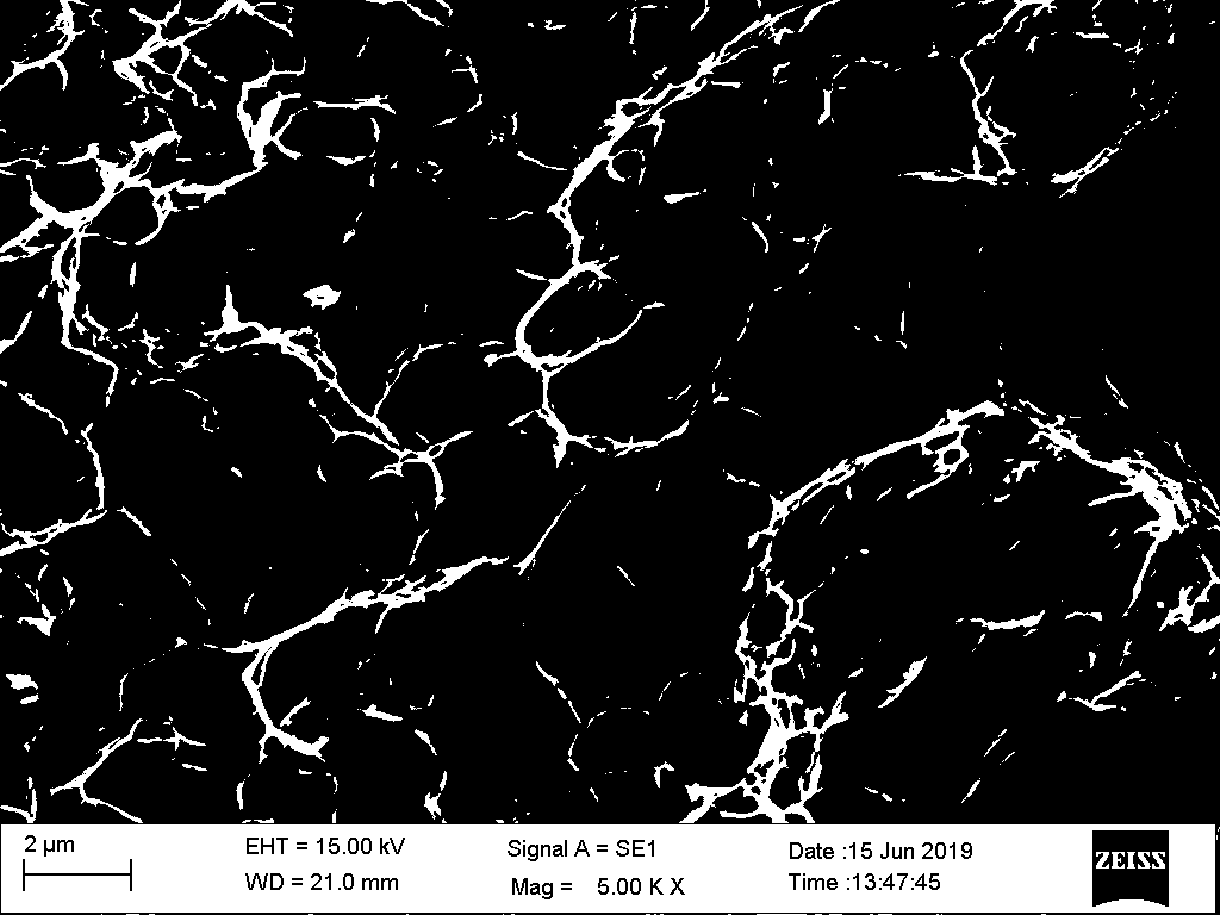

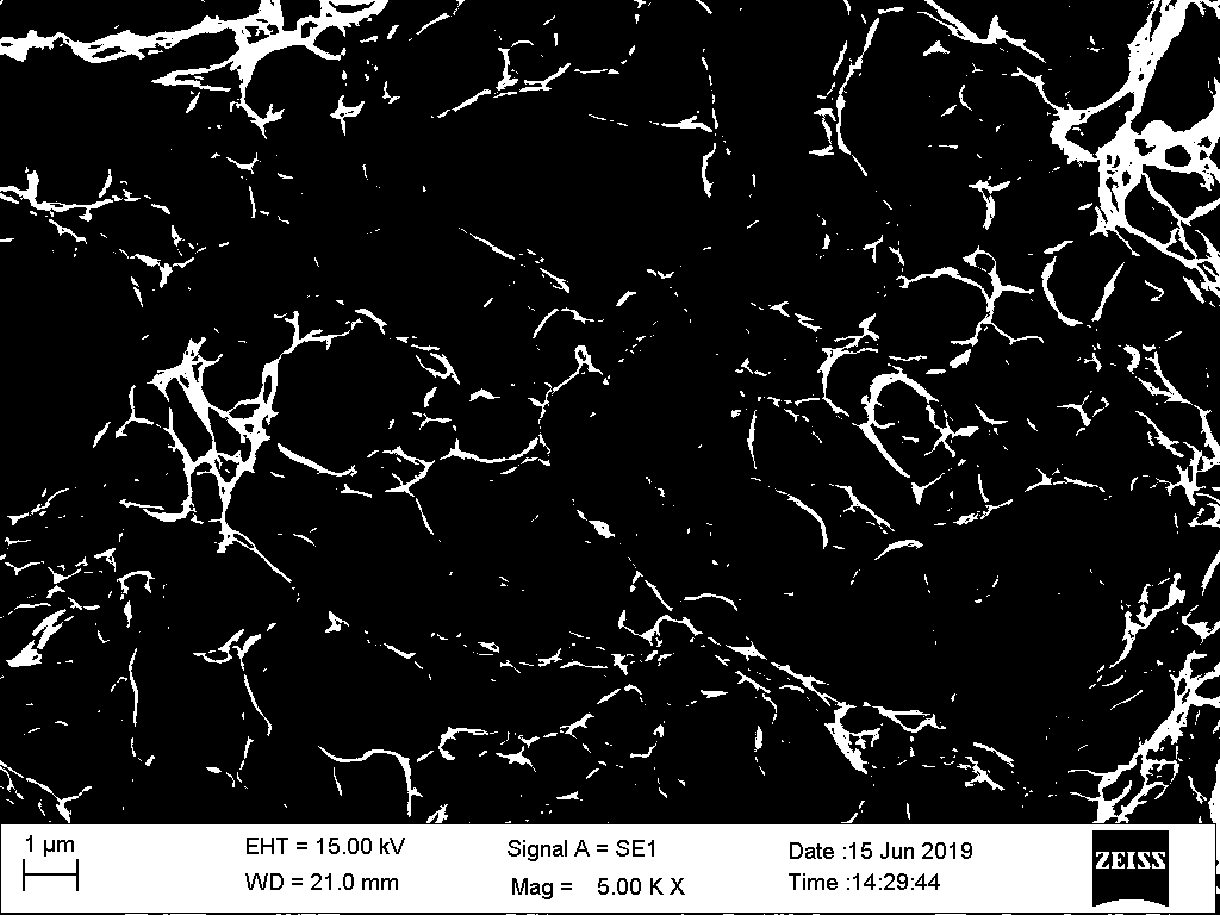

C-N-O supersaturated solid solution martensitic stainless steel powder, preparation method and cladding method

ActiveCN110938772AGood electrochemical corrosion performanceImprove wear resistanceAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyMartensitic stainless steel

The invention discloses a C-N-O supersaturated solid solution martensitic stainless steel powder, a preparation method and a cladding method, and relates to the technical field of laser additive and re-manufacturing. The elements contained in the powder comprise, by weight, 0.18-0.23 part of C, 0.09-0.12 part of N, 0.75-0.90 part of Si, 12.0-14.0 parts of Cr, 0.80-0.95 part of Mn, 1.30-1.80 partsof Ni, 0.45-0.55 part of Al, 0.22-0.30 part of V, 0.045-0.055 part of O, and 81.1-84.16 parts of Fe. After the above elements undergo vacuum melting according to a proportion, the C-N-O supersaturatedsolid solution martensitic stainless steel powder can be obtained by adopting high-purity nitrogen gas atomization. The method for cladding a laser forming layer based on the powder comprises the following steps that 1, raw material treatment is performed; 2, parameter setting is performed; and 3, cladding of the laser forming layer is performed. According to the C-N-O supersaturated solid solution martensitic stainless steel powder, the preparation method and the cladding method, laser fast cooling is used for inducing the non-equilibrium phase change, three interstitial atoms of C-N-O are dissolved in a body-centered structure in a supersaturated mode, then the martensite is formed, and a self-organizing interstitial atom short-range combined unit with the relatively lower energy stateis formed through short-range migration.

Owner:NANHUA UNIV

Multiple laser composite scanning process

InactiveCN108339982APlay a warm-up roleSmall temperature differenceAdditive manufacturing apparatusIncreasing energy efficiencyOptoelectronicsMetal powder

The invention discloses a multiple laser composite scanning process. According to the multiple laser composite scanning process, two total laser generators of a first laser and a second laser are adopted to perform laser melting on metal powder, when melting in performed, firstly scanning preheating is performed on a metal powder area by the first laser adopting a first power, then scanning melting is performed on the metal powder area by the second laser adopting a second power, finally scanning modification is performed on the metal powder area by the first laser or the second laser adoptinga third power, the first power is less than the third power, and the third power is less than the second power. By means of the multiple laser composite scanning process, a large number of cracks andpores can be reduced, each layer surface of a workpiece is made to be sintered sufficiently, the workpiece molding quality is good, and the fatigue life is significantly prolonged.

Owner:ANHUI TUO BAO ADDITIVE MFG TECH CO LTD

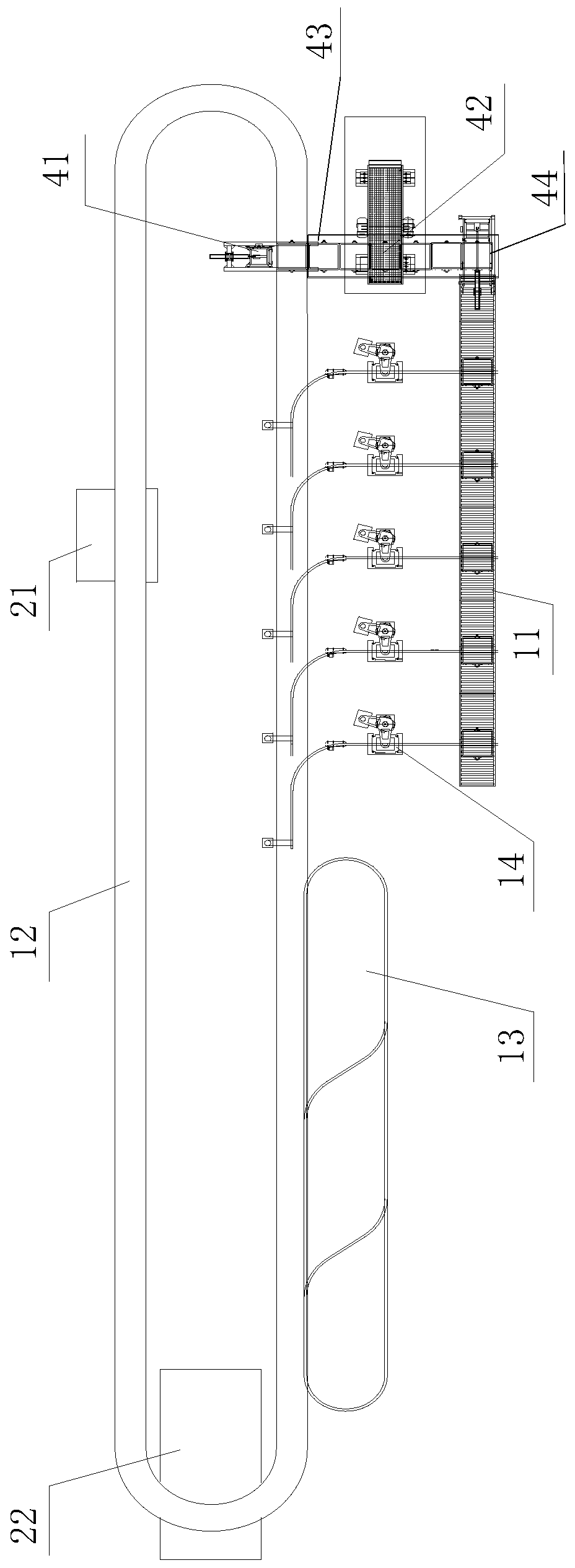

Pump body molding and cooling device for production of electromechanical equipment

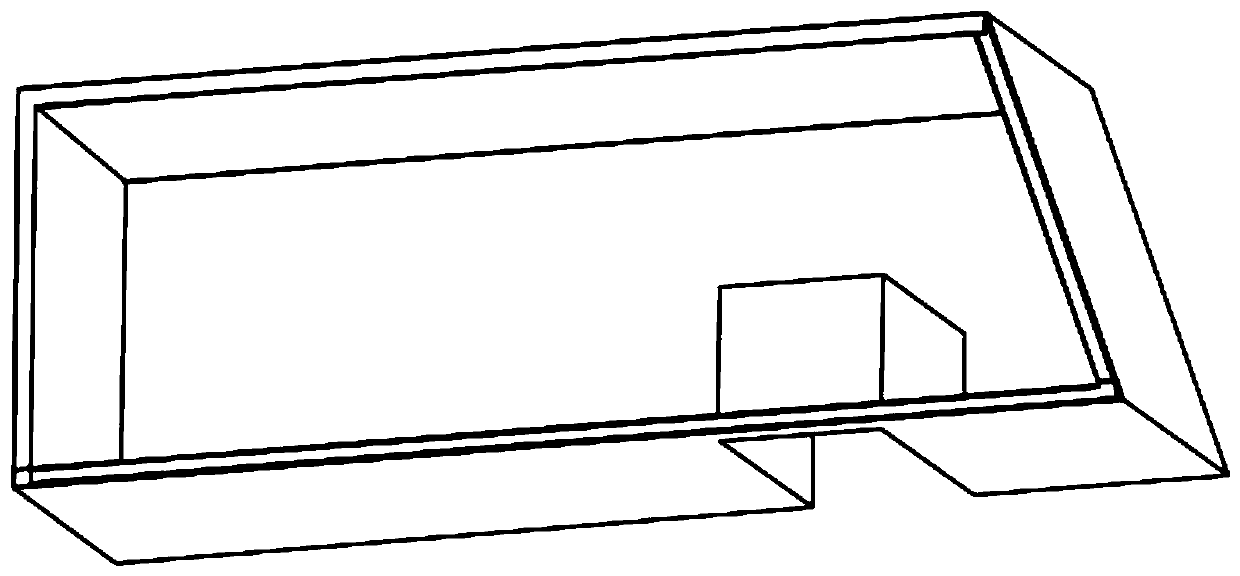

InactiveCN111673038AGuaranteed molding efficiencyGuaranteed cooling effectFurnace typesHeating/cooling devicesCooling effectEngineering

The invention belongs to the technical field of pump body cooling and molding, and particularly discloses a pump body molding and cooling device for production of electromechanical equipment. Aiming at the problems that most of traditional pump body cooling and molding devices have simple structures, the temperature of a coolant can slowly increase with the cooling and molding operation, and the molding effect is affected, the following scheme is proposed. The pump body molding and cooling device comprises a main body with supporting legs welded to four corners of the bottom outer wall, a U-shaped plate is welded to the inner wall of one side of the main body, a heat dissipation port is formed in the side, close to the U-shaped plate, of the main body, a molding cavity is formed by the topend of the main body and the opposite side of the U-shaped plate, a cooling end is formed by the inner bottom of the main body and the opposite side of the U-shaped plate, and an installation grooveis formed in the bottom end of the cooling end. According to the pump body molding and cooling device, through the mutual matching of a heat conductive plate seat, a heat exchange water channel and arectangular branch pipe, the contact area between a heat exchange end and a coolant can be effectively increased, the heat exchange area is increased, thus the cooling effect of the coolant is improved, and the cooling effect of the device on a pump body is ensured.

