Sludge conveying and dewatering equipment used for sludge treatment

A dehydration device and sludge treatment technology, which is applied in sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of reducing the space utilization rate of collection containers, sludge is difficult to dry, etc., to achieve It is convenient for collection and arrangement, reduces water content, and improves the effect of space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

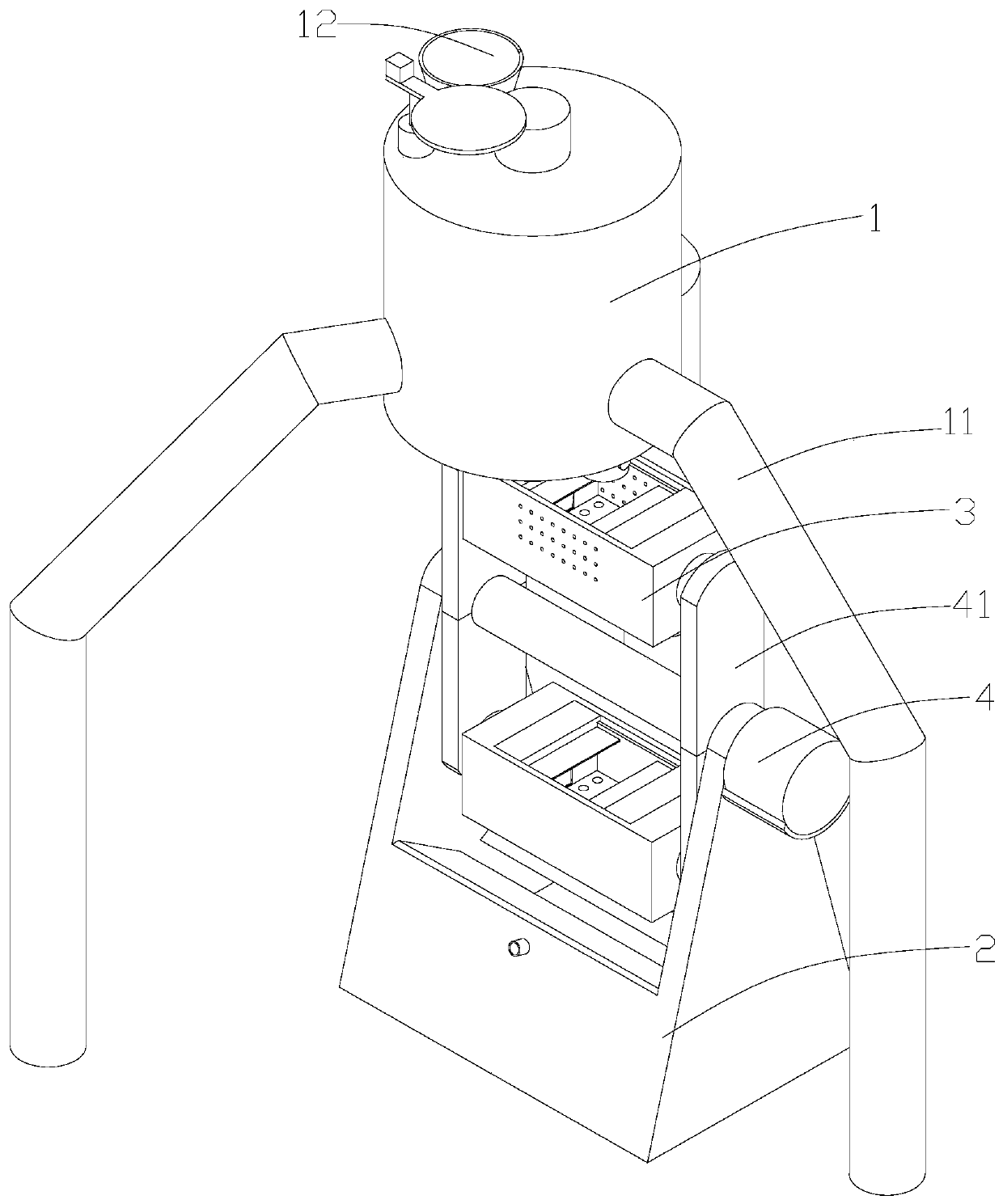

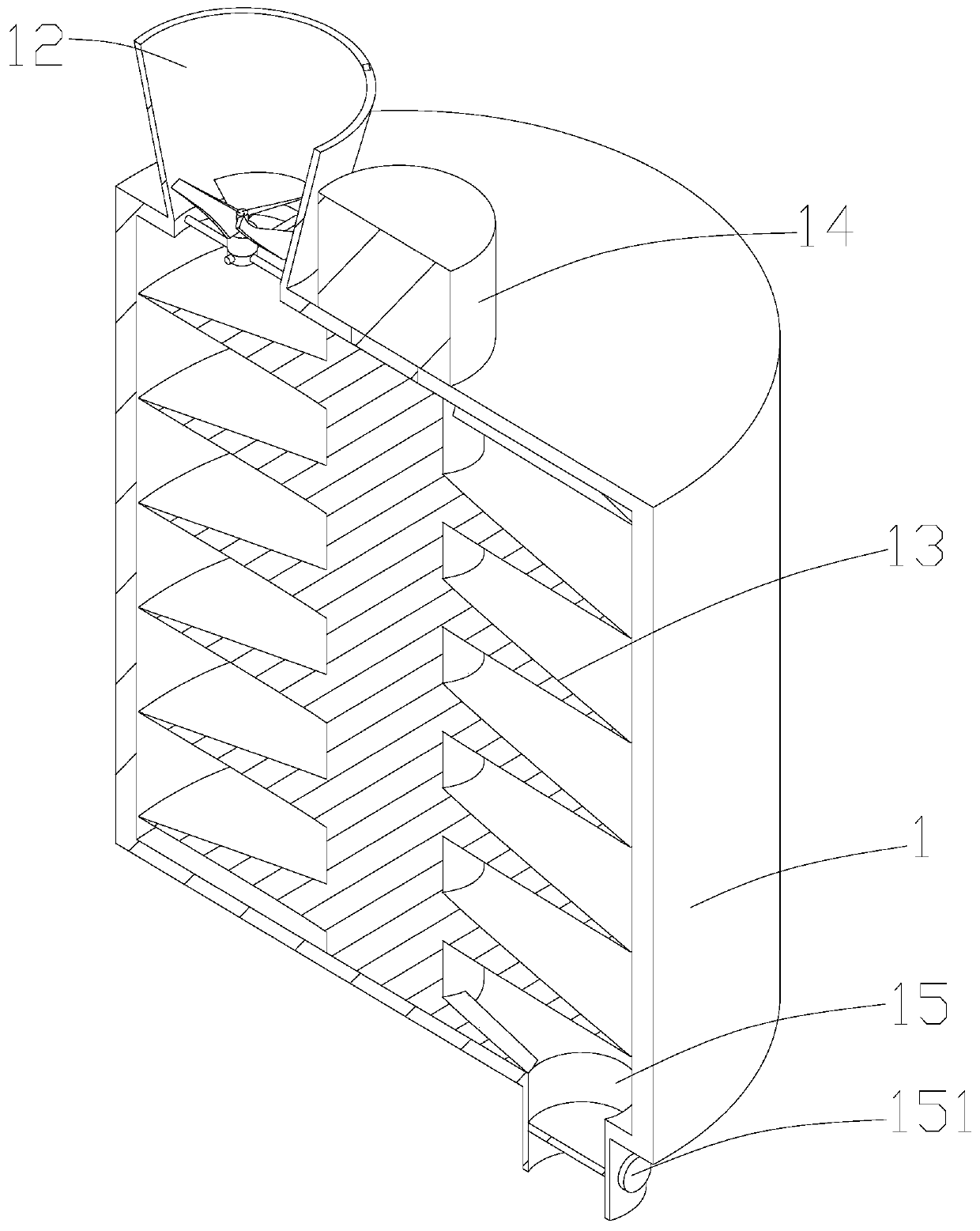

