Plug-in type steel pipe concrete column base for large power transmission tower and construction method thereof

A concrete-filled steel tube and plug-in technology, which is applied in the direction of towers, building types, and basic structure engineering, can solve problems such as application obstacles of concrete-filled steel tube towers, large tensile stress of concrete shells, and impacts on construction quality of transmission towers, achieving convenient construction and guarantee Crack resistance, ensuring the effect of stress consistency and balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

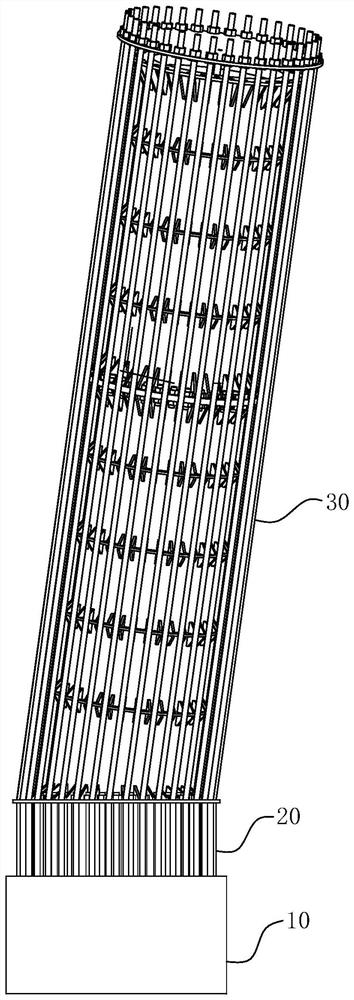

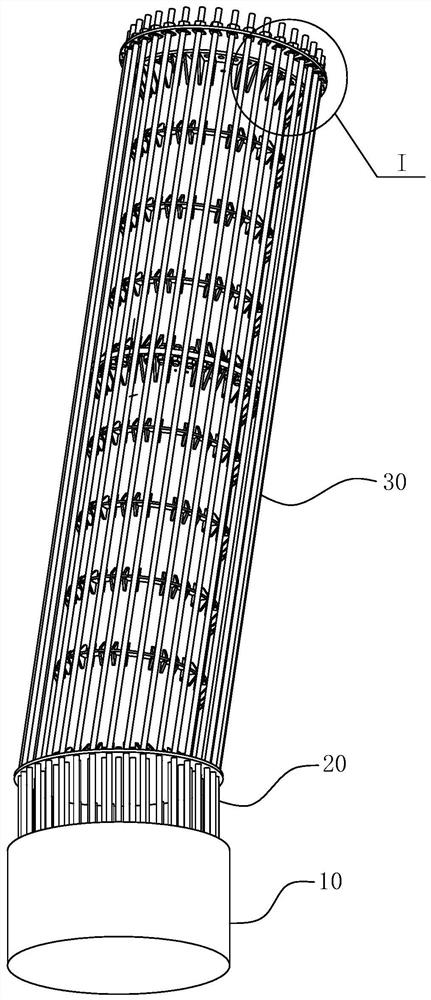

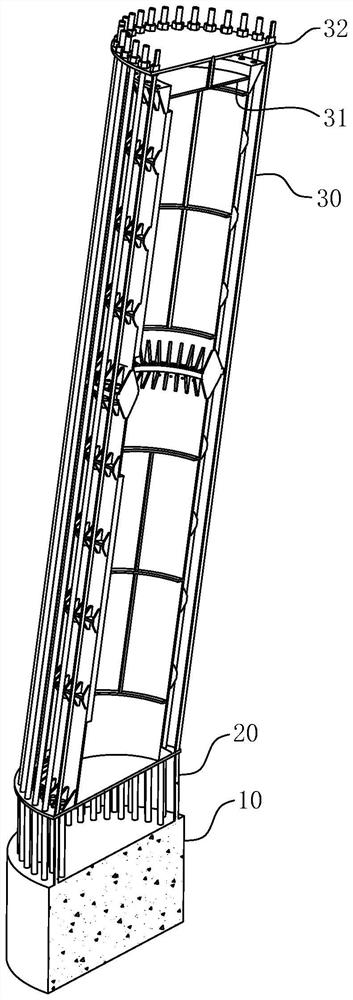

[0031] For ease of understanding, combined here Figure 1-6 , the concrete structure and working mode of the present invention are further described as follows:

[0032] After the present invention is fully formed, usually the periphery also needs to be coated with a concrete shell 40, and finally forms such as Figure 6 Prestressed foundation shown. while wrapping Figure 6 Before the concrete shell 40 shown, the construction of the present invention refers to Figure 1-5 shown, where:

[0033] refer to Figure 1-3 As shown, the present invention includes a bottom pile foundation anchorage pier 10, a foundation cap 20 and an inserted concrete filled steel tube 30 arranged sequentially from bottom to top; Figure 6 Add one deck concrete shell 40 in. Between the anchor pier 10 of the pile foundation at the bottom and the anchor plate 32 designed at the top of the inserted steel pipe concrete 30, an axial tie rod 35, that is, a steel strand, is arranged along the circumfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com