Owner:烟台福慧智能科技有限公司

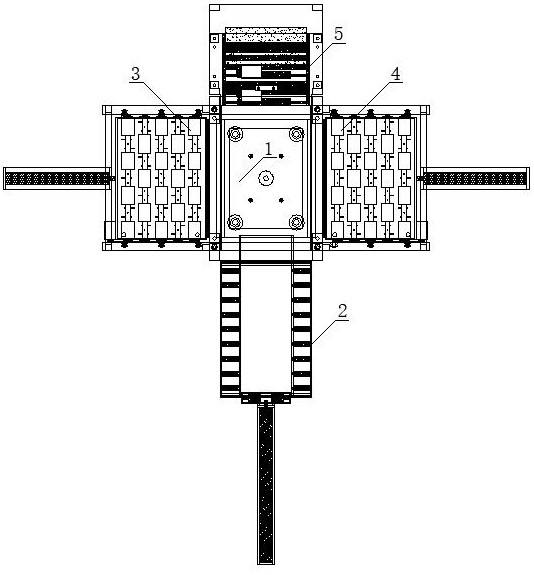

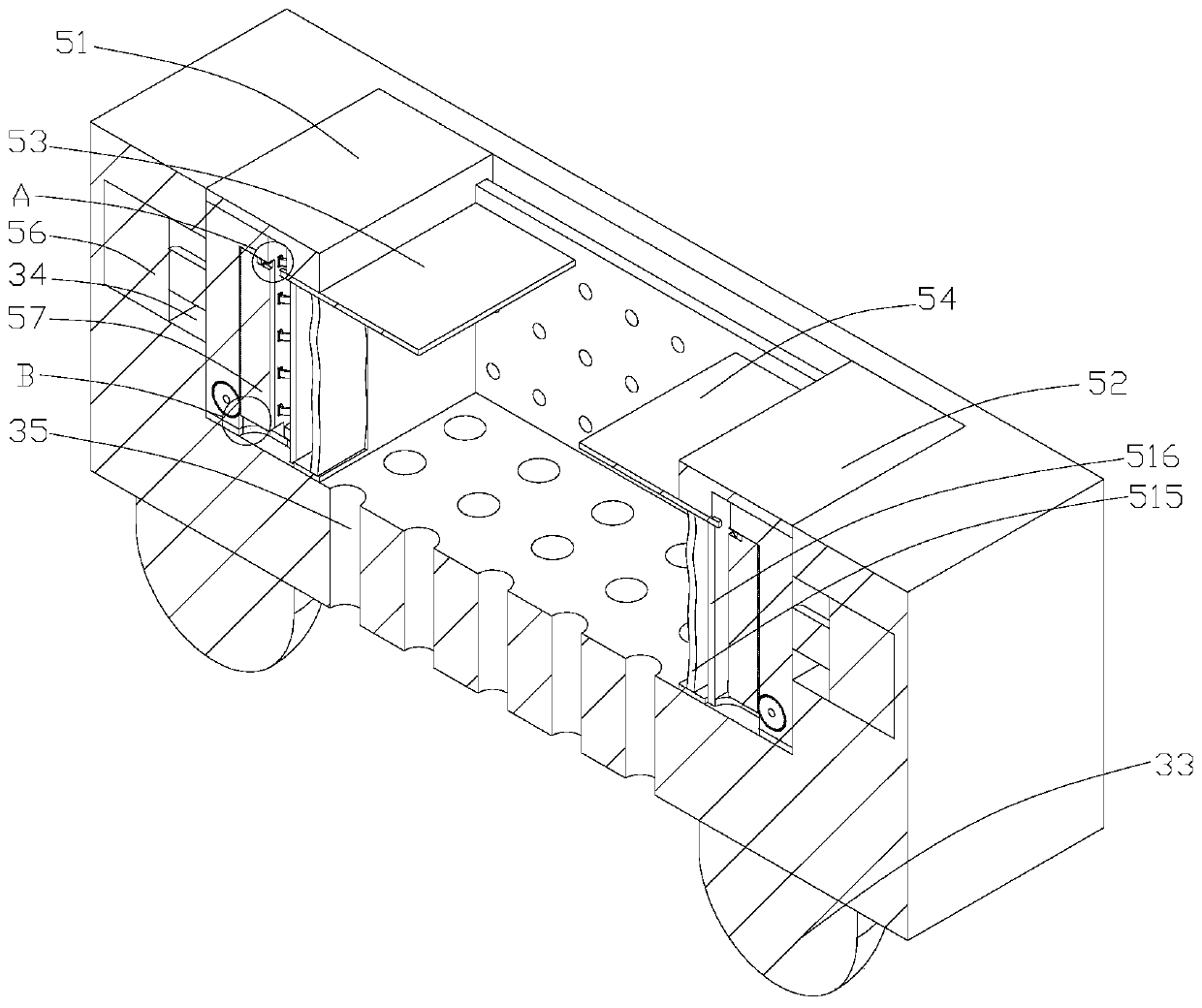

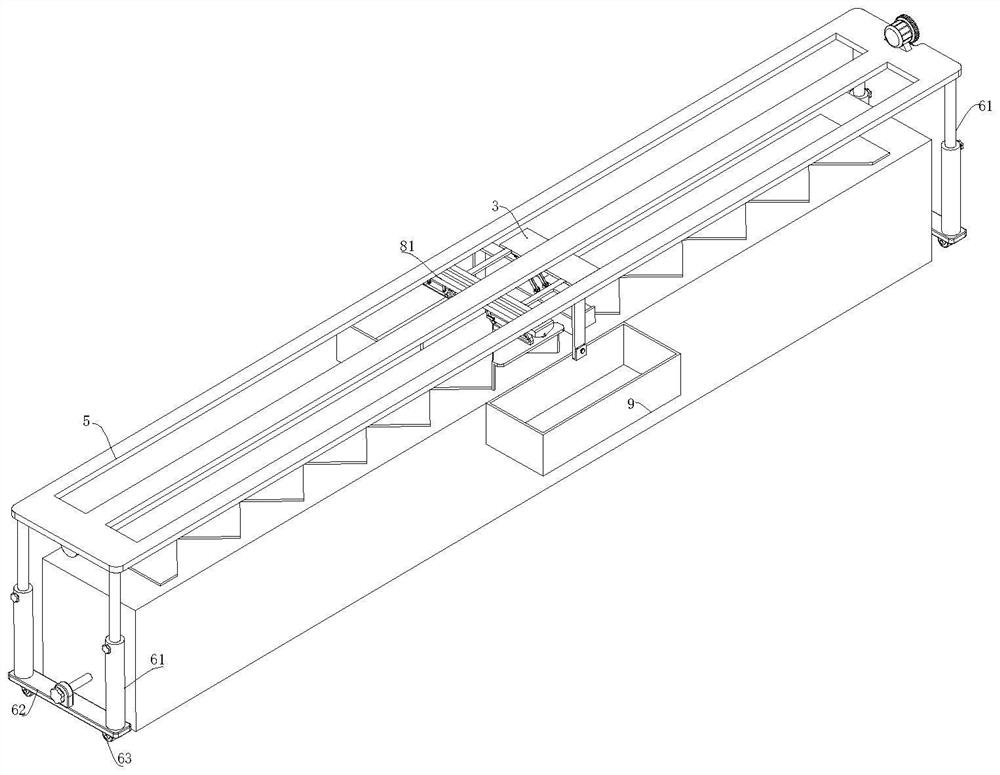

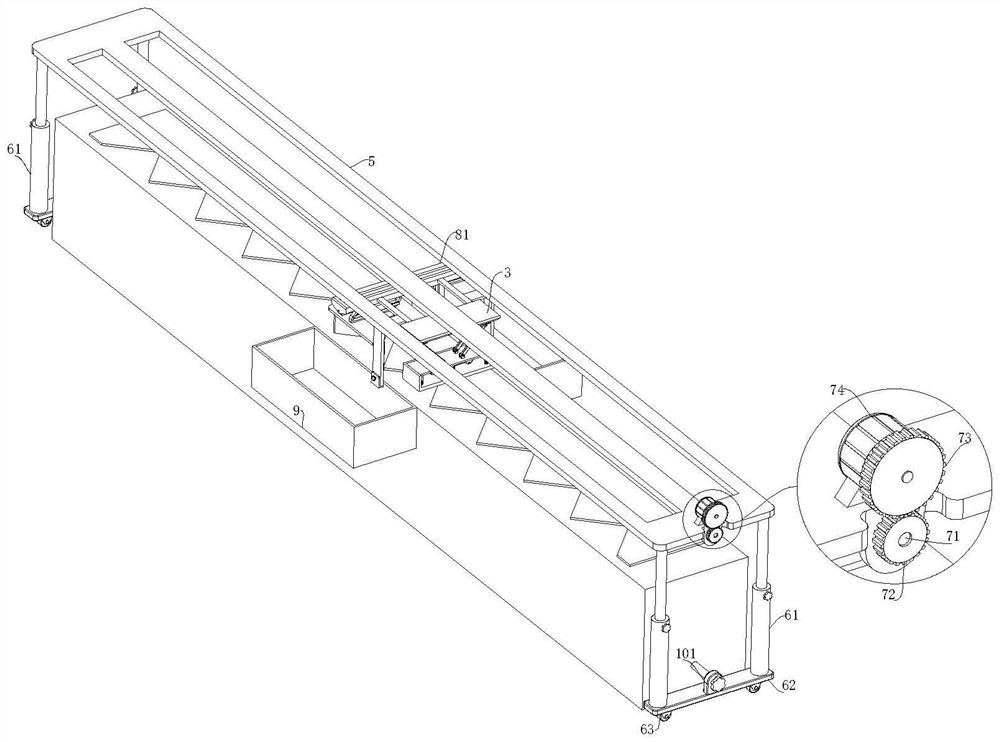

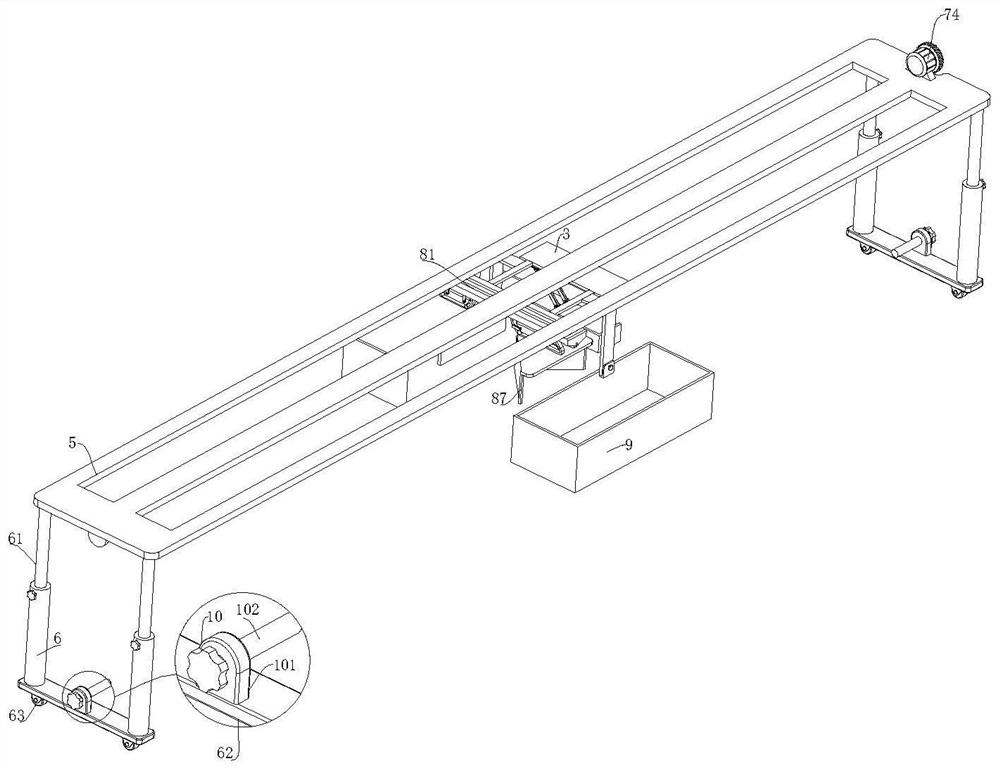

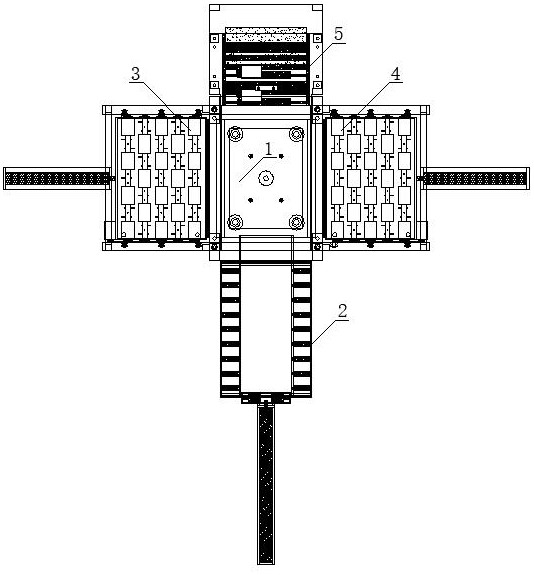

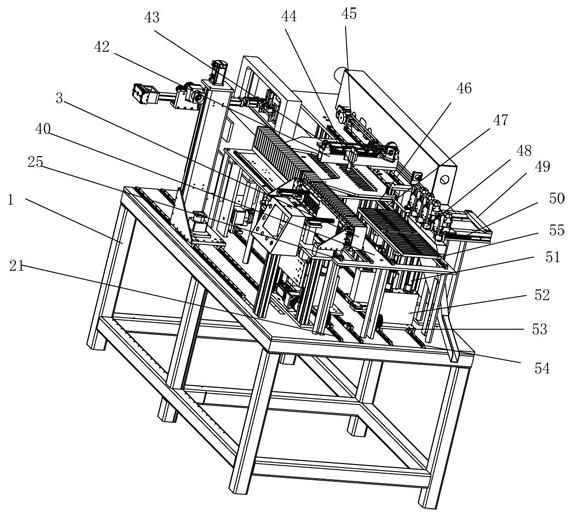

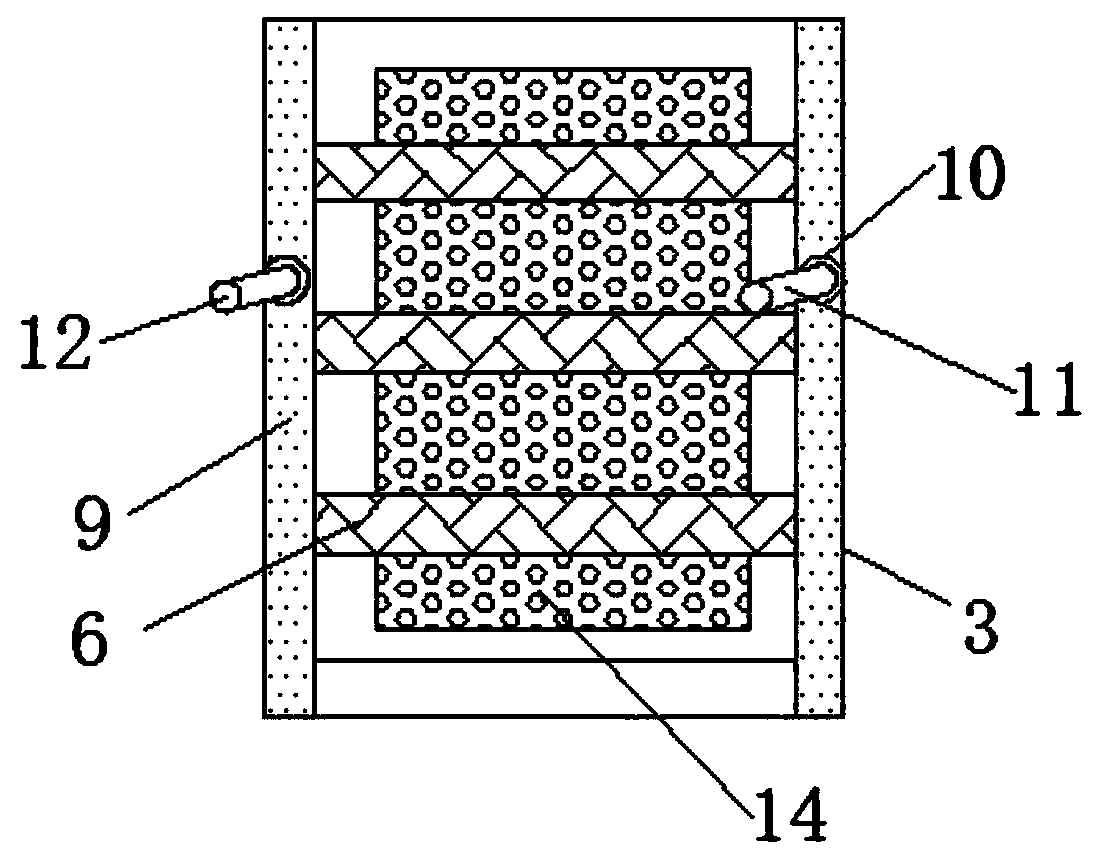

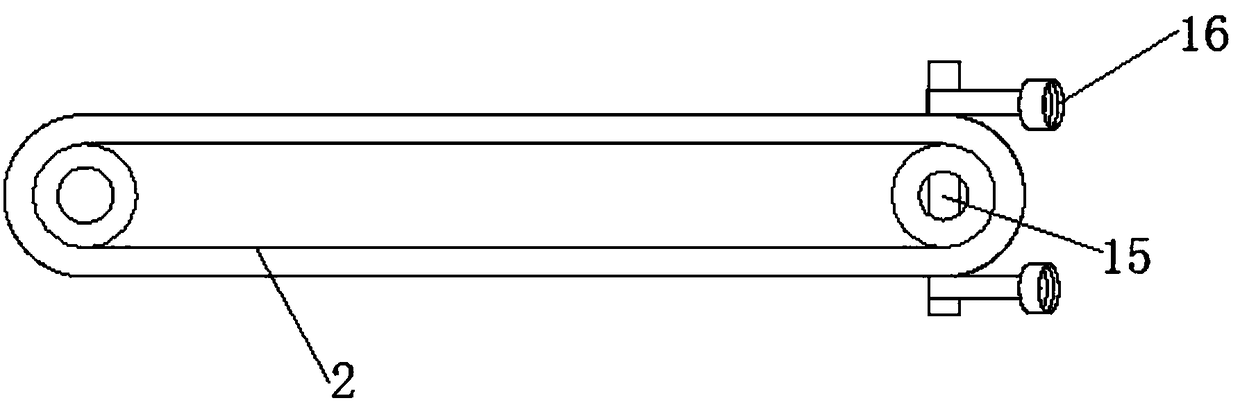

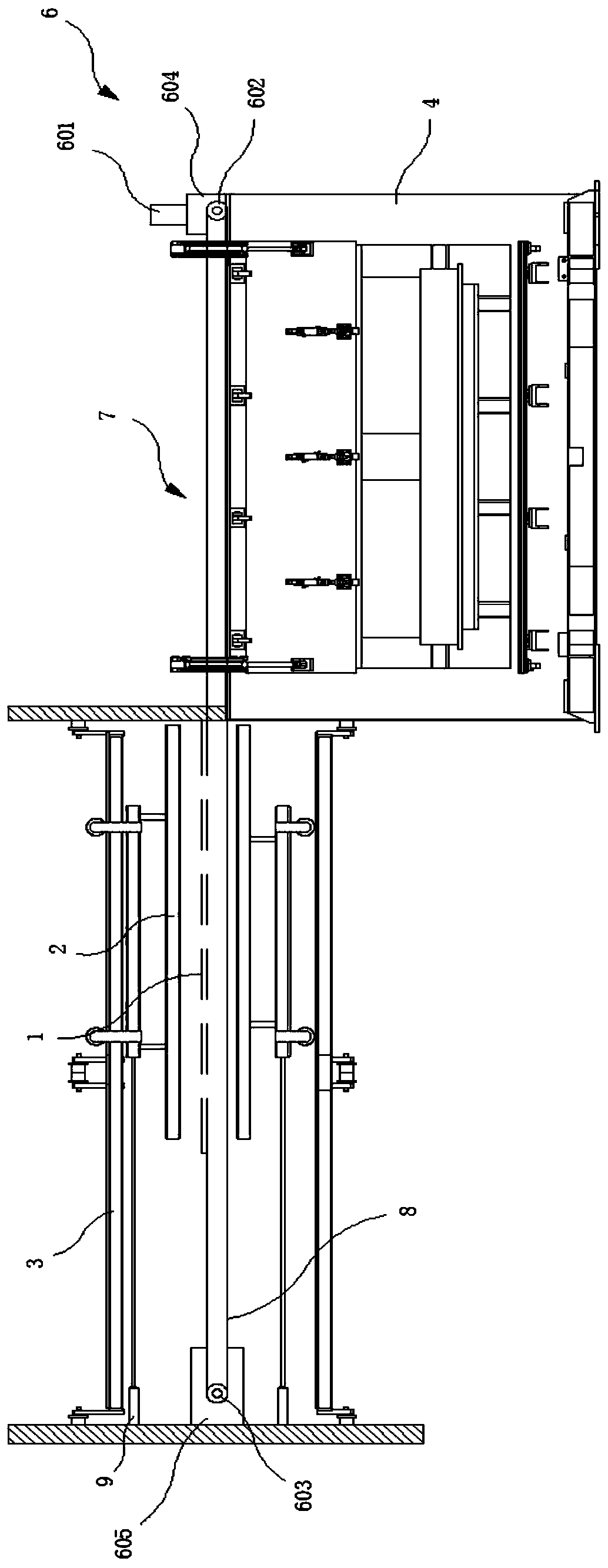

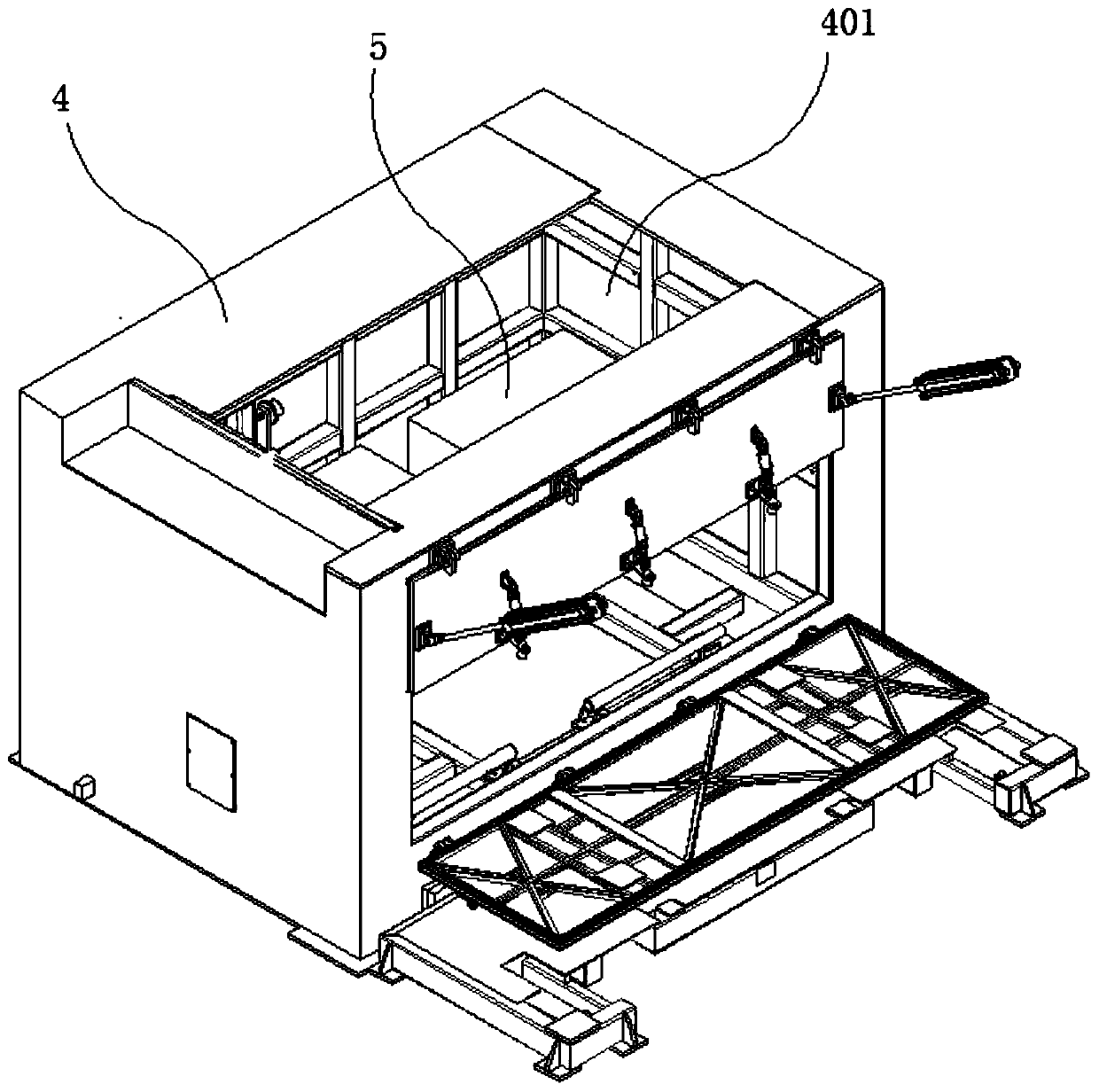

Production equipment for seepage-proofing permeable plate-shaped sand products and matching production method thereof

ActiveCN111975936AGuaranteed flexural strengthImprove demoulding difficultiesDischarging arrangementSolid waste managementProcess engineeringMaterial distribution

The invention discloses production equipment for seepage-proofing permeable plate-shaped sand products and a matching production method thereof, and belongs to the technical field of seepage-proofingpermeable sand application. The problem of lacking special plate-shaped product equipment and a matching production method for seepage-proofing permeable sand is solved. The production equipment comprises a push plate supply device, a bottom material distribution device, a top material distribution device and a mesh cloth supply device which are connected around a forming main machine, and the mesh cloth supply device is in front of the forming main machine; the push plate supply device is behind the forming main machine; the bottom material distribution device is on the left side of the forming main machine; the top material distribution device is on the right side of the forming main machine; and the positions of the bottom material distribution device and the top material distribution device can be interchanged. The method comprises the steps of debugging and production. According to the production equipment, aiming at the characteristics of high viscosity of a raw material mixtureof the seepage-proofing permeable plate-shaped sand products, and uniform distribution is achieved through interchangeable bottom material distribution device and the top material distribution device;and according to the matching method, a new direction is opened for the application of seepage-proofing permeable sand, and a good industrialization prospect is achieved.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