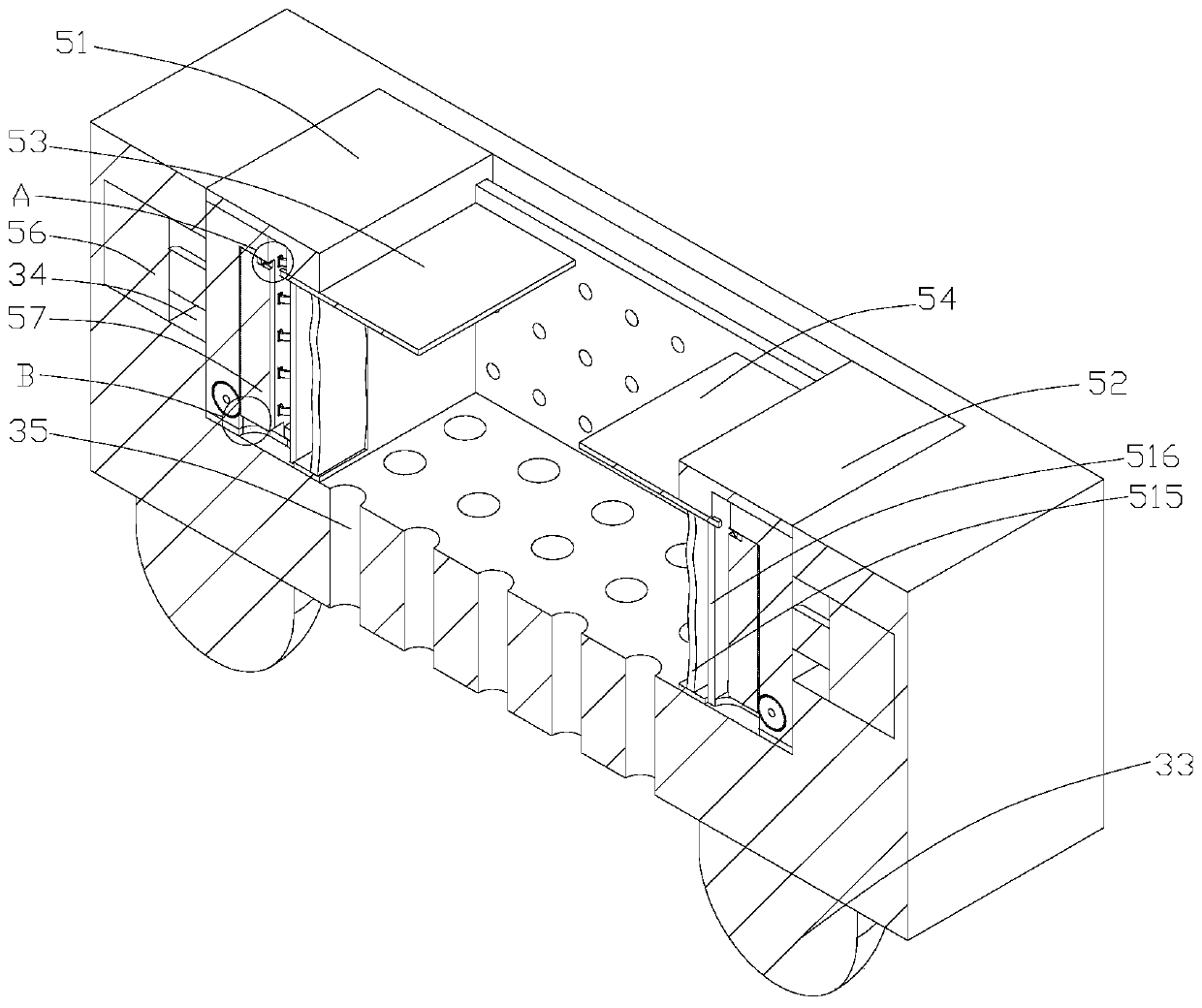

[0026] Such as Figure 1-10As shown, a sludge feeding and dehydrating device for sludge treatment includes a feeding cylinder 1 for conveying sludge, a plurality of support legs 11 for supporting the feeding cylinder 1 and a handle for collecting treated sludge Collecting box 2, described feeding cylinder 1 is provided with feed hopper 12 and screw feeding rod 13, and the bottom of described feeding cylinder 1 is provided with at least one dehydration tank 3 for dehydrating sewage and for driving dehydration The first driver 4 for the rotation of the box 3, the first driver 4 is fixed on the collection box 2, the dehydration box 3 is provided with a dehydration device, through the setting of the above structure, the sludge can pass through the feeding cylinder Uniform transportation to realize the treatment of sludge volume and avoid clogging caused by excessive sludge volume. At the same time, the sludge can be treated through the dehydration device, so that the sludge can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com