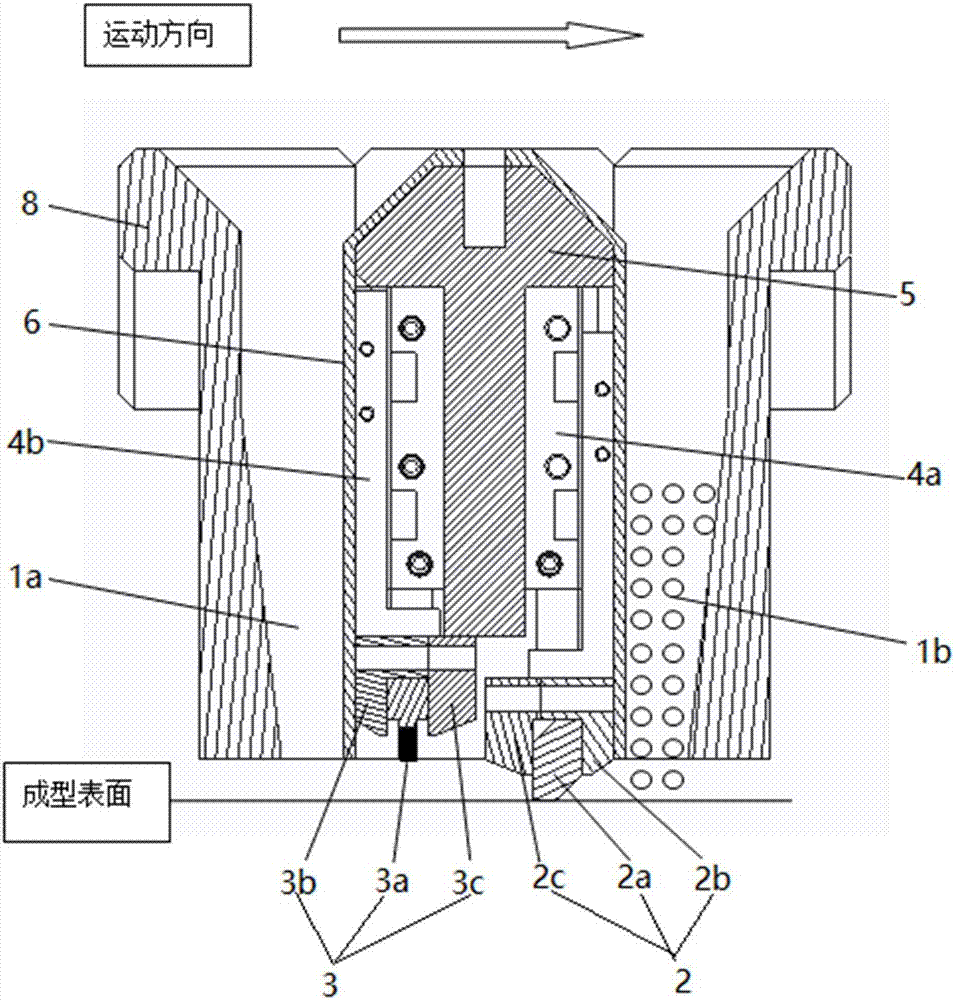

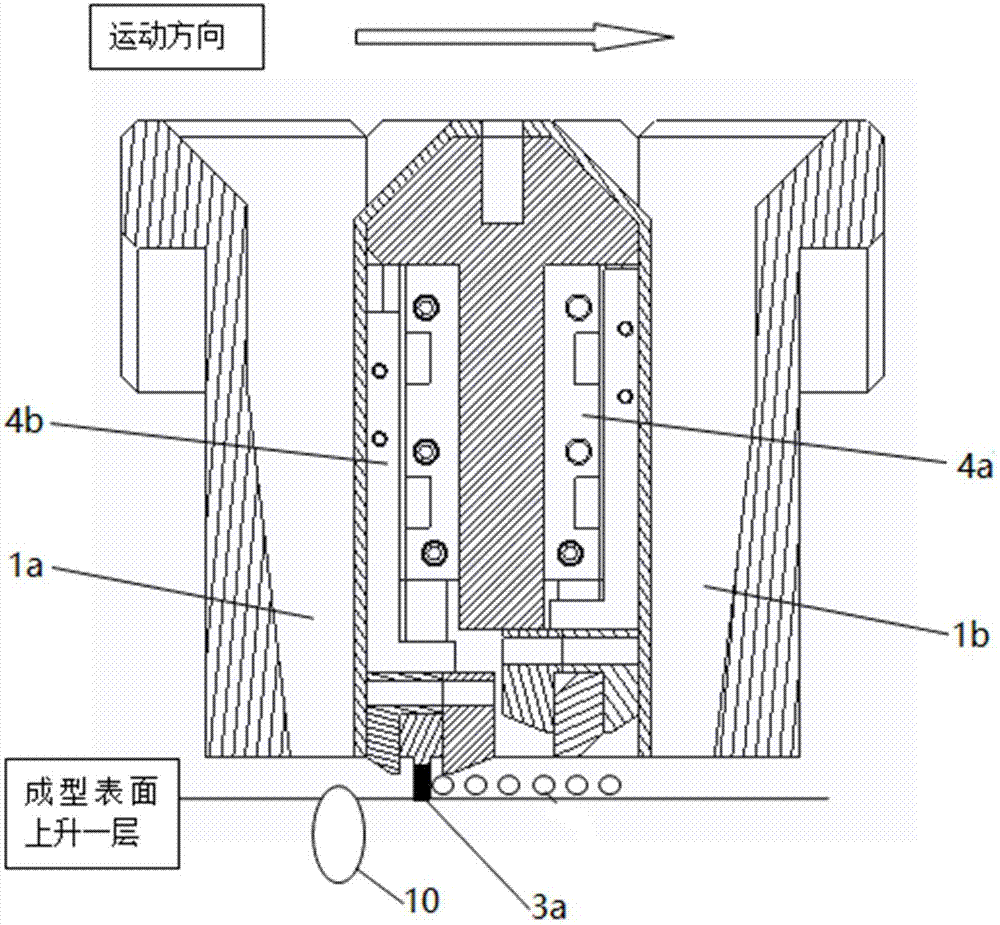

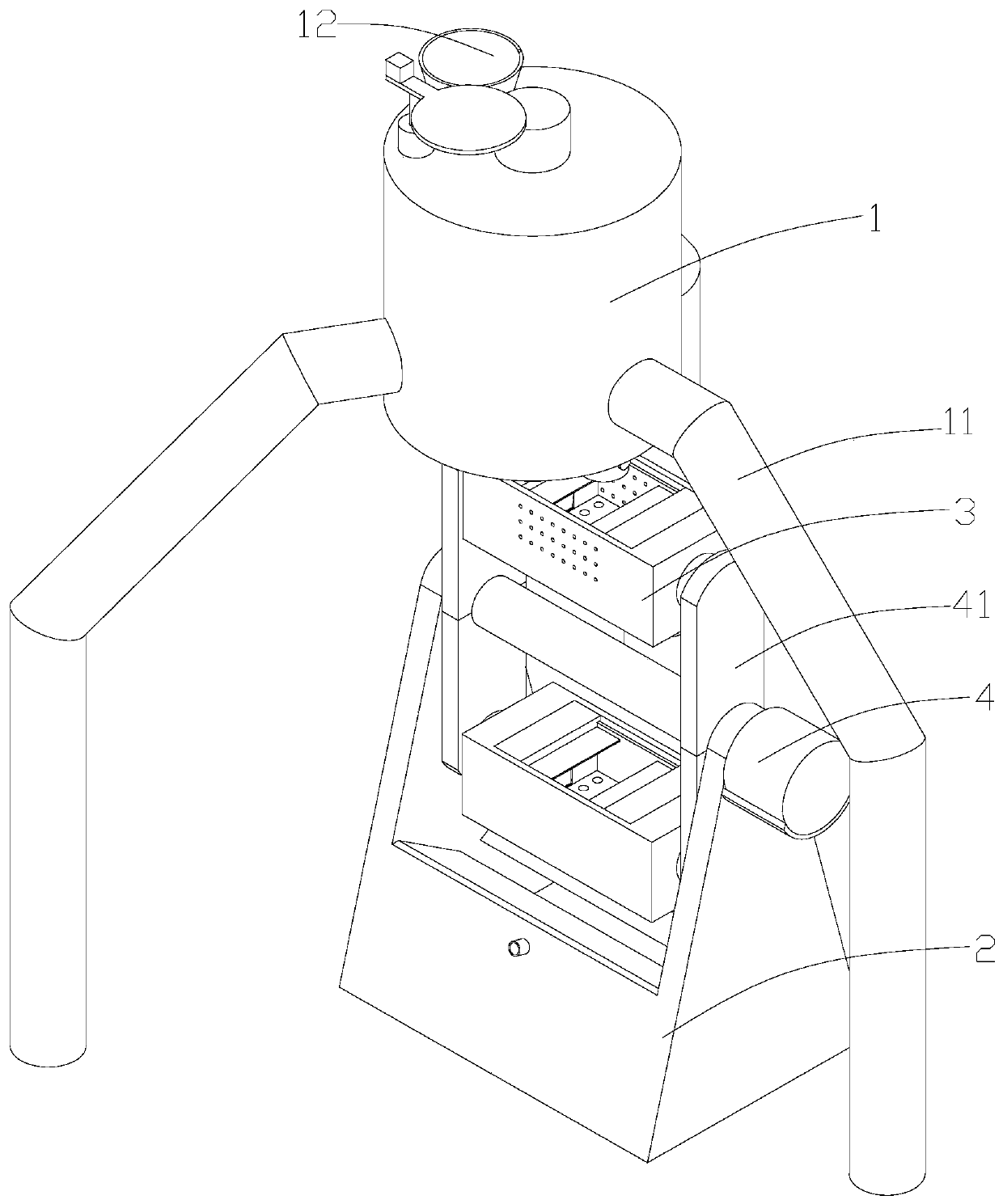

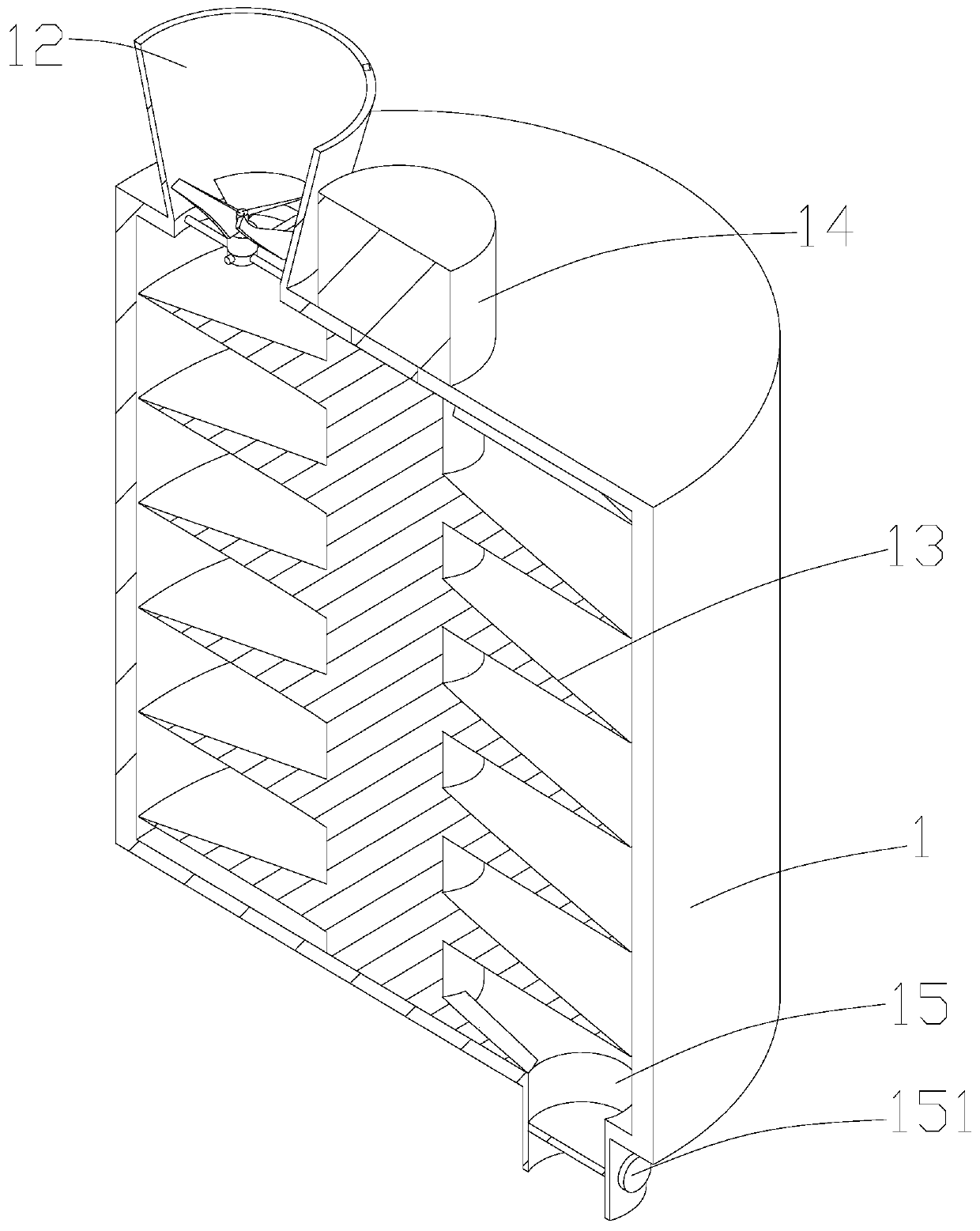

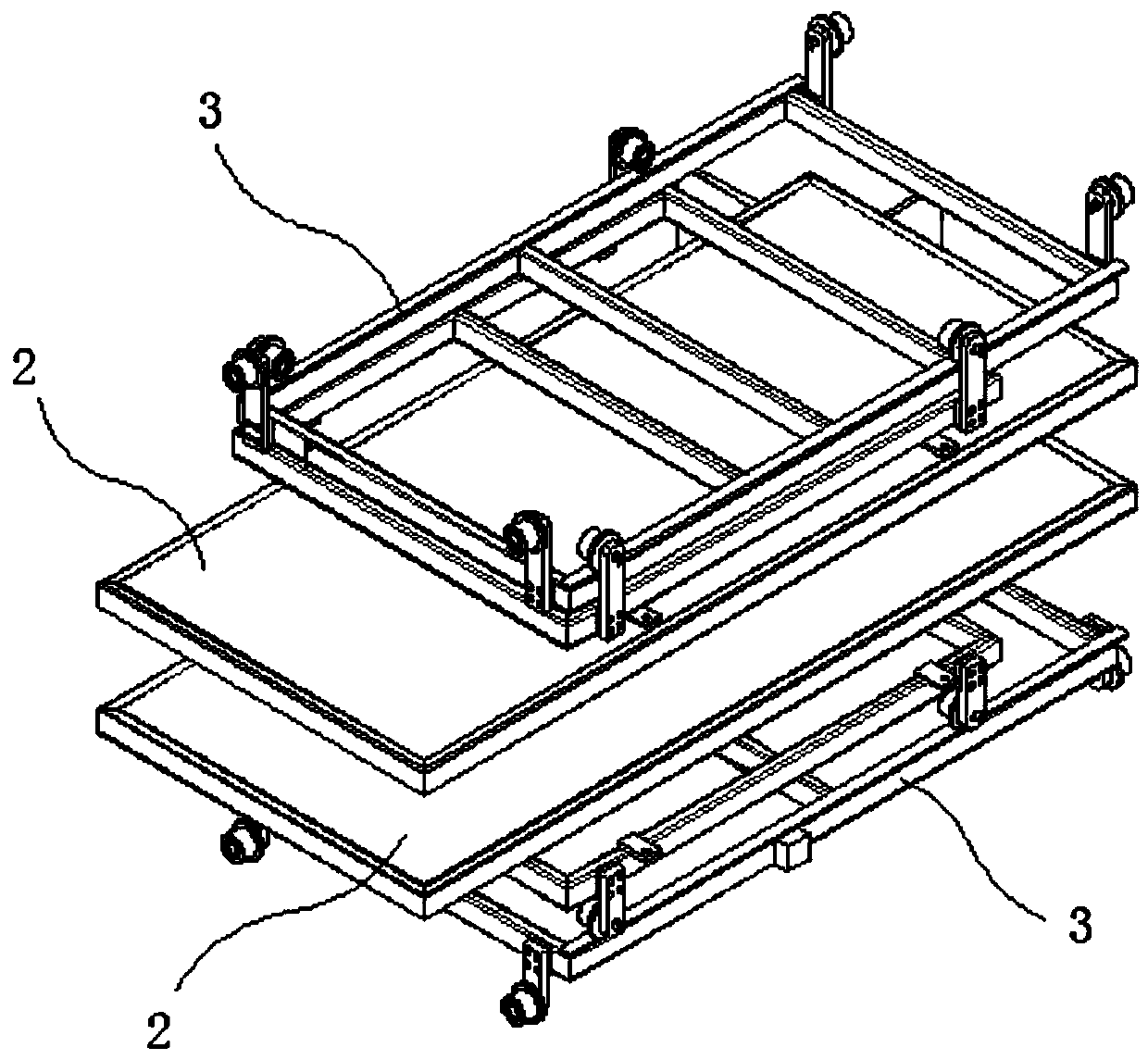

Dual-material powder laying device of additive manufacturing laser forming device

PendingCN107876772AEnabling Hybrid MoldingAchieving Cumulative ShapingAdditive manufacturing apparatusIncreasing energy efficiencyBiomedical engineeringAdditive layer manufacturing

The invention provides a dual-material powder laying device of an additive manufacturing laser forming device. The device comprises a powder falling part, a scraper assembly, a brush assembly and a drive part; the powder falling part is composed of a first powder falling part body and a second powder falling part body; the scraper assembly comprises a scraper, the scraper is fixed to a scraper mounting frame, the brush assembly comprises a brush, the brush is parallel to the extension direction of the scraper, the driving part is fixed to the side wall of the scraper mounting frame, and the scraper assembly is connected with the brush assembly and used for controlling the scraper and the brush to move. According to the dual-material powder laying device, forming efficiency is effectively ensured, and mixed forming of two materials can be achieved.

Owner:HKUST TIANGONG INTELLIGENT EQUIP TECH (TIANJIN) CO LTD

Sludge conveying and dewatering equipment used for sludge treatment

InactiveCN110002713AAchieve exclusion effectReduce moisture contentSludge treatmentSewageMaterial supply

The invention discloses sludge conveying and dewatering equipment used for sludge treatment. The equipment comprises a material conveying cylinder used for conveying sludge, a plurality of supportinglegs used for supporting the material conveying cylinder and a collecting box used for collecting the treated sludge; and the material conveying cylinder is provided with a material inlet hopper and aspiral material supply rod, at least one dewatering box used for dewatering treatment of the sludge and first driving member used for driving rotation of the dewatering box are arranged below the material conveying cylinder, the first driving member is fixedly arranged on the collecting box, and the dewatering box is provided with a dewatering device. According to the equipment provided by the invention, through arrangement of the above structure, the sludge can be uniformly conveyed through the material conveying cylinder, so that volume treatment of the sludge is realized, and blockage caused by a too large volume of the sludge is avoided; and at the same time, the sludge can be treated by the dewatering device, so that the sludge can be dried in a certain shape in batches, forming specifications of the sludge are substantially same, mutual adhesion of the sludge can be avoided, collection arrangement of the sludge is facilitated, and the control utilization rate of the collection container is improved.

Owner:杭州更蓝生物科技有限公司

Concrete prefabricated part troweling device

InactiveCN114851349AGuaranteed molding efficiencyEasy to polishAuxillary shaping apparatusArchitectural engineeringSupport plane

Owner:邢洁

Middle sealing bag making machine former and forming method

PendingCN111907129AEasy to useLarge adjustment rangeBag making operationsPaper-makingEngineeringMachine

The invention relates to the technical field of middle sealing bag making machines, in particular to a middle sealing bag making machine former and a forming method. The middle sealing bag making machine former comprises a machine body, an adjusting device, a guiding device and a detecting device, a controller is fixedly connected to the front end face of the machine body, a first conveying rolleris fixedly connected to the inner side of the machine body, and an adjusting device is arranged on the left side of the first conveying roller. A fixing box is arranged on the right side of the firstconveying roller, the fixing box is fixedly connected with the machine body through a connecting block, a supporting rod is slidably connected to the inner side of the fixing box, the supporting rodpenetrates through the fixing box, and a first spring and a sliding plate which are arranged up and down are arranged at the top end of the outer side of the supporting rod. Due to a fixing ring and asecond spring which are arranged, the arrangement is matched with the elastic force of the fixing ring and the second spring to a sleeve rod and an inner rod, the spiral connection of a first threaded shaft and the inner rod and the fixed connection of a fixing rod and the fixing ring, when the device is in use, deviation prevention treatment can be conducted on blanks of different sizes, and normal use of the device is guaranteed.

Owner:泉州市华山彩色印刷有限公司

A kind of anti-permeation gas plate-shaped sand product production equipment and its supporting production method

ActiveCN111975936BGuaranteed flexural strengthImprove demoulding difficultiesDischarging arrangementSolid waste managementProcess engineeringMaterial distribution

The invention discloses production equipment for anti-permeation gas plate-shaped sand products and a supporting production method thereof, belonging to the technical field of anti-permeation gas sand application, and aims to solve the problem that the anti-permeation gas sand lacks special plate-shaped product equipment and a supporting production method. The device includes a push plate device, a bottom material distribution device, a top material distribution device, and a grid cloth supply device connected around the forming main machine. The front of the forming main machine is a grid cloth supply device; the rear of the forming main machine is a push plate device; The bottom material distribution device is on the left; the top material distribution device is on the right of the molding machine; the positions of the bottom material distribution device and the top material distribution device are interchangeable. The method includes debugging and production links. The equipment of the present invention aims at the characteristics of high viscosity of the raw material mixture of anti-permeable gas plate-shaped sand products, and realizes uniform material distribution through the bottom material distribution device and the top material distribution device with interchangeable positions; the matching method of the equipment of the present invention makes the anti-seepage The application of air-permeable sand has opened up a new direction, and the industrialization prospect is good.

Owner:GANSU BUILDING MATERIALS DESIGN & RES INST CO LTD

Preparation method of walnut kernel bean curd sheet

InactiveCN109156542AGuaranteed molding efficiencyRich in nutrientsCheese manufactureFood scienceCuticleFiltration

The invention belongs to the technical field of bean product deep processing, and specifically relates to a preparation method of a walnut kernel bean curd sheet. The preparation method comprises thefollowing steps: (1) pretreating walnut kernels; (2) screening soybeans to get rid of impurities and bad soybeans, and adding water to carry out soaking, defibrination and filtration so as to obtain soybean milk; (3) adding the soybean milk into a cooking barrel and heating to 95 DEG C, adding walnut kernel juice under a condition of slow stirring and heating to 105-110 DEG C, and preserving the heat for 20 min to obtain walnut kernel and soybean milk mixed solution; (4) pouring the walnut kernel and soybean milk mixed solution into a bean curd sheet forming pot to carry out heat preservationand forming; (5) naturally drying the formed bean curd sheet so as to obtain the walnut kernel bean curd sheet. According to the preparation method, skins of the walnut kernels are removed to preventthe bitterness of the skins and prevent the skins from affecting the forming in the bean curd sheet forming process, so that the bean curd sheet forming efficiency is ensured; through addition of thewalnut kernels in the bean curd sheet, the nutritional ingredients of the bean curd sheet is further enriched and the taste of the bean curd sheet is improved.

Owner:刘冉

A ring mode straw briquetting machine constant temperature device and its control method

ActiveCN103407198BImprove stabilityImprove heat transfer efficiencyPressesLoop controlControl system

The invention relates to the technical field of crop straw processing, in particular to a circular mould type straw briquetting machine thermostat and a control method thereof. The thermostat comprises a circular mould, cooling devices, heating devices and a control system, the circular module comprises an upper press plate, a lower press plate and circular mould blocks, each of the upper press plate and the lower press plate is provided with the cooling devices and the heating devices, and the control system is a closed-loop control system, arranged in a control cabinet and composed of a temperature detection control end, a relay control end and a motor control end. When an actual temperature value of the circular mould is higher than T, a heating coil is powered off to stop heating, a motor is started, a water pump starts to work, and cooling water in a circular pipe starts to circulate to cool; when the actual temperature value of the circular mould is lower than T, the motor is powered off, the water pump stops working, the cooling water does not circulate, and the heating coil starts to be powered on to heat until the temperature value reaches T. The circular mould type straw briquetting machine thermostat and the control method are simple and low in cost, the temperature of the circular mould can be controlled in a relative constant state, and stability in the forming process is guaranteed.

Owner:WANHUA ECOBOARD INTEGRATED EQUIP CO LTD

An automatic ice cream stick forming packing machine

ActiveCN112454827BEnsure consistencyHighly integratedBundling machine detailsSmall footprintMechanical engineering

The invention relates to an ice cream stick production device. An ice cream stick automatic forming packer, including a frame, on which a discharge tray is arranged, the shape of the discharge tray is the same as that of the ice cream board to be cut, and a cutting and feeding device is provided on one side of the discharge tray, The shaped ice cream sticks after cutting are sent to the storage rack, which is installed on the frame, and one side of the storage rack is provided with an ice cream stick transmission device, and the ice cream sticks are transported to the binding structure by the transmission device. The invention provides an ice cream stick automatic forming packing machine with high production efficiency, simple operation, ice cream stick forming and packaging on one device, good integration, high degree of automation, less land occupation and low cost; solves the problem The ice cream sticks that exist in the technology are low in production efficiency, low in automation, large in number of equipment, high in cost, and large in floor space.

Owner:义乌市康朔塑料制品有限公司

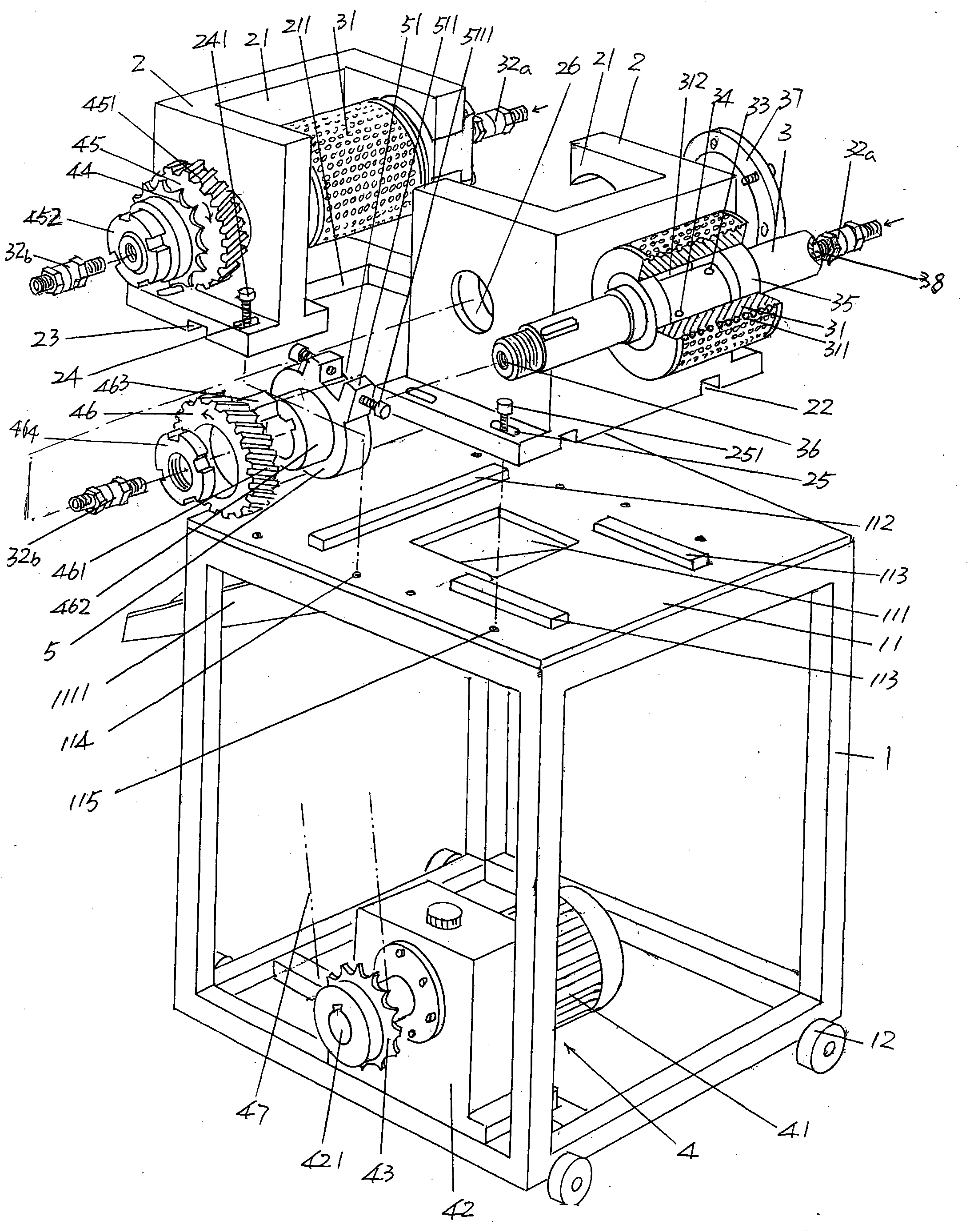

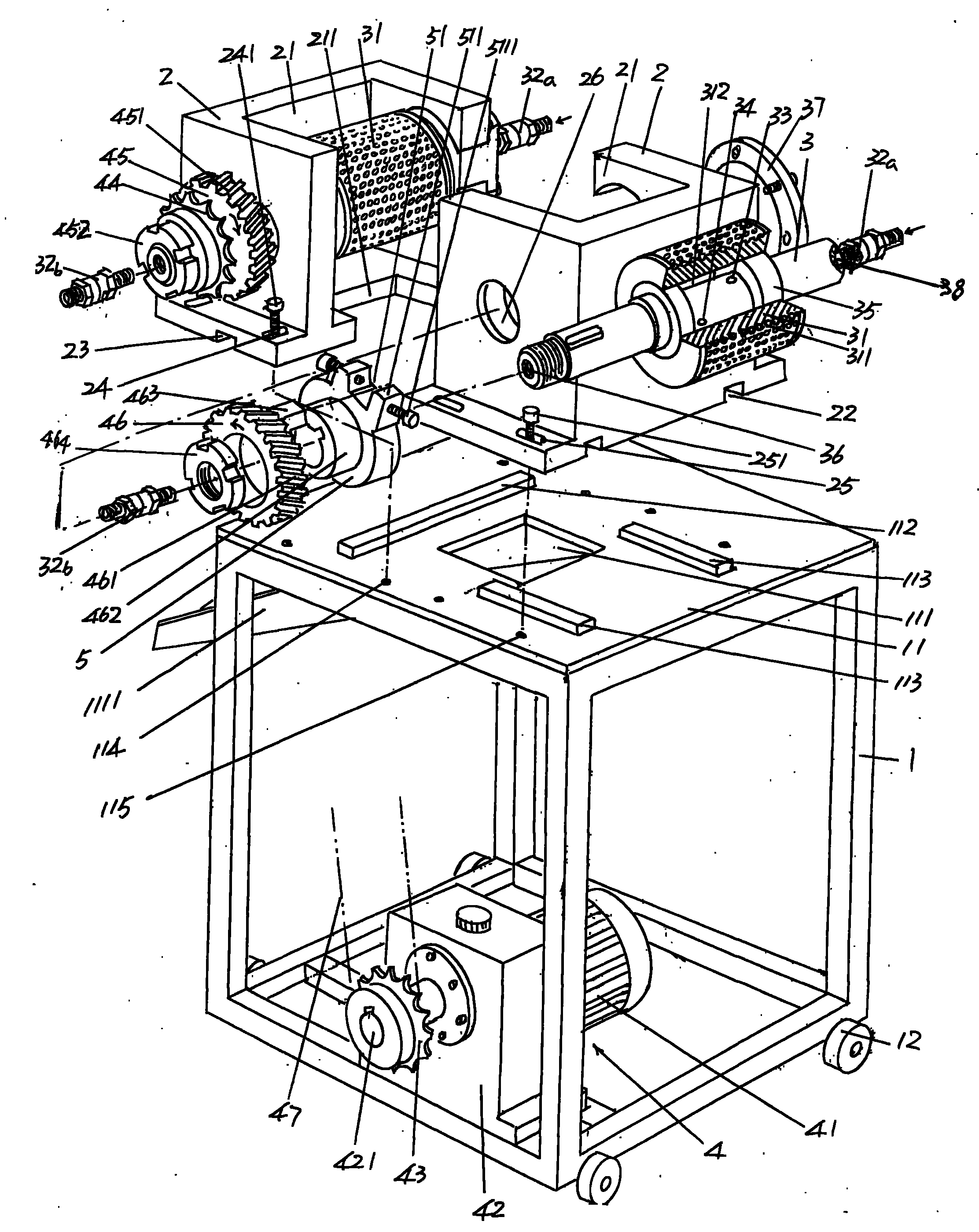

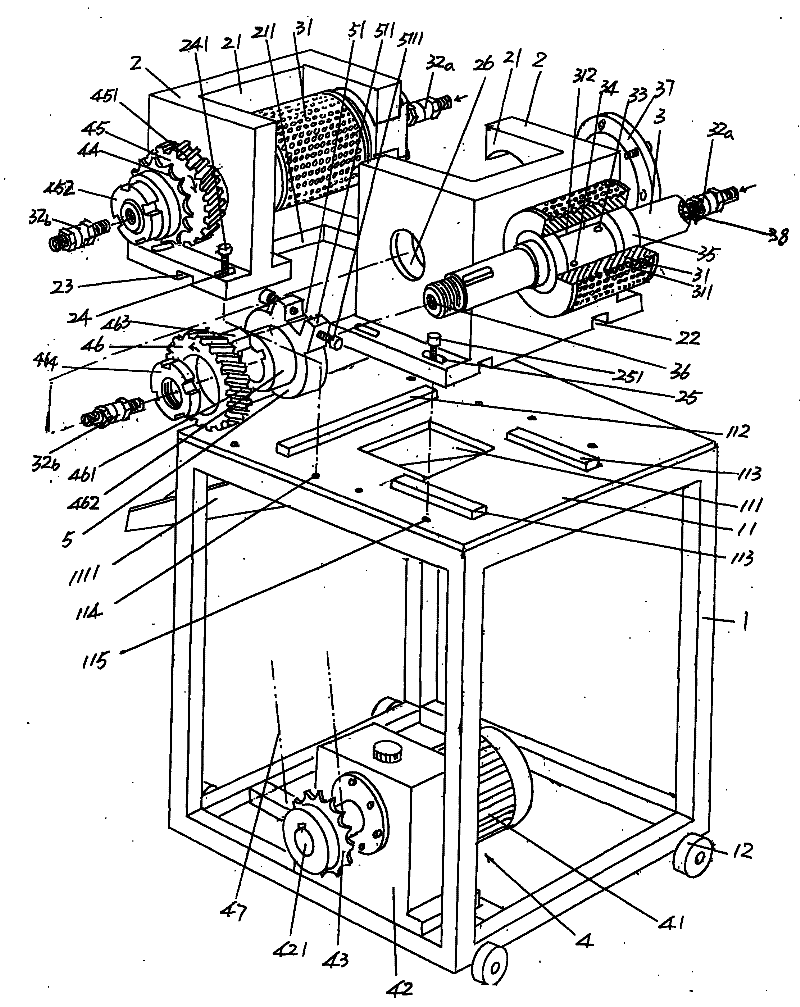

Glass bead forming machine

InactiveCN101935150AGuaranteed service lifeSimple structureGlass shaping apparatusWater dischargeEngineering

The invention relates to a glass bead forming machine belonging to the field of glass product forming machines. The glass bead forming machine comprises a stand, a pair of mould shaft seats, a pair of mould shafts and a power transmission mechanism, wherein the top of the stand forms a stand platform, and the stand platform is provided with a discharge opening, a longitudinal guide rail and a horizontal guide rail; the pair of mould shaft seats are respectively provided with mould containing cavities and matched face to face, and the bottoms of the mould containing cavities are provided with discharge cavities; the pair of mould shafts are respectively fixedly provided with glass bead forming moulds; the power transmission mechanism is arranged on the stand and connected with the pair of mould shafts; one ends of the pair of mould shafts are respectively matched and connected with water inlet flexible joints, and the other ends thereof are respectively matched and connected with water outlet flexible joints; a water discharge hole and a water return hole are arranged in the middles of the pair of mould shafts; and water cooling cavities are formed between the inner walls of the glass bead forming moulds and the outer walls of the middles of the pair of mould shafts. The invention is simple in structure and can meet the requirements on industrialized batch production by efficiently forming glass beads and ensure the service life and the forming efficiency.

Owner:常熟市沙家浜镇建国玻璃模具厂

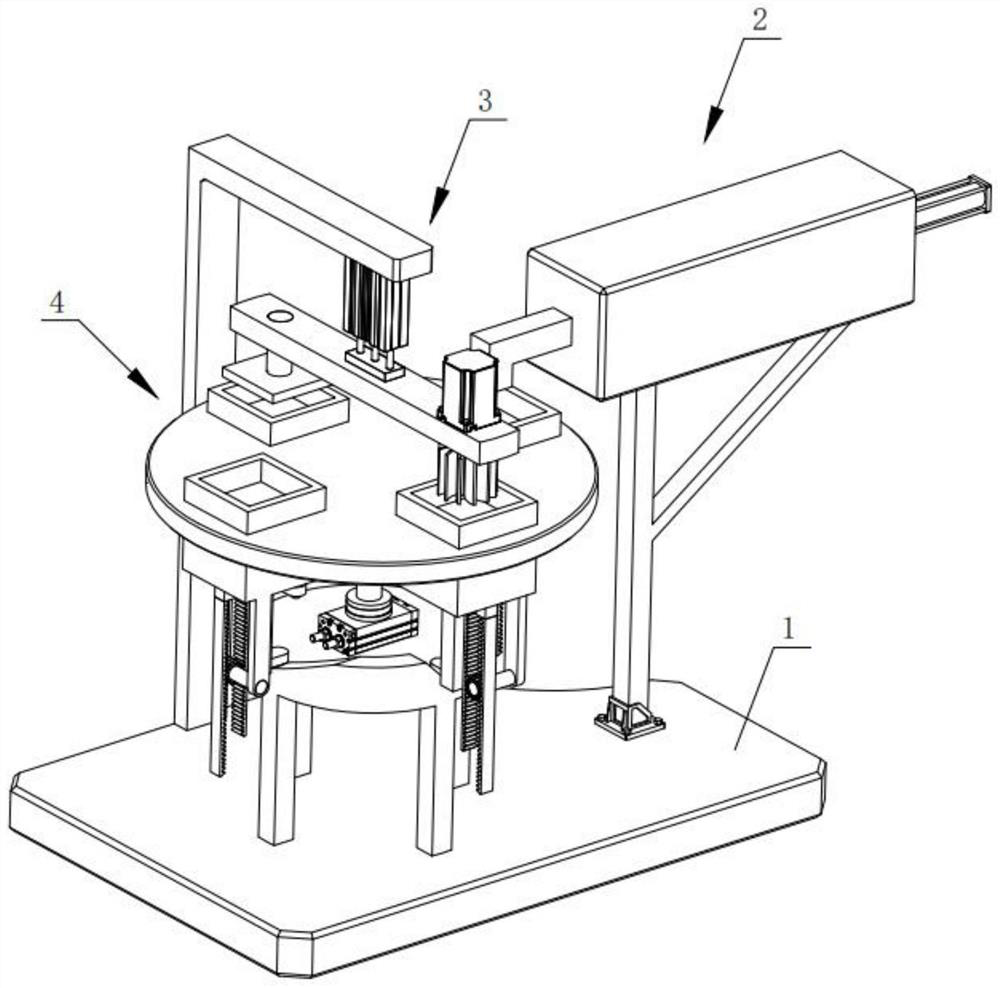

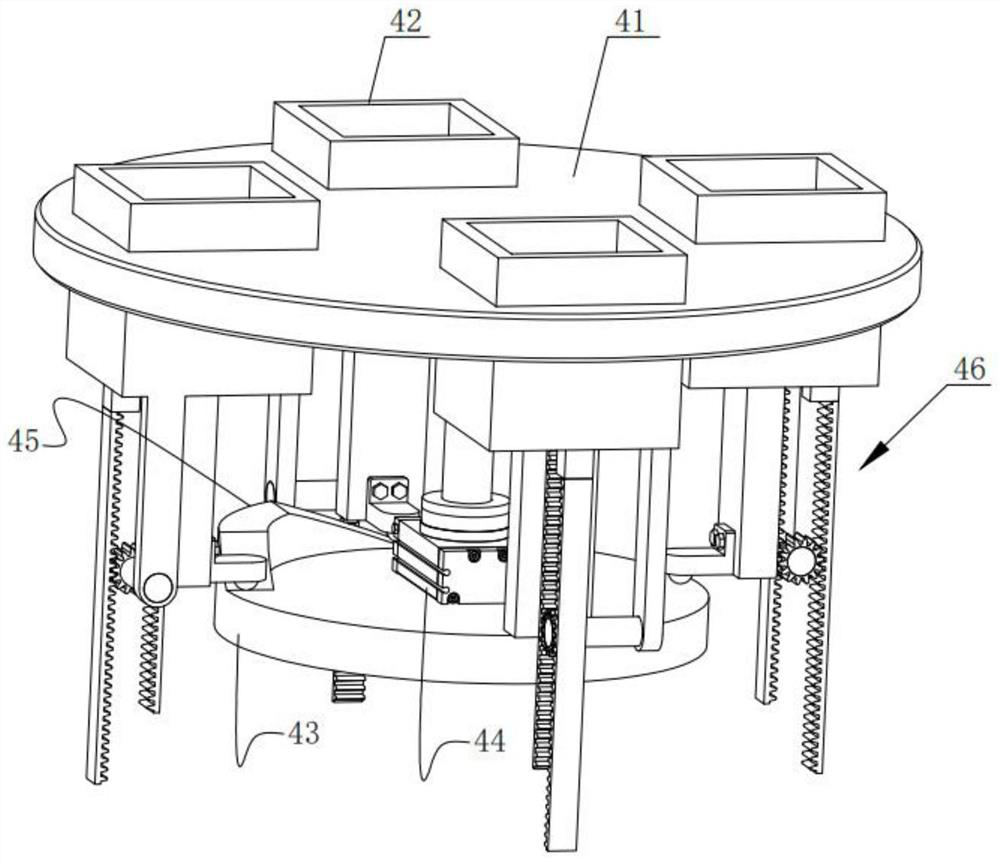

Dough sheet forming device for blackberry biscuit production

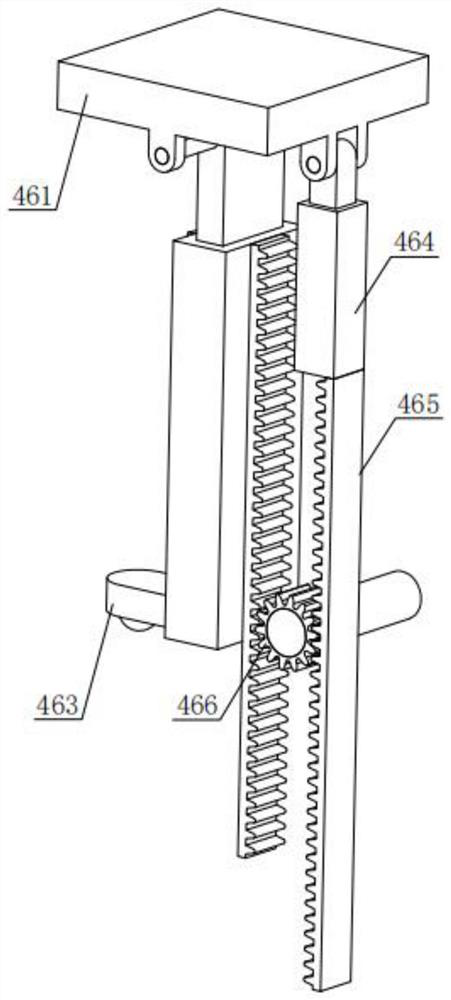

ActiveCN112690303BGuaranteed molding efficiencyAchieve the effect of automatic unloadingDough extruding machinesDough processingBiotechnologyCompression molding

The invention provides a dough sheet forming device for blackberry biscuit production, which includes a bottom plate, a quantitative cutting assembly, a diagonal processing assembly and a multi-station forming assembly, the quantitative cutting assembly is arranged on the bottom plate, and the diagonal processing assembly is located Above the station molding assembly, it is used for compression molding and cleaning the residual impurities in the multi-station molding assembly. Components include piston plate, telescoping rod assembly, baffle, damper, rack and pinion. The four-station forming chamber realizes blanking, compression molding, automatic discharge and cleaning of the chamber wall, thereby ensuring the molding efficiency, and the jacking assembly lifts the telescopic rod assembly through the raised block, then the two racks Under the action of the gear, it moves in the opposite direction. At this time, the piston plate protrudes from the forming chamber and tilts, thereby achieving the effect of automatic unloading and avoiding manual operation.

Owner:ANHUI DINGKANG FOOD

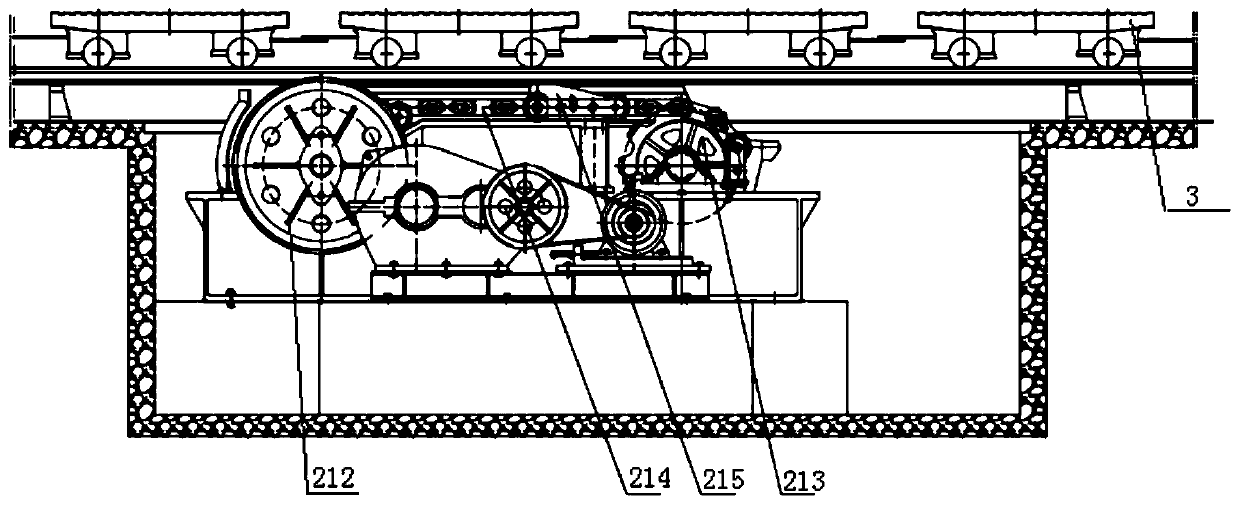

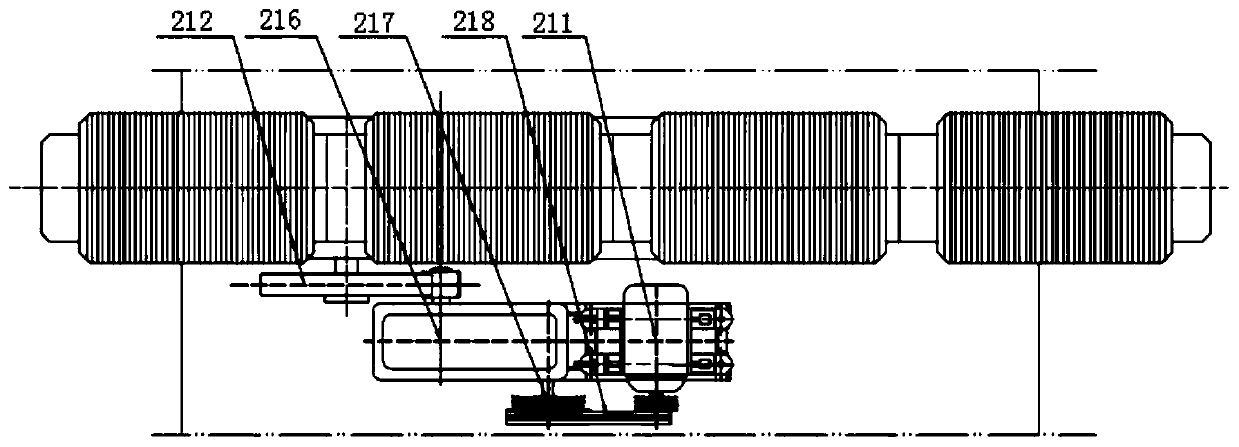

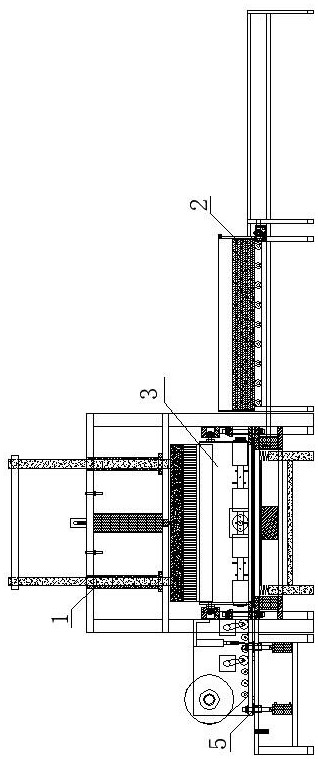

Four-spindle drilling machine for wearing plate on bogie side frame

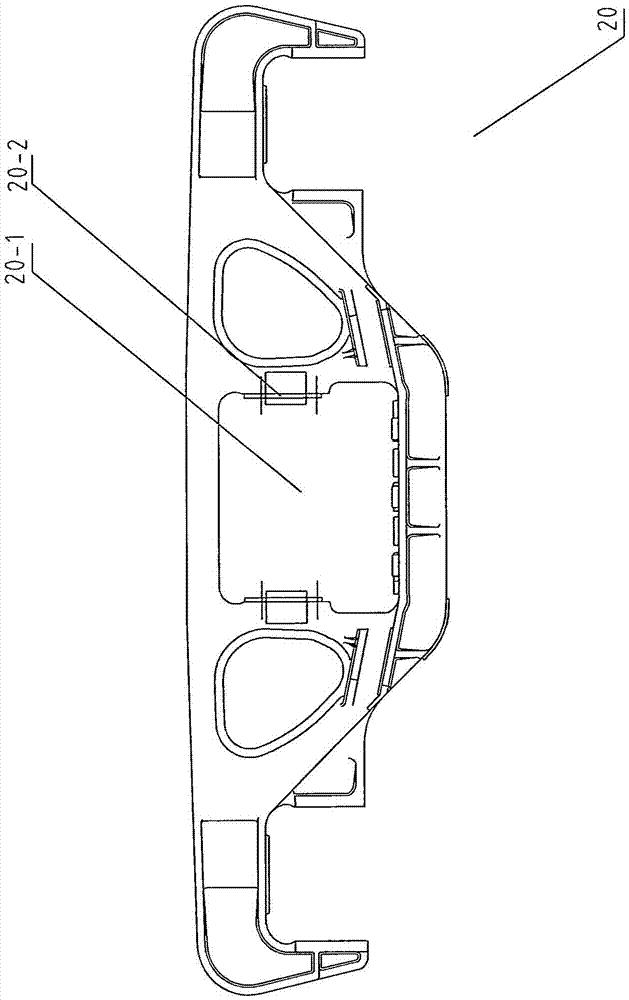

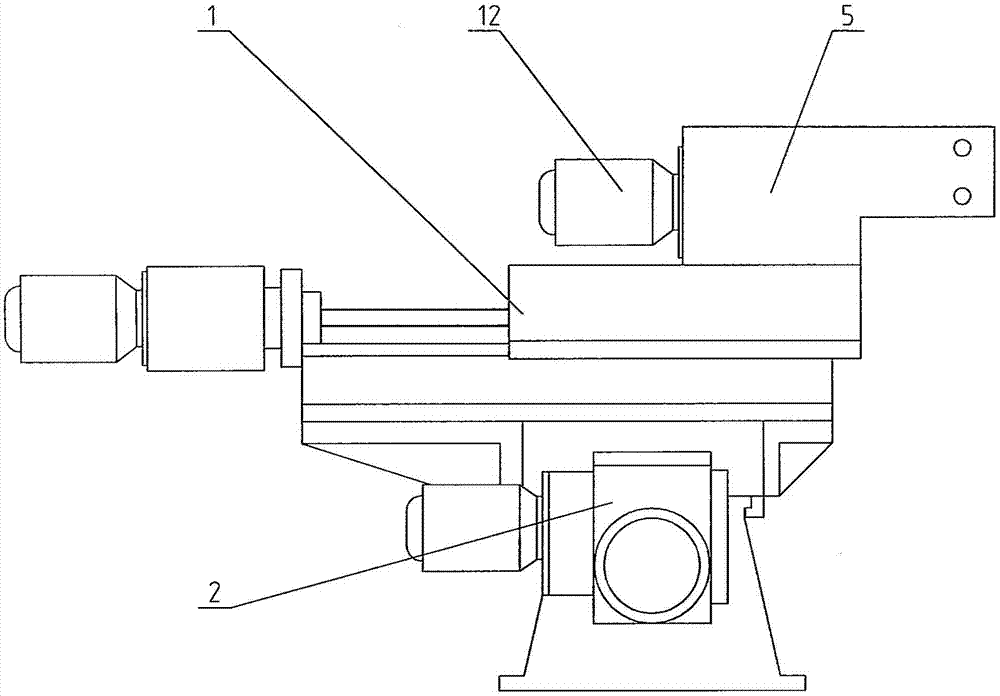

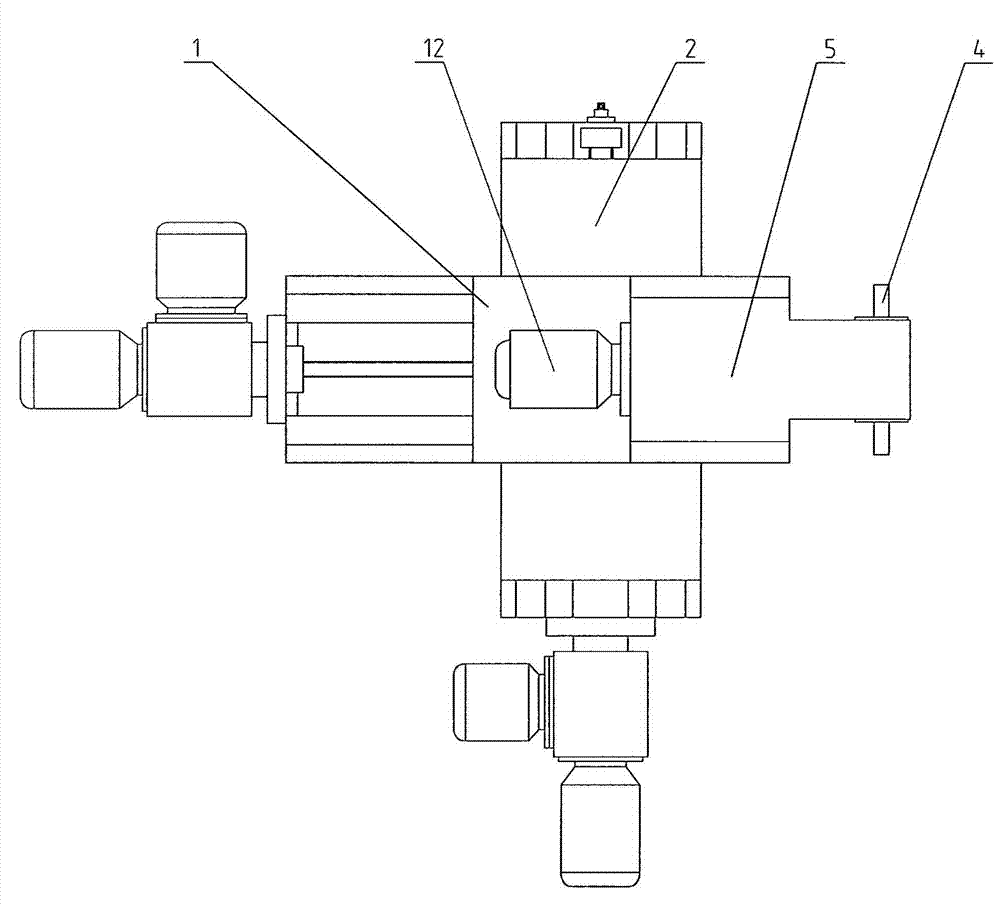

ActiveCN102921996BSolve the problem of interchangeabilityGuaranteed positioning accuracyBoring/drilling componentsMaintainance and safety accessoriesBogieEngineering

The invention discloses a four-spindle drilling machine for a wearing plate on a bogie side frame. The four-spindle drilling machine comprises a longitudinal mechanical sliding table, a transverse mechanical sliding table, four drilling power heads and a power box, the power box drives the four drilling power heads to rotate, the power box can be longitudinally movably installed on the longitudinal mechanical sliding table, the longitudinal mechanical sliding table can be transversely movably installed on the transverse mechanical sliding table, two main spindles are installed in the power box, one drilling power head is sleeved at two ends of each main spindle respectively, and the four drilling power heads are symmetrically arranged on two sides of the power box. According to the four-spindle drilling machine for the wearing plate on the bogie side frame, the position accuracy and forming efficiency of wearing plate mounting holes are guaranteed, the interchangeability of replacing and installing the wearing plate can be achieved, and the production circle is reduced.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

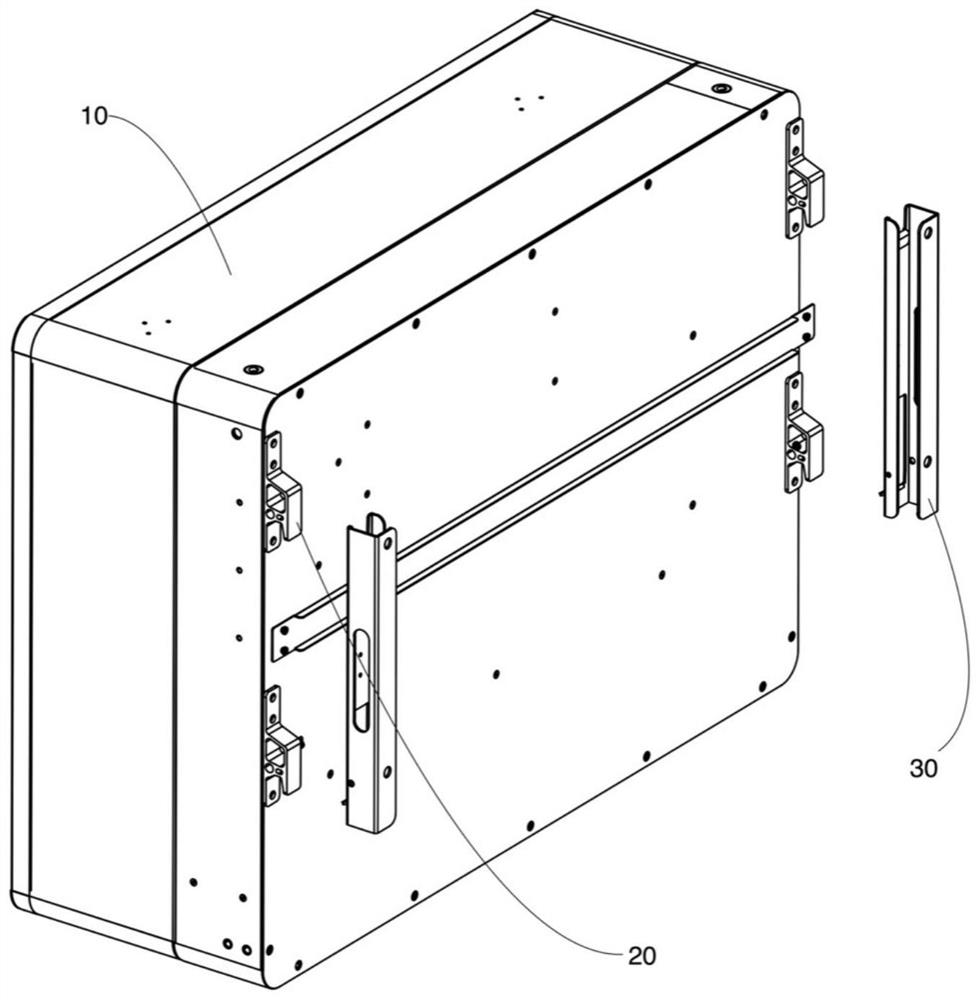

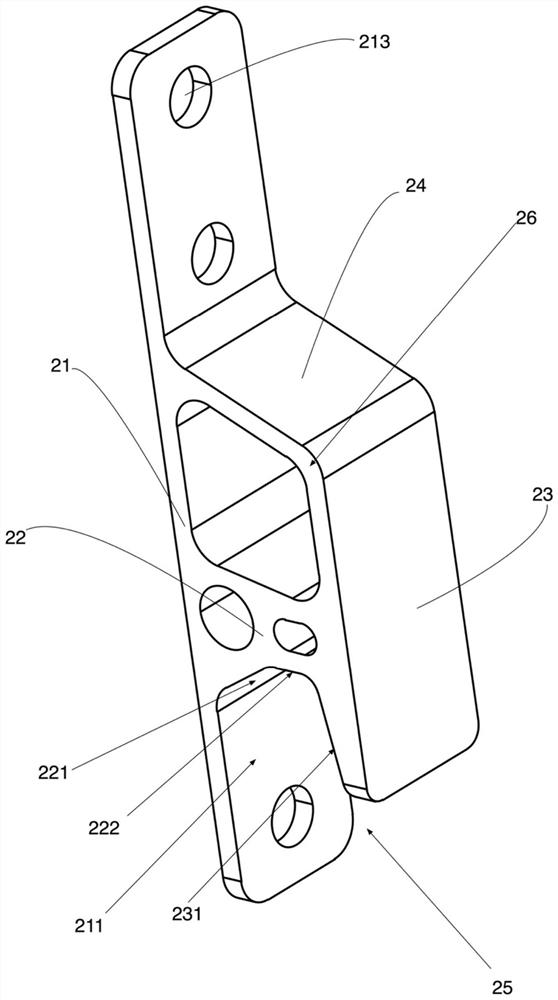

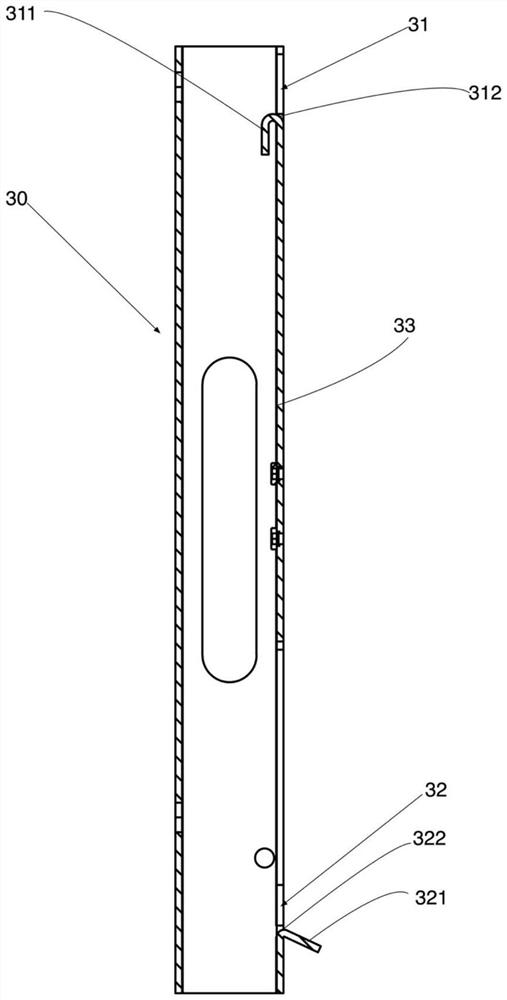

Hooking piece, hooking structure and electrical equipment assembly

PendingCN114151434AWide range of applicationsPrevent disengagementMachine supportsCasings/cabinets/drawers detailsHeavy equipmentStructural engineering

The invention discloses a hooking piece, a hooking structure and an electrical equipment assembly, a hooking groove with a downward opening is defined by a third plate, a first plate and a second plate which are arranged on the hooking piece, a first surface, a second surface, a third surface and a fourth surface which are connected in sequence are formed in the hooking groove, and the first surface, the third surface and the fourth surface are located on the first plate, the second plate and the third plate respectively. The second surface is located on the second plate or the first plate; the third surface is perpendicular to the first plate and is suitable for abutting against and matching with the wall surface support, and the second surface is inclined upwards relative to the first surface and is suitable for guiding and matching with the wall surface support; meanwhile, the wall surface bracket is arranged in the hooking structure, and the first extension arm and the second extension arm are arranged on the wall surface bracket, so that the hung wall-mounted equipment can be kept in a vertical state after being hung by the wall-mounted structure, the transverse shearing force borne by the hooking piece is reduced, the deformation of the hooking piece is avoided, and the safety of the hooking piece is improved. The hooking piece can be suitable for hanging heavy equipment, can limit the moving space of the wall hanging equipment in the horizontal direction after hooking is completed, has a wide application range, and can effectively improve the structural stability of the hooking piece during hooking.

Owner:厦门科华数能科技有限公司

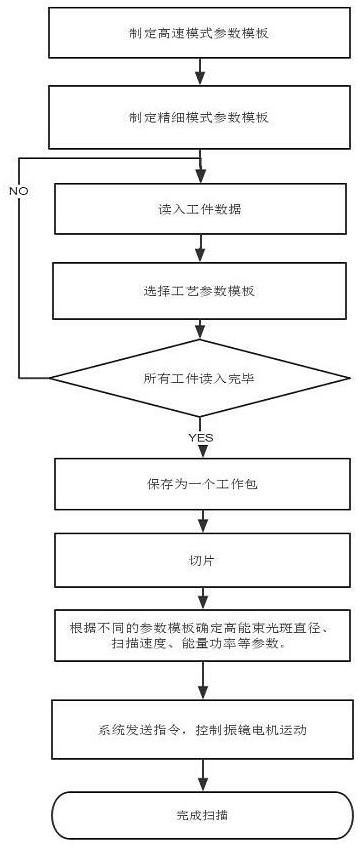

Additive manufacturing method, device, and readable storage medium for manufacturing three-dimensional objects

ActiveCN109773186BGuaranteed molding efficiencyMeet the molding precision requirementsAdditive manufacturing apparatusIncreasing energy efficiencyIt equipmentProcess engineering

The present application relates to an additive manufacturing method for manufacturing a three-dimensional object, a device thereof, and a readable storage medium, wherein the additive manufacturing method for manufacturing a three-dimensional object comprises the steps of: according to the shape features of each workpiece to be formed in the work package , select the corresponding sintering parameter mode from the pre-stored sintering parameter mode database; for each slice section of each workpiece to be formed, use the same corresponding sintering parameter mode to scan, the additive material used for manufacturing three-dimensional objects of the present invention The manufacturing method, its equipment, and the readable storage medium can select appropriate sintering parameter modes according to the shape and structure features of different workpieces to be formed in a work package, so that not only the requirements for the forming accuracy of the workpieces to be formed can be met, but also the maximum guarantee is achieved. The molding efficiency of the entire work package.

Owner:HUNAN FARSOON HIGH TECH CO LTD

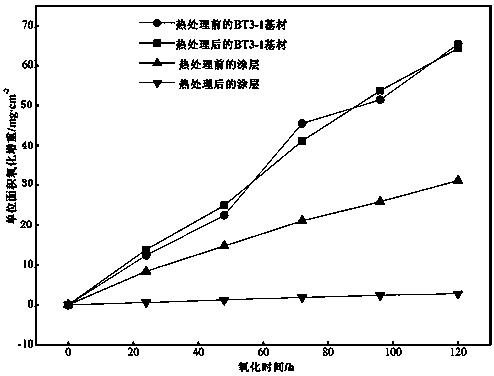

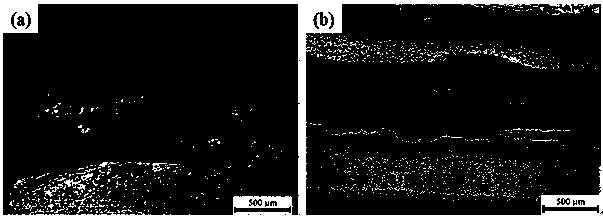

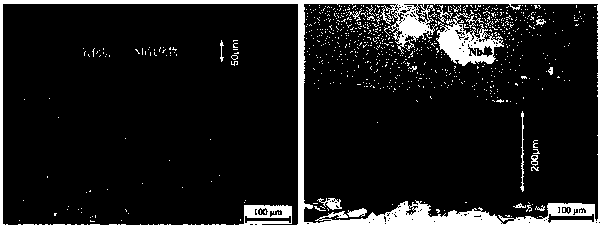

A method for preparing high-nb titanium-aluminum-based alloy anti-oxidation coating on the surface of titanium alloy

ActiveCN105331973BSolve the problem of poor high temperature oxidation resistanceIncrease temperatureMetallic material coating processesStructure analysisOxidation resistant

The invention discloses a method for preparing a preparing high-Nb titanium aluminum based anti-oxidization coating on a titanium alloy surface. According to the method, by utilizing in-situ synthetic reaction and thermal treatment of Ti-Al-Nb blended element powder under action of a CO2 laser beam, a high-Nb titanium aluminum coating layer is prepared on the titanium alloy surface. The method comprises the following preparation steps: titanium alloy surface pre-treatment, powder preparation and ball-milling, powder presetting, powder laser sintering, coating thermal treatment, anti-oxidization performance test and microscopic structure analysis. According to the performance test results, the method can effectively reduce vigorous oxidation, in a high-temperature environment, of the titanium alloy, and greatly improves usage temperature limit of the titanium alloy. The invention provides the coating preparation method which is short in period, low in comprehensive cost and high in flexibility degree. On the premise of not greatly affecting the high temperature anti-oxidization performance of the alloy coating, a coating component proportion is flexibly regulated to obtain a high-Nb titanium aluminum based alloy dual-phase coating which is high in compactness, uniform in thickness and excellent in anti-oxidization performance.

Owner:KUNMING UNIV OF SCI & TECH

Glass bead forming machine

InactiveCN101935150BGuaranteed service lifeSimple structureGlass shaping apparatusWater dischargeEngineering

The invention relates to a glass bead forming machine belonging to the field of glass product forming machines. The glass bead forming machine comprises a stand, a pair of mould shaft seats, a pair of mould shafts and a power transmission mechanism, wherein the top of the stand forms a stand platform, and the stand platform is provided with a discharge opening, a longitudinal guide rail and a horizontal guide rail; the pair of mould shaft seats are respectively provided with mould containing cavities and matched face to face, and the bottoms of the mould containing cavities are provided with discharge cavities; the pair of mould shafts are respectively fixedly provided with glass bead forming moulds; the power transmission mechanism is arranged on the stand and connected with the pair of mould shafts; one ends of the pair of mould shafts are respectively matched and connected with water inlet flexible joints, and the other ends thereof are respectively matched and connected with wateroutlet flexible joints; a water discharge hole and a water return hole are arranged in the middles of the pair of mould shafts; and water cooling cavities are formed between the inner walls of the glass bead forming moulds and the outer walls of the middles of the pair of mould shafts. The invention is simple in structure and can meet the requirements on industrialized batch production by efficiently forming glass beads and ensure the service life and the forming efficiency.

Owner:常熟市沙家浜镇建国玻璃模具厂

Casting forming machine for skateboard wheel

A pouring forming machine for skateboard wheels relates to the technical field of pouring forming equipment and comprises a constant temperature assembly for guaranteeing the forming temperature of a mold, the constant temperature assembly is provided with a plurality of heating barrels for temperature control, the side edge of the constant temperature assembly is provided with a limiting assembly for limiting the position of the mold, and the limiting assembly fixes the mold through a belt at the same time. The constant temperature assembly is provided with a plurality of sets of forming assemblies used for containing molds and driving the molds to move in the constant temperature assembly, the multiple molds can be placed on the forming assemblies at the same time for forming, and the constant temperature assembly is provided with a demolding assembly for automatically demolding the molds on the forming assemblies. And the demolding assembly is used for demolding the mold and then pouring the mold, a driving assembly for driving the constant-temperature assembly to rotate is arranged on the demolding assembly, and the driving assembly can be matched with the demolding assembly to synchronously work through arrangement of a cam. And the working efficiency of pouring is improved.

Owner:JIANGSU YAOZHANG SPORTING GOODS

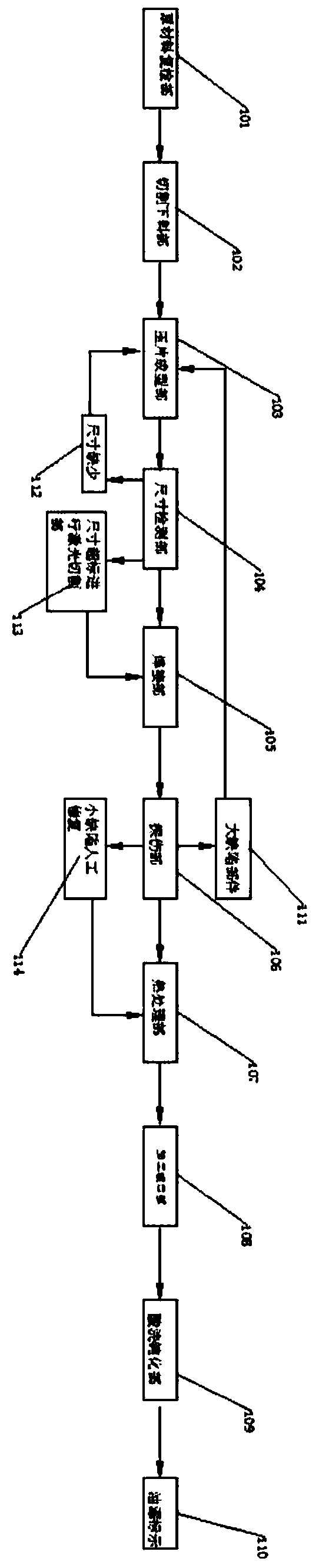

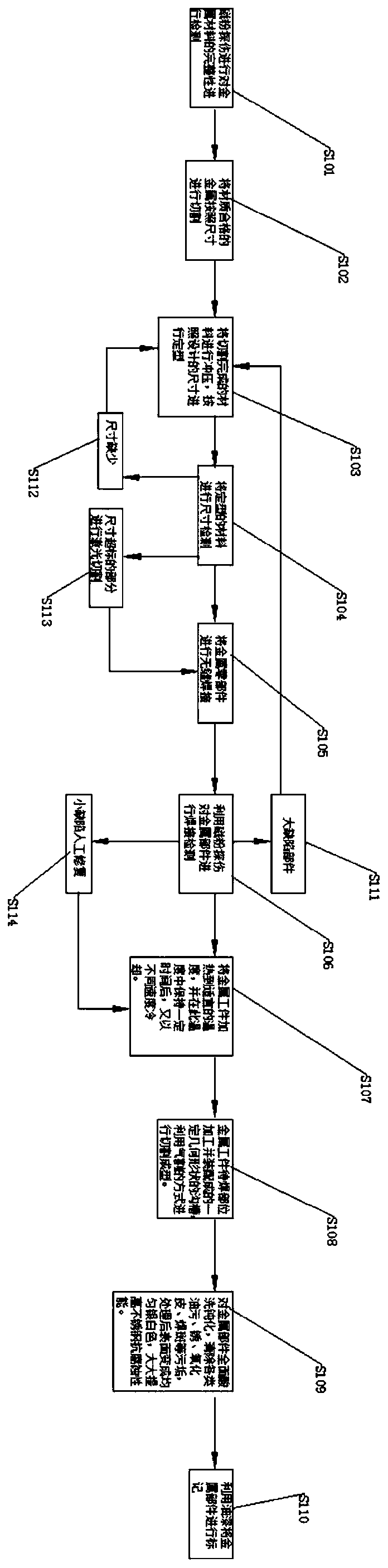

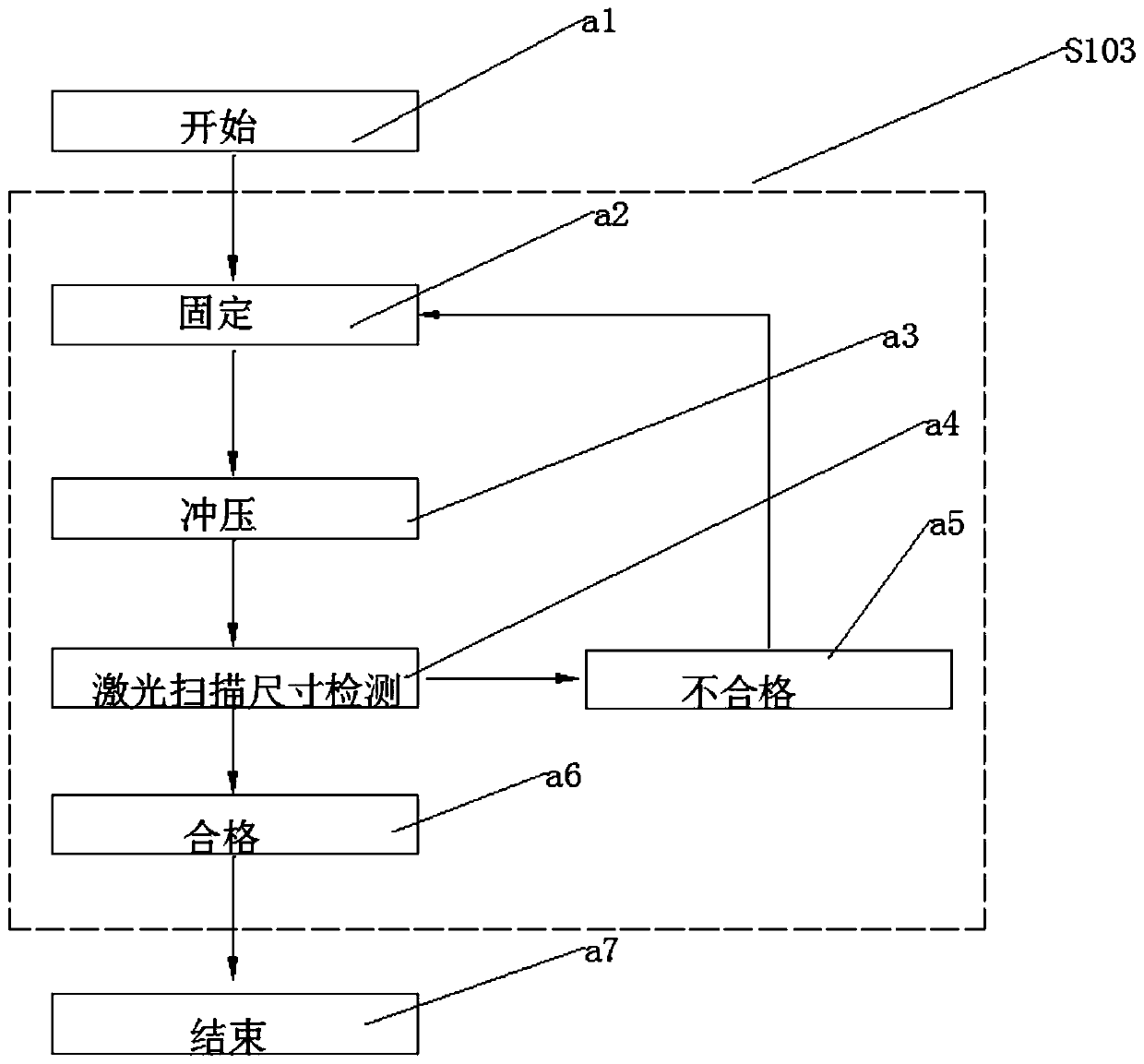

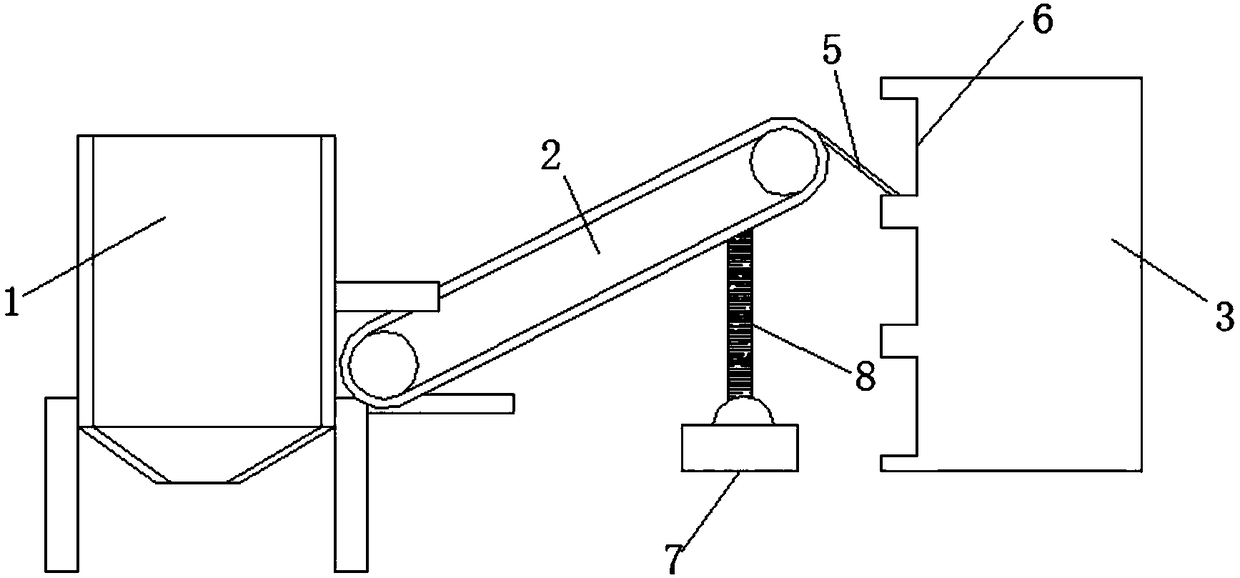

Shaping method of spigot and faucet pipe fitting of pipeline

The invention discloses a shaping method of spigot and faucet pipe fitting of a pipeline. The shaping method of the spigot and faucet pipe fitting of the pipeline involves a raw material reinspectionportion detecting the texture and quality of raw materials to guarantee the yield of the materials, a cutting blanking portion cutting the raw materials according to detected length, a stamping forming portion conducting stamping shaping on the cut raw materials, a dimension detecting portion detecting the size of the stamped and formed materials, a exceeding dimension laser cutting portion cutting off the portion exceeding the standard after detection and a welding portion welding the components with qualified dimensions. The shaping method of the spigot and faucet pipe fitting of the pipeline has the beneficial effects that qualified materials are guaranteed by means of reinspection of the raw materials, and cutting and blanking are conducted to guarantee the formation efficiency; and besides, stamping control is conducted through the stamping forming portion, so that the shaping effect is improved, the stamping yield is improved; and in this way, material waste is reduced, and the utilization rate of the materials is improved.

Owner:无锡市星达石化配件有限公司

Production line of nanometer coating film

PendingCN108101380AEnsure mixing uniformityGuaranteed molding efficiencyProduction lineBiochemical engineering

The invention discloses a production line of a nanometer coating film. In the production line of the nanometer coating film, a nanometer coating film processing box, a conveying belt and a finished product placing box are provided; the conveying belt is positioned on one side of the nanometer coating film processing box; the other side of the conveying belt is movably connected with the finished product placing box; a guide groove is formed in an inner cavity of the side surface wall of the finished product placing box; the internal part of the guide groove is movably connected with a rollingwheel; the side surface wall of the rolling wheel is fixedly connected with a moving rod; a threaded hole is formed at the other end of the moving rod; mounting frames are arranged at the two ends ofthe conveying belt; a threaded pipe is arranged on one side of each mounting frame; and the conveying belt is connected with the threaded hole of the side surface wall of the finished product placingbox through the threaded pipe. According to the production line of the nanometer coating film, the structure is simple, the production efficiency of the nanometer coating film is effectively improved,the nanometer coating film is placed in the finished product box with different layers, the production line of the nanometer coating film is convenient and rapid, and the surface cleanliness of the nanometer coating film is guaranteed conveniently, so that the working efficiency is improved, time and labor are saved and operation is facilitated.

Owner:PINGHU HUARUI GLASS

Heating forming mechanism for plate material

The invention discloses a heating forming mechanism for a plate material. The heating forming mechanism comprises a heating mechanism and a forming mechanism body, wherein the heating mechanism and the forming mechanism body are connected through a conveying mechanism, and the plate material is conveyed from the heating mechanism to the forming mechanism body through the conveying mechanism; the heating system comprises a heating box and a guide rail, a heating assembly is arranged on the guide rail, and the travelling speed of the heating assembly is matched with the conveying speed of the plate material; the forming mechanism body comprises a forming box, a forming assembly is arranged in the forming box, an opening is formed in the top of the forming box, and the width of the opening ismatched with the width of the plate material; and the conveying mechanism comprises a driving part and a conveying and executing unit, the plate material is arranged on the conveying and executing unit, one end of the conveying and executing unit is arranged on the side, away from the forming mechanism body, of the interior of the heating box, and the other end of the conveying and executing unitis located at the top of the side, away from the heating box, of the forming box. According to the forming mechanism, the distance between the heating mechanism and the forming mechanism body can berelatively shortened, rapid cooling of the plate material is prevented, and the forming efficiency is improved.

Owner:ANHUI XINMENG EